CanyCom S160 Operator's Manual

Read this manual completely before operating or maintaining this machine.

Failure to follow safety precautions could result in serious injury or death.

Keep this manual for future reference by you and by all those who operate

and maintain this machine.

CHIKUSUI CANYCOM, INC.

90-1 Fukumasu, Yoshii-machi,

Ukiha-shi, Fukuoka, Japan 839-1396

Tel.+81-(0)943-75-2195 Fax.+81-(0)943-75-4396

Original Instructions

(in English)

Off-road Rubber Track Dumper

S160

Operator's Manual

3683 5101 002

http://www.canycom.co.jp/

■

Sales Headquarters TEL +81-(0)943-75-2195 FAX +81-(0)943-75-4396

■

Foreign Trade Center

TEL +81-(0)3-3552-6277 FAX +81-(0)3-3552-6288

All rights reserved. Unauthorized use or reproduction of this material is prohibited.

Authorized Dealer

CHIKUSUI CANYCOM, INC.

Notice to Users and Maintenance Personnel

• This machine can be very dangerous if the safety precautions in this manual

and on the labels attached to this machine are not followed. Read and

understand this manual and the safety labels on the machine thoroughly before

using this machine. Always follow the instructions and safety precautions, or

serious injury or death could result.

• This machine should only be used for its intended purpose: hauling and

dumping. Any other use could be dangerous.

• This machine may not be operated on public road or what is considered to

be public road. It is the sole responsibility of the operator to consult the local

regulations.

• Do not modify this machine, or do not operate this machine with the safety

covers removed or open. A serious accident could result.

Thank you for purchasing this machine.

This manual provides information needed for safe and effective use of this machine to

those who operate or maintain the machine. Make sure to read and understand the manual

thoroughly before operating this product. Also make sure to read the separate operator's

manual for the engine.

• Store this manual in a safe, accessible place for easy reference.

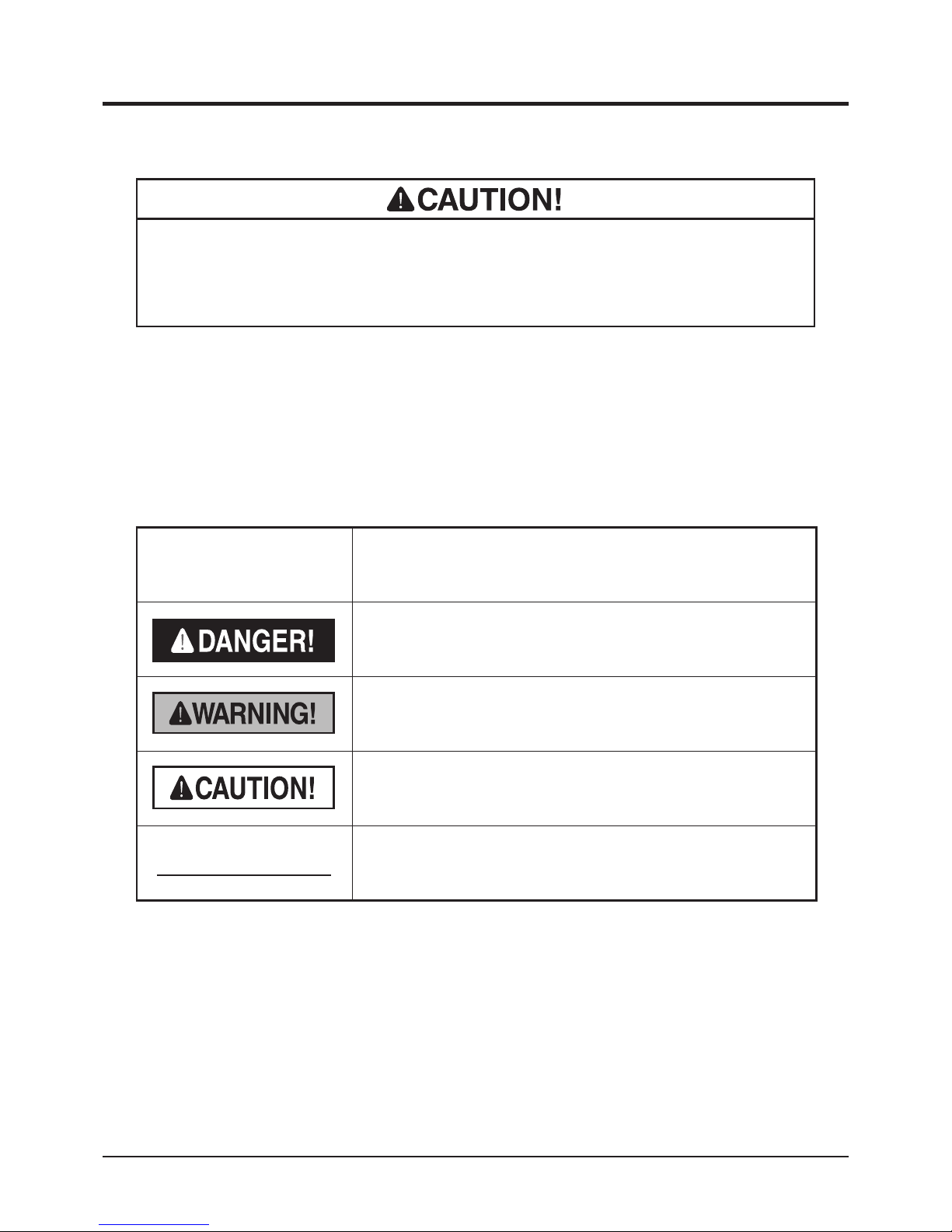

Warning Term Denition

Indicates an imminently hazardous situation which will result

in death or serious injury if the user does not follow the

procedures or the instructions.

