CanyCom CG431 Operator's Manual

Read this manual completely before operating or maintaining this machine.

Failure to follow safety precautions could result in serious injury or death.

Keep this manual for future reference by you and by all those who operate

and maintain this machine.

CHIKUSUI CANYCOM, INC.

90-1 Fukumasu, Yoshii-machi,

Ukiha-shi, Fukuoka, Japan 839-1396

Tel.+81-(0)943-75-2195 Fax.+81-(0)943-75-4396

Front Flail Brushcutter

CG431 Tractor

Operator's Manual

5116 5106 000

http://www.canycom.co.jp/

■

Sales Headquarters TEL +81-(0)943-75-2195 FAX +81-(0)943-75-4396

All rights reserved. Unauthorized use or reproduction of this material is prohibited.

Authorized Dealer

CHIKUSUI CANYCOM, INC.

Notice to Users and Maintenance Personnel

• This machine can kill you if the safety precautions in this manual and on the

labels attached to this machine are not followed. Read and understand this

manual and the safety labels on the machine thoroughly before using or

servicing the machine. Always follow the instructions and safety precautions,

or serious injury or death could result.

• This machine should only be used with the implements that are specically

designed for this machine, or expressly certied for the use with this machine,

for the intended purpose of this machine: brushcutting and haymaking. Any

use other than these, i.e. towing, pushing other vehicle or material, carrying

peo p le other than the operator o r material, o r any other us e other than

brushcutting or haymaking, or any use with implements other than the ones

mentioned above could be dangerous.

• This machine may not be operated on public road or what is considered to

be public road. It is the sole responsibility of the operator to consult the local

regulations.

• Do not modify this machine, or do not operate this machine with safety covers

removed or open. A serious accident could result.

Thank you for purchasing this machine.

This manual provides information needed for safe and effective use and maintenace of this

machine to those who operate or maintain the machine. Make sure to read and understand

the manual thoroughly before operating or servicing the machine. Also make sure to read

the separate operator's manual for engine.

• Store this manual in a safe, accessible place for easy reference.

Warning Term Denition

Indicates an imminently hazardous situation which will result

in death or serious injury if the user does not follow the

procedures or the instructions.

Indicates a potentially hazardous situation which could result

in death or serious injury if the user does not follow the

procedures or the instructions.

Indicates a potentially hazardous situation which could result

in minor to moderate injury or damage to the machine if the

user does not follow the procedures or the instructions.

Indicates important information which needs particular

attention.

In this manual, the following four warning terms are used to signal the four levels of hazard

(or seriousness of possible accidents). Read and understand what they mean and always

follow the instructions in this manual.

Warning Terms Used in this Manual

NOTE

Notice to Owner

• Be sure that everyone who uses this machine, including those who rent or

lease this machine, receives a copy of this Operator's Manual and understands

the importance of reading and following the information in this manual.

Warranty and After-Sales Service

Warranty

Consult your local CANYCOM dealer or our company’s sales department regarding service

orders or any questions or problems that may arise when using this machine. Please

make sure to have the product name, serial number, and the make and type of engine

handy at the time of contact. The model and serial numbers can be found on the model

label as shown below, and the make and type of the engine can be found in Chapter 3

"Specications" of this manual (Page14).

After-Sales Service

Location of Model Label Model Label

The replacement or repair parts for this product shall remain available for seven years after

the production of this type of machine is discontinued.

Availability of Spare Parts

5116M-0004-030US

2011 1590

CG431

5116M-0004-010E

Location of Model Label

CHIKUSUI CANYCOM, INC. provides you a warranty through Canycom U.S.A. A copy of

this warranty is reproduced in the back of the manual.

Contents

1. Safety 1

Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Training

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Servicing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

2. Controls and Components 10

Name and Function of Controls . . . . . . . . . . . . . . . . . . . 10

3. Specications 14

Product Specications . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Contents of Tool Bag

. . . . . . . . . . . . . . . . . . . . . . . . . . .

