Off-road Rubber Track Dumper

S25A

Operator's Manual

Read this manual completely before operating or maintaining this machine.

Failure to follow safety precautions could result in serious injury or death.

Keep this manual for future reference by you and by all those who operate

and maintain this machine.

Original Instructions

3670 5601 004

(in English)

http://www.canycom.co.jp/

90-1 Fukumasu, Yoshii-machi,

Ukiha-shi, Fukuoka, Japan 839-1396

Sales Headquarters (International) TEL +81-(0)943-75-2195

FAX +81-(0)943-75-4396

Authorized Dealer

All rights reserved. Unauthorized use or reproduction of this material is prohibited.

Notice to Users and Maintenance Personnel

Thank you for purchasing this machine.

This manual provides information needed for safe and effective use of this machine to

those who operate or maintain the machine. Make sure to read and understand the manual

thoroughly before operating this product. Also make sure to read the separate operator's

manual for the engine.

• This machine can be very dangerous if the safety precautions in this manual

and on the l abels attach ed to this m achine are n ot fol lowed. Read and

understand this manual and the safety labels on the machine thoroughly before

using this machine. Always follow the instructions and safety precautions, or

serious injury or death could result.

• This machine should only be used for its intended purpose: hauling and

dumping. Any other use could be dangerous.

• This machine may not be operated on public road or what is considered to

be public road. It is the sole responsibility of the operator to consult the local

regulations.

• Do not modify this machine, or do not operate this machine with the safety

covers removed or open. A serious accident could result.

• Store this manual in a safe, accessible place for easy reference.

Notice to Owner

• Be sure that everyone who uses this machine, including those who rent or

lease this machine, receives a copy of this Operator's Manual and understands

the importance of reading and following the information in this manual.

Warning Terms Used in this Manual

In this manual, the following four warning terms are used to signal the four levels of hazard

(or seriousness of possible accidents). Read and understand what they mean and always

follow the instructions in this manual.

Warning Term Definition

Indicates an imminently hazardous situation which will result

NOTE

in death or serious injury if the user does not follow the

procedures or the instructions.

Indicates a potentially hazardous situation which could result

in death or serious injury if the user does not follow the

procedures or the instructions.

Indicates a potentially hazardous situation which could result

in minor to moderate injury or damage to the machine if the

user does not follow the procedures or the instructions.

Indicates important information which needs particular

attention.

Warranty and After-Sales Service

3670M-0005-023E

3670M-0005-013E

Location of Model Label

Warranty

CHIKUSUI CANYCOM, INC. guarantees this product, based on the terms of warranty. A

copy of this warranty is reproduced in the back of this manual.

After-Sales Service

Consult your local CANYCOM dealer or our company’s sales department regarding service

orders or any questions or problems that may arise when using this machine. Please

make sure to have the product name, serial number, and the make and type of the engine

handy at the time of contact. The model and serial number can be found on the model

label as shown below, and the make and type of the engine can be found in Chapter3

"Specifications" of this manual (Page17).

Location of Model Label Model Label

Availability of Spare Parts

The replacement or repair parts for this product shall remain available for seven years after

the production of this type of machine is discontinued.

Contents

1. Safety

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1

2. Controls and Components 14

Name and Function of Controls . . . . . . . . . . . . . . . . . . . 14

3. Specifications 17

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Contents of the Tool Bag . . . . . . . . . . . . . . . . . . . . . . . . 18

4. Operation 19

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Pre-start up Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Checking and Filling Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Adjusting Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Using Seat Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Driving. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Stopping with Fuel Cutoff Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Parking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Dumping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Dumping and Turning Bucket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Using Safety Prop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5. Maintenance 33

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . 33

List of Fluids and Lubricants . . . . . . . . . . . . . . . . . . . . . 38

List of Consumables and Spares . . . . . . . . . . . . . . . . . . 39

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Fan Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Drive Train. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Tracks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

HST (Hydrostatic Transmission) Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Steering Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Travel Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Greasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

After Use Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

After Normal Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

After Cold Weather Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6. Troubleshooting 64

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7. Transporting 68

Hauling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Loading and Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Hoisting and Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Hoisting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Warranty

Warranty Certificate is attached at the end of this manual.

* Have the warranty certificate signed and sealed after you have received and fully

understood the instructions for handling this machine and received the receipt.

Appendix

• Operator's Manual for the Engine

* Be sure to read and understand it together with this manual .

Safety 1

3670M-0101-013E

(Left and right)

<Both Models>

Safety Labels

The safety labels shown on the next page are attached to the machine. See the illustration

below for the location and the illustration on the next page for the content of each label on

the machine.

• Locate all the warning labels attached to this machine. Read and follow the

instructions and precautions in them. Failure to do so could result in serious injury

or death to the operator or bystanders.

• Keep the labels clean and legible. Do not use solvents or gasoline to clean the

labels.

• Replace these labels immediately if they have been removed, have fallen off or

become illegible. Use the part number, on the label or shown in this manual, to

order a replacement label from your CANYCOM representative.

-1-

Safety

-2-

1

(Back of load-deck)(Back of load-deck)

<One-side-dump>

<Turn & Dump>

3670M-0101-023E

3670M-0101-033E

1

52295124000 36675068000 36675065000

52295119000

2 3 4

Safety 1

-3-

11

8

5 6 7

36675063000

52295116000

52345067000

52295107000

36675064000

36675066000

52295104000

9

10

3670M-0101-043E

Safety

-4-

1

12 13

14

16

52295138000

52295111000

36705114000

52295112000

3670M-0101-053E

ATTENTION

Ne surchargez jamais la benne.

Ne dépassez pas la vitesse limite

décrite sur la graphe ci-dessous

lorsque vous vous déplacez sur

une pente raide

.

Si vous allez trop vite, vous risquez

de ne pas pouvoir freiner la machine

avec le frein.

Si vous decendez une pente avec une

charge, ralentissez si la pente

devient plus raide

.

La plage de sécurité

en charge maximum

est représentée avec

la coloration

Pente

Vitesse de déplacement

0

1 2 3 4 5 6 7 8 9 10

2

4

6

8

10

12

14

16

(Degrés)

17

36705111000

Safety 1

-5-

15

36775063000

3670M-0101-063E

AVERTISSEMENT

Ne faites pas d marrer

le moteur dans un local

clos. Les gaz d' chappement

peuvent provoquer un

empoisonnement gazeux.

La machine doit tre charg e et d charg e

lentement,sur un terrain fe

rme et bien horizontal.

Le v hicule doit tre vide, les op rations se

faire lentement et on doit utiliser des planches

de roulage. Le v hicule doit monter en marche Avant

et descendre en marche Arri re. Le chargement et le

d chargement de la machine doit se faire prudemment,

parce que le centre de gravit peut bouger brusquement.

Si vous changez brusquement la direction alors que

vous tes sur les planches de roulage, cela risque

de faire tomber la machine. Ceci est donc ˆ viter.

Si une charge est pos e sur la

machine avec un quilibre mal

r parti, ceci peut faire ren

verser

la machine. Assurez vous que la

charge est bien r partie

.

Barre de soutien

pour emp cher la

benne de descendre

Levier de

benne

Plaque de

blocage

du levier

Ne laissez pas la machine avec la benne relev e tel quel. En effet,si quelqu' un

venait ˆ toucher au levier de benne par erreur, celle-ci pourrait descendre et

causer un accident.

Lorsque des v rifications sont en cours avec la benne relev e, vous riquez de

vous laisser prendre par la benne. Il faut donc tendre le v rin au maximum

de sa course,arr ter le moteur, puis verrouiller le levier de benne et soutenir

celle-ci fe

rmement au moyen de la tige anti-chute de benne.

Les op rations avec le levier de benne doivent se faire autant que possible

sur des terrains plats et fe

rmes. Sur des zones en pente ou de plan in gal, le

centre de gravit se d place et la machine risque de se ren

verser.

Avant d' actionner le levier de benne, assurez vous qu' il n' y a personne autour.

Ne pas conduire la machine avec la benne relev e. Cesi rend non seulement la

visibilit mauvaise, mais le centre de gravit devient plus haut, ce qui peut

pro

voquer le renversement de la machine.

AVERTISSEMENT AVERTISSEMENT

AVERTISSEMENT

Avant d' actionner le levier de benne, retirez la tige anti-chute qui est sous la

benne. Si la benne est actionn e alors que la tige anti-chute n ' est pas enlev e,

le cadre ainsi que la tige anti-chute risquent d' tre ab”m s.

