Capital SL ECO Series, SCENE ECO, BASSINGTON ECO, BASSINGTON, AVEBURY Installation And Operating Instructions Manual

...

APPROVED - CONFORMING TO EN13240:2001 and

EN13240 A2:2004

APPLICABLE TO THE FOLLOWING STOVE MODELS:

VEGA EDGE 200SL (ECO)

AVEBURY (ECO)

BASSINGTON (ECO)

SCENE (ECO)

SIGMA (ECO)

STOVES MUST BE FITTED BY APPROVED, QUALIFIED AND

COMPETENT INSTALLERS

PLEASE LEAVE THIS BOOKLET WITH THE HOUSEHOLDER

Stoves operate at very high temperatures. All persons

including children and the infirm should be warned of this and not

allowed to touch any surfaces whilst in use. The operator must use

the glove provided.

SL ECO SERIES INSTRUCTION – REV.C – NOV 2018

These appliances have been approved by HETAS Ltd as an intermittent operating appliance for

burning wood and approved smokeless fuels at the nominal output of 5.0kW only.

INSTALLATION AND OPERATING

INSTRUCTIONS

1

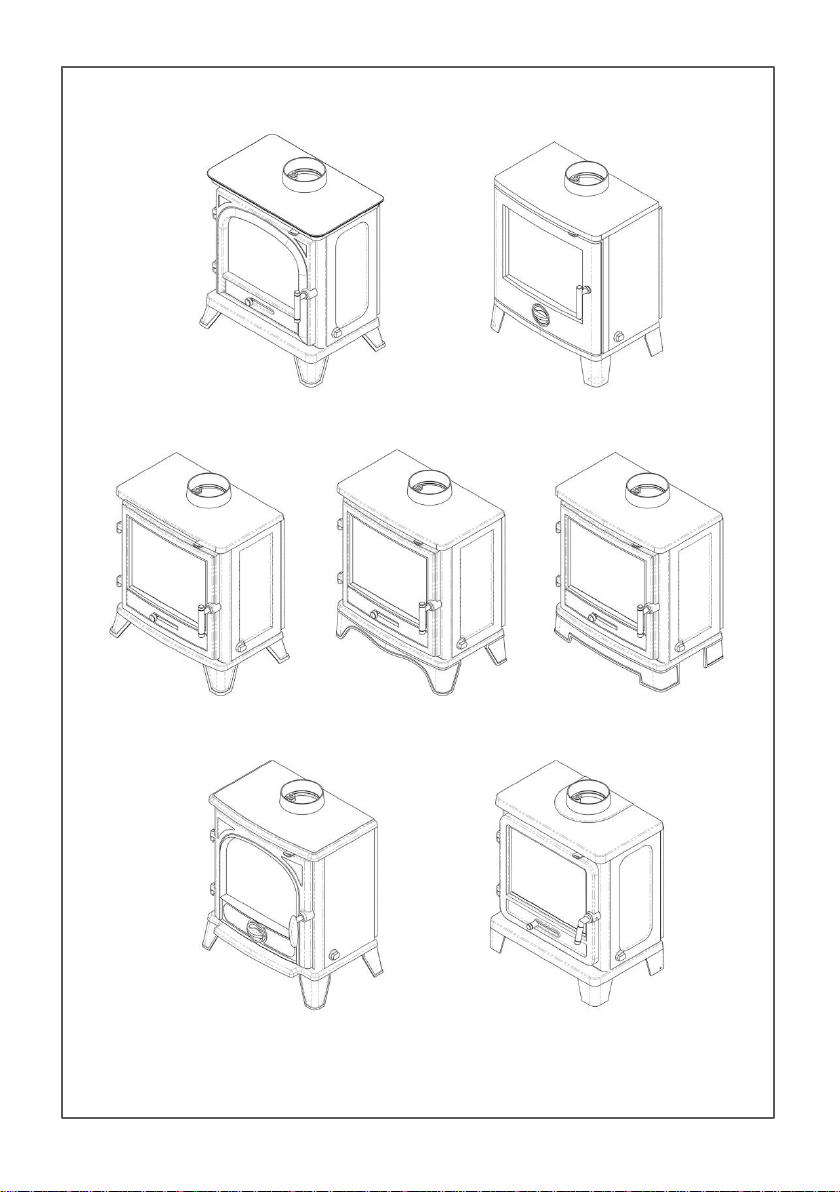

AVEBURY (ECO)

