Canyon Mountain bike User Manual

PURE CYCLING

BICYCLE MANUAL MOUNTAIN BIKE

1

13

14

15

2

3

4

e

c

a

I

II

f

b

III

5

6

7

d

IV

8

9

10

11

12

Your bicycle and this bicycle manual comply with the safety requirements of the European standard

!

EN 14766 for mountain bicycles.

16

17

18

19

20

21

22

23

24

25

26

Attention!

Assembly instructions page 12. Before your first ride please read pages 7-11.

TABLE OF CONTENTS

COMPONENTS

1 Frame:

a Top tube

b Down tube

c Seat tube

d Chainstay

e Rear stay

f Rear shock

2 Saddle

3 Seat post

4 Seat post clamp

5 Rear brake

6 Cassette sprockets

7 Rear derailleur

8 Chain

9 Front derailleur

10 Chainring

11 Crank set

12 Pedal

GENERAL NOTES ON THIS MANUAL

PAY PARTICULAR ATTENTION TO THE FOLLOWING SYMBOLS:

Please note that the aforementioned consequences

will not be repeated each time the symbols appear in

the manual.

13 Stem

14 Handlebars

15 Brake lever

16 Shift lever

17 Headset

18 Suspension fork:

I Fork crown

II Stanchion tube

III Lower leg

IV Drop-out

19 Front brake

20 Rotor

Wheel:

21 Quick-release

22 Rim

23 Spoke

24 Tyre

25 Hub

26 Valve

This symbol warns you about actions that

!

could lead to damage to property or the environment.

2 Welcome

4 Intended use

7 Before your first ride

10 Before every ride

12 Assembly from the BikeGuard

24 Packing your Canyon bike

25 How to use quick-releases and thru axles

25 How to securely mount the wheel

27 How to mount thru axle wheels

30 What to bear in mind when adding components or

making changes?

31 Special characteris tics of carbon

32 Care instructions

33 Special features of freeride bikes

35 After an accident

37 Framesets – assembly technical data

42 Adjusting the Canyon bike to the rider

43 Adjusting the saddle to the correct height

45 Adjusting the height of the handlebars

45 Aheadset

48 Fore-to-aft position and saddle tilt

49 Adjusting saddle position and tilt

51 Handlebars and brake lever adjustment

51 Adjusting the handlebar position by turning the

53 Adjusting the brake lever reach

54 The pedal systems

54 Different systems at a glance - how they work

56 Adjustment and maintenance

57 The brake system

58 Brakes – how they work and what to do about

59 Checking and readjusting disc brakes

59 Functional check

60 AVID, FORMULA, MAGURA and SHIMANO

61 The gears

62 The gears - how they work and how to use them

65 Checking and readjusting the gears

handlebar

wear

brakes

®

-stems or threadless system

65 Rear derailleur

65 Adjustment of limit stops

67 Front derailleur

68 Crank gear

68 Chain maintenance

69 Chain wear

70 The wheels - tyres, inner tubes and air pressure

73 Rim trueness, spoke tension

74 Wheel fastening with quick-releases

74 Wheel fastening with thru axle systems

75 Repairing punctures

75 Wheel removal

76 Removing clincher and folding tyres

77 Mounting clincher and folding tyres

79 Removing tubeless/UST tyres

79 Repairing tubeless/UST tyres

80 Mounting tubeless/UST tyres

81 Mounting wheels

82 The headset

82 Checking and readjusting

83 Threadless headset: Aheadset

84 Suspension

84 Glossary - suspension

85 The suspension fork

85 How suspension forks work

86 Adjustment and maintenance

89 Full-suspension

89 What to bear in mind when adjusting the

saddle

89 Adjustment and maintenance

92 Transport of your Canyon bike

94 General notes on care and inspection

94 Washing and cleaning your Canyon

96 Safekeeping and storing your Canyon

97 Servicing and inspection

98 Service and maintenance schedule

100 Recommended tightening torques

104 Legal requirements for riding on public roads

107 Guarantee

108 Crash replacement

®

This symbol indicates an imminent risk to

your life or health unless you comply with

the instructions given or take preventive measures.

This symbol signifies information about

i

how to handle the product or refers to a

passage in the operating instructions that deserves your special attention.

WELCOME

2 3

WELCOME

DEAR CANYON CUSTOMER,

In this manual we have compiled for you lots of tips on

how to use your Canyon bike, instructions for maintenance and care, plus a wealth of things worth knowing on bicycle technology. Please read this manual

thoroughly. You will find it worth your while; even if

you have cycled all your life and feel like a veteran

with your new bike. Bicycle technology has developed

tremendously over the past few years.

For your enjoyment and safety when cycling, please

read the complete first part of this manual thoroughly

and

strictly follow the assembly instructions given in

chapter “Assembly from the BikeGuard“.

read chapter “Before your first ride“ and

see chapter “Intended use“ to read up on how to use

your new bike and on the permitted overall weight

(rider, clothing and baggage) and

carry out the minimum functional check before

every ride. For more details on how to proceed, read

chapter "Before every ride“ of this manual. Do not

ride your bike unless it has passed the functional

check one hundred per cent!

On the digital data medium enclosed with this manual

you will find a number of maintenance and repair routines in detail. When carrying out these routines, be

aware that the instructions and information provided

in your manual only refer to this Canyon bike and that

they do not necessarily apply to other bikes. Due to

numerous designs and model changes, it may be that

some of the routines are not described in every detail.

For this reason be sure also to observe the operating instructions of our component suppliers enclosed

with the BikeGuard.

Note that the instructions and tips may require further explanation depending on various factors, such

as the experience and skills of the person doing the

work or the tools being used, and some jobs may require additional (special) tools or measures not described in the manual.

Furthermore, you will find numerous service movies

on our website www.canyon.com that will help you

carry out small repair and maintenance works.

For your own safety, never do work on your bicycle

unless you feel absolutely sure about it. If you are in

doubt or if you have any questions, please contact

our service hotline +44 (0) 20 8501 2582!

Please note: This manual cannot teach you all mechanical skills. Even a manual as big as an encyclopaedia could not describe every possible combination

of available bicycles and components. For this reason

this manual focuses on your newly purchased bike

and standard components by drawing your attention

to important notes and warnings. It does, however,

not teach you the basic skills of a bike mechanic or

help you assemble a complete bike from the Canyon

frameset.

This manual cannot teach you how to ride. For this

reason this manual focuses on your newly purchased

bike by drawing your attention to the most important

notes and warnings. This manual cannot teach you

riding a bike or make you familiar with the traffic

rules.

Please be aware that cycling is a hazardous activity

that requires that the rider stays in control of his or

her bike at all times.

Like any sport, bicycling involves risk of injury and

damage. By choosing to ride a bike, you assume the

responsibility for the risk. Always keep in mind that

you have no protection technique around you, which

could avoid injuries, such as e.g. the bodywork or the

airbag of a car.

Therefore, always ride carefully and respect the other

traffic participants.

Never ride under drugs, alcohol or when you are tired.

Do not ride with a second person on your bike and

never ride without having your hands on the handlebars.

Before you set off please note: Always ride carefully

so as not to endanger yourself or others. Please respect nature when touring through forests and meadows. Make it a habit to only ride with appropriate

equipment. At least you should wear a properly adjusted bike helmet, sturdy shoes and suitable, bright

coloured clothing.

Your Canyon team wishes you lots of fun and enjoyment with your bike!

This manual does not help you to assemble a bicycle

from individual parts or to repair it! Technical details

in the text and illustrations of this manual are subject

to change. This manual conforms with the requirements of the CE-standard EN 14766. This manual is

subject to European legislation.

On delivery of the bike, the manufacturer has to attach

additional manuals. Please visit www.canyon.com for

supplementary manuals.

Concept, text, photos and graphic design:

Zedler – Institut für Fahrradtechnik

und -Sicherheit GmbH

www.zedler.de

Revised in July 2013, edition 6

© No part of this brochure may be published, reprinted, translated or reproduced in extracts or with electronical systems or used for other business purposes

without prior written permission of the author.

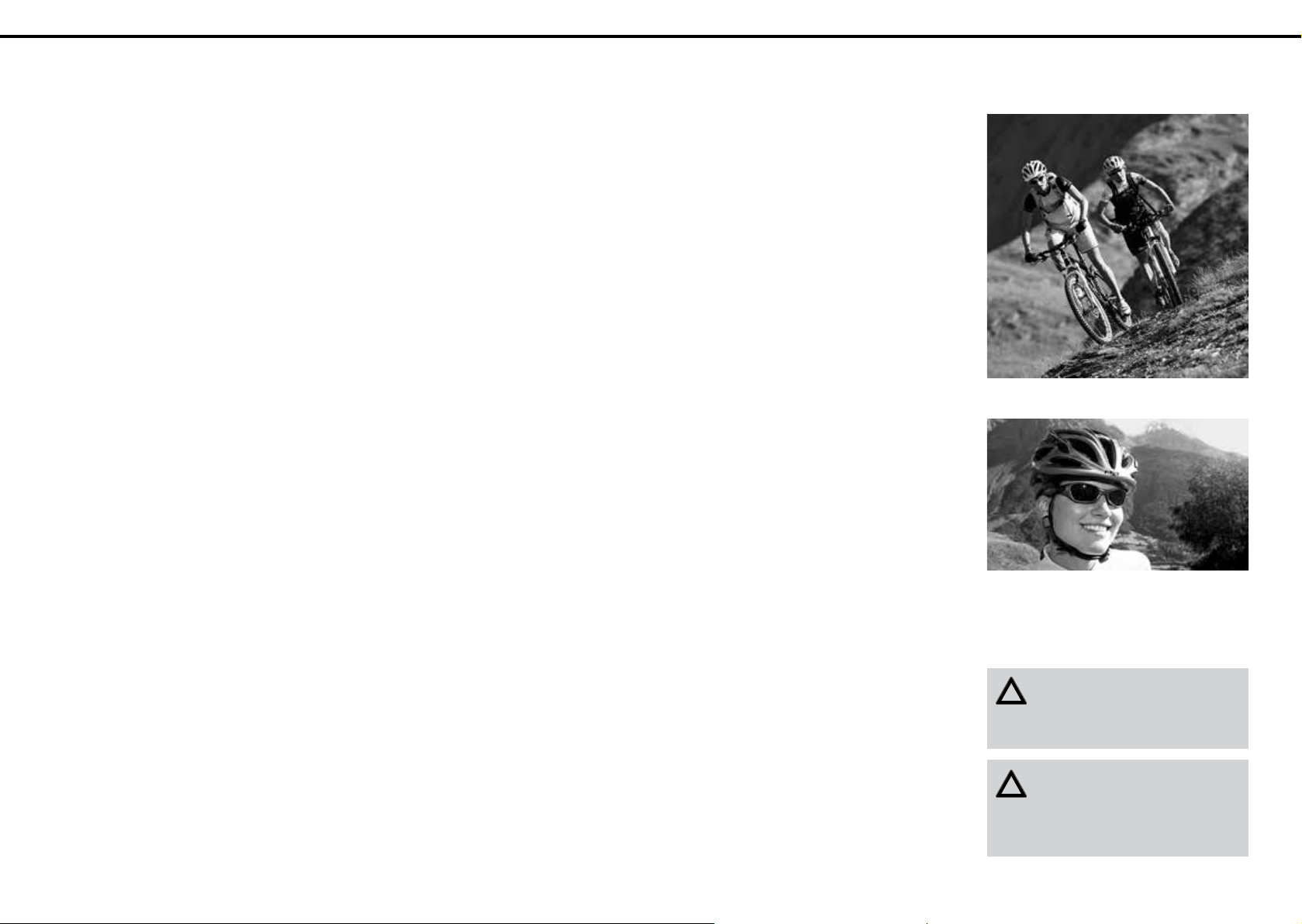

Off-road cycling

Always with helmet and glasses

Please visit our website at www.canyon.com.

i

There you will find the latest news, useful

tips as well as the addresses of our distribution

partners.