Indicates a potentially hazardous situation which could result

in death or serious injury if the user does not follow the

procedures or the instructions.

Indicates a potentially hazardous situation which could result

in minor to moderate injury or damage to the machine if the

user does not follow the procedures or the instructions.

Indicates important information which needs particular

attention.

In this manual, the following four warning terms are used to signal the four levels of hazard

(or seriousness of possible accidents). Read and understand what they mean and always

follow the instructions in this manual.

Warning Terms Used in this Manual

NOTE

Notice to Owner

• Be sure that everyone who uses this machine, including those who rent or

lease this machine, receives a copy of this Operator's Manual and understands

the importance of reading and following the information in this manual.

Warranty and After-Sales Service

Warranty

Consult your local CANYCOM dealer or our company’s sales department regarding service

orders or any questions or problems that may arise when using this machine. Please make

sure to have the product name, serial number, and the make and type of the engine handy at

the time of contact. The model and serial number can be found on the model label as shown

below, and the make and type of the engine can be found in Chapter5 "Specications" of this

manual (Page13).

After-Sales Service

Location of Model Label Model Label

The replacement or repair parts for this product shall remain available for seven years after

the production of this type of machine is discontinued.

Availability of Spare Parts

3683M-0005-020E

3683M-0005-010E

Location of Model Label

CHIKUSUI CANYCOM, INC. guarantees this product, based on the terms of warranty. A

copy of this warranty is reproduced in the back of this manual.

Contents

1. Safety 1

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2. Controls and Components 10

Name and Function of Controls . . . . . . . . . . . . . . . . . . . 10

3. Specications 13

Product Specications . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Contents of the Tool Bag . . . . . . . . . . . . . . . . . . . . . . . . 14

4. Operation 15

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pre-start up Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Checking and Filling Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Using ROPS (on ROPS Model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Adjusting Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Using Seat Belt (on ROPS Model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Dumping and Turning Bucket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Using Safety Prop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5. Maintenance 32

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . 32

List of Fluids and Lubricants . . . . . . . . . . . . . . . . . . . . . 37

Greasing Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

List of Consumables and Spares . . . . . . . . . . . . . . . . . . 38

Removing and Installing Body Panels . . . . . . . . . . . . . . 39

Engine Compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Step and Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Drive Train . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Tracks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

HST (Hydrostatic Transmission) Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Transmission Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Drive Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Greasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

After Use Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

After Normal Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

After Cold Weather Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6. Troubleshooting 59

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7. Transporting 63

Hauling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Loading and Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Hoisting and Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Warranty

Warranty Certicate is attached at the end of this manual.

* Have the warranty certicate signed and sealed after you have received and fully

understood the instructions for handling this machine and received the receipt.

Appendix

• Operator's Manual for the Engine

* Be sure to read and understand it together with this manual .