SCENE (ECO)

BASSINGTON (ECO)

STANDARD LEGS

BASSINGTON (ECO)

SKIRTED LEGS

BASSINGTON (ECO)

BASELINE LEGS

SIGMA (ECO)

VEGA EDGE 200SL (ECO)

2

CONTENTS

STOVE DIMENSIONS, OUTPUT & EFFICIENCY PAGE 04

INSTALLATION PAGE 05

OPERATION PAGE 11

GENERAL MAINTENANCE PAGE 17

SAFETY NOTES & TROUBLESHOOTING PAGE 19

STOVE ACCESSORIES PAGE 22

COMPONENT PARTS PAGE 23

TECHNICAL FICHE PAGE 30

3

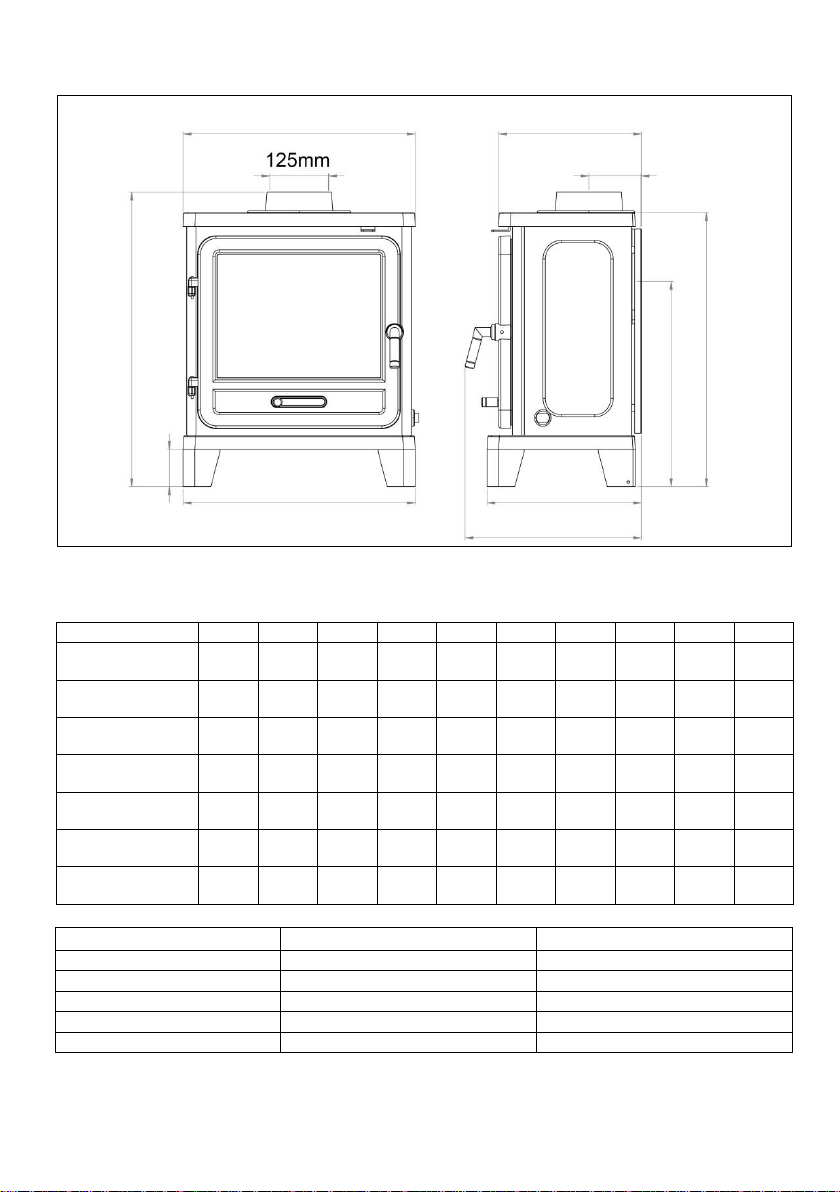

A B C D E F G H I J

AVEBURY (ECO)

531mm

630mm

80mm

325mm

114mm

350mm

365mm

453mm

590mm

531mm

BASSINGTON (ECO)

BASELINE LEGS

500mm

615mm

80mm

317mm

114mm

317mm

364mm

443mm

575mm

511mm

BASSINGTON (ECO)

SKIRTED LEGS

500mm

640mm

105mm

317mm

114mm

317mm

364mm

468mm

600mm

511mm

BASSINGTON (ECO)

STANDARD LEGS

500mm

615mm

80mm

317mm

114mm

324mm

364mm

443mm

575mm

530mm

SCENE (ECO)

485mm

635mm

95mm

327mm

114mm

324mm

352mm

456mm

595mm

504mm

SIGMA (ECO)

500mm

645mm

105mm

313mm

114mm

322mm

369mm

468mm

605mm

536mm

VEGA EDGE 200SL (ECO)

501mm

634mm

80mm

309mm

114mm

336mm

380mm

454mm

590mm

501mm

WOOD

ANTHRACITE

EFFICIENCY

84%

71.5%

FLUE GAS TEMPERATURE

244 ˚C

280˚C

EMISSION OF CO @ 13% O2

0.11%

0.24%

RATED OUTPUT

5.0kW

5.0kW

OUTPUT RANGE*

2.5 – 8.0kW

2.5 – 8.0kW

A

