CanyCom CMX 227, CM226, CMX186, CM185, CMX 253 Operator's Manual

...

Original Instructions

(in English)

5321 5311 003

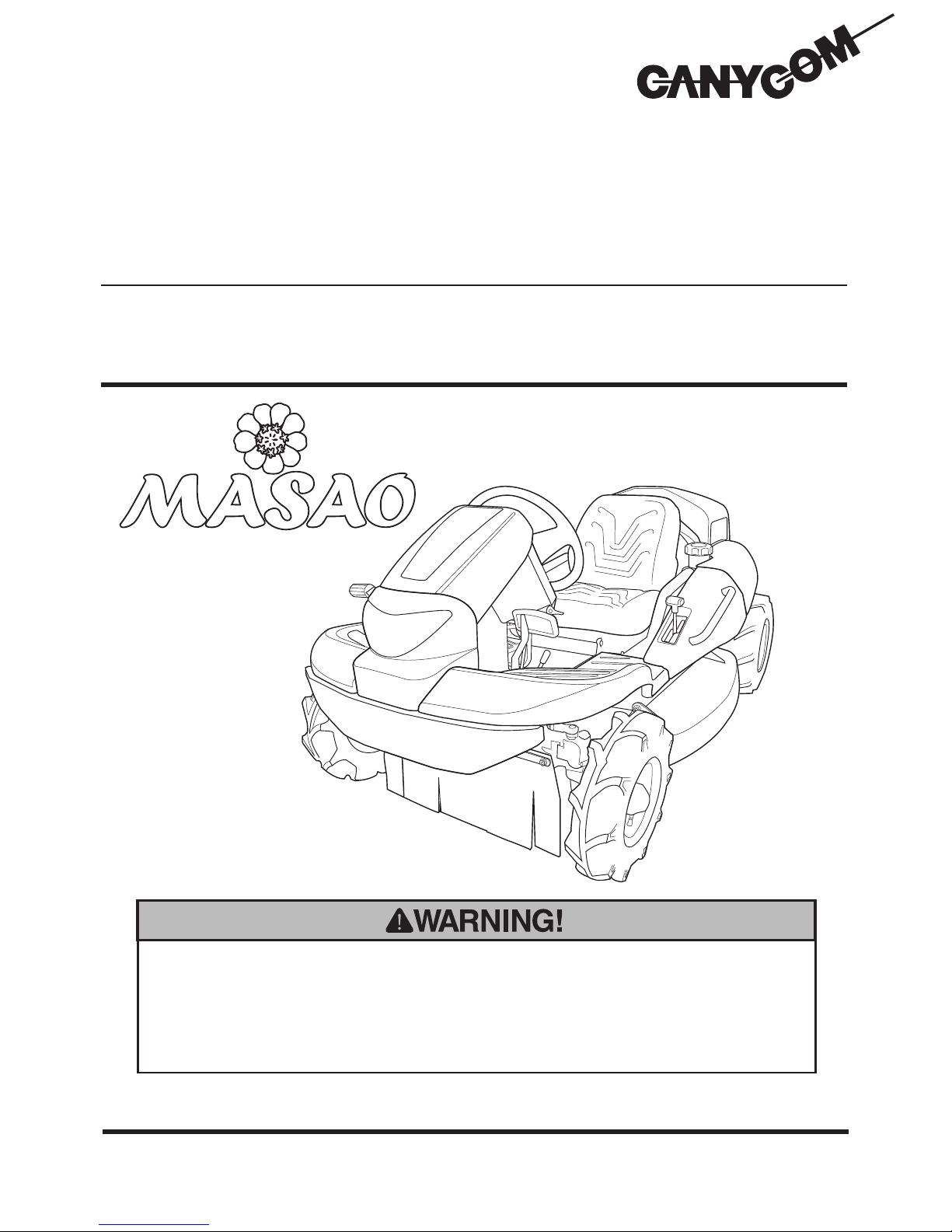

Ride-on Brushcutter

CMX 227/ CM226/ CMX186/ CM185

Operator's Manual

Read this manual completely before operating or maintaining this machine.

Failure to follow safety precautions could result in serious injury or death.

Keep this manual for future reference by you and by all those who operate

and maintain this machine.

5347 5351 000

http://www.canycom.co.jp/

Authorized Dealer

90-1 Fukumasu, Yoshii-machi,

Ukiha-shi, Fukuoka, Japan 839-1396

Sales Headquarters (International) TEL +81-(0)943-75-2195

FAX +81-(0)943-75-4396

All rights reserved. Unauthorized use or reproduction of this material is prohibited.

Notice to Users and Maintenance Personnel

Thank you for purchasing this machine.

This manual provides information needed for safe and effective use of this machine to those

who operate or maintain machine. Make sure to read and understand the manual thoroughly

before operating this product. Also make sure to read the separate operator's manual for

engine.

• This machine can be very dangerous if the safety precautions in this manual

and on the labels attached to this machine are not followed. Read and

understand this manual and safety labels on machine thoroughly before using

this machine. Always follow the instructions and safety precautions, or serious

injury or death could result.

• This machine should only be used for its intended purpose: cutting grass and

bushes. Any other use could be dangerous.

• This machine may not be operated on public road or what is considered to

be public road. It is the sole responsibility of the operator to consult the local

regulations.

• Do not modify this machine, or do not operate this machine with the safety

covers removed or open. A serious accident could result.

• Store this manual in a safe, accessible place for easy reference.

