Canovate Can BREEZE Series, Can BREEZE 8 kW, Can BREEZE 14 kW, Can BREEZE 7 kW Operating And Maintenance Instructions Manual

IT’s

far and away

the BEST

Can BREEZE

Operating and Maintenance of

Cooling Unit Instructions 8-14 kW

1. Canovate Legal Disclaimer

The information presented in this manual is not

warranted by the Canovate to be authoritative, error

free, or complete. This publication is not meant to be

a substitute for a detailed operational and site specifi c

development plan. Therefore, Canovate assumes no

liability for damages, violations of codes, improper

installation, system failures, or any other problems

that could arise based on the use of this Publication.

The information contained in this Publication is

provided as is and has been prepared solely for

the purpose of evaluating data center design and

construction. This Publication has been compiled in

good faith by Canovate. However, no representation

is made or warranty given, either express or implied,

as to the completeness or accuracy of the information

this Publication contains.

IN NO EVENT SHALL CANOVATE, OR ANY PARENT,

AFFILIATE OR SUBSIDIARY COMPANY

OF CANOVATE CORPORATION OR THEIR

RESPECTIVE OFFICERS, DIRECTORS, OR

EMPLOYEES BE LIABLE FOR ANY DIRECT,

INDIRECT, CONSEQUENTIAL, PUNITIVE,

SPECIAL, OR INCIDENTAL DAMAGES (INCLUDING,

WITHOUT LIMITATION, DAMAGES FOR LOSS

OF BUSINESS, CONTRACT, REVENUE, DATA,

INFORMATION, OR BUSINESS INTERRUPTION)

RESULTING FROM, ARISING OUT, OR IN

CONNECTION WITH THE USE OF, OR INABILITY

TO USE THIS PUBLICATION OR THE CONTENT,

EVEN IF CANOVATE CORPORATION HAS BEEN

EXPRESSLY ADVISED OF THE POSSIBILITY

OF SUCH DAMAGES. CANOVATE RESERVES

THE RIGHT TO MAKE CHANGES OR UPDATES

WITH RESPECT TO OR IN THE CONTENT OF THE

PUBLICATION OR THE FORMAT THEREOF AT

ANY TIME WITHOUT NOTICE.

Copyright, intellectual, and all other proprietary rights

in the content (including but not limited to software,

audio, video, text, and photographs) rests with

Canovate or its licensors. All rights in the content not

expressly granted herein are reserved. No rights of

any kind are licensed or assigned or shall otherwise

pass to persons accessing this information.

This Publication shall not be for resale in whole or in

part

2 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 7-14 kW www.canovate.com l info@canovate.com l P. +90 216 484 2222

2. Contents

1. Canovate Legal Disclaimer 2

2. Contents 3

3. General Information 4

3.1 Save these instructions 4

3.2 Intended users 4

3.3 Legal information concerning the

operating instructions

3.4 Copyright 4

3.5 Revision Rev. 4

3.6 Proper use 5

3.7 Precautionary measures 5

3.8 Safety Instructions 5

3.9 Symbols in these operating 5

3.10 instructions 5

3.11 Important safety instructions 6

3.12 Service and technical staff 7

3.13 RoHS compliance 7

4. Transport and handling 8

4.1 Scope of delivery of Front Cooler 8

4.2 Transport 8

4.3 Unpacking 9

6. COMPONENTS 11

6.1

6.2 Components of Fan Unit 11

7. UNITS INSTALLATION 12

7.1 UNIT INSTALLATION 12

7.1.1 FACTORY-SUPPLIED ACCESSORIES 12

7.1.2 INITIAL CHECK 13

8. DRAIN PIPING 13

8.1 GENERAL 13

8.2 DRAIN PIPE CONNECTION 14

9. ELECTRICAL WIRING 16

9.1 ELECTRICAL WIRING CONNECTION

9.2 SETTINGS OF DIP SWITCHES 17

10. MAINTENANCE 19

Components of CAN-BREEZE 11

FOR INDOOR UNIT

4

16

10.1

10.2 CLEAN THE FILTER 20

10.3 RESET OF FILTER INDICATION 20

11. OUTDOOR UNIT 21

11.1 Important Notice 21

12. TRANSPORTATION AND HANDLING 23

13. BEFORE OPERATION 23

14. AUTOMATIC CONTROLS 24

15. BASIC TROUBLESHOOTING 25

16. NAME OF PARTS OUTDOOR UNIT 27

17. UNIT INSTALLATION 29

17.1 OUTDOOR UNIT INSTALLATION 29

17.2 Installation space 30

17.3 Installation place provision 32

18. REFRIGERANT PIPING &

18.1 PIPING MATERIALS 34

18.2 SUSPENSION OF REFRIGERANT

18.3 PIPING CONNECTION FOR

18.4 Refrigerant charge 41

18.5 Caution of the pressure by check joint 41

18.6 Refrigerant Charging Quantity 41

18.7 ELECTRICAL WIRING CONNECTION

18.7.3 Setting of DIP Switches for Outdoor Unit 43

18.7.4 System installation DIP Switch Setting 45

19. TEST RUNNING 47

19.1 TEST RUN PROCEDURE BY REMOTE

19.2 TEST RUN FROM OUTDOOR UNIT

20. Specifi cations 52

21. TROUBLESHOOTING 53

TAKE OUT THE FILTER 19

34

REFRIGERANT CHARGE

35

PIPING

36

OUTDOOR UNIT

42

FOR OUTDOOR UNITS

49

CONTROL SWITCH (PC-ART

EXAMPLE)

50

SIDE

www.canovate.com l info@canovate.com l P. +90 216 484 2222 Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 3

3. General Information

3.1 Save these instructions

This manual contains important instructions that must

be followed during the installation of this

equipment.

3.2 Intended users

This manual is intended for Canovate authorized

personnel. It provides component specifi cations and

instructions for installing and commissioning the

equipment.

3.3 Legal information concerning the

operating instructions

We reserve the right to make changes in content.

Canovate is not responsible for mistakes in this

documentation. Liability for indirect damages which

occur through the delivery or use of this documentation

is excluded to the extent allowable by law.

3.4 Copyright

The distribution and duplication of this document and

the disclosure and use of its contents are prohibited

unless expressly authorised.

Offenders will be liable for damages. All rights created

by a patent grant or registration of a utility model or

design are reserved.

3.5 Revision Rev.

0 of 24 November 2008

4 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com l info@canovate.com l P. +90 216 484 2222

3.6 Proper use

The Liquid Cooling Package Inline serves to dissipate

high heat losses and for the effective cooling of

devices built into a server enclosure. The unit is state

of the art and built according to recognised safety

regulations. Nevertheless, improper use can present

a hazard to life and limb of the user or third parties, or

result in possible impairment of the system and other

property. The unit should thus only be used properly

and in technically sound condition. Any malfunctions

which impair safety should be rectifi ed immediately!

Follow the operating instructions! Intended use also

includes following the operating instructions and

fulfi lling the inspection and maintenance conditions.

3.7 Precautionary measures

Inappropriate use may result in danger. Inappropriate

use may include:

- Use of impermissible tools.

- Improper use.

- Improper rectifi cation of malfunctions.

- Use of replacement parts which are not authorised

by Canovate

3.8 Safety Instructions

The Front Coolers produced by Canovate are

developed and produced with due regard to all safety

precautions.

Nevertheless, the unit still causes a number of

unavoidable dangers and risks. The safety instructions

provide you with an overview of these dangers and

the necessary safety precautions.

In the interest of your safety and the safety of others,

please read these safety instructions carefully before

assembly and commissioning of the Front Cooler.

Follow the user information found in these instructions

and on the unit carefully.

3.9 Symbols in these operating

3.10 instructions

Danger!

This warning symbol is used to indicate great

dangers caused by the product which may

result in injury and even death if the indicated

preventative measures are not followed.

Caution!

This warning symbol is used to indicate

procedures which may cause risk of equipment

damage or personal injury.

Note:

This instruction symbol indicates information

concerning individual procedures, explanations,

or tips for simplifi ed approaches.

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 5

3.11 Important safety instructions

Danger! Electric shock!

Contact with live electrical parts may be deadly.

Before switching on, ensure that it is not

possible to come into contact with live electrical

parts.

Danger! Injury caused by fan impellors!

Keep persons and objects away from the fan

impellors! Do not remove covers until the power

supply is disconnected and impellors are not

moving! Always use mechanical protection

when working! Shut down the respective fan

as much as possible during maintenance work!

Tie long hair back! Do not wear loose clothing!

Fans start up automatically following power

disruptions!

Danger! Cut wounds, especially through sharp

edges of the fan module and heat exchanger

modules!

Put on protective gloves before beginning

assembly or cleaning work!

Danger! Injury due to falling loads!

Do not stand under suspended loads when

transporting the unit with a hoist trolley, a

forklift, or a crane.

Caution! Risk of malfunction or damage!

Do not modify the unit! Use only original spare

parts!

Caution! Risk of malfunction or damage!

Proper and fl awless unit operation can only be

ensured when it is operated under the intended

ambient conditions. As far as possible, be sure

that the ambient conditions for which the unit is

designed are complied with, e.g. temperature,

humidity, air purity.

Caution! Risk of malfunction or damage!

All media necessary for the control system,

e.g. cooling water, must be available during the

entire operating time.

Caution! Risk of malfunction or damage!

In order to avoid frost damage, the minimum

permissible input water temperature of +6 °C

must not be undercut at any point in the water

cycle!

