CanyCom CM1802 Operator's Manual

Ride-on Brushcutter

CM1802

OPERATOR'S MANUAL

WARNING

Read and understand this manual completely before attempting

to operate, maintain, and inspect this machine.

Keep this manual with care so that it may be consulted in oper-

ating, maintaining, or inspecting this machine.

5324 5201 000

CHIKUSUI CANYCOM, INC.

90-1 Fukumasu, Yoshii-machi,

Ukiha-shi, Fukuoka, Japan 839-1396

Tel. +81-(0)943-75-2195 Fax.+81-(0)943-75-4396

Notice to the User

Thank you for purchasing our product.

Please read and understand the comments of this manual for proper operation before

using this machine.

WARNING

WARNING

WARNING

The user must know that this machine can be potentially dan-

gerous. Always follow the instructions in this manual when oper-

ating, maintaining, or inspecting machine.

This machine is a work vehicle for mowing. Do not use it for

other purposes. Driving this machine on a public road (or its

equivalent) may be illegal. CHIKUSUI CANYCOM, INC. does

not bear responsibility for accidents or violations of local regulations.

Do not modify this machine. Do not remove safety covers when

operating, or serious accidents can occur.

Contents

1. Introduction 1

1.1 Purpose of This Manual ............................................. 1

1.2 Contents .............................................................. 1

1.3 Warning Terms Used in This Manual ............................... 2

1.4 Safety Labels ......................................................... 3

2. Warranty and After-Sales Service 4

4. Controls and Components 10

5. Specifications 12

5.1 Product Specifications ............................................. 12

5.2 Contents of Tool Bag ............................................... 13

3. Safety 5

3.1 Safety Precautions ................................................... 5

3.1.1 Training ............................................................... 5

3.1.2 Prepeartion ............................................................ 5

3.1.3 Operation ............................................................. 6

3.1.4 Servicing .............................................................. 8

7. Maintenance 26

7.1 Maintenance Schedule ............................................. 26

7.2 List of Fluids and Lubricants ....................................... 30

7.3 List of Consumables and Spares .................................. 31

7.4 Fluids and Lubricants ............................................... 32

7.4.1 Engine Oil ........................................................... 32

7.4.2 Transmission Oil ...................................................... 33

7.4.3 HST Oil .............................................................. 34

7.5 Greasing and Oiling ................................................ 35

7.5.1 Greasing ............................................................ 35

7.5.2 Oiling ............................................................... 36

7.6 Electrical System ................................................... 37

7.6.1 Battery .............................................................. 37

6. Operation 14

6.1 Preparation .......................................................... 14

6.1.1 Checking and Filling Fuel .............................................. 14

6.1.2 Inspecting and Filling Engine Oil ........................................ 15

6.1.3 Inspecting and Filling HST Oil .......................................... 15

6.2 Starting .............................................................. 16

6.3 Driving ............................................................... 20

6.4 Stopping ............................................................. 21

6.5 Parking ............................................................... 22

6.6 Transporting in Case of Emergency ............................... 22

6.7 Locking Differential ................................................. 23

6.8 Adjusting Steering Wheel .......................................... 23

6.9 Working .............................................................. 24

9. Troubleshooting 51

9.1 Troubleshooting Chart .............................................. 51

8. Storage 48

8.1 Chassis .............................................................. 48

8.2 Battery ............................................................... 49

8.3 Engine ............................................................... 49

8.3.1 Fuel Cock

............................................................ 49

8.3.2 Air Cleaner

........................................................... 50

8.3.3 Engine Oil

........................................................... 50

7.7 Cleaning ............................................................. 39

7.7.1 Air Cleaner ........................................................... 39

7.7.2 Spark Plugs .......................................................... 40

7.7.3 Fuel Cock (Fuel Filter) ................................................. 41

7.7.4 Blower Housing and Cooling Fan

....................................... 42

7.8 Adjusting ............................................................. 43

7.8.1 Drive Belt ............................................................ 43

7.8.2 Rotary Drive Belt ..................................................... 43

7.8.3 Rotary Brake ......................................................... 43

7.8.4 Parking Brake ........................................................ 44

7.8.5 Drive Lever .......................................................... 44

7.8.6 Tires ................................................................ 44

7.9 Replacing ............................................................ 45

7.9.1 Oil Filter Cartridge .................................................... 45

7.9.2 Hoses ............................................................... 45

7.9.3 Cutting Blades

....................................................... 45

7.10 After Use Care ...................................................... 47

6

10. Transporting 56

<Guarantee certificate>

Attached to the end of this manual.