Safety 1

-1-

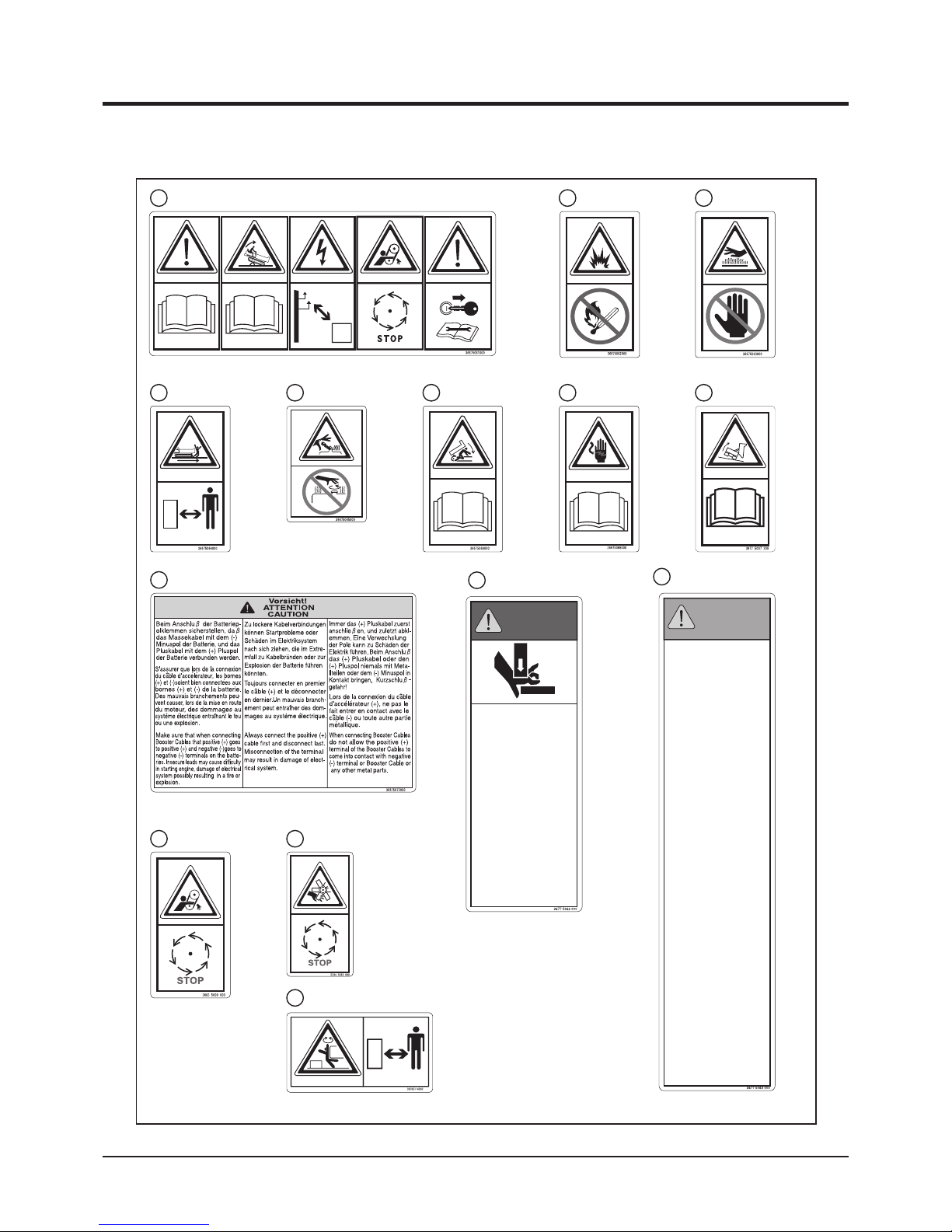

Safety Labels

The safety labels shown on the next page are attached to the machine. See the illustration

below for the location and the illustration on the next page for the content of each label on

the machine.

• Locate all the warning labels attached to this machine. Read and follow the

instructions and precautions in them. Failure to do so could result in serious injury

or death to the operator or bystanders.

• Keep the labels clean and legible. Do not use solvents or gasoline to clean the

labels.

• Replace these labels immediately if they have been removed, have fallen off or

become illegible. Use the part number, on the label or shown in this manual, to

order a replacement label from your CANYCOM representative.

4

3683M-0101-010E

Back of Bucket

(Both Sides)

(Both Sides)

Safety

-2-

1

CRUSH HAZARD

Keep hands away from ROPS

joint. Shearing action of ROPS

can cause serious injury or

death.

RISQUE D'ECRASEMENT

Tenir les main s éloignées du

ROPS. A ction d e cisai llement

du ROPS peut causer de

graves blessu res ou la mor t.

RISCHIO DI

SCHIACCIAMENTO

Non avvicinate le mani ai giunti

del ROLL-BAR. Pericolo di

morte o lesioni personali.

EINKLEMMGEFAHR

Ha lten Si e al le Kör per teil e

weg von Stel len, an welche n

beim Umk ippen

Einklemm gefahr besteht.

DANGER!

DANGER!

PERICOLO!

GEFAHR!

WARNING!

AVERTISSEMENT!

AVVERTENZA!

WARNUNG!

The pr otection of fered by th is

ROPS will be impair ed if it ha s

been altered, damaged , or has

been involved i n an ove rturn.

Inspect ROPS, seatbelts, and their

attachin g c omponents d aily for

cracks, d eformations or ot her

unsafe conditions. Seatbelts must

be worn whi le operating veh icle.

Failure to properly use and maintain

ROPS, se atbelts, and the ir

attaching components may result in

severe in jury or d eath to t he

operator or a bystander.

La protection offerte par ce ROPS

sera di minuée s 'il a été altéré,

endommagé ou a été impliqué lors

d'un renverseme nt. In specter le

ROPS, les ceintur es de sécurité,

leurs fixations ou autres conditions

d'inséc urité. I l faut por ter les

ceintur es de sécur ité lo rs de

l'utilisat ion du véhicule. Nég liger

l'utilisation correcte et l'entretien du

ROPS, des ceintures de sécurité et

de leurs fixations, peut entraîner de

graves ble ssures ou la mort de

l'opérateur ou du spectateur.

La p rotezione offer ta da q uesto

ROLL-BA R diminui sce qualor a

ess o ve nga mod ific ato,

danneggiato o la macchina si sia

ribaltata. Controllate giornalmente il

ROLL-BAR, le cintur e e le loro

componenti affinchè n on ci siano

rottur e, d eformazio ni o alt re

condizioni di pericolo. Le cinture di

sicurezza devono essere allacciate

durante l'utilizzo della macchina. Un

uso im proprio e la man cata

manutenzione del ROLL-BAR, delle

cinture e de lle lo ro comp onenti

possono causa re ser ie les ioni

corporee o la morte dell'operatore o

della persone circostanti.

Der Schutz des ROPS-Daches ist

nicht mehr g ewährleistet, we nn

dieses beschädigt oder verformt ist.