It is vital that the manufacturers’ consent is

obtained before adding anti-freeze!

6 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Caution! Risk of malfunction or damage!

During storage and transportation below

freezing point, the water cycle should be

drained completely using compressed air!

Caution! Risk of malfunction or damage!

Only set the temperature control setpoint as

low as is strictly necessary, since the danger

of condensation through undercutting the

dew point increases with a falling water inlet

temperature!

Ensure that the enclosure is sealed on all

sides, particularly at the cable

entry (condensation)!

3.12 Service and technical staff

The installation, commissioning, maintenance and

repair of this unit may only be carried out by qualifi ed

mechanical and electro-technical trained personnel.

Only properly instructed personnel may carry out

service on a unit while in operation.

3.13 RoHS compliance

Front Cooler fulfi ls the requirements of EU directive

2002/ 95/EC on the Restriction of Use of Certain

Hazardous Substances in Electrical and Electronic

Equipment (RoHS) of 13 February, 2014.

Note:

Corresponding information concerning the RoHS

directive is provided by our fi rm on the Internet at

www.canovate.com

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 7

4. Transport and handling

4.1 Scope of delivery of Front Cooler

The scope of delivery of a Front Cooler includes:

Qty. Parts

Front Cooler, ready for connection

1

1

1

1

1

1

1

4

1 Assembly instructions

Accessories:

Pipe fi tting condensate pump

Condensate hose for condensate pump

Condensate hose emergency overfl ow

Sealing strip

Connection plug

Cable tie and spreading anchor

Jumper for connection plug (strain relief for connection cable)

Eyebolts

4.2 Transport

The Front Cooler is delivered shrink-wrapped on a

pallet.

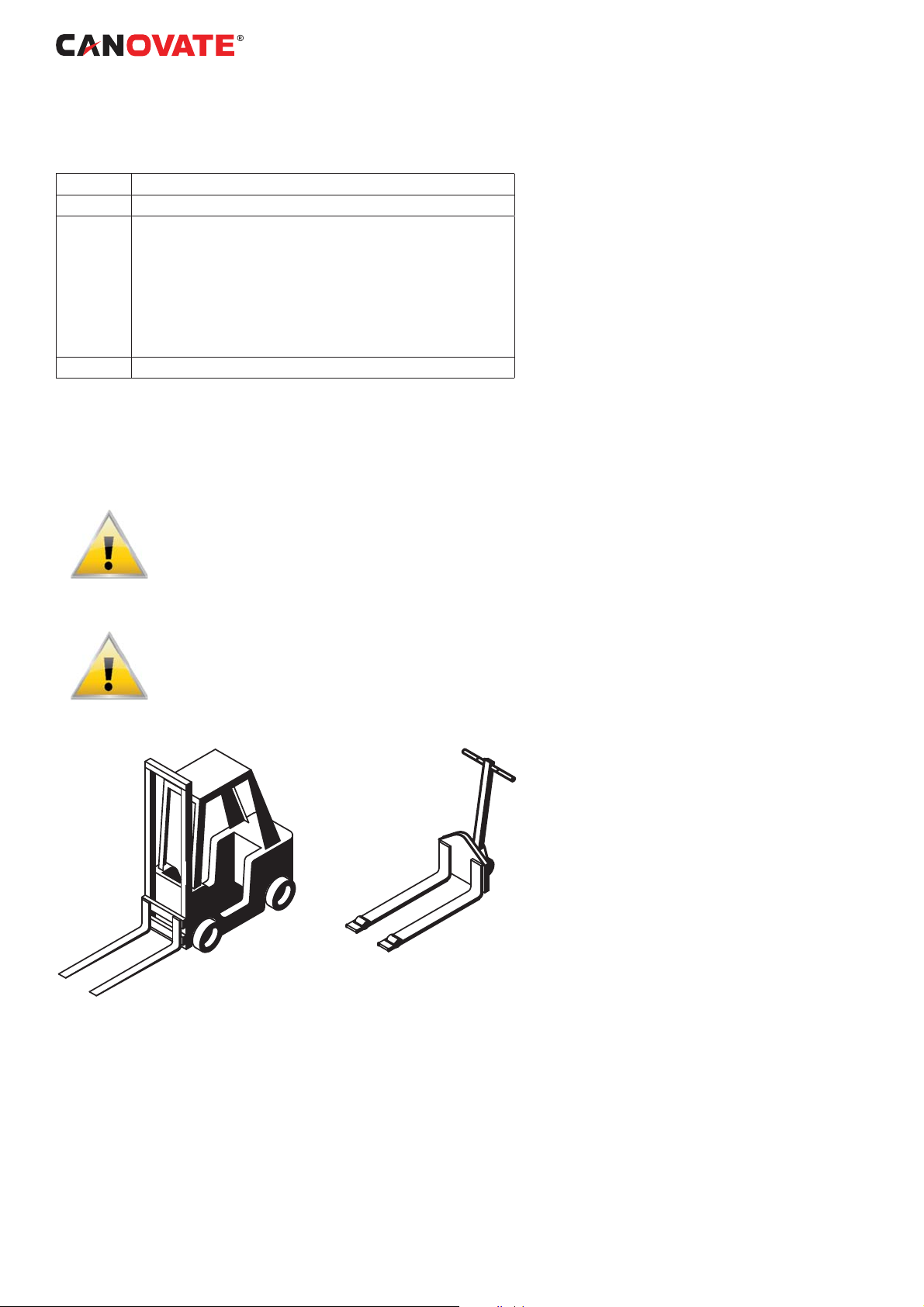

Caution!

Because of its height and small base, the Front Cooler

is subject to tipping. Risk of toppling, especially

after the unit is removed from the pallet!

Caution!

Transport of the Front Cooler without a pallet:

- Use only suitable and technically sound lifting

gear and load-bearing devices with suffi cient

load capacity.

Recommended module handling equipment

Pallet Jack

Forklift

Module Handling

If possible, transport the module using a forklift or

pallet jack.

• If using a forklift or pallet jack, ensure that the fork

tine length is suitable to safely move the packaged

module.

• Canovate recommends keeping the module in the

protective packaging until it has been moved to the

installation site.

• When handling and unpacking the module, exercise

8 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com l info@canovate.com l P. +90 216 484 2222

great care to prevent damage.

• Do not lift the module any higher than 6” (152mm)

while moving it. If it must be lifted higher than 6”

(152mm), exercise great care and keep all personnel

who are not helping move the module at least 20’

(5m) away from the module.

• The Front Cooler ships with four outrigger-style

wheels to permit rolling it into position. Canovate

recommends using a forklift or pallet jack to move the

Front Cooler as near as practical to its installation site

before removing it from the shipping pallet.

4.3 Unpacking

Upon arrival of the module and before unpacking,

verify that the labeled equipment matches the bill of

lading. Carefully inspect all items for either visible or

concealed damage. Damage should be immediately

reported to the carrier and a damage claim fi led with a

copy sent to Canovate or to your sales representative.

If you later fi nd any concealed damage, report it to

both the shipping company and your local Canovate

representative.

Check to be sure all required assemblies and parts

have been received.

