Page 1

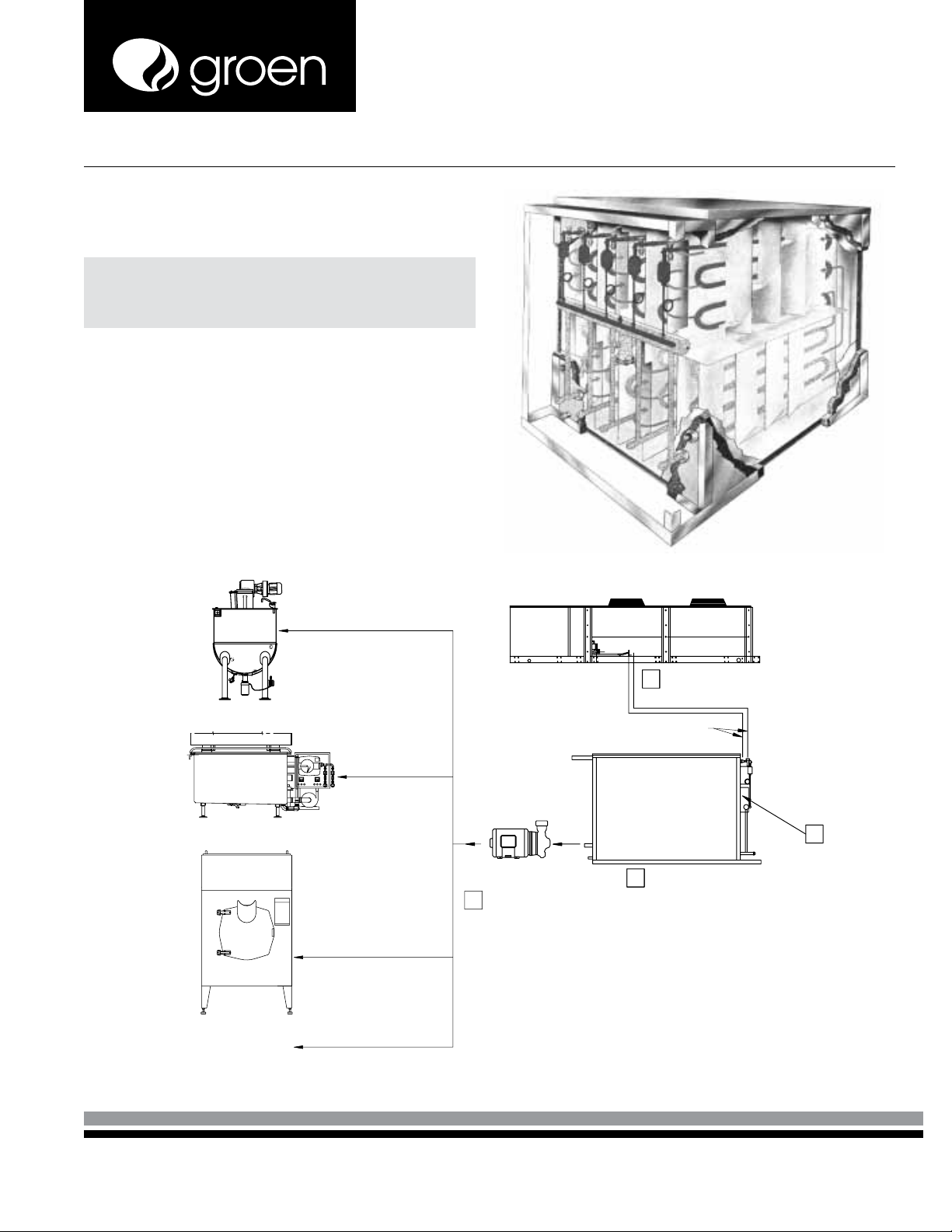

CapKold Cook-Chill Production Systems

Ice Builder Based Chilled

Water Production

Chilled Water Applications

A reliable and cost effective source of chilled water is key to the rapid

chilling of kettle cooked and Cook Tank prepared foods and also a

valuable resource in other food prep and production applications. The

sizing of the Ice Building Tank and supporting Refrigeration System

is a function of the estimated daily chilled water requirements for all

applications. Typical Production Equipment Chilled Potential growth,

future equipment additions, added production shifts and physical

layout and relationship of Ice Building Tank to production areas will

all impact proper sizing of Ice Builders.

Refrigeration/Chilled Water Production

DIRECT STEAM KETTLE(S)

COOK TANK(S)

CASING COOLER(S)

CHILLING

WATER

CHILLING

WATER

CHILLING

WATER

OTHER APPLICATIONS

REFRIGERATION

A

SYSTEM

B

SYSTEM WATER

C

RECIRCULATION

PUMP

ICE BUILDING TANK

Ice Builder System Components:

(A) Air Cooled Refrigeration System

(B) Ice Building Tank

(C) Sytem Water Circulation Pump

(D) Ice Water Thickness Control Panel

REFRIGERATION

LINES

THICKNESS

CONTROL

PANEL

D

1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, unifiedbrands.net

Please reference our website for the most

updated product information and specifications.