For your own safety, never do any assem-

!

bly or adjusting work on your bike, unless

you feel absolutely sure about it. If you are unsure

about anything, please call our service hotline

+44 (0) 20 8501 2582. E-mail: info@canyon.com

INTENDED USE

4 5

INTENDED USE

INTENDED USE

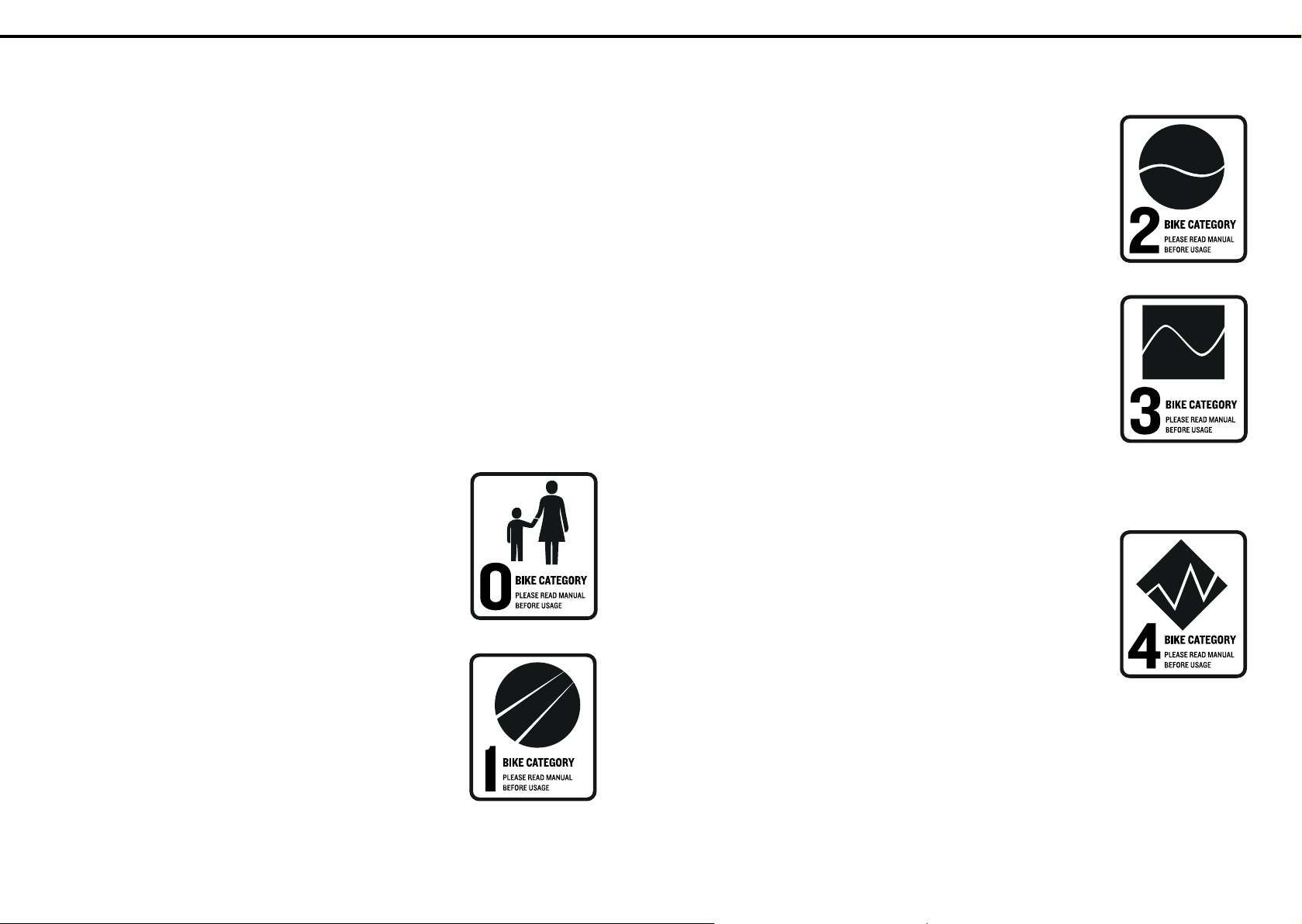

To define the intended purposes for the different types of bicycles, we have classified our bikes in different

categories. The purpose of this classification is to define the test requirements complying with the respective

stress as early as during the development of our bikes. This is to ensure the highest possible level of safety for

the use of our bikes.

It is therefore of major importance that the bikes are not used under conditions beyond the intended use, as this

bears the risk that the bikes’ maximum load is exceeded and the frame or other components are damaged. This

can result in severe crashes.

The rider’s maximum weight incl. baggage should not exceed 120 kg. Under certain circumstances this permissible maximum weight can be further limited by the component manufacturers’ recommendations for use.

The frame of your bike is marked according to one of the following symbols indicating the category your bike

belongs to. If you are not sure about the category your bike belongs to, please contact our service centre.

Condition 0

This category is intended for childrens’ bicycles.

Children should not ride near precipices, staircases

or swimming pools as well as on paths used by automotive mobiles. In general, this applies to bicycles

with wheel sizes of 12 to 24 inches.

Condition 1

Bikes of this category are designed for riding on

hard-surface roads where the wheels remain in

permanent contact to the ground. These are in general road racing bicycles with racing handlebars or

straight handlebars, triathlon or time trial bicycles.

The rider’s maximum weight incl. baggage should

not exceed 120 kg. Under certain circumstances this

permissible maximum weight can be further limited

by the component manufacturers’ recommendations

for use.

Condition 2

Bicycles of category 1 and bicycles designed for well

paved gravel paths and off-road trails with a slight

slope where a short loss of tyre contact with the

ground due to small steps can occur. This condition

comprises urban and city bicycles as well as cyclocross bikes with road racing handlebars and cantilever or disc brakes.

Condition 3

Bikes of this category comprise the bicycles of the

categories 1 and 2 and are in addition suitable for

rough and unpaved terrains. Sporadic jumps of a

maximum height of approx. 60 cm are also included

in the field of use of these bicycles. But inexperienced

riders doing jumps of this height may land inappropriately, thus increasing the acting forces significantly

which may result in damage and injuries. This category is represented by MTB hardtails and full suspension bicycles with short suspension travel.

Condition 4

This category includes bikes of the categories 1 to 3.

In addition, bicycles of this category are suitable

for very rough and partly blocked terrain with steep

slopes and higher speeds as a result thereof. Regular, moderate jumps by experienced riders are no

problem for these bicycles. The regular and durable use of the bicycles on North Shore trails and in

bike parks should, however, be excluded. Due to the

higher stresses, these bicycles should be checked

for possible damage after every ride. Full suspension

bikes with medium suspension travel are typical for

this category.

INTENDED USE

6 7

BEFORE YOUR FIRST RIDE

Condition 5

This type of use stands for very challenging, highly

blocked and extremely steep terrains, which can

only be mastered by well-trained riders with technical skills. Rather high jumps at very high speeds as

well as the intensive use of specific, identified bike

parks or downhill trails are typical for this category.

In the case of these bicycles it must be considered

that a thorough check for possible damage is carried

out after every ride. Preliminary damage with clearly

inferior further stress can result in failure. A regular

replacement of safety-relevant components should

also be taken into account. Wearing special protectors is strongly recommended. Full suspension bikes

with long suspension travel as well as dirt bikes are

typical for this category.

BEFORE YOUR FIRST

RIDE

1. Have you ever ridden a mountain bike? Please note

that riding over rough terrain requires concentration, fitness and practice. Make yourself gradually familiar with your new mountain bike in an

unfrequented area and only approach the terrain

you want to bike on step by step. Attend a riding

technique course. For more information visit www.

canyon.com

2. Are you familiar with the brake system? Canyon

bikes are normally delivered with the left brake lever operating the front brake. Check whether the

lever of the front brake is in the position you are

used to. If it is not, you will need to train to get used

to the new configuration, as inadvertent use of the

front brake can throw you off your bike! Have the

lever-to-brake assignment changed by an expert.

Your new bike is equipped with modern brakes

which may be far more powerful than those you are

used to! Due to the specific intended use, some dirt

bikes are fitted with only one brake.

Be sure to first practise using the brakes off public

roads! Do approach the maximum possible deceleration gradually. For more information about the

brakes, read chapter “The brake system“.

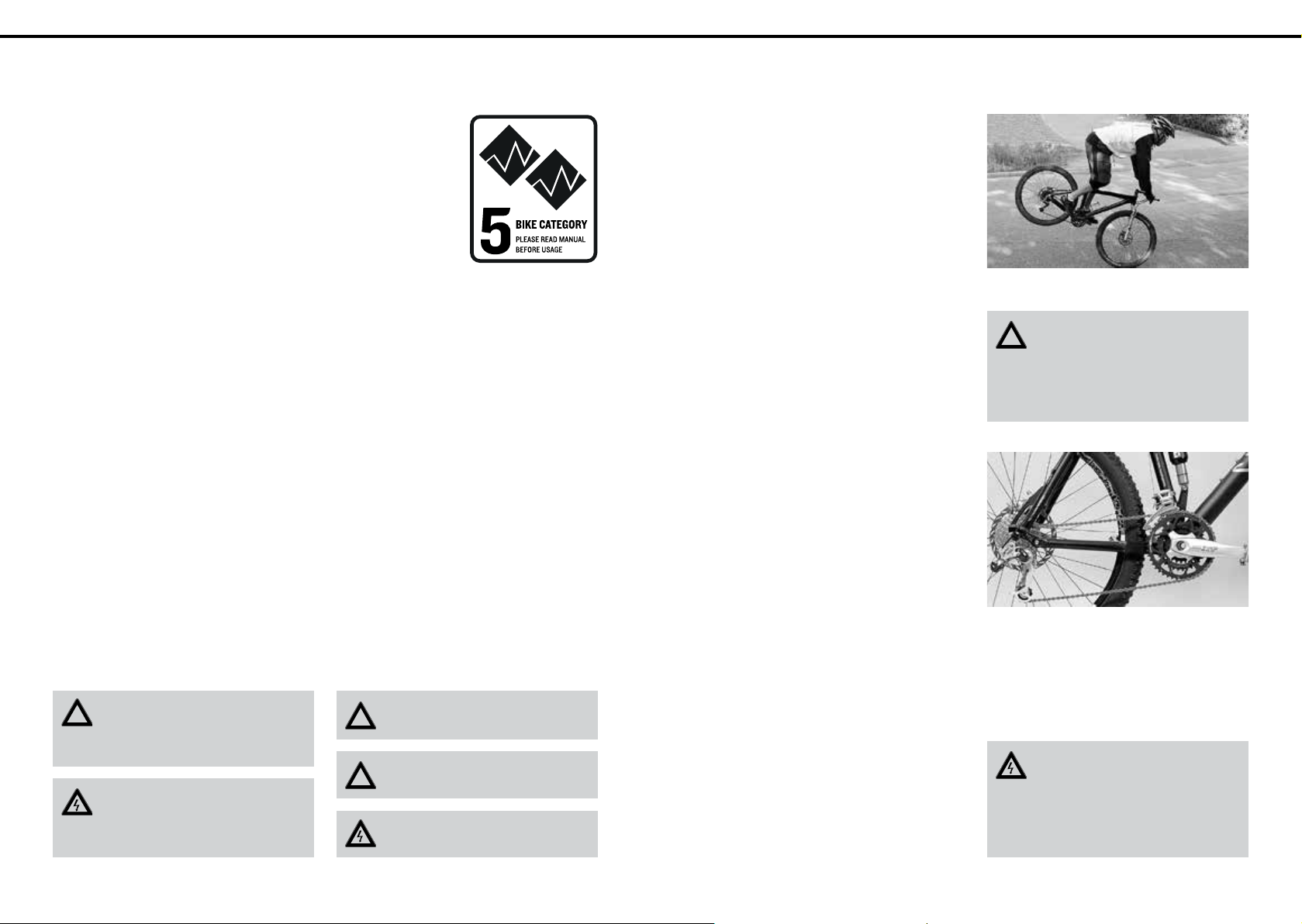

Too hard braking with front brake; do not imitate!