Überp rüfen Si e t äglich, den

Zustand d es ROPS-Dac hes, der

Sich erheits gurte und dere n

Befestig ung au f Bes chädigung,

Verschlei ss ode r Defe kt. Die

Sicherhe itsgurte m uss getragen

3683M-0101-020E

3667 5061 0001 3667 5062 0002

3667 5064 000

4 3667 5065 0005

3667 5063 000

3

3667 5073 000

9

3683 5008 000

10 5234 5063 00013

3670 5114 000

14

3677 5062 000

11

3677 5063 000

12

3677 5007 3003667 5066 000

6 3667 5068 0007

8

Safety 1

-3-

This section contains safety precautions to follow when operating and maintaining the

machine. Read and understand the precautions in this section as well as throughout this

manual and follow them when operating or maintaining the machine. Failure to follow safety

precautions could result in property damage, serious injury or death to the operator or

bystanders.

Safety Precautions

All operators and mechanics should receive practical instructions from their employer or

renter. Such instructions should cover the following issues:

• It is essential to familiarize yourself with the controls, safety labels and the proper

use of the machine.

• Never allow people unfamiliar with these instructions to operate or service the

machine. Do not let anyone under 18 years of age to operate this machine. Local

regulations may restrict the minimum age for operating the machine. Consult your

local authority.

• The operator is responsible for the accidents or hazards caused to other people or

their property.

• This machine has a riding capacity for one person only. Do not carry passengers

other than the operator.

• Always keep in mind that care and concentration is required when working with

ride-on machines.

• Loss of control on a slope cannot be regained by the application of the brake. The

main reasons for loss of control are:

→ insufcient grip of tracks.

→ excessive speed.

→ misjudging of the ground conditions, especially slopes.

→ excessive load.

→ incorrect distribution of load.

Training

Safety

-4-

1

Operation

• Fuel is highly ammable. See Checking and Filling Fuel, page 15, for important

safety information on handling fuel.

• Do not operate the engine in a conned space where dangerous carbon monoxide

fumes can accumulate.

• Do not touch the engine, mufer or exhaust pipe while the engine is running or soon

after it has stopped. These areas will be very hot and can cause burns.

This machine is intended for carrying sand and dirt. Carrying other materials may damage

the machine. Avoid carrying liquid concrete. That will damage the machine.

The stability of the machine is affected by the speed, rate of steering, terrain and the load.

Always pay close attention to these factors or a loss of control or tip over could occur,

resulting in property damage, serious injury or death.

General Driving

• Always wear protective footwear, long trousers, hardhat, safety glasses and ear

protection when operating or servicing the machine. Proper clothing will minimize

the chance of injury. Do not operate the equipment if you have long hair, loose

clothing, or jewelry; all of which may get tangled in moving parts. Do not operate

the machine barefoot or with open sandals.

• Prepare beforehand the working rules and procedures such as signaling and trac

control for the work place. Following such rules will reduce the risk of accidents.

• Never handle fuel or grease, service the engine, or recharge the battery in the

presence of re or spark.

• Perform the daily pre-startup inspection (see Preparation, pages 15-18) before

starting the machine. Repair or replace damaged parts before starting the machine.

Preparation

Safety 1

-5-

• Do not operate the machine under the inuence of alcohol or drugs. Do not operate

the machine when you are tired, ill, or not feeling well.

• Always check for obstacles before operating on new terrain.

• Before starting the engine and moving the machine, scan around your surroundings

and make sure all persons and other vehicles are a safe distance away from the

machine. Sound the horn to warn bystanders.

• On the machine equipped with the optional ROPS, always keep the ROPS in the

extended position when in use. Fold the ROPS only when it is absolutely necessary

to do so when transporting the machine.

• On the machine equipped with the ROPS, always wear the seat belt when in use.

• Always stay seated in the operator's seat when driving the machine. Never operate

the steering lever off of the machine.

• On a slippery surface, travel slowly and exercise caution to reduce the chance of

skidding or sliding out of control. Never operate on ice.

• Always make certain that there is no obstacle or a person behind the machine when

backing up. After conrming that it is safe to back up, move slowly and avoid sharp

turns.

• To reduce the risk of tip over, pay special attention when encountering an obstacle

or a slope, or when braking on a slope or during a turn. See Driving on a Slope on

the next page.

• Never attempt to drive over a large obstacle such as rock or fallen tree.

• Always travel slowly and use extra caution when operating on unfamiliar terrain. Be

alert when traveling on changing terrain.

• Never operate on terrain that you are not comfortable with. Avoid terrain that is so

rough, slippery or loose that you feel like you could tip over.

Safety

-6-

1

Driving on a Slope

• Always follow proper procedures for driving on a slope as described in this manual.

• Driving on a slope in a wrong manner can cause a loss of control or a vehicle tip

over. Check the terrain carefully before attempting to drive on a slope.

• Never drive on a slope that you are not comfortable with. Avoid a slope that is so

rough, slippery, or loose that you feel like you could tip over.

• When driving up a slope, proceed at a steady rate of speed and throttle position.

• Never move the throttle lever or the control lever suddenly.

• Never use on a slope steeper than 20 degrees.

• Driving on a slope can be dangerous. It can result in a tip over and cause

serious injury or death. Take the following precautions.

• Do not operate the machine near the edge of a cliff, an overhang or a slide area.

• Do not make sudden maneuvers. A sudden start, stop, or turn can make the machine

lose control and could cause a tip over. Be especially cautious when traveling on

soft or wet ground.

• Drive at a safe speed, taking into account the surface gradient, surface conditions

and load.