B D C E F G H I J

STOVE DIMENSIONS, OUTPUT AND EFFICIENCY

For illustrative purposes the Vega Edge 200SL is shown above and throughout this

manual. Other stove models may have a different appearance.

*See page 10 for ventilation requirements.

Outputs stated are under ideal test conditions carried out at SGS Environmental Services in the

Netherlands. Variations may occur due to installation, atmospheric conditions and fuel quality.

4

INSTALLATION, OPERATION AND MAINTENANCE

IMPORTANT: THIS APPLIANCE MUST BE INSTALLED BY A COMPETENT PERSON AND THE

INSTALLATION MUST COMPLY WITH BS8303 – CODE OF PRACTICE FOR INSTALLATION OF

DOMESTIC HEATING AND COOKING APPLIANCES BURNING SOLID MINERAL FUEL, NATIONAL

BUILDING REGULATIONS, LOCAL BY-LAWS AND STANDARDS AND THE REQUIREMENTS OF THE

HEALTH AND SAFETY AT WORK ACT - IN PARTICULAR:

HANDLING – ADEQUATE FACILITIES MUST BE AVAILABLE FOR LOADING, UNLOADING AND SITE

HANDLING.

FIRE CEMENT – SOME TYPES ARE CAUSTIC AND SHOULD NOT BE ALLOWED TO COME INTO

CONTACT WITH THE SKIN. IN CASE OF CONTACT WASH IMMEDIATELY WITH PLENTY OF WATER.

ASBESTOS – THESE STOVES CONTAIN NO ASBESTOS. IF THERE IS A POSSIBILITY OF DISTURBING

ANY ASBESTOS IN THE COURSE OF INSTALLATION THEN PLEASE SEEK THE GUIDANCE OF A

SPECIALIST AND USE APPROPRIATE PROTECTIVE EQUIPMENT.

