Capital SIRIUS, SIERRA Installation And Operating Instructions Manual

Solid Fuel Stoves Manual vI2. Issued - 28/11/2014 (392)

'SIRIUS' SOLID FUEL HEATING

STOVES - 'SIERRA' INSET MULTI-

FUEL MODELS

Incorporating GH-T Firebox

INSTALLATION AND OPERATING INSTRUCTIONS

LEAVE THIS DOCUMENT WITH THE HOUSEHOLDER!

All these Stoves exceed the safety and performance requirements of European Standards

Intermittent burning solid fuel roomheaters for installation with a single dedicated chimney.

Independently tested in 2010 by SGS Approved Laboratory No 0608

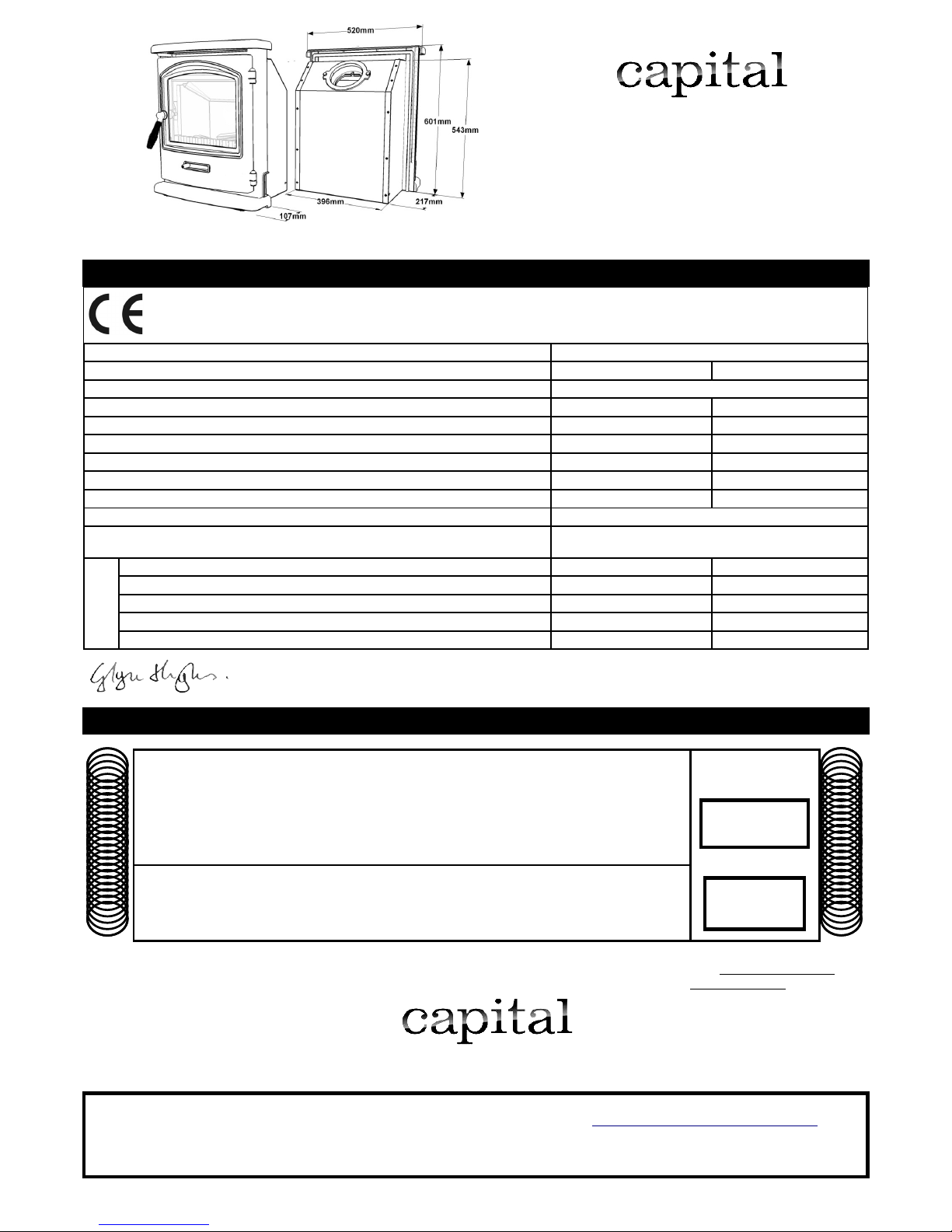

Inset Stove with GHT-T Firebox

Fuel Wood (Beech) Mineral Fuel (Anthracite)