15

4. Operation 16

Preparation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16

Pre-start up Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Checking and Filling Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Unfolding/Folding Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Driving. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Driving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Working . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Operating Implement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Changing PTO Speed (Variable PTO Speed Model Only) . . . . . . . . . . . . . . 29

Translating Implement

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30

Levelling Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Hydraulic Cooling Fan

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32

Fire Extinguisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Fire Extinguisher Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Using Fire Extinguisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5. Maintenance 34

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . 34

List of Fluids and Lubricants

. . . . . . . . . . . . . . . . . . . . .

39

Grease Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

List of Consumables and Spares . . . . . . . . . . . . . . . . . . 40

Body Panels

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

43

Opening Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Removing Side Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Removing Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Removing Controls Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Fan Belt

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

51

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Bleeding

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

52

Draining Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Fuel Filter Cartridge

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

53

Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Hydraulic Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Suction Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Return Filter Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Drive Train. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Drive Motor Lubricant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Greasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Control Stick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Electrical System

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

62

Battery Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Charging Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Slow-Blow Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Imprement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Attaching/Detaching Implement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Appendix

• Operator's Manual for Engine

* Be sure to read and understand it together with this manual .

After Use Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

After Normal Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

After Cold Weather Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6. Troubleshooting 71

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7. Transporting 76

Hauling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Loading and Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Hoisting and Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Safety 1