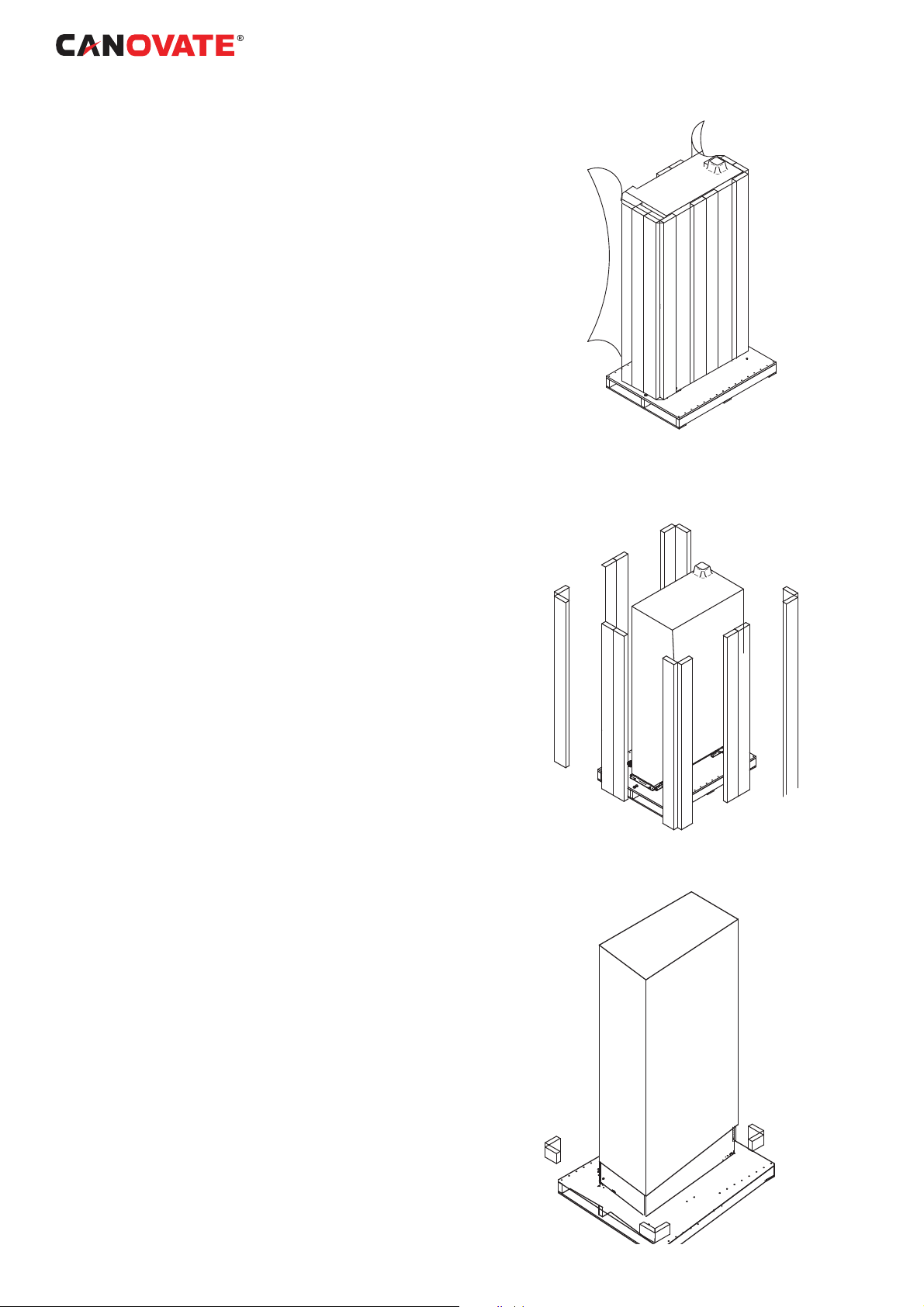

The Front Cooler is shipped in protective packaging

and secured to a pallet (see Figure 5). Do not remove

these protective items from the Front Cooler before

it is at the installation location. When unpacking and

handling the Front Cooler, exercise extra care to

prevent damage.

Caution

Risk of sudden refrigerant discharge. Can cause loss

of charge and minor injury.

If the optional pre-charged option is chosen, the

Front Cooler module is shipped with a full charge of

R-134a refrigerant under pressure. Do not remove

the pipe caps or plugs before the module is ready for

connection to Front Cooler Piping.

Supply and return fi ttings on the pre-charged Front

Cooler modules are one-shot couplings.

Do not disconnect one-shot couplings after they

have been connected. Disconnection will release

pressurized R-134a refrigerant from the Front Cooler.

Recyclable Packaging

All material used to package this module is recyclable.

Please save for future use or dispose of the material

appropriately.

WARNING : Risk of top-heavy module falling over.

Can cause equipment damage, injury and death.

Read all of the following instructions before attempting

to move, lift, remove packaging from the module, or

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 9

preparing module for installation.

Use extreme caution and care when moving and

installing this unit. Use lifting equipment that is rated

for the weight of the unit by an OSHA-certifi ed rating

organization. Personnel should be properly trained

and qualifi ed to move and rig equipment

CAUTION: Risk of sharp edges, splinters and

exposed fasteners. Can cause personal injury.

Only properly trained personnel wearing appropriate

safety headgear, gloves, shoes and glasses should

attempt to move, lift, remove packaging from, or

prepare module for installation

NOTICE :Risk of overhead interference. Can cause

module or structure damage.

The module may be too tall to fi t through a doorway

while on the skid. Measure the module and doorway

heights and refer to the installation plans before

moving the module to verify clearances.

NOTICE: Risk of improper storage. Can cause

module damage.

Keep the module indoors and protected from

dampness, freezing temperatures and contact

damage.

Exterior stretch wrapping

surrounds other protective

shipping features

Planks at the corners and on the sides

protect the Front Cooler during shipping

NOTICE :Risk of damage from forklift. Improper

handling with the forklift can cause exterior and/or

underside damage.

Keep tines of the forklift level and at a height suitable

to fi t below the pallet.

Domestic Packaging

1. Remove the exterior stretch-wrap packaging from

around the module, exposing the protective corner

and side packaging planks.

2. Remove corner and side packaging planks from

the module, exposing the bag over the module.

Remove the bag when ready to install the Front

Cooler.

Remove the Stabilizers at the corners

10 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com l info@canovate.com l P. +90 216 484 2222

5.

6. COMPONENTS

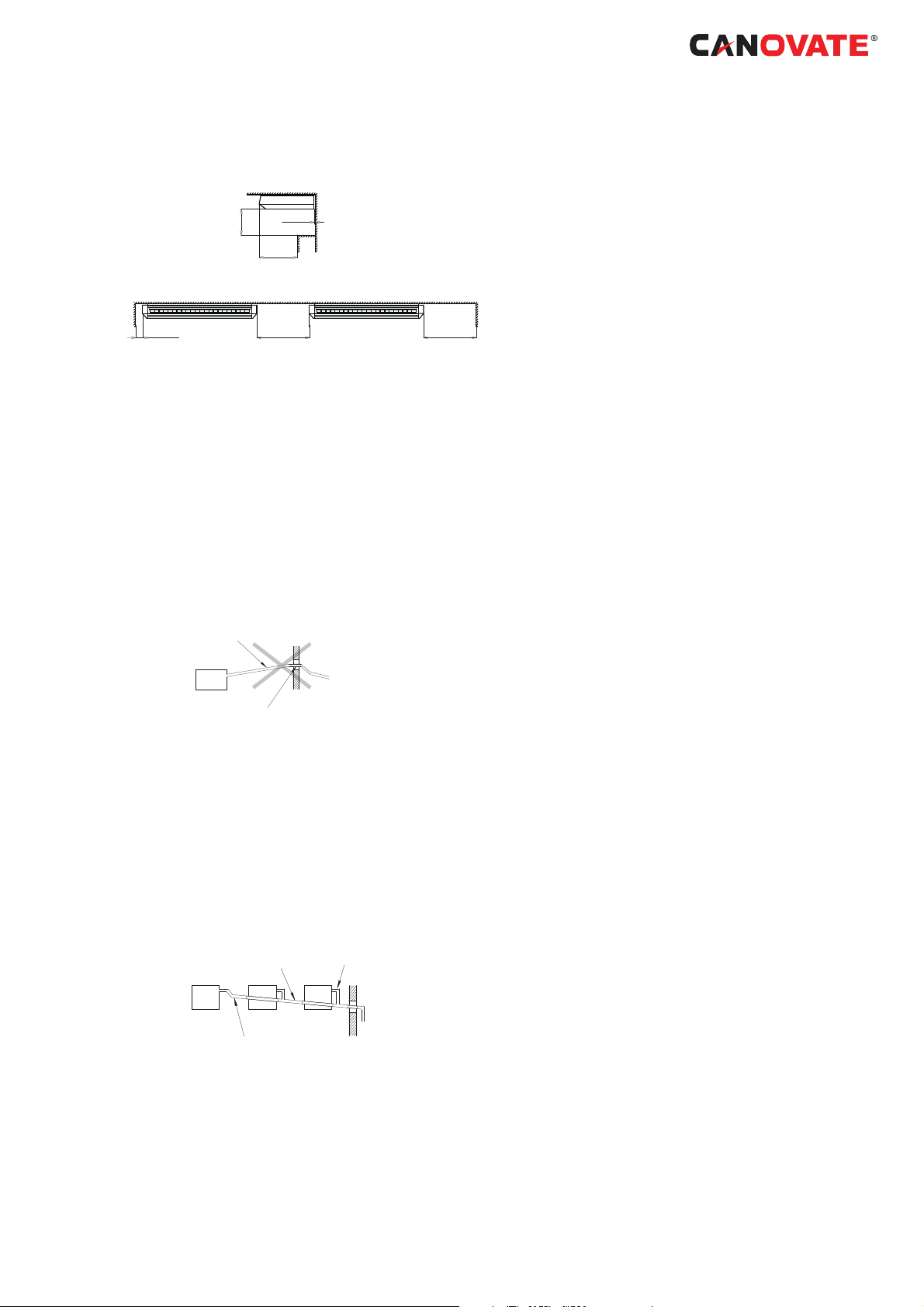

6.1 Components of CAN-BREEZE

1 Cabinet Frame

2 Removable Front Glass Door

3 Removable Rear Solid Door

4 Removable Side Panel

5 Fan Unit

6 Rear Panel of Fan’s Filter

7 Heat Exchanger

8 Air Duct

9 Remote Controller

10 Cover of Remote Controller

11 Adjustable Feet

6.2 Components of Fan Unit

1 Fan Motor

2 Fan

3 Fan Case

4 Electrical Control Box

5 Rail of Fan

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 11

7. UNITS INSTALLATION

WARNING:

- Check to ensure that the accesso.ries are packed

with the indoor unit.

- Do not install the indoor units outdoors. If installed

outdoors, an electric hazard or electric leakage will

occur.

- Consider the air distribution from each indoor unit to

the space of the room, and select a suitable location

so that uniform air temperature in the room can be

obtained.

- Avoid obstacles which may hamper the air intake or

the air discharge fl ow.

- Pay attention to the following points when the indoor

units are installed in a hospital or other places where

there are electronic waves from medical equipment,

etc.