Note that the assignment of brake lever to

!

brake caliper can vary from country to

country. Check the brake assignment. If it does

not comply with your habits, we recommend you

having an expert change the lever-to-brake assignment!

Derailleur gears

Keep yourself informed by visiting our al-

i

ways updated website at www.canyon.com.

There you will find an illustration visualising the

intended use of all Canyon bikes.

Bikes with carbon seat posts are not ap-

proved for mounting pannier racks. The

only way of riding with baggage is by using a special backpack.

Canyon bikes are not approved for mount-

!

ing child carriers.

Canyon bikes are not approved for towing

!

trailers.

Due to the specific intended use, some dirt

bikes are fitted with only one brake.

3. Are you familiar with the type and functioning of the

gears? If not, make yourself familiar with the gears

in a place clear of traffic. Make sure not to shift

gears on the front and rear derailleur at the same

time and not to pedal with too much force when

shifting. For more information about the gears,

read chapter “The gears“.

If you hold your MTB handlebars by the

bar ends, you cannot reach the brake levers as quickly as you would from other positions,

and your stopping distance therefore becomes

longer. Look well ahead as you ride and be prepared for longer stopping distances.

BEFORE YOUR FIRST RIDE

8 9

BEFORE YOUR FIRST RIDE

4. Are frame size, saddle and handlebars properly

adjusted? Stand over the top tube of your bike

and check whether there is enough clearance between the top tube and your crotch (at least one

handbreath). If there is not, read the more detailed chapter of the manual further below or on

the enclosed CD or contact our service hotline at

+44 (0) 20 8501 2582. Riding with a too big frame

may cause injuries, when getting off your bike

quickly! With cross-country and marathon bikes

the saddle should be set to a height from which you

can just reach the pedal in its lowest position with

your heel. Check whether your toes reach to the

floor when you are sitting on the saddle. With all

mountain, enduro and freeride bikes the saddle is

normally brought to a lower position. A lower saddle position is particularly advisable when riding

downhill. For more information about the saddle

position, read chapter “Adjusting the Canyon bike

to the rider”.

5. Have you ever tried clipless or step-in pedals and

the shoes they go with? Before riding with clipless

pedals for the first time, carefully practise locking

one shoe onto a pedal and disengaging it while the

bike is stationary. Lean against a wall when practising so that you do not topple over. Adjust the

locking and release mechanism, if necessary. Be

sure to first read the operating instructions that

you will find in the BikeGuard. For more information about the pedals, read chapter “The pedal sys-

tems”.

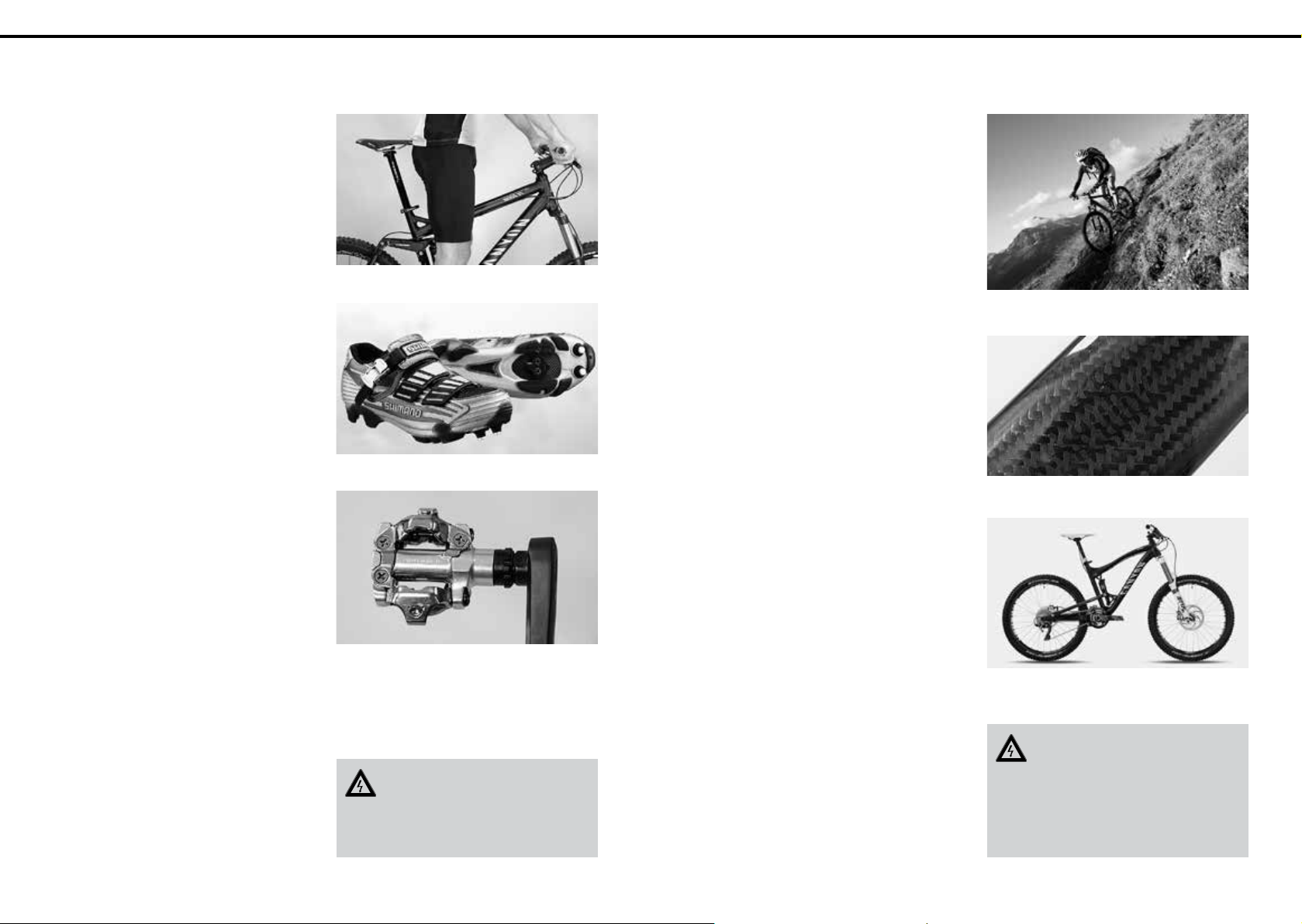

Checking the clearance between top tube and crotch

Shoes for step-in pedals

6. Note that you should only use your Canyon for its

intended purpose! Mountain bikes intended for

cross-country and marathon use are not suitable

for hard downhill rides on blocked terrain or jumps

etc. For all mountain or enduro use we recommend

our special models. The Torque models are also

suitable for freeriding. Please keep in mind that

though looking easy the tricks of a professional

actually require a lot of training and experience.

For your own safety, do not overestimate your riding abilities. In general, Canyon bikes are designed

for an overall load (rider and baggage) of 120 kg.

Make sure not to exceed this limit. For more information about the use, read chapter “Intended use”.

7. Are parts of your Canyon bike made of carbon?

Please note that this material requires special care

and particular use. In any case, be sure to read

chapter “Special characteristics of carbon”.

8. If you have bought a suspension bicycle, you should

check the air pressure of the suspension fork. If

necessary, use the pump included in the BikeGuard for the adjustment. An improperly adjusted

suspension fork is liable to malfunction or damage. In any case they will impair the performance

of your bicycle as well as your safety whilst riding.

For more information read chapters “Suspension

fork” and “Full-suspension”.

Riding off-road

Carbon

Step-in pedal

A lack of practice when using clipless

pedals or too much spring tension in the

mechanism can lead to a very firm connection,

from which you cannot quickly step out! Risk of

an accident!

Full-suspension bike

Canyon mountain bikes are high-end

sports equipment, representing lightweight construction as pinnacle of engineering.

Also be a professional when it comes to handling

of the material. Misuse, unprofessional assembly

or insufficient servicing can render the racing machine unsafe. Risk of an accident!

BEFORE EVERY RIDE

10 11

BEFORE EVERY RIDE

BEFORE EVERY RIDE

CHECK THE FOLLOWING POINTS BEFORE EVERY

RIDE:

1. Are the quick-release levers of the front and rear

wheel, seat post and other components as well as

of available thru axles properly closed? For more

information, read chapter “How to use quick-re-

leases and thru axles”.

2. Are the tyres in good condition and do they have

sufficient pressure? Spin the wheels to check

whether the rims are true. Also look out for tyres

with ruptured sides or broken axles or spokes

while you do this. For more information, read chapter “The wheels - tyres, inner tubes and air pres-

sure”.

3. Test the brakes while standing by firmly pulling

brake levers towards the handlebars. A pressure

point should be reached after the lever has only

travelled a short distance; the lever must, however, not touch the handlebars! Make sure no liquid

leaks out from hydraulic (disc) brakes. For more

information about the brakes, read chapter “The

brake system“.

Check the tyre pressure

4. If you intend to ride on public roads or in the dark,

check the lighting set, see chapter “Legal requirements”.

5. Let your Canyon bounce on the ground from a

small height. If there is any rattling, see where it

comes from. Check the bearings and bolted connections, if necessary.

6. Due to their intended use, freeride bikes, such as

the Strive or the Torque, must withstand particular

strains. If you are owner of such a bike, be sure to

check it for impairments and material fatigue, such

as cracks, dents and bends, before every ride.

7. The major accessory for a successful cycling tour

is a small tool bag fitted underneath the saddle.

The tool kit should include two plastic tyre levers,

the most commonly used Allen keys, a spare tube,

a tyre repair kit, your mobile phone and a little

cash. Do not forget a tyre pump mounted to the

frame.

8. Take a sturdy lock with you, if you intend to leave

your Canyon in a public area. The only way to protect your Canyon against theft in a public area is to

lock it to an immovable object!

Never ride without lighting in the dark

Emergency kit

You should not be able to pull the brake lever all the way to the

handlebars

Improperly closed quick-releases can

cause bicycle components to come loose.

Risk of an accident!

Do not use your Canyon, if it fails on one of

these points!

To safe your Canyon from damage,

!

please observe the maximum overall load

and the regulations regarding the transport of

baggage and children given in chapter “Intend-

ed use”. Furthermore, we recommend reading

chapter “Transport of your Canyon bike” before

transporting your Canyon by car or plane.

During use your Canyon is undergoing

stress resulting from the surface of the

road and through the rider’s action. Due to these

dynamic loads, the different parts of your bike

react with wear. Please check your Canyon regularly for wear marks as well as for scratches,

dents, bent parts and incipient cracking. Components that have passed their normal service life

may suddenly fail. Have your Canyon inspected

regularly so that components can be replaced, if

necessary. For more information on maintenance

and operational safety, read chapters “General

notes on care and inspection”, “Recommended

tightening torques” and “Service and maintenance

schedule”.

ASSEMBLY FROM THE BIKEGUARD

12 13

ASSEMBLY FROM THE BIKEGUARD

ASSEMBLY FROM THE

BIKEGUARD

Assembling the bike from the BikeGuard is no witchcraft, but you should proceed with care and deliberation. Unprofessional assembly can render the bike

unsafe.

First we should like to make you familiar with the various components of your Canyon.

