Page 1

CAPKOLD

TUMBLE CHILLER

MODEL CKTC-320

Instruction & Parts Manual

January 2007

CKTC-320 01-03-07.doc

MODEL # CKTC·320·1101

MACHINE SERIAL # 5846·07·01·102

Page 2

TABLE OF CONTENTS

Instruction & Parts Manual

CapKold Tumble Chiller

Model CKTC-320

Forward.......................................................................................................................................3

Chapter One...................................................................................................................................4

Introduction................................................................................................................................4

Safety...........................................................................................................................................4

Chapter Two...................................................................................................................................5

Installation..................................................................................................................................5

General....................................................................................................................................................5

Receiving and Setting..............................................................................................................................5

Utility Connections..................................................................................................................................6

Chapter Three................................................................................................................................7

Equipment Description..............................................................................................................7

General....................................................................................................................................................7

General Specifications.............................................................................................................................7

Standard Features and Component Details.............................................................................8

Optional Equipment...................................................................................................................9

Machine Specification Sheet....................................................................................................10

Chapter Four................................................................................................................................13

Operations.................................................................................................................................13

Safety Precautions and Instructions.......................................................................................................13

Preoperational Checks...........................................................................................................................14

Machine Controls..................................................................................................................................15

Chiller Operation...................................................................................................................................17

Manual Operation..................................................................................................................................24

Troubleshooting.....................................................................................................................................27

Chapter Five.................................................................................................................................28

Maintenance and Repair .........................................................................................................28

Scheduled Maintenance.........................................................................................................................28

Sensor Adjustment................................................................................................................................28

Water and Steam Valves.......................................................................................................................29

Door Seal...............................................................................................................................................32

Drive Assembly.....................................................................................................................................33

Chapter Six...................................................................................................................................34

Spare Parts List........................................................................................................................34

Chapter Seven..............................................................................................................................35

Diagrams...................................................................................................................................35

Pneumatic Diagram...............................................................................................................................35

Water Valve Diagram............................................................................................................................36

2

Page 3

Instruction & Parts Manual

Forward

The purpose of this manual is to provide information that will aid in the installation, operation,

maintenance and repair of a CapKold Tumble Chiller. This manual should be read completely

before installing and/or operating this machine. While every effort is made to provide accurate

and up-to-date information, CapKold reserves the right to change the specifications herein

without notice. CapKold also reserves the right to make changes and improve this product

without obligating itself to install any such changes or improvements in products previously

manufactured. The illustrations and descriptions herein are general in nature and may not include

all standard equipment or may include optional equipment.

The only applicable warranty is our standard written warranty, and there is no other warranty,

written or implied.

3

Page 4

Chapter One

Introduction

The information in this section will aid in the operation of the CapKold Tumble Chiller and must

be read completely before operating the unit.

The CapKold Model CKTC-320 front loading batch tumble chiller is designed to rapidly chill

food packaged in flexible plastic casings by gently agitating the casings in a water bath that

accelerates product chilling from 180 deg F to 40 deg F in less than 60 minutes. The touch screen

control provides easy operator interface and is also password protected to add or change formulas

to meet the customer’s product requirements. The chilled water source provided by the customer

is pumped through a heat exchanger which includes an automatic back flush to maintain optimal

heat transfer efficiency. A recycle tank is available to reuse chilled water after each cycle saving

water and energy.

Safety

The CapKold Tumble Chiller was designed with the safety of the operator and maintenance

personnel in mind, as well as the safe functioning of the machine. Continuous safety of the

operators and plant personnel can only be maintained through cautious and competent operation

as well as regular and complete maintenance.

Safety precautions and warnings are noted in this manual as their need occurs. Please make note

of them and pay special attention.

This tells the operator that extreme danger exists and explains the necessary and safe actions to

This tells the operator that equipment may be damaged unless certain actions are taken.

Calls attention to an important condition or event.

WARNING

protect himself and others.

CAUTION

NOTE

4

Page 5

Chapter Two

Installation

General

The following instructions will aid in a quick and correct installation of your new Tumble Chiller.

Receiving and Setting

Receiving: Immediately upon receipt, the unit should be inspected for any damage that may have

occurred during shipping. Any damage should be reported to the driver and the freight company

immediately.

Tools Required: Open end wrenches and flat blade screwdriver.

Lifting and Handling: The approximate weight of the tumble chiller is 2500 lbs. The machine

may be lifted by fork truck from the front of the machine.

Setting Machine: Choose a clean level area protected from weather conditions, moisture, heat,

and any foreign debris above or around the unit. Insure that adequate clearance exists between

machine and other machines and obstructions. A minimum of 3 feet should be maintained.

Final Machine Leveling: Machine must be level from front to back as well as side to side. If

not level, adjust leveling legs maintaining a minimum of 6 inch clearance from floor to bottom of

machine.

Optional Recycle Tank: The approximate weight of the recycle tank is 700 lbs. The tank may

be lifted by fork truck from the front of the machine. Align the 4 pins with the holes on the base

machine and lower in place. Connect hoses to base machine.

Panels: Install all panels using the truss screws provided.

5

Page 6

Utility Connections

Electrical: Installation and grounding must conform with local codes, or in absence of local

codes, with the National Electrical Code.

Branch Circuit Protection

Machine Voltage Wire Size * Breaker Size

208 VAC 12 15 AMP, 3 Pole

220 VAC 12 15 AMP, 3 Pole

460 VAC 12 15 AMP, 3 Pole

* Wire size based on THW or MTW wire. If run exceeds 300 ft, use next larger size.