-1-

Safety Labels

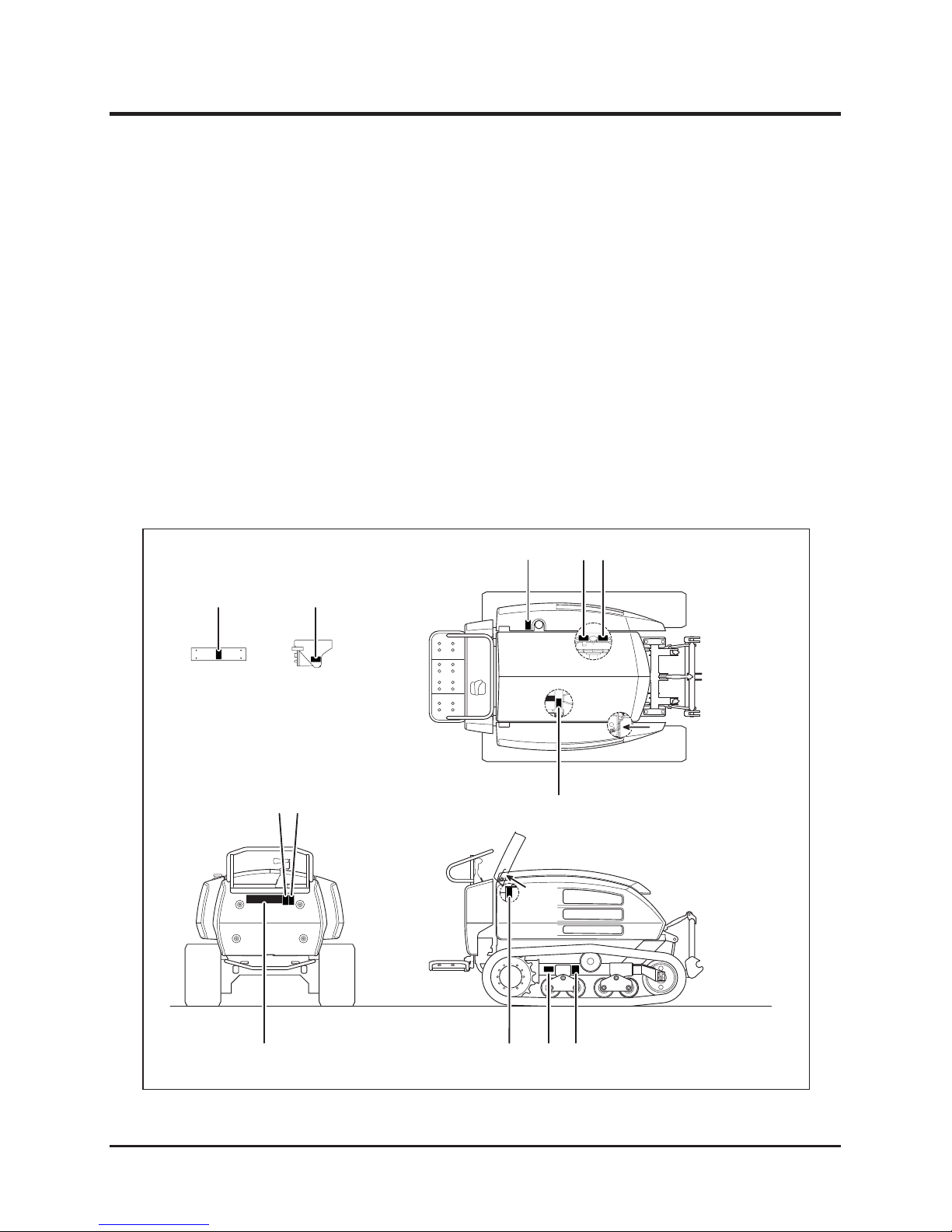

Safety labels shown on the next page are attached to the machine. See the illustration below

for the location and the illustration on the next page for the content of each label on the

machine.

• Locate all warning labels attached to this machine. Read and follow the instructions

and precautions in them. Failure to do so could result in serious injury or death to

the operator or bystanders.

• Keep labels clean and legible. Do not use solvents or gasoline to clean labels.

• Replace these labels immediately if they have been removed, have fallen off or

become illegible. Use part number written on the label or shown in this manual to

order a replacement label from your CANYCOM representative.

View BView A

View B

5116M-0101-010US

View A

5

1 2 3

7 8

42

9 10 116

Safety

-2-

1

Explo sion ha zard.

Fla mmable liqu id

p re s en t . Ke e p

awa y a ll ig nit io n

s o u rc es . N e

ve r

drill , cut with gas,

hit or disassemble

.

3670 5138 001

DANGER!

Moving fan blades

ca n se

ve r ha nd

and fingers. Keep

h an d s a wa y

t o

avoid injury.

3683 5026 001

WARNING!

Hot liq uids . B urn

ha zar d. D o N OT

ope n t he

radi ator

cap after operating

this machi ne

.

3677 5045 001

WARNING!

Hot sur face s. Do

NOT tou ch.

3677 5043 001

WARNING!

Tur n the mow er swi tch onl y wh en mowi ng.

Keep it off all the ot her times.

Rep lac e the flai ls wh en da maged or b roken.

Using dama ged o r bro ken fl ails cause damg es

or ac ciden ts du e to imbal ance.

If a vi ne-like object gets tangl ed to the mo

wer

rotor, immed iatel y sto p the engi ne an d rem ove

it.

Such objec t can cause damg es or accid ents

due t o imb alanc e or overlo ading .

D o n ot o pe ra t e o n an

in cli ne st eep er th an 30

degre es.

Do no t tur n on an i nclin e

.

D o n o t o p er a te o n a

slipp ery surfac e

.

L o c a te o bs ta cl es a n d

holes befor e ope ratio n.

I f th e e n g i n e

ap pe ars to st op

due to overheating,

r e a d t h e

Operator's Manual.

Th is m ach in e is

e qu ip ed

w it h a

safegu ard system

to halt the en gine

bef ore it actu ally

overheat s

.

CAU T IO N! CAUTION! CAU T IO N!

D o n o t u s e t h e

mowe r in reverse

m od e wh en th e

m o

w e r d e ck i s

tr an sl at ed t o

th e

side .

Ob jects can

be thrown, causing

i n j u r i e s a n d

property damages

.

WARNING!

5116 5318 000

Read the

Operator's Manual

before operating

or servicing the

machine

.

5116 5323 000

WARNING!

St op the e ng ine

before servicing.

5116 5327 000

WARNING!

Explosion hazard.

Do not use drill,

torch or hammer.

Do not disassemble. Keep

fire away

.

5116 5361 000

WARNING!

Do not undo the

grease nipple at

once. Greas is

under pressure

and can eject the

nipple. Read the

Operator's Manual

when servicing.

5116 5341 000

WARNING!

Always remove the valve

when loosening the

crawler. When installing

the valve, make sure the

O-ing is free of damages.

Install carefully not to jam

the O-ring.

5116 5358 000

CAUTION!