Unfold the front cover of this manual. Here you will

find the illustration of a Canyon bike showing all the

essential components. Leave the page unfolded as

you read so that you can easily locate the components as they are referred to in the text.

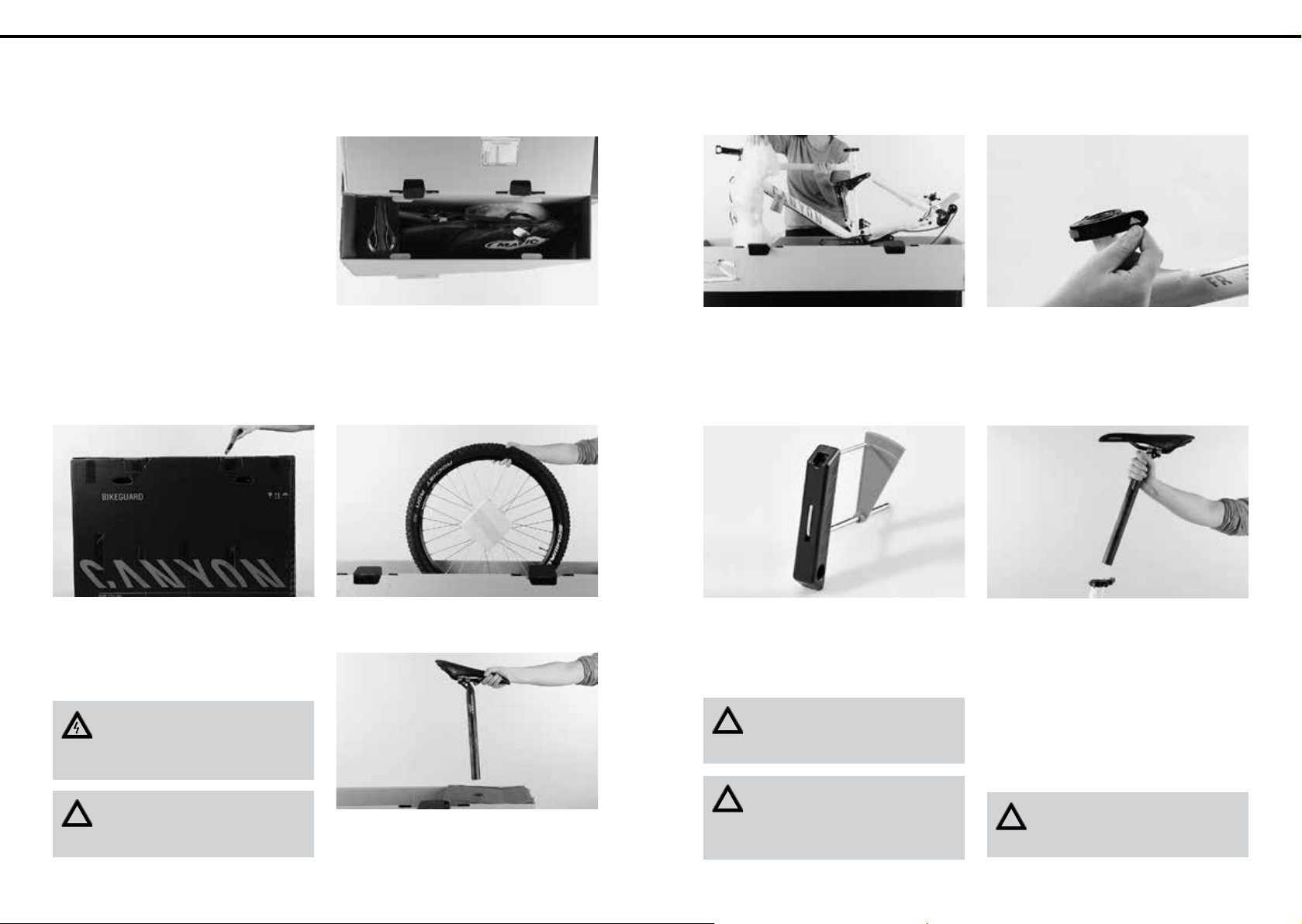

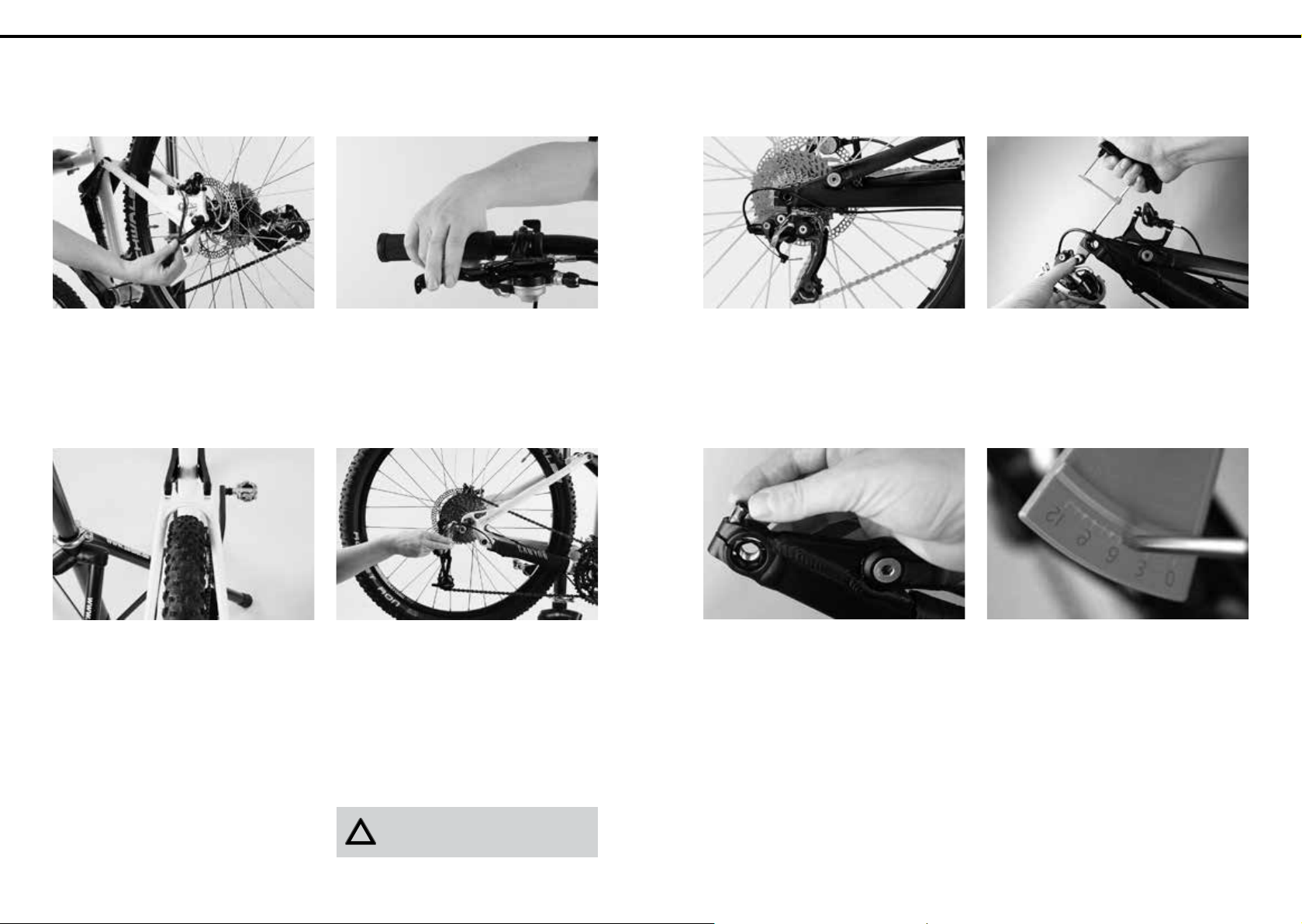

CHECKING THE CONTENTS OF THE BIKEGUARD

The BikeGuard contains the assembled frame with all

add-on parts as well as the wheel set, the saddle and

a box with small parts, e.g. quick-releases, reflectors

and pedals, as the case may be.

UNPACKING

Lift the frame carefully off the BikeGuard and take out

the cardboard box with the small parts that you will

find on the bottom or the side of the BikeGuard.

BIKE ASSEMBLY

Release the quick-release or the seat post binder

bolt. Read chapter “How to use quick-releases and

thru axles” beforehand.

Before mounting the seat post to the frame, make

sure the seat tube is absolutely free of sharp edges

and burrs.

The illustration shows an arbitrary Canyon mountain

bike – this is not what every bike will look like. First,

open the BikeGuard. This is best done by using a box

cutter.

When using a box cutter make sure neither

to damage the component nor to hurt

yourself. Make it a rule to cut away from you and

the component!

The easiest and safest way to assemble the

i

bike is when you use a workstand or ask

someone to help you.

Remove the padding (cardboard boxes), if available,

and take the wheels out of the BikeGuard.

Undo the saddle from the BikeGuard. First, remove

the protective film, if available, from the seat post.

The following section gives you a concise description

of the assembly. In the event you are neither skilled

nor experienced in that kind of work, please read the

more detailed chapters of this manual further below

or read up on this matter on the enclosed CD.

Assemble your Canyon by using the

i

Canyon torque wrench enclosed with the

BikeGuard.

Keep the entire packaging material as well

i

as the BikeGuard in a dry place, so you will

have everything at hand for a future dispatch of

your Canyon or for a travel together with your bike.

Mount an aluminium seat post or ask a helper to hold

your Canyon during the assembly. Clean and deburr

the seat tube, if necessary. You should be able to insert the seat post easily into the frame without pressing or turning.

Hold the handlebars tight while lifting the

!

frame out to avoid that it drops and gets

damaged.