* Receive the guarantee certificate together with a receipt after you have received

instructions for handling of this machine.

<Appendix>

"Instruction manual for engine" (Included in the tool bag)

* Be sure to read it together with this manual.

1

Introduction

– 1 –

1. Introduction

1.1 Purpose of This Manual

The purpose of this manual is to provide the user with appropriate information in detail about how to operate,

maintain, and inspect this machine.

This manual has been prepared for people who use this machine for the first time.

1.2 Contents

This manual gives information by dividing it into the following chapters.

1. Introduction

This chapter explains the purpose and contents of this manual and warning terms used in this manual.

It also includes the description of warning labels attached to this machine.

2. Warranty and After-Sales Service

This chapter describes the warranty and after-sales service for this machine.

3. Safety

This chapter describes the general safety rules which the user must observe when operating and working.

4. Controls and Components

This chapter explains the names and functions of the component parts.

5. Specifications

This chapter describes the specifications of this machine. It also describes the contents of the tool bag.

6. Operation

This chapter explains the preparations before operation, operating procedure, and how to use the control devices.

7. Maintenance

This chapter gives information about maintenance such as regular inspection, supplying oil, grease,

lubricant, and fluids, cleaning, adjustments, and after-use maintenance.

8. Storage

This chapter gives information about the storage (long-term storage) of this machine.

9. Troubleshooting

This chapter describes the troubleshooting on this machine.

10. Transporting

This chapter explains the procedures and precautions for transporting this machine.

1

Introduction

– 2 –

1.3 Warning Terms Used in This Manual

In this manual, safety information is classified into the following four categories according to the degree of

hazard (seriousness of possible accidents). Read and understand the contents below and always observe the

safety instructions in this manual.

Warning Term Definition

Indicates an extremely hazardous situation which will result in death or serious

injury if the user does not follow appropriate instructions.

Indicates a potentially hazardous situation which could result in death or serious

injury if the user does not follow appropriate instructions.

Indicates a potentially hazardous situation which could result in injury to the user

or damage to the machine if the user does not follow appropriate instructions.

Used to emphasize information which needs particular attention.

CAUTION

WARNING

DANGER

NOTE

1

Introduction

– 3 –

1.4 Safety Labels

The safety labels shown below are attached to this machine. When warning labels have come off or become

difficult to see, order new ones from a dealer by the part numbers shown below labels and attach them.

1 5234 5064 000

2 5321 5116 000

3 5321 5113 000 5 5305 5327 000

4 3667 5062 000

2

2

1

4 5

3

2

2. Warranty and After-Sales Service

Warranty

Our company guarantees this product based on the contents of the written warranty. For more information, refer to

the written warranty attached to the end of this manual.

After-Sales Service

Please feel free to consult with the store of purchase or with our company's sales department in regard to service

orders or in case trouble or questions arise during the course of using the unit. At such times, please be prepared to

report the product model and product's serial number shown in the model label, as well as the names of the manufacturer and model of the engine installed. (For the names of the manufacturer and model of the engine installed,

refer to Chapter 5 Specifications in this manual. Page 12 )

<Location of model label> <Model label>

Availability of Spare Parts

The term (period) of supply of repair parts for this product shall be seven years after manufacturing is discontinued.

