Canplas 394600 User Manual

ENDURA® GREASE MANAGEMENT

Taking

the

guesswork

of

out

grease

Recordable Data

• Sentry holds 14 months of

rolling data downloadable to

your PC, providing a denitive

proof of maintenance

and compliant operation

Using the

latest wireless

technology

• Sensor located in the

GI transmits status to

the remote receiver

User Friendly

• No electrical supply or

installation – Sensor and

Display operate on AA batteries

• Easy installation, easy setup

• Suitable for use with all full height

Endura

®

Grease Interceptors

management

The biggest challenge with

any Grease Interceptor is

regular maintenance to ensure

operation within its rated

capacity.

all but guesswork on the part of the restaurant

operator, often resulting in the interceptor

becoming overloaded and FOG being released to the

municipal or private sewer system – the very thing

that the interceptor was put in place to prevent.

Until now this process has been

FCC ID: S3PCM91

www.endurainterceptor.com

DUAL MONITORING:

The Endura Sentry monitors your grease interceptor in two ways. The rst is based

on grease accumulation against rated capacity, set using the dipswitches on the

Display Unit accordingly. As the FOG (Fat, Oil and Grease) accumulates, the monitor

tracks this changing the display and activating the alarm accordingly.

The second means of monitoring is time based. Based on best practice, no grease interceptor should operate for

extended periods of time without servicing. Regardless of FOG accumulation Sentry will sound the alarm every 120

days (4 months) indicating the need for servicing. This means that the interceptor will be serviced at least 3 times per

12 month period, or when FOG accumulation dictates.