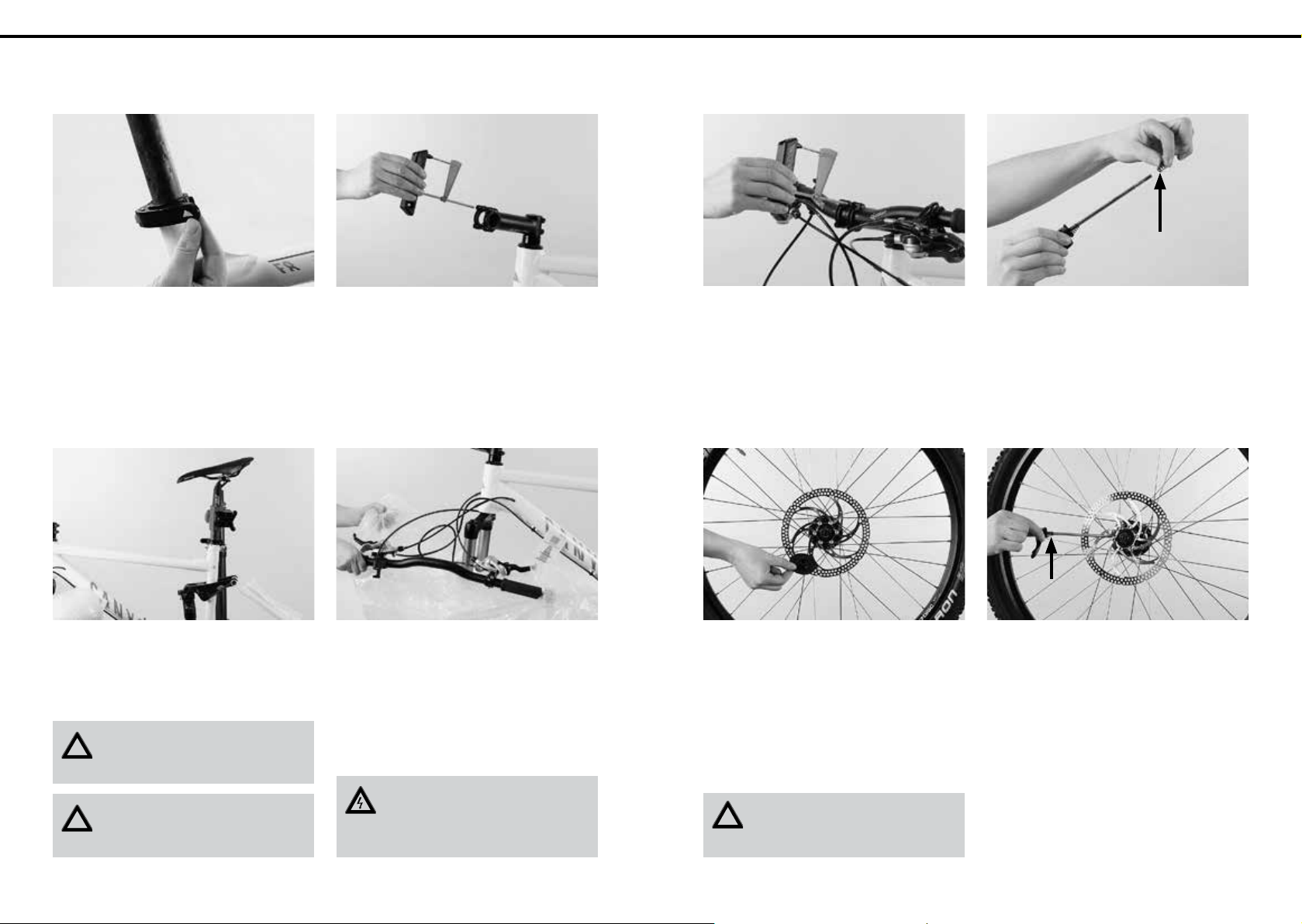

ASSEMBLY FROM THE BIKEGUARD

14 15

ASSEMBLY FROM THE BIKEGUARD

Tighten the quick release or the seat post binder bolt.

Take care not to overtighten the seat post binder bolt

or quick-release. Please note the details given in

chapter “Adjusting the saddle to the correct height”

as well as the permitted tightening torques in chapter

“General notes on care and inspection” and follow the

instructions of the component manufacturers, as well.

Clamp your Canyon with the aluminium seat post into

the workstand or ask a helper to hold your Canyon

during the assembly.

Do not clamp a frame tube or a carbon

!

seat post of your Canyon in the holding

jaws of the workstand!

Please note the details given in chapter

!

“Special characteristics of carbon”, as

well.

Release the clamping bolts of the stem face plate and

remove the face plate.

Remove the protective film and sleeves from the handlebars. Hold the handlebars tight while you do this

so that they do not drop and get damaged.

It is recommended that you remove the protective

material in general by hand. In case you do not succeed, carefully use a box cutter or a pair of scissors.

When using a box cutter make sure neither

to damage the component nor to hurt

yourself. Make it a rule to cut away from you and

the component!

Make sure the handlebars are accurately centred in

the stem clamp. Take care that the bowden cables are

not twisted or bent, but run in a smooth curve to the

cable stops or brakes. Retighten the clamping bolts

until they lightly hold the handlebars in place. Do not

finish mounting the handlebars until you have mounted the wheels.

Remove both protective caps from either side of the

front wheel axle.

Assemble your Canyon by using the

i

Canyon torque wrench enclosed with the

BikeGuard.

Take the quick-release for the front wheel out of the

small part box. Release the counternut and remove

one of the springs from the quick-release skewer.

Insert the quick-release from the rotor side into the

hollow axle of the front wheel. Make sure there is one

spring on either side of the hub. When mounting the

springs on either side of each wheel, make sure their

small-diameter ends face the hub.

The quick-release lever is mounted to the left side,

i.e. opposite the chain drive.

ASSEMBLY FROM THE BIKEGUARD

16 17

ASSEMBLY FROM THE BIKEGUARD

Tighten up the counternut of the quick-release until

the quick-release lever builds up force when closed.

Close the quick-release. Read up on quick-releases

in chapter “How to use quick-releases and thru axles”;

also observe the enclosed operating instructions of

the component manufacturers.

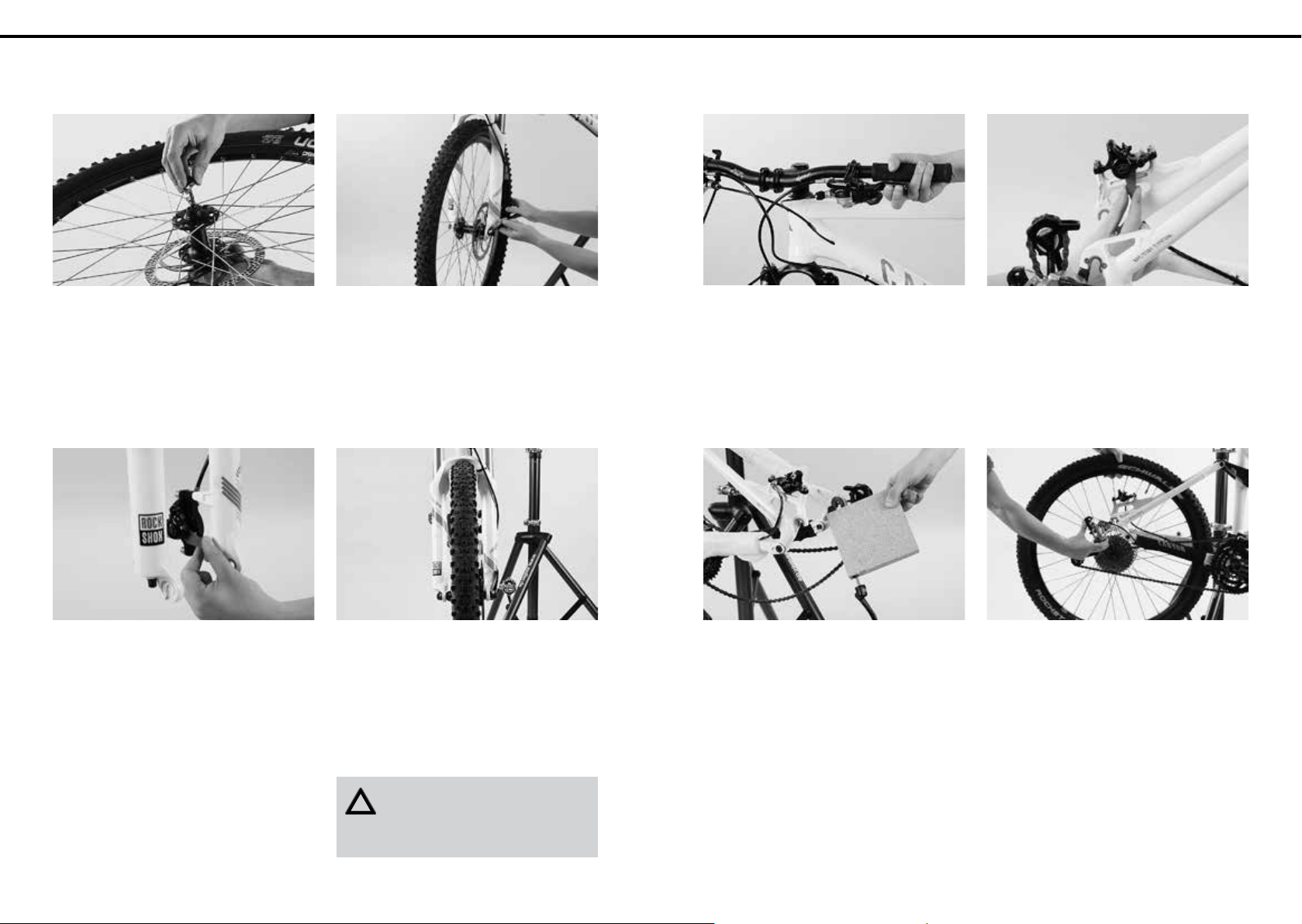

MOUNTING A FRONT WHEEL WITH DISC BRAKES

Remove the transport lock from the front wheel

brake. For more information about brakes, read chapter “The brake system“.

If your Canyon has disc brakes, check before mounting the wheel whether the brake pads rest snugly in

their seats in the brake calliper body. This is the case

when the gap between the brake pads is parallel and

the wear indicators are in their correct position.

Mount the front wheel and make sure you guide the

rotor between the brake pads carefully. Close the

quick-release and verify that the wheel is securely

fixed. Read chapter “How to use quick-releases and

thru axles” beforehand.

Make sure the wheel is correctly seated in the dropouts and accurately centred between the fork legs.

Make sure the quick-release lever and the drop-out

safety-tabs are properly closed.

New brake pads of disc brakes have to

!

be bedded in before they reach their optimum braking performance. For more information

read chapter “The brake system”.

After mounting the wheel and tightening the quickrelease pull the brake lever several times and spin the

wheel subsequently. The rotor should not drag on the

brake caliper or on the brake pads.

MOUNTING A REAR WHEEL WITH DISC BRAKES

Open the quick-release at the rear axle, remove

the board and pull the quick-release off the board.

Proceed as you did when mounting the front wheel.

Verify, in this case as well, the correct position of the

small springs. Read up on quick-releases in chapter

“How to use quick-releases and thru axles”.

Remove the protective film from both chainstays. It is

recommended that you remove the protective material by hand. In case you do not succeed, carefully use

a box cutter or a pair of scissors.

Remove the transport lock from the rear wheel brake.

For more information about brakes, read chapter

“The brake system“. If your Canyon has disc brakes,

check before mounting the wheel whether the brake

pads rest snugly in their seats in the brake calliper

body. This is the case when the gap between the

brake pads is parallel and the wear indicators are in

their correct position.

Actuate the right shift lever until the rear derailleur

is in its outermost position. Pull the rear derailleur

slightly to the rear, position the chain on the outermost sprocket and mount the rear wheel. Make sure

you guide the rotor between the brake pads carefully.

Read chapter “How to use quick-releases and thru ax-

les” beforehand.

ASSEMBLY FROM THE BIKEGUARD

18 19

REAR DERAILLEUR ASSEMBLY CANYON STRIVE ES / ESX

ASSEMBLY FROM THE BIKEGUARD

Close the quick-release and verify that the wheel is securely fixed. Read chapter “How to use quick-releases

and thru axles” beforehand.

Verify that the rear wheel is accurately centred between the rear stays. Make sure the quick-release lever and the drop-out safety-tabs are properly closed.

CHECKING THE BRAKE AND THE GEARS

After mounting the wheel and tightening the quick-release pull the brake lever several times

wheel subsequently.

and spin the

The rotor should not drag on the brake caliper or on

the brake pads. Spin both wheels to make sure they

run true. For more information, read chapter “The

wheels - tyres, inner tubes and air pressure”.

Check the proper functioning of the gears. Shift

through all gears and make sure the rear derailleur

does not collide with the spokes when the chain runs

on the largest sprocket. Read up on how to adjust the

gears in chapter “The gears“. After the wheel mounting do a brake test in stationary. Actuating the brake

lever should generate a clear-cut braking response

before the lever touches the handlebars.

To ensure a secure transport the Strive is supplied

with the rear derailleur dismounted. The rear derailleur can be assembled with a few simple steps.

The rear derailleur is mounted to the derailleur hanger. This derailleur hanger connects the rear derailleur

to the frame. The derailleur hanger is mounted to the

right drop-out at the Strive’s rear frame.

Slide the greased bolt through the drop-out.

Start by screwing the bolt into the derailleur hanger

without tightening it. Mount the rear wheel, as described in chapter “How to use quick-releases and

thru axles”.

Tighten the derailleur hanger by using the torque

wrench supplied with the Strive.

Do observe the appriopriate torque value of 6 Nm.