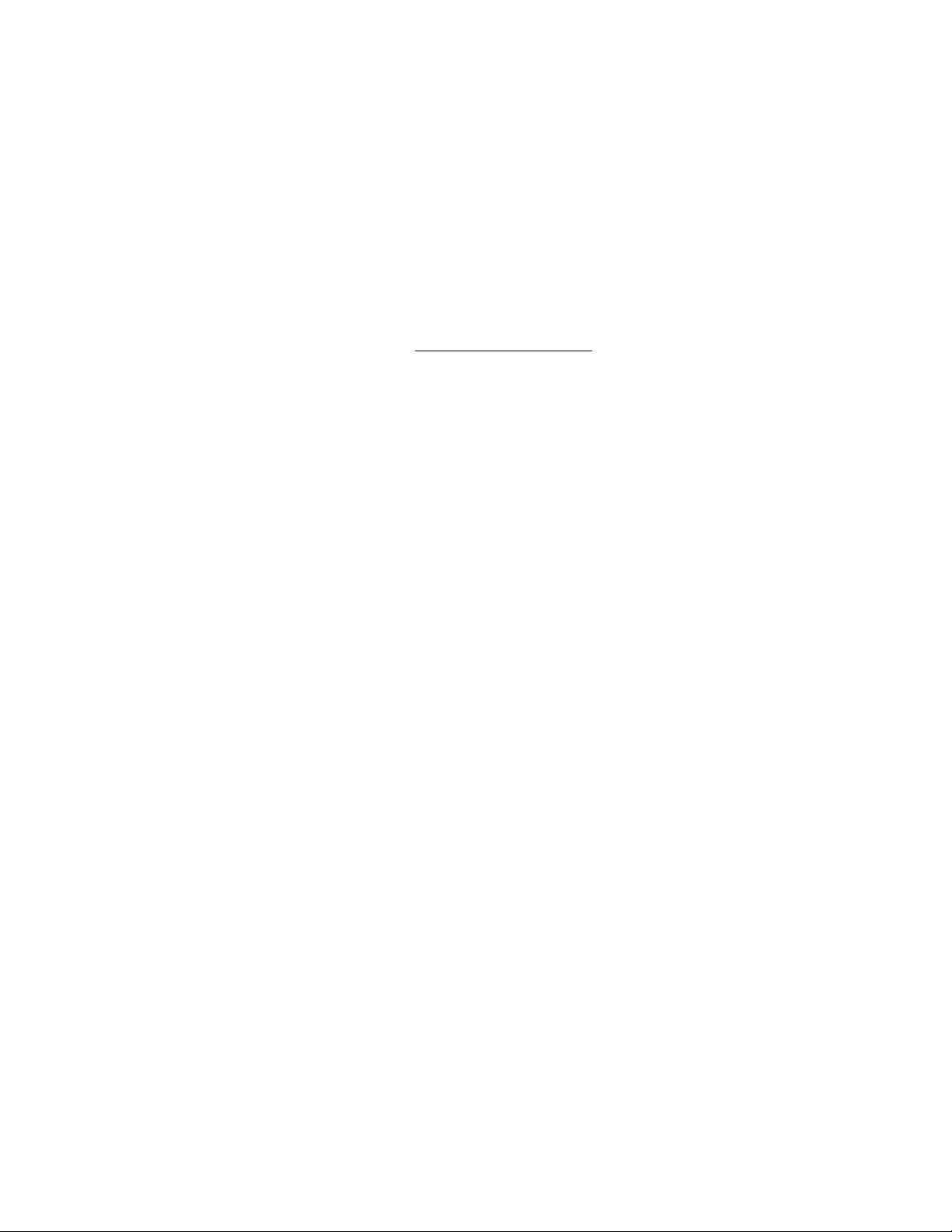

Air: The air supply is connected to a 1/4” pipe at the rear left side of the machine. The air supply

must be 90-100 PSIG. A shut off valve should be provided at or near the connection.

Mains Water: The mains water supply is connected to a 1 1/2” pipe located at the rear right side

of the machine (see Figure 2). A shut off valve should be provided at or near the connection.

Chilled Water: The chilled water supply is connected to a 1 1/2” pipe located at the rear right

side of the machine (see Figure 2). The chilled water return is connected to a 1 1/2” pipe located

above the chilled water supply connection. A shut off valve should be provided at or near the

connections.

Steam: The steam supply is connected to a 1-1/4” pipe located at the rear right side of the

machine (see Figure 2). A shut off valve should be provided at or near the connection.

Waste Drain: The waste drain is connected to a 2” pipe located at the rear bottom right side of

the machine (see Figure 2).

6

Page 7

Chapter Three

Equipment Description

General

The CapKold Model CKTC-320 batch tumble chiller will chill up to 320 gallons of bagged

product. The machine is stainless steel construction throughout with a perforated stainless steel

basket. An inclined loading chute allows continuous loading of product while the basket is in

motion.

The touch screen control provides easy operator interface, with simple custom programming.

The drive system consists of a variable speed 1 HP motor and a selectable reversing function for

improved tumble action while chilling and a manual jog for distribution while unloading. Power

transmission to the cylinder is performed by a direct drive gear box to achieve smooth operation.

The door is locked and sealed pneumatically and may not be opened while the tumble chiller is

operating. This interlock also requires that the door be shut and sealed prior to starting.