METAL PARTS – WHEN INSTALLING OR SERVICING THIS STOVE CARE SHOULD BE TAKEN TO AVOID

THE POSSIBILITY OF PERSONAL INJURY

UNLESS THE INSTALLER IS QUALIFIED TO APPROVE INSTALLATION THEN APPROVAL MUST BE

SOUGHT FROM YOUR LOCAL BUILDING CONTROL DEPARTMENT. THE SUPPLIERS ACCEPT NO

RESPONSIBILITY IF THIS ADVICE IS NOT FOLLOWED. THIS APPLIANCE HAS BEEN EXTENSIVELY

TESTED FOR SAFETY AND EFFICIENCY, DO NOT ATTEMPT TO MODIFY IT. ALWAYS USE GENUINE

REPLACEMENT PARTS AS RECOMMENDED BY YOUR SUPPLIER. FAILURE TO ADHERE TO THIS

ADVICE WILL INVALIDATE YOUR GUARANTEE.

TRY TO AVOID FITTING AN EXTRACTOR FAN IN THE SAME ROOM AS THIS STOVE. IF THIS IS

UNAVOIDABLE THEN SEEK SPECIALIST ADVICE TO ENSURE THAT THE INSTALLATION IS TESTED

FOR SAFETY. A SUITABLE TEST COMPRISES CHECKING FOR SPILLAGE IF THE ROOM WHERE THE

APPLIANCE IS FITTED IS SUBJECTED TO THE GREATEST POSSIBLE DEPRESSURISATION. THIS

MEANS FIRING THE APPLIANCE WITH ALL THE EXTRACT FANS IN THE BUILDING OPERATING AT

THEIR MAXIMUM AND WITH ALL DOORS, ADJUSTABLE VENTILATORS AND WINDOWS CLOSED.

IF SPILLAGE OCCURS THEN ADDITIONAL PERMANENT VENTILATION DIRECT FROM OUTSIDE WILL

BE REQUIRED. ONCE THE ADDITIONAL VENTILATION IS FITTED, RETEST AS NOTED ABOVE,

IT IS ESSENTIAL AND REQUIRED BY BUILDING REGULATIONS THAT A CARBON MONOXIDE (CO)

ALARM IS INSTALLED IN THE SAME ROOM AS THIS STOVE.

THIS STOVE MUST HAVE ITS OWN CHIMNEY AND MUST NOT SHARE A CHIMNEY WITH ANOTHER

APPLIANCE.

THIS STOVE IS FOR INTERMITTENT USE ONLY AND SHOULD BE SHUT DOWN OVERNIGHT.

VENTILATION MAY BE REQUIRED INTO YOUR ROOM, PLEASE SEE PAGE 10.

5

INSTALLATION

Once the installation is complete, the installer must advise the householder on

the correct use of the stove and warn them to use only the recommended fuels

listed in this document. The installer must also advise the householder on the

actions to be taken should smoke or fumes be emitted from the stove.

This stove must not share a chimney with any other appliance

Where the chimney is believed to have previously served an open fire

installation it is possible that the higher flue gas temperature from a closed

appliance may loosen deposits that were previously firmly adhered, with the

consequent risk of flue blockage. It is therefore recommended that the chimney

be swept a second time within a month of regular use after installation.

Check the chimney is in good condition, dry, free from cracks, leaks and

obstructions. The diameter of the flue should be no more than 230mm. If this

cannot be met then an appropriate liner should be fitted by a suitably approved

method.

A 125mm flue liner may be used in accordance with the Building Regulations.

The chimney and connecting flue pipe should not narrow to less than the size of

the outlet socket (collar) of the stove at any point. It is essential that only

recommended fuels are used – see page 15 for more information.

The chimney height and the position of the chimney terminal must conform to

Building Regulations and the latest edition of BS EN 15287-1:2007, Design,

Installation and Commissioning of Chimneys should be followed.