• Use an observer to help direct the machine when the visibility is poor, terrain is

rugged or hilly, or maneuvering room is limited. The observer should be able to see

the machine and its immediate surroundings, and should give pre-arranged signals

to direct the operator.

Safety 1

-7-

• If the engine stalls or loses traction during a climb and cannot make it to the top

of the slope, do not try to turn the machine around. Carefully back down slowly,

straight down the slope.

• Drive straight up or down slopes. Avoid turning on a slope.

• When going over the top of a slope, go slow; an obstacle, a sharp drop, or another

vehicle or person could be on the other side of the crest.

• Avoid driving the machine across a slope.

• Without a load, drive the machine backwards up a slope (operator's seat toward the

top) when climbing, and drive it forward when going down a slope.

• With a load, drive the machine forward up a slope (operator's seat away from the

top) when climbing, and drive it backwards when going down a slope. Be especially

cautious when operating on a slope with a load.

• When driving down a slope, use the steering levers so that the machine travels

down at the minimum speed. Use the engine speed to help keep the machine speed

low.

Loading and Driving with a Load

• The maximum payload for this machine is 15.7kN (1600kg). Do not exceed this

maximum payload under any circumstance.

• Do not operate on a slope steeper than 20 degrees when carrying a load. Do not

carry more than 800 kg when operating on a slope between 15 and 20 degrees.

• Load cargo in the bucket so the weight is evenly distributed. When carrying a

cargo, strap the cargo to the load deck to prevent the cargo from shifting. Ensure

that cargo does not obstruct the operator's eld of view.

• When carrying a load, drive at a reduced speed. Allow a greater distance for

braking.

• Before crossing a bridge or an overpass, make certain that the total combined

weight of the machine, the load and the driver is within the stated weight limit for

the bridge or the overpass. Then, proceed carefully and at a constant speed.

Safety

-8-

1

Parking

• Park the machine on a at, level and stable surface. Never park on a slope steeper

than 15 degrees. Avoid parking on a slope less than 15 degrees. If parking on

a slope less than 15 degrees is unavoidable, turn the bucket straight, apply the

parking brake and block the tracks at the lower end of the machine.

→ Without a load, park the machine with the operator's seat facing downhill

→ With a load, park the machine with the operator's seat facing uphill

→ Do not park sideways on a slope.

• Observe all the previous precautions for driving, driving on a slope, loading and

driving with a load, and dumping.

Dumping/Turning

When turning the bucket and dumping material from the bucket, take the following

precautions.

• Always follow the proper procedures for dumping or turining as described in this

manual.

• Only operate the bucket with the engine running.

• Always stay seated in the operator's seat when dumping or turning the bucket.

Never operate the dump or turn lever off of the machine.

• Perform the dump operation on a at, level and stable surface whenever possible.

Raising or lowering the load deck on a slope or rough terrain could result in a tip

over.

• Pay special care when dumping with the bucket turned to a side. Be tentative when

raising the bucket which is turned to a side.

• Make certain that all persons are at a safe distance away from the machine when

raising, lowering, or turning the bucket.

• Do not move the machine or leave it unattended with the bucket in the raised

position.

• Engage the bucket safety prop if you must place any part of your body under the

bucket in the raised position.

Safety 1

-9-

Servicing

• Do not service the machine when the engine is running. If it is absolutely necessary

to run the engine while servicing, pay attention to the moving parts; keep hands,

feet, clothing and any part of the body away from any moving part, especially the

cooling fan and the belts at the side of the engine.

• Do not operate the engine in a conned space where dangerous carbon monoxide

fumes can accumulate.

• Make sure all hydraulic line connectors are tight and all hydraulic hoses and lines

are in good condition and leak-free before applying hydraulic pressure to the

system.

• Keep your body and hands away from pinhole leaks or nozzles that eject hydraulic

fluid under high pressure. Use paper or cardboard, not your hands, to search

for leaks. Hydraulic fluid escaping under pressure can have sufficient force to

penetrate the skin and cause serious injury.

• Check all fuel lines on a regular basis for tightness and wear. Tighten or repair them

as needed.

• Do not touch the engine, muffler, or exhaust pipe while the engine is running or

soon after it has stopped. These areas will be very hot and can cause burns.

• The engine must be shut off before checking or adding oil.

• Whenever you park the machine, apply the parking brake and stop the engine.

Remove the k e y whe n e ver y o u leav e the machine unattende d to p revent

unauthorized use or accidental starting.

• Diesel fuel is ammable and can be explosive. When parking the machine indoors,

make certain that the building is well ventilated and that the machine is not close to

any source of ame or spark, including appliances with pilot lights.