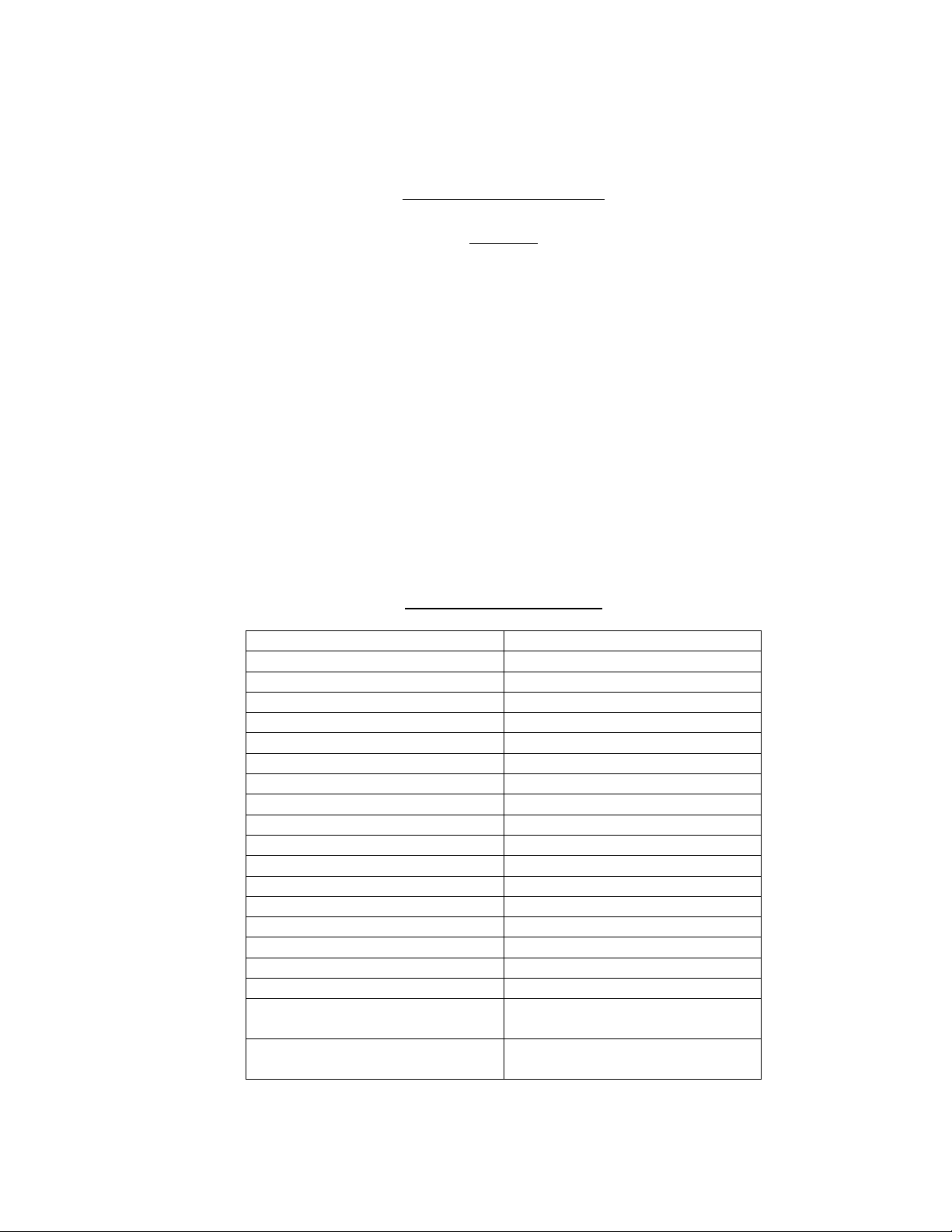

General Specifications

Basket Size 58” Diameter x 46” Depth

Basket Volume 70.3 Cubic Ft.

Basket Material 14 Gauge 304 Stainless Steel

Basket Rib Size Four 4 1/4” High Triangular Ribs

Basket Angle 10 Degrees

Door Opening Size 30” Diameter

Door Chute Opening Size 12” Diameter

Drive Motor 1 HP

Centrifugal Pump Motor 1 1/2 HP

Basket RPM 2-8 RPM

Water Inlet Size 1 1/2”

Chilled Water Inlet Size 1-1/2”

Steam Inlet Size 1 1/4”

Drain Size 2”

Overflow/Vent Size 1 1/2”

Electrical Service 208VAC-16 Amps

Air Supply 1/4”, 90-100 PSI

Shipping Weight 2,500 LBS

Shipping Dimensions Tumble

Chiller

Shipping Dimensions Optional

Recycle Tank

64” Wide x 96” Deep x

80” High

64” Wide x 83” Deep x

24” High

7

Page 8

Standard Features and Component Details

Gear Motor Drive with Inverter: The machine includes a 1 HP single motor drive and AC

variable frequency inverter. This arrangement provides precise speed control of the inner basket

between 2 and 8 rpm’s through a gearbox motor mounted directly to the basket’s main shaft. The

basket rotation options include one way, oscillate and gentle. The energy efficient motor is rated

for continuous duty. The inverter is safely mounted in the electrical cabinet.

Front Door: The front door includes an inclined loading chute to allow continuous loading of

product while the basket is in motion. Pneumatics are used to seal/lock and unlock the door.

Heat Exchanger: The chilled water source is pumped through a high heat transfer coefficient

plate heat exchanger.

Leveling System: A leveling system consisting of four adjustable legs. No special foundation is

required other than a floor with the capacity to hold the static weight load of the machine, water,

and products contained within.

Bearing Design: A shaft mounted flange bearing design and integrated bearing/motor/gear box

supports the cantilevered load of the inner basket. The front and rear bearings are sealed ball

bearings and do not require grease.

Seal Housing: A housing containing a spring loaded ceramic seal keeps water and chemicals

contained in the machines shell from leaking out, while allowing the machine’s main basket shaft

to rotate freely. The ceramic seal is lubricated with water and the basket will not rotate without

the centrifugal pump turned on or without the mains fill open.