Groen CapKold Refrigeration, Page 27

CKIB 160670A

Revised 08/06

Page 2

CKIB Ice Builder

System Mini Spec/General

Description:

CapKold Chilled Water Production System to provide cold water

for the rapid chilling of packaged product in:

• Tumble Chillers

• Cook Tanks

• Direct Steam Kettles

System to consist of the following items:

• Model GT _ ice builder of __ Ibs capacity

• Model__,__ refrigeration (air or water) cooled

• Ice thickness control panel

• Optional ___ Hp chilled water circulation pump

• Optional remote, system on off panel

(A) Ice Builder Refrigeration:

Provides the chilling capacity for the Ice Building Tank

and features:

• A sealed Compressor, designed for efficient operation with

R22, R404A, or Ammonia (Please Specify)

• Liquid line dryer and suction line accumulator

• Fixed suction line core type filter

• Suction & Discharge line vibration eliminators

• Integrated controls include:

- Head pressure controls

- Oil failure switch

- Sight glass

- Liquid line solenoid valve and switch

- Head pressure control

- Fan cycling system if required

• Available Options:

- Oil separator

- Suction accumulator with heat exchanger

- Crank case heater

- Full size receiver

- Air or Water cooled condenser (Consult CapKold)

- Alternative refrigerants

• Standard units ship in one piece.

• Available Options:

- Remote start stop station

- On and Off timer

- Remote pump control panel with disconnect

160670 REV A

(C) System Water Circulation Pump:

To pump chilled water from Ice Building Tank to remote CapKold

Tumble Chillers, Cook Tanks and Kettle jackets and back to Ice

Builder.

_ Horsepower (refer to page 3) either cast iron or stainless steel

construction.

