CanyCom CM 230 Operator's Manual

CHIKUSUI CANYCOM, INC.

90-1 Fukumasu, Yoshii-machi,

Ukiha city, Fukuoka, Japan 839-1396

Tel. 81-(0)943-75-2195 Fax. 81-(0)943-75-4396

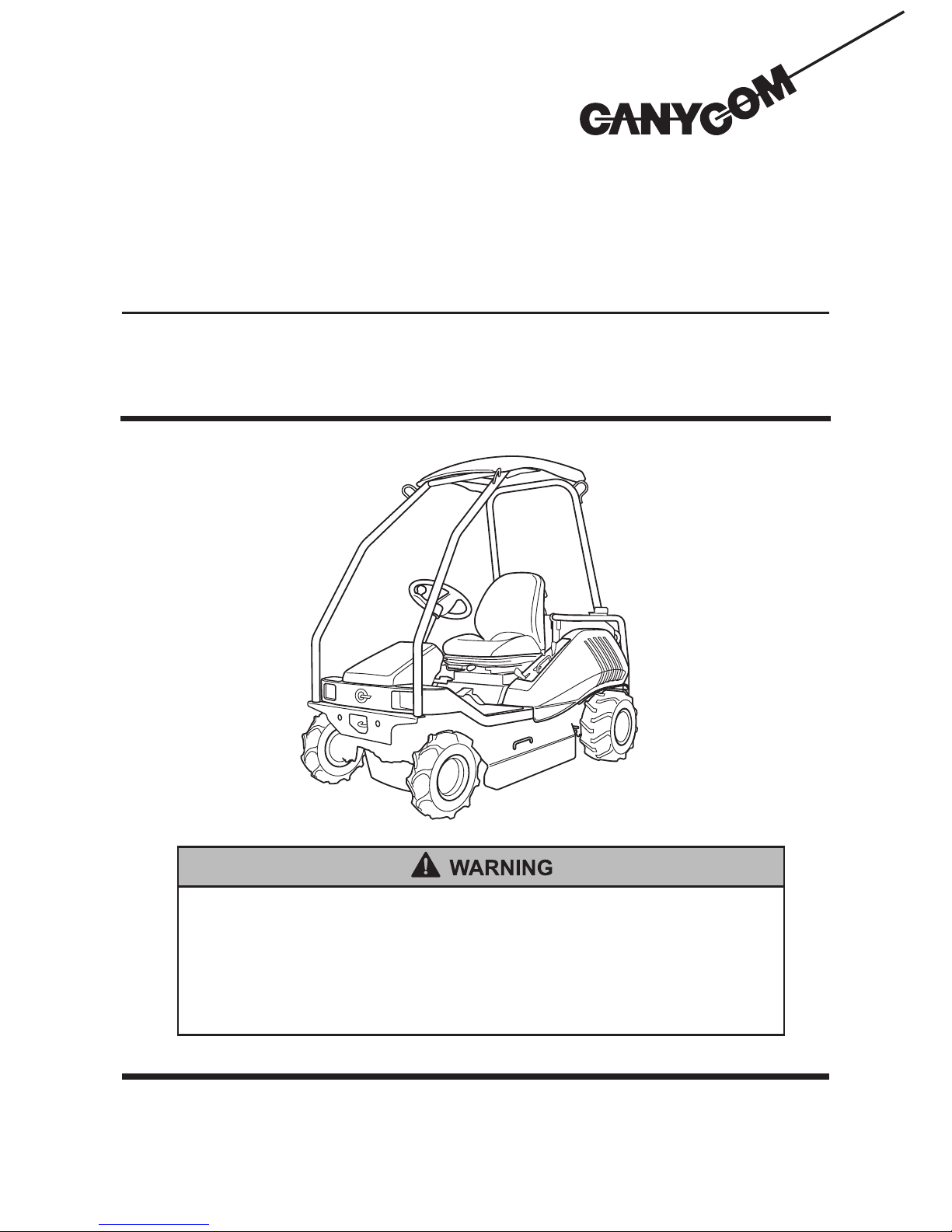

Ride-on Brushcutter

CM 230

OPERATOR'S MANUAL

October 2005, 5317 5201 000 01

* Read this manual completely before operating or maintaining this machine.