5116M-0101-020US

1. 3670 5138 001 2. 3683 5026 001

7. 5116 5323 000

3. 3677 5045 001 4. 5116 5362 000 5. 3677 5043 001

6. 5116 5318 000

8. 5116 5327 000 9. 5116 5361 000 10. 5116 5341 000

11. 5116 5358 000

E le ct ri c sh oc k

haza rd. Read the

O p e p a t o r ' s

M a n u a l w h e n

servicing.

5116 5362 000

WARNING!

Safety 1

-3-

This section contains safety precautions to follow when operating and maintaining the

machine. Read and understand the precautions in this section as well as throughout this

manual and follow them when operating or maintaining machine. Failure to follow safety

precautions could result in property damage, serious injury or death to the operator

or bystanders.

Safety Precautions

All operators and mechanics should receive practical instructions from their employer or

renter. Such instructions should cover the following issues:

• It is essential to familiarize yourself with the controls, safety labels and proper use

of the machine.

• Never allow people unfamiliar with these instructions to operate or service the

machine. Do not let anyone under 18 years of age to operate this machine. Local

regulations may restrict the minimum age for operating this type of machine.

Consult your local authority.

• Operator is responsible for the accidents or hazards caused to other people or to

their property.

• This machine has a riding capacity for one person only. Do not carry any passenger

other than the operator.

• Always keep in mind that attention and concentration is required when working with

ride-on machines.

• Loss of control on a slope cannot be regained by the application of the brake. Main

reasons for the loss of control are:

→ insufcient grip of tracks.

→ excessive speed.

→ misjudging of ground conditions, especially slopes.

→ excessive load.

→ incorrect distribution of load.

Training

Safety

-4-

1

Operation

• Fuel is highly ammable. See Checking and Filling Fuel, page 16, for important

safety information on handling fuel.

• Do not operate the engine in a conned space where dangerous carbon monoxide

fumes can accumulate.

This machine is intended for brushcutting. By using other implements made or certied

for this machine, it can perform other tasks. Use only the implements designed or certied

specicly for this machine. Use of other implements may adversely affect the performance or

stability of the machine and can cause damage or accident.

The stability of the machine is affected by the speed, rate of steering, terrain and load.

Always pay close attention to these factors or a loss of control or overturn could occur,

resulting in property damage, serious injury or death.

General Driving

• Always wear protective footwear, long trousers, hardhat, safety glasses and ear

protection when operating or servicing the machine. Proper clothing will minimize

the chance of injury. Do not operate the machine if you have long hair, loose

clothing, or jewelry; all of which may get tangled in the moving parts. Do not

operate the machine barefoot or with open sandals.

• Prepare beforehand the working rules and procedures such as signaling and trac

control for the work place. Following such rules will reduce the risk of accidents.

• Never handle fuel, lubricants or other ammable materials, service engine, or

recharge battery in the presence of re or spark.

• Perform daily pre-startup inspection (see Preparation, page 16) before starting the

machine. Repair or replace damaged parts before starting the machine. Clean the

machine of cut grass or such refuse to avoid re.

Preparation

Safety 1

-5-

• Do not touch the engine, mufer or exhaust pipe while the engine is running or

soon after it has stopped. These areas will be very hot and can cause burns.

• Do not operate the machine under the inuence of alcohol or drugs. Do not operate

the machine when you are tired, ill, or not feeling well.

• Always check for obstacles before operating on new terrain.

• Before starting the engine and the moving machine, scan around your surroundings

and make sure all persons and other vehicles are a safe distance away from the

machine. Sound the horn to warn bystanders.

• Stand rmly on the step. Always hold the guide rail with one hand to keep your

posture when the machine is moving.

• On a slippery surface, travel slowly and exercise caution to reduce the chance of

skidding or sliding out of control. Never operate on the ice.

• Always make certain that there is no obstacle or a person behind machine when

backing up. After conrming that it is safe to back up, move slowly and avoid sharp

turns.

• To reduce the risk of overturning, pay special attention when encountering an

obstacle or a slope, or when braking on a slope or during a turn. See Driving on a

Slope on the next page.

• Never attempt to drive over large obstacles such as rocks or fallen trees.

• Always travel slowly and use extra caution when operating on unfamiliar terrain. Be

alert when traveling on changing terrain.

