Page 1

GAS OVENS

Installation - Use - Maintenance

GB

Page 2

Dear customer,

We thank you and congratulate you on your choice.

THE MANUFACTURER

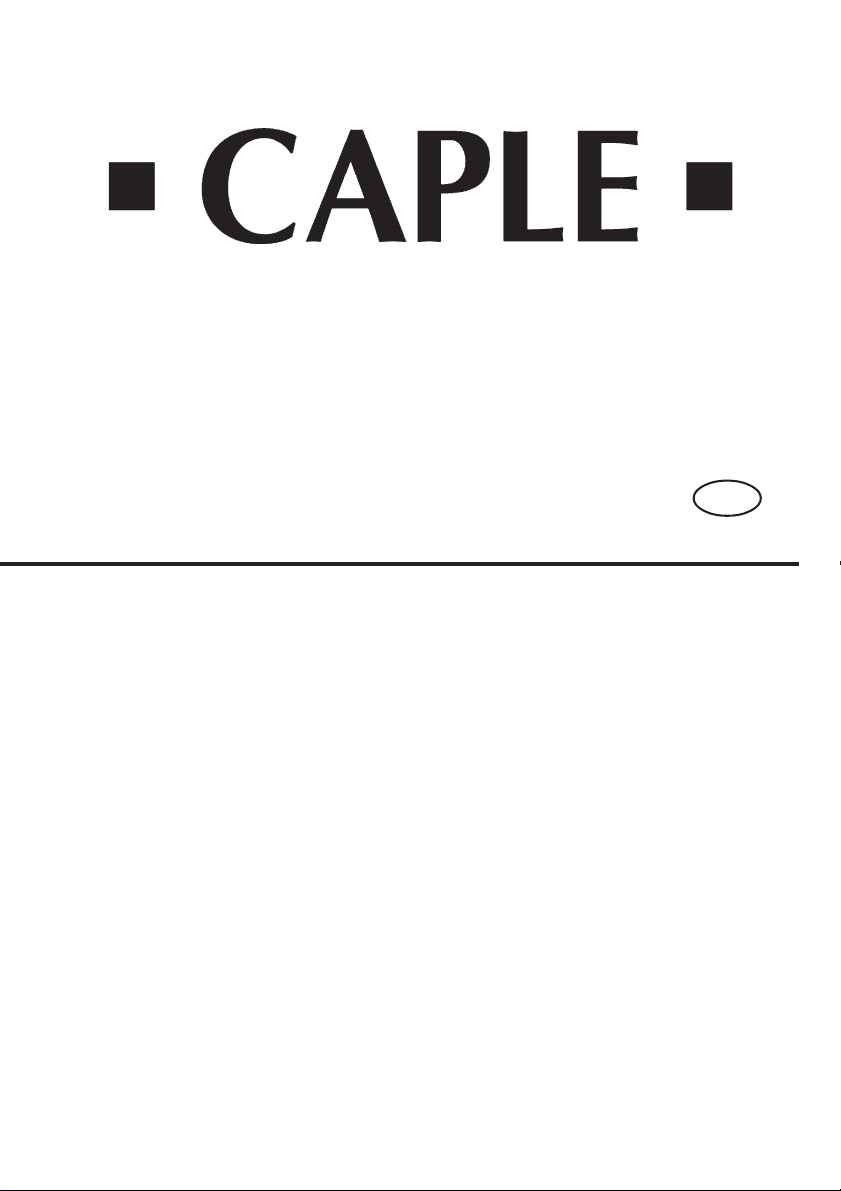

Fig. 1

!! IMPORTANT !!

The appliance must be connected by qualified technician in accordance with the applicable

regulations. The data plate (a) of the oven is still visible after the appliance has been

installed. This plate, which is visible when the oven door is open, contains all the

identification data of the appliance, as well the type of gas and service pressure for which it

!

has been calibrated. Follow the instructions and suggestions carefully to ensure the safe

and proper use of this product.