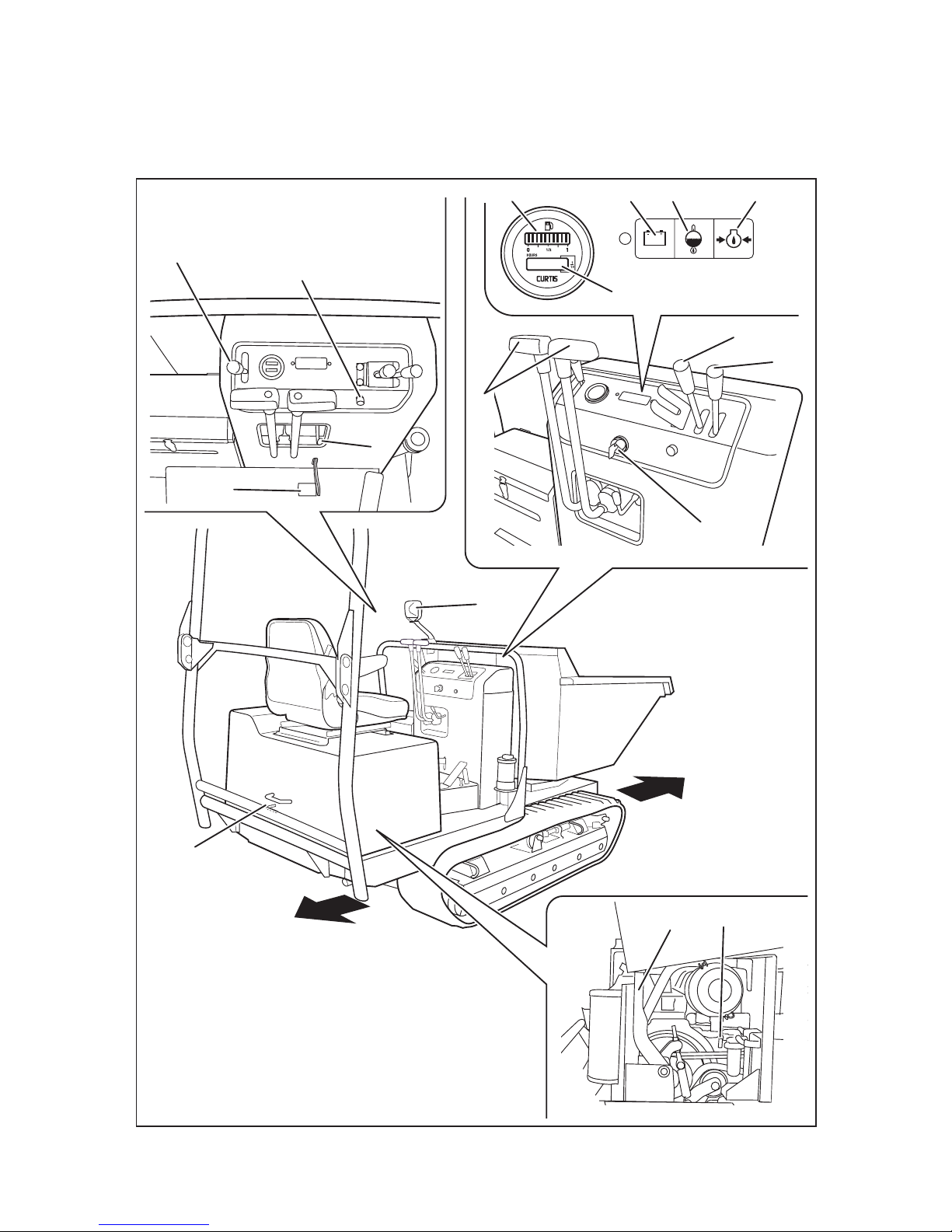

Name and Function of Controls

3683M-0201-010US

Forward

Backward

1

3

4

5

7

6

8

9

14

15

16

17

11 12 13

2

10

1 Dump Lever . . . . . . . . . . . . . Raises or lowers bucket.

2 Turn Lever . . . . . . . . . . . . . . Turns bucket.

3 Main Switch . . . . . . . . . . . . . Main Switch is used to start or stop the engine.

4 Steering Levers . . . . . . . . . . Steering Levers are used to control the traveling direction

(forward or backward) and speed of the tracks.

5 Parking Brake Pedal . . . . . . Parking Brake Pedal is used to park the machine securely.

6 Parking Brake Lock Lever . . Parking Brake Lock Lever is used to lock or release

Parking Brake.

7 Throttle Lever . . . . . . . . . . . . Throttle Lever is used to control the engine speed.

8 Horn Button . . . . . . . . . . . . . Pressing this button sounds the horn. Use this for warning

during traveling or signaling during operation.

9 Fuel Gauge . . . . . . . . . . . . . . Displays the amount of fuel in the tank.

10 Hour Meter . . . . . . . . . . . . . . Hour Meter displays and records the total amount of time

the machine has been in use, in the unit of 0.1 hour.

11 Battery Warning Lamp . . . . . Lights up when Main Switch is turned to the [ | (run)]

position. If there is no problem, it goes off when the engine

is started. If a problem with battery charge system is

detected when the engine is running, it lights up.

12 Coolant Temperature . . . . . . It lights up when the coolant temperature is beyond normal

operating range.

13 Oil Pressure Warning . . . . Lights up when Main Switch is turned to the [ | (run)]

position. If there is no problem, it goes off when the engine

is started. If a low oil pressure is detected when the engine

is running, it lights up.

Lamp

Warning Lamp

Controls and Components

-12-

2

14 Work Light . . . . . . . . . . . . . . Work Light provides illumination for operation in the dark.

It is turned on or off by the switch on its back.