– 4 –

Warranty and After-Sales Service

Location of model label

Product model

Serial number

3

Safety

– 5 –

3. Safety

3.1 Safety Precautions

This section contains safety precautions to follow when operating and maintaining the machine. Read and

understand the precautions in this section as well as throughout this manual and follow them when operating

or maintaining the machine. Failure to follow safety precautions could result in property damage, serious

injury or death to the operator or bystanders.

3.1.1 Training

All operators and mechanics should receive practical instructions from their employer or renter. Such instructions should cover the following issues:

• It is essential to familiarize yourself with the controls, safety labels and the proper use of

the machine.

•Never allow people unfamiliar with these instructions to operate or service the machine.

Do not let anyone under 18 years of age to operate this machine. Local regulations may

restrict the minimum age for operating the machine. Consult your local authority.

• The operator is responsible for the accidents or hazards caused to other people or their

property.

• This machine has a riding capacity for one person only. Do not carry passengers other

than the operator.

• Observe the weight limit of this machine: 120kg.

• Always keep in mind that care and concentration is required when working with ride-on

machines.

• Loss of control on a slope cannot be regained by the application of the brake. The main

reasons for loss of control are:

» insufficient grip of tires.

» excessive speed.

» misjudging of the ground conditions, especially slopes.

3.1.2 Preparation

• Always wear protective footwear, long trousers, hardhat, safety glasses and ear protection when operating or servicing the machine. Proper clothing will minimize the chance of

injury. Do not operate the equipment if you have long hair, loose clothing, or jewelry; all of

which may get tangled in moving parts. Do not operate the machine barefoot or with

open sandals.

• Fuel is highly flammable. See Checking and Filling Fuel,

page 18, for important safety information on handling fuel.

WARNING

3

Safety

– 6 –

• Prepare beforehand the working rules and procedures such as signaling and trafic control for the work place. Following such rules will reduce the risk of accidents.

•Never handle fuel or grease, service the engine, or recharge the battery in the presence

of fire or spark.

•Perform the daily pre-startup inspection (see Preparation, pages 18) before starting the

machine. Repair or replace damaged parts before starting the machine.

3.1.3 Operation

This machine is intended for cutting grass and bushes. Any other use may pose hazard or cause damage to the

machine.

The stability of the machine is affected by the speed, rate of steering, terrain and the operator's weight. Always

pay close attention to these factors or a loss of control or tip over could occur, resulting in property damage,

serious injury or death.

General Driving

• Do not operate the engine in a confined space where dangerous carbon monoxide fumes

can accumulate.

• Do not touch the engine, muffler or exhaust pipe while the engine is running or soon after

it has stopped. These areas will be very hot and can cause burns.

•Do not operate the machine under the influence of alcohol or drugs. Do not operate the

machine when you are tired, ill, or not feeling well.

• Always check for obstacles before operating on new terrain. This includes overhead

obstacles such as the branches of a tree.

• Before starting the engine and moving the machine, scan around your surroundings and

make sure all persons and other vehicles are a safe distance away from the machine.

• On a slippery surface, travel slowly and exercise caution to reduce the chance of skidding

or sliding out of control. Never operate on ice.

• Always make certain that there is no obstacle or a person behind the machine when

backing up. After confirming that it is safe to back up, move slowly and avoid sharp turns.

•To reduce the risk of tip over, pay special attention when encountering an obstacle or a

slope, or when braking on a slope or during a turn. See Driving on a Slope on the next

page.

•Never attempt to drive over a large obstacle such as rock or fallen tree.

• Always travel slowly and use extra caution when operating on unfamiliar terrain. Be alert

when traveling on changing terrain.

•Never operate on terrain that you are not comfortable with. Avoid terrain that is so rough,

slippery or loose that you feel like you could tip over.

3

Safety

– 7 –

• Do not operate the machine near the edge of a cliff, an overhang or a slide area. Pay

special attention after heavy rain or earthquake.

• Do not make sudden maneuvers. A sudden start, stop, or turn can make the machine

lose control and could cause a tip over. Be especially cautious when traveling on soft or

wet ground.