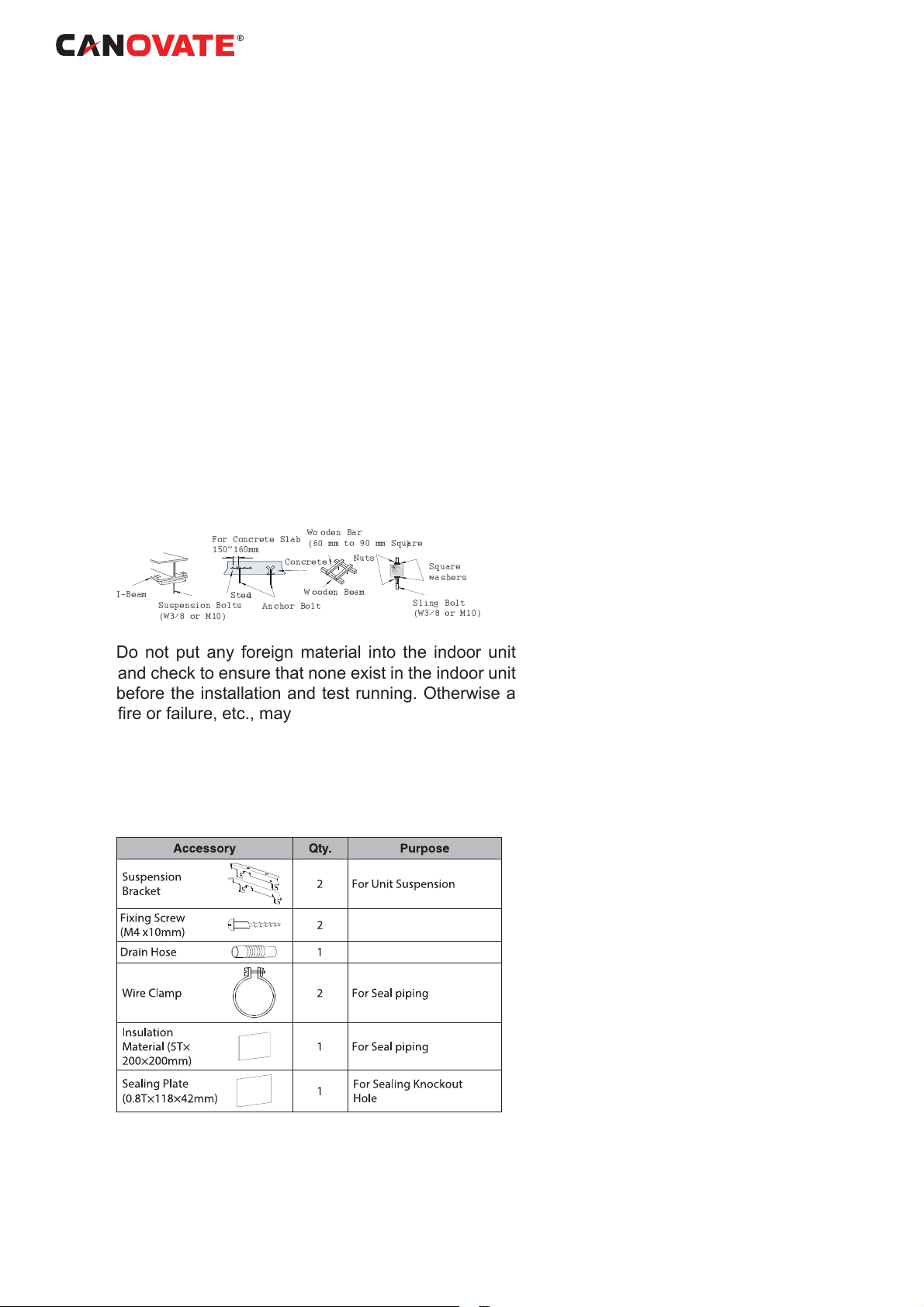

Mount suspension bolts using M10 (W3/8) as size, as

shown below:

For Concrete Slab

150~160mm

I-Beam

Suspension Bolts

(W3/8 or M10)

Steel

Do not put any foreign material into the indoor unit

and check to ensure that none exist in the indoor unit

before the installation and test running. Otherwise a

fi re or failure, etc., may occur.

Wo oden Bar

(60 mm to 90 mm Square)

Concrete

W ooden Beam

Anchor Bolt

Nuts

Square

washers

Sling Bolt

(W3/8 or M10)

7.1 UNIT INSTALLATION

7.1.1 F A C T O R Y -SUPPLIED

ACCESSORIES

12 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com l info@canovate.com l P. +90 216 484 2222

7.1.2 INITIAL CHECK

Indoor unit with proper clearance around it for

operation and maintenance working space, as

shown below

Min. 500

Min.400

Min. 40

Check down slope pitch of drain piping is following

the specifi cation indicate in chapter ‘Drain Piping’

8. DRAIN PIPING

8.1 GENERAL

CAUTION:

- Do not create an upper-slope or rise for the drain

piping, since drain water will fl ow back to the unit

and

leakage to the room will occur when the unit

operation is stopped.

Incorrect: Upward Slope

Min. 8

(mm)

Min. 300Min. 300

INCORRECT

Incorrect: Rising Part

Do not connect the drain pipe with sanitary or

sewage

piping or any other drainage piping.

- When the common drain piping is connected

with other indoor units, the connected position of

each indoor unit must be higher than the common

piping.

The pipe size of the common drain pipe must

be large enough according to the unit size and

number of unit.

Drain Piping connection

CORRECT

1/25~1/100 Down Slope

Common Drain Piping

Drain piping will require insulating if the drain is

installed in a location where condensation forming

on

the outside of drain pipe may drop and cause

damage. The insulation for the drain pipe must

be selected to insure vapor sealing and prevent

condensation forming.

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 13

Drain trap should be installed next to indoor unit. This

trap must be designed to good practice and be

checked with water (charged) and tested for correct

fl ow. Do not tie or clamp the drain pipe and refrigerant

pipe together.

NOTE:

Install drainage in accordance with national and local

codes.

After performing drain piping work and electrical

wiring, check to ensure that water fl ows smoothly as

in the following procedure:

Checking Unit without Drain-up Mechanism

- Pour approximately 1.8 liters of water into the drain

pan.

- Check to ensure that the water fl ows smoothly or

whether no water leakage occurs. When water cannot

be found at the end of the drain piping, pour another

approximately 1.8 liters of water into the drain pan.

NOTE:

Pay attention to the thickness of the insulation when

the left side piping is performed. If it is too thick, piping

can not be installed in the unit.

8.2 DRAIN PIPE CONNECTION

The standard direction of drain piping connection

is right side as viewed from the discharge grilles.

However, it can be performed from the left side

connection is required due to the building construction.

For Right Side Connection

1. Insert the hose into the wire clamp.

2. Push the drain hose onto the drain boss until the

hose reaches the end of the drain pan.

3. Tighten the screw for the wire clamp in order to

hold the hose around the drain connection without

any leakage of drain water as shown bellow.

4. Insulate the drain hose around the wire clamp to

prevent any condensation as shown.

Drain Hose

Wire Clamp A

Wire Clamp b

14 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

Drain Pipe

Insulation

Drain Boss

www.canovate.com l info@canovate.com l P. +90 216 484 2222

For Left Side Connection

Fan Runner

Drain Boss

Fan Motor

Rear Side

Insulation Plug

Drain Plug

Fastener Band

Drain Plug

Remove the drain plug of the left-side drain boss as

indicated in the following procedure.

1. Cut the fastener.

2. Remove the insulation material.

3. Remove the drain plug.

4. Insert the drain plug into the right-side and drain

boss using a driver as shown below.

Driver

Drain Plug

Drain Connection

Unit

Side

5. After inserting the drain plug into the right-side drain

boss, seal the jointed part by using a water-proof

chloride type sealing material and secure it with a

fastener.

Seal Material

Plug

6. Wrap the insulation material around the drain

connection.

7. Connect the drain hose to the left side drain

connection using the same procedure as for the right

side drain connection.

Connecting a Drain Piping

1. Prepare a polyvinyl chloride (PVC) tube with an

outer diameter of 26mm. (VP20)

2. Pay attention to the position of the drain pipe. Keep

the down-slope, 1/25 to 1/100. Do not create an upper

slope or rise for the drain piping.

3. Seal the connecting part of the drain pipe by using

the water-proof chloride type sealing material.

4. Wrap the insulation material around the connecting

part perfectly.

5. Fasten the drain pipe to the connecting part using

the factory-supplied clamp.

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 15

Drain Hose

(

)

Insulation

eld supplied

Secure

Downward

Slope

Insulation

Clamp

6. Do not connect the drain pipe with sanitary sewage

or any other drainage pipe.