2

Page 3

CONTENTS

INSTRUCTIONS FOR THE INSTALLER (PAG. 4)

INSTRUCTIONS FOR INSTALLATION OF THE APPLIANCE PAG. 4

POSITIONING 4

VENTILATION 4

GAS CONNECTION 5

RIGID PIPE CONNECTION 5

CONVERSION TO A DIFFERENT TYPE OF GAS 6

NOZZLE TABLE 6

ADJUSTMENT OF THE MINIMUM SETTING FOLLOWING

CONVERSION TO A DIFFERENT GAS TYPE 7

FLUSH FITTING 8

ELECTRICAL CONNECTIONS 9

INSTRUCTIONS FOR THE USER (PAG. 10)

THE FIRST TIME YOU USE THE OVEN PAG. 10

SELF-CLEANING CATALYTIC PANELS 11

DESCRIPTION OF THE FRONT CONTROL PANEL

- GAS OVEN WITH ELECTRIC GRILL 12

- OVEN TEMPERATURE CONTROL 12

- ELECTRIC GRILL 12

- MECHANICAL MINUTE TIMER 13

DESCRIPTION OF THE FRONT CONTROL PANEL

- GAS OVEN WITH GAS GRILL 14

- OVEN TEMPERATURE CONTROL 14

- GAS GRILL 15

- OVEN LIGHT- SPIT ROASTER 15

COOKING IN THE OVEN 16

REMOVAL OF THE BURNER COVER PLATE 17

REPLACING THE OVEN LIGHT 17

REMOVING THE OVEN DOOR 18

RESPECT FOR THE ENVIRONMENT 18

3

Page 4

INSTRUCTIONS FOR THE INSTALLER

INSTRUCTIONS FOR INSTALLATION OF THE APPLIANCE

(positioning and ventilation requirements)

The regulations covering the installation, maintenance and operation of gas appliances

for domestic use are applicable regulations.

An extract of these regulations appears below. For all indications not covered, refer to

the above-mentioned regulations.

POSITIONING:

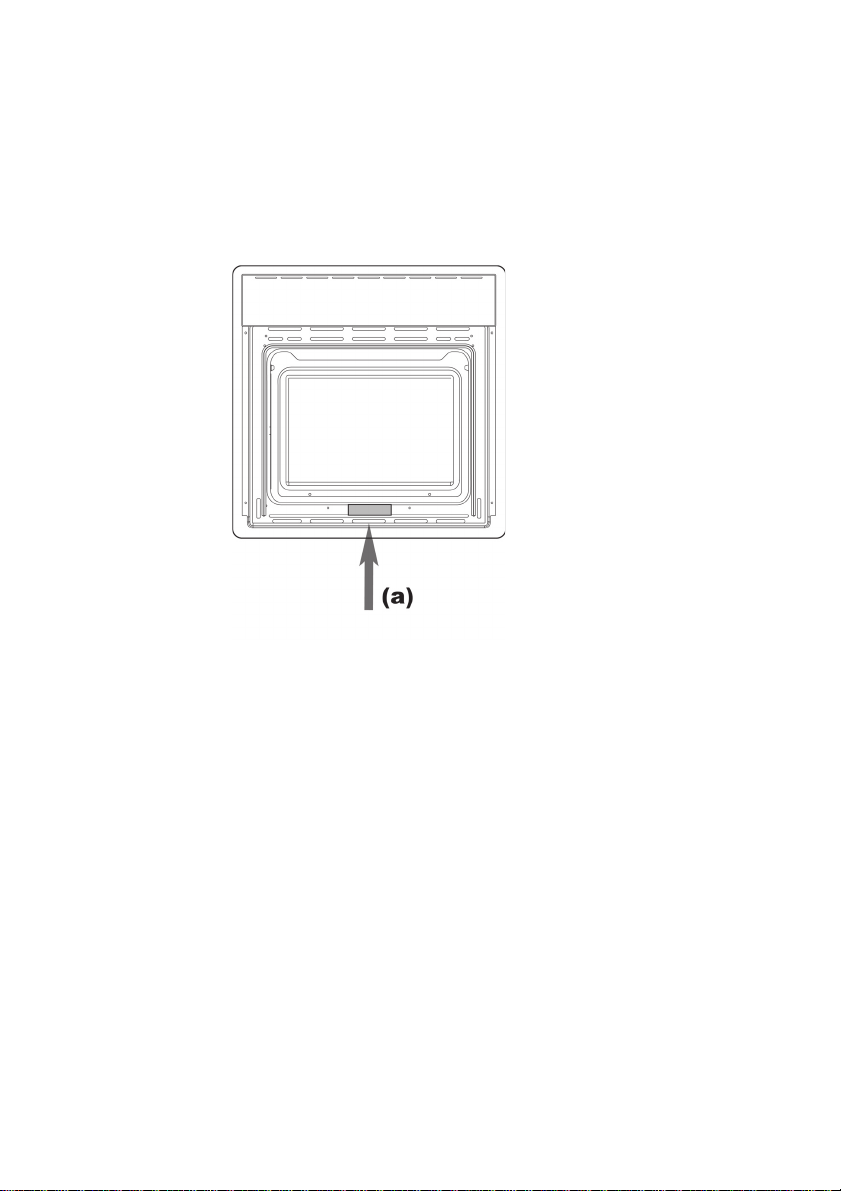

(Fig. 2) the products of combustion from cooking appliances must always be discharged