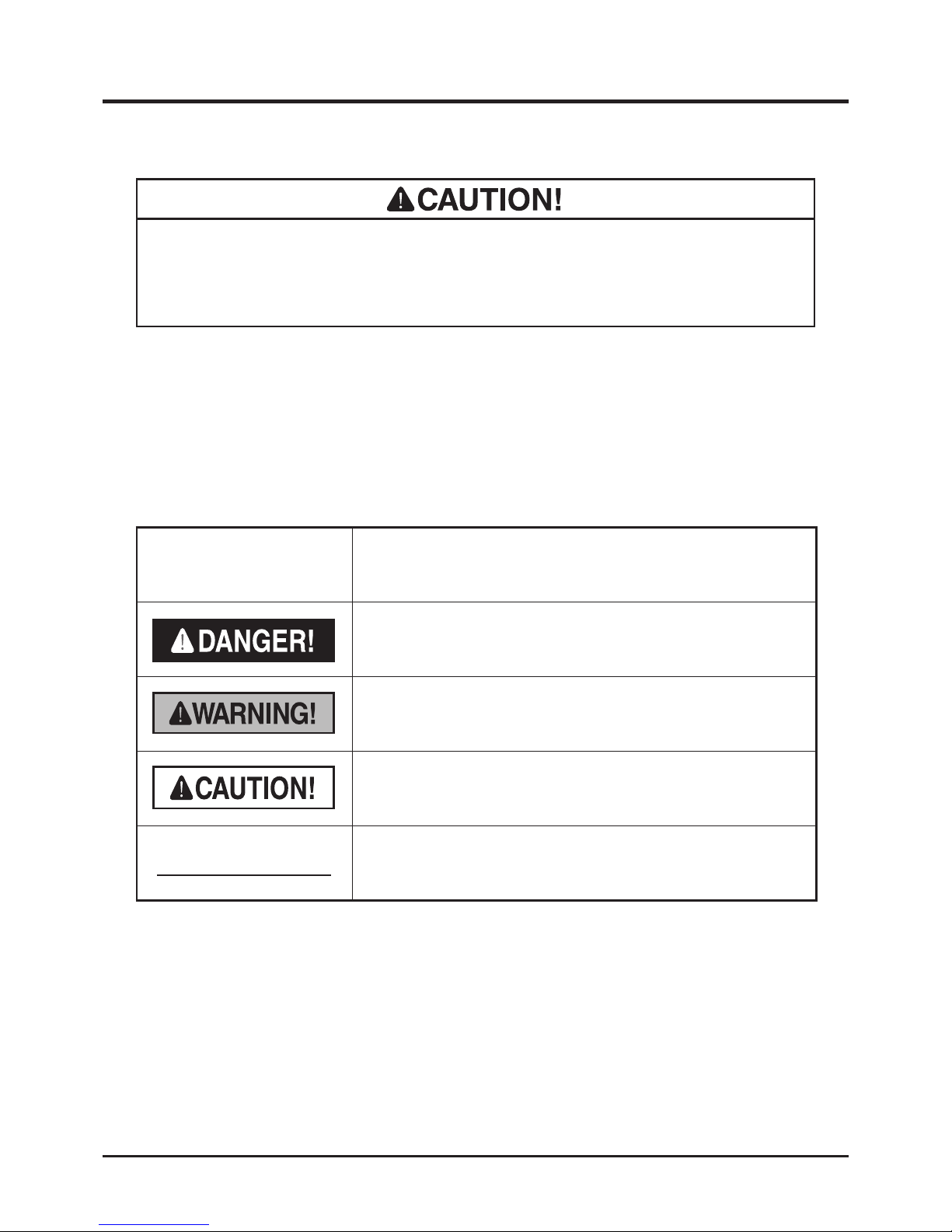

Warning Term Denition

Indicates an imminently hazardous situation which will result

in death or serious injury if the user does not follow the

procedures or the instructions.

Indicates a potentially hazardous situation which could result

in death or serious injury if the user does not follow the

procedures or the instructions.

Indicates a potentially hazardous situation which could result

in minor to moderate injury or damage to the machine if the

user does not follow the procedures or the instructions.

Indicates important information which needs particular

attention.

In this manual, the following four warning terms are used to signal the four levels of hazard (or

seriousness of possible accidents). Read and understand what they mean and always follow

the instructions in this manual.

Warning Terms Used in this Manual

NOTE

Notice to Owner

• Be sure that everyone who uses this machine, including those who rent or

lease this machine, receives a copy of this Operator's Manual and understands

the importance of reading and following the information in this manual.