Failure to follow safety precautions could result in serious injury or death.

* Keep this manual for future reference for you and for all those who operate

and maintain this machine.

Memo of address and telephone number

(Name of dealer)

■

Sales Headquarters

0943(75)2195 FAX (75)4396

■

Foreign Trade Center

03(3552)6277 FAX (3552)6288

■

Tok y o Cente r

03(3552)6255 FAX (3552)6288

■

Sendai Center

022(281)1255 FAX (281)3141

■

Saitama Center

0495(77)4511 FAX (77)1561

■

Osaka Ce nter

0790(42)6031 FAX (42)6035

■

Hiroshima Center

0824(34)5996 FAX (34)5997

■

Matsuyama Center

089(983)2701 FAX(983)5749

■

Fukuoka Center

0943(76)2583 FAX (75)5126

■Kagoshima Center 0995(58)3011 FAX (58)2344

CHIKUSUI CANYCOM, INC.

We prohibit unauthorized reprinting and reproduction of this document.

Contents

Introduction 1

Introduction …………………………………………………… 1

Safety Rules 2

Safety Declaration

……………………………………………

2

Safety Operation (B71.4) …………………………………… 2

Training ……………………………………………………………………………… 2

Preparation …………………………………………………………………………… 2

Operation……………………………………………………………………………… 3

Maintenance and Storage …………………………………………………………… 4

Rules for Safe Operation and Work ………………………… 5

Safety Precautions Before Operation ……………………………………………… 5

Do Not Start, Accelerate, Turn, or Brake Quickly ………………………………… 6

Safety Precautions When Operating

………………………………………………

7

Precautions When Parking ………………………………………………………… 8

Precautions When Performing Maintenance ……………………………………… 9

Inclination measuring Gage …………………………………10

Warning Words Used in This Manual ……………………… 11

Explanation of Warning Labels on the Machine…………… 12

Specications 15

Specications

…………………………………………………

15

Gasoline and Oil 17

Explanation of Gasoline ……………………………………… 17

Recommended Gasoline ………………………………………………………… 17

Refueling fuel tank ………………………………………………………………… 18

Explanation of Oil

……………………………………………

19

Recommended Oil ………………………………………………………………… 19

Inspecting Engine Oil ……………………………………………………………… 19

Preparation 20

Details of Attachments ………………………………………20

Preparation for Starting ………………………………………20

Adding Grease and Oil …………………………………………………………… 20

Inspecting Engine Oil ……………………………………………………………… 21

Inspecting HST Oil

…………………………………………………………………

22

Checking Tire Pressure ………………………………………………………… 23

Checking Rotary Height ………………………………………………………… 23

Checking Grass Chute Cover …………………………………………………… 24

Operation 25

Observance of Safety First …………………………………25

For Use of ROPS ……………………………………………25

Component Names and Functions …………………………26

Location

……………………………………………………………………………

26

Component Names Functions and Operations ………………………………… 27

How to Drive ………………………………………………… 28

How to Adjust Seat………………………………………………………………… 28

How to Apply Parking Brake……………………………………………………… 28

Explanation of Safety Interlock…………………………………………………… 28

Starting……………………………………………………………………………… 29

Operating…………………………………………………………………………… 33

Stopping …………………………………………………………………………… 35

How to Perform Work…………………………………………37

Checking Cutting Blades ………………………………………………………… 37

Adjusting Blade Height …………………………………………………………… 37

Working Procedure

………………………………………………………………

38

Transportation …………………………………………………41

Loading …………………………………………………………………………… 41

Lifting by Crane …………………………………………………………………… 42

Emergency Transferring ………………………………………………………… 43

Maintenance 44

Periodic Check Sheet ………………………………………44

Fuel / Grease / Lubricant / Fluid Chart ……………………47

Consumable (Replacement Parts) Chart …………………48

Engine …………………………………………………………49

Inspecting, Adding and Replacing Engine Oil

…………………………………

49

Replacing Engine Oil Filter ……………………………………………………… 51

Cleaning and Replacing Air Cleaner …………………………………………… 52

Cleaning Cooling System ………………………………………………………… 53

Inspecting, Cleaning, and Replacing Ignition Plug …………………………… 53

Fuel System