18

19

36705103000

36705105000

Safety

-6-

1

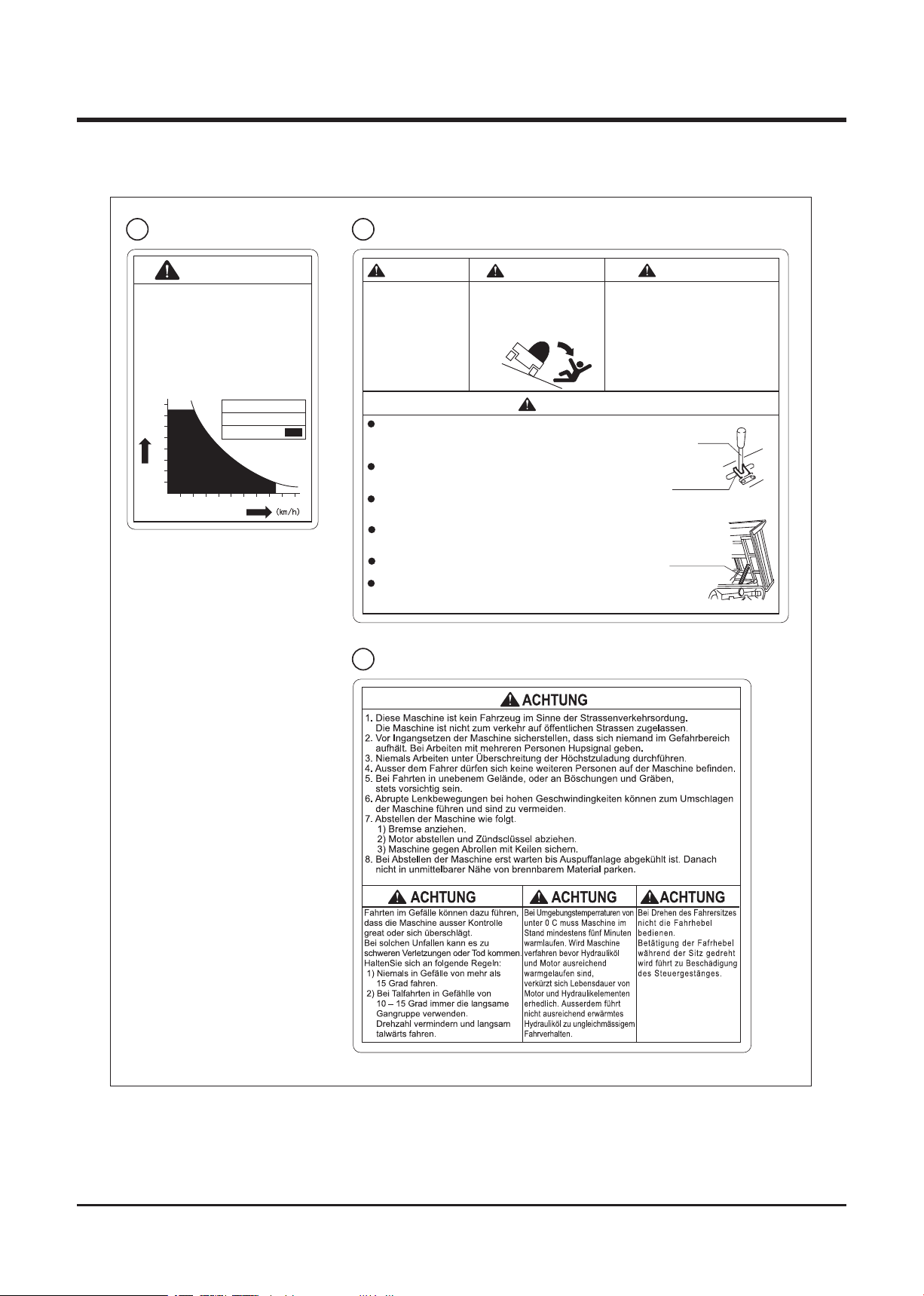

ACHTUNG

Kipper niemals überladen.

Bei Fahrten im Gefälle keinesfalls

die unten angegebene

Höchstgeschwindigkeit überschreiten.

Bei Überschreiten der

Höchstgeschwindigkeit besteht

Gefahr dass Bremsen das Fahrzeug

nicht zum Stehen bringen können.

Bei Gefällefahrten unter Last,

Fahrgeschwindigkeit zurücknehmen

wenn Gefälle zunimmt.

Zulässiger

Arbeitsbereich unter

Höchstzuladung

Gefälle

Fahrgeschwindigkeit

0

1 2 3 4 5 6 7 8 9 10

2

4

6

8

10

12

14

16

(Grad)

Motor nicht in

geschlossenen RŠumen

laufen lassen.

Vergiftungsgefahr durch

Motorabgase.

Be-und Entladen des Kippers nur auf ebenen,

festem Untergrund vornehmen.

Langsam beladen,und eine Rampe verwenden.

Wenn Rampe verwendet wird , auf

Schwerpunktverlagerung achten.

Rasche Ve

rlagerung des Schwerpunktes kann

zum Umschlagen der Maschine fŸhren.

BergwŠrts im

VorwŠrtsgang,

TalwŠrts im RŸckwŠrtsgang fahren.

Kipper nur gleichmŠssig beladen.

Bei einseitiger Beladung besteht

Gefahr dass Maschine sich

ŸberschlŠgt.

Sicherungsblock

Kipphebel

Kulissensicherung

Kippvorgang mšglichst nur auf ebenem, festem Grund durchfŸhren.

Im GefŠlle und auf unebenem Boden besteht Gefahr dass die Maschine

aufgrund der Schwer punktverlagerung umschlŠgt.

Niemals zwischen ungesicherten Kipper und Maschine aufhalten.

MŸssen Wa

rtungen durchgefŸhrt werden erst Hubzylinder bis zum Anschlag

ausfahren, dann Kipphebel mit Kulissensicherung blockieren.

Danach Kipper mit Sicher ungsblock abstŸtzen. Erst danach Wartung durchfŸhren.

Sicherungsblock vor Einfahren des Kippers abrŸsten. Einfahren des

Kippers gegen Sicherungsblock fŸhr t zu BeschŠdigung von

Kipper, Sicherungsblock und Hydraulikzylinder

.

Maschine nicht mit aufgestelltem Kipper fahren. Der erhobene Kipper engt das

Sichtfeld ein, und fŸhrt zu hoher Schwerpunktlage

.

Dies kann zum Umschlagen der Maschine fŸhren.

Vor Einfahren des Kippers sicherstellen dass sich niemand im

Gefahrenbereich des Kippers aufhŠlt.

WARNUNG

Maschine niemals mit erhobenem Kipper abstellen. Andere Personen kšnnten

irrtŸmlich den Kipphebel betŠtigen und zwischen Maschine und einfahrenden

Kipper geraten.

WARNUNG

WARNUNG

WARNUNG

20 21

22

36705112000

36705104000

36705106000

3670M-0101-073E

Safety 1

-7-

Safety Precautions

This section contains safety precautions to follow when operating and maintaining the

machine. Read and understand the precautions in this section as well as throughout this

manual and follow them when operating or maintaining the machine. Failure to follow safety

precautions could result in property damage, serious injury or death to the operator or

bystanders.

Training

All operators and mechanics should receive practical instructions from their employer or

renter. Such instructions should cover the following issues:

• It is essential to familiarize yourself with the controls, safety labels and the proper

use of the machine.

• Never allow people unfamiliar with these instructions to operate or service the

machine. Do not let anyone under 18 years of age to operate this machine. Local

regulations may restrict the minimum age for operating the machine. Consult your

local authority.

• The operator is responsible for the accidents or hazards caused to other people or

their property.

• This machine has a riding capacity for one person only. Do not carry passengers

other than the operator.

• Always keep in mind that care and concentration is required when working with

ride-on machines.

• Loss of control on a slope cannot be regained by the application of the brake. The

main reasons for loss of control are:

→ insufficient grip of tracks.

→ excessive speed.

→ misjudging of the ground conditions, especially slopes.

→ excessive load.

→ incorrect distribution of load.

Safety

-8-

1

Preparation

• Fuel is highly flammable. See Checking and Filling Fuel, page 19, for important

safety information on handling fuel.