into suitable extractor hoods, which must be connected to a chimney, flue or vented

directly to outside the building. In situations where it is not possible to install an

extractor hood, an electric extractor fan installed in a window or external wall may be

used, provided that all requirements of the ventilation regulations are satisfied; the fan

should switch on whenever the appliance is in operation.

VENTILATION:

(Fig. 2) it is essential that the room in which gas appliances are installed is adequately

ventilated to ensure that all the appliances receive the required quantity of fresh air for

combustion.

To ensure an adequate air flow, it may be necessary to create apertures in accordance

with the following requirements:

a) with cross-sectional area of 6 cm2 per kW with a minimum cross-sectional area of 100

2

cm

(these apertures may also be created by increasing the gap between the bottom

of doors and the floor);

b) situated at the bottom of an external wall, preferably opposite the wall on which

combustion products are extracted ;

c) the positions of the apertures should selected so as to avoid the possibility of their

Fig. 2

being obstructed and, if made in external walls, they must be protected with grilles,

metal meshes, etc. installed on the outside face of the wall.

If an electric extractor fan for the removal of foul air is installed in the room, the

apertures provided for air changes must allow a ventilation rate of at least 35 m

kW of power installed.

3

/h per

4

Page 5

GAS CONNECTION

The oven is designed to operate with both natural gas (methane) and liquid gas (LPG),

and can be easily converted from one type to another following the instructions given in

the relative section of this booklet. Connection to the gas supply must be carried out by

qualified technicians and in conformance with the requirements.

If the appliance is to operate with gas bottles (LPG), a pressure regulator conforming to

the requirements.