New brake pads of disc brakes have to be

!

bedded in.

ASSEMBLY FROM THE BIKEGUARD

20 21

ASSEMBLY FROM THE BIKEGUARD

MOUNTING THE PEDALS

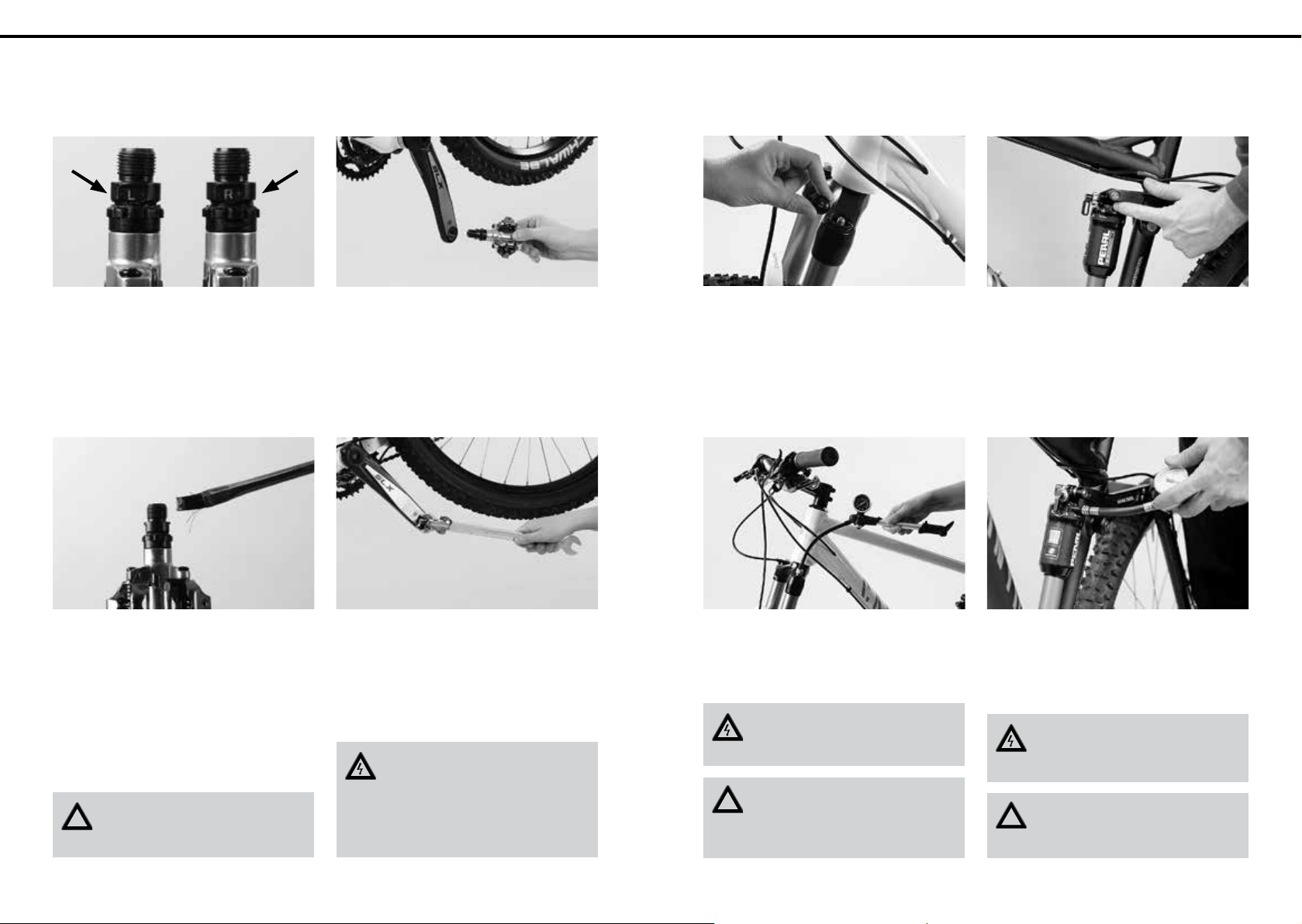

Before mounting the pedals, check the marking on

the pedal axles first. “R” stands for right pedal and “L”

for left pedal. Note that the left pedal has a left-handed thread that has to be tightened contrary to the

direction you are accustomed to, i.e. anticlockwise.

Screw each pedal manually into the thread of its

crank by two to three full turns.

HOW TO INFLATE THE SUSPENSION FORK

Before transport the suspension fork was completely

deflated. The suspension fork has to be filled with the

proper air pressure.

Remove the cap of your suspension fork.

HOW TO INFLATE THE REAR SHOCK

If you have a full-suspension mountain bike you have

to check the air pressure.

Open the cap of your rear shock.

Apply a little grease on the pedal threads before

screwing in the pedals.

Read up on the road traffic regulations in

!

the country where you use the mountain

bike.

Continue by using a pedal spanner to tighten the pedals firmly.

Check the reliable fit of the pedals after

about 100 km (60 miles). Pedals can come

loose, and this can destroy the thread and throw

the rider off his bike. Also check the reliable fit of

the other bolts according to the prescribed tightening torques.

Inflate the suspension fork with the special pump enclosed with the BikeGuard, according to the recommendations on the spring rate of the fork manufacturer. Read up on suspension forks in chapter “The

suspension fork”.

Improperly adjusted suspension forks are

liable to malfunction or damage to the suspension fork.

You will find the operating instructions of

i

the fork manufacturer on the enclosed CD.

Read them thoroughly before inflating the suspension fork!

Inflate the rear shock with the special pump enclosed

with the BikeGuard, according to the recommendations of the rear shock manufacturer. Read up on the

adjustment of your rear shock in chapter “Full-sus-

pension“.

Improperly adjusted rear shocks are liable

to malfunction or damage to the rear

shock.

You will find the operating instructions of

i

rear shock on the enclosed CD. Read them

thoroughly before inflating the suspension fork!

ASSEMBLY FROM THE BIKEGUARD

22 23

CHECKING AND ADJUSTING

ASSEMBLY FROM THE BIKEGUARD

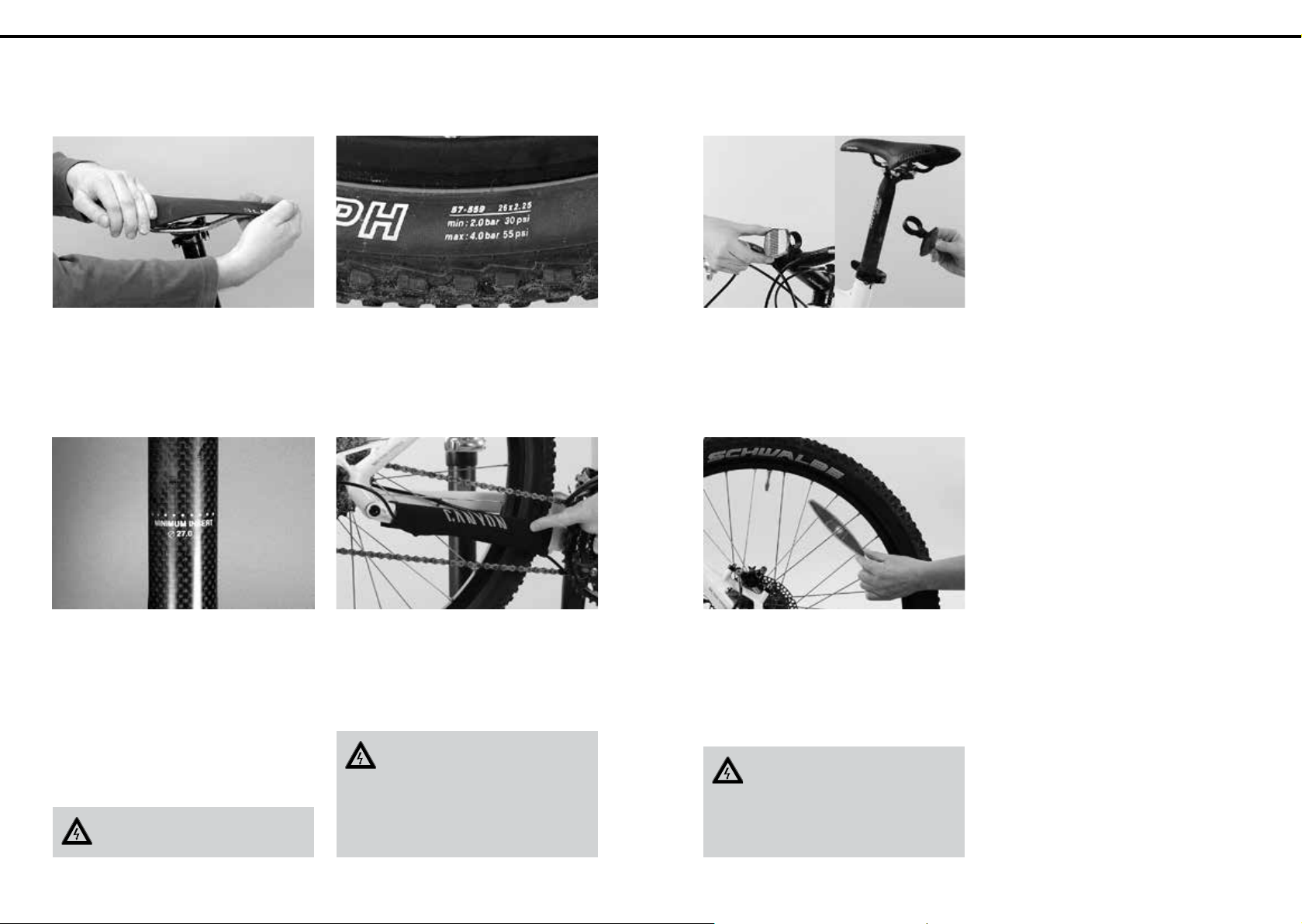

Adjust the position of the saddle and handlebars and

check that the handlebars, grips and seat post are

securely fastened, as described in chapter “Adjusting

the Canyon bike to the rider”.

Slide your seat post into the seat tube beyond its minimum mark and make sure its end reaches beyond the

top tube.

Never ride your Canyon with the minimum

mark of the seat post being visible.

Inflate both tyres to the pressure indicated on the

side of the tyres. Read up on tyres and inner tubes in

chapter “The wheels - tyres, inner tubes and air pres-

sure”. Finish the assembly by carrying out thoroughly

the tests described in chapter “Before your first ride”.

Take the chainstay protection out of the small part

box and fit it around the chainstay.

After completing the assembly and checks

it is essential to give your Canyon a test

ride in a level, unfrequented area (e.g. in a parking lot)! Wrong assembly or improper adjustments that become apparent in road traffic or

during off-road use can make you lose control of

your Canyon!

Fix the white reflector to the handlebars and the red

reflector to the seat post.

Finish by mounting the spoke reflectors. Make sure

that both reflectors of either wheel are fixed to the

spokes opposite to one another.

Check the reliable fit of all bolts once again

according to the prescribed tightening torques after 100 to 300 km (60 to 180 miles). For

more information, read chapters “General notes

on care and inspection”, “Recommended tightening

torques” and “Service and maintenance schedule”.