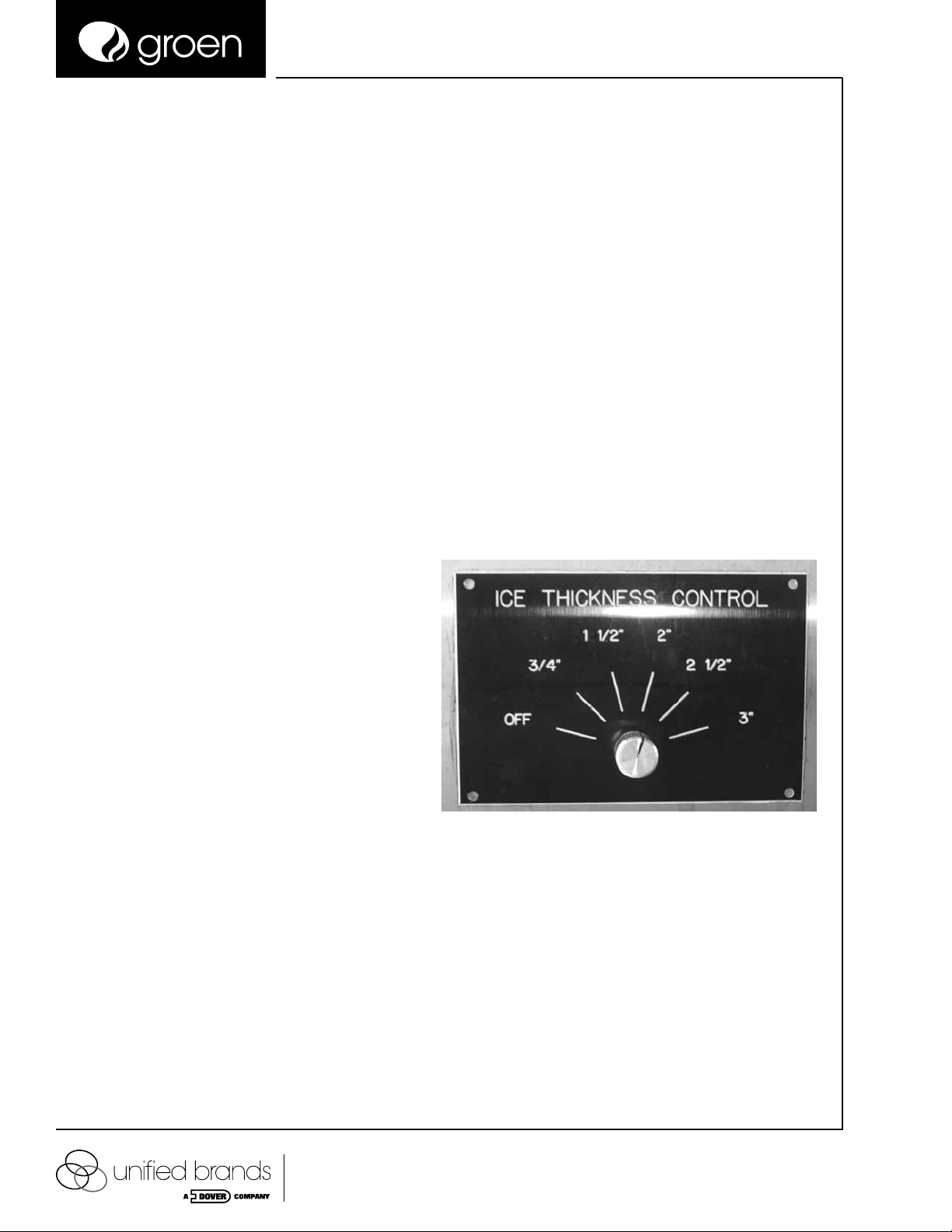

(D) Ice Thickness Control Panel:

Regulates ice production in the Ice BuildingTank. Control Panel to

consist of the following features:

• Stainless steel wall-mounted housing which is usually installed

in the control panel of the ice building unit. It is easily changed

but selecting the amount of ice required. You can also turn it

off during periodic shutdown and save on utility costs.

• Standard controls include:

- Ice pilot light

- Ice inventory system, thickness adjustable

Ice Water Thickness Control Panel

(B) Ice Building Tank Model:

Used to build ice around a series of refrigeration coils

and features: (see next page for drawings and charts)

• Tank fabricated from 3/16” stainless steel

• 2” foam insulation with 18 gauge stainless steel outer skin

• Insulated stainless steel covers

• Designed for indoor or outdoor installation

• Heavy duty coils, schedule 40, stainless steel with

structural supports

• Automatic water fill

• Ice thickness control to regulate ice buildup around coils

[See Ice Thickness Control Panel]

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 3

CKIB Ice Builder

(B) Ice Building Tank Model

160671 REV A

Ice Builder System Component Ordering Guide: [Contact CapKold for assistance or review of Ice Builder Sizing]

B

C

A

ICE BUILDER DATA

MODEL ICE STORAGE

CAPACITY

GIR-2052 600 72” 28” 29” 135 1300 2450

GIR-2072 900 96” 28” 29” 200 1800 3400

GIR-2063 1,200 86” 28” 38” 230 2270 4700

GIR-2083 1,800 114” 28” 38” 325 2525 6400

GIR-2084 2,500 114” 28” 50” 435 2835 6550

GIR-3084 3,750 114” 40” 50” 655 3700 9400

GIR-3104 4,685 138” 40” 50” 825 4350 11500

GIR-4084 5,000 114” 52” 50” 870 4565 12250

GIR-5084 6,250 114” 64” 50” 1090 5430 15100

GIR-3106 7,030 138” 40” 74” 1235 5980 16850

GIR-6084 7,500 114” 76” 50” 1310 6300 17950

GIR-5104 7,800 138” 64” 50” 1375 6390 18500

GIR-3126 8,435 162” 40” 74” 1490 6850 19900

GIR-5086 9,375 114” 64” 74” 1635 6890 22500

GIR-6086 11,250 114” 76” 74” 1960 7920 25599

GIR-4108 12,500 138” 52” 98” 2150 8895 28400

GIR-6106 14,060 138” 76” 74” 2475 10070 32100

GIR-4128 15,000 162” 52” 98” 2600 9600 31500

GIR-5146 16,405 186” 64” 74” 2910 11400 37000

GIR-5128 18,750 138” 64” 98” 3245 11600 39500

GIR-6128 22,500 138” 76” 98” 3895 13850 47750

GIR-5168 25,000 210” 64” 98” 4455 15650 47600

GIR-6206 28,125 258” 76” 74” 5030 18560 62700

GIR-7148 30,625 186” 88” 98” 5440 18760 67760

GIR-5208 31,250 258” 64” 98” 5590 18830 68000

GIR-6228 41,250 282” 76” 98” 7390 25500 91500

GIR-7208 43,750 258” 88” 98” 7825 26050 96050

NOTE: LARGER SIZES AVAILABLE – PLEASE CALL THE FACTORY FOR INFORMATION

TANK LENGTH

(A)

TANK WIDTH

(B)

TANK HEIGHT

(C)

TANK CAPAC-

ITY (GALLONS

OF WATER)

SHIPPING

WEIGHT IN

LBS.

OPERATING

WEIGHT IN

LBS.

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Page 4

CKIB Ice Builder

(C) Ice Water Circulation Pump

160671 REV A

1055 Mendell Davis Drive, Jackson, MS 39272, 888-994-7636, unifiedbrands.net

© 2009 Unified Brands. All Rights Reserved. DOVER® and the DOVER® Logo are registered

trademarks in the United States [and various other countries] of Unified Brands, a

wholly-owned subsidiary of Dover Corporation.

Loading...

Loading...