Page 1

Instruction manual forCEILINGHOODS

Model code: CE1500 Model code: CE1100

Model code: CE1105

Contact Caple on 0844 800 3830 or for spare parts www.4caple.co.uk

Page 2

2

Page 3

Warnings

Uses

Installation

Working

Maintenance

CONTENTS

GB

3

Page 4

WARNINGS

The appliance is not intended for use by

young children or infirm persons without

supervision. Young children should be supervised to ensure they do not play with

the appliance.

The air sucked canʼt be conveyed throu-

gh or into a duct used to let out fumes

from appliances fed by energy other than

electric power (eg. centralized heating, radiators, water-heaters, etc.).

To evacuate the air outlet, please comply

with the pertaining rules given by competent authorities.

Provide the room with an adequate aeration

when a cooker hood and appliances fed by

energy other than electric power (gas-, oil-,

or coal- stoves, etc.) are used simultaneously.

The cooker hood, when evacuating the sucked

air, could generate a negative pressure in the

room- which canʼt exceed the limit of 0.04

mbar, in order to avoid the suck of exhausts

deriving from the heat-source. Therefore the

room should be provided with air-intakes to

allow a costant flow of fresh air.

If the rating lable in the cooker-hood shows

the symbol , the appliance is built in class

II° and it does not need any earth connection.

If the rating lable in the cooker-hood does

not show the symbol , the appliance is

built in class I° and it needs the earth connection.

When performing the electrical connections

on the appliance, please make sure that the

current-tap is provided with earth connection

and that voltage values correspond to those

indicated on the label placed inside the appliance itself.

another device ensuring omnipolar disconnections from the grid, with an opening distance between the contacts of at least 3 mm,

then such disconnecting devices must be

supplied within the fixed installation.

If the appliance is endowed with a supply cord

and a plug, the appliance has to be put in a

place where the plug can be reached easily.

The use of materials which can burst into

flames should be avoided in close proximity of the appliance. When frying, please

pay particular attention to fire risk due to

oil grease. Being highly inflammable, fried

oil is especially dangerous. Do not use uncovered electric grills. In order to avoid

possible fire risk, all instructions for grease-filter cleaning and for removing eventual grease deposits should be strictly followed.

USES

CE1500 - CE1100 - CE1105 with external

motors manufactured by the same producer.