PACKING QUICK-RELEASES AND THRU AXLES

24 25

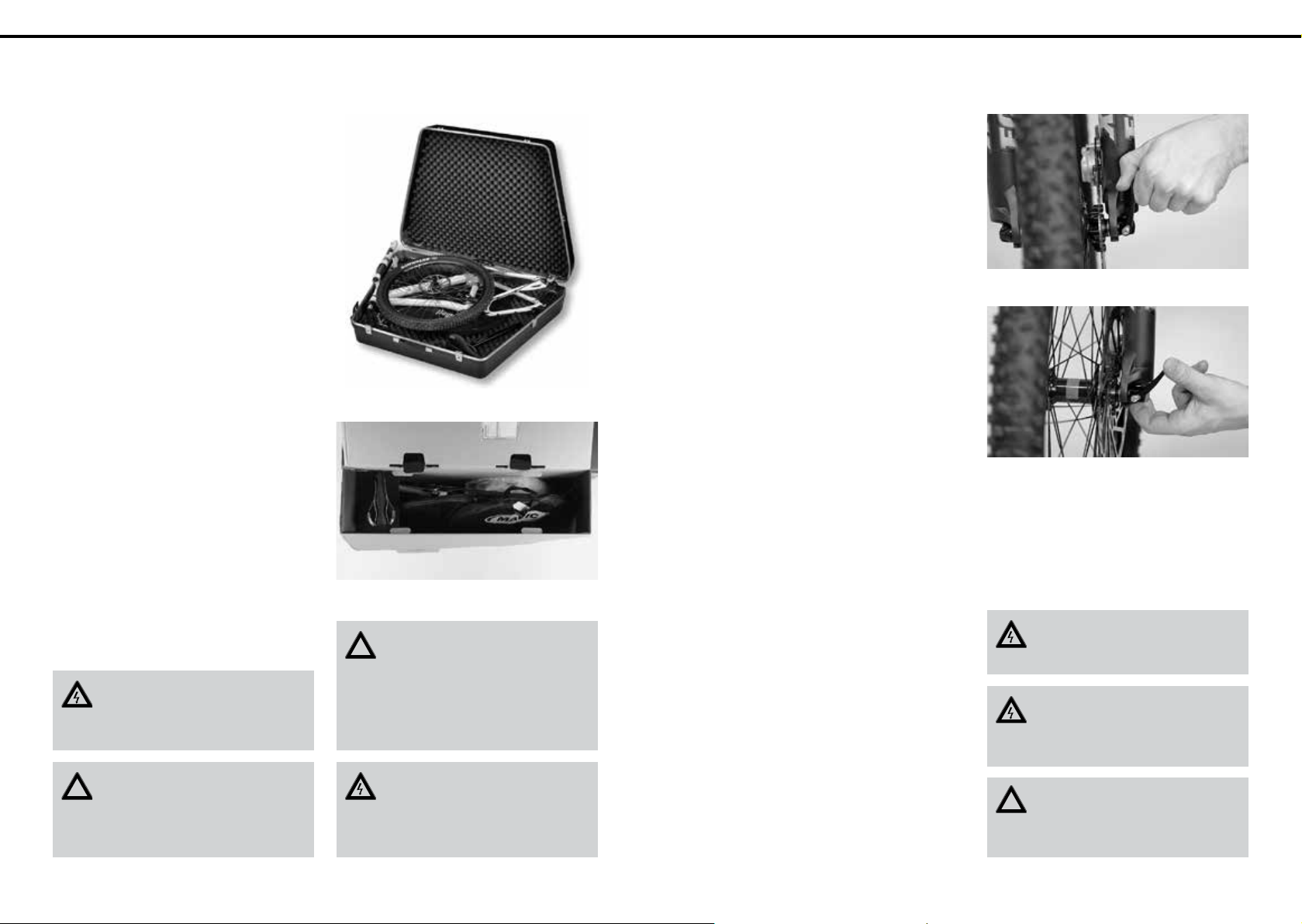

PACKING YOUR

CANYON BIKE

If you pack your Canyon, e.g. to send it in for servicing to our workshop, or if you want to take it with you

on holidays, you must bear in mind a few things to

bring your bike safe and sound to destination.

Your BikeGuard contains the packing instructions

„How to pack your mountain bike“. Strictly follow

these instructions, whenever you pack your bike.

Our packing instructions that will help you pack your

Canyon step-by-step are also posted at our website

www.canyon.com.

For travelling with your bike by plane pack your bike

either into the Canyon BikeGuard or use a suitable

bike case, e.g. the Canyon BikeShuttle.

For a transport by car be sure to secure your bike appropriately in order to avoid any shifting inside the

car. If you are in doubt or if you have any questions,

read the more detailed chapter of the manual further

below or on the enclosed CD or contact our service

hotline at +44 (0) 20 8501 2582.

Always secure the bicycle or bicycle com ponents when putting it/them into the interior of your car. Parts shifting around can impair

your safety.

The Canyon BikeShuttle

The Canyon BikeGuard

Most clamps of bike carrier systems are

!

potential sources of damage to large-diameter frame tubes! As a result thereof carbon

frames may fail abruptly during use, aluminium

frames are susceptible to dents. Suitable, special-purpose models are, however, available in the

car accessory trade.

HOW TO USE QUICKRELEASES AND THRU

AXLES

Although the use of quick-releases is very easy, they

have repeatedly been the cause of accidents as a result of a wrong handling.

Quick-release retention mechanisms essentially consist of two manipulable parts:

The hand lever on one side of the hub which creates

a clamping force via a cam when you close it.

The tightening nut on the other side of the hub with

which to set the initial tension on the threaded rod.

HOW TO SECURELY MOUNT THE WHEEL

Open the quick-release. You should now be able to

read “OPEN” on the lever.

Move the lever back, as if to close it. Now you

should be able to read “CLOSE” on the outside of

the lever. From the start of the closing movement up

to about the first half of its travel the lever should

move very easily, i.e. without clamping the wheel.

Over the second half of its travel, the force you need

to move it, should increase considerably. Towards

the end of its travel the lever should be very hard to

move. Use the ball of your thumb while your fingers

pull on an immovable part such as the fork or frame,

but not on a rotor or spoke, to push it in all the way.

In its end position the lever should be parallel to the

bike, i.e. it should not stick out to the side. The lever must lie close to the frame so that it cannot be

opened accidentally.

To check whether the lever is securely locked try to

turn it while it is closed.

Open the quick-release lever

Close the quick-release lever

Improperly mounted wheels may throw you

off your bicycle or result in serious accidents!

Never ride a bicycle without having first

checked whether the wheels are securely

fastened! A wheel that comes loose whilst riding

will throw you off your bicycle!

In the event your Canyon has not been

!

packed for dispatch according to the enclosed packing instructions, you have no right to

claim refund of repair costs for possibly occurring

transport damage from Canyon Bicycles GmbH.

When taking your bike by car, make sure to

remove all parts from your bike (tools,

pannier bags, child carriers etc.) which might

come loose during transport and cause an accident.

If your bicycle is equipped with quick-

i

releases, be sure to lock the frame to an

immovable object together with the wheels when

you leave it outside.

QUICK-RELEASES AND THRU AXLES

26 27

QUICK-RELEASES AND THRU AXLES

If you can turn the lever around, the wheel is not se-

curely fastened. Open the lever again and screw the

tightening nut clockwise by half a turn to increase

the initial tension.

Close the lever again and check it again for tight-

ness. If the lever can no longer be turned, it is properly fastened.

Finally lift the bike a few centimetres from the

ground so that the wheel is suspended and hit

the tyre from above. If it is properly fastened, the

wheel will remain firmly fixed in the drop-outs of the

frame.

If your seat post is equipped with a quick-release

mechanism, check whether the saddle is firmly fixed

by trying to twist it relative to the frame.

Closing the quick-release with the ball of your thumb

Try twisting the saddle relative to the frame

HOW TO MOUNT THRU AXLE WHEELS

Thru axles are mounted when the bicycle has to withstand high stress occurring e.g. during freeriding,

downhill riding etc. or jumps. They provide suspension forks with a suitable stiffness.

There is currently a wide range of thru axle systems

available on the market. Some systems are tightened

with quick-releases. Other systems may require special tools for assembly or disassembly.

If you are in doubt or if you have any questions, please

contact our service hotline +44 (0) 20 8501 2582!

With the conventional thru axle system slide the thru

axle through fork and hub in a way that the head of

the Allen bolt comes to a rest on the right side, seen

in direction of motion. Let the fork retract a few times

when you have mounted the axle to make sure it is

not canted. Screw the nut onto the axle and tighten

it. Then tighten the four Allen bolts at the front side of

the fork to clamp the axle tight. Check the bolts after

about one to two hours of riding and after that every

20 hours.

If your bike is equipped with a Maxle thru axle system

with quick-releases, put the wheel into the fork and

mount the rotor in the brake caliper. Bring the wheel

into the right position between the drop-outs and

slide the axle with open Maxle quick-release levers

from the right side through the drop-out and the hub.

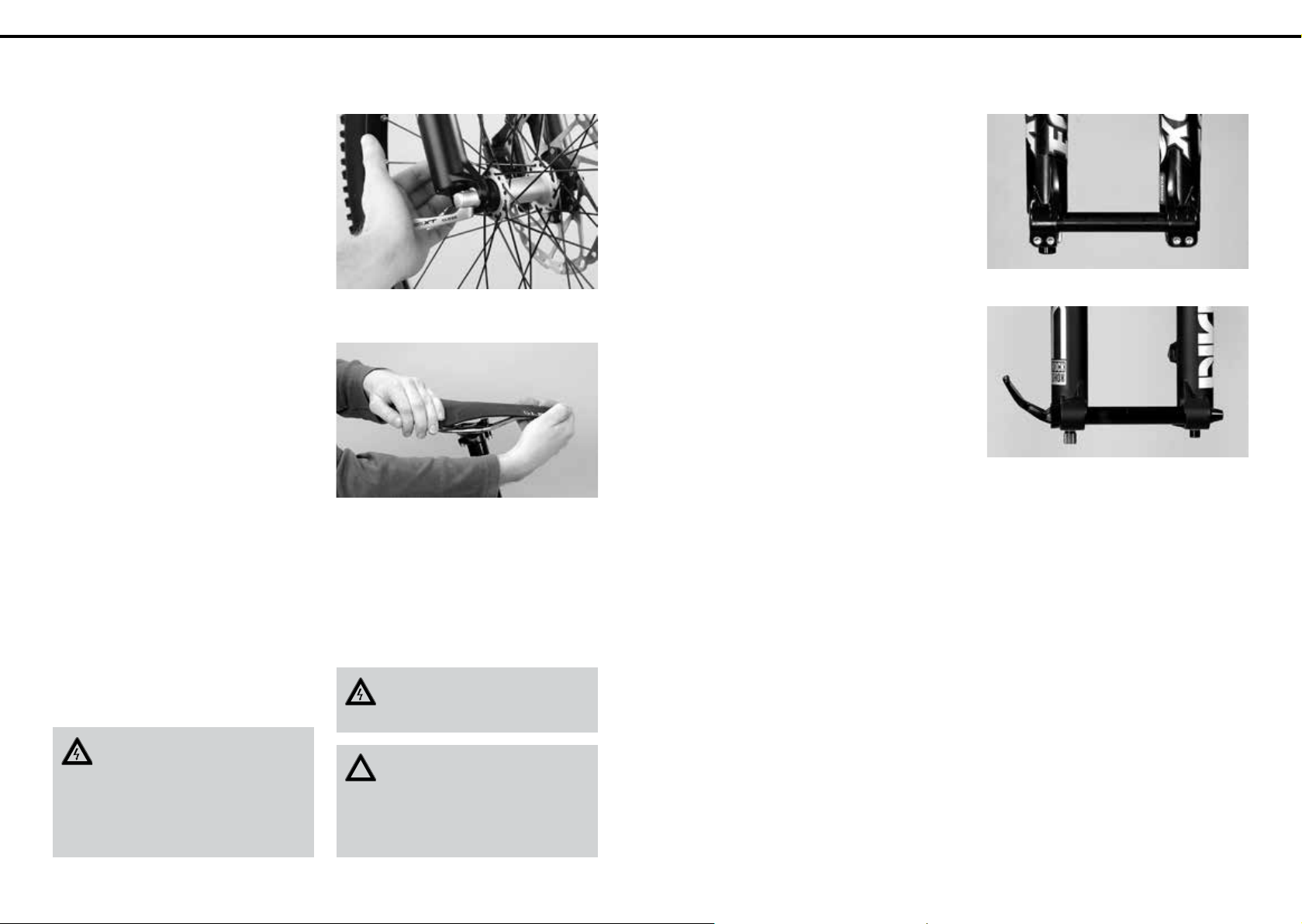

Conventional thru axle system (Fox fork)

Maxle thru axle system (Rockshox fork)

Make sure the levers of both quick-

releases are always on the left side of your

Canyon (opposite the chain side). This will help

you to avoid mounting the front wheel the wrong

way round.