……………………………………………………

55

Draining Fuel ……………………………………………………………………… 55

Inspecting Fuel Filter ……………………………………………………………… 56

Hydraulic System ……………………………………………57

Inspecting, Adding and Replacing HST Oil

……………………………………

57

Replacing HST Oil Filter ………………………………………………………… 59

Running System ………………………………………………60

Inspecting, Adding and Replacing Transmission Oil…………………………… 60

Replacing Differential Oil and Knuckle Oil ……………………………………… 61

Inspecting and Adjusting Driving V-Belt ………………………………………… 62

Adjusting Brake Pedal …………………………………………………………… 62

Checking Tire Pressure ………………………………………………………… 63

Checking Wheel Bolts …………………………………………………………… 63

Electrical Equipment …………………………………………64

Inspecting Battery Electrolyte and Adding Water ……………………………… 64

Charging Battery

………………………………………………

65

Electric Circuit Diagram ………………………………………67

Cutting Unit ……………………………………………………68

Opening Grass Chute Cover …………………………………………………… 68

Inspecting and Replacing Cutting Blades

………………………………………

69

Inspecting and Adjusting Rotary Driving V-Belt………………………………… 71

Inspecting and Adjusting Rotary Cutter Brake ………………………………… 71

Lubrication and Greasing ……………………………………73

Disposal of Waste ……………………………………………73

Storage 74

Maintenance After Use ……………………………………… 74

Maintenance After Use in Normal Conditions ………………………………… 74

Maintenance After Use in Cold Season ………………………………………… 74

Long-Term Storage…………………………………………… 75

Troubleshooting 76

Troubleshooting ……………………………………………… 76

Guarantee and After-Sales Service 79

Guarantee and After-Sales Service …………………………79

Guarantee

…………………………………………………………………………

79

After-Sales Service ……………………………………………………………… 79

Availability of Replacement Parts ……………………………………………… 79

-1-

Introduction 1

Location of model label

5317M-0101-010-E

Please read this manual to completely understand the machine operation and maintenance

procedures before using the machine. Following this manual’s instructions may help avoid

human injury and mechanical damage. This machine has been designed and manufactured

with due regard to safety. Operators and service staff however, should also take safety

precautions when working with this machine. For service, genuine parts, or questions about

the machine, consult the dealer from whom you purchased the machine. Tell the dealer the

machine model and product numbers indicated on the model label, as shown below.

Write the model and product numbers in the table below for easy future reference.

Introduction

Location of Model Label Model Label

Machine identification table

Model

Product No.

5317M-0101-020

Introduction

Safety Rules

-2-

2

This machine meets the requirements of ANSI B71.4 2004, which was being valid at the time

it was manufactured. The ROPS installed in the machine meets the requirements of SAE

J2194 Standard, and the ROPS conforms to the requirements of OSHA1928.52.

Safety Declaration

* Operating this machine equipped with one or more attachments produced by

any other manufacturer will not meet the requirements of the ANSI standard.

Improper use and insufficient maintenance may cause damage to the owner

or operators of the machine. In order to avoid accidents, observe safety

operations, especially descriptions with the warning symbol "!". Not complying

with these warnings may result in serious injury or death.

Safety Operation (B71.4)

1. Read and understand the manuals and other educational material. The owner of the

machine is responsible for explaining the contents of these documents to his operators

and maintenance staff who do not understand English.

2. Read and understand the safety operation and warning labels pasted on the machine.

3. All operators and maintenance persons must be trained. The owner of the machine is

responsible for training people all staff who will work with this machine.