15 Engine Cover Latch Lever . Engine Cover Latch Lever releases engine cover .

16 Clutch Lever . . . . . . . . . . . . . Disengages the clutch.

17 Fuel Cock . . . . . . . . . . . . . . . Shuts off fuel ow.

-13-

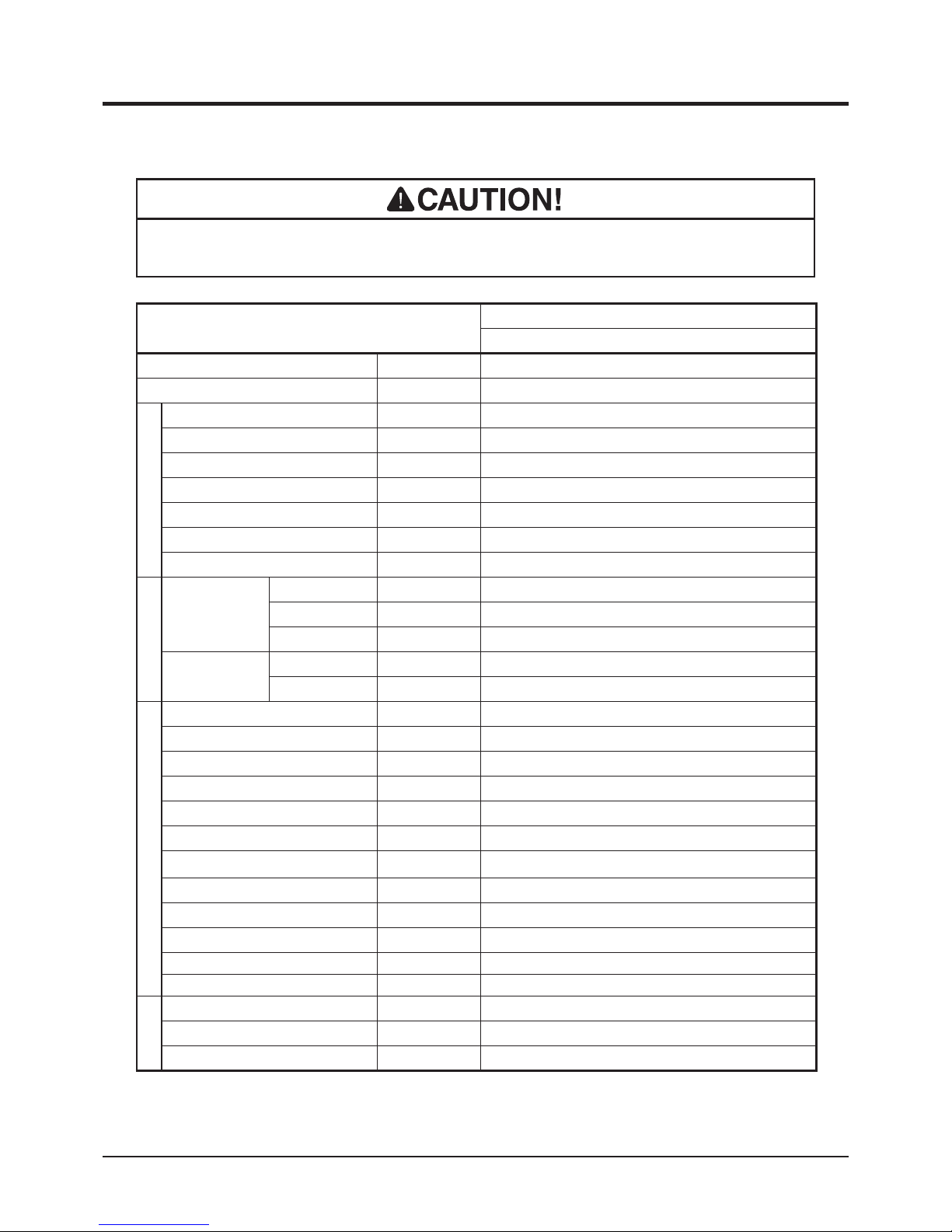

Specications 3

· Use this product properly after understanding its specications thoroughly.

Product Specications

Model and Type

S160

Swivel Dump

Machine Mass kg

1340 [1400]

Maximum Payload kN(kgf) 15.7(1600)

Dimensions

Overall Length mm

2850 [2940]

Overall Width

mm

1120 [1150]

Overall Height mm

1575 [2385]

Track Contact Length

mm

1195

Track Gauge

mm

840

Ground Clearance

mm

160

Loading Deck Height

mm

630

Loading Deck

Inside

Dimensions

Length

mm

1475

Width

mm

1010

Height

mm

550

Payload

Struck m

3

0.6

Heaped m

3

0.74

Engine

Model Kubota D1105-E3B

Type Water-cooled 4-cycle Diesel, in-line 3 cylinder

Cylinder (Bore×Stroke)

mm

78X78.4

Displacement cm

3

1123

Rated Output kw(PS) 15.1(20.5)

Maximum Torque N•m(kgf•m) 70.3(7.2)

Starter System Electric

Fuel Diesel No.2-D (ASTM D975)

Fuel Consumption

g/kW•h(g/PS•h)

255(190)

Fuel Tank Capacity L 22

Oil Capacity L 3.3

Coolant Capacity L 3.5 (excluding reservoir)

Electrical

Battery Type 95D31R

Battery Capacity V/AH 12/65

Working Lamp V/W 12/18.4

*[ ] The gure in the brackets indicates when ROPS is installed.