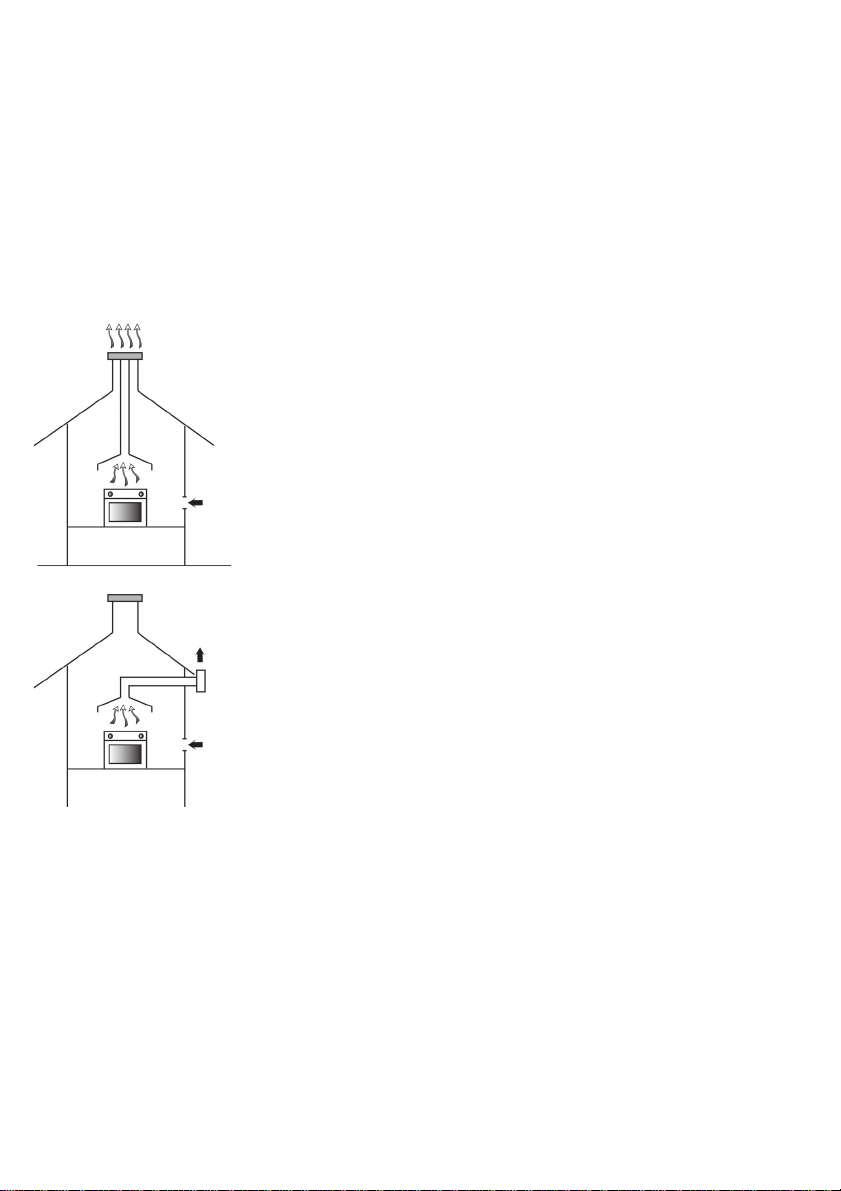

RIGID PIPE CONNECTION

Connection to the mains gas supply may be made via a rigid pipe firmly attached to the

fitting “G” (Fig. 3), or via a flexible stainless steel continuous-wall hose, conforming with

a maximum length of 2 metres.

The fitting “G” and seal “C” are supplied with the appliance, and comply with standards.

Important:

Use two wrenches to turn the fitting “G” to the required position. When the fitting is in the

desired position, firmly tighten nut “A” (Fig. 3).

Fig. 3

WARNING - IMPORTANT: after connecting the appliance to the gas supply (or

to the liquid gas bottles) CHECK FOR LEAKS at the union using a solution of

soapy water (never use a naked flame).

5

Page 6

CONVERSION TO A DIFFERENT TYPE OF GAS

Before converting the appliance for operation with a different gas type, check which type

of gas it is currently set to operate with (adhesive label (Figure 1) on appliance).

For the correct nozzle diameter, refer to the relative table in this booklet.

- Conversion procedure

*Disconnect the electrical power supply to the appliance;

* Change the main oven nozzle:

1) Remove the burner cover plate (see REMOVAL OF THE BURNER COVER PLATE

page 42).

2) Remove the screw securing the oven burner and withdraw the burner from the support

together with the heat sensor and the ignition spark plug. (Figure 5)

3) Remove the nozzle using a 7 mm box wrench (Figure 6)

4) Screw the new nozzle in fully (diameter in hundredths of millimetre stamped on the

nozzle), taking care not to cross the thread.

5) Replace the burner reversing the operations in step 2 above.

6) Replace the cover plate.

Fig. 5 Fig. 6

NOZZLE TABLE

The diameters in hundredths of millimetre are stamped on the nozzle.

Burner

Oven burner

Grill burner

kW

rated load

2,50

2,20

Ø Nozzle bore in

mm

G20 G30 G30

20 mbar 50 mbar 29 mbar

1,13 0,67 0,76

1,12 0,65 0,75

6

Page 7

ADJUSTMENT OF THE MINIMUM SETTING FOLLOWING CONVERSION TO A

DIFFERENT GAS TYPE:

1) Conversion from natural gas to LPG:

Ovens with stainless steel front

Turn the temperature control knob to the minimum position, then remove the knob.

Insert a screwdriver through the aperture to engage the bypass screw “A” . Turn the

screw fully to the right (see fig. 4).

Ovens with glass fronts

Remove the front by unscrewing the two ring nuts. Insert a screwdriver through the

hole in the front wall of the oven and turn the screw A fully clockwise.

2) Conversion from LPG to natural gas:

Turn the oven temperature control knob to the “min” position and allow the appliance

to warm up for about 10 minutes.

Then turn the bypass screw anticlockwise to a obtain a low but stable flame. Replace

the front.

After converting the appliance to a different type of gas, remember to change the data

plate to one with the new data (gas type and pressure). (Fig. 1).

Fig. 4

7

Page 8

FLUSH FITTING

The oven can be installed under a work top or in a cooking column. The dimensions of

the housing for the oven are given in figure 7.

Make sure that surrounding materials are heat resistant. Align the oven centrally with

respect to the side walls of the units surrounding it and fix it in place with the screws and

Allen screws provided.