•Drive at a safe speed, taking into account the surface gradient, surface conditions and

load.

Driving on a Slope

• Always follow proper procedures for driving on a slope as described in this manual.

•Driving on a slope in a wrong manner can cause a loss of control or a vehicle tip over.

Check the terrain carefully before attempting to drive on a slope.

•Never drive on a slope that you are not comfortable with. Avoid a slope that is so rough,

slippery, or loose that you feel like you could tip over.

• When driving up a slope, proceed at a steady rate of speed and throttle position.

•Never move the throttle lever, the drive lever, the drive pedal or the steering wheel suddenly.

• If the engine stalls or loses traction during a climb and cannot make it to the top of the

slope, do not try to turn the machine around. Carefully back down slowly, straight down

the slope.

•Drive straight up or down slopes. Avoid turning on a slope.

• When going over the top of a slope, go slow; an obstacle, a sharp drop, or another vehicle or person could be on the other side of the crest.

•Avoid driving the machine across a slope.

• Before driving down a slope, stop and shift auxiliary transmission to [LOW] position.

Drive slowly. Use the engine speed to help keep the machine speed low.

•Never use on a slope steeper than 15 degrees.

•Driving on a slope can be dangerous. It can result in a tip

over and cause serious injury or death. Take the following

precautions.

WARNING

3

Safety

– 8 –

Cutting

When conducting cutting operation, take the following precautions.

• Always follow the proper procedures for cutting as described in this manual.

• Shutt off the work site. Post signs to inform of the cutting operation. Close off the site with

rope if necessary to keep people, especially children, off the work site.

•Pay attention to the surrounding area. Rotating cutting bladethrows stones, rocks and

debris. This may cause property damage, injury, or death.

•Drive forward when cutting. This best prevents the cutting blades from throwing stones,

rocks, or debris.

•Pay attention to obstacles. This includes overhead obstacles such as the branches of a

tree.

Parking

•Park the machine on a flat, level and stable surface. Never park on a slope steeper than

10 degrees. Avoid parking on a slope less than 10 degrees. If parking on a slope less

than 10 degrees is absolutely unavoidable, apply the parking brake and block the wheels

at the lower end of the machine.

» Park the machine facing uphill

» Do not park sideways on a slope.

•Never park on an instable surface. Do not park near the edge of a cliff.

• Observe all the previous precautions for driving, driving on a slope, loading and driving

with a load, and dumping.

• Whenever you park the machine, apply the parking brake and stop the engine. Remove

the key whenever you leave the machine unattended to prevent unauthorized use or accidental starting.

• Gasoline is extremely flammable and can be explosive. When parking the machine

indoors, make certain that the building is well ventilated and that the machine is not close

to any source of flame or spark, including appliances with pilot lights.

3.1.4 Servicing

• Do not service the machine when the engine is running. If it is absolutely necessary to

run the engine while servicing, pay attention to the moving parts.

• Do not operate the engine in a confined space where dangerous carbon monoxide fumes

can accumulate.

• Make sure all hydraulic line connectors are tight and all hydraulic hoses and lines are in

good condition and leak-free.

•Keep your body and hands away from pinhole leaks or nozzles that eject hydraulic fluid

under high pressure. Use paper or cardboard, not your hands, to search for leaks.

Hydraulic fluid escaping under pressure can have sufficient force to penetrate the skin

and cause serious injury.

• Check all fuel lines on a regular basis for tightness and wear. Tighten or repair them as

needed.

3

Safety

– 9 –

• If the engine must be running to perform a service, keep hands, feet, clothing and any

part of the body away from any moving part, especially the cooling fan and the belts at

the side of the engine.

• Do not touch the engine, muffler, or exhaust pipe while the engine is running or soon

after it has stopped. These areas will be very hot and can cause burns.

• The engine must be shut off before checking or adding oil.