4. Children or untrained people should never operate or maintain this machine. Local

ordinances regulating the operator’s age limits should be observed.

5. The owner and operators of the machine are responsible for protecting people and

property from any accidents and injuries during operation.

Training

1. Check the operating area before deciding the accessories and attachments required

for safe operation. Only use accessories and attachments approved by CHIKUSUI

CANYCOM, INC. (hereafter called “Manufacturer”).

2. The operators of the machine must wear proper protective clothing including safety

helmets, protective glasses, ear plugs, etc. Long hair, loose clothes, jewelry or other

accessories which could be caught in rotating parts should be removed or secured.

3. Before using the machine remove all obstacles from the operating area (stones, toys,

wires, etc.) which could be thrown by the machine or cause damage to the machine.

4. Handle gasoline or other fuels with extreme care to avoid flame and explosion risks.

a. Only use certified containers for storing and transporting fuel.

b. Never start the engine when the fuel tank cap is removed or during refueling. Do not

Preparation

Safety Rules

-3-

Safety Rules 2

1. Do not start the engine in a closed space.

2. Operate the machine in an area that is free from holes and dangerous material and where

operator can maintain good visibility.

3. Put the driving system into neutral and apply the parking brake before starting the engine.

Start the engine with operator sitting in the operator’s seat. Fasten the seat belt after

starting engine.

4. Reduce speed when operating the machine on inclined areas. Move the machine in

recommended directions on inclined areas. The grass condition affects the stability of the

machine. Use special care when operating the machine on areas where there is a risk of

turnover.

5. When changing driving direction on inclined areas. Reduce speed and use extreme care.

6. Never open the rotary cutter cover when the rotary cutter is rotating.

7. Always attach and close cutter cover before driving and grass cutting.

8. Do not change the adjusted position of the engine governor and do not increase the

rotation speed of the engine.

9. When parking the machine, park on level ground, disconnect the rotary cutter from the

driving system, and apply the parking brake. Leave the operator’s seat after stopping the

engine, and remove grass choking the rotary cutter.

10. When a sudden impact or irregular vibration occurs in the rotary cutter during cutting,

stop the machine to check the cause operation. Confirm rotary cutter and machine are

not damaged before restarting the work.

11. Keep hands and feet off the rotary cutter unit.

12. Periodically check the machine rear and under carriage areas for potential problems.

13. Do not carry passengers on the machine and do not let people or pets stand close to the

machine during operation.

14. When driving the machine across a road or pedestrian crossing, reduce its speed and

use care. Stop the rotary cutter after ending cutting operations.

15. Do not direct the grass outlet toward people.

16. Do not drive and operate machine when under the influence of alcohol or drugs, or when

fatigued.

17. Use caution when loading or unloading the machine into or out of a truck or trailer.

18. Use caution when approaching corners, bushes, trees, and other obstacles where

visibility is poor.

Operation

smoke near machine during refueling.

c. Do not add or remove fuel indoors.

5. Confirm that the seat-adjusting device for the operator, safety switches, and shields are

installed and function properly before using machine. If they do not function properly, do

not operate the machine.

Safety Rules

-4-

2

1. Before maintaining or storing the machine, disconnect the running and cutting systems

from their driving units, apply the parking brake, and pull the ignition plug cord out. Before

storing the machine, adjust, clean, and repair the movable parts.

2. Remove remaining grass and foreign matter from the cutter blades and under carriage to

prevent fires.

3. Cool the engine completely and do not place any flammable material near the machine.

4. Park the machine on level ground. Any person not trained to handle the machine should

not maintain the machine.

5. Use jacks if necessary to raise machine.

6. Carefully relieve pressure from the pressurized parts.

7. Always remove the battery cords and ignition plug cords before repairing any part.

Remove the minus side first, and then the plus side. Install the plus side first, and then

the minus side.

8. Check the cutting blades with caution by covering the blades with proper material or

wearing protective gloves. When replacing the cutting blade, do not straighten or weld it.

9. Keep hands and feet off the moving parts. Do not make adjustments when the engine is

operating.