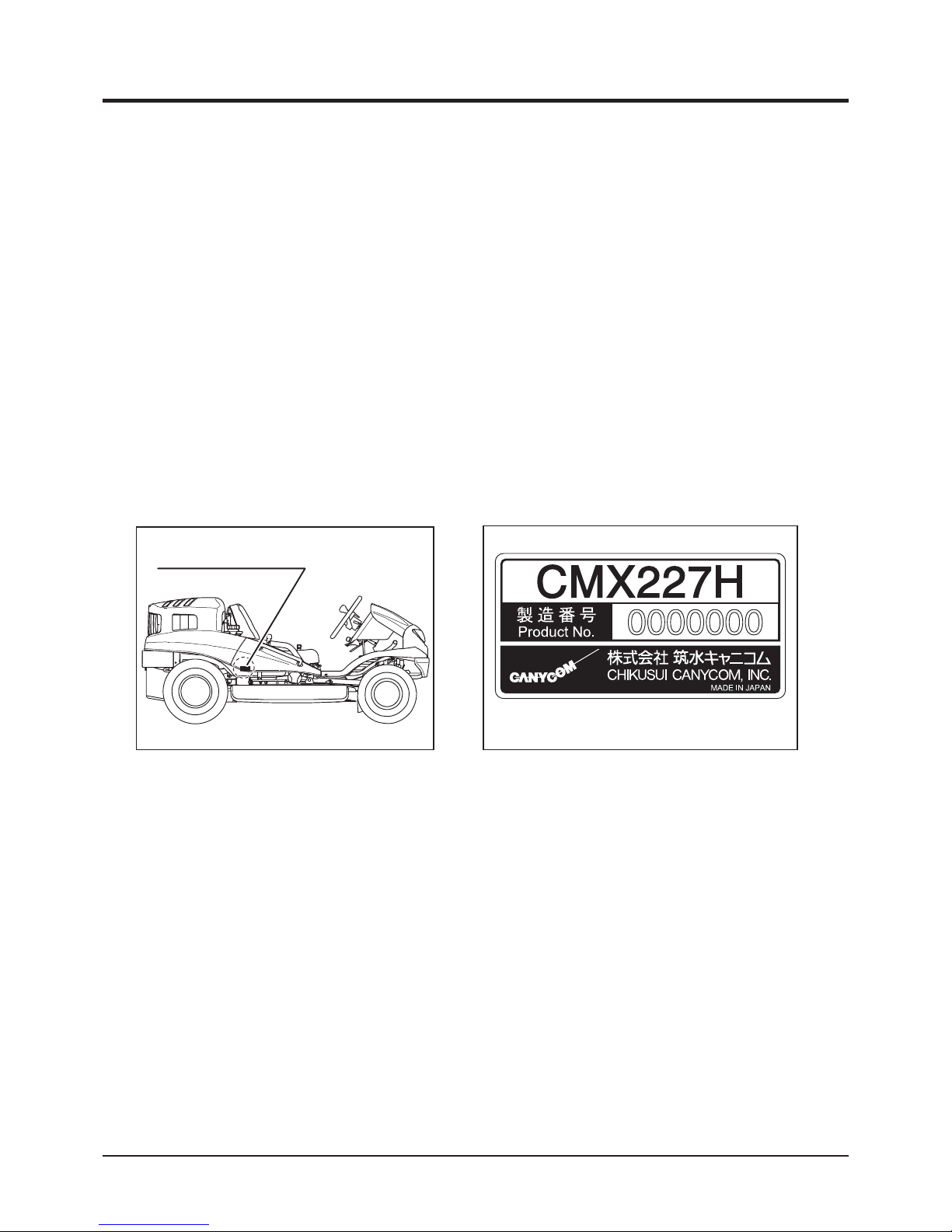

Location of Model Label

5332M-0005-010E

Location of Model Label

Model Label

5347M-0005-020E

The replacement or repair parts for this product shall remain available for seven years after

the production of this type of machine is discontinued.

Availability of Spare Parts

Warranty and After-Sales Service

CHIKUSUI CANYCOM, INC. guarantees this product, based on the terms of warranty.

Warranty

Consult your local CANYCOM dealer or our company’s sales department regarding service

orders or any questions or problems that may arise when using this machine. Please make

sure to have the product name, serial number, and the make and type of engine handy at

the time of contact. The model and serial number can be found on the model label as shown

below, and the make and type of the engine can be found in Chapter 3 "Specications" of

this manual (Page15).

After-Sales Service

Contents

1. Safety 1

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Mechanisms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2. Controls and Components 11

Name and Function of Controls . . . . . . . . . . . . . . . . . . . 11

3. Specications 15

Product Specications . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Contents of Tool Bag . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4. Operation 17

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Pre-start up Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Checking and Filling Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Adjusting Steering Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Adjusting Seating Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Adjusting Drive Pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Shifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Shifting Between 2WD and AWD (AWD models) . . . . . . . . . . . . . . . . . . . . . 31

Locking Differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Parking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Inspecting Cutting Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Adjusting Cutting Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Cutting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5. Maintenance 41

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

List of Fluids and Lubricants . . . . . . . . . . . . . . . . . . . . . 45

Greasing Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Greasing Points (CMX227H / CMX186H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Greasing Points (CM226H / CM185H) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

List of Consumables and Spares . . . . . . . . . . . . . . . . . . 48

Removing and Installing Body Panels . . . . . . . . . . . . . . 50

Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Head Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Engine Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Lower Rear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Seat Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Cutting Blade Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Oil Filter Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Spark Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Drive Train . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Tires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Transmission Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Front Axle Oil (AWD models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

HST (Hydrostatic Transmission) Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Parking Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Cutting System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Cutting Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Cutting Rotary Drive Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Cutting Rotary Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Light Bulbs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

After Use Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Cutting System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

After Normal Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

After Cold Weather Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

6. Troubleshooting 82

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Warranty

Warranty Certicate is attached at the end of this manual.

* Have the warranty certicate signed after you have received and fully understood

the instructions for handling this machine and received the receipt.

Appendix

• Operator's Manual for the Engine

* Be sure to read and understand it together with this manual .

7. Transporting 87

Hauling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Loading and Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Hoisting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Noise and Vibration Levels

Noise and vibration levels are stated in the end of this manual.