• Never operate on terrain that you are not comfortable with. Avoid terrain that is so

rough, slippery or loose that you feel like you could overturn.

• Do not operate the machine near the edge of a cliff or a ditch, an overhang or a slide

area. Pay special caution after rain or earthquake.

Safety

-6-

1

Driving on a Slope

• Always follow the proper procedures for driving on a slope as described in this

manual.

• Driving on a slope in a wrong manner can cause a loss of control or a vehicle

overturn. Check terrain carefully before attempting to drive on a slope.

• Never drive on a slope that you are not comfortable with. Avoid a slope that is so

rough, slippery, or loose that you feel like you could overturn.

• When driving up a slope, proceed at a steady rate of speed and throttle position.

• Never move the throttle lever or control stick suddenly.

• If the engine stalls or loses traction during a climb and cannot make it to the top of

a slope, do not try to turn the machine around. Carefully back down slowly, straight

down the slope.

• Never use on a slope steeper than 20 degrees.

• Driving on a slope can be dangerous. It can cause an overturn, resulting in

serious injury or death. Take the following precautions.

• Do not m ake sudden maneuvers. A sudden start, stop, or turn can make the

machine lose control and could cause an overturn. Be especially cautious when

traveling on soft or wet ground.

• Drive at a safe speed, taking into account the surface gradient, surface conditions

and load.

• Use an observer to help direct the machine when the visibility is poor, terrain is

rugged or hilly, or maneuvering room is limited. The observer should be able to see

the machine and its immediate surroundings, and should give pre-arranged signals

to direct the operator.

Safety 1

-7-

• Drive straight up or down a slope. Avoid turning on a slope.

• Avoid driving machine across a slope.

• When going over the top of a slope, go slow; an obstacle, a sharp drop, or another

vehicle or person could be on the other side of the crest.

• Before driving down a slope, stop and turn auxiliary transmission switch to [LOW]

position. Drive slowly. Use engine speed to help keep machine speed low.

• When driving down a slope, use the control stick so that the machine travels down

at the minimum speed. Use engine speed to help keep machine speed low.

Cutting

When conducting cutting operation, take the following precautions.

• Always follow the proper procedures for cutting as described in this manual.

• Shutt off the work site. Post signs to inform that cutting operation is underway.

Close off the site with rope if necessary to keep people, especially children, off the

work site.

• Pay attention to the surrounding area. Running cutting rotor or implement throws

stones, rocks and debris. This can cause property damage, injury, or death.

• Drive forward when cutting. This best prevents the cutting rotor or implement from

throwing stones, rocks, or debris.

• Pay attention to obstacles. This includes overhead obstacles such as branches of a

tree.

Safety

-8-

1

Parking

• Park the machine on a at, level and stable surface. Never park on a slope steeper

than 15 degrees. Avoid parking on a slope less than 15 degrees. If parking on a

slope less than 15 degrees is unavoidable, apply parking brake and block the tracks

at the lower end of the machine.

→ Park the machine with operator's step uphill

→ Do not park sideways on a slope.

• Observe all the previous precautions for driving, driving on a slope and cutting.

• Whenever you park the machine, apply parking brake and stop the engine. Remove

the key whenever you leave the machine unattended to prevent unauthorized use or

accidental starting.

• Clean the machine of cut grass or such refuse after each use to avoid re.

• Diesel fuel is ammable and can be explosive. When parking the machine indoors,

make certain that building is well ventilated and that the machine is not close to any

source of ame or spark, including appliances with pilot lights.

Servicing

• Do not service the machine when the engine is running. If it is absolutely necessary

to run the engine while servicing, pay attention to the moving parts; keep hands,

feet, clothing and any part of your body away from any moving part, especially

cooling fan and belts at the side of the engine.

• Do not operate the engine in a conned space where dangerous carbon monoxide

fumes can accumulate.

• Make sure all hydraulic line connectors are tight and all hydraulic hoses and lines

are in good condition and leak-free before applying hydraulic pressure to the

system.

• Keep your body and hands away from pinhole leaks or nozzles that eject hydraulic

uid under high pressure. Use paper or cardboard, not your hands, to search

for leaks. Hydraulic uid escaping under pressure can have sufcient force to

penetrate the skin and cause serious injury.