Test Standard EN 13229

Test Cycle 1.0 kg per 45 mins 0.7 kg per 1.01 hrs

Settings Primary=0, 2nd=25% Primary 100%, 2nd 0.5 cm

Flue Draught Pa (ins WG) 12 Pa 12 Pa

Efficiency % 82.2% 77%

Recommended Output Rating kW 4.9 kW 4.9 kW

Mean Flue Gas Temp Rise ºC 218 °C 279 °C

Minimum air entry requirement 2750 mm²

Minimum Clearance to combustibles (allow min 50 mm clearance to non-combustibles)

When fitted in masonry fireplace,

15cm at sides, 30cm above

Emissions as

if 02=13%

NOx mg/m³ 77 mg/m³ NPD

CO % 0.3% 0.06%

CxHy mg/m³ NPD NPD

Gas flow g/sec 3.9 g/sec 5.2 g/sec

Smoke Emission mg/m³ 142 mg/m³ NPD

I declare that this information is true, these products meet the requirements of Harmonised Standards and are fit for sale.

Signed on behalf of the manufacturer by Glyn Hughes, Design Engineer, at Winster, Derbyshire, England 28. Nov. 2014

Read these instructions! Use only recommended fuels!

This document, when completed by the installer, constitutes part of a 'Hearth Notice' for purposes of

Building Law. It must be left with the householder and placed where it can easily be found.

INSTALLED AT LOCATION:

BY:

EMERGENCY CONTACT:

Flue Draught

measured on

commissioning:

Fuel used on

commissioning

I definitively assert that this installation is safe, has been lit and demonstrated to the

householder, conforms with current building regulations and with these instructions

SIGNED: DATE:

TO FIND A QUALIFIED INSTALLER, FUEL SUPPLIER or CHIMNEY SWEEP, CONTACT:

UK: The Solid Fuel Association, 7 Swanwick Court, Alfreton, Derbyshire DE55 7AS Tel:0845-601-4406 www.solidfuel.co.uk

RoI: Irish Nationwide Fireplace Organisation, 162 Capel Street, Dublin 1 Tel:01-801-5959 www.fireplace.ie

www.capitalfireplaces.co.uk

Capital Fireplaces, Unit 12, Henlow Ind Est, Henlow Camp, Beds SG16 6DS UK

Tel: 01462-813138 Tel: 01204-868-550

This Inset Stove incorporating the GH-T firebox may be used in smoke control areas when operated strictly in accordance

with these instructions and with the attached Soliftec Smoke Advice Sheet No1 (www.soliftec.com/smokeadvice.htm), when

burning:

UK: Untreated wood logs or authorised smokeless fuels (Exempted from s20 of the Clean Air Act 1993)

RoI: Wood logs, smokeless fuels or peat briquettes, but not petroleum coke (Control of Atmospheric Pollution Regulations, 1970)

1

Pa

WG

Building regulations are available at www.soliftec.com

ABOUT YOUR INSET STOVE

This Inset is a solid multi-fuel heating stove designed to fit into

masonry fireplaces. It has convection chambers behind, above, at

the sides and even underneath the firebox to collect hot air and

distribute it into the room so that it is every bit as efficient, or more

so, than a free-standing stove.

INSTALLING a stove is a 'controlled service', the law expects that

it is either supervised by a qualified installer or that the building

inspector is informed. Check with your local authority.

ASBESTOS: Your stove does not contain asbestos, but take care

to avoid disturbing asbestos in an old installation.

WEIGHT: Your stove is heavy (94kg) take great care when moving

it and ensure that the intended fireplace can support the weightconsider fitting a load distributing plate.

YOUR CHIMNEY, by becoming warm, makes the gas inside it

rise, pulling fresh air into the stove to make it work. It must:

•Generate a draught in use of at least 12Pa (0.05ins wg)

•Be capable of withstanding the temperatures generated.

•Be absolutely incapable of leaking fumes into the dwelling

•This may commonly be achieved by it:

•Being at least 5m high.

