Page 1

CapKold Cook-Chill Production Systems

Rapid Product Chiller/Cook Tank

r CKWJ

General Description:

Rapid Product Chiller/Cook Tank shall be a CapKold WaterJet™ Model

WJ100 gallon (product chilling capacity) fully automatic Cook/Chill

unit designed to rapidly chill pump-able food products and ingredients

packaged in special plastic casings in a rapid and turbulently circulating water bath. Unit to chill most products from bag fill temperature

of approximately 180° F to 40° F in 60 minutes or less. Unit to also

slow cook or slack prepackaged raw meats, vegeta-bles and starches;

or rapidly reheat cook-chill or ven-dor prepared foods in a circulating

hot water bath. Unit to include internal hoist mechanism to raise and

lower product baskets and not require any external device for this function, powerful water circulation pump, fully automatic operator control

package, and sheathed and air gap insulated tank with splash covers.

WaterJet Chiller/Cook Tank to include the following standard features:

Standard Features:

• Type 304 stainless steel tank with 1” radius corners

• Insulating, non-corroding double wall construction on exposed

tank sides

• Fully enclosed and vented pump/utility housing

• 6” legs with adjustable floor mounting flanges

• Attached stainless steel splash covers with lift assist

• Probe for recording internal temperature of solid muscle products

• Diverter valve to control water discharge flow and turbulence

• Foreign object screen protects pump

• Water level overflow protection

• Automatic 2” drain with 75 GPM capacity

• NSF listed

Cook Tanks & Chillers

• Cook Tank Operation: Select (cook to internal product temperature or time), Digital Water Temperature (actual and set point),

Digital Product Temperature (actual and set point), Soak Time (for

thawing frozen products)

• Heat Only Operation: Digital display of water temperature only

(Meat probe not active)

Chilled Water Production (Self-Contained):

No Ice Builder needed. For Remote Refrigeration Package see CapKold

Spec CK-83 or CK-84.

Water Heating System:

This unit is direct steam heated and requires a steam source of 20-50 PSI.

Agency Approvals:

• Unit NSF Listed

• Unit UL Listed

• Built to ASME Code

Control Package:

Control box is NEMA-4 water resistant enclosure. Integrated Operator

Controls mounted on tank front and include:

• Function selection for: Tumble Chill, Cook-Chill, Heat only and

Pump only (for cleaning)

• Rapid Chill Operation: digital display of chilling time, digital

display of water temperature

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Options:

r 24 Hour Time/Temperature Recorder (For recording water and

product time and temperature)

Notes:

• WJ100 requires double doors or 55” wide minimum access to

site of installation

Groen CapKold Cook Tanks & Chillers, Page 22

CKWJ 160377A

Revised 08/06

Page 2

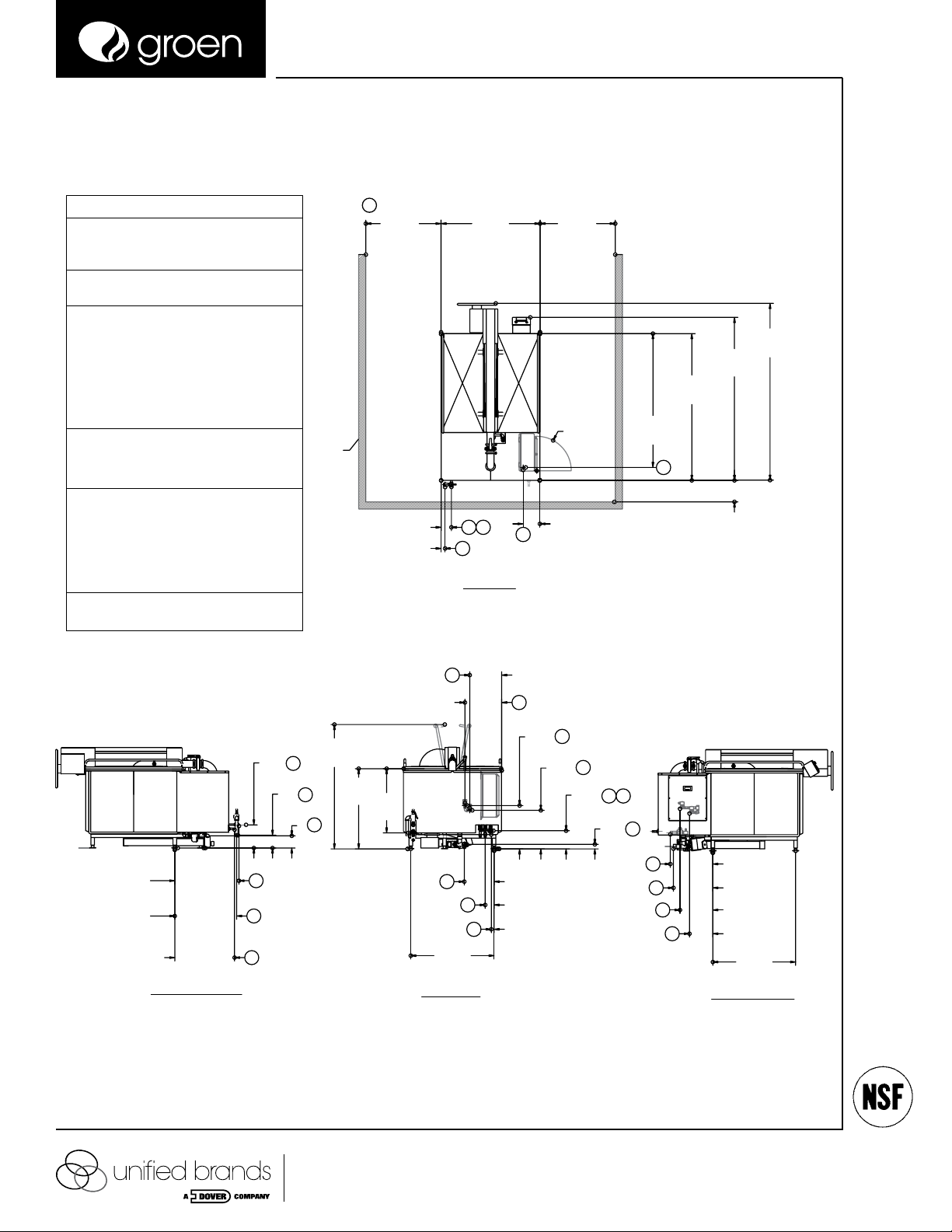

100 GALLON WATERJET

CKWJ Product Chiller/Cook Tank

160663 REV A

UTILITY REQUIREMENTS

CW = COLD POTABLE WATER INLET

HW = HOT POTABLE WATER INLET

DR = DRAIN LINE

2" NPT 75 GPM

SI = STEAM INPUT 3/4" NPT

SO = STEAM OUTLET

SS = STEAM SAFETY VALVE

REFRIGERATION INSTALLATION

RL=REFRIGERANT LIQUID LINE

RG=REFRIGERANT GAS LINE

(dependant on distance and elevation)

EP = POWER SUPPLY

208/240-20 AMPS

480-20 AMPS

CONNECTION PER LOCAL CODES

208 OR 230/460/3/60

DISCONNECT SUPPLIED BY OTHERS

(CUSTOMER TO SPECIFY REQUIRMENTS)

APROX. SHIPPING WEIGHT

APPROX. OPERATING WEIGHT

NOTES:

1) PRIOR TO INSTALLATION OF THIS EQUIPMENT,

CAPKOLD SERVICE DEPARTMENT MUST AUTHORIZE

THE USE OF RSES CERTIFIED REFRIGERATION

TECHNICIANS.

2) MINIMAL REQUIREMENT FOR FUNCTION ONLY.

CONSULT STATE LOCAL CODES BEFORE INSTALLING.

3/4" NPT - 15 GPM

3/4" NPT - 90 PSI MAX

400 lbs/Hr MIN

3/4" NPT

1-1/4" NPT

7/8" OD

1-5/8" OD

1560 LBS

3700 LBS

13 1/4

7 1/4

WALL

2

42

MINIMUM

5 3/4

2 1/8

55 1/4

SI

SO

SS

EP

42

MINIMUM

R19 1/4

9 3/8

98 3/4

91

81 7/8

74 3/4

EP

12 MINIMUM

TOP VIEW

HW

18

24 1/4

HW

21 5/8

CW

10 1/4

RG RL

2 1/2

DR

CW

20 5/8

69 3/4

SI

SS

7

45

36

SO

36 5/8

35 1/4

34 1/8

RIGHT SIDE VIEW

RG

SI

SS

RL

DR

46 3/4

16 3/4

RL

5

1 5/8

RG

DR

HW

CW

REAR VIEW

24

22 1/4

18 1/2

13 1/8

46 3/4

LEFT SIDE VIEW

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Loading...

Loading...