With RockShox Maxle thru axle systems the Maxle

quick-release lever is always on the right side.

If your bike has disc brakes, you should on

no account replace the standard quick-release with a lightweight substitute.

As an anti-theft measure you can replace

i

the quick-releases by special locks. They

can only be opened and closed with a special,

coded key or an Allen key. If you are in doubt or

if you have any questions, please contact our service hotline +44 (0) 20 8501 2582!

QUICK-RELEASES AND THRU AXLES

28 29

QUICK-RELEASES AND THRU AXLES

As soon as the axle thread engages with the thread of

the left fork leg, close it by turning it clockwise. Close

the Maxle thru axle quick-release lever like a usual

quick-release lever. From the start of the closing

movement up to about the first half of its travel the

lever should move very easily without clamping the

wheel, whereas over the second half of its travel the

force you need to move it should increase considerably. Towards the end of its travel the lever should be

very hard to move. Use the palm of your hand while

your fingers pull on an immovable part, such as the

fork leg, but not on a spoke or the rotor. In its end position the quick-release lever should be tight so that

it can no longer be turned.

The E-Thru system has been developed jointly by

Shimano and Fox and has a 15 mm thru axle that optimises weight. It is mounted like the Maxle system and

also operated with a quick-release lever. The special

feature of the E-Thru compared to usual quick-release systems is the firm, bolted connection of the

tightening nut to the fork leg on the opposite side of

the quick-release lever.

For the removal of the front wheel you may need tools

depending on fork manufacturer and thru axle system. To remove the wheel, loosen the axle support at

the fork and remove the axle completely from the hub.

To remount the front wheel procede in the reverse order. Make sure all bolts/quick-release systems are

tightened properly.

E-Thru system

Tool for dismounting

Besides the front thru axle systems, there are also

rear thru axle systems, such as the X-12 rear axle

system from Syntace. This system combines extreme

stiffness with light weight. The X-12 system comes in

two different versions:

The key version (with Allen bolt)

The QR version (with RWS quick-release lever)

To remove the rear wheel of a Torque and Strive you

have to release the bolt positioned on top of the dropout (derailleur hanger mount) by two to three turns.

Release the axle (with the quick-release or by using

an Allen key depending on the system) and remove it.

Now you can remove the rear wheel as you are used

to.

Make sure not to insert the axle into the hub before

mounting the rear wheel.

Perform the rear wheel mounting in the usual manner.

Due to the axle guides the rear wheel is automatically

in its correct position and requires no further adjustment. Once you have mounted the rear wheel, insert

and tighten the axle.

In the case of the models Torque and Strive tighten

the derailleur hanger mount to 6 Nm.

Thru axle system Syntace X-12

Axle guides Syntace X-12

To mount the axle use only the tools

!

recommended by the manufacturer. Make

it a rule to use a torque wrench. Tighten carefully

by approaching the prescribed maximum torque

in small steps (0.5 Nm increments) whilst constantly checking the proper fit of the component.

Never exceed the maximum tightening torque indicated by the manufacturer! A too tight fixing of

the axle can damage the axle or the fork leg.

Do not use any other tools to fix the axle.

!

A too tight fixing of the axle can damage

the axle or the fork leg.

Manufacturers of thru axle systems deliver

i

their products with detailed operating instructions. Read them carefully before removing

the wheel or doing any maintenance work.

ADD-ON PARTS AND CHANGES

30 31

CARBON

WHAT TO BEAR IN

MIND WHEN ADDING

COMPONENTS OR

MAKING CHANGES?

Canyon bikes are sport machines which are fitted according to the respective usage. Please note that the

mounting of mudguards or such like may impair the

functioning and hence the safety whilst riding. Before

buying and mounting any accessory, please check

whether this particular accessory part matches with

your Canyon. With additional bells, horns or lighting

accessories, inform yourself thoroughly whether they

are permitted and tested and accordingly approved

for use on public roads. Battery/accumulator-operated lights have to be marked with the wavy line and the

letter “K” (see chapter “Legal requirements”).

If you want to mount a pannier rack or a child seat

or trailer, please read chapter “Intended use” beforehand to make sure whether it is permitted. If a

mounting is permitted, in general, please contact our

service hotline at +44 (0) 20 8501 2582 and ask for

suitable models.

Only perform jobs you are absolutely sure of.

Handlebars, stems and forks should only be replaced

by a skilled mechanic. Be sure to follow the operating of the accessory manufacturer in any case. When

mounting other components and accessories, it is

your responsibility to mount the components appropriately. Bring your Canyon to our service workshop,

if you have the slightest doubt.

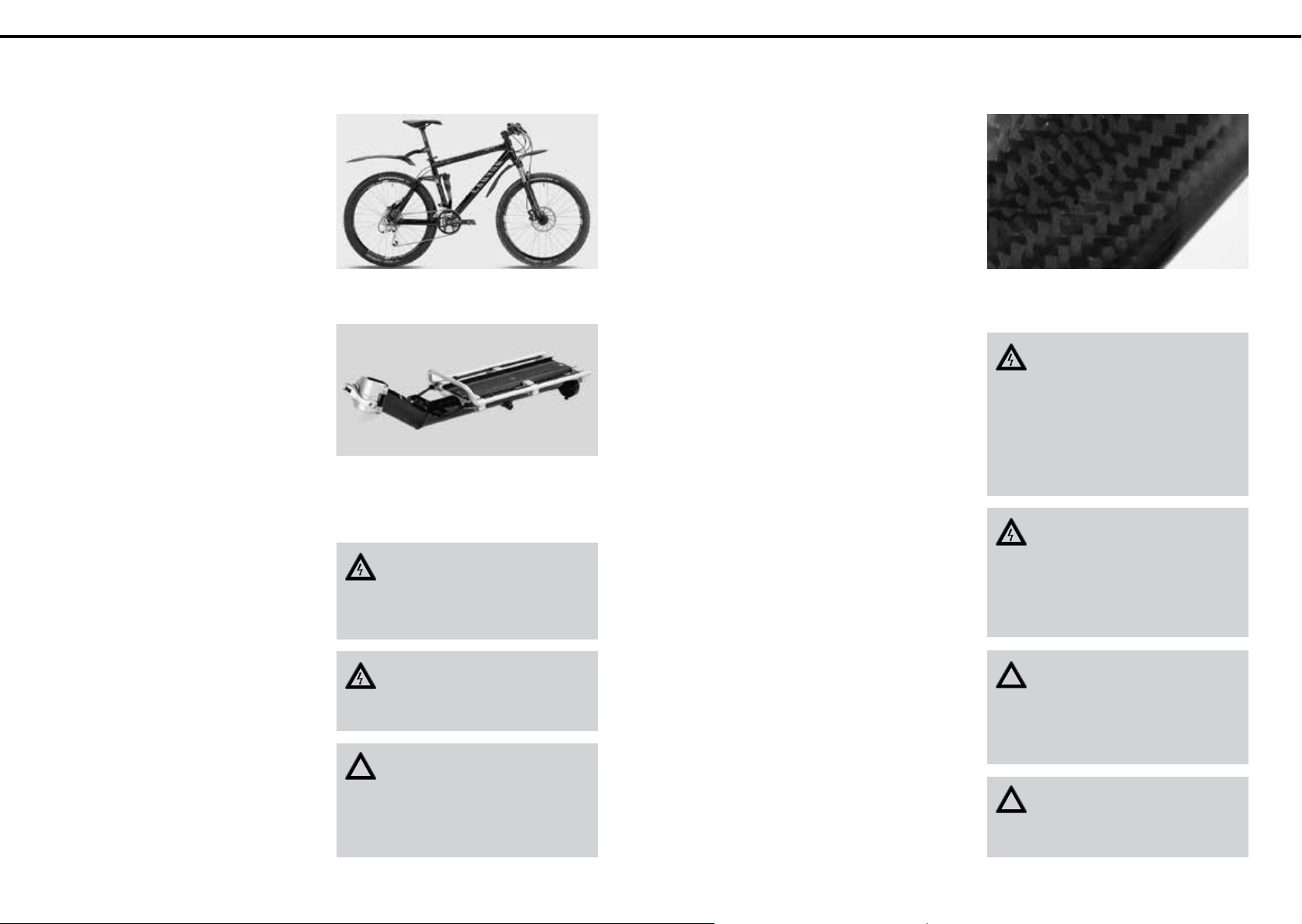

Canyon with mudguards

Pannier rack

Retrofitted accessories, such as mud-

guards, pannier racks etc., can impair the

functioning of your Canyon. We therefore advise

you to use accessories from our product range.

This will ensure you use matching components.

Components that come loose or break off

as a result of improper mounting can

cause serious accidents. Safety relevant bolts

must be tightened to their specified torques.

In case of any questions regarding com-

i

ponent assembly, compatibility or if you

want to make any changes, read the more detailed chapter of the manual further below or on

the enclosed CD or contact our service hotline at

+44 (0) 20 8501 2582.

SPECIAL

CHARACTERIS TICS OF

CARBON

Carbon fibre reinforced plastic, also referred to as

carbon (or CRP), has a number of special characteristics compared to conventional lightweight materials. Having some knowledge of these characteristics

is important so that you can enjoy your high-quality

Canyon for many years and have full confidence in its

material.

Carbon fibre reinforced plastic has proved its value in

road racing with numerous wins. Components made

of this material are extremely lightweight and - presupposing proper design, processing and treatment

- of outstanding strength and stress resistance.

However, there is one particular drawback of this

material – its brittleness. Therefore, when subjected

to stress it does not undergo permanent deformation,

even though its inner structure may have sustained

damage. In the extreme case, the fibres may separate, thus resulting in the so-called delamination and

reducing the strength properties of the component.

In contrast to steel or aluminium, carbon components

that have sustained damage to their inner fibres as

a result of excessive stress will show no outwardly

visible deformation. Carbon components that have

been subjected to overstress are therefore liable to

fail during use, possibly causing an accident with unforeseeable consequences. If you have had a critical

incident with your bike, we advise you to have the relevant component inspected by our service workshop,

or better still, the whole Canyon.

Always park your Canyon carefully and make sure it

does not topple over. Carbon frames and parts may

already sustain damage by simply toppling over.

Carbon

Be attentive during riding. If your carbon

component produces any creaking, this

may indicate a material defect. Stop using your

bike and contact our service hotline to discuss

the steps to be taken. For your own safety, never

ask for CRP components to be repaired! Damaged

carbon components should be replaced immediately and prevented from being used by anyone

else.

Carbon components should never be

exposed to high temperatures, as occurring during powder coating or enamelling. The

heat generated by these processes may destroy

the component. Do not leave carbon items in a car

in direct sunlight for prolonged periods or near

sources of heat.

Most clamps of bike carrier systems are

!

potential sources of damage to large-diameter frame tubes! As a result thereof carbon

frames may suddenly fail during use. Suitable,

special-purpose models are available in the car

accessory trade.

Make sure the maximum overall weight of

i

rider, baggage (rucksack) and bicycle

does not exceed 100 kg. Carbon wheels are generally not approved for trailer towing!

Loading...

Loading...