Mains Water Inlet Valve: The water inlet valve is pneumatically operated, 1 1/2” butterfly type,

and is closed by spring pressure.

Chilled Water Inlet Valve: The water inlet valve is pneumatically operated, 1 1/2” butterfly

type, and is closed by spring pressure.

Steam Inlet Valve: The steam inlet valve is pneumatically operated, 1-1/4” butterfly type, and is

closed by spring pressure. The standard machine is outfitted with one valve for direct steam

injection into the bottom of the shell through a diffuser nozzle. Steaming does not occur until the

water level has been satisfied. If no steam is available, hot water supply can be used and must be

programmed in the formula.

Drain Valve: A pneumatically operated, 2” butterfly type valve mounted below the outside shell

allows for rapid gravity draining of waste water.

Automatic Back Flush: An automatic back flush of the heat exchanger will back flush build up

of foreign matter which has entered the heat exchanger in order to maintain optimal heat transfer

between chilled water and product.

In-Line Filter: An easily accessible in-line filter provides protection for the pre piped centrifugal

pump in the event a plastic bag breaks open.

8

Page 9

Touch Screen Controller: A PLC-based, Operator Interface Terminal with a graphical touch

screen provides the formula control for the machine. It provides a storage capacity for up to 99

formulas, up to 99 events (steps) per formula, and 99 product codes. Functions include step time,

rotation intervals and speed, water addition and draining, temperature control, chemical and

steam injection, door operation and safety interlocks for the protection of the operator and

machine. The OIT connects to the machine’s PLC allowing multiple input/output capability,

while providing the operator and maintenance personnel with an easy to program control system.

Optional Equipment

Recycle Tank: An insulated recycle tank with high and low level sensors and 1” water valves to

direct water to the tank. The tank also includes a 1 1/2” drain valve which drains the water into

the shell.

Control Right Side/Left Hinged Door: A control mounted on the right side of the machine with

a left hinged door is available.

Prison Package: The prison package includes tamper proof hardware per the American

Correctional Food Service Association Guidelines.

Automatic Sanitizer Injection: The machine supports liquid supply injection with 1 standard

connection port. Automatic liquid injection can be controlled by the BTC-8 touch screen formula

control with outputs from the PLC terminal strip.

RS232 Port: A 9 pin RS232 port will be available for communication.

9

Page 10

Machine Specification Sheet

Front Elevation

Figure 1

10

Page 11

Rear Elevation

Figure 2

11

Page 12

Right Elevation

Figure 3

12

Page 13

Chapter Four

Operations

Safety Precautions and Instructions

The following instructions will aid in a quick and correct installation for your new CapKold

Tumble Chiller.

**To avoid serious bodily Injury or Equipment damage operate equipment in strict

accordance with manufacturer’s operating instructions**

DO NOT operate machine unless all original safeties are installed and in proper working order

including door interlocks, access panels and signal devices.

DO NOT exceed designed load capacity of machine (100 gallons to 320 gallons of bagged

product).

DO NOT process material containing flammable or volatile cleaning agents into machine.

DISCONNECT power to machine when not in use to limit risk of unauthorized operation.

IN CASE OF EMERGENCY: Push the red “EMERGENCY STOP” switch located on the

operator station, the control circuit will be disabled, turning off the machine.

ALWAYS DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE:

• Performing any type of maintenance, repair, or inspection.

• Entering the basket or area beneath the tub.

• Removing any safety covers, guards, or access panels.

NEVER REMOVE, DISCONNECT, OR ALTER MACHINE SAFETY FEATURES,

MECHANICAL INTERLOCKS, ELECTRICAL INTERLOCKS, OR SIGNAL DEVICES.

DO NOT OPERATE, REPAIR, MAINTAIN, OR ADJUST THIS EQUIPMENT:

• Without reading and understanding this manual.

• Unless these precautions are understood.

• If under the influence of drugs or alcohol.

• If taking medication which distorts judgment or causes drowsiness.

• If advised by doctor or other medical personnel not to operate heavy machinery.

• If, at any time, you doubt your own ability to safely operate this machinery.

IF THERE ARE ANY QUESTIONS CONCERNING SAFETY PRECAUTIONS OF

MACHINE OR ITS OPERATION, CONTACT CAPKOLD.

WARNING

13

Page 14

Preoperational Checks

• Verify air supply pressure is in accordance with nameplate data. Open air supply valve

slowly to prevent injury to personnel.

• Ensure the main air pressure regulator is set at 80 psi.

• Verify steam supply pressure is in accordance with nameplate data. Open supply valve

slowly to prevent shock to steam lines. If not using steam, check temperature of hot water.

• Ensure water supply pressure is in accordance with nameplate data. Check individual

pressures of mains and chilled water. Open all water supply valves slowly.

• Open the control panel and inspect for cleanliness – panel must be free of dirt and debris

before energizing. Clean panel interior with vacuum cleaner and a dry or slightly damp cloth

only. Inspect control panel door seal and replace if worn or damaged. Check electrical

connections for tightness.

• Close all electrical panel doors and ensure all latches are properly fastened.

• Verify that proper voltage and current are available at disconnect in accordance with

nameplate data. Use voltage meter to verify voltage.

• Centrifugal Pump - Do not run pump dry as permanent damage to the mechanical seal will

result.

• Important: Proper Rotation – Power supply should be applied momentarily to the pump at

first and the direction of rotation checked. When viewing the front of the pump, the motor

shaft (impeller) should be rotating counterclockwise. If it is not, disconnect power and recheck wiring to motor. To change rotation on three-phase models, interchange any two

incoming line (power) leads.

• Do not rotate basket without water connected as permanent damage to the mechanical seal

will result.