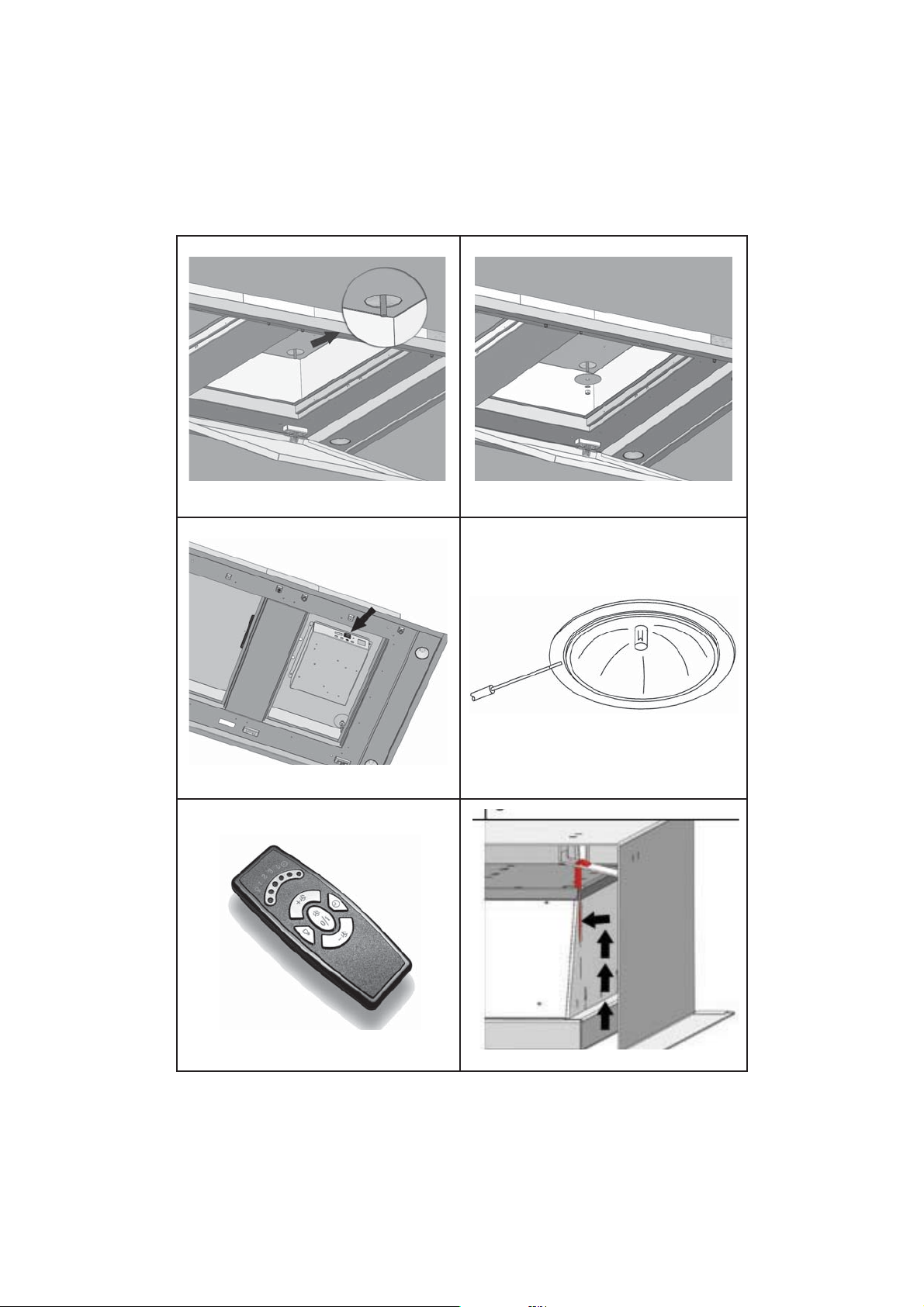

PANELS OPENING

In CE1500, CE1100 models it is possible to

open the steel panels, which cover the grease

filters, by slightly pulling on a side of the panel itself, as shown in Fig. 3.

In CE1105 model, to open the panels you

need to push the appropriate hooks placed

on the sides of the panel , as shown in Fig. 11

and then rotating the panel downwards.

To achieve the complete opening of panels,

you need to release the safety chains, by

using the appropriate spring catches.

Before carrying out any cleaning or maintaining operations, the appliance needs to be

removed from the electric grid.

If the appliance is not provided with a nonseparable flexible cable and plug, or with

4

Page 5

For proper working, it is recommended to install the appliance at a distance of 2000

- 2100 mm from the floor.

Before starting the appliance installation,

please check that all components are not damaged,

in such a case contact your retailer and do not

carry out installation.

Furthermore, please read carefully all of the

following installation instructions.

- Use an exhausting pipe whose maximum

length does not exceed 5 meters.

- Limit the no. of elbows in the piping, since

each elbow reduces the air capacity

of 1 linear meter. (Ex.: if you use no. 2 x 90 °

elbows, the length of piping must not exceed

3 meters).

- Avoid abrupt direction changes.

- Use a 150 mm constant diameter pipe for

the whole length.

- Use piping approved by standards in force.

INSTALLATION

CE1500 - CE1100 - CE1105

Fit a false ceiling with an opening of the following sizes:

CE1500: 1465x965 mm with a minimum distance of 270 mm between the ceiling and

the false ceiling;

CE1100: 1065x665 mm with a minimum distance of 270 mm between the ceiling and

the false ceiling.

CE1105: 1050x645 mm with a minimum distance of 250 mm between the ceiling and

the false ceiling;

It is possible to select the side of the hood

where the air suctioned can be discharged.

After having chosen the most suitable position, prepare the ducting: an air outlet connection piece, with a diameter of 150 mm to

be installed in the side selected, is provided

with the appliance.

Leave any unused exhaust outlets closed.

Draw the outline of the hole to house the ceiling-mounted hood on the solid ceiling (Fig.

1), according to the model chosen; make 4

holes in the ceiling according to the dimensions shown in (Fig. 2); place the metric plugs

provided in the holes.

Open the stainless steel panels, following

the instructions mentioned in the USES section, and remove the grease filters in order

to avoid damaging them in any way and too

allow installation (Fig. 3); screw the threaded bars provided into the plugs (Fig.4); the

threaded bars are 250 mm long and serve to

install the ceiling-mounted hood at a distance from the solid ceiling of between 270 mm

and 370 mm (Fig. 5); If the hood is installed

with lateral air outlet, fit a false ceiling with

an opening that has a minimum gap of 210

mm between the ceiling and the false ceiling

(Fig. 12); in case of a larger gap between the

hood and the ceiling, you need to use longer

threaded bars.