4

4. Controls and Components

Name of Components

Controls and Components

– 10 –

Differential Lock Lever

Drive Lever

Throttle Lever

Cutting Height Adjust Lever

Rotary Clutch Lever

Parking Brake Lock Lever

Brake Pedal

Aux. Transmission Shift Lever

Cutting Blade Shield

Forward

Backward

Grass Outlet

Head Lamp Switch

Main Switch

Choke Knob

4

Controls and Components

– 11 –

Function of Components

• Main Switch .......................Starts or stops engine.

*When machine is not in use, remove key.

• Throttle Lever .....................Increases and decreases engine speed.

• Choke Knob .......................When choke knob is pulled, choke valve closes, and when it is

returned, choke valve opens. Pull choke knob when starting engine

and return it after engine is started.

• Drive Lever ........................Drive lever changes the discharge of hydraulic pump in HST and

changes the travelling speed and direction in a stepless manner.

When drive lever is pushed forward from neutral position, machine

moves forward. Pushing lever backward makes machine travel backward. Speed increases proportional to the angle of lever.

•Aux. Transmission Shift Lever ....Use this lever when shifting auxiliary transmission to high/low gear.

• Brake Pedal .......................Stops machine.

When depressing brake pedal, drive lever returns to neutral and

machine stops.

• Differential Lock Lever ............Use this lever when one side of the rear wheels is slipping.

When lever is pushed to [ON], differential lock is engaged. When

lever is [OFF], differential lock is released (normal driving position).

* During normal driving, always put the lever to [OFF] position.

• Head Lamp Switch.................Head lamp is turned on when switch is pulled.

•Parking Brake Lock Lever ........After stopping machine, pull lock lever downward to lock brake

pedal.

• Cutting Height Adjust Lever ........Adjusts the height of blade (5 steps)

• Rotary Clutch Lever ...............Turns on and off the power to cutting rotary.

When moving this lever to [OFF] position, rotary brake is applied.

• Grass Outlet ......................Secure area around machine before opening. Opening outlet allows

cut grass to be easily removed. Open outlet when changing cutting

blades.

* Outlet should be closed during normal use to prevent debris or

other objects from being thrown from machine.