CAUTION

CAUTION

14

Page 15

Machine Controls

Panel Disconnect: An electrical disconnect is provided on the exterior of the rear electrical

panel. This switch shall be in the down or “OFF” position when the tumble chiller is not in use.

The disconnect has provisions for being locked in the “OFF” position. This feature must be used

during machine maintenance. The rear panel door is mechanically interlocked with the

disconnect switch in order to prevent the door from being opened while the disconnect is in the

up or “ON” position.

**To prevent electric shock ensure there is no voltage available to input lugs of panel

disconnect switch prior to service in panel.**

Control Panel: See Figure 5 for the control panel.

WARNING

Figure 5

15

Page 16

On/Off/Reset: The On/Off/Reset switch is located below the Emergency Stop switch and is of a

rocker type. The first two positions are maintained while the third (RESET) is momentary and

spring returns to center (ON).

Off: Power is removed from all control circuits. However, the two transformers remain

energized. This is the desired position when the tumble chiller is temporarily not in use.

This does not sufficiently remove power for maintenance purposes. Always use the

Panel Disconnect for this purpose.

On: Power is available to control circuits if the switch has been first placed in the

“RESET” position. The switch must momentarily be in this position for any machine

function to occur.

Reset: Energizes control circuits by creating a “latching” circuit. This circuit is

maintained through the Emergency Stop switches and the On/Off/Reset switch as long as

it is in the “ON” position. Anytime the tumble chiller loses power the control circuits

must be energized by momentarily placing the On/Off/Reset switch to “RESET”.

Emergency Stop: The Emergency Stop is located on the top center of the panel and is easily

identified by its large red mushroom shaped operator. Pushing the Emergency Stop push button

at any time will stop machine action. The PLC outputs for machine motion may be disabled more

completely by turning the On/Off/Reset switch to “Off”. The tumble chiller has been designed

to fail safe. This means that when power is lost (due to power outage, On/Off/Reset switch, etc.)

the door will remain sealed and locked.

The Emergency Stop switches are a push-pull type. To reset the Emergency Stop, it must be

pulled out. To restore machine function, simply push the Power switch to the “RESET” position

and SLOWLY release. The power switch will return to the “ON” position.

16

Page 17

Chiller Operation

**Ensure all preoperational checks of Chapter 4 have been satisfactorily completed prior to

performing startup**

• Press rocker switch to RESET position momentarily and then slowly release. The switch will

remain in the ON position

o Chiller powers up, PLC runs internal I/O and software check

**Push the red Emergency Stop switch if any unsafe or unexpected condition appears to

exist**

• Start of Chill Cycle

o Close door, LOCK DOOR button appears.

o Press LOCK DOOR.

o UNLOCK DOOR button appears and can be unlocked provided the basket is empty.

o Press “Cycle” area on screen, list of cycle formulas appear.

NOTE

CAUTION

17

Page 18

o Select the desired Chill cycle formula by highlighting and then pressing SELECT.

o Press START CYCLE.

o Drum will fill with water, the centrifugal pump and the basket will rotate when the low

water level is reached and the chilled water valve will open.

o Operator will be alerted “Ready to Load Bags” and the BAGS LOADED button will

appear.

o Operator will load bags and then press BAGS LOADED.

18

Page 19

o The chill cycle will run for the programmed time or when the temperature has been

maintained for 5 minutes and the timer has ran for 1/2 the programmed time, then the

operator will be alerted to “Check Bags”.

o Press PAUSE CYCLE to stop basket rotation and centrifugal pump to remove a bag

to sample the temperature.

o If the temperature of the product is below 40 deg F, then press END CYCLE. If the

temperature of the product is above 40 deg F, then press START and continue the

chill cycle. The chill cycle will continue until the operator is alerted to “Check Bags”

and the temperature verification process is repeated.

o After the temperature of the product is below 40 deg F and the END CYCLE button

is pressed, the basket will stop rotation, the chilled water valve will close, and the

centrifugal pump will stop.

19

Page 20

o Press the appropriate button DRAIN TO TANK or DRAIN TO WASTE.

o When the water has drained completely, the operator is alerted to “Remove Bags”.

o Press UNLOCK DOOR.

o Unload bags and press JOG button as required to redistribute the bags.

20

Page 21

• Start of Clean Cycle

o Close door, LOCK DOOR button appears.

o Press LOCK DOOR.

o UNLOCK DOOR button appears and can be unlocked provided the basket is empty.

o Press “Cycle” area on screen, list of cycle formulas appear.

o Select the desired Clean cycle formula by highlighting and then pressing SELECT.

21

Page 22

o Press START CYCLE.

o Drum will fill with water, the centrifugal pump and the basket will rotate when the low

water level is reached and the steam valve will open.

o The automatic sanitizer injection will start (option) or a sanitizer can be added manually

through the chute opening.

o The drum will continue filling to programmed temperature and level, then the timer will

start.

o When the timer reaches 00:00, the basket and the centrifugal pump will stop. The

transfer valves will open and the water will be transferred to the tank.

o When the tank is full, the timer will start.

o When the timer reaches 00:00, the tank will drain and the operator will be alerted to

“Clean Out In-Line Filter”.

o Press END CYCLE.

o Press UNLOCK DOOR

o Repeat with a Rinse Cycle if chemicals were used.

22

Page 23

• Start of Back Flush Cycle

o Close door, LOCK DOOR button appears.

o Press LOCK DOOR.

o UNLOCK DOOR button appears and can be unlocked provided the basket is empty.

o Press “Cycle” area on screen, list of cycle formulas appear.

o Select the desired Back flush cycle formula by highlighting and then pressing SELECT.

o Press START CYCLE. Valves will open to back flush heat exchanger and timer will

start.

o Press END CYCLE when the timer reaches 00:00.

o UNLOCK DOOR appears.

