Page 1

CapKold Cook-Chill Production Systems

Mobile Pump/Fill Station

r CKPF/3

r CKPF/3NSF

General Description:

CapKold Model CKPF/3 & CKPF/3NSF Mobile Pump/Fill Stations with

integrated rotary positive displacement pump, for the transfer of hot

and cold food from a steam jacketed kettle into flexible plastic casings

or other containers. Pedestal mounted control package allows fast

and simple adjustment of pumping speed and volume.

Standard Features:

• Heavy duty stainless steel construction

• Unit mounted on four 5” heavy duty locking swivel casters

• Air actuated casing clipper complete with regulator and filter. 15’

air hose supplied for easy field connection

• Quick action air activated product flow control valve

• USDA food transfer hose. Two (2) hose sections 3” in diameter by

3’ long, with fittings to interconnect kettle and fill station

• Exterior rear mounted rotary positive displacement pump

for easy cleaning

• Full surface spill tray with drain and removable stainless

steel grate

• Stainless steel elbow with 10’ hose provided for spill tray

• Manufactured to latest sanitary standards and HACCP compliant

• CKPF/3NSF is NSF listed

Integral Control Package:

Control panel is pedestal mounted to fill station and provided with a

water resistant case to simplify cleanup and protect solid state control

systems. Eye level digital input of pump speed and volume setting

changes for different products. Operating controls include:

• Selection of manual, metered or continuous pumping modes

• Operator input of pump speed from 0 to 20 gallons per minute

• Operator input of metered volume from 0.5 to 2.0 gallons in 0.01

gallon increments

• Foot activated fill switch

• Knee and hand operated emergency stop switches

• LED digital display of volume pumped per casing, total casings

pumped and total fill volume per batch

Packaging

Options & Accessories:

r Temperature monitor with casing clipper lockout to prevent

packaging at less than 180°F (82°C)

r Product temperature recorder

r High volume air eductor (For vacuum packaging products for

Cook Tank Production)

r Empty casing holding bin (Hangs on side of Fill Station)

r Pan fill adapter

r Pan fill conveyor

r Stand alone label printer

r Additional 3’ food transfer hose section with fittings

r In-line ricer for size reduction of food solids

r Prison package

Notes:

• Unit requires single phase electric service

• Clipper sold separately on CKPF/3NSF

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Groen CapKold Packaging, Page 14

CKPF 160380A

Revised 08/06

Page 2

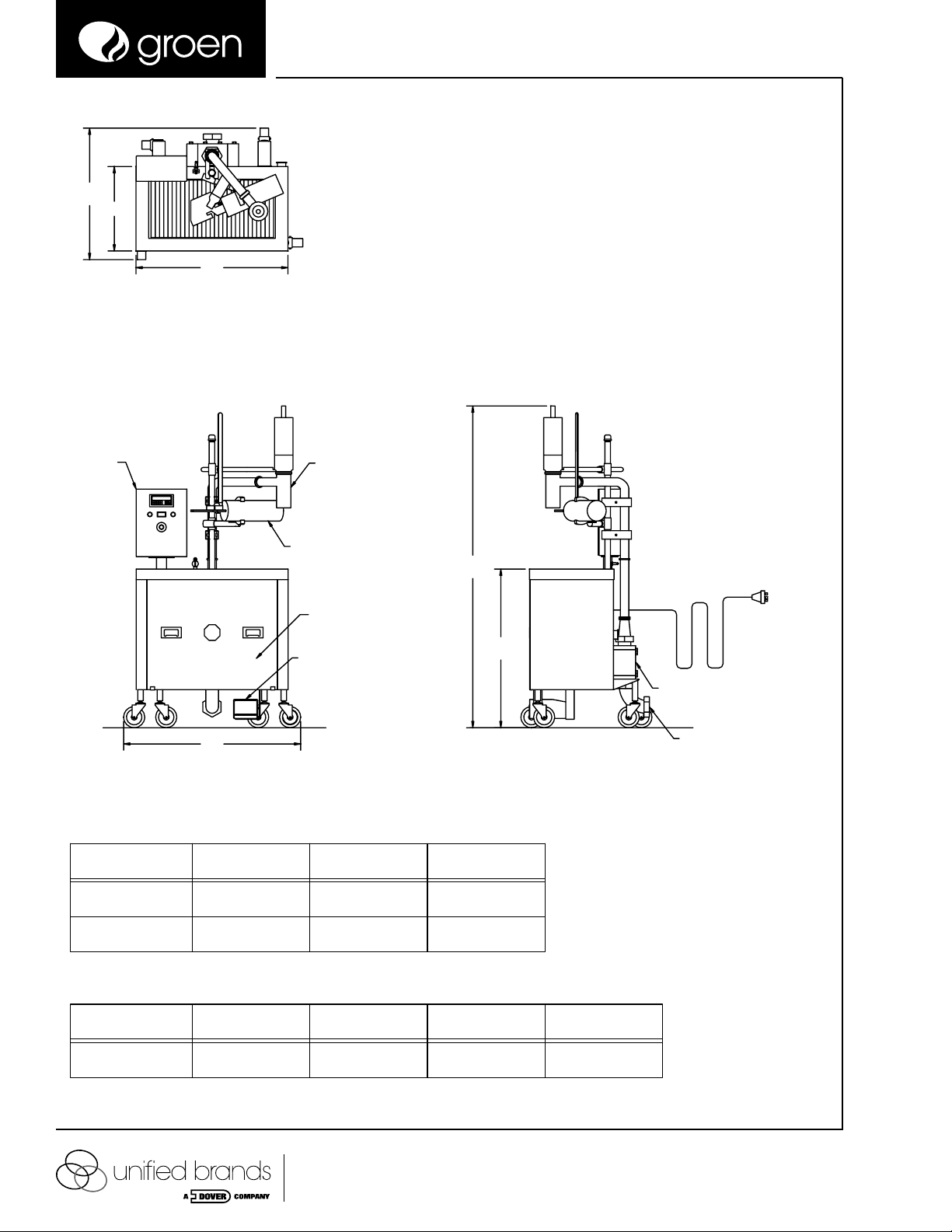

CKPF/3 & CKPF/3NSF Mobile Pump/Fill Station

160379 REV A

31 1/4"

CONTROL

PANEL

20"

CA

TOP VIEW

CA

36"

IW

PRODUCT VALVE

OUTLET

CLIPPER (SOLD

SEPARATELY ON

CKPF/3NSF)

76 1/4"

EP

FRONT VIEW SIDE VIEW

UTILITY CONNECTIONS

SYMBOL

DESCRIPTION

CONNECTION

UTILITY REQUIREMENTS

MODEL

CKPF/3 &

CKPF/3NSF

ACCESS/EMERGENCY STOP

PANEL

FOOT SWITCH

42"

CA

COMPRESSED AIR

INLET

3/8 DISCONNECT #2621 HUBBLE PLUG

W/ 15 FT HOSE

COMPRESSED AIR

INLET

8 CFM @ 80-90 PSI

IW EP

INDIRECT WASTE POWER SUPPLY

2" HOSE

ELECTRICAL

208/1/60 @ 10A

37 1/2"

W/ 15 FT CORD

SHIPPING WEIGHT OPERATING WEIGHT

755 LBS

IW

PUMP

PRODUCT INLET

650 LBS

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Loading...

Loading...