• Always wear protective footwear, long trousers, hardhat, safety glasses and ear

protection when operating or servicing the machine. Proper clothing will minimize

the chance of injury. Do not operate the equipment if you have long hair, loose

clothing, or jewelry; all of which may get tangled in moving parts. Do not operate

the machine barefoot or with open sandals.

• Prepare beforehand the working rules and procedures such as signaling and trafic

control for the work place. Following such rules will reduce the risk of accidents.

• Never handle fuel or grease, service the engine, or recharge the battery in the

presence of fire or spark.

• Perform the daily pre-startup inspection (see Preparation, pages 19) before starting

the machine. Repair or replace damaged parts before starting the machine.

Operation

This machine is intended for carrying sand and dirt. Carrying other materials may damage

the machine. Avoid carrying liquid concrete. That will damage the machine.

The stability of the machine is affected by the speed, rate of steering, terrain and the load.

Always pay close attention to these factors or a loss of control or tip over could occur,

resulting in property damage, serious injury or death.

General Driving

• Do not operate the engine in a confined space where dangerous carbon monoxide

fumes can accumulate.

• Do not touch the engine, muffler or exhaust pipe while the engine is running or soon

after it has stopped. These areas will be very hot and can cause burns.

Safety 1

-9-

• Do not operate the machine under the influence of alcohol or drugs. Do not operate

the machine when you are tired, ill, or not feeling well.

• Always check for obstacles before operating on new terrain.

• Before starting the engine and moving the machine, scan around your surroundings

and make sure all persons and other vehicles are a safe distance away from the

machine. Sound the horn to warn bystanders.

• On the machine equipped with the ROPS, always wear the seat belt when in use.

• Always stay seated in the operator's seat when driving the machine. Never operate

the steering lever off of the machine.

• On a slippery surface, travel slowly and exercise caution to reduce the chance of

skidding or sliding out of control. Never operate on ice.

• Always make certain that there is no obstacle or a person behind the machine when

backing up. After confirming that it is safe to back up, move slowly and avoid sharp

turns.

• To reduce the risk of tip over, pay special attention when encountering an obstacle

or a slope, or when braking on a slope or during a turn. See Driving on a Slope on

the next page.

• Never attempt to drive over a large obstacle such as rock or fallen tree.

• Always travel slowly and use extra caution when operating on unfamiliar terrain. Be

alert when traveling on changing terrain.

• Never operate on terrain that you are not comfortable with. Avoid terrain that is so

rough, slippery or loose that you feel like you could tip over.

• Do not operate the machine near the edge of a cliff, an overhang or a slide area.

• Do not make sudden maneuvers. A sudden start, stop, or turn can make the machine

lose control and could cause a tip over. Be especially cautious when traveling on

soft or wet ground.

Safety

-10-

1

• Drive at a safe speed, taking into account the surface gradient, surface conditions

and load.

• Use an observer to help direct the machine when the visibility is poor, terrain is

rugged or hilly, or maneuvering room is limited. The observer should be able to see

the machine and its immediate surroundings, and should give pre-arranged signals

to direct the operator.

Driving on a Slope

• Never use on a slope steeper than 20 degrees.

• Driving on a slope can be dangerous. It can result in a tip over and cause

serious injury or death. Take the following precautions.

• Always follow proper procedures for driving on a slope as described in this manual.

• Driving on a slope in a wrong manner can cause a loss of control or a vehicle tip

over. Check the terrain carefully before attempting to drive on a slope.

• Never drive on a slope that you are not comfortable with. Avoid a slope that is so

rough, slippery, or loose that you feel like you could tip over.

• When driving up a slope, proceed at a steady rate of speed and throttle position.

• Never move the throttle lever or the control lever suddenly.

• If the engine stalls or loses traction during a climb and cannot make it to the top

of the slope, do not try to turn the machine around. Carefully back down slowly,

straight down the slope.

• Drive straight up or down slopes. Avoid turning on a slope.

• When going over the top of a slope, go slow; an obstacle, a sharp drop, or another

vehicle or person could be on the other side of the crest.

Safety 1

-11-

• Avoid driving the machine across a slope.

• Without a load, drive the machine backwards up a slope (operator's seat toward the

top) when climbing, and drive it forward when going down a slope.

• With a load, drive the machine forward up a slope (operator's seat away from the

top) when climbing, and drive it backwards when going down a slope. Be especially

cautious when operating on a slope with a load.

• When driving down a slope, use the steering levers so that the machine travels

down at the minimum speed. Use the engine speed to help keep the machine speed

low.

Loading and Driving with a Load

• The maximum payload for this machine is 24.5kN (2500kg). Do not exceed this

maximum payload under any circumstance.

• Do not operate on a slope steeper than 20 degrees when carrying a load. Do not

carry more than 1250 kg when operating on a slope between 15 and 20 degrees.

• Load cargo in the bucket so the weight is evenly distributed. When carrying a

cargo, strap the cargo to the load deck to prevent the cargo from shifting. Ensure

that cargo does not obstruct the operator's field of view.

• When carrying a load, drive at a reduced speed. Allow a greater distance for

braking.

• Before crossing a bridge or an overpass, make certain that the total combined

weight of the machine, the load and the driver is within the stated weight limit for

the bridge or the overpass. Then, proceed carefully and at a constant speed.

Safety

-12-

1

Dumping/Turning

When turning the bucket and dumping material from the bucket, take the following

precautions.

• Always follow the proper procedures for dumping or turining as described in this

manual.

• Only operate the bucket with the engine running.

• Always stay seated in the operator's seat when dumping or turning the bucket.

Never operate the dump or turn lever off of the machine.

• Perform the dump operation on a flat, level and stable surface whenever possible.

Raising or lowering the load deck on a slope or rough terrain could result in a tip

over.

• Pay special care when dumping with the bucket turned to a side. Be tentative when

raising the bucket which is turned to a side.

• Make certain that all persons are at a safe distance away from the machine when

raising, lowering, or turning the bucket.

• Do not move the machine or leave it unattended with the bucket in the raised

position.

• Engage the bucket safety prop if you must place any part of your body under the

bucket in the raised position.

Parking

• Park the machine on a flat, level and stable surface. Never park on a slope steeper

than 15 degrees. Avoid parking on a slope less than 15 degrees. If parking on

a slope less than 15 degrees is unavoidable, turn the bucket straight, apply the

parking brake and block the tracks at the lower end of the machine.

→ Without a load, park the machine with the operator's seat facing downhill

→ With a load, park the machine with the operator's seat facing uphill

→ Do not park sideways on a slope.

• Observe all the previous precautions for driving, driving on a slope, loading and

driving with a load, and dumping.

Safety 1

-13-

• Whenever you park the machine, apply the parking brake and stop the engine.

Rem ov e the k ey wh en ev er yo u le ave t he ma ch in e u na tt en d ed t o pre ve nt

unauthorized use or accidental starting.

• Diesel fuel is flammable and can be explosive. When parking the machine indoors,

make certain that the building is well ventilated and that the machine is not close to

any source of flame or spark, including appliances with pilot lights.

Servicing

• Do not service the machine when the engine is running. If it is absolutely necessary

to run the engine while servicing, pay attention to the moving parts; keep hands,

feet, clothing and any part of the body away from any moving part, especially the

cooling fan and the belts at the side of the engine.

• Do not operate the engine in a confined space where dangerous carbon monoxide

fumes can accumulate.

• Make sure all hydraulic line connectors are tight and all hydraulic hoses and lines

are in good condition and leak-free before applying hydraulic pressure to the

system.

• Keep your body and hands away from pinhole leaks or nozzles that eject hydraulic

fluid under high pressure. Use paper or cardboard, not your hands, to search

for leaks. Hydraulic fluid escaping under pressure can have sufficient force to

penetrate the skin and cause serious injury.

• Check all fuel lines on a regular basis for tightness and wear. Tighten or repair them

as needed.

• Do not touch the engine, muffler, or exhaust pipe while the engine is running or

soon after it has stopped. These areas will be very hot and can cause burns.

• The engine must be shut off before checking or adding oil.