If a gas hob is to installed in combination with the oven refer to the instructions

supplied with the hob (figure 8).

Fig. 7

Fig. 8

8

Page 9

ELECTRICAL CONNECTIONS

Before connecting the oven to the mains power supply, make sure that:

- The supply voltage corresponds to the specifications on the data plate on the front of the

oven.

- The mains supply has an efficient earth (ground) connection complying with all applicable

laws and regulations. Correct earthing (grounding) is a legal requirement. If the appliance

is not pre-fitted with a power cable and/or plug, use only suitable cables and plugs

capable of handling the power specified on the appliance’s data plate and capable of

resisting heat. The power cable should never reach a temperature 50° C above ambient

temperature at any point along its length. If the appliance is to be connected directly to

mains terminals, fit a switch with minimum aperture of 3 mm between the contacts. make

sure that the switch is of sufficient capacity for the power specified on the appliance’s

data plate, and compliant with applicable regulations. The switch must not break the

yellow-green earth wire. The socket or switch must be easily reachable with the oven

fully installed.

Fig. 9

* CABLE TYPES AND DIAMETERS 230V

N.B. The manufacturer declines all responsibility for damage or injury if the above

instructions and normal safety precautions are not respected.

H05RRF 3 x 1 mm

2

9

Page 10

INSTRUCTIONS FOR THE USER

THE FIRST TIME YOU USE THE OVEN

Clean the oven thoroughly with soapy water and rinse well. To remove the lateral frames

from smooth-walled ovens, proceed as shown in the figure.

Operate the oven for about 20 minutes at maximum temperature to burn off all traces of

grease which might otherwise create unpleasant smells when cooking.

Fig. 10

Important:

As a safety precaution, before cleaning the oven, always disconnect the plug from the

power socket or the power cable from the oven. Do not use acid or alkaline substances to

clean the oven (lemon juice, vinegar, salt, tomatoes etc.). Do not use chlorine based

products, acids or abrasive products to clean the painted surfaces of the oven.

10

Page 11

SELF-CLEANING CATALYTIC PANELS

Our smooth walled ovens can be fitted with self-cleaning panels to cover the inside walls.

These special panels are simply hooked on to the walls before the side frames are fitted.

They are coated in a special, micro-porous catalytic enamel which oxidises and gradually

vaporises splashes of grease and oil at cooking temperatures above 200° C.

If the oven is not clean after cooking fatty foods, operate the empty oven for 60 minutes

(max.) at maximum temperature.

Never wash or clean self-cleaning panels with abrasive, acid, or alkaline products.

Fig. 11

11

Page 12

Fig. 13

DESCRIPTION OF THE FRONT CONTROL PANEL

GAS OVEN WITH ELECTRIC GRILL

CONTROLS (Fig. 12)

1. Gas oven temperature control

2. Grill, spit roaster and oven light knob

3. Gas oven indicator light

4. Mechanical timer

5. Grill indicator light

Fig. 12

OVEN TEMPERATURE CONTROL

The temperature control knob serves to set the desired oven temperature and is equipped

with a safety valve. When the oven is in operation the green light is illuminated.

The minimum position corresponds to an oven temperature of 130°C. The control knob has

stop in the minimum position.

The “max” position corresponds to an oven temperature of 250°C, and is obtained when

the knob is turned fully anticlockwise.

To light the burner, push in the temperature control knob and turn it anticlockwise to the

desired temperature.

Hold the knob pressed in for 5-10 seconds. The burner will be ignited electrically, and the

safety valve temperature sensor will heat up thereby allowing gas to continue to flow to the

burner.

Do not operate the ignition for longer than 15 seconds. If the burner fails to ignite, leave the

door open for at least one minute, then try again.

If the electrical ignition fails to produce a spark, hold a lit taper or match near the burner

inspection hole and press and hold the temperature control knob in the “max” position for 5

to 10 seconds.

Fig. 14

ELECTRIC GRILL

Infrared grill: equipped with an energy regulator. The heat intensity of the grill can be set

from 1 to MAX using the relative control knob (Fig. 14). When the grill is in operation, the

grill indicator light and the oven interior light will be illuminated. To operate the spit roaster

motor, turn the knob to the symbol until you feel a click. Then turn the knob to desired

power setting from 0 to 8.

WARNING: The grill will not operate when the oven is on.

12

Page 13

Fig. 15

MECHANICAL MINUTE TIMER

The minute timer can be set to a maximum time of 60 minutes; it emits an alarm tone when

the set time period has elapsed. The minute timer operates independently of the oven.