•Terminating at least 1m above any roof ridge.

•Having an internal cross-section equivalent to never less than

125mm diameter, and never more than 0.14m² (eg 375 x

375mm)

•Being free from even the slightest crack or source of leakage.

•Having no bends sharper than 45º.

•Being swept and entirely free of obstructions

•Being connected only to this one appliance.

•Being of thick masonry or otherwise highly insulated.

•Conforming to local building regulations.

Special rules apply where the flue passes through timber, thatch or

other vulnerable materials- take specialist advice.

Although it is possible to access the chimney through the fire with

the throat plate removed, fit hatches to provide access if needed.

YOUR FIREPLACE: Stoves become VERY hot, the setting must

be made entirely of durable fireproof materials. Thin (<50mm)

stone slabs risk cracking unless cut into sections to allow for

expansion and backed with a heat resistant concrete. Even

beyond the safety clearance items can still become very hot - take

great care in siting wax, paper etc.

AIR SUPPLY: Your stove needs air to breathe - there should be a

permanent fresh air supply into the space in which it is installed

equal to about 550mm² for each kW of nominal output.

This degree of air can often be provided by leakage around door

frames etc, especially in older buildings. It is commonly accepted

that this alone may suffice for appliances below about 5kW output.

It must be a matter for the judgement of the installer as to whether

an extra permanent air vent is required. Where is needed, it is

wise to fit an outside vent as close to the fire as possible, to

prevent unpleasant draughts. An extractor fan, or another fuelusing appliance in the same building, can remove this air.