5

Specifications

– 12 –

5. Specifications

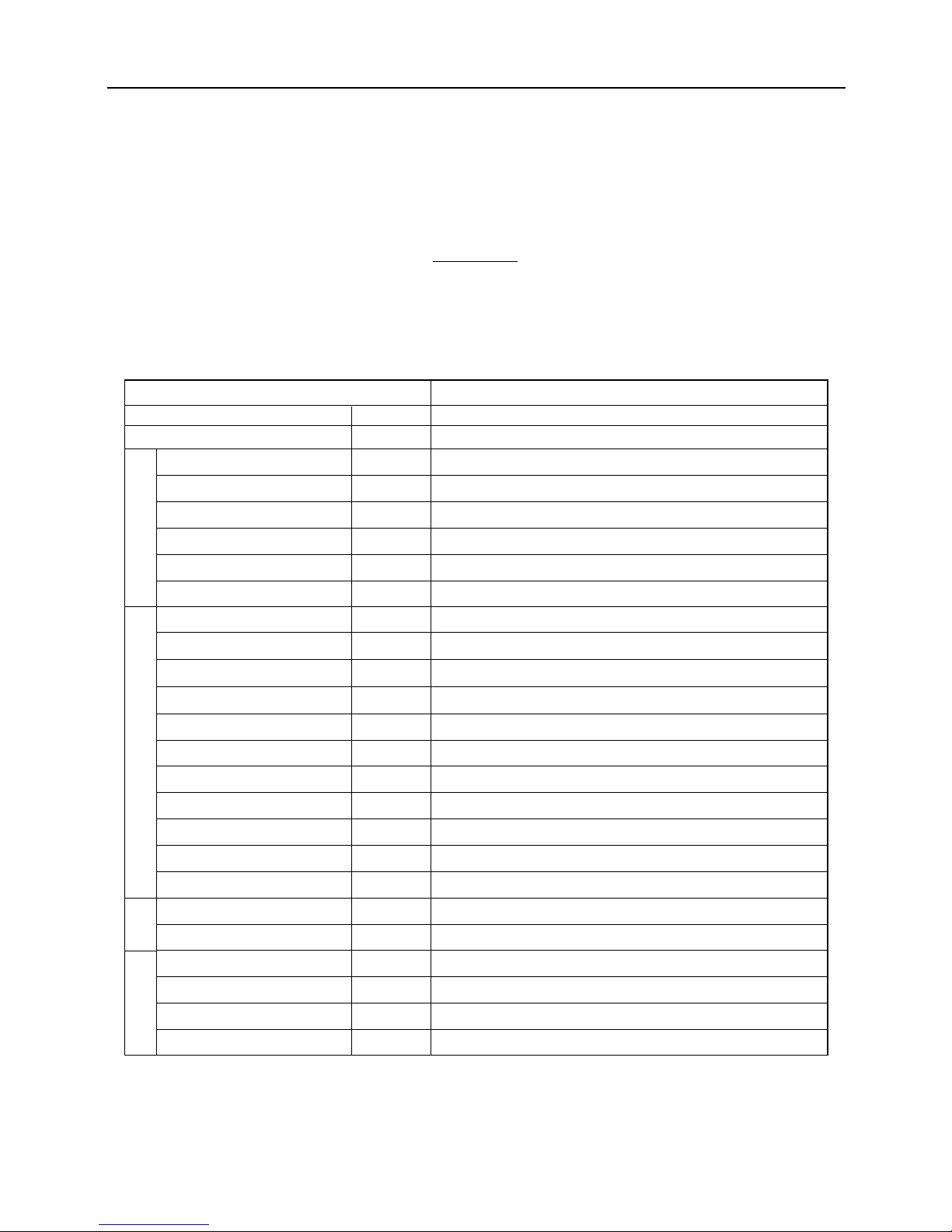

5.1 Product Specifications

*1 Estimated at the maximum speed with the auxiliary transmission in Low position (5.9km/h).

Use this product properly after understanding the specifications

of this product.

NOTE

Model and Type CM1802

Machine Mass kg 260

Mowing Rate m2/h 5300

*1

Overall Length mm 1840

Overall Width mm 995

Overall Height mm 885

Wheelbase mm 1200

Tread mm Front 800, Rear 735

Ground Clearance mm 105

Model FH541V

Type 4-cycle, air-cooled, V-twin vertical-shaft OHV gasoline

Cylinder (Bore x Stroke) mm 2-74x68

Displacement cm3(cc) 585 (585)

Maximum Output kW(PS)/rpm 12.5(17.0)/3600

Maximum Torque

N•m(kgf•m) 40.3(4.11)

Starting System Electric

Fuel Automotive Unleaded Gasoline

Fuel Tank Capacity L 11

Ignition Electronic ignition

Spark Plug Champion RCJ8Y

Battery Type 40B19R

Battery Capacity V/AH 12/28

Speed km/h High 0 - 10.7 / Low 0 - 5.9

Minimum Turning Radius m 1.9

Gradeability degrees 15

Stability Angle degrees Right 45 / Left 45

DimensionsEngine

Electrical

Performance

5

Specifications

– 13 –

*We reserve the right to change the specifications without prior notice.

5.2 Contents of Tool Bag

Model and Type CM1802

Main Transmission HST (Continuously Variable)

Auxiliary Transmission Constant Mesh

Tires Front AGR 3.50-7 / Rear 16 x 7.00-8

Steering Rack and Pinion, Round Steering Wheel

Brake Internally Expanding

Cutting Width mm 900

Cutting Height mm 0 - 75 (5 steps)

Blade Type Free / Fixed Knife & Stepped Stay

Number of Blades 2

Blade Drive Train Belt Drive

No. Content Quantity Note

1 Operator's Manual 1 This manual

2 Operator's Manual for the Engine 1

3 Engine Service Tool 1 for servicing engine

Drive Train

Cutting System

Loading...

Loading...