The timer knob (Fig. 15) must first be turned clockwise to the 60 minute position and then

turned anti-clockwise to the desired time setting.

When the set time has elapsed, the alarm will sound. The alarm tone will stop automatically

after a certain period.

13

Page 14

Fig. 17 - Abb. 17 - Afb. 17

DESCRIPTION OF THE FRONT CONTROL PANEL

GAS OVEN WITH GAS GRILL

CONTROLS (Fig. 16)

1. Lower burner and gas grill temperature control knob

2. Oven and spit roaster control knob light

3. Gas oven indicator light

4. Mechanical timer

5. Electrical indicator light

Fig. 16 - Abb. 16 - Afb. 16

OVEN TEMPERATURE CONTROL

The temperature control knob serves to set the desired oven temperature and is equipped

with a safety valve. When the oven is in operation the green light is illuminated.

To turn on the bottom burner, push in the temperature control knob and turn it anticlockwise

to the desired temperature.

The minimum position corresponds to an oven temperature of 130°C. The control knob has

stop in the minimum position.

The maximum position corresponds to an oven temperature of 250°C, and is obtained

when the knob is turned fully anticlockwise.

Hold the knob pressed in for 5-10 seconds. The burner will be ignited electrically, and the

safety valve temperature sensor will heat up thereby allowing gas to continue to flow to the

burner.

14

Page 15

Fig. 18 - Abb. 18 - Afb. 18

GAS GRILL

The gas grill must only be operated with oven door slightly open and the heat shield

(supplied) inserted in the slots under the control panel.

To turn on the grill, turn the knob clockwise to the position and hold it pressed in for

5-10 seconds.

Fig. 19 - Abb. 19 - Afb. 19

OVEN LIGHT - SPIT ROASTER

This knob is used to switch on the oven interior light and the spit roaster (on models so

equipped).

15

Page 16

COOKING IN THE OVEN

With this cooking method, you can operate the oven in the normal way and follow the instructions

in recipe books.

The food to be cooked should preferably be placed on the middle shelf of the oven.

MAIN COURSE

GENOESE SPONGE

(SWISS ROLL)

SHORT PASTRY (BISCUITS)

DOUGH WITH RAISING AGENT

(SCHIACCIATA)

SPONGE CAKE

(SMALL PAPER PASTRY CASES)

LEAVENED DOUGH (STRUDEL)

PUFF PASTRY (TARTLETS)

SOUFFLÉ

SACHERTORTE

FRUIT PIE

CHOUX PASTRY

ROAST BEEF (APPROX. 1.5 KG)

ROAST PORK (APPROX. 1.5 KG)

PIZZA

BAKED FISH

BAKED VEGETABLES

POULTRY

SHELF

4

5

4

4

4

4

4

4

2

5

2

2

2

4

4

4

TEMPERATURE

(°C)

210

200

200

190

180

190

180

180

160

200

200

200

190

180

170

190 - 200

COOKING TIME

(min)

15 - 20

10 - 12

25 - 30

20 - 25

40 - 50

20 - 30

35 - 40

55 - 60

160 - 180

35 - 40

90 - 120

100 - 120

20 - 25

50 - 60

30 - 40

60 - 70

PREHEAT

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Guideline values for cooking with the grill:

MAIN COURSE

STEAKS

CUTLET

SHELF

5

5

16

POSITION

10

10

COOKING TIME

(min)