23

Page 24

Manual Operation

• To perform Manual Operation or to check Input/Output Screen

o Press MENU button.

o Press MACHINE INFO button.

24

Page 25

o Key in password and press ENTER.

o Press I/O SCREEN button or Press MANUAL OPERATION

25

Page 26

o Sample display of inputs. Press OUTPUT1 or OUTPUT2 button to display output

screens. The dark filled circle indicates the input/output is active.

o Sample display of manual operation. Press button and hold to manually activate

desired operation.

o Press PAGE 2 or PAGE 3 to view additional manual operation screens.

o Press MAIN SCREEN button to return to main screen.

26

Page 27

Troubleshooting

Fault Probable Cause

Door will not lock Check door close sensor

Check door lock sensor

Check air pressure

Shim door locks as required

Door will not unlock Check door lock sensor

Check air pressure

Shim door locks as required

Door will not seal Inspect and replace seal

Shim door hinge and door locks as required

Product will not chill properly Clean strainer

Perform automatic back flush cycle on heat exchanger

Check temperature probe

Check chilled water temperature and flow

Pump motor O.L. Clean strainer

Perform automatic back flush cycle on heat exchanger

Drive Motor Thermal O.L. Drum overloaded

Emergency Stop Switch Pressed After investigation, pull out on emergency stop switch

Water Level Too High Check float level

Formula Not Loaded No valid product/item selected

Water valves not opening Check air pressure

Check air lines for leaks

27

Page 28

Chapter Five

**To avoid personal injury disconnect all power before servicing.**

CAUTION

Maintenance and Repair

Scheduled Maintenance

Daily

• Empty pneumatic system water separator bowl.

• Check water and air lines for leakage.

• Check for abnormal noises.

• Check water leaking from seal housing (1/4 plastic drain line in seal housing).

• Empty inline filter (ensure the drum is empty).

Monthly

• Check and fill the oil level in the gear box to the fill plug. Lubrication type is

mineral oil per ISO VG220.

Sensor Adjustment

Door Open/Close Sensor

• Adjust door closed sensor so there is a 1/16 to 1/8 inch gap between the sensor and

the front panel when door is closed.

Door Lock/Seal Sensor

• Remove cover plates to access door lock sensor.

• Close door and press LOCK DOOR button.

• The red LED light should be illuminated with the door in the lock position.

• To adjust sensor, loosen clamp holding the sensor on the air cylinder and move the

sensor up/down until red LED light illuminates and tighten clamp.

• Check functionality by cycling UNLOCK DOOR and LOCK DOOR button and

readjust as required.

• Install covers.