10. Charge the battery in a well ventilated area without sparks or flammable material nearby.

Pull the charger power plug out before connecting or disconnecting the charger to or from

the battery. Wear protective clothing and use insulated tools.

11. Keep all parts in clean, dry storage and ensure that they are correctly installed. Replace

all deteriorated labels with new ones.

Maintenance and Storage

-5-

Safety Rules 2

Rules for Safe Operation and Work

Perform the daily pre-operation check before

starting the machine.

Repair or replace damaged parts before starting

the machine.

Pre-work Check

This chapter shows the general safety precautions to be observed during driving or

operation. Try to carry out driving or operation safely by being sure to follow the safety

instructions in other chapters as well.

Do not handle fuel or grease, service the engine,

or recharge the battery while smoking or when

near an open flame.

Fuel Handling

Wear clothes suitable for driving and operating

the machine. Casual wear and sandals should not

be use for driving and operating. Wear protective

accessories such as protective helmets, shoes,

glasses, and gloves.

Wear proper clothes and protective

accessories

CM-01-030

CG-01-010

CM-01-020

Safety Precautions Before

Operation

Safety Rules

-6-

2

This machine has one seat only: the operator’

s seat. It is extremely dangerous to drive this

machine with passengers. Never allow a person

or persons other than the operator to ride on the

machine.

Do Not Carry Passengers on This Machine

Do not operate this machine when under the

influence of alcohol or drugs or when fatigued.

No one under age 18 should operate this vehicle.

Do Not Drive Recklessly

Before starting the machine, always confirm the

conditions of the operating area, and drive it at

a safe speed according to the inclination and

surface conditions of the operation area.

Observe Safety Speed

Drive safely and avoid sudden changes of speed

or direction. Make sure the area around the

machine is safe for driving. Do not make sudden

maneuvers or turn sharply when driving on soft or

wet ground; this can cause the machine to lose

traction or turn over.

CM-02-010

CM-02-020

CM-01-040

CM-01-050

Avoid Quick Starting, Accelerating,

Turning and Braking

Do Not Start, Accelerate, Turn,

or Brake Quickly

-7-

Safety Rules 2

Stop before driving downhill, shift the auxiliary

speed change lever to the “LOW” speed position,

and drive downhill at reduced speed.

Reduce Driving Speed going Downhill

Post notice boards before that operation to show

that job site is under operation. If necessary,

apply guard ropes to enclose and restrict access

so that people (especially children) may not enter

the work area and safety may be ensured.

Secure Area (No Admittance) During

Operation

Use care during operation to avoid throwing

stones and small objects that may be

dangerously toward nearby persons, animals,

crops, cars or other objects.

Beware of Flying Objects

Before performing cutting work, always check

holes and other obstacles in the operation area.

Use caution to avoid these obstacles.

Safety Precautions When

Operating

CM-03-010-E

Of

f Limit

CM-02-030

CM-03-020

CM-03-030

Caution for Holes and Obstacles

Safety Rules

-8-

2

Always travel straight up or down a slopes.

Never travel across slopes or along contour lines.

Driving across steep slopes or along contour lines

is dangerous and may cause the machine to tip

over, causing serious injury or death.

Beware of driving in trenches and on banks.

There is a danger of the ground crumbling due

to the machine weight. When travelling on soft

ground, drive slowly and safely.

Precautions on Crumbling Ground

When parking always apply brake and stop

engine. Always remove key.

Safety Actions When Parking

Park the machine on stable, level, flat surfaces.

Do not park on unstable or inclined surfaces.

Do Not Park on Unstable or Inclined

Surfaces

CM-03-040

CM-03-050

CM-04-010

CM-04-020

Precautions When Parking

Avoid Driving Across Slopes

-9-

Safety Rules 2

Avoid parking the machine on slopes. If there

are no other options, apply the parking brake

securely and block the wheels at the lower end .

Do not carry out maintenance with the engine

running. Always stop the engine before starting

maintenance.