Controls and Components

-14-

2

Head Lamp

Roller Bracket

Track

Sprocket

Roller

Upper Roller

Idler

Tailgate

Seat

Parking Brake Lamp

Hour Meter

Horn Button

Lock Plate

Lamp Switch

Dump Lever

Turn Lever

(Turn and Dump Model)

Oil Puressure Lamp

Coolant

Temperature Lamp

Parking Brake Switch

Steering Lever

Accelerator Lever

Ignition Switch

H/L Speed Selecter Switch

Fuel Gauge

Charge Lamp

3670M-0201-013E

Name and Function of Controls

-15-

Controls and Components 2

Accelerator Lever

Steering Lever

Dump Lever

Lock Plate

H/L Speed Selecter Switch

Parking Brake Switch

Lamp Switch

. . . . . . . . . . . . . . . This is used to raise or lower the dump body.

. . . . . . . . . . . . . . . . This is used to lock the dump lever.

. . . . . . . . . . This increases or decreases the engine speed.

. . . . . . . . . . . . T hi s is us ed when turnin g the m ac hine an d when

. . . . . . . This is used when parking the machine. (When the

. . . . . . . . . . . . . . Pressing this button lights up the head lamps.

changi n g t h e d i r ec t i o n o r tr a v e l ( F O R WARD o r

REVERSE).

. . . This is used to switch the travel speed between [HI] and

[LO].

parking brake switch is at the [P] position, the machine

does not move even when the steering lever is operated.)

Horn Button

Turn Lever

Dump Lever

Ignition Switch

Coolant Temperature Lamp

. . . . . . . . . . . . . . . Pressing this switch sounds the horn.

. . . . . . . . . . . . . . . . This lever is used when turning the load deck body (turn

. . . . . . . . . . . . . . . This lever is used when dumping the load deck body.

. . . . . . . . . . . . . This also acts as the main switch. When the key is turned

and dump model).

to the [ ] position, electric current passes through the

electrical circuits of the machine. If the key is turned

further to the [ ] position, the starting motor is cranked. If

the key is turned to the [ ] position, electricity flows to the

glow lamp.

. . This lights up when the engine cooling water temperature

rises abnormally (overheats).

2

Controls and Components

Oil Pressure Lamp

Parking Brake Lamp

Charge Lamp

Fuel Gauge

Hour Meter

. . . . . . . . . . . . . . . . This shows the remaining amount of fuel.

. . . . . . . . . . . . . . . . This displays the total number of hours that the machine

. . . . . . . . . . This shows if the engine oil pressure is normal. When the

. . . . . . . . . . . . . . This displays the condition of the battery charge. When

engine starting switch is turned to the [ ] position,it lights

up, and if the conditions are normal it will go out after the

engine starts.

. . . . . . . . This lights up when the parking brake switch is at the [P

(parking)] position.

the engine starting switch is turned to the [ ] position, it

lights up, and if the condition is normal, it will go out after

the engine starts.

has been working in units of 0.1 hour.

-16-

Specifications 3

Product Specifications

· Use this product properly after understanding its specifications thoroughly.

Model and Type

S25A

One-Side-Dump Turn & Dump

Machine Mass kg 2230 2430

Maximum Payload kN(kgf) 24.5(2500)

Overall Length mm 3295 3665

Overall Width mm 1775 1775

Overall Height mm 2370

Track Contact Length mm 1960

Track Tread mm 1230

Dimensions

Ground Clearance mm 295

Loading Deck Height mm 770 910

Inside

Dimensions

Loading Deck

Payload

Model Kubota V2203

Type 4-cycle, Water-cooled Diesel, in-line 4 cylinder

Length mm 1685 2155

Width mm 1420 1300

Height mm 370 495

Struck m

Heaped m

3

3

0.89 1.03

1.26 1.40

Cylinder (Bore×Stroke) mm 87 X 92.4

Displacement cm

Rated Output kw(PS) 34.1 (46.4)

Maximum Torque

Starter System Electric

Fuel Diesel Fuel

Engine

Fuel Consumption

Fuel Tank Capacity L 45

Oil Capacity L 9.7

Coolant Capacity L 7.2

Battery Type 100E41R

Battery Capacity V/AH 12/80

N•m(kgf•m)/rpm

g/kW•h(g/PS•h)

3

139.6/1600 to 1800 (14.2/1600 to 1800)(7.2)

251 (185)

-17-

2197

3

Specifications

Model and Type

S25A

One-side-Dump Turn & Dump

Travel

Speed

Minimum Turning Radius m 2.0

Gradability Degrees 30 (unloaded)

Performance and

Operating Range

HST Oil Capacity L 36

Main Transmission HST (2-Speed Motor)

Steering System 2-Pump/2-Motor System

Brakes Hydraulic

Drive Train

Dump System Hydraulic Dump

Load Deck Type One-side-Dump Turn & Dump

Hydraulic

Pump

Relief Pressure MPa(kgf/cm2) 15.7 (160) 11.8 (120)

Cylinder(Bore X Stroke) mm 80 X 407

Dumping System

Performance

High Speed km/h 0 to 11

Low Speed km/h 0 to 6

Type Gear Pump

Max. Speed

Max. Discharge

Max. Angle Degrees 60 85

Lifting Time Sec approx. 4.0 approx. 7.4

rpm 2,800

L/min 31

Lowering Time

Hydraulic Fluid Capacity L Shared with HST System

Swivel System - Hydraulic (Twin cylinder)

Swiveling Angle Degrees - 90(Right) - 90 (Left)

Swiveling Time Sec - approx. 6.0

Cylinder(Bore X Stroke) mm - 60 X 250

Swivel System

*These specifications are subject to change without notice.

Sec approx. 3.0 approx. 5.3

Contents of the Tool Bag

No. Content Quantitiy Note

1 Operator's Manual 1 This Manual

2

Operator's Manual for the Engine

1

-18-

Preparation

3670M-0401-010E

Main Switch

Fuel Gauge

3670M-0401-020E

Engine Hood

Handle

Pre-start up Inspection

Always perform an inspection before use.

Operation 4

Refer to

Maintenance Schedule

(page 33) for the inspection schedule and procedure.

Checking and Filling Fuel

• Keep fire and spark away when handling fuel.

• Always stop the engine before refueling.

• Do not overfill fuel so that fuel will not overflow. Check fuel gauge when filling.

In case fuel is spilt, wipe out immediately.

Checking Fuel

1. Insert key into main switch.

2. Turn main switch to [ | (on)] position and

wait a few seconds.

3. Check fuel gauge.

4. Turn main switch to [ (off)] position and

remove key.

Filling Fuel

1. Open engine hood.

-19-

Operation

-20-

4

3670M-0401-040E

Lock Lever

Slide Lever

Seat Back Adjuster

Firmness Adjuster

3670M-0401-050E

3670M-0401-030E

Fuel Filler Cap

2. Open fuel filler cap.

3. Insert key in main switch and turn it to

[ | (On)] position.

4. Fill fuel. Check fuel gauge when filling.

5. Turn main switch to [ (Off)] position and

remove key.

6. Put fuel filler cap back and tighten it securely.

7. Close engine hood.

NOTE

• Fuel : Diesel Fuel.

• Fuel Tank Capacity : 45L

Adjusting Seat

• When adjusting seat, make certain the seat is securely locked.

Turning seat

1. Pull up lock lever to turn seat.

NOTE

• When seat is turned, the direction that seat

is facing is FORWARD for the operation of

steering levers.

Adjusting seat

1. Pull slide lever to slide seat to a desired

position.

2. Pull seat back adjuster to adjust seat back to

the desired position.

3. Pull firmness adjuster lever to adjust the

seat firmness to suit operator's weight and

preference. Pull firmness adjuster lever fuilly

to undo it.

-21-

Operation 4

Seat Belt

3670M-0401-060E

Using Seat Belt

• On machine equipped with ROPS, Always wear seat belt.

1. Buckle up seat belt. Adjust seat belt so that it

fits snugly over the pelvis.

Driving

Starting

• Always start and run the engine in a well ventilated place.

• Always make certain of the safety of your surroundings when starting the

engine.

• An engine that has been running is very hot. Avoid touching the engine and its

ancillaries, or severe burns may result.

• Do not open engine hood while engine is running.

Operation

-22-

4

3670M-0402-010E

Parking Brake Switch

• Do not turn the starter when the engine is running. Starter motor and/or the

engine may be damaged.

• Do not turn the starter for more than 15 seconds. If the engine does not start,

wait for 30 seconds or more before attempting to start again.

• Do not use this machine in temperatures above 40ºC or below -15ºC. This

machine cannot perform adequately in these temperature ranges. Using this

machine under such conditions may result in an accident or cause damage to

the machine.

