Page 1

INTEGRATED EXTRACTOR

Instruction Manual

Model No: 1MINCH6&2MINCH6

Page 2

▇

P1

▇ TABLE OF CONTENTS

▇▇

Contents

1. Extraction Without Intrusion P1~3

Extraction Without Intrusion

The extractor is designed to give you the option to extract air by the

outside and away (via exterior wall), or to re-circulate air through

designed filters to minimize odors, steam and condensation. For internal

recycling the following is required .CF11 Charcoal Filter .Contact 01

4505327 To order

The choice is yours to decide at installation, and both systems are

explained in this booklet.

We recommend that you read this booklet from cover to cover before

attempting to install or operate the extractor

2. Safety & Cleaning P4~5

3. Alternative Methods Of Extraction P6

4. Operation P7

5. Fitting Charcoal Filter / Bulb Replacement P8

6. Electrical Connections P9

7. Not Working Properly P12

8. Technical Data P13

Installation

THESE INSTRUCTION MUST BE STRICTLY ADHERED TO, FAILURE

TO COMPLY COULD RESULT IN OVERHEATING AND SERIOUS

DAMAGE TO YOUR APPLIANCE

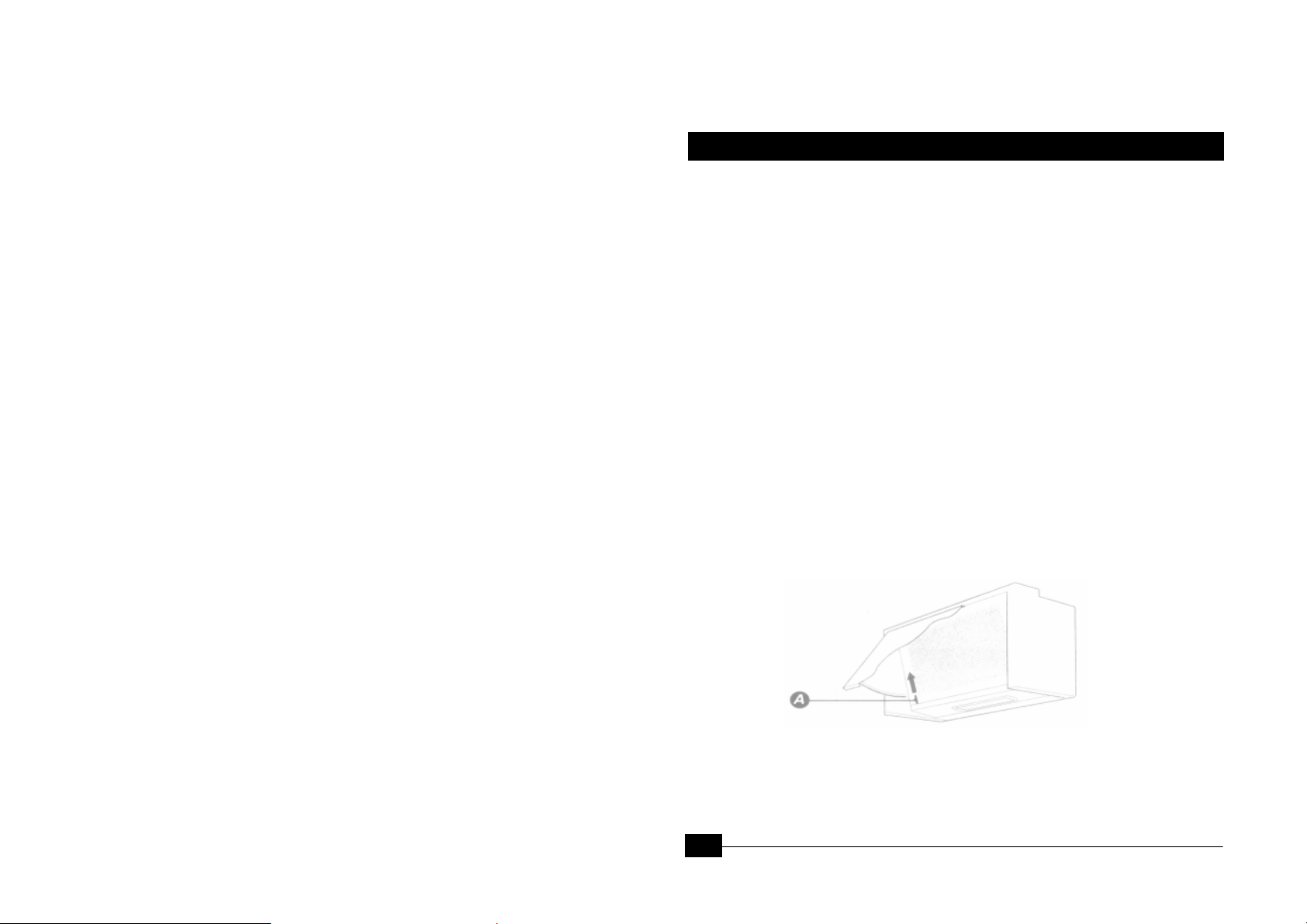

To secure the product to the wall you must initially remove the

grille/anti-grease filters. This is achieved by opening the front panel and

pushing the two catches (A) upwards which will then release the grille.

Page 3

P2 P3

Extraction Without Intrusion Cont..

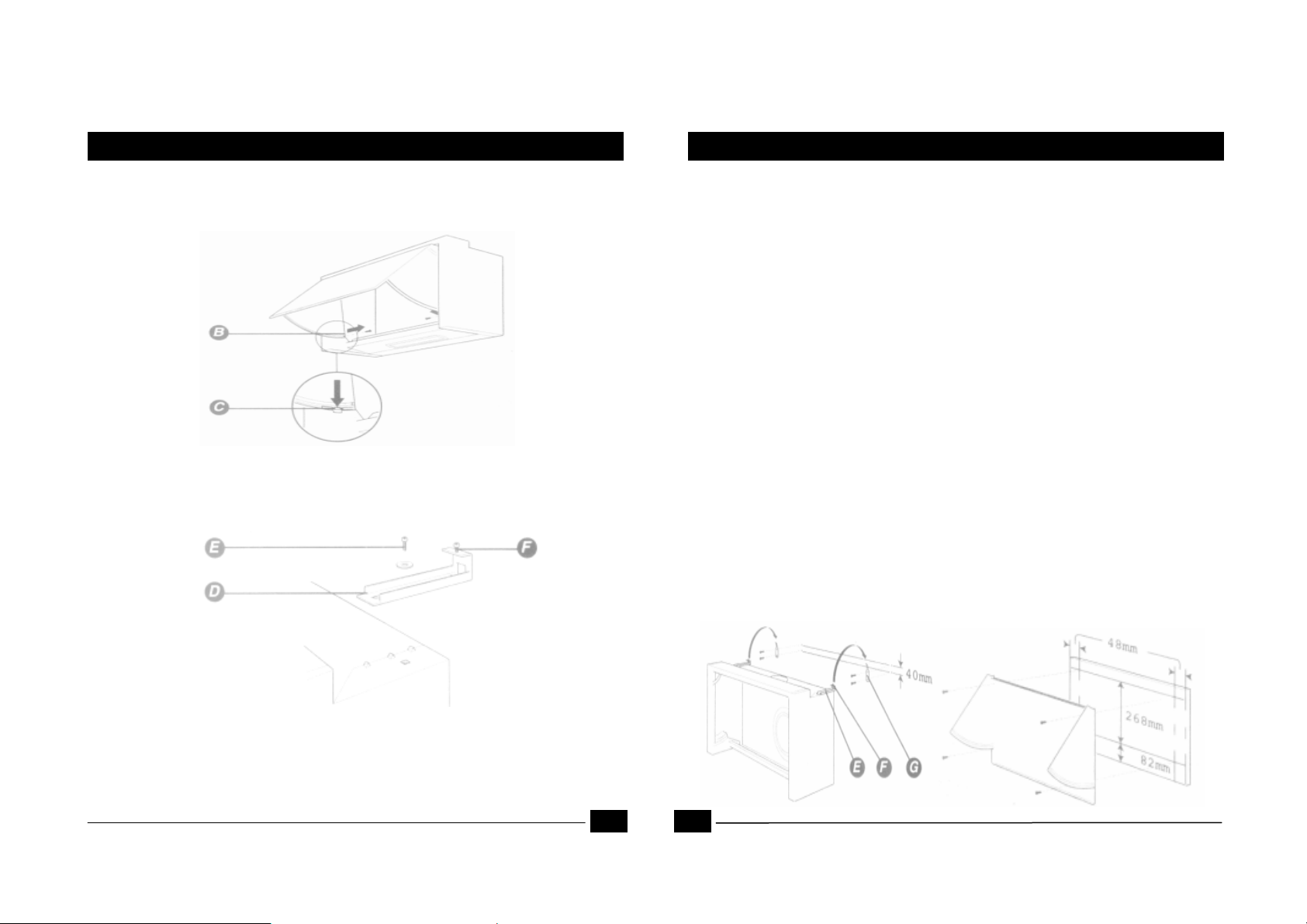

Once the grill has been removed, The front door panel should also be

removed.