5

Page 6

Make the electrical connections and connect

the air outlet pipe; place the ceiling-mounted

hood into the niche, by inserting the threaded

bars into the holes (Fig.6); the outer edge of

the hood needs to be perfectly flush with the

false ceiling. Insert the plates and nuts provided into the threaded bars, making sure to

tighten them securely (Fig. 7); refit the grease

filters and filter cover panels.

WORKING

6 - channel radio control for cooker hood remote (fig. 10).

Technical data:

Alkaline battery powered: 12v mod. 23A

Operating frequency: 433.92 Mhz

Combinations: 4096

Max. consumption: 25mA

Operating temperature: -20° : +55°C

- To light the cooker hood on or to

light it off press the button:

- To increase the speed up to the

fourth one press the button:

- To reduce the speed up to the

second one press the button:

- To go from a high speed back to

the first one press twice the button:

- To give power to the lights or to

shut them down press the button:

The “light” switch can turn the lights on and

off. after the first touch of the light switch the

lamps turn on at the maximum power. Keeping the switch pressed the intensity of the

light decreases and then increases continuously. Leaving the switch the brightness remains set up. Touching again the light switch

it is possible to turn the lamps off.

- To set the timer up press the

button:

The LED on the right side will start to flash

(every 5 seconds), the hood will work for 10

minutes at the selected speed and then it lights automatically off. If the client increases

or reduces the speed while the timer is on,

this is automatically stopped.

6

Page 7

Standard configuration

If two cookerhoods-radiocontrol system are

installed in the same room or in the immediate

vicinity, each system may affect the operation

of the other, due to the fact that they have the

same code. Therefore it will be necessary to

change the code of one of the radio controls.

Warning:

The battery should be replaced every yearto guarantee the optimal range of

the transmitter. To replace the exhausted

battery, take the plastic lid off, remove the

battery and replace it with a new one, observing the correct battery polarities. Used

batteries should be discarded in special

collection bins.

Generating a new transmission code

The radiocontrol is supplied by the manufacturer with default codes stored. If you want to

create a new set of codes, proceed as follows:

press and hold the UP, STOP and DOWN buttons simultaneously for 2 seconds. Afterthe

LEDS light up, press the UP and DOWN button

swithin 5 seconds. The LEDS will flash 3 times

to indicate that the process is completed.

WARNING: This procedure deletes all previously stored codes.

Learning the new transmission code

After changing the transmission code on the

radio control, the cooker hood electronic control unit must be made to set the new code

as follows: press the main Power Off button

on the cookerhood (fig. 8) and then restore

power to the electronic control unit. Within

the next 15 seconds, press the Light button.

This will ensure the control unit is synchronized with the new code.

MAINTENANCE

An accurate maintenance guarantees good

functioning and long-lasting performance.

A special care must be paid with grease fil-

ters: to remove the grease filter please follow

the instructions given in the ʻUSESʼ section ,

according to the model chosen.

Remove the grease filter by pulling its handle.

To reinsert the grease filter after the cleaning,

just perform the opposite operation.

Attention: after refastening the stainless steel

panel make sure that it is properly fixed.

To clean the appliance itself tepid water and

neutral detergents are recommended, while

abrasive products must be avoided.

For steel appliances specialized detergents are recommended (please follow the instructions mentioned on the product itself to

obtain the desired results).

To replace the lamp, (CE1500 - CE1100) remove the lamp (Fig. 9) and replace it with a

lamp of the same kind.

To replace the fluorescent lamps (CE1105)

you need to disconnect the appliance from

the electrical network, then open the panel

following the instructions given in the ʻUSESʼ

section.

Remove the perimeter screws shown in fig.

13; pull the fluorescent lamps support out

(fig.14), and replace the old lamp with a new

one of the same kind.

Refit the panel and the screws previously re-

moved.

To replace the fluorescent lamps ballast plea-

se follow the steps described above.

7

Page 8

1

3

CE1500

CE1100

CE1105

2

4

5

8

Page 9

6

7

8

10

9

11

9

Page 10

12

14

13

10

Page 11

11

Page 12

90095000422 - GM 11/11

Loading...

Loading...