• In the winter or cold climate, warm up the engine thoroughly before driving

the machine. A cold engine delivers poor performance, which may result in an

accident. It also causes excessive wear.

• Do not use this product in dusty places such as desert. Dust may clog the air

cleaner or enter the engine, which may reslt in loss of performance and an

accident. It also causes excessive wear.

• Do not use this machine in the altitude above 1500m in its original configuration.

This machine cannot perform adequately above that altitude. Using this

machine under such conditions may result in an accident or cause damage to

the machine. If you need to use this machine above that altitude, contact your

CANYCOM representative.

1. Make sure parking brake switch is in [

(parking)] position.

-23-

Operation 4

3670M-0402-020E

Dump Lever

Lock Plate

3670M-0402-030E

Steering Levers

3670M-0402-040E

Main Switch

OFF

Preheat

3670M-0402-050E

Main Switch

OFF

ON

Start

2. Make sure dump and turn (Turn & Dump

model) levers are in the neutral position and

lock plate is in the locked position (around

the base of the levers).

3. Make sure steering levers are in the neutral

position.

4. Insert key into main switch.

5. Turn main switch to [ (preheat)] position.

NOTE

• Preheat engine for about 10 seconds when

star ting in n orma l te mper atur e and for

about 20 to 30 seconds when starting in

cold weather (ambient temperature below -5

°C).

• There is no need to preheat if the engine is

already warm.

7. Turn main switch to [ (start)] position to

start the engine. Once the engine starts,

rel e a s e k e y i m m e d i a t e l y ; s w i t c h w i l l

automatically return to [ | (on)] position.

Operation

-24-

4

3670M-0402-060E

Parking Brake Lamp

Coolant Temperature Lamp

Oil Pressure Lamp

Charge Lamp

8. Move throttle lever to [ (slow)] position.

9. Make certain the warning lamps are not lit.

10. Allow the engine to warm up by running

it for 3-5 minutes without any load. (It is

not necessary when the engine is already

warm.)

NOTE

• Drive the machine gently in the first 40 to 50

hours of use after purchase for breaking-in.

• I f an y of wa rnin g la mps is lit, sto p th e

engine immediately a n d investigate the

cause.

Driving

• Do not allow bystanders to come near the machine when driving.

• Always make certain of the safety of your surroundings before driving; start

slow.

• Always stay seated in the operator's seat when driving the machine. Never

operate the steering lever off of the machine. This may cause the machine to

run over or crush the operator.

• Always make certain of the safety of your surroundings before turning

• Do not make sudden starts, acceralation, change of speed, change of direction,

or stop. Do not turn at speed. Avoid sudden maneuvers; this may cause the

operator to fall or to be thrown, or the machine to tip over.

• Do not turn the key to [ (off)] position while traveling. Machine can lose

stability and tip over.

-25-

Operation 4

3670M-0402-070E

H/L Speed Selecter Switch

Parking Brake Switch

3670M-0402-080E

Steering Levers

• Always move the steering levers back to the neutral position before releasing.

Letting it go from other operating positions may result in sudden deceleration

and can cause the machine to tip over or the operator to fall or to be thrown.

• Do not operate steering levers when the parking brake is engaged (parking

brake pedal is pressed down). It can wear out the brake.

1. M a ke ce r ta i n o f t he sa f et y o f y o ur

surroundings.

2. Turn parking brake switch to [TRAVEL]

position.

3. Push H/L speed selecter switch to either

[ (LO)] or [ (HI)] position. For the

speed range in either position, see "Product

Specification (page 17-18)."

3. Move the throttle lev e r t o w a r d [

(fast)] position or depress throttle pedal to

increase the engine speed.

Moving Forward

4. Move left and right steering levers gradually

for ward together to move the ma chine

forward. The angle of steering levers controls

the machine speed.

NOTE

• When seat is turned, the direction that seat

is facing is FORWARD for the operation of

steering levers.

Operation

-26-

4

3670M-0402-090E

Steering Levers

3670M-0402-120E

Steering Lever (Right)

3670M-0402-110E

Steering Lever (Left)

3670M-0402-100E

H/L Speed Selecter Switch

Moving Backward

5. Move both steering levers gradually

backward together to move the machine

backward. The angle of steering levers

controls the machine speed.

Selecting Speed

6. Push H/L speed selecter switch to either

[ (LO)] or [ (HI)] position. This can

be done while machine is in travel.

Turning Forward

7. Move left steering lever gradually forward to

turn right.

8. Move right steering lever gradually forward

to turn left.

-27-

Operation 4

3670M-0402-130E

Steering Lever (Left)

3670M-0402-140E

Steering Lever (Right)

3670M-0402-150E

Steering Levers

Turning Backward

9. Move left steering lever gradually backward

to turn right backwards.

10. Move right steering lever gradually backward

to turn left backwards.

Pivot Turning

11. Move steering levers in opposite directions

to make a turn on spot (pivot turn).

Operation

-28-

4

3670M-0402-160E

Steering Levers

Neutral

3670M-0402-200E

Fuel Cutoff Lever

Stopping

• Do not make a sudden stop. The machine may skid or tip over.

• Do not release steering levers suddenly. The machine may stop suddenly and

skid or tip over.

• Always park on a firm, level place. Never park on a potentially dangerous place.

1. Move steering levers gradually to the neutral

position to stop machine.

Stopping with Fuel Cutoff Lever

• Do not open engine hood while engine iw running. If it is absolutely necessary

to open engine hood while engine is still running, keep away from moving or

hot parts.

1. Open engine hood.

2. Move fuel cutoff lever to stop engine.

-29-

Operation 4

3670M-0402-170E

Throttle Lever

3670M-0402-180E

Parking Brake Switch

3670M-0402-160E

Steering Levers

Neutral

Parking

• Always park on a firm, level place. Never park on a potentially dangerous place.

• Avoid parking on a slope. Never park on a slope with an incline of 15 degrees or

steeper. If it is absolutely necessary to park the machine on a slope less than

15 degrees, make certain to apply parking brake firmly and block the tracks

with chocks.

1. Move steering levers gradually to the neutral

position to stop machine.

2. Move throttle lever toward [ (slow)]

position to decrease the engine speed.

3. Turn parking brake switch to [P (parking)]

position.

Operation

-30-

4

3670M-0402-190E

Main Switch

OFF

ON

Working

4. Turn main switch to [ (off)] position.

Remove the key from main switch.

NOTE

• Le a vi n g t he ma i n s w it c h i n [ | ( o n ) ]

position drains the battery and cause it to

discharge.

• Always make certain of the safety of your surroundings when dumping or

turning bucket.

• Never operate the dumping or turning lever off of the machine. This may cause

the bucket to hit or cruch the operator or bystander.

• Avoid dumping or turning bucket on a slope. The machine may tip over.

• Always run the engine when dumping or turning bucket.

• When lowering the loaded bucket, slow the engine speed and lower the bucket

gently.

-31-

Operation 4

Dumping

3670M-0403-010E

Throttle Lever

3670M-0403-020E

Dump Lever

Lock Plate

UPDOWN

3670M-0403-030E

Dump Lever

Left Turn

Right Turn

Lock Plate

Turn Lever

1. Move the throttle lever to [ (fast)] position

to increase the engine speed.

2. Turn the lock plate to the side so that the

dump lever can be operated.

Dumping and Turning Bucket

3. M o ve d u m p l e v er gr a du a ll y t o wa r d

[ (up)] to raise bucket.

4. When bucket reaches its upper limit, a

hissing noise is heard; move dump lever

back to [ (neutral)] position.

5. M o ve d u m p l e v er gr a du a ll y t o wa r d

[ (down)] to lower bucket.

6. When bucket r eaches its lower limit, a

hissing noise is heard; move dump lever

back to [ (neutral)] position.

7. Turn lock plate back in place to lock dump

lever.

8. Turn lock plate to the side so that turn lever

can be operated.

9. M o ve t u r n l ev e r g ra du a l l y t o w a r d

[ (left)] to turn bucket left.

10. When bucket reaches its limit, a hissing

noise is heard; move turn lever back to

[ (neutral)] position.

11. M o v e tu r n l e v er g r a du a ll y t o wa rd

[ (right)] to turn bucket right.