Safety 1

-1-

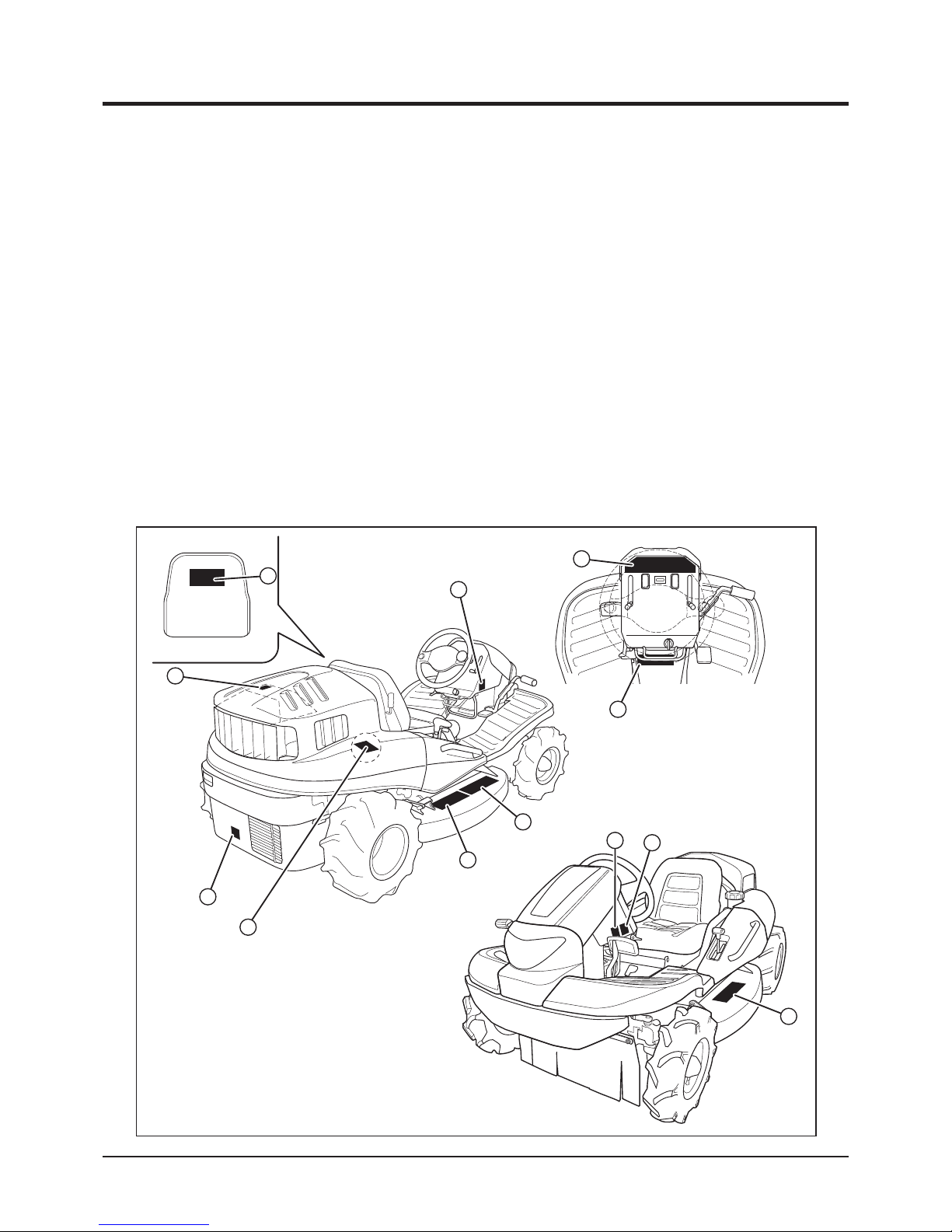

Safety Labels

The safety labels shown on the next page are attached to the machine. See the illustration

below for the location and the illustration on the next page for the content of each label on

the machine.

• Locate all the warning labels attached to this machine. Read and follow the instructions

and precautions in them. Failure to do so could result in serious injury or death to the

operator or bystanders.

• Keep the labels clean and legible. Do not use solvents or gasoline to clean the labels.

• Replace these labels immediately if they have been removed, have fallen off or become

illegible. Use the part number, on the label or shown in this manual, to order a replacement

label from your CANYCOM representative.

5

2

4

3

6

8

6

10

9

1

7

5347M-0101-010E

(Models with the

Charge-pump only)

CMX227H and

CMX186H

11

Safety

-2-

1

5332 5127 0008

5332 5127 000

10

5347 5109 000

1

5332 5121 000

3

5332 5122 000

4

5332 5128 000

5

5321 5116 000

6

3667 5063 000

11

5347 5114 000

2

5347M-0101-020E

5305 5326 0007

5335 5125 000

9

Safety 1

-3-

Safety Mechanisms

This product is equipped with the following safety mechanisms.

Engine can be started only when parking brake is in [ (engaged)] position and cutting

rotary clutch in [OFF] position. This is to prevent unintended movement of machine or cutting

blade when starting engine.

Start Interlock Mechanism

Engine stops if operator is not seated while cutting blade is rotating. This is to reduce the

possibility of accident related to moving blade when machine is turned over.

Automatic Blade Stopping Mechanism

Safety

-4-

1

This section contains safety precautions to follow when operating and maintaining the

machine. Read and understand the precautions in this section as well as throughout this

manual and follow them when operating or maintaining the machine. Failure to follow safety

precautions could result in property damage, serious injury or death to the operator or

bystanders.

Safety Precautions

All operators and mechanics should receive practical instructions from their employer or

renter. Such instructions should cover the following issues:

• It is essential to familiarize yourself with the controls, safety labels and the proper use of

the machine.

• Never allow people unfamiliar with these instructions to operate or service the machine.

Do not let anyone under 18 years of age to operate this machine. Local regulations may

restrict the minimum age for operating the machine. Consult your local authority.

• The operator is responsible for the accidents or hazards caused to other people or their

property.

• This machine has a riding capacity for one person only. Do not carry passengers other

than the operator.

• Observe the weight limit of this machine: 120kg.

• Always keep in mind that care and concentration is required when working with ride-on

machines.

• Loss of control on a slope cannot be regained by the application of the brake. The main

reasons for loss of control are:

→ insufcient grip of tires.

→ excessive speed.

→ misjudging of the ground conditions, especially slopes.

Training

Safety 1

-5-

• Fuel is highly ammable. See Checking and Filling Fuel, page 17, for important safety

information on handling fuel.

• Always wear protective footwear, long trousers, hardhat, safety glasses and ear protection

when operating or servicing the machine. Proper clothing will minimize the chance of

injury. Do not operate the equipment if you have long hair, loose clothing, or jewelry; all of

which may get tangled in moving parts. Do not operate the machine barefoot or with open

sandals.

• Prepare beforehand the working rules and procedures such as signaling and trac control

for the work place. Following such rules will reduce the risk of accidents.

• Never handle fuel or grease, service the engine, or recharge the battery in the presence of

re or spark.

• Perform the daily pre-startup inspection (see Preparation, pages 17) before starting the

machine. Repair or replace damaged parts before starting the machine.

Preparation

Safety

-6-

1

Operation

• Do not operate the engine in a conned space where dangerous carbon monoxide fumes

can accumulate.

• Do not touch the engine, mufer or exhaust pipe while the engine is running or soon after

it has stopped. These areas will be very hot and can cause burns.

• Do not operate the machine under the inuence of alcohol or drugs. Do not operate the

machine when you are tired, ill, or not feeling well.

