Canplas 3915A02 User Manual

ENDURA® GREASE MANAGEMENT

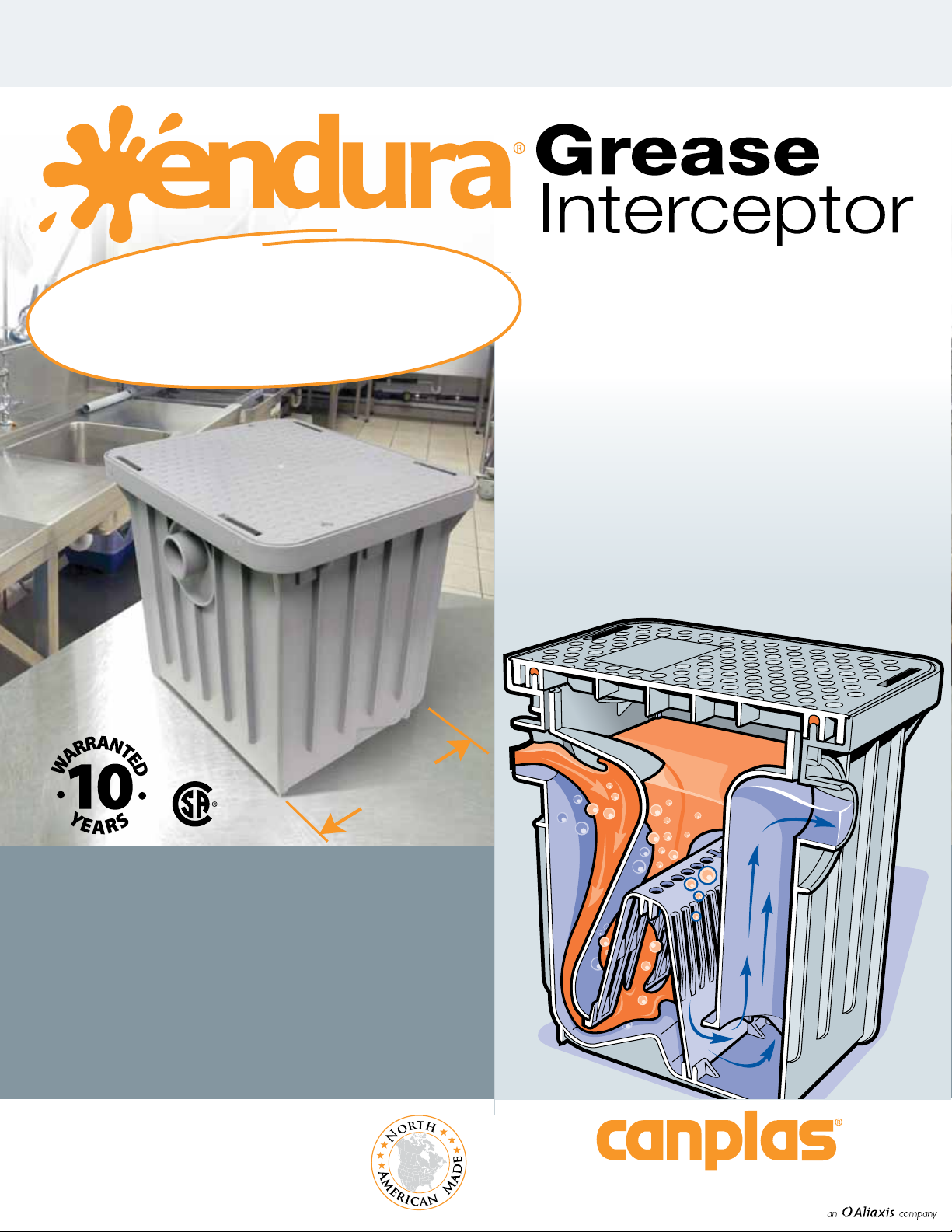

The latest additions to

The best things come

in small packages!

the Endura family provide

improved performance

in a smaller footprint.

The line now includes 7gpm & 10gpm models

with our 15gpm model moving to the same

compact platform. All new models use a

development of our patented bae system to

enhance separation performance at low ow

rates. Based on end user feedback, these units

also feature the new EZ-Clean exterior tank

prole, a non-ribbed section for the lower

two inches.