Safety 1

-9-

• Check all fuel lines on a regular basis for tightness and wear. Tighten or repair them

as needed.

• Do not touch the engine, mufer, or exhaust pipe while the engine is running or

soon after it has stopped. These areas will be very hot and can cause burns.

• Engine must be shut off before checking or adding oil.

Controls and Components

-10-

2

Name and Function of Controls

Step

Track

Idler Wheel

Guide Rail

Controls Cover

Return Roller

Sprocket

Top Cover

Right Side Cover

Left Side Cover

Fire Extinguisher

Roller

5116M-0201-010E

Front Cover

Hydraulics Connectors

Upper Hitch

Lower Hitch

Lower Hitch

-11-

Controls and Components 2

9

4

Variable Speed PTO Model

Normal Model

4 5 6 7

14

15

8

10

11

12

13

1

3

5116M-0201-021E

1

2 5 6 7

14

15

8

9

10

11

12

13

Controls and Components

-12-

2

1 Throttle Lever . . . . . . . . . . Throttle Lever is used to control engine speed.

2 Implement Direction . . . . . Implement direction switch changes the rotating direction

of implement.

3 Implement Direction. . . . . . Implement direction switch changes the rotating direction

of implement and adjust revolution speed.

4 Auxiliary Transmission . . . Au xiliary transmission sw itch i s used to select the

auxiliary transmission speed.

5 Parking Brake Switch . . . . Parking brake switch is used to engage parking brake.

6 Main Switch . . . . . . . . . . . . Main Switch is used to start or stop engine.

7 Implement Translation . . . . Implement translation switch is used to move implement

sideways.

8 Horn Button . . . . . . . . . . . . Pressing this button sounds horn. Use this for warning

during traveling or signaling during operation.

9 Control Stick. . . . . . . . . . . . Control Stick is used to control the traveling direction

(forward or backward) and speed of machine.

10 Implement Lift Switch . . . . Implement lift switch is used to lift or lower implement.

11 Implement Switch

. . . . . . . .

Implement switch is used to start or stop implement.

Switch

Switch

Switch

Lever

16 17 18 19 20 21

22 23 24

5116M-0201-030E

-13-

Controls and Components 2

12 Automatic Step Levelling . Automatic step levelling switch turns on or off automatic

leveling function of step.

13 Manual Step Levelling . . . . Manual step levelling switch is used to level step manually.

14 Implement Height . . . . . . . Implement height lever is used to set the minimum height

of implement.

15 Safety Switch . . . . . . . . . . . Machine stops if safety plug is detached.

16 Parking Brake Indicator. . . Parking brake indicator lights when parking brake is

engaged.

17 Coolant Temperature . . . . . Coo la nt t ep er at ur e wa rning l am p li gh ts u p wh en

coolant temperature is beyond normal operating range

(overheating).

18 Oil Pressure Warning . . . Oil pressure warning lamp indicates if oil pressure is

normal. Under normal condition, it goes off when engine

starts.

19 Charge Lamp . . . . . . . . . . . Charge lamp indicates the condition of battery charge

system. Under normal condition, it goes off when engine

starts.

20 Implement Indicator . . . . . . Implement indicator lamp lights up when implement is

rotating. It also indicates the rotating direction.

21 Auxiliary Transmission . . Auxiliary transmission indicator lights up when auxiliary

tramsmission is in [ (fast)] mode.

22 Fuel Gauge . . . . . . . . . . . . . Fuel gauge indicates the fuel level.

23 Hour Meter . . . . . . . . . . . . . Hour Meter displays and records the total amount of time

machine has been in use, in the unit of 0.1 hour.

24 Coolant Temperature . . . . . Coo la nt te mp era tu re me te r dis pl ay s t he c oo l an t

temperature.

Switch

Switch

Lever

Warning Lamp

Lamp

Lamp

Meter

Specications

-14-

3

· Understand the specifications of this product thoroughly before use.