28

Page 29

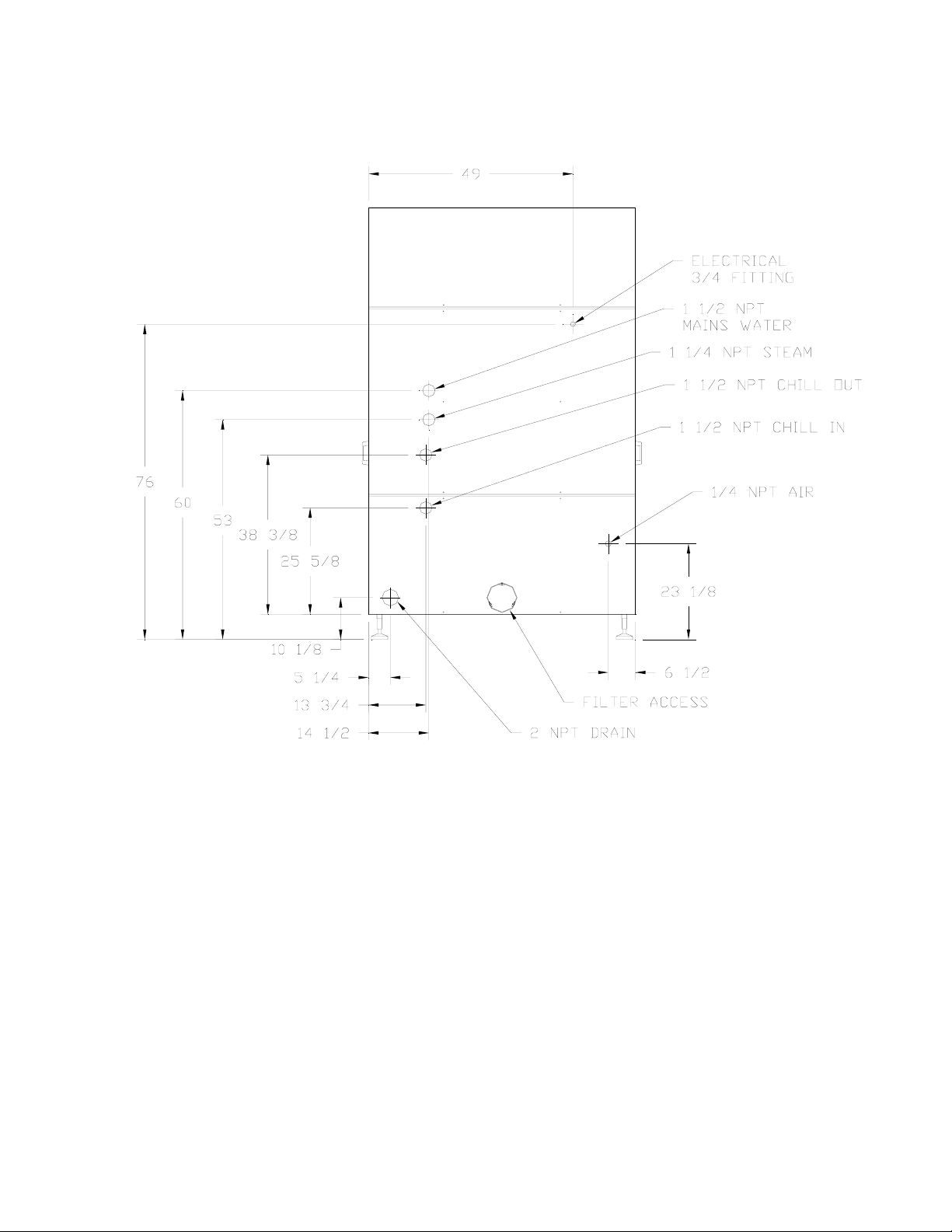

Water and Steam Valves

Removal of Actuator from Water Valve Body: Apply 80 psi air pressure to the valve actuator.

This will retract the valve plunger from the seat, relieving the pressure on the actuator. Loosen

the retaining nut and remove the actuator assembly from the body. There is a gasket located

under the nut. This gasket must be properly seated when reassembling the valve or leakage will

occur. The steam valve actuator does not require air to disassemble as its spring is much weaker.

Valve Assembly: See Figure 4

1. To insert spindle seals into actuator base

sequence elastomer-teflon-flexible elastomer-teflon with support ring (7), spring (6), guide

ring (5) and wiping ring (13) into the actuator base (25) and secure with circlip (3).

2. To assemble spindle

(19). Secure plug (15) onto spindle (2) with pin (16). Caution: Valve plug should be flexible

on spindle.

3. To insert spindle and fit piston

through the spindle seals located within the actuator base. Position the piston assembly (20),

which is complete with lip ring (21) and O-ring (22), over the spindle (22) and secure with

lock nut (11).

4. To assemble actuator

(20). Grease the sliding surface of the actuator housing (10), insert the O-ring (24) into the

groove on the face of the sleeve (10.02). Place the actuator housing (10.01) over the spring

(17)(18) and piston assembly in the inverted position. Mount on actuator base, use a press

and clamp the actuator housing (10) to the actuator base (25), ensuring that the O-ring (24) is

located within the groove, and secure with screw (23).

5. Valve fitting

actuator and pressurize the actuator. Secure the retaining nut (7) to the valve body (1).

6. Dismantling

**Dismantling of the actuator must be undertaken using a press, as the actuator is spring

loaded**

Fitting Instructions:

1. The valve can be mounted in any position.

2. An arrow indicates the flow direction which must be adhered to. See Figure 5.

3. Maximum permissible working pressure is indicated on the type label.

4. Minimum and maximum control pressures are indicated on the type label.

5. The valve is easy to clean and is achieved by loosening and removing the retaining nut and

actuator assembly from the body.

Reassembly of Actuator to Valve Body: Apply 80 psi air pressure to the actuator. This will

retract the plunger. Place the actuator into the valve body. Check that the air inlet is in the

correct location (the actuator may be assembled with air inlet pointing in any direction) so that the

machine air line may be attached. Ensure that the retaining nut gasket is in place in the valve

body. Tighten the nut. Remove air pressure from the actuator. Reconnect the machine’s air line.

: Insert gasket (4) into the valve body (1). Connect the control media to the

: Dismantling is done in the reverse sequence.

: Insert the seat seal (14) into the plug (15) and secure with retaining nut

: Slide the spindle assembly, with twisting movements,

: Place the spring(17) [also spring (18) where required] over the piston

: Insert ring (9), packing rings (8) and (33) in the

CAUTION

29

Page 30

Valve Diagram

Figure 4

1 Valve body 14 Seat seal, PTE

2 Spindle 15 Plug

3 Circlip 16 Pin

4 Gasket 17 Spring

5 Guide ring 18 Spring

6 Spring 19 Retaining nut

7 Support Ring 20 Piston assembly

8 Packing ring, PTFE 21 Lip ring

9 Ring 22 O-ring

10.01 Actuator housing 23 Socket head cap screw

10.02 Sleeve 24 O-ring

11 Lock nut 25 Actuator base

12 Cap 26 Lip ring

13 Wiping ring 33 Packing ring EPDM

Seal Kit (Items 4, 6, 7, 8, 9, 13, 14, 33)

30

Page 31

Valve Flow Direction

Figure 5

31

Page 32

Door Seal

Door Seal Removal

• To replace door seal, remove old door seal and clean off the residual silicone adhesive.

• Place a small bead of clear silicone adhesive/sealant 5005 or equivalent in the door

groove.

• Firmly press door seal in groove starting at the top of the door and cutting off the excess

at the end. Ensure seal is seated properly in groove all around.

• Remove excess silicone adhesive and allow to cure for 24 hours.

Door Lock/Seal Adjustment

• To adjust door lock/seals, add or remove shims beneath door hinges as required.

• Remove cover plates to access door locks.

**Disconnect and bleed off air supply prior to disconnecting air lines**

• Disconnect air line to access bolt for air cylinder bracket.

• Remove air cylinder bracket and add or remove shims beneath bracket as required.

• Reassemble in reverse order.

• Check functionality by cycling UNLOCK DOOR and LOCK DOOR button and readjust

as required.

• Install covers.

WARNING

32

Page 33

Drive Assembly

**To avoid personal injury, disconnect and lock out power to machine prior to performing

any work on drive assembly**

Drive Assembly Removal

• To remove gearbox motor, flange bearing and/or shaft seal , the basket needs to be

secured as described.