4

3670M-0403-050E

Safety Prop

3670M-0403-040E

Clockwise Turn

Counterclockwise Turn

Using Safety Prop

Operation

12. When bucket reaches its limit, a hissing

noise is heard; move turn lever back to

[ (neutral)] position.

13. Turn lock plate back in place to lock turn

lever.

• Place safety prop under bucket when inspecting or working under bucket.

• Make certain to undo safety prop before lowering bucket.

1. Raise bucket.

2. Hold the bucket with safety prop.

-32-

Maintenance 5

Maintenance Schedule

• Follow the scheduled maintenance as described below. Failure to do so may

result in mechanical or property damage, injury or death.

• Perform a pre-startup inspection (PSI) before each use, a monthly inspection once a

month, and a yearly inspection once a year.

• Some maintenance procedures described below may require special knowledge

or tools and instruments. Contact your CANYCOM representative to perform such

procedures.

Item Description

Engine shall start easily without making any

irregular noise.

Glow plugs work correctly.

Engine speed shall be set properly at idle

and at full without loading. Engine shall stay

running smoothly.

When accelerating engine, throttle lever shall

move smoothly, and engine shall accelerate

smoothly without stopping or knocking.

Warm up engine thoroughly, and observe

exhaust sound and gas from idle to fast

speed; exhaust sound shall be normal and

smoke shall not be excessive.

There shall be no leak in exhaust system or

muffler.

Air cleaner case shall not be deformed or

cracked. Case lid and connecting air hose

shall be firmly in place.

Cleaner element shall be in good shape

without damage or excessive dust.

Bolts and nuts fastening cylinder head,

intake and exhaust manifolds shall be tightly

fastened.

* this may be skipped if there is no gas or

water leaks found in these areas.

Engine

General

Starting

Running

Exhaust

Air

Cleaner

Fasteners

Schedule

PSI

Mon

√ √ √

√ √ √

√ √

√ √ √

√ √ √

√ √

√ √

√ √

√

Note

Year

Contact your CANYCOM

representative for

inspection.

Cleaning/Replacing:

Page 44

-33-

Maintenance

-34-

5

Item Description

Valve clearance shall be correct.

Valve

Clearance

Compression

General

Engine

Mount

Lubrication

System

Engine

Fuel System

Cooling

System

* this may be skipped if there is no noise due

to incorrect valve clearance, and engine

runs normally.

Compression shall be normal

* this may be skipped if running and exhaust

conditi on is n ormal at idle and under

acceleration.

Engine base shal l be fre e of cra cks or

deformation.

Mounting bolts and nuts shall not be loose or

missing.

Oil shall be clean and at correct level.

No noticable oil leaks shall be found in head

cover, oil pan, or pipes.

There shall not be any leaks in fuel tank,

hoses, or pipes.

Fuel hos es s hall be fre e of da mage or

deterioration.

Fuel filter shall not be excessively dirty or

clogged.

There shall not be sediment or water in fuel

tank.

Injection puressure and injection condition

from the nozzle shall be normal.

* this may be skipped if running and exhaust

co nd it io n is no rm al a t i dl e an d und er

acceleration.

Coolant shall be clean and at the correct

level.

There shall not be any leaks from radiator,

engine, water pump, or hoses.

Radiator fins shall be free of clogging.

Radiator cap valve shall function properly.

Fan belt shall be free of wear and damage,

and shall be properly tensioned.

Cooling fan, duct, and cover shall be free of

cracks, damage, or deformation.

Mounting bolts and nuts on cooling fan, duct,

and covers shall not be loose or missing.

Schedule

PSI

Mon

√

√

√ √ √

√ √ √

√ √ √

√ √ √

√ √ √

√ √ √

√ √

√ √

√

√ √ √

√ √ √

√ √ √

√

√

√

√

Note

Year

Contact your CANYCOM

representative for

inspection.

Contact your CANYCOM

representative for

inspection.

Inspecting/Changing:

Page 42

Inspecting: Page 49

Inspecting/Removing

water: Page 49

Contact your CANYCOM

representative for

inspection.

Inspecting/Filling:

Page 45

Adjusting: Page 47

-35-

Maintenance 5

Item Description

Charge

System

Battery

Engine

Electrical System

Wiring

HST Pump

Drive Train

Linkage

Wheels

Sprockets

Idlers

Undercarriage

Tracks

Charge system is working correctly.

Battery electrolyte level shall be correct.

Terminals shall be free of marked corrosion

and are tightly secured.

Connections shall be securely connected.

Wiring shall be free of damages.

Drive the machine forward and backward,

turn left and right in both directions; machine

shall move normally and free of irregular

noise or overheating.

Hydraulic fluid shall be filled to a proper

level.

Hydraulic fluid shall be clean and free of dirt

or contamination.

There shall be no fluid leaks in or around

fluid tank.

Rods, links, and wires in linkage shall be free

of deformation or damage.

Connections shall be free of looseness,

excessive play, or missing cotter pins.

Shall be free of cracks, defromation, or

excessive wear.

There shall not be excessive play in axle.

Irregular noise or overheating shall not be

observed when traveling.

Mounting bolt or nut shall not be loose or

missing.

There shall be no oil leak in or around axle.

There shall not be marked cut, deterioration,

or wear.

Track shall be properly tensioned; shall not

be too loose or too tight.

Track core shall not be missing or damaged.

Tension bolt shall be free of deformation or

corrosion.

Schedule

PSI

Mon

√

√ √

√ √

√ √

√ √

√ √ √

√ √

√ √

√ √

√ √

√ √

√ √ √

√ √ √

√ √ √

√ √

√ √ √

√ √ √

√ √ √

√ √ √

Note

Year

Contact your CANYCOM

representative for

inspection.

Inspecting/Filling:

Page 58

Inspecting/Changing:

Page 52

Inspecting/Changing:

Page 52

Adjusting: Page 50

Maintenance

-36-

5

Parking Brake

Linkage

Brake System

Hydraulic

Pump

Hydraulic System

Hydraulic

Valve

Plumbing

Hydraulic System

Hydraulic

Cylinders

Item Description

Parking brake shall work properly.

Parking b rake sha ll be able to hol d the

machine on a 20-degree slope.

Rods, links, and wires in linkage shall be free

of deformation or damage.

Connections shall be free of looseness,

excessive play, or missing cotter pins.

There shall be no leak in or around hydraulic

pump.

Fastening bolts and nuts shall not be loose

or missing.

No irregular vibration, noise, or heat shall

be observed when hydraulic pump is in

operation.

Amount and pressure of discharge under

load shall be within the s tandard range

specified by the manufacturer.

*this may be skipped if irregular vibration,

noi se , or he at d escri be d above i s not

observed.

There shall be no leak in or around hydraulic

valve.

Plumbing shall be free of cracks, damage,

twists, or deterioration.

There shall be no leaks in pipes, hoses,

joints, or seals.

Plumbing shall be mounted properly, and

fastening bolts and nuts shall not be loose or

missing.

Breather shall not be clogged.

Shall work smoothly.

There shall be no leaks when extending and

contracting cylinder.

Exte nd dum p c ylinder fu lly un der loa d

and hold. Stroke shall be within the range

specified by manufacturer.

Cylinder tube and rod shall be free of dents,

cracks, bends, or scratches.

Cylinder mounting pins shall be free of

damage or excessive wear.

Schedule

PSI

Mon

√ √ √

√ √

√ √

√ √

√ √

√ √

√ √

√

√ √

√ √

√ √

√ √

√ √

√ √

√ √

√

√ √

√ √

Note

Year

-37-

Maintenance 5

Item Description

Shall be free of cracks, deformation, or

Chassis

Frame

Body Panels

Loading Deck

Body, Chassis, Loading Deck

Safety Prop

Labels

Work Lamp

Safety Devices

Horn

corrosion.

Fastening bolts or nuts shall not be loose or

missing.

Shall be free of cracks or deformation.

Doors shall open, close, and lock properly.

Fastening bolts or nuts shall not be loose or

missing.

Loading deck shall be raised,lowered and

turned smoothly.

Shall be free of cracks, deformation, or

corrosion.

Fastening bolts or nuts shall not be loose or

missing.

Safety prop shall be free of any deformation.

Warning labels and instruction plates shall

be clean, legible, and free of damage.

Work lamp shall work.

Lamp lens shall be free of cracks or chipping

and water shall not be in the lamp.

Horn shall work.