141/2”

Sewer authorities and building owners spend

millions of dollars every year combating

grease accumulation in plumbing systems.

Grease accumulation causes sewer blockages and overows.

These overows are a health risk to you, your employees, your

customers and the general public. Injection molded in engineered

thermoplastic, the Endura® Grease Interceptor provides restaurant

operators the best value and performance on the market today.

www.endurainterceptor.com

Contractor shall install a Canplas Endura® Grease Interceptor, Part No. . An accessible ow control with a rate of gpm will also be installed in

accordance to manufacturer’s instructions. The unit shall be comprised of engineered thermoplastics to withstand operational temperatures up to 220°F (104°C) and

incorporate a lid with air tight seal and the capability of supporting 440 lbs. (200 Kgs). The unit will be supported by a 10 year manufacturer’s extended warranty. The

grease interceptor shall be certied to the current version of the PDI-G101 standard and where locally applicable to ASME112.14.3 or have CSA approval. Contractor shall

provide two mechanical joint couplings to connect the grease interceptor.

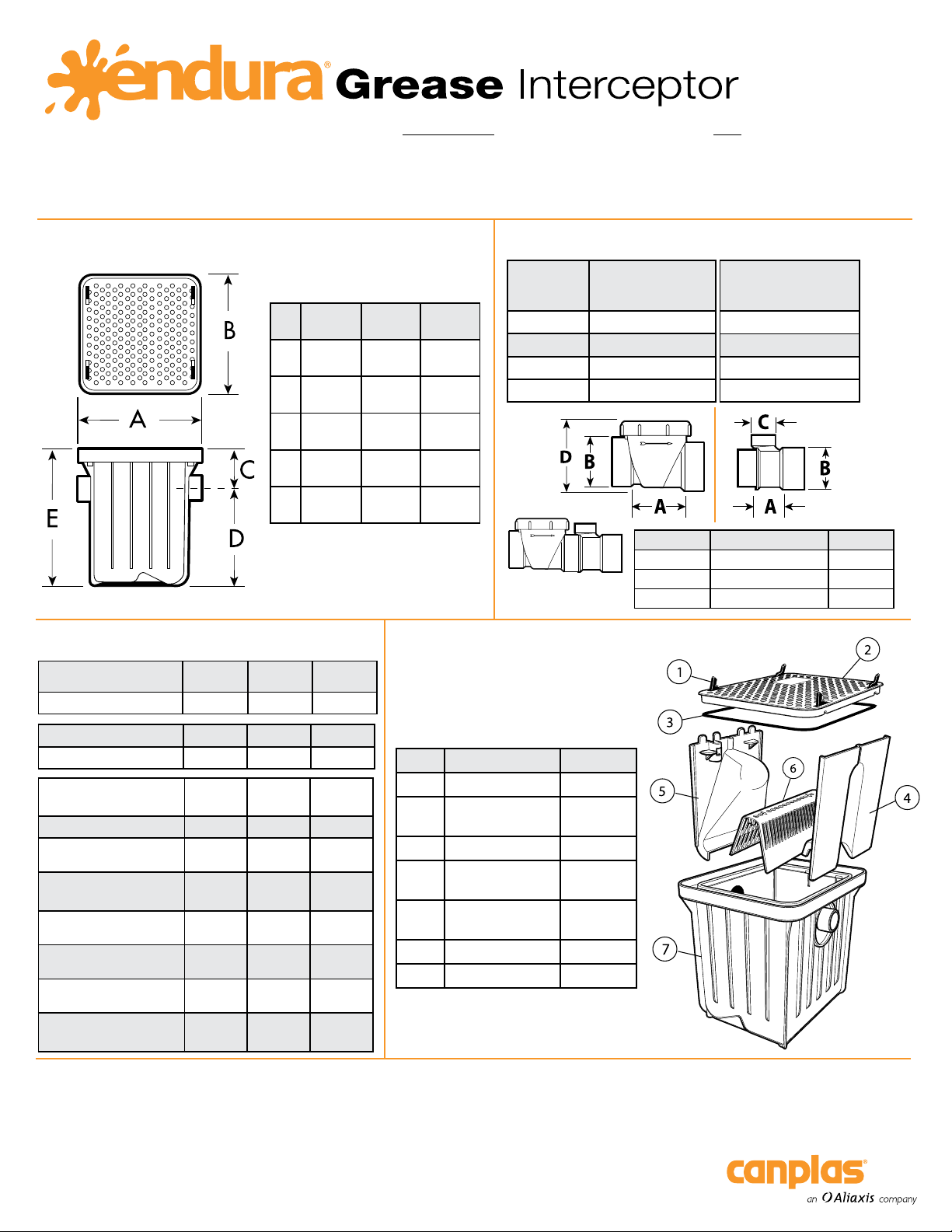

DIMENSIONS

CAPACITY

US Gallons Per Minute (GPM)

CAPACITY - Pounds

Litres Per Second (LPS)

CAPACITY - Kilograms

Average Eciency %

(ASME 112.4.3)

Part Number

Grease Capacity lbs (Kg) actual

Operating Temperature

Capabilities

Surface Load Capacity

Unit Weight (Empty)

Liquid Capacity

Connection size (mechanical)

(110 mm available on request)

0.44 0.63 0.94

6.35 9.07 13.6

95.5% 92.5% 92.0%

3907A02 3910A02 3915A02

31.95 lbs

(14.49 kgs)