• Always check for obstacles before operating on new terrain. This includes overhead

obstacles such as the branches of a tree.

• Before starting the engine and moving the machine, scan around your surroundings and

make sure all persons and other vehicles are a safe distance away from the machine.

• On a slippery surface, travel slowly and exercise caution to reduce the chance of skidding

or sliding out of control. Never operate on ice.

• Always make certain that there is no obstacle or a person behind the machine when

backing up. After conrming that it is safe to back up, move slowly and avoid sharp turns.

• To reduce the risk of tip over, pay special attention when encountering an obstacle or a

slope, or when braking on a slope or during a turn. See Driving on a Slope on page 8.

• Never attempt to drive over a large obstacle such as rock or fallen tree.

This machine is intended for cutting grass and bushes. Any other use may pose hazard or

cause damage to the machine.

The stability of the machine is affected by the speed, rate of steering, terrain and the

operator's weight. Always pay close attention to these factors or a loss of control or tip over

could occur, resulting in property damage, serious injury or death.

General Driving

Safety 1

-7-

• Always travel slowly and use extra caution when operating on unfamiliar terrain. Be alert

when traveling on changing terrain.

• Never operate on terrain that you are not comfortable with. Avoid terrain that is so rough,

slippery or loose that you feel like you could tip over.

• Do not operate the machine near the edge of a cliff, an overhang or a slide area. Pay

special attention after heavy rain or earthquake.

• Do not make sudden maneuvers. A sudden start, stop, or turn can make the machine lose

control and could cause a tip over. Be especially cautious when traveling on soft or wet

ground.

• Drive at a safe speed, taking into account the surface gradient, surface conditions and

load.

Safety

-8-

1

Driving on a Slope

• Always follow proper procedures for driving on a slope as described in this manual.

• Driving on a slope in a wrong manner can cause a loss of control or a vehicle tip over.

Check the terrain carefully before attempting to drive on a slope.

• Never drive on a slope that you are not comfortable with. Avoid a slope that is so rough,

slippery, or loose that you feel like you could tip over.

• When driving up a slope, proceed at a steady rate of speed and throttle position.

• Never move the throttle lever, the drive lever, the drive pedal or the steering wheel

suddenly.

• If the engine stalls or loses traction during a climb and cannot make it to the top of the

slope, do not try to turn the machine around. Carefully back down slowly, straight down the

slope.

• Drive straight up or down slopes. Avoid turning on a slope.

• When going over the top of a slope, go slow; an obstacle, a sharp drop, or another vehicle

or person could be on the other side of the crest.

• Avoid driving the machine across a slope.

• Before driving down a slope, stop and shift auxiliary transmission to [L (low)] position. Drive

slowly. Use the engine speed to help keep the machine speed low.

• Never use on a slope steeper than 25 degrees for the CMX227H and the CMX186H,

and 15 degrees for the CM226H and CM185H.

• Driving on a slope can be dangerous. It can result in a tip over and cause serious

injury or death. Take the following precautions.

Safety 1

-9-

Cutting

When conducting cutting operation, take the following precautions.

• Always follow the proper procedures for cutting as described in this manual.

• Shutt off the work site. Post signs to inform of the cutting operation. Close off the site with

rope if necessary to keep people, especially children, off the work site.

• Pay attention to the surrounding area. Rotating cutting blade throws stones, rocks and

debris. This may cause property damage, injury, or death.

• Drive forward when cutting. This best prevents the cutting blades from throwing stones,

rocks, or debris.

• Pay attention to obstacles. This includes overhead obstacles such as the branches of a

tree.

Parking

• Park the machine on a at, level and stable surface. Never park on a slope steeper than

10 degrees. Avoid parking on a slope less than 10 degrees. If parking on a slope less than

10 degrees is absolutely unavoidable, apply the parking brake and block the wheels at the

lower end of the machine.

→ Park the machine facing uphill

→ Do not park sideways on a slope.

• Never park on an instable surface. Do not park near the edge of a cliff.

• Observe all the previous precautions for driving, driving on a slope, loading .

• Whenever you park the machine, apply the parking brake and stop the engine. Remove

the key whenever you leave the machine unattended to prevent unauthorized use or

accidental starting.

• Gasoline is extremely flammable and can be explosive. When parking the machine

indoors, make certain that the building is well ventilated and that the machine is not close

to any source of ame or spark, including appliances with pilot lights.

Safety

-10-

1

Servicing

• Do not service the machine when the engine is running. If it is absolutely necessary to run

the engine while servicing, pay attention to the moving parts.

• Do not operate the engine in a conned space where dangerous carbon monoxide fumes

can accumulate.

• Make sure all hydraulic line connectors are tight and all hydraulic hoses and lines are in

good condition and leak-free.

• Keep your body and hands away from pinhole leaks or nozzles that eject hydraulic

uid under high pressure. Use paper or cardboard, not your hands, to search for leaks.

Hydraulic uid escaping under pressure can have sufcient force to penetrate the skin and

cause serious injury.

• Check all fuel lines on a regular basis for tightness and wear. Tighten or repair them as

needed.

• If the engine must be running to perform a service, keep hands, feet, clothing and any

part of the body away from any moving part, especially the cooling fan and the belts at the

back of the engine.

• Do not touch the engine, mufer, or exhaust pipe while the engine is running or soon after

it has stopped. These areas will be very hot and can cause burns.

• The engine must be shut off before checking or adding oil.

-11-

Controls and Components 2

Name and Function of Controls

Steering Wheel

Cutting Blade

Shield, Right

Rear Lamp

(AWD Models Only)

Rear Tire

Engine Hood

Plastic Bottle Holder

Side Cover, Right

Rear Bumper

Lower Rear Cover

Forward

Fuel Filler Cap

Cutting Blade Shield, Left

Tool Box

(Under Front Cover)

Front Cover

Front Tire

Head Lamp

Side Cover, Left

Handrail

5347M-0201-010E

Seat

Front Bumper

Controls and Components

-12-

2

15

1816

6

7

8

910

2

1

3

14

13

4

5

11

12

17

5347M-0201-020E

-13-

Controls and Components 2

1 Main Switch . . . . . . . . . . . . . Main switch is used to start or stop engine.

2 Choke Knob . . . . . . . . . . . . . Choke Knob is used to help start engine by closing choke

valve.