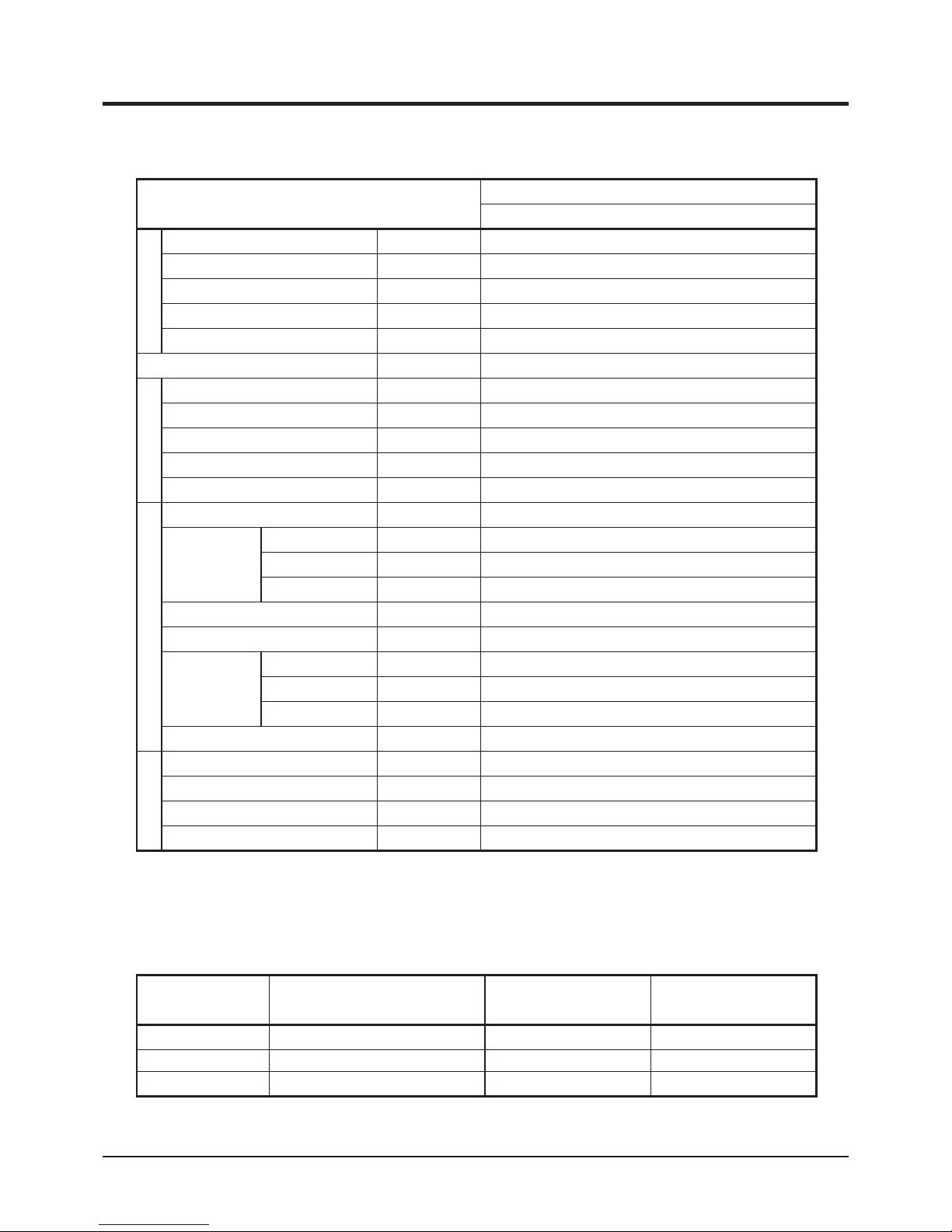

Specications

-14-

3

Model and Type

S160

Swivel Dump

Speed km/h 0-7.0

Minimum Turning Radius m 3.2

Gradability Degrees 25(Empty)

Operating Temperature °C -15~40

Altitude m 0~1,500

HST Oil Capacity L 32

Drive Train

Main Transmission

Twin HST

Steering

Twin HST, 2 Lever

Brakes Internally Expanding

Track Size 280×51×72

Tranamission Oil Capacity L 3.2

Dumping System

Dumping System Swivel Dump

Hydraulic

Pump

Type Gear Pump

Max. Speed

rpm 2,100

Max. Discharge

L/min 16.8

Relief Pressure MPa(kgf/cm

2

) 14.0(145)

Cylinder(Bore X Stroke) mm 465X625

Performance

Max. Angle Degrees 90

Lifting Time Sec approx. 7.4

Lowering Time

Sec approx. 5.0

Hydraulic Fluid Capacity L Shared with HST System

Swivel System

Swivel System Hydraulic (Twin cylinder)

Swiveling Angle Degrees 90(Right) - 90 (Left)

Swiveling Time Sec approx. 6.6/180°

Cylinder(Bore X Stroke) mm 50X160

*These specications are subject to change without notice.

Performance and

Operating Range

No. Content Quantitiy Note

1 Operator's Manual 1 This Manual

2

Operator's Manual for the Engine

1

3 Engine Service Tool 1

for Servicing the Engine

Contents of the Tool Bag

Loading...

Loading...