10 - 15

15 - 25

PREHEAT

--

--

Page 17

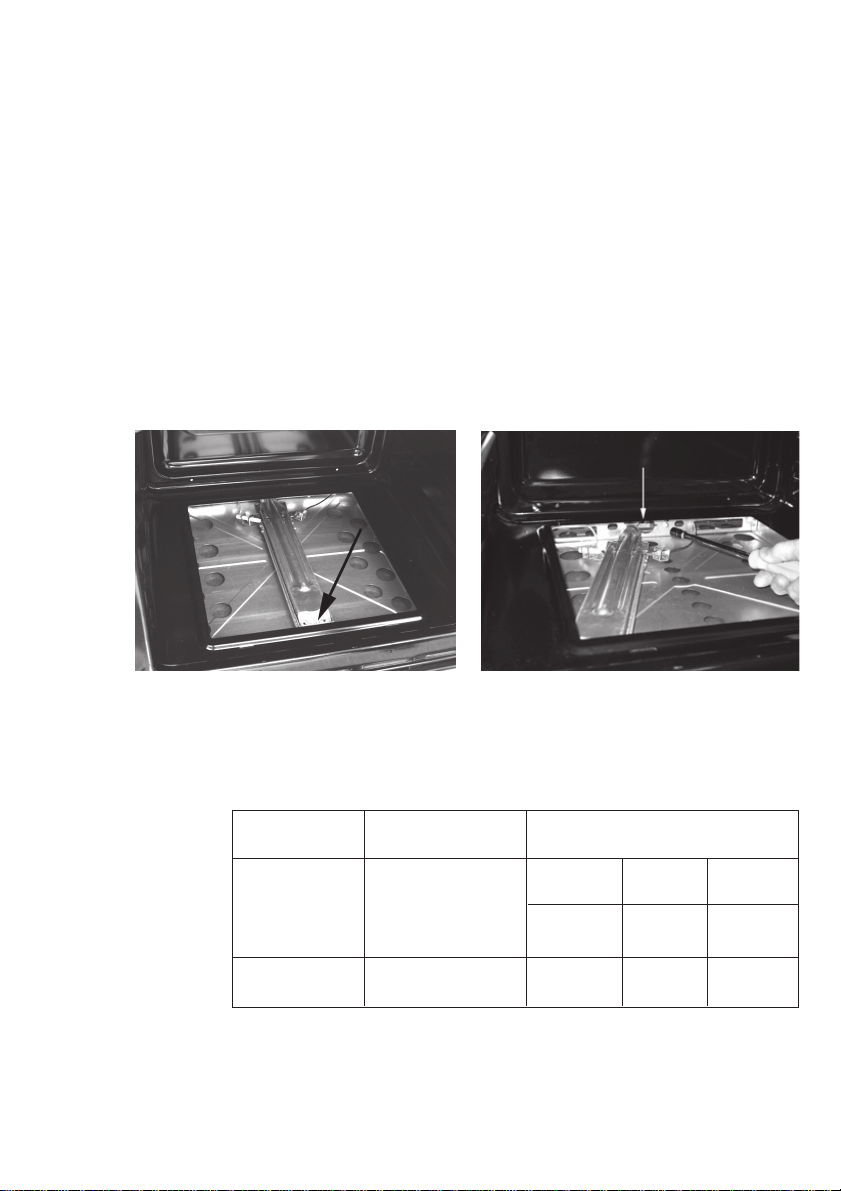

REMOVAL OF THE BURNER COVER PLATE: (see fig. 20)

The burner cover plate is secured at the front by two tabs inserted in two slots; to remove the

cover plate, raise the rear of the plate so that it pivots at the front and withdraw the tabs form

the slots.

Fig. 16

REPLACING THE OVEN LIGHT

IMPORTANT:

The oven light must have these precise features:

a) it must be able to resist high temperatures (up to 300

b) power supply: see V/Hz indicated on data plate.

c) power 25W.

d) E 14 connection.

Before proceeding, disconnect the appliance from the main electricity supply.

-to prevent damage, place a tea cloth in the oven

- unscrew the glass cover of the light

- unscrew the old light bulb and replace it with the new one

- put back the glass cover and remove the tea cloth

- connect the appliance to the main electricity supply.

°C)

17

Page 18

REMOVING THE OVEN DOOR

The oven door can be removed quickly and easily. To do so, proceed as follows:

- Open the door fully.

-Lift the two levers shown in fig. 21.

-Close the door as far as the first stop (caused by the raised levers).

-Lift the door upwards and outwards to remove it from its mountings.

To replace fit the door, fit the hinges in their mountings and lower the two levers.

Fig. 17 Fig. 18

RESPECT FOR THE ENVIRONMENT

The documentation provided with this oven has been printed on chlorine free bleached

paper or recycled paper to show respect for the environment.

The packaging has also been designed to avoid environmental impact. Packaging material

is ecological and can be re-used or recycled.

By recycling the packaging, you will help save raw materials as well as reducing the bulk of

domestic and industrial waste.

18

Page 19

Page 20

The manufacturer declines all responsibility for possible inaccuracies contained in this pamphlet, due

to printing or copying errors. We reserve the right to make on our own products those changes to be

considered necessary or useful, without jeopardizing the essential characteristics.

COD. 2.000.73.0

Loading...

Loading...