Product Specications

Model and Type CG431

Machine Mass kg (lbs) 1590 (3510)

Dimensions

Overall Length mm (in) 3465 (136.4)

Overall Width mm (in) 1700 (66.9)

Overall Height mm (in) 1405 (55.3)

Track Contact Length mm (in) 1345 (52.9)

Track Gauge mm (in) 1170 (46.1)

Track Width

mm (in) 320 (12.6)

Ground Clearance mm (in) 280 (11.0)

Average Ground Pressure kgf/cm2 (PSI) 0.24 (0.082)

Engine

Model Kubota V2203

Type Water-cooled 4-cycle Diesel, in-line 4 cylinder

Cylinder (Bore×Stroke) mm (in) 87X92.4 (3.43X3.64)

Displacement cm3 (cu. in) 2197 (134.1)

Rated Output kw(PS)/rpm 33.0(44.8)/2600

Maximum Torque

N•m(lbf•ft)/rpm

145.1(107.2)/1500

Starter System Electric

Fuel Diesel Fuel

Fuel Consumption

g/kW•h(oz/PS•h)

255(6.67)

Fuel Tank Capacity L (US gal) 52 (13.7)

Oil Capacity L (US qt) 9.7 (10.2)

Coolant Capacity L (US gal) 8.5 (2.2)

Electr.

Battery Type 100E41R

Battery Capacity V/AH 12/80

Performance

Speed

FWD HI

km/h (mph) 0 - 9 (0 - 5.6)

FWD LO km/h (mph) 0 - 6 (3.7)

REV HI km/h (mph) 0 - 7 (4.4)

REV LO km/h (mph) 0 - 4.5 (2.8)

Minimum Turning Radius m (ft) 2.0 (6.6)

Gradeability Degrees 35

Stability

Angle

Left Degrees 40

Right Degrees 40

-15-

Specications 3

Model and Type CG431

Drive Train

Main Transmission HST (2 Speed Motor)

Steering Twin HST

Tranamission Oil Capacity L (US gal) 42 (11.1)

Brakes Hydraulic

*These specications are subject to change without notice.

No. Content Quantitiy Note

1 Operator's Manual 1 This Manual

2

Operator's Manual for Engine

1

3

Fire Extinguisher

1

4

Operator's Manual for Extinguisher

1

Contents of Tool Bag

Operation

-16-

4

• Keep re and spark away when handling fuel.

• Always stop engine before refueling.

• Do not ll beyond the limit (bottom of ller lter) so that fuel will not overow. In

case fuel is spilt, wipe out immediately.

Pre-start up Inspection

Preparation

Always perform an inspection before use.

Refer to Maintenance Schedule (page 34) for the inspection schedule and procedure.

Checking and Filling Fuel

1. Check fuel gauge. If fuel level is low, ll fuel.

Fuel Gauge

5116M-0401-010E

Fuel Filler Cap

5116M-0401-020E

2. Open fuel ller cap to ll fuel.

3. Replace ller cap back in place and close it

securely.