3 Throttle Lever . . . . . . . . . . . Throttle lever is used to control engine speed.

4 Drive Pedal . . . . . . . . . . . . . . Drive pedal is used to control the traveling direction and

speed of the machine. Machine moves forward when the

front of drive pedal is depressed and backward when

the rear of drive pedal is depressed. Angle of drive pedal

determines the speed.

5 Drive Lever . . . . . . . . . . . . . . Drive lever is used to control the traveling direction and

speed of machine. Machine moves forward when lever is

tilted forward and backward when lever is tilted backward.

Angle of drive lever determines the speed. (On the right

lever model, this lever is on the right -hand side. See

illustration.)

6 Brake Pedal. . . . . . . . . . . . . . Brake pedal is used to stop machine. When brake pedal

is depressed, drive lever returns to neutral position and

brake is engaged. (On the right lever model, this lever is

on the right -hand side. See illustration.)

7 Parking Brake Lock . . . . . . . Parking brake lock lever is used when parking machine

securely. Pulling parking lock lever while brake pedal is

depressed locks brake pedal. (On the right lever model,

this lever is on the right -hand side. See illustration.)

8 Auxiliary Transmission . . . . Auxiliary transmission shift lever is used to shift auxiliary

transmission to change the speed of the machine.

9 2WD/AWD Shift Lever . . . . . 2WD/AWD shift lever is used to switch between 2WD

(rear-wheel drive) and AWD (all-wheel drive) modes.

Lever

Shift Lever

(on AWD models)

Controls and Components

-14-

2

10 Differential Lock Lever . . . . Differential lock lever is used to lock differential when rear

wheels slip. Tilting differential lock lever to [ON] position

locks differential.

11 Cutting Height Adjust . . . . . Cutting height adjust lever is used to adjust the cutting

height. Grab and hold cutting height adjust lock and move

cutting height adjust lever back or forth to adjust cutting

height.

13 Cutting Rotary Clutch . . . . . Cutting rotary clutch lever is used to start or stop rotating

cutting rotary.

14 Tilt Lever . . . . . . . . . . . . . . . . Tilt lever is used to adjust the angle of steering wheel.

15 Head Lamp Switch . . . . . . . . Head lamp switch is used to turn on or off head lamp.

When umain switch is on, head lamp switch illuminates.

16 Tail Lamp Switch . . . . . . . . . Tail lamp switch is used to turn on or off tail lamp. When

umain switch is on, head lamp switch illuminates.

17 Fuel Gauge . . . . . . . . . . . . . . Fuel gauge indicates the amount of fuel in fuel tank.

18 Hour Meter . . . . . . . . . . . . . . Hour meter indicates the cumulative total operating time of

the machine in 0.1 hour increments.

(AWD models Only)

12 Cutting Height Adjust

Lever

Lock

Lever

-15-

Specications 3

Product Specications

Model and Type

CMX227 CM226 CXM186 CM185

Machine Mass kg

350 330 330 325

Mowing Rate m

2

/h 7300

*1

7000

*1

Dimensions

Overall Length mm

1947 [1997]

*2

1947

Overall Width

mm

1020

Overall Height mm

860 [905]

*3

840

Wheelbase

mm

1300

Tread

Front

mm

860

Rear

mm

800

Ground Clearance

mm

130 110

Engine

Model Robin EH65DS Robin EH63DS

Type Air-cooled 4-cycle V-twin Gasoline

Cylinder (Bore×Stroke)

mm

80X65

Displacement cm

3

653

Maximum Output kw(PS)/rpm 16.4(22)/3600 13.4(18.3)/3600

Maximum Torque

N•m(kgf•m)/rpm

45.6(4.65) 43.3(4.42)

Starter System Electric

Fuel Automotive Unleaded Gasoline

Fuel Consumption

g/kW•h(g/PS•h)

310 (230)

Fuel Tank Capacity L 20

Ignition Contactless Magneto

Spark Plug NGK BPR5ES

Electrical

Battery Type 40B19R

Battery Capacity V/Ah 12/28

Performance

Speed

High

km/h

0 to 13.8 0 to 12.8

Low

km/h

0 to 7.7 0 to 7.2

Minimum Turning Radius m 1.8

Gradeability Degrees 25 15 25 15

Stability

Angle

Left Degrees 30

Right Degrees 30

*1 Estimated at the maximum speed with the auxiliary transmission in Low position (7.5km/h)

*2 [ ] indicates the Step Bumper model

*3 [ ] indicates the Extra Seat model

· Use this product properly after understanding its specications thoroughly.

Specications

-16-

3

Model and Type

CMX227 CM226 CMX186 CM185

Drive Train

Main Transmission

HST (Continuously

Variable)

Auxiliary Transmission

Constant Mesh

Tires

Left 4.00-7 (4PR) AGR 3.50-7 (2PR)

Right 17X8.00-8 (4PR) 16X7.00-8 (2PR)

Steering

mm

Rack and Pinion

Round Steering Wheel

Brakes Internally Expanding

Cutting System

Cutting Width

mm

975

Cutting Height

mm

0~150 (21 Steps) 0~130 (21 Steps)

Blade Type Free Knife & Stepped Stay

Number of Blades 2

Blade Drive Train Shaft Drive

*These specications are subject to change without notice.

No. Content Quantity Note

1 Operator's Manual 1 This Manual

2

Operator's Manual for the Engine

1

4 Engine Service Tool 1

for Servicing Engine

Contents of Tool Bag

-17-

Operation 4

• Keep re and spark away when handling fuel.

• Always stop engine before refueling.

• Do not fill beyond the limit (bottom of the filler filter) so that fuel will not

overow. In case fuel is spilt, wipe out immediately.