Open the front panel and remove the two screws (B) as illustrated above.

Press the tab (C) down and remove the front panel from its guides

Extractor Without Intrusion cont..

Ensuring there is a minimum distance if 65cm between the bottom of the

extractor and hob surface. Then fix the two mounting brackets (G) to the

rear wall.

Once the two mounting brackets are in position hook the extractor

mounting bracket (D) onto the wall mounting bracket

Some adjustment is provided within the brackets. For forward and

backward adjustment use screw (E) and for height alignment adjusts

screws (F).

Once the adjustment is complete fully tighten all screws.

If after installation there is a gap between the rear wall and the extractor

a spacer is provided. This can be fixed to the rear of the extractor and

cut to accommodate the gap.

IMPORTANT NOTE: After the extractor has been positioned correctly

the extractor must be fixed to the adjacent through the fixing holes in the

sides of the extractor.

All that remains is to fix the front wooden door panel to the extractor by

using the diagram below fix the front panel

Secure brackets(D) onto the top of the extractor using the fitting

screws and washer (E).Check that adjustment screw (F) is fitted.

Note: Note some units may have bracket fitted.

Page 4

P5

P4

Extractor

Electrical Safety

Before you think about fixing give care consideration to the power

connection. It is vital that the supply cable should be well shielded from

your grill, hob or oven. If it isn’t, heat from any one of these sources may

damage the cable insulation and give rise to a fire risk. Under no

circumstances should the exposed power supply cable come within

70cm of a direct source of heat, ideally it should be channeled into the

wall, well out of harm’s way.

For Your Safety

In order to protect your appliance and minimize the risk of fire, don’t

barbecue food directly under the extractor. Similarly, do not prepare

flambé dishes immediately off the flame. Your extractor is designed to

draw gases up and away from your hob. This means that exposed

flames may behave unpredictably in the vicinity of the appliance while it

is switch on. When frying take particular care to prevent the oil from

catching fire and never leave unattended.

Cleaning

IMPORTANT: Before attempting any cleaning or maintenance, ensure

your extractor is disconnected from the power source.

GENERAL CLEANING: Regular and thorough maintains guarantee will

provide long lasting operation.

Wipe the external surface of the appliance regularly using warm and a

mild detergent, never use products containing abrasive

Cleaning

Particular care must be paid to the grease filtering panels which must be

periodically cleaned in relation to use (at least once every two months)

Alternative Methods Of

1. Extraction Via Ducting (fig.1)

The very best method of cleaning the kitchen of unwanted odors is

by connecting the appliance to an exhaust duct and venting to the

outside atmosphere via exterior wall (suitable ducting kits may be

purchased from the store where you buy your extractor.) Ducting

your extractor negates the need for charcoal filters.(Fig.1)

Remember: Before drilling or chiseling the wall, check for the pipes and

power cables.

1. Ensure the ducting tube is kept as short as possible and

with minimum of bends to permit the most smooth airflow.

(Maximum length 3M)

Page 5

Alternative Methods Of

Extractor

P6

Alternative Methods Of

Extractor

P7

2. Ducted air must not be discharged into a flue which is used for

exhausting fumes from appliances supplied with energy other than

electricity.

3. Ensure the requirement of the local authorities are adhered to

concerning the discharged of exhaust air.

4. Ensure adequate room ventilation is provided when the extractor is

used in the same room as appliances supplied with energy other

than electricity.

5. Never duct into a hot air flow such as a central heating dust.

We strongly advise that all exterior outlets be fitted with a non return

valve of louvered slotting.

2. The Re-circulation Mode (Fig.2)

When there is no easy access to an outside wall, the extractor can

easily be adapted to clean air polluted by cooking smells, by using a

charcoal filter which can be purchased from the store where you buy

your extractor. Remember the re-circulation mode can not be used

without a charcoal.