• Remove 3/4 plugs from bottom of shell and replace with 3/4-10 x 4 long hex bolt. Screw

bolts in until they touch basket.

• Secure basket from front to prevent the basket from sliding towards rear of machine.

• Place saddle underneath shaft between gearbox motor and flange bearing.

• Unbolt motor and remove shims between motor plate and motor.

• Remove key retainer and slide motor off shaft with minimal up/down and side/side

movement.

• Remove locking collar.

• Unbolt flange bearing and slide rearward to saddle. Place second saddle in front of

flange bearing and remove first saddle and flange bearing.

• Unbolt seal housing and remove drain line. Slide seal housing back carefully ensuring

the housing is perpendicular to the shaft to prevent damage to ceramic seat. Slide off

shaft using two saddles with one saddle always supporting shaft.

• Slide spring/seal assembly off shaft (lubricant may be required) using two saddles with

one saddle always supporting shaft.

• Reassemble in reverse order.

CAUTION

33

Page 34

Chapter Six

Spare Parts List

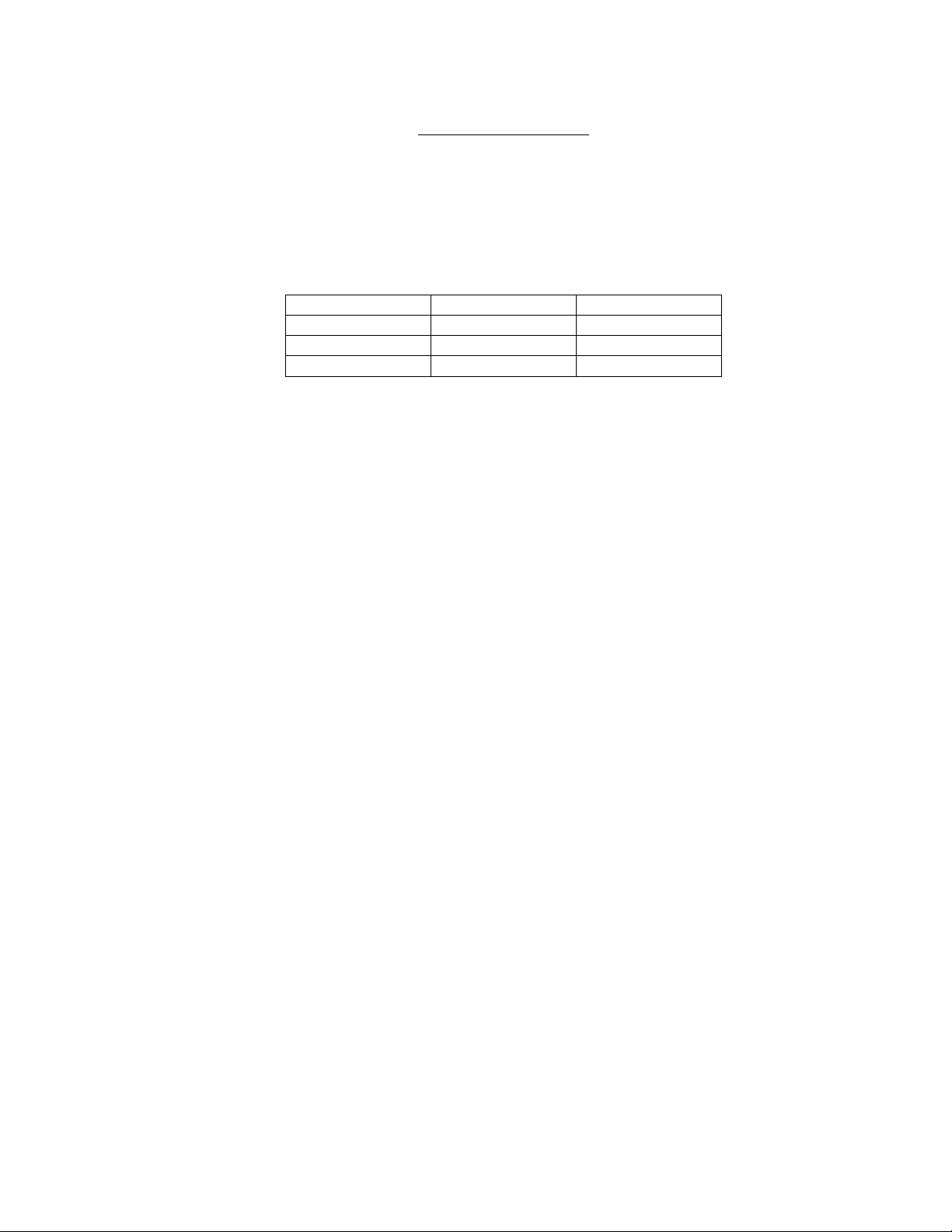

Mechanical/Electrical Spare Parts List

Item Part Number Description

1 1060035 1 HP Motor Gearbox

2 1220080 1 1/2 HP Centrifugal Pump

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

1450081

1300070

1210055

1220078

1210052

1210053

5846256

0316031

2000103

2000102

2000110

2000094

1220079

2160143

2020063

2160181

TBD

Flange Bearing

Ceramic Seal

Door Damper

Flow Control Valve

Air Cylinder

Switch Assembly NPN Sinking

Door Seal

1 NPT Water Valve

1 1/2 NPT Water Valve

2 NPT Water Valve

1 1/4 NPT Steam Valve

Valve 120/60, 3W

Liquid Level Control

RTD Probe

Sensor Assembly

Monochrome Touch Screen

Inverter, 1 HP, 208VAC

34

Page 35

Chapter Seven

Diagrams

Pneumatic Diagram

35

Page 36

Water Valve Diagram

36

Loading...

Loading...