Pre-start up Inspection

Preparation

Always perform an inspection before use.

Refer to the Maintenance Schedule (page 41) for the inspection schedule and procedure.

Checking and Filling Fuel

1. Check fuel gauge. If fuel level is low, ll fuel.

5347M-0401-010E

Fuel Gauge

• Always perform an inspection before every use. If a problem is found, solve or

repair it before use.

• Clean the mowing dust before use to avoid re.

• Make sure the cooling air intake is not blocked or clogged. If it is blocked, the

engine overheats.

Operation

-18-

4

Adjusting Height

1. Pull top edge of front cover to unlock latch.

5347M-0401-040E

Latch

Front Cover

• After adjusting steering wheel, try moving steering wheel back and forth and up

and down to make sure it is securely locked in its position.

Adjusting Steering Wheel

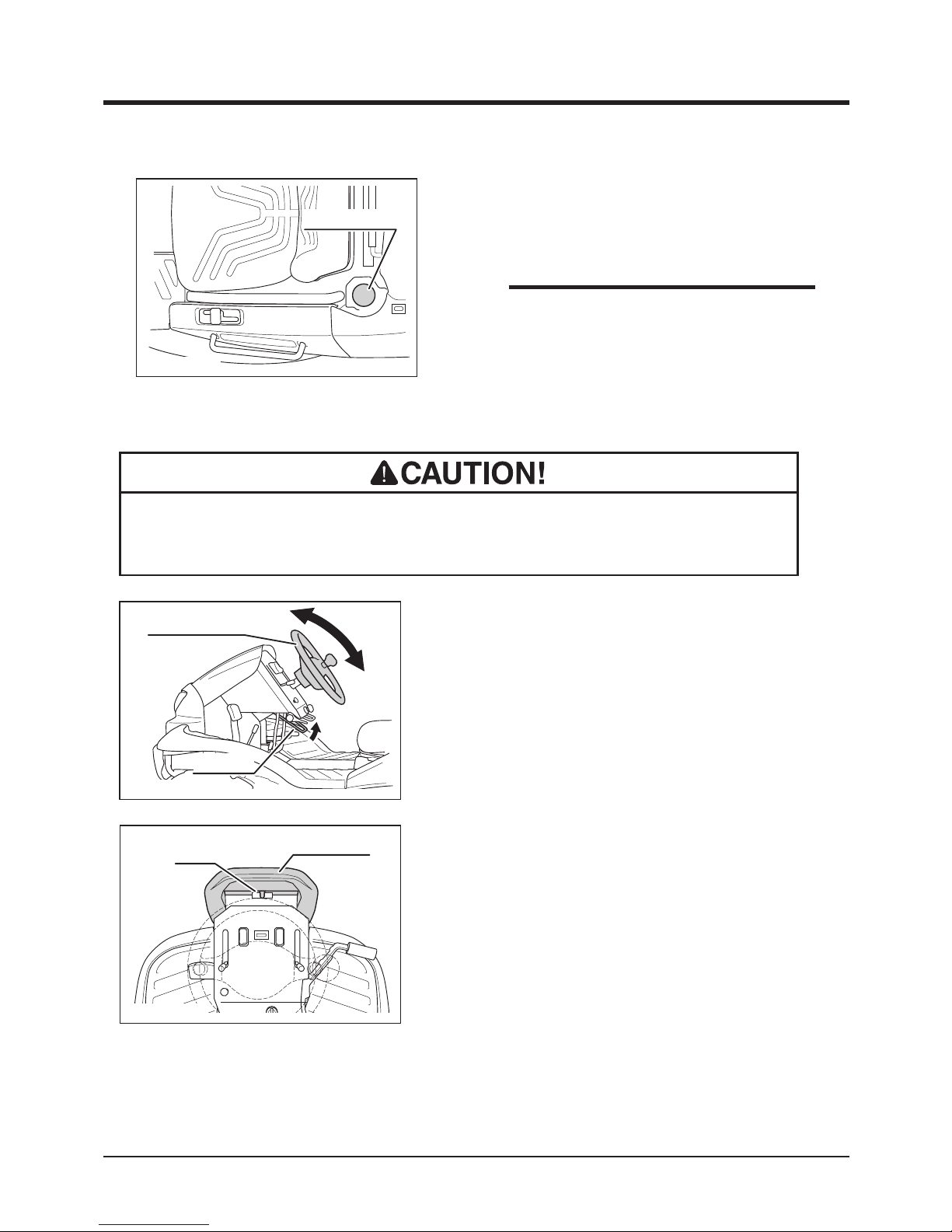

1. Pull up tilt lever to adjust steering wheel

angle.

2. There are five positions for steering wheel

angle.

3. After adjusting angle, return tilt lever to lock

steering wheel securely.

Adjusting Angle (Tilting)

5347M-0401-030E

Tilt Lever

Steering Wheel

2. Open fuel ller cap and ll fuel.

3. Put fuel filler cap back in place and close it

securely.