7. When installing the pipe, do not tie the drain pipe

and refrigerant pipe together. Tie the drain pipe as

shown below

Band

Rear Side piping

Band

8. After completing the drain pipe work, pour water

into the drain pan and check to ensure that water

fl ows smoothly

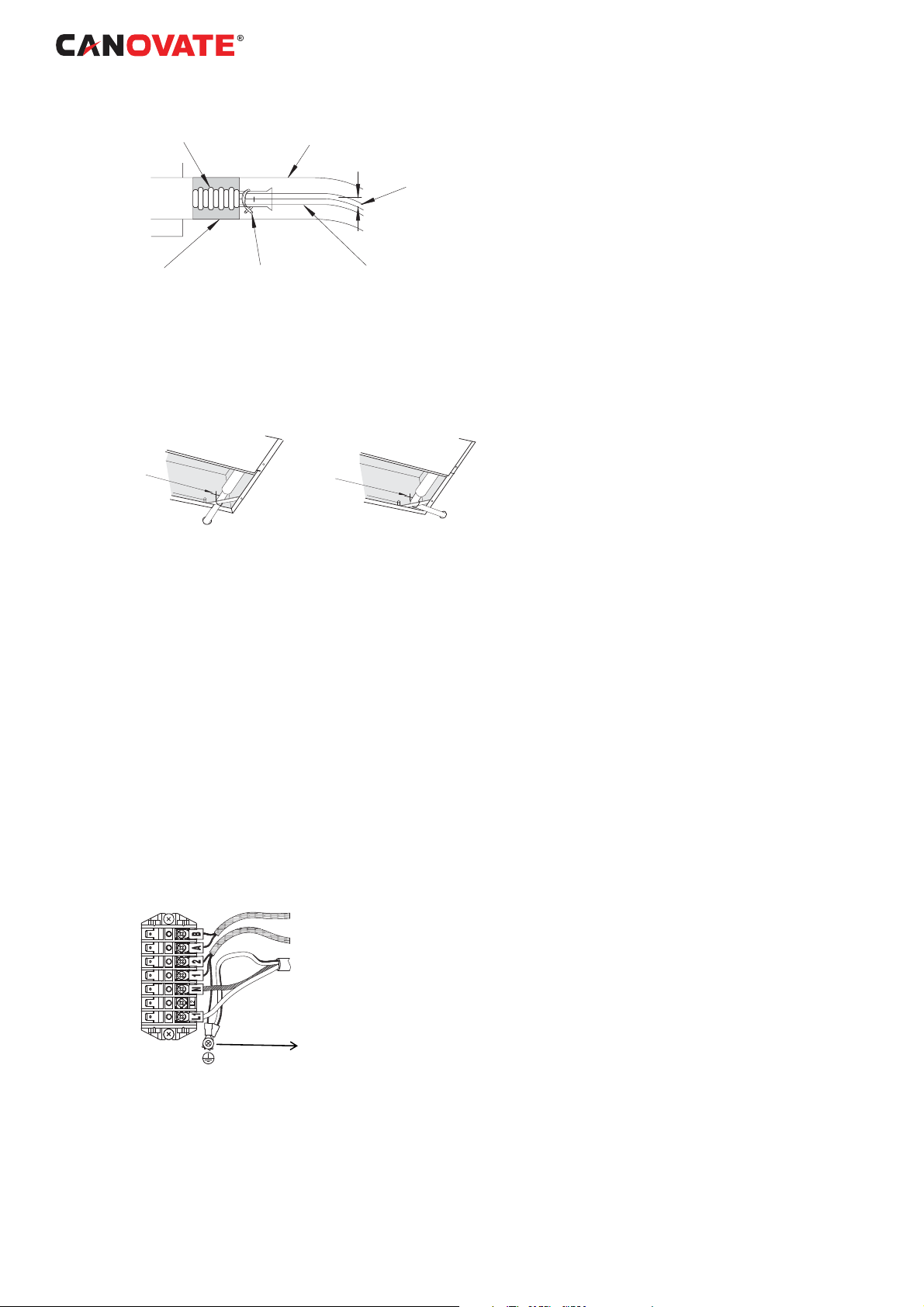

9. ELECTRICAL WIRING

9.1 ELECTRICAL WIRING CONNECTION

FOR INDOOR UNIT

CAUTION:

Use twisted shielded pair cable or shield pair cable

for transmission wires between the indoor and the

outdoor units, and connect the shielded part to the

earth screw in the electrical box of the indoor unit as

shown below.

Single phase connection

Remote Control (PC-ART)

Transmission Wires

Power supply wires

(Single phase)

Earth Screw

Rear Side piping

16 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com l info@canovate.com l P. +90 216 484 2222

The electrical wiring connection for the indoor unit is

shown below.

1. Connect the cable of the remote control switch to

the terminals A and B in electrical box through the

connecting hole in the cabinet, as shown below.

2. Connect the power supply and ground wires to the

terminals in the electrical box.

3. Connect the wires between the indoor unit and the

outdoor unit to the terminals 1 and 2 in the electrical

box, as shown below:

Knockout hole

for wirings

Grille

Electrical Box

Connector

Cord clamp

RCS (Optional)

Transmission wires

Power wires

RCS (Optional)

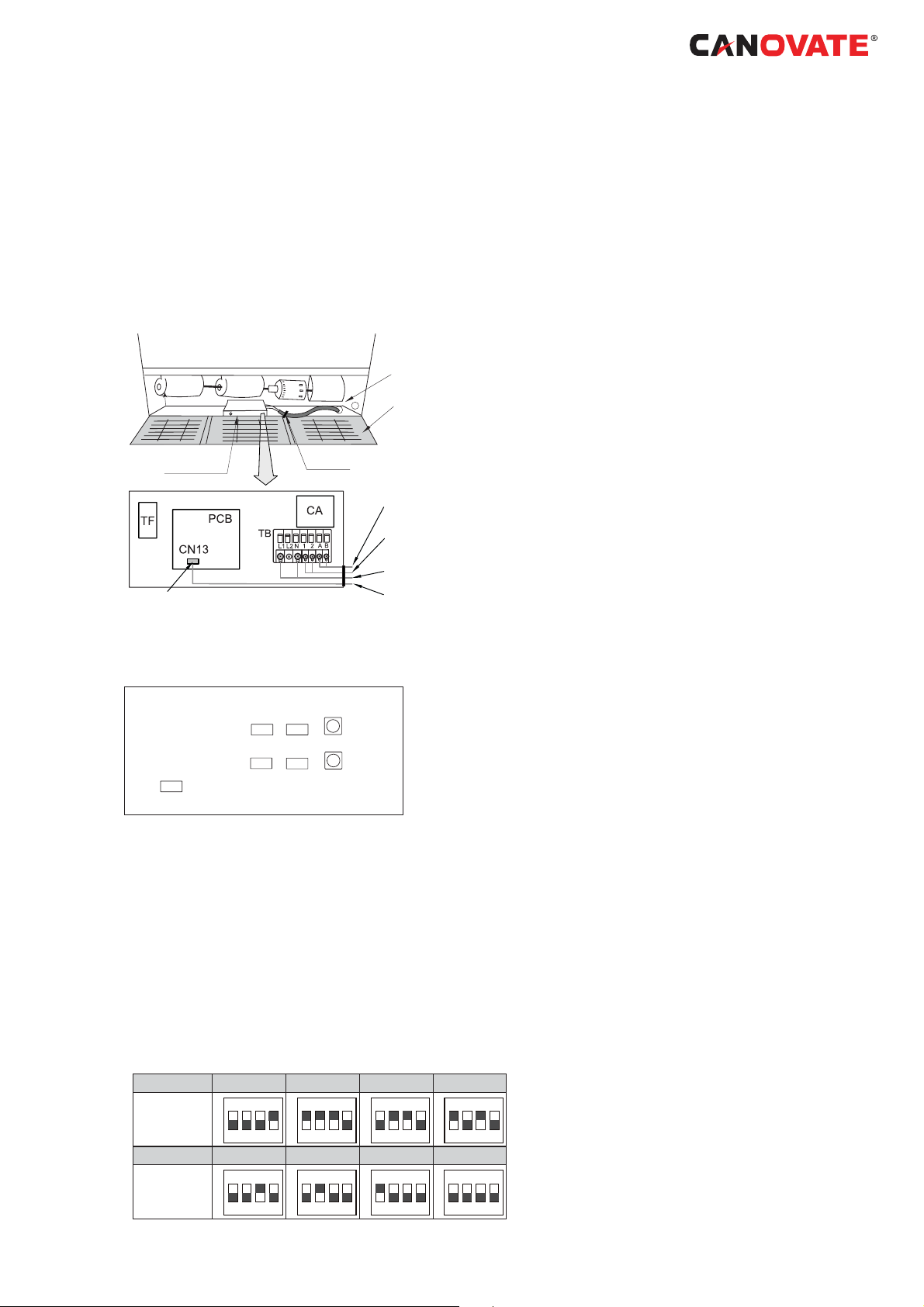

9.2 SETTINGS OF DIP SWITCHES

Quantity and Position of Dip Switches

Dips switches position is the following:

RSW2

DSW5

DSW4

DSW3

DSW6

RSW1

DSW7

CAUTION:

Before setting dips switches, fi rstly turn off power

source and set the position of the dips switches. If the

switches are set without turning off the power source,

the contents of the setting are invalid.