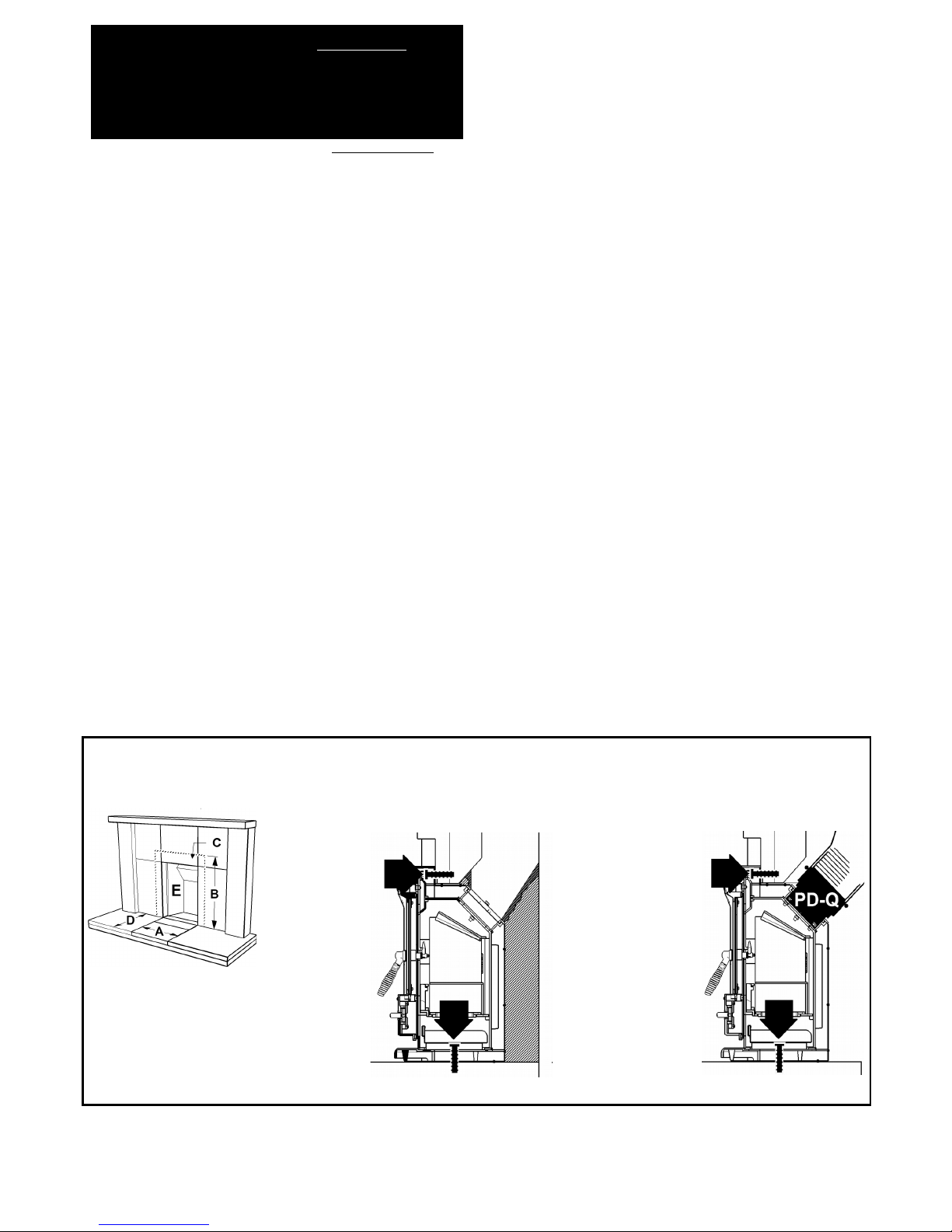

FITTING

This model can fit straight into a standard British or Irish fireplace

conforming to BS1251 & BS8303. The fireplace can be of any

shape, but will always have:

• Have an opening width (A) of between 400 and 420mm,

• An opening height (B) of between 540 and 560mm,

• A flat area (C) extending 70mm around the opening

• A hearth extending at least 225mm in front of the fire (D), without

obstructions to prevent the door opening

(The fireplace will become VERY hot - Where thin slabs of mineral

material (marble, limestone etc) are used to face a fireplace, we

recommend using 5 separate panels, as shown, to allow for

differential expansion.)

The Inset will fit directly into any correctly constructed fireplace

with the fireback (E) broken up and removed, so that a clear, level

depth of at least 260mm is available.

The stove must be firmly fixed in place through the fixing hole(s)

(G) BOTH in the base AND against the face of the fireplace.

Screws are provided for use in sound masonry, but, depending on

the substrate, other fixings may need to be substituted.

This stove is double-cased - it is not necessary to fill any small gap

behind the appliance – larger gaps should be filled with rubble,

vermiculite granules or mineral fibre wool.

It is highly advisable, where fitted into a masonry flue, to form a

smooth mortar flaunching between the flue outlet and the flue.

With care, this can be done through the flue outlet.

A soft seal is fixed to the back seating surface of the stove. A thicker seal for rough materials such as stone is available from your

dealer. Pull off top and push stove into the opening. Screw to the masonry of the fireplace at the FOUR points arrowed (two through

the base, two above the fire opening) and proceed with the fix as shown below.

Suitable masonry fireplace.

Opening width (A) 400 to

420mm, height (B) 540 to

560mm. Flat area (C) extending

70mm around the opening, a

hearth extending at least

225mm in front of the fire(D),

without obstructions to prevent

the door opening.

'FIREPLACE SEAL' METHOD:

Fix the four bolts

to hold the stove

in place and,

through the flue

outlet, fill any gap

behind with

vermiculite

granules topped

with mortar.

Carefully check

that the fire has an

absolutely airtight

seal against the

fireplace.

FAST-FIX 'CHIMNEY SEAL' METHOD:

Obtain a PD-Q flue

connector. Fit the flue

pipe, or 150mm flexible

liner, into the chimney

and fasten its loose end

to the PD-Q connector,

sealing well with fire

cement. Fix the four

bolts to hold the stove.

Smear a little fire

cement around the flue

outlet and bolt the

connector and pipe

back in place from

inside. Check that the

pipe forms a clear route

from stove to chimney

terminal with no leaks

into the masonry space.

Whichever method is used it is imperative that: (1) The route for gases from the stove to the chimney terminal is completely air-tight;

even the tiniest gap or crack can spoil the updraught. Seal all joins with fireproof cement and/or heatproof rope. (2) It is possible to

sweep the entire length- access doors may be required. (3) The entire construction is of durable fireproof materials. (4) It is wise to fit a

CO alarm.

2

THIS APPLIANCE BECOMES EXTREMELY HOT

AND CAN PRODUCE POISONOUS GASES.

A fire-guard should be used if children or the infirm are

present. The installer is required to EXACTLY follow

these instructions and to completely comply with all

local, national and international standards.

Loading...

Loading...