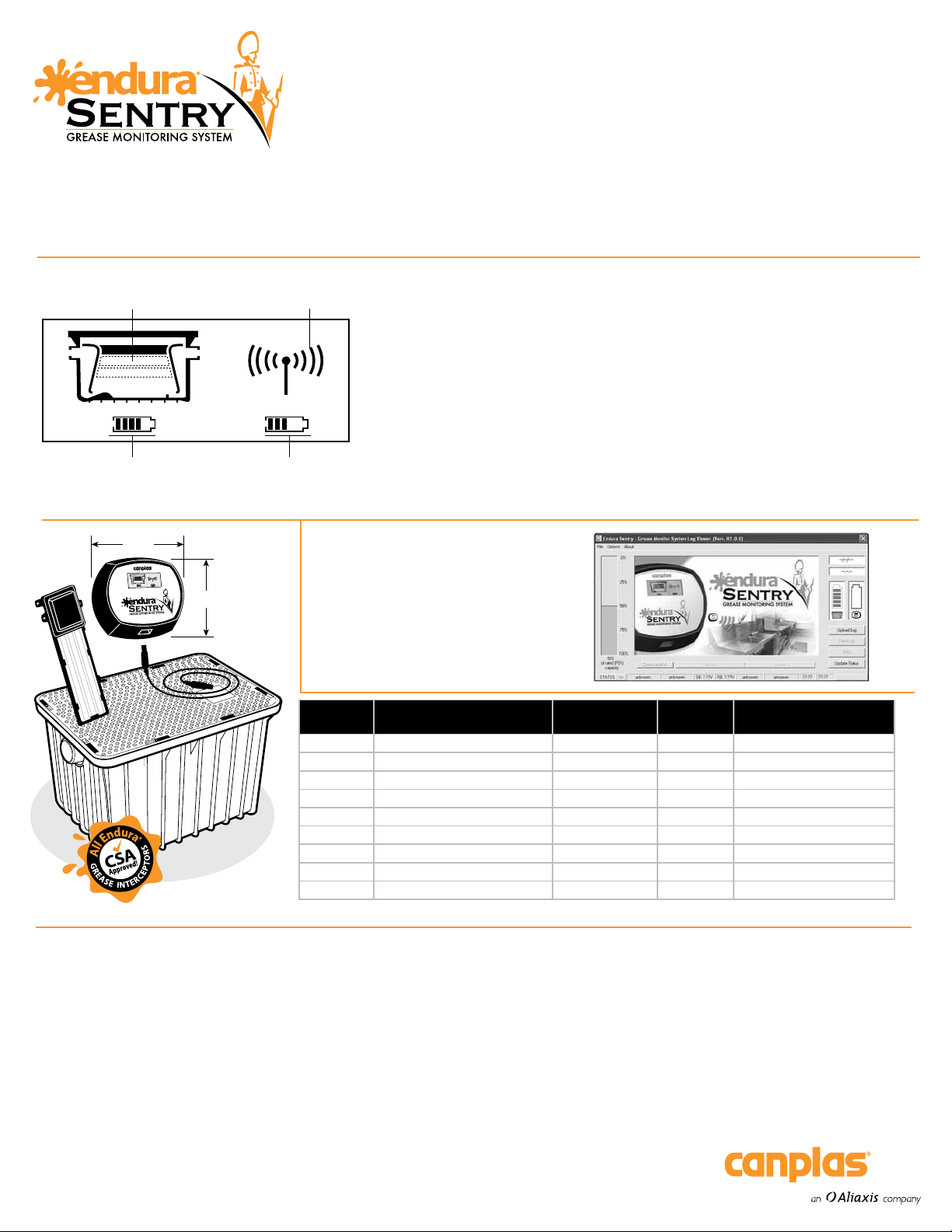

Interceptor Icon

Grease Level Indicators

Sensor Battery

Status (80%)

6-1/4”

Communication Icon

Signal Activity Indicator

Display Unit Battery

Status (60%)

Display

Unit is wall

5-1/4”

mountable

COMBO

PACKS:

MONITORING GREASE LEVELS:

Endura Sentry is supplied complete with all the necessary sundries to complete

installation. Both the Sensor and Display unit are supplied with industrial quality AA

batteries installed which will draw no charge until the unit is made operational. Battery

life expectation for the Sensor is in excess of 5 years and the display unit, depending on

frequency of alarm activation and sounding duration, is in excess of 3 years.

The display unit when operational provides quick reference as to battery life remaining

and will indicate by the icon ashing when the batteries need to be replaced. In

addition the display will also provide indication of the wireless signal status and of

course display the current status of the grease interceptor by an increasing number

of bars being shown on the interceptor icon. When the interceptor reaches 90% of its

rated capacity, the interceptor icon will ash and after 12 consecutive alarm readings,

an audible alarm will sound 6 times per hour until the interceptor is serviced.

SENTRY SOFTWARE:

All of the accumulated data about the

interceptor operation can be downloaded

at any time to a PC running Windows™

Software. This simple user friendly

interface allows the data to be both

displayed on screen and printed to allow

maintenance of hard copy records.

PART # Description

394600 Endura Sentry Grease Monitor N/A Yes All full height Endura models

394615 15GPM GI (2”) c/w Sentry Monitor Yes Ye s Supplied complete

394620 20GPM GI (2”) c/w Sentry Monitor Yes Ye s Supplied complete

394622 25GPM GI (2”) c/w Sentry Monitor Yes Ye s Supplied complete

394625 25GPM GI (3”) c/w Sentry Monitor Yes Ye s Supplied complete

394633 35GPM GI (3”) c/w Sentry Monitor No* Ye s Supplied complete

394634 35GPM GI (4”) c/w Sentry Monitor No* Ye s Supplied complete

394653 50GPM GI (3”) c/w Sentry Monitor No* Ye s Supplied complete

394654 50GPM GI (4”) c/w Sentry Monitor No* Ye s Supplied complete

When ordering add sux ‘S’ for Spigot Flow device or

sux ‘T’ for threaded Interceptor/Flow control connections.

Molded Sensor

Locations

Software

Supplied

* Fixings supplied for sensor mounting.

Notes:

SAMPLE SPECIFICATION:

Contractor will install an injection moulded grease interceptor with a ow rating of __________GPM, which is to be supplied with a PDI-G102

APPROVED wireless monitoring device that will sound an interceptor servicing alarm based on 1. FOG accumulation against rated ow

capacity; or 2. Operational time of the interceptor no greater than 120 days (3 times annually). Said monitoring device will be capable of

retaining at least 12 months of operational data which should be downloadable and able to be both easily interpreted and printed to provide

the foodservice operator or third party with operational traceability of the grease interceptor.

GD-00052-05-10-EN

Canplas Industries Ltd.

P.O. Box 1800, 500 Veterans Drive

Barrie, Ontario, Canada L4M 4V3

Tel: (705) 726-3361

Toll Free: 1-800-461-5300

Fax: (705) 726-2186

www.canplasplumbing.com

Canplas LLC

11402 East 53rd Ave.

Suite 200, Denver, CO, U.S.A. 80239

Tel: (303) 373-1918

Toll Free: 1-888-461-5307

Fax: (303) 373-1923

Loading...

Loading...