• Fuel to use and capacity: Page 39

NOTE

-17-

Operation 4

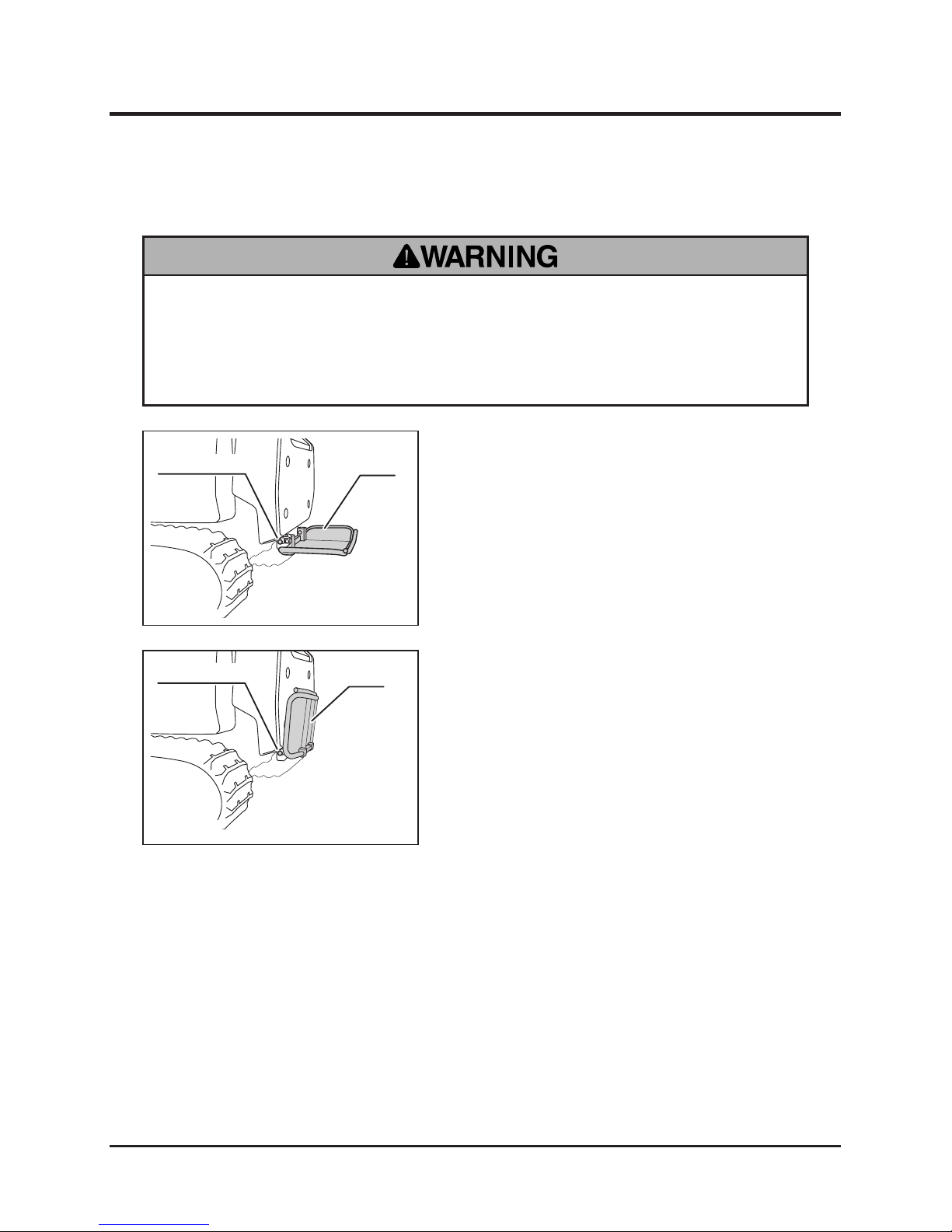

• Hold step rmly when folding or unfolding step. Make certain that hands or

ngers are not in the way to be caught by step when folding or unfolding.

• Make certain that step is securely locked with stopper in either position.

Unfolding/Folding Step

1. Pull stopper knob and fold step.

2. Once step is fully folded, release stopper

knob so that step locks in this position.

Step

Stopper Knob

5116M-0401-040E

1. Hold step rmly and pull stopper knob.

2. Unfold step. Once step is fully unfolded,

release stopper knob so that step locks in

this position.

Step

Stopper Knob

5116M-0401-030E

Folding Step

Unfolding Step

Operation

-18-

4

Driving

• Always start and run engine in a well ventilated place.

• Always make certain of the safety of your surroundings when starting engine.

Always unfold step and stand on step when starting engine to avoid accident.

• Do not open engine cover while engine is running. An engine that has been

running is very hot. Avoid touching engine and its ancillaries, or severe burns

may result.

• Always attach string on safety switch to your body so machine stop if you fall

off machine.

• Do not turn main switch to [ (start)] when engine is running. Starter motor

and/or engine may be damaged.

• Do not turn starter for more than 15 seconds. If engine does not start, turn main

switch back to [ (off)] and wait for 30 seconds or more before attempting to

start again.

• Do not use this machine in temperatures above 40ºC (104ºF) or below -15ºC (5

ºF). This machine cannot perform adequately in these temperature ranges.

Using this machine under such conditions may result in an accident or cause

damage to the machine.

• In t he winter o r cold clim ate, warm up engine thoroughly before driving

machine. A cold engine delivers poor performance, which may result in an

accident. It also causes excessive wear.

Starting

Loading...

Loading...