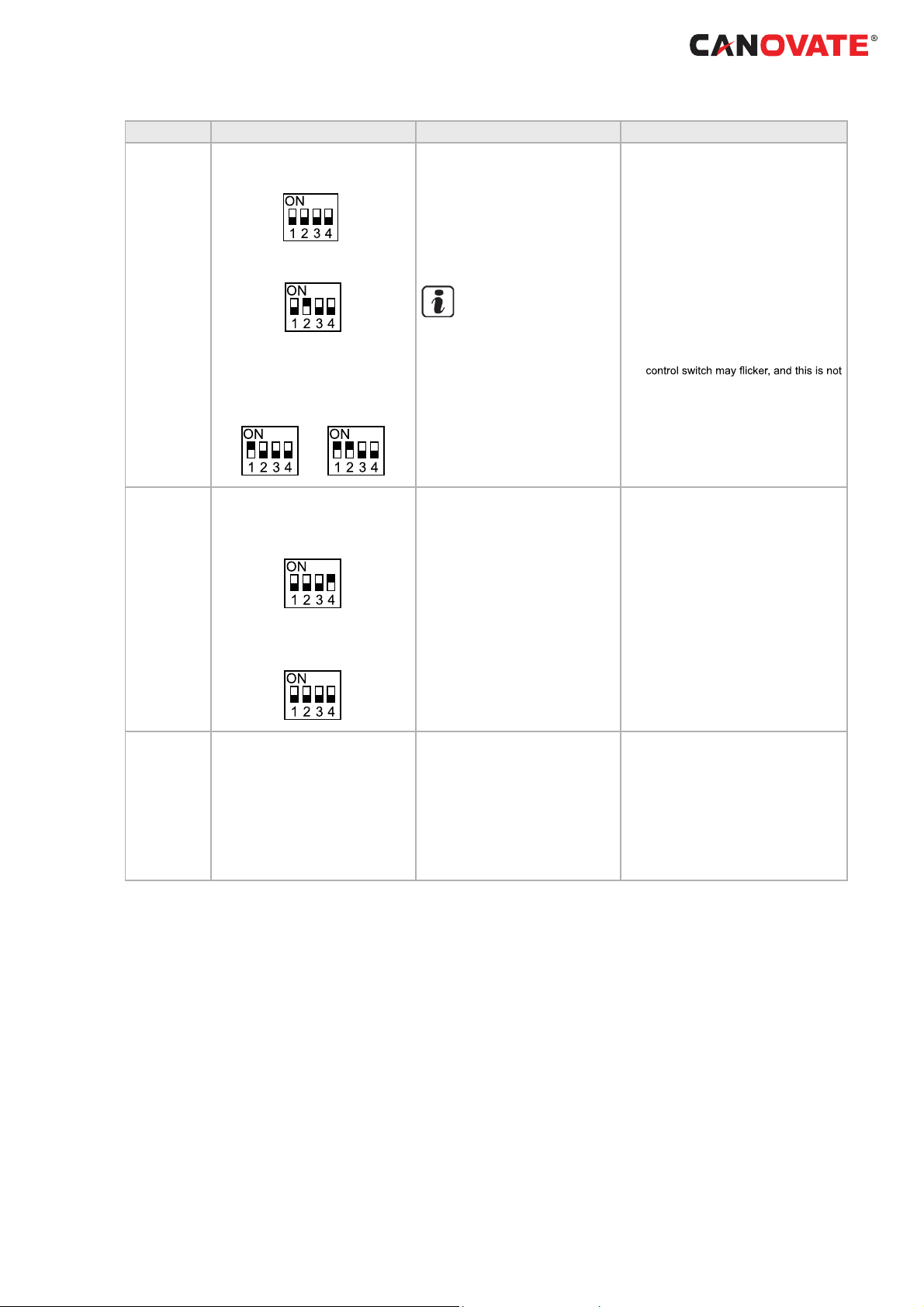

DSW3: Capacity Code Setting

No setting is required, due to setting before shipment.

This dip switch is utilized for setting the capacity code

which corresponds to the Horse Power of the indoor

unit.

HP 1.8 2.0 2.3 2.5

Setting

Position

ON

1 2 3 4

3.0 4.0 5.0 6.0

Setting

Position

www.canovate.com l info@canovate.com l P. +90 216 484 2222

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

ON

1 2 3 4

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 17

DSW6 and RSW1: Unit No. Setting

The below fi gure indicates the position before

shipment.

Indication

Use athead driver

DSW6 RSW1

ON

1 2 3 4 5 6

Here is set DSW6 and RSW1 before shipment up to 63

can be set.

Ex. Setting nº16

ON

1 2 3 4 5 6

Nº 1 PIN is on

RSW1

Fix to 6

DSW5 and RSW2: Refrigerant Cycle No. Setting

Setting is required. Setting position before shipment

in

DSW5 RSW2

ON

1 2 3 4 5 6

Here is set DSW5 and RSW2 before shipment up to 63

can be set.

Ex. Setting 5

system

RSW2

ON

1 2 3 4 5 6

All pins are OFF

Fix to 5

DSW4: Unit Model Code Setting

No setting is required. This switch is utilized for setting

the model code which corresponds to the indoor unit

type.

Indoor Unit Model DSW4 Setting

RPC

18 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

ON

1 2 3 4

www.canovate.com l info@canovate.com l P. +90 216 484 2222

DSW7: Fuse Recover

In case of applying high voltage to the terminal

1,2 of TB1, the fuse on the PCB1(M) is cut. In

such a case, rstly correct the wiring to TB1 and

then turn ON #1 (as showing beside)

DSW7: Remote Control Selection

No setting is required. Setting position before

shipment is all OFF (PC-ART) Remote Control

Switch Selected).

NOTE:

- The mark “■“ indicates position of dips switches.

Figures show setting before shipment or after

selection.

10. MAINTENANCE

Do not operate the system without the air fi lter to

protect the indoor unit heat exchanger against being

clogged. Turn OFF the main power switch before

taking out the fi lter. (The previous operation mode

may appear.)

The indication, “FILTER” is shown on the display

of the remote control switch. Take out the air fi lter

according to the indicated steps for each unit.

ON

ON

1 2

1 2

10.1 TAKE OUT THE FILTER

Ceiling Type

1. Side the knobs.

Knob

2. Open the air inlet grille.

3. Take out the air fi lter from the air inlet grille.

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 19

10.2 CLEAN THE FILTER

Clean the air fi lter according to the following steps:

1. Use a vacuum cleaner or let water fl ow onto the air

fi lter for removing the dirt from the air fi lter.

CAUTION:

Do not use hot water higher than approximately 40ªC

2. Dry the air fi lter in the shade after shaking off

moisture.

3. Do not use cleaner or other chemicals

10.3 RESET OF FILTER INDICATION

After cleaning the air fi lter, press the “RESET” button.

The FILTER indication will disappear and the next

fi lter cleaning time is set.

20 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com l info@canovate.com l P. +90 216 484 2222

11. OUTDOOR UNIT

11.1 Important Notice

• No part of this manual may be reproduced without

written permission.

• If you have any questions, contact your service

contractor of Canovate.

• This manual gives a common description and

information for this air conditioner which you operate

as well as for other models.

• Check and make sure that the explanations of each

part of this manual correspond to your air conditioner

model.

• Refer to the models codifi cation to confi rm the main

characteristics of your system.

• Signal words (DANGER, WARNING and CAUTION)

are used to identify levels of hazard seriousness.

Defi nitions for identifying hazard levels are provided

below with their respective signal words.

• It is assumed that this unit will be operated and

serviced by English speaking people. If this is not the

case, the customer should add safety, caution and

operating signs in the native language of the personal.

• This air conditioner has been designed for the

following temperature. Operate the air conditioner

within this range:

Temperature

Maximum Minimum

Cooling

Mode

Heating

Mode

DB: Dry Bulb Temperature

WB: Wet Bulb Temperature

Indoor 32°C DB/23°C WB

Outdoor 46 ºC DB

Indoor 27 °C DB

Outdoor 15 °C WB

21°C DB/15°C WB

-5 °C DB

15 °C DB

-20 °C WB

These operations modes are controlled by the remote

control switch.

• This manual should be considered as a permanent

part of the air conditioner. This manual gives a

common description and information for this air

conditioner which you operate as well as for other

models.

DANGER

Pressure Vessel and Safety Device: This air

conditioner is equipped with a high pressure vessel

under PED (Pressure Equipment Directive). The

pressure vessel has been designed and tested

before shipment according to PED. Also, in order to

prevent the system from an abnormal pressure, a high

pressure switch, which needs no fi eld adjustment, is

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 21

utilized in the refrigeration system.

Therefore, this air conditioner is protected from

abnormal pressures. However, if abnormally high

pressure is applied to the refrigeration cycle including

the high pressure vessel(s), it will result in serious

injury or death due to explosion of the pressure

vessel.

Do not apply a pressure higher than the following

pressure to the system, by modifying or changing the

high pressure switch.

CAUTION

This unit is designed for commercial and light industrial

application.

If installed in house hold appliance, it could cause

electromagnetic interference.

Start-up and Operation: Check to ensure that all the

stop valves are fully opened and no obstacle exists

at the inlet/outlet sides before start-up and during the

operation.

Maintenance: Periodically check the high pressure

side pressure.

If the pressure is higher than the maximum allowable

pressure, stop the system and clean the heat

exchanger or remove the cause.

Maximum Allowable Pressure and High Pressure

Cut-out Value:

Outdoor Unit Model Refrigerant

8 kW

14 kW R410A 4.15 4.00 ~ 4.10

R410A

Maximum Allowable

Pressure (MPa)

4.15

High Pressure Switch

Cut-out Value (MPa)

4.00 ~ 4.10

NOTE

The label for the vessel under PED are attached

on the high pressure vessel. The pressure vessel

capacity and vessel category are indicated on the

vessel.

Location of High Pressure Switch

Compressor

NOTE

The high pressure switch is indicated on the electrical

wiring diagram in the outdoor unit as PSH connected

to printed circuit board (PCB1) in the outdoor unit

22 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Structure of High Pressure Switch

Contact Point Pressure Detected

Connected to the electrical wire

DANGER

Do not change the high-pressure switch locally or

change the high pressure cut-out set value locally. If

changed, it will cause serious injury or death due to

explosion. Do not attempt to turn service valve rod

beyond its stop.