Schedule

PSI

Mon

√ √

√ √

√ √

√ √ √

√ √

√ √

√ √

√ √

√ √

√ √ √

√ √ √

√ √

√ √ √

Note

Year

Maintenance

-38-

5

List of Fluids and Lubricants

Item Schedule Grade Cap.

Fuel As needed. Diesel Fuel

Engine Oil

HST Fluid Change

Travel Motor Oil Change

C y li nd e r Pi n ,

Ro lle r S u pp o rt

Shaft

Engine Coolant

Battery Electrolyte

Fill

Inspect daily. Fill as needed.

Change

Init i a l l y - A f t e r 5 0 h o u r s o f u s e .

Every 200 hours afterwards.

Initially - After 500 hours.

Every 1000 hours afterwards.

Initially - After 200 hours.

Every 1000 hours afterwards.

Every 1000 hours.

Check Everyday

Add as needed

Change every 2 years

Inspect daily. Distilled Water

Diesel Engine Oil

API rating: CD or better.

SAE rating: 10W-30

High viscosity index hydraulic fluid,

ISO VG46

Engine Oil

API rating: CD or better.

SAE rating: 10W-30

*When using in cold areas

(below -15°C), use wear resistant

hydraulic fluid VG32

Gear Oil

API rating: GL-4

SAE rating: 90

Lithium all-round grease (NGL

No.2 or equivalent)

Long Life Coolant (LLC) and pure

water Mixture

45L

9.7L

or

36L

0.6L

-

7.2L

-

-39-

Maintenance 5

List of Consumables and Spares

• When replacing consumable or spare, always use CANYCOM genuine part.

Item Part No. Schedule Qty.

Engine

Air Cleaner Element (Outer)

Air Cleaner Element (Inner)

Oil Filter

Fuel Filter

Push-Pull Wire (Engine Control)

Wire

Drive Train

Track

Sprocket 15T

Track Roller A Assembly

Track Roller B Assembly

Carrier Roller Assembly

Idler Assembly

Electrical System

Battery (100E41R)

Hydraulic System

R1401-4227-0

R2401-4228-0

3661 0001 300

3664 0221 500

3707 3321 000

3655 0105 100

3663 2111 999

3663 2106 0X0

5232 2201 000

5232 2211 000

3640 2218 0X0

3640 2331 0X0

3661 0502 000

Replace every 1000 hours or if

defective.

Replace every 1000 hours or if

defective.

Initially: 50 hours.

Every 200 hours afterwards.

Replace every 450 hours or if

defective.

Replace if defective. 1

Replace if defective. 1

Replace if defective

or reaches the wear limit.

Replace if defective. 2

Replace if defective. 8

Replace if defective. 4

Replace if defective. 2

Replace if defective. 2

Replace if defective. 1

1

1

1

2

Contact your

Hydraulic Hoses (Dump, Turn,

Oil Cooler, HST)

Suction Filter

Line Filter

CANYCOM

representative for

parts information.

3663 6029 000

3661 6036 300

NOTE

• Track wear limit: 5mm of lug height

Every 2 years

or if defective.

Every 1000 hours. 1

Every 500 hours. 1

1

Maintenance

-40-

5

Item

Hydraulic Hoses

HST Pump Front Right A1 to

HST Motor Top Left P1

HST Pump Front Left B1 to

HST Motor Bottom Left P2

HST Pump Front Left B2 to

HST Motor Bottom Right P2

HST Pump Front Right A2 to

HST Motor Top Right P1

HST Motor Left Drain Bottom T1

to Oil Tank

HST Motor Right Drain Bottom T1

to Oil Tank

Pump Top Front Drain to

Oil Cooler Top

Oil Cooler Bottom to

Oil Tank (Pipe)

Solenoid Valve A2 to

T-Junction (PS)

T-Junction (Solenoid Valve A1)

to T-Junction (P3)

T-Junction (Solenoid Valve A1)

to T-Junction (Servo)

T-Junction (Motor Right PS)

to Motor Left PS

T-Junction (Motor Right P3)

to Motor Left P3

T-Junction (Motor Left PS)

to Motor Right PS

T-Junction (Motor Left PS)

to Motor Right P3

Solenoid Valve T to Oil Tank

Gear Pump Discharge Top Rear

to Control Valve P

Gear Pump Suction Bottom Rear

to Oil Tank (Flange)

Solenoid Valve P to

T-Junction (Line Filter OUT)

Control Valve T to Line Filter IN

Part No. Schedule Qty.

5229 6101 000

5229 6102 000

3664 6101 200

5229 6104 000

5229 6111 000

5229 6112 000

5229 6115 000

5229 6116 000

5229 6117 000

5229 6118 000

5229 6119 000

5229 6121 000

5229 6122 000

5229 6123 000

5229 6124 000

5229 6125 000

3664 6128 000

5229 6126 000

5229 6131 000

5229 6132 000

Replace every 2 years or if

defective.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

-41-

Maintenance 5

Item Part No. Schedule Qty.

Hydraulic Hoses

HST Servo Front to

T-Junction (Servo)

HST Searvo Rear to

T-Junction (Servo)

Control Valve A to

Cylinder Bottom

Control Valve B to

Cylinder Top

NOTE

• Rubber products such as the hydraulic hose deteriorate over time. Replace them

3664 6141 000

5229 6119 000

3661 6163 000

5229 6142 000

Replace every 2 years or if

defective.

1

1

1

1

every 2 years.

Maintenance

-42-

5

3670M-0504-010E

Dip Stick

Engine

• Always stop the engine before servicing.

• An engine that has been running is very hot. Allow the engine to cool before

servicing, or severe burns may result.

• Keep fire and spark away when handling fuel.

Engine Oil

• Dispose of the drained oil properly. Check the national and local regulations for

discarding engine oil.

• Make certain to fill the engine with correct grade of oil to the specified level.

Insufficient amount or wrong grade of oil reduces performance and may cause

permanent damage to the engine.

Inspecting

1. Park the machine on a level surface.

2. Open engine hood.

3. Follow the instructions in the

Manual for the Engine

to inspect oil.

Operator's

NOTE

• To obtain correct reading, check oil level

before starting, or wait about 10 minutes

after stopping the engine to allow oil to

drain back to the oil pan.

• Always check oil level on a level surface.

-43-

Maintenance 5

3670M-0504-020E

Oil Filler Cap

3670M-0504-030E

Drain Plug

3670M-0504-040E

Oil Filter Cartridge

Filling

1. Remove oil filler cap.

2. Follow the instructions in the

Manual for the engine

to fill oil.

Operator's

3. Put oil filler cap back in place and tighten it

securely.

Changing

1. Have an appropriate oil drain pan.

2. Remove drain plug to drain oil.

3. Clean drain plug and put it back in place and

tighten it securely.

4. Fill oil.

5. Close engine hood.

NOTE

• Oil Capacity: 9.7L

• Oil to Use: Diesel Engine Oil, API rating CD

Oil Filter

or above, SAE index 10W-30.

• Removing oil filler cap helps drain oil faster.

1. Open engine hood.

2. Follow the instructions in the

Manual for the engine

to change oil filter

Operator's

cartridge.

3. Fill oil.

4. Close engine hood.

Maintenance

-44-

5

3670M-0504-050E

Grip Hole

Side Cover

3670M-0504-060E

Air Cleaner

Spring Hook

Air Cleaner

• Clean air cleaner element regularly. Dirty cleaner element reduces engine

performance and life.

• Replace cleaner element if damaged.

1. Open side cover.

2. Undo spring hooks to remove air cleaner lid.

3. Follow the instructions in the

Manual for the engine

change air cleaner element.

4. Close side cover.

to inspect, clean or

Operator's

-45-

Maintenance 5

3670M-0504-070E

Coolant Reservoir

LOW

FULL

Radiator Cap

3670M-0504-080E

Coolant

• Do not open radiator cap when engine or radiator is hot. Opening cap when

they are still hot may release boiling coolant and cause severe burns. Wait for

engine to cool after operation (about 10 minutes) before opening.

• Tak e ex tre me c are w he n h an dl i ng t he co ol ant ; an tif re ez e s ol ut ion i s

inflammable. Avoid exposure to open flame. It is also toxic. If coolant is caught

in the eye, wash the eye clean with running water and consult a physician

immediately.

• Di spose of t he dr ained coo l ant prope rly. C heck the n ation al an d loc al

regulations.