220˚F

(104˚C)

440 lbs

(200 kgs)

13.8 lbs

(6.26 kgs)

12.96 gal

(49.06 L)

7/14

GPM/lbs

A 14.5”

(368mm)

B 17.5”

(444mm)

C 3.5”

(89mm)

D 12.8”

(325mm)

E 16.3”

(414mm)

7 10 15

14 20 30

38.1 lbs

(17.28 kgs)

220˚F

(104˚C)

440 lbs

(200 kgs)

13.8 lbs

(6.26 kgs)

12.96 gal

(49.06 L)

2” 2” 2”

40.97 lbs

(18.58 kgs)

220˚F

(104˚C)

440 lbs

(200 kgs)

13.8 lbs

(6.26 kgs)

12.96 gal

(49.06 L)

Connection

Iron Pipe Size

(Solvent weld)

10/20

GPM/lbs

14.5”

(368mm)

17.5”

(444mm)

3.5”

(89mm)

12.8”

(325mm)

16.3”

(414mm)

15/30

GPM/lbs

14.5”

(368mm)

17.5”

(444mm)

3.5”

(89mm)

12.8”

(325mm)

16.3”

(414mm)

A 3.0” (76.2 mm)

B Nom. Dia. 2” (50.8 mm)

C -

D 3.84” (97.5 mm)

Components for:

7GPM - 10GPM - 15GPM

3907A02 - 7GPM (0.44 LPS)

3910A02 - 10GPM (0.63 LPS)

3915A02 - 15GPM (0.94 LPS)

ITEM Description Part No:

1 - Latches #3920A-9

2 - Reinforced

polypropylene cover

3 - Rubber gasket #3910A-5

4 - Removable

Outlet Bae

5 - Removable

Inlet Bae

6 - Directional Diuser #3910A-3

7 - One-piece tank #3910A-1

#3910A-2

#3910A-4

#3920A03-3

FLOW

CONTROL

2” h x h

AIR INTAKE

2” spg x h

2.91” (73.9 mm)

Nom. Dia. 2” (50.8 mm)

Nom. Dia. 1.5” (38.1 mm)

-

Part No: Description CTN. QTY.

#3922107 2” 7 GPM (.44 LPS) 1

#3922110 2” 10 GPM (.63 LPS) 1

#3922115 2” 15 GPM (.94 LPS) 1

GD-000255-EN-09-10

Canplas Industries Ltd.

P.O. Box 1800, 500 Veterans Drive

Barrie, Ontario, Canada L4M 4V3

Tel: (705) 726-3361

Toll Free: 1-800-461-5300

Fax: (705) 726-2186

Canplas LLC

11402 East 53rd Ave.

Suite 200, Denver, CO, U.S.A. 80239

Tel: (303) 373-1918

Toll Free: 1-888-461-5307

Fax: (303) 373-1923

Loading...

Loading...