12. TRANSPORTATION AND

HANDLING

When hanging the unit, ensure a balance of the unit,

check safety and lift it up smoothly

Do not remove any packing materials.

Hang the unit under packing condition with two ropes.

For safety reasons ensure that the outdoor unit is

lifted smoothly and does not lean

Model

8-14 kW

Gross

Weight (kg)

90

13. BEFORE OPERATION

CAUTION

Supply electrical power to the system for approximately

12 hours before start-up or a long shutdown. Do not

start the system immediately after power supply,

it may cause a compressor failure because the

compressor is not heated well.

When the system is started after a shutdown longer

that approximately 3 months, it is recommended to

check the system by your service contractor.

> 60º

0.7 -1.0 m

Turn OFF the main switch when the system is to be

stopped for a long period of time: If the main switch

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 23

is not turned OFF

the oil heater is always energised during compressor

stopping.

Make sure that the outdoor unit is not covered with

snow or ice.

If covered, remove it by using hot water (approximately

50°C). If the water temperature is higher that 50 °C, it

will cause damage to plastic parts.

, electricity will be used, because

14. AUT

The system is equipped with the following functions.

Three minute guard

The compressor remains of

once it has stopped. If the system is started within

approximately 3 minutes after it has stopped, the

RUN indicator is activated. However, the cooling

operation or the heating operation remains off and

does not start until after 3 minutes has elapsed.

Operation may stop for 6 minutes maximum to protect

compressor.

Frost prevention during cooling operation

When the system is operated in a low temperature

room, the cooling operation may be changed to fan

operation for a while to avoid frost formation on the

indoor heat exchanger.

Automatic restart after power failure

If the power supply is interrupted for short periods of

time (up to 2 seconds) the Remote Control switch will

retain the settings and the unit will restart when the

power is restored. If Automatic Restart is required after

periods of lost power supply in excess of 2 seconds

please contact your distributor (optional function).

OMATIC CONTROLS

f for at least 3 minutes

Slow air control during heating operation

Can be setting than when the compressor is stopped

while the thermostat is OFF, or the system is

performing the automatic defrosting operation, the

fan speed is set at the slow position.

Automatic defrosting cycle

When the heating operation is stopped by pressing

RUN/STOP switch, frosting on the outdoor unit

is checked and the defrosting operation may be

performed for the maximum of 10 minutes.

Prevention of overload operation

When the outdoor temperature is too high during

heating operation, heating operation is stopped

due to activation of the outdoor thermistor until the

temperature becomes low.

Hot start during heating operation

To prevent cold air discharge, the fan speed is

controlled from the slow position to the set position

according to the discharge air temperature. At this

time the lover is fi xed horizontally.

24 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW www.canovate.com l info@canovate.com l P. +90 216 484 2222

15. BASIC TROUBLESHOOTING

CAUTION

When water leakage from the indoor unit occurs, stop

the operation and contact your contractor

When you smell or white smoke occurs from the unit,

stop the system and contact your contractor.

This is not abnormal

• Sound from deforming Part

During system starting or stopping, and abrading

sound might be heard. However, this is due to thermal

deformation of plastic parts. It is not abnormal.

• Refrigerant Flow Sound

While the system is being started or stopping, sound

from the refrigerant fl ow may be heard.

• Smells from Indoor Unit

Smell adheres on indoor unit after a long period of

time. Clean the air fi lter and panels or make a good

ventilation.

• Steam from Outdoor Heat Exchanger

During defrosting operation, ice on the outdoor heat

exchanger is melted, resulting in making steam.

• Dew on Air Panel

When the cooling operation continues for a long

period of time under high humidity conditions (higher

than 27°C DB/80% R.H.), dew can form on the air

panel.

• Dew on Cabinet

When the cooling operation continues for a long

period of timer (higher than 27°C DB/80% R.H.), dew

can form on the cabinet.

• Sound for the indoor unit heat exchanger

During the cooling operation, a sound may be heard

from the indoor unit heat exchanger due to water

freezing or melting.

No operation

Check whether the SET TEMPERATURE is set at the

correct temperature.

Not cooling well or heating well

-- Check for obstruction of air fl ow of the outside or

inside units.

-- Check if too much heat source exists in the room.

-- Check if the air fi lter is clogged with dust.

-- Check to see if the doors or windows are opened

or not.

-- Check if the temperature condition is not within the

operating range.

Abnormal swing louver’s position

Check if the four louver’s position at the air outlet are

in same

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 25

position.

If trouble still remains...

If the trouble still remains even after checking the

above items, contact your service contractor and

inform the following data:

-- Unit Model Name

-- Content of Trouble

-- Alarm Code no. on Liquid Crystal Display

NOTE

Except for a long period of shutdown, keep the main

switch ON, since the oil heater is energised when the

compressor is stopped.

26 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com l info@canovate.com l P. +90 216 484 2222

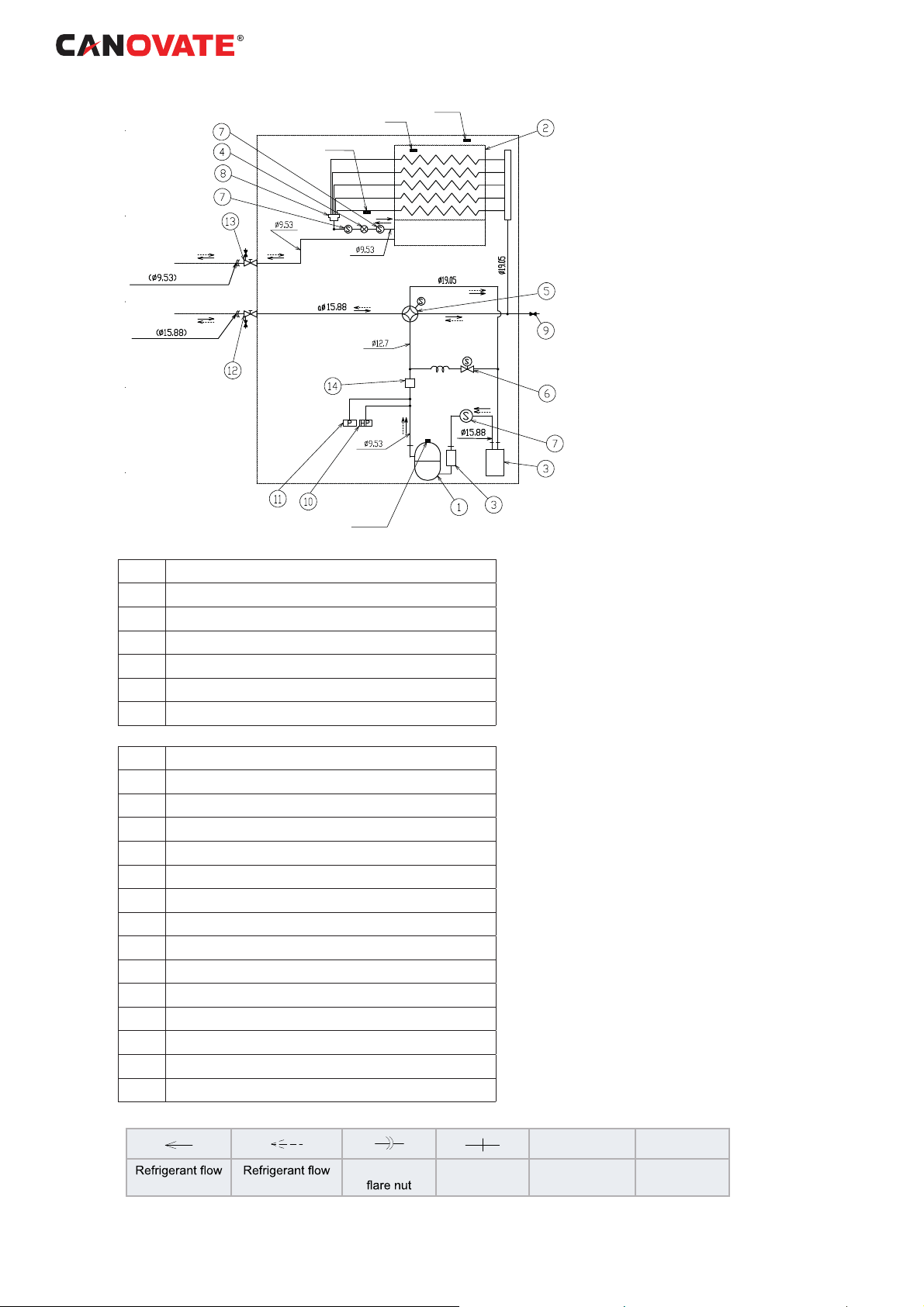

16. NAME OF PARTS OUTDOOR UNIT

No. Part Name

1 Compressor

2 Accumulator

3 Heat exchanger

4 Propeller fan

5 Fan motor

6 Strainer

7 Distributor

8 Reversing valve

9 Micro-computer control expansion

valve

10 Solenoid valve for hot gas

11 Stop valve for gas line

12 Stop valve for liquid line

13 Check Joint

14 Electrical box

15 High pressure switch for protection

17 Pressure switch for control

18 Silencer

19 Crankcase heater

20 Vibration absorbing rubber (3pcs.)

21 Air outlet

22 Air inlet

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 27

C

F

D

F

B

A

E

Mark Part name

A Gas line refrigerant piping connection

B Liquid line refrigerant piping connection

C Outdoor unit

D Ambient thermistor

E Discharge gas thermistor

F Pipe thermistor

No Part name

1 Compressor

2 Heat exchanger

3 Accumulator

4 Micro-Computer control expansion valve

5 Reversing valve

6 Solenoid valve for gas bypass

7 Strainer

8 Distributor

9 Check joint

10 High pressure switch for protection

11 Pressure switch for control

12 Stop valve for gas line

13 Stop valve for liquid line

14 Silencer

or cooling for heating

28 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

Connection by

Connection by

welding

www.canovate.com l info@canovate.com l P. +90 216 484 2222

R410A 4.15 MPa

Gas refrigerant

Leakage test

pressure

17. UNIT INSTALLATION

17.1 OUTDOOR UNIT INSTALLATION

CAUTION

Transport the products as close to the installation

location as practical before unpacking.