Inspecting/Filling

1. Open engine hood.

2. When the engine is cold, check engine

coolant level in reservoir tank. If the level is

below [FULL] mark, add water.

3. Open radiator cap.

4. Check engine coolant level. If the level is

low, add water.

5. Put radiator cap back in place.

6. Close engine hood.

NOTE

• When coolant temperature warning lamp

is lit, it may mean the coolant level is low.

Imm ed iat el y i ns pe ct an d a dd wa te r as

necessary.

Maintenance

-46-

5

Drain Cock

CLOSED

OPEN

3670M-0504-090E

Ambient

Temperature

-10 °C

-15 °C

-20 °C

-25 °C

-30 °C

-35 °C

-40 °C

* The value for the ambient temperature

is 5°C lower than the actual minimum

temperature.

Antifreeze

Mixture

30%

35%

40%

45%

50%

55%

60%

Antifreeze Mixture (Reference)

When this machine is shipped from the factory,

it is filled with a mixture of 50% antifreeze and

50% water. To prevent coolant from freezing, use

a mixture of water and antifreeze determined by

the minimum temperature in the operation area

using the table on the left.

NOTE

• Antifreeze to use: Long Life Coolant (LLC).

• Use pure water to make antifreeze mixture.

Changing

1. Prepare a suitable container for drained

coolant.

2. Remove radiator cap and reservoir lid.

3. Open drain cock at the bottom of radiator.

4. Drain coolant. Then clean inside radiator.

5. Clsoe drain cock.

6. Fill radiator and reservoir with antifreeze

mixture.

7. Put adiator cap and reservoir lid back in

place.

NOTE

• Coolant Capacity: 7.2L

•R emo vin g r adi ato r c ap hel ps dra in th e

coolant.

-47-

Maintenance 5

3670M-0504-140E

Fan Belt

10kgf

Approx.

7-9mm

Fan Belt

• Check belt tension regularly. Loose fan belt causes premature wear on belt or

insufficient cooling.

1. Open engine hood.

2. Press the middle of fan belt with a force of

10kgf to see belt deflects between 7 and 9

mm

3. If the deflection is not within this range,

loosen alternator mounting bolts and move

alternator to adjust belt tension.

Maintenance

-48-

5

3670M-0504-100E

Fuel Filter

3670M-0504-110E

Oil Seal

Fuel System

• Fuel is highly flammable. Keep fire and spark away when servicing fuel filter. If

fuel is spilt, wipe immediately.

• Dispose risidual fuel in fuel filter or drained fuel or water properly. Check the

national and local regulation for discarding such fluids.

Changing Fuel Filter

1. Open engine hood.

2. Using oil filter wrench, remove fuel filter

cartridge.

3. Apply thin coat of new fuel on oil seal.

4. Install fuel filter. Tighten fully by hand.

NOTE

• Do not use oil filter wrench when installing

fuel filter.

5. After installation, bleed air in the fuel system.

6. Close engine hood.

-49-

Maintenance 5

3670M-0504-120E

Fuel Filter

Air Bleed Plug

Injector Pump

3670M-0504-130E

Fuel Cock

Limit Line

Fuel Bowl

Close

Bleeding Air in the Fuel System

NOTE

Bleed air when air enters the fuel system

• After changing fuel filter or disconnecting fuel line.

• After running engine until fuel tank is completely dry.

1. Open engine hood.

2. Make sure th e components in t he fuel

system is securely installed.

3. Fill fuel in fuel tank.

NOTE

• Fill enough amount of fuel so that air is not

sucked into the fuel system.

4. Open side cover (page 44).

5. Loosen air bleed plug.

6. Turn main switch to [ | (ON)] position to

actuate fuel pump.

7. When fuel comes out of air bleed plug,

tighten plug.

8. Close side cover and engine hood.

Inspecting Water in Fuel

1. Open side cover.

2. Visually inspect water in fuel bowl. If it

reaches limit line or above, drain water.

3. Close side cover.

Removing Water in Fuel

1. Open side cover.

2. Close fuel cock.

3. Follow Operator's Manual for the Engine to

remove fuel bowl and discard its content.

4. REinstall fuel bowl.

5. Open fuel cock.

6. Close side cover.

Maintenance

-50-

5

Drive Train

• Stop engine when servicing the drive train.

• Allow machine to cool off before servicing. Engine is very hot after operation

and may pose a burn hazard.

Tracks

• J ac k u p ma ch i ne s ec u re ly w i th a c o m m er ci al gr ad e j ac k ca p ab le o f

supporting machine's weight when inspecting or adjusting track. Follow jack

manufacturer's instructions to raise one side of machine until track is a few

centimeters off the ground.

• Once jacked up, support machine securely with rigid racks.

• Make certain to adjust track tension properly. Inproperly tensioned tracks may

wear or come off, resulting in property damage, serious injury or death.

• Always unload machine before jacking up.

• When loosening track adjuster valve, loosen slowly and gradually so that it will

not come off. Track adjuster cylinder is under pressure, and if adjuster valve

comes off, it may be projected out, possibly causing injury or damage.

NOTE

• Track stretches during its use-life. Inspect and adjust regularly.

• During the first 100 hours of use, track tends to get broken in and stretch more than

usual. Inspect often and adjust as necessary.

-51-

Maintenance 5

3670M-0505-010E

Track

Valve Cover

Track Adjuster Valve

3670M-0505-020E

Track

Fork

Sprocket

Adjusting

1. Park machine on a horizontal ground.

2. Jack up the front and the rear of chassis to

raise track on one side. Make sure track is

parallel to the ground surface.

3. Remove track adjuster valve cover.

4. Inspect the gap between track and track

frame ( A )to be between 224 and 225mm.

5. Slowly loosen track adjuster valve to let

grease come out around valve and track to

loosen.

6. When track is loose enough, tighten valve.

Make sure not to have valve O-ring get

caught.

7. Attach grease pump to track adjuster valve

and pump grease into track adjuster cylinder

until the gap A is between 224 and 225mm.

8. Remove grease pump and install valve

cover.

Replacing/Installing

1. Park machine on a horizontal ground.

2. Jack up the front and the rear of chassis to

raise track on one side. Make sure track is

parallel to the ground surface.

3. Remove track adjuster valve cover.

4. Slowly loosen track adjuster valve to let

grease come out around valve to reduce

pressure inside track adjuster cylinder.

5. Remove valve.

6. Push idler wheel fork in, toward the front of

machine.

7. Remove track.

8. Fit new track, first on sprocket, then on idler.

9. Reinstall and tighten valve securely. Make

sure not to have valve O-ring get caught.

Maintenance

-52-

5

3670M-0401-020E

Engine Hood

Handle

10. Attach grease pump to track adjuster valve

and pump grease into track adjuster cylinder

until the gap A is between 224 and 225mm.

11. Remove grease pump and install valve

cover.

HST (Hydrostatic Transmission) Fluid

• Inspect and maintain fluid level regularly. If fluid level is low, air may be trapped

into the hydraulic system, causing loss of perwormance or premature wear..

• Dispose of the drained fluid properly, according to the national and local regula-

tions.

• Burn hazard; pay special attention when handling the hydraulic fluid. Hot fluid

may cause burns.

NOTE

• HST fluid is used for driving as well as for hydraulic apparatus .

Inspecting/Filling

1. Park machine on the level ground.

2. Open engine hood.

-53-

Maintenance 5

3670M-0505-050E

Drain Plug

3670M-0505-060E

Line Filter

3670M-0505-040E

HST Fluid Filler Caps

3670M-0505-030E

Fluid Level Window

3. Visually inspect oil level window.

4. If the level is low, open filler cap and fill fluid.

Put filler cap back in place.

5. Start and run engine for a while to circulate

the fluid. Then, stop engine.

6. Visually inspect fluid level to be within the

fluid level window.

7. Close engine hood.

Changing

1. Park machine on the level ground.

2. Have an appropriate oil drain pan.

3. Remove drain plug to drain fluid.

4. Install drain plug.

NOTE

• R ep la ce b ot h li ne fi lt er c ar tr id ge a n d

suction filter element when hydraulic fluid

is changed.

6. Open engine hood.

7. Remove line filter cartridge with the oil filter

wrench.

8. Have a new line filter cartridge ready. Apply

clean hydraulic fluid (oil) on the cartridge oil

seal evenly.

Maintenance

-54-

5

3670M-0505-070E

Suction Filter

9. Screw in the new line filter cartridge. Tighten