A flue draught of minimum 12 Pascals is required for satisfactory appliance

performance. The flue draught should be checked under fire at high output and

if it exceeds 25Pa, a draught stabiliser may be required so that the rate of

burning can be controlled, and to prevent possible over-firing.

If you have any doubts about the suitability of your chimney, consult your local

dealer/stockist. He will also be able to provide advice about the possible need

for a specialist cowl.

6

The chimney must be swept before connection to the stove and swept every

twelve months thereafter. It is recommended that your chimney is swept every

six months.

An existing fireplace opening can be modified to accommodate the stove. The

following pages identify some typical installation scenarios and provides the

necessary specific installation information for your new stove. Always consult

your stove supplier for a detailed survey of your particular circumstances.

To make it easier to handle the stove on installation, remove the baffle plates,

bricks and door. Place in a secure place to avoid damage. Refit after

installation.

Upon completion of installation, the appliance should be checked under fire for

soundness of joints and seals, and also that all smoke and fumes are taken from

the appliance, up the chimney and emitted safely.

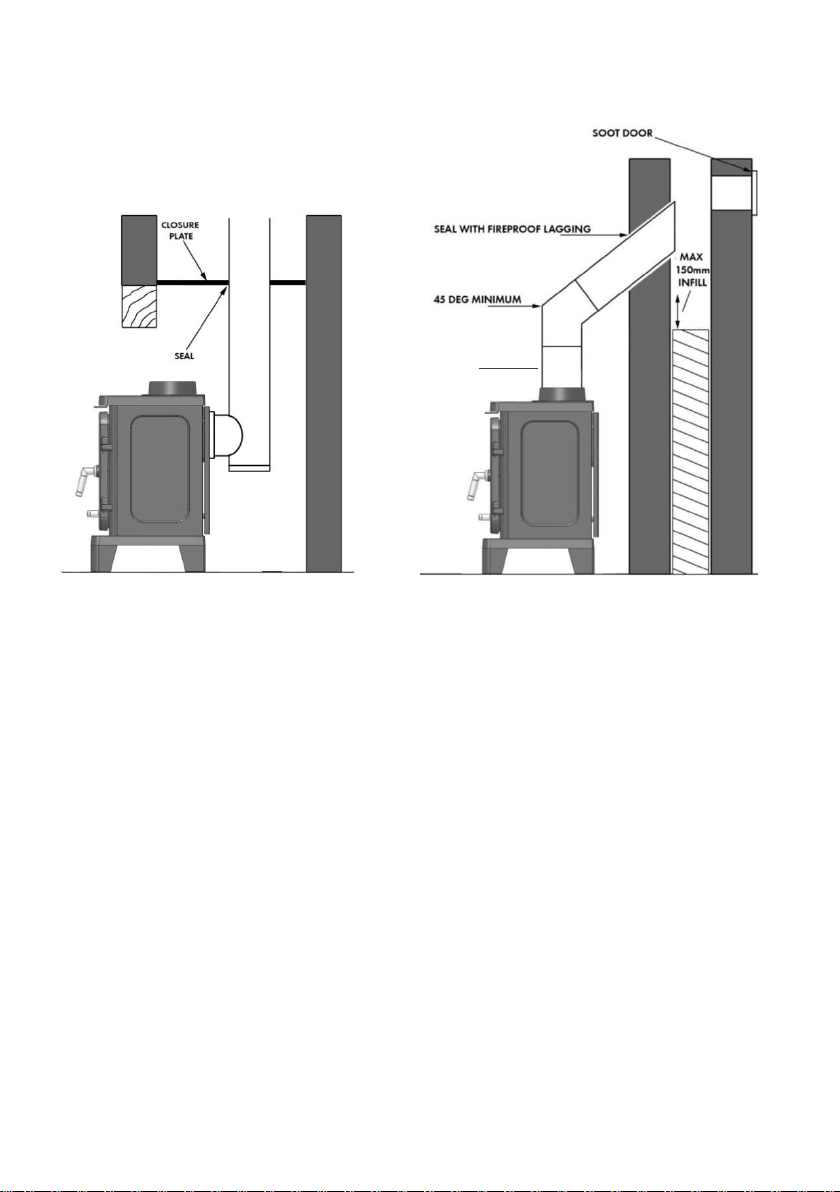

Typical Installation for Inglenook Fireplaces – top flue

Inglenook fireplaces can have very

large bore chimneys. Check with your

installer – you are likely to require a

stainless steel flexible liner for solid

fuel if your chimney is larger than

230mm x 230mm. A closure plate

with access for cleaning may also be

required together with a short length

of flue pipe of the same diameter as

the stove flue collar.

7

MINIMUM 600MM STRAIGHT

BEFORE 45 DEG BEND.

Typical Installation for Inglenook Typical Installation Into In-filled

Fireplaces – rear flue – Side View Masonry Fireplaces

SPECIFIC INSTALLATION INFORMATION

Legs

Remove the legs from inside the stove. Note that the Bassington legs are not

contained inside the stove but packaged separately. Carefully lay the stove on

its back and using the screws provided fit the legs in place. Carefully set the

stove upright and check that all internal components are correctly positioned.

Clearances

If the stoves are to be installed adjacent to materials that can catch fire like

wood then the following clearances must be adhered to:

Clearance to rear = 600mm

Clearance to sides = 600mm

The stove can be recessed into a suitably sized fireplace built from noncombustible materials, but a permanent free air gap of at least 100mm should

be left around the sides and top to obtain maximum heat output and for access

to the rear of the stove.

8

1

12mm

NON-COMBUSTIBLE

MATERIAL HEARTH