The Charcoal Filter

Filters do have a limited life. We advise you to change it when there is a

noticeable drop in performance. The intervals between changing the

filter will depend entirely upon the amount of cooking you do. But on

average they will last about 4 months.

The Grease Filter

The grease filter requires cleaning every 3 months. If the mat is a

metallic mater it can be cleaned in a dishwasher or washed with a

neutral detergent.

IMPORTANT: You should never attempt to use the extractor without

the grease filter as grease build-up could prevent the motor working

properly. If either filter is not supplied pull out the plug before

changing the filters.

Operation Your Extractor

The motor will automatically operate by opening and closing the

front door panel as long as the switch is set accordingly. The

extractor fan has three speed settings for light, medium or heavy

extraction of cooking vapors. The different levels of extraction are

number 1 ,2&3 and can be recognized by the changes in noise level

of the extractor fan when operating.

To switch on the light simply move the switch to position 1.

NOTE: The light is not effected by opening or closing the front

panel.

Page 6

P8

Electrical Connections

P9

Alternative Methods Of

Extractor

Bulb Replacement

To replace a bulb simply remove the grill and unscrew the bulb. Replace

with one of the identical type.

Note: The bulb is not covered by the guarantee.

Always switch off the electricity supply prior to changing the bulb.

IMPORTANT: ENSURE THAT THE ELECTRICITY SUPPLY IS

SWITCHED OFF BEFORE CONNECTING.

Your appliance must be connected to fix wiring via the use of a

double pole switched fused spur outlet with at least 3 mm contact

separation, and preferably with a pilot lamp. (See technical data

for fuse rating). We strongly recommend the appliance is

connected by a qualified electrician

NOTE: The terminology “DOUBLE POLE” means that both the

live and neutral supplies are switched and disconnected at the

same time.

The terminations labeled SUPPLY are for the connection for the

internal house wiring and the terminations labeled LOAD are for

connection for the appliances.

Page 7

P10 P11

Electrical Connections

Important:

The wires in this mains lead are colored in accordance with the following

code:

Blue Neutral

Brown Live

As the colors of the wires in the mains lead of this appliance may

correspond with the colors markings identifying the terminals in your spur

box, proceed as follow:

The wire which is colored blue must be connected to the terminal which is

marked with the letter “N” or colored black. The wire which is colored brown

must be connected to the terminal which is marked with the Letter ‘L’ or

colored red.

WARNING

This appliance has such technical particulars that it belongs to Class 2

insulation and therefore neither wire should be connected to the terminal

marked with the letter E or by the earth symbol.

Not working Properly ?

Light bulb doesn’t come on

A replacement is probably necessary, But check first that the bult

is firmly screwed in to its holder. If the filament is broken,

remember that the light bulbs are not covered by our guarantee.

Remember to disconnect power supply before removing the bulb.

Motor is on but fan doesn’t seem to be as efficient as usual

Check grease filter. If it hasn’t been cleaned recently, It might be

clogged with grease. If filter is relatively clean, check charcoal

filters. If this hasn’t been replaced for more than six months.

Remove and replace a new one. As charcoal filters is just the

same way as the grease filter, thereby reducing the efficiency of

both the fan and the filter itself.

Works normally but cooking smells linger

If you’re using the unit in re-circulation mode, change charcoal

filter. It is obviously past its prime.

Controls fail to switch motor no

Check plug, socket and fuse. If these are in order and fault

persists, it could be that an accumulation of grease has impaired

the efficiency of the switch mechanism. Try rapidly moving switch

Page 8

P13 P12

Not Working Properly ?

on and off several times in succession to clear grease deposit. If

fault continues, call service agent.

Appliance does not work at all

Check your extractor is switched on at the mains. Next, check out for an

unexpected power strike by switching on adjacent lights etc.

Still not working? Call the service agent

If, having consulted the above diagnostic chart you are still unable to

remedy the situation, please call Service Call 0870 2411 142..

Technical Data

Single Motor Model

Voltage 220V~240V / 50Hz

Rotation method Single Motor

Rated motor input power 120W

Illumination

Rated input power 145W

Suction power 210m3/h

Noise

Outlet diameter 120mm

Twin Motor Model

Voltage 220V~240V / 50Hz

Rotation method Single Motor

Rated motor input power 120W x 2

Illumination

Rated input power 290W

Suction power 270 m3/h

Noise

Outlet diameter 120mm

≤

25W

≤

61dBA

≤

25W x 2

≤

65dBA

Loading...

Loading...