• Fuel : Automotive Unleaded Gasoline

• Fuel Tank Capacity : 20L

NOTE

5347M-0401-020E

Fuel Filelr Cap

-19-

Operation 4

5347M-0401-110E

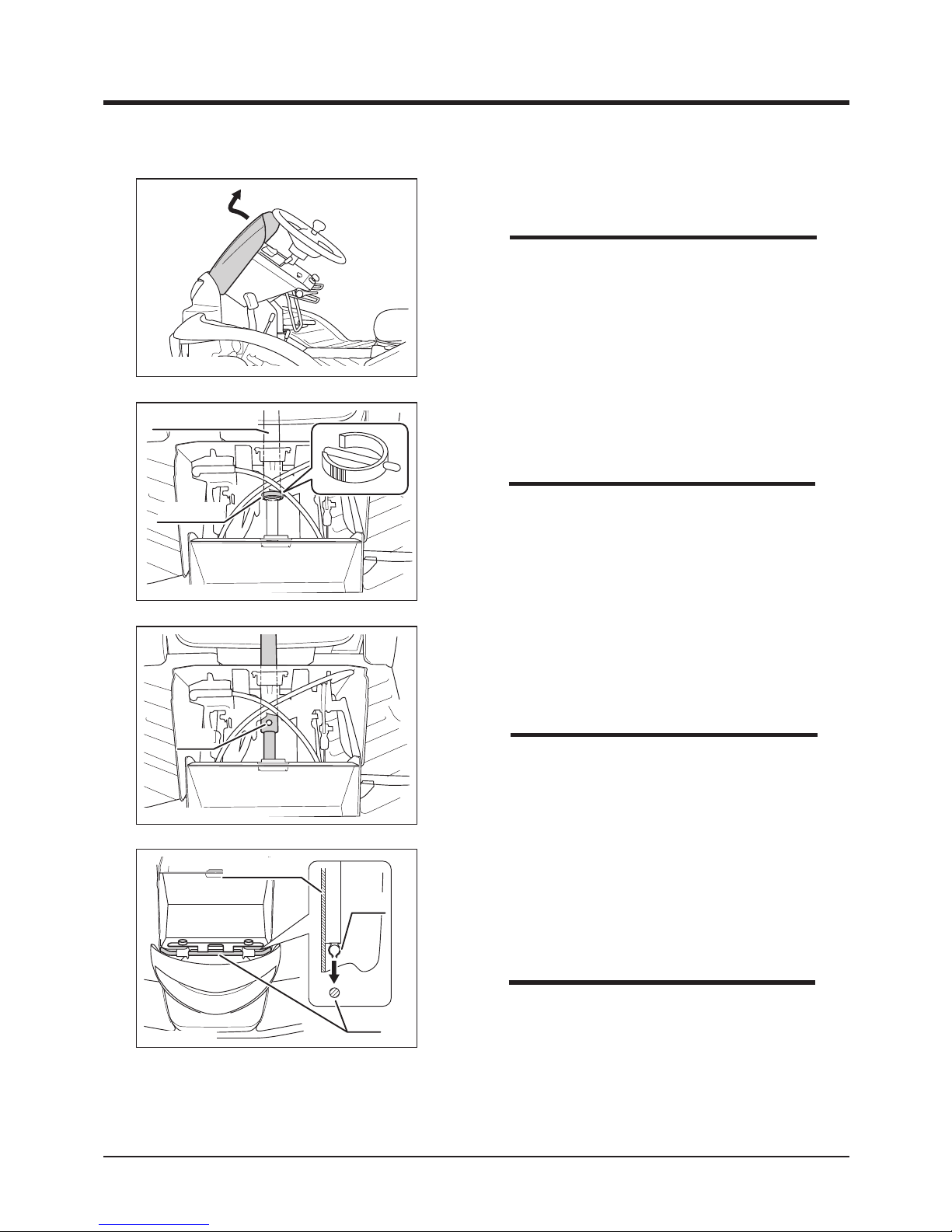

2. Pull out front cover.

• Inside of the front cover is made as tool

box. Use this box to store items such as

tools or substitute cutting blades.

5332M-0401-120E

Fixing Pin

Steering Column

3. Remove fixing pin from steering column in

the front of machine.

• If fixing ping is in the difficult direction to

remove, steer the steering wheel to change

direction of the pin so that the pin can be

easily removed.

NOTE

NOTE

5332M-0401-130E

Hole

4. Adjust steering wheel height in prefered

position. Line up holes on steering shafts and

insert pin.

• Move steering wheel up and down to check

if the steering wheel is xed securely.

5332M-0401-140E

Front Cover

Clip

Rod

5. Raise steering wheel angle.

6. Fit clip on back side of front cover into the

rod.

7. Latch top edge of the front cover.

• Pay attention not to catch the front cover by

the plate on both sides when installing front

cover.

NOTE

NOTE

Operation

-20-

4

1. Pull slide lever to the right to slide seat

forward or backward.

2. When seat is in a desired position, release

slide lever and lock seat securely.

Sliding seat

5347M-0401-050E

Slide Lever

Seat

• Beware of pinch points when adjusting seating position.

• After adjusting seat, try moving seat back and forth and up and down to make

sure it is securely locked in its position.

Adjusting Seating Position

5347M-0401-060E

Seat Suspension

Stiffness Adjust Lever

Adjusting Stiffness

1. Move seat suspension stiffness adjust lever

to adjust desired seat stiffness.

5347M-0401-070E

Reclining Adjust Knob

Adjusting Reclining Angle

1. Rotate reclining adjust knob on the right of

seat to adjust reclining angle of the seat.

• Do not ajust seat posision to the end and

recline the seat. The seat may contact with

rear cover. This may activate seat switch

and stop engine. Adjust seat within the

range of not contacting with rear cover.

NOTE

-21-

Operation 4

5332M-0401-080E

Safety Pin

Adjusting Height (Rear Part)

1. Slide seat to the rear-most position.

2. Pull up seat and push safety pin toward

inside to hold seat lifted.

• Move seat and to check if the seat is locked

securely.

• Height at the rear can be adjusted in 4 levels

(2 for the Oceania version).

• Seat switch b r ac k e t is mounted i n the

hei g hest po si tion whe n shi pped fr o m

factory.

NOTE

Adjusting Height (Front Part)

1. Pull up seat and push safety pin toward

inside to hold seat lift up.

Height of seat at front can be set in one of two positions.

• Height of seat at front is set at the high position when shipped from the factory.

• Seat switch bracket needs to be in the highest position when setting the front in

high position.

NOTE

5347M-0401-150E

Bolt

Front Hole

Seat hinge Bracket

2. Remove 2 bolts that mount seat hinge

bracket. This bracket holds the entire seat,

so make sure to hold seat when removing

bolts.

3. Turn around bracket and mount it to floor,

with bolts through front holes.

4. Pull back seat safety pin and lower seat.

Loading...

Loading...