It is possible to fit the stove with less clearance around it – down to 50mm, but

the non-combustible material around it must be at least 150mm thick. This is

normally achieved when installing into a standard brick-built chimney breast

with double thickness walls to the rear and sides of the builder’s opening. Take

care that the wall finish is suitable to withstand temperatures of up to 200oC.

Hearths

Allow an apron of at least 225mm at the front of the stove and 150mm on either

side. Care should be taken to level the stove and secure the hearth. If existing

floors do not have adequate load bearing capacity then suitable modifications

must be adopted.

When the stove is in the desired position, fix the brackets provided to the back

feet and level the stove using the levelling screws, then mark the hearth through

the holes, remove the stove, and drill and plug the hearth for securing the stove.

Light Duty Hearths

Excluding the Bassington Baseline model, so long as the stove is installed in

accordance with the minimum clearance distances below then a light duty

hearth may be placed on a wooden floor. Note that all clearance distances to

combustible materials must be adhered to (see page 8).

9

SCREWS

Ventilation Into a Room For Combustion Air is an Essential Requirement.

Any apertures provided for this purpose must not be restricted or blocked.

Flues Without a Flue Draft Stabiliser 2.5kW-5kW Output

When installing without a flue draft stabiliser into houses built before 2008, no

additional permanent ventilation will be required.* Houses built after this date will

require additional means of permanent ventilation direct to outside of at least 4400

mm2. * Note: Installers must verify adequate draw and install ventilation if required. See Appendix F of

Building Regulations Approved Document J.

5kW-8kW Output - If you are intending to burn the stove above the independently

tested 5kW output, then a permanently open air vent into the room where the stove is

situated will be required. For house built before 2008, the vent must have a free area of

at least 1650mm2. For house built after 2008, the vent must have a free area of at least

4400mm2.

Flues With a Flue Draft Stabiliser 2.5kW-5kW Output

When installing with a flue draft stabiliser into houses built before 2008, at least

1500mm2 additional means of permanent ventilation direct to outside is required.

Houses built after this date will require additional means of permanent ventilation direct

to outside of at least 6800 mm2.

5kW-8kW Output - If you are intending to burn the stove above the independently

tested 5kW output, then a permanently open air vent into the room where the stove is

situated will be required. For house built before 2008, the vent must have a free area of

at least 4050mm2. For house built after 2008, the vent must have a free area of at least

6800mm2.