Do not put any material on the products.

Apply four lifting wires on to the outdoor, when lifting

it by crane

CAUTION

• Install the outdoor unit with suffi cient clearance

around it for operation and maintenance as shown in

the next fi gures. Install the outdoor unit where good

ventilation is available

• Do not install the outdoor unit where is a high

level of oil mist, salty air or sulphurous atmosphere.

• Install the outdoor unit as far as practical (being

at least 3 meters) from electromagnetic wave radiator

(such as medical equipment).

• For cleaning, use noninfl ammable and

nontoxic cleaning liq- uid. Use of infl ammable agent

may cause explosion or fi re.

• Work with suffi cient ventilation, for working in

an enclosed space may cause oxygen defi ciency.

Toxic gas may be pro- duced when cleaning agent is

heated to high temperature by, e.g., being exposed to

fi re.

• Cleaning liquid shall be collected after cleaning.

• Pay attention not to clamp cables when

attaching the service cover to avoid electric shock or

fi re.

C A U T I O N

Keep clearance between the units of more than

100mm, and avoid obstacles that may hamper air

intake, when installing more than one units together.

Install the outdoor unit in the shade or not exposed

to direct sun- shine or direct radiation from high

temperature heat source.

Do not install the Outdoor Unit in a space where a

seasonal wind directly blows to the Outdoor fan.

Check to ensure that the foundation is fl at, level and

suffi ciently strong.

Install the unit in a restricted area not accessible by

the general public Aluminium fi ns have very sharp

edges. Pay attention to the fi ns to avoid injury

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 29

17.2 Installation space

(Unit: mm)

Single Installation Multiple Installation (Two units or more)

Blocked in Inlet Side

Upper Side Open

200 or more of the back space is acceptable when the right and

left sides are open.

Allow 100 mm of space between units. Leave open both right and left sides.

30 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Blocked in Inlet Side

Be sure to use the fan direction guide. Leave open both right and

left sides.

Upper Side Blocked

Single Installation Multiple Installation (Two units or more)

Be sure to use the fan direction guide. Allow 100 mm of space between units.

Leave open both right and left sides.

100 mm or more of the side space is acceptable on the service

cover side.

Leave open both right and left sides.

The length A is as shown in the following table:

LA

0 < L+ 600 or greater

+/+ 1400 or greater

Single Installation Multiple Installation (Two units or more)

Allow 100 mm of space between units. Leave open both right and left sides..

Be sure to use the fan direction guide. Allow 100 mm of space between units.

Leave open both right and left sides.

No more than 2 units for multiple installation.

When L!+XVHDEDVHIRURXWGRRUXQLWWRPDNHL+

Close the base not to allow the outlet air bypassed.

Outlet Side Blocked

Upper Side Open

Allow 100 mm of space between units. Both right and left sides shall be open.

Be sure to use the fan direction guide. Leave open both right and

left sides.

The length A is as shown in the following table:

LA

0 < L+ 600 or greater

+/+ 1400 or greater

Be sure to use the fan direction guide. Allow 100 mm of space between units.

Leave open both right and left sides.

No more than 2 units for multiple installation.

When L!+XVHDEDVHIRURXWGRRUXQLWWRPDNHL+

Close the base not to allow the outlet air bypassed.

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 31

17.3

Installation place provision

Concrete Foundation

1

Foundation could be on fl at and is

recommended be 100-300 mm higher than ground

level.

2 Install a drainage around foundation for smooth

drain

3 When installing the outdoor unit fi x the unit by

anchor bolts of M10.

4 When installing the unit on a roof or a veranda,

drain water sometimes turns to ice on a cold morning.

Therefore, avoid draining in an area that people often

use because it is slippery.

Space for downward piping space

*

Nº

Outdoor Unit

1

2

Mortar Hole (Ø100xDepth 150)

3

Anchor Bolt M10 (Ø12.5 Hole)

4

Drainage (Wide 100xDepth 150)

5

Drainage

6

V

ibration-proof rubber

7

Description

N O T E

When the mark * dimension is secured, piping work

from bottom side is easy without interference of

foundation.

5

The whole of the base of the outdoor unit

should be installed on a foundation. When using

vibration-proof mat, it should also be positioned the

same way. When installing the outdoor unit on a fi eld

supplied frame, use metal plates to adjust the frame

width for stable installation as shown in below fi gure.

32 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW www.canovate.com l info@canovate.com l P. +90 216 484 2222

Outdoor unit is

unstable

Frame

Outdoor unit is

stable

Frame

INCORRECT

70 mm

Base width of outdoor unit

60mm

Frame with (Field supplied)

CORRECT

70 mm

Base width of outdoor unit

100mm or more

Metal plate

Recommended Metal Plate Size

- (Field-Supplied) Material: Hot-Rolled Mild

Steel

- Plate (SPHC) Plate Thickness: 4.5 T

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 33

Fix Unit to the wall

1. -

2. Ensure the foundation so that avoid

the deforming and noise.

3. In case of prevention from vibration

transfer to the building, use rubber

Mat.

Suspended unit

1. Suspend the unit as the drawing

indicates.

2. Ensure that wall can resist the Outcation label plate.

3. It is recommended to select each foot

support to bear the full weight of

the unit (in order to consider stress

fatigue applied when unit is working

too).

Installing location where the unit will be exposed to strong wind.

-

(*) Field supplied

Rubber Material

(Field Supplied)

Wall bracket (*)

Anchor Bolts (*)

Mark Dimension

Model

A (mm) 529

7-14 kW

CAUTION

Pay attention to the following for installation:

Installation shall ensure that outdoor

unit will not incline, vibrate, make noise

or fall down by a blast of wind or in an

earthquake. Calculate quake-resistance

strength to ensure that installation is

strong enough against falling. Fix the unit

in a location without walls or windbreak

and likely exposed to a blast of wind.

to the front and back.

Follow the instructions below to install

on the rooftop or a location without surrounding buildings, where strong wind is

expected against the product.

1. Choose a location where the outlet or

inlet side of the product will not be

exposed to strong wind.

2. When the outlet is exposed to strong

wind:

Direct strong wind may cause lack

operation.

18. REFRIGERANT PIPING &

REFRIGERANT CHARGE

18.1 PIPING MATERIALS

1 Prepare locally-supplied copper pipes.

2 Select the piping size with the correct thickness

and correct material which can have suffi cient

pressure strength.

3 Select clean copper pipes. Make sure there is

no dust and moisture inside. Blow the inside of the

pipes with oxygen free nitrogen to remove any dust

and foreign materials before con- necting pipes.

CAUTION

Excessive strong wind against the outdoor unit

outlet may cause inverse rotation and damage

the fan and motor.

N O T E

A system with no moisture or oil contamination will

give maximum performance and lifecycle compared

34 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com l info@canovate.com l P. +90 216 484 2222

to that of a poorly prepared system. Take particular

care to ensure all copper piping is clean and dry

internally.

There is no refrigerant in the cycle of the indoor unit.

C A U T I O N

Cap the end of the pipe when pipe is to be inserted

through a hole

Do not put pipes on the ground directly without a cap

or vinyl tape at the end of the pipe

If piping installation is not completed until next day

or over a long- er period of time, braze off the ends

of the piping and charge with oxygen free nitrogen

through a Schrader valve type access fi tting to

prevent moisture and particle contamination.

Do not use insulation material that contains NH3

because it can damage cooper pipe material and can

be a source of future leak- age.

Completely insulate both refrigerant gas piping and

liquid piping between the indoor unit(s) and the

outdoor unit.

If not insulated, dew will ocur on the piping surface

18.2 SUSPENSION OF REFRIGERANT

PIPING

Suspend the refrigerant piping at certain points and

prevent the refrigerant piping from touching the weak

part of the building such as wall, ceiling, etc…

(If touched, abnormal sound may occur due to the

vibration of the piping. Pay special attention in case

of short piping length).

1~15m

Fire-Proof

Section Treatment

Indoor unit

Do not fi x the refrigerant piping directly with the

metal fi ttings (The refrigerant piping may expand and

contract).

Some examples for suspension method are shown

below.

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 35

For Suspending

Heavies

For piping along

the wall

For instant

installation work

18.3 PIPING CONNECTION FOR

OUTDOOR UNIT

1 The pipes can be connected from 4 directions.

Make holes in the piping cover or cabinet for taking

out pipes. Take the pip- ing cover away from the unit,

and make holes by cutting along the guideline at the

rear of the cover or punching with a driver. Remove

the burr with a cutter, and place a insulation (fi eld

supplied) to protect cables and pipes

(picture as example)

No Description

1 Rear side piping work

2 Pipe Cover

3 Right side piping work

4 Bottom