When operating engine indoors, always ensure

that there is adequate ventilation to prevent

poisoning by exhaust gas.

Ventilate Properly When Operating

Indoors

Avoid Parking on Slopes

CM-04-030

CM-05-010

CM-05-020

Precautions When Performing

Maintenance

Never Carry Out Maintenance with Engine

Running

Safety Rules

-10-

2

Inclination measuring Gage

EXAMPLE:COMPARE

SLOPE WITH FOLDED EDGE

ALIGN THIS EDGE WITH A VWRTICAL SURFACE

(TREE,BUILDING,FENCEPOST,POLE ETC.)

THIS IS

A

5°SLOP

E

THIS IS A

10°SLOP

E

THIS IS A

15°SLOP

E

THIS IS A 20°SLOP

E

FOLD ALONG APPROPRIATE LINE

5317M-0204-010

Copy this page. Do not remove from this manual.

-11-

Safety Rules 2

Warning Words Used in This Manual

Signal word Meaning

In dicate s an i mmine ntly h a z ardous situ ation w hich, if not

avoided by following these instructions and precautions, could

result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided

by following these instructions and precautions, could result in

serious injury or death.

Indicates a potentially hazadous situation which, if not avoided

by following these instructions and precautions, may result in

minor or moderate injury.

This word is used for precautions that are recommended or to

emphasize the importance of information.

To indicate the level of danger (or the degree of the failure), the following four signal words

are used to identify the safety messages in this manual. Their meanings are as follows:

NOTE

* The machine can be very dangerous if the safety precautions in this manual

and on the labels attached to this machine are not followed. Always follow the

instructions and safety precautions or serious injury or death could result.

* This machine is a work vehicle for mowing. Do not use it for other purposes.

Any other use could be dangerous.

* Driving this machine on a public road or a road regarded as a public road may

be illegal, depending on local regulations.

* Do not modify this machine. Also do not remove the safety cover of the body

before running. A serious accident could result.

Safety Rules

-12-

2

Explanation of Warning Labels on the Machine

NOTE

*Replace these labels immediately if they have been removed, have fallen off, or have become

illegible. Use the part numbers on the label to order replacement labels from dealer.

5317M-0206-010

-13-

Safety Rules 2

1

2

3

4

5

6

7

5317M-0206-020-E

1211

Safety Rules

-14-

2

5317M-0206-030-E

5316 5003 000 5316 5004 000

-15-

Specications 3

* Read and understand specifications before using this product.

Specifications

Model CM230

Machine weight kg 490

Machine dimensions

Overall length mm 2170

Overall width mm 1110

Overall height mm 1840

Wheel base mm 1460

Tread

Front mm 810

Rear 900

Minimum freeboard mm 115

Engine

Model - Air-cooled 4-cycle gasoline

Type - KAWASAKI FH680V

Cylinder (Bore X Stroke) mm 75.2 × 76.0

Total displacement cm3(cc) 675 (675)

Maximum output

㎾

[ps] / rpm

17.2 [23] / 3600

Starting system Self-starter type

Fuel used Gasoline

Fuel tank capacity Liter 30

Ignition plug no. - NGK BPR4ES

Electrical

device

Battery type - 40B19R

Battery capacity V / AH 12 / 28

Travelling performance

Travelling speed

Low

km / h

0 - 6.0

High

km / h

0 - 9.0

Minimum turning radius m

1.9

Gradeability degree

25

Stability inclination

angle

Left degree

30

Right degree

30

test result

(standstill)

Left degree

42

Right degree

41

Specications

Specications

-16-

3

Model CM230

Power transmission

device

Main speed shift HST (Hydrostatic) drive

Steering device - Rack and pinion type round steering wheel

Brake type - Internal expanding type brake

Tire

Front wheel

- 4.00-7

Rear wheel

- 17 × 8.00-8

Cutter blade

Blade type mm Free knife & stepped stay

Cutter blade width mm 900

Cutter blade height mm

30 ~ 11 0 (free stage)

Noise level

dB 92

* These specifications are subject to change without notice, for product improvement.