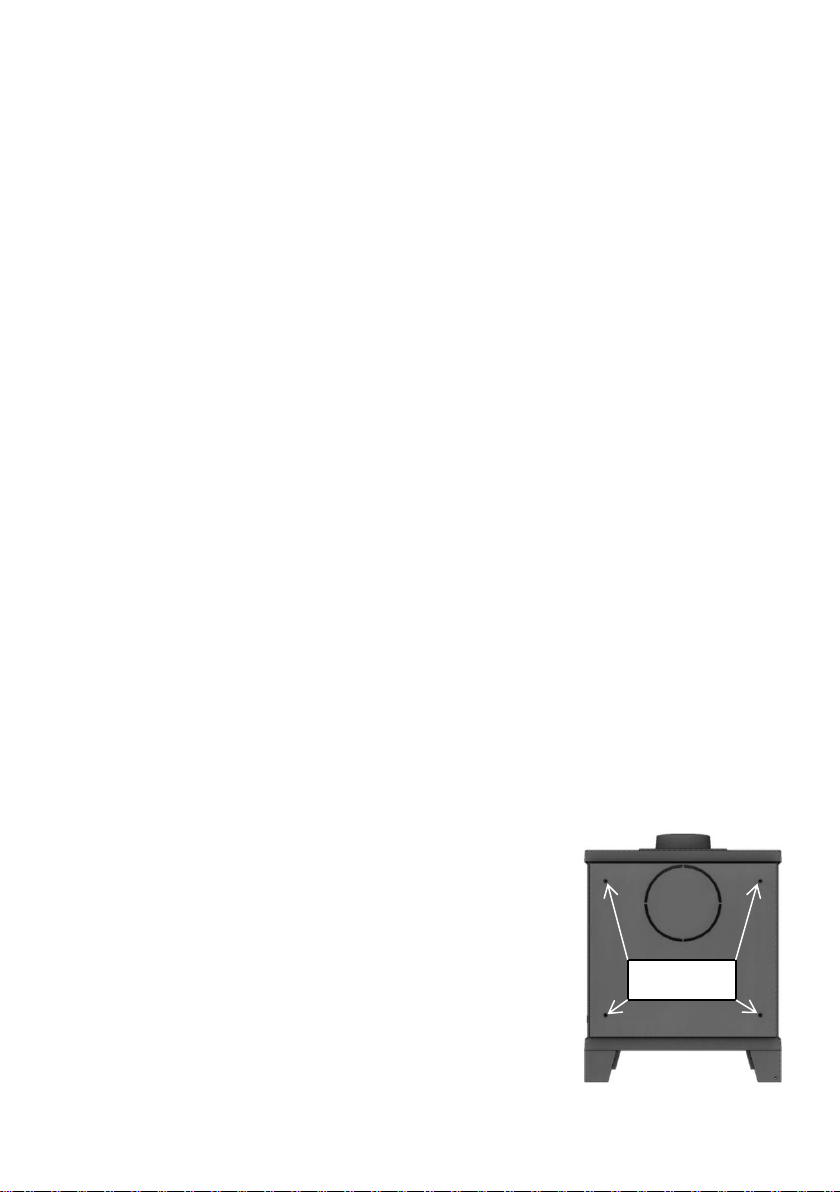

Top or Rear Flue

Remove the collar and accessory pack from the stove. The

stove will arrive with the blanking plate fitted to the rear.

This can be removed if required allowing the collar to be

fitted for rear flue installations. The circular cut out in the

rear heat shield must be removed to enable this style of

connection – see image.

Remove the panel from the stove by unscrewing the four

screws and then remove the circular cut out for rear flue

installations. Replace the rear heat shield. Remember to fit

the blanking plate to the unused flue position if it has been

removed.

10

Loading...

Loading...