-17-

Gasoline and Oil 4

Explanation of Gasoline

Recommended Gasoline

* Use fresh lead-free gasoline. In order to prevent knocking, use gasoline with a

octane number higher than 87. If knocking still occurs, replace the gasoline brand

or with an even higher octane number composition.

* Do not use fuel containing alcohol.

Gasoline and Oil

Gasoline and Oil

-18-

4

1. Open the fuel tank cap.

2. Add fuel.

* Gasoline may cause res or explosions leading to serious injuries or death.

Always refuel the fuel tank outdoors in open air.

* When adding fuel, keep open flames (lighted cigarettes, etc.) away from fuel and

engine. Flames will cause the fuel to ignite.

* Always stop the engine before adding fuel.

* Do not overfill so that fuel spills out of filler cap. Wipe up any spilled fuel before

starting engine.

Refueling fuel tank

* Refuel the fuel tank so that the fuel surface does not exceed the upper limit

(equal to the bottom level of the filter installed in the fuel inlet port) to reduce

the risk of fire.

* Perform refueling slowly, or the fuel may spill over the fuel inlet port.

Filter

Upper limit of oil level

(Base of filter)

Fuel tank cap

5310M-0601-010-E

* Refueling should be done slowly. The fuel

tank is divided into right and left sections. It

takes 2 to 3 minutes until the fuel levels of

both sections become even.

NOTE

3. Close the fuel tank cap firmly.

-19-

Gasoline and Oil 4

Inspecting Engine Oil

1. Park machine on level ground.

2. Open the engine cover.

3. Pull out the oil gauge. Clean the gauge with

clean cloth. Reinsert to measure oil level.

Inspection

NOTE

4. When the oil level is lower than the range

indicated by "A" on the oil level gage, add fresh

specified engine oil.

5. When the oil is dirty or has deteriorated into

lower viscosity, replace it with fresh oil.

6. After adding oil, securely attach the cap of the

oil inlet port.

Filler cap

Oil level gauge

* Always stop the engine before checking the engine oil.

Explanation of Oil

Recommended Oil

Use the oil specified by the manufacturer as show in the list of specifications for oil, grease,

fuel, and water. (See Page 47)

5310M-0601-040-E

5310M-0601-050-E

* Check the amount of oil before the engine is

started or at least 10 minutes or more after

the engine has stopped. Immediately after

the engine is stopped, oil still remains in parts

of the engine, so oil checks are not accurate.

Preparation

-20-

5

Details of Attachments

Before using the machine the first time after purchasing it, perform the following inspections

and checks.

Preparation for Starting

Adding Grease and Oil

When using a manual grease pump, push its handle five to six times. When resistance

becomes heavy, immediately stop pushing. When using a pneumatic grease pump,

pumping for two to three seconds is enough.

* Periodically perform greasing and oiling. Neglected grease and oil may

result in parts seizing and rusting, which may hinder the smooth rotation and

operation of the machine.

Grease point

Oil point

5317M-0502-010-E

Before using the machine the first time after purchasing it, check that all the attachments

shown below are available.

Part name Quantity Remarks

1

Operator's manual

1

This manual

2

Instruction manual for engine

1

3

Plug wrench

1

4

Closed wrench

1

Preparation

-21-

Preparation 5

Inspecting Engine Oil

1. Park machine on level ground.

2. Open the engine cover.

3. Pull out the oil gauge. Clean the gauge with

clean cloth. Reinsert to measure oil level.

Inspection

4. Check the oil level visually and confirm that the

oil level is within the range indicated by "A" on

the oil level gage.

5. After adding oil, securely attach the cap of the

oil inlet port.

Filler cap

Oil level gauge

5310M-0601-050-E

* Check the amount of oil before the engine is

started or at least 10 minutes or more after

the engine has stopped. Immediately after

the engine is stopped, oil still remains in parts

of the engine, so oil checks are not accurate.

NOTE

* Always stop the engine before checking the engine oil.

5310M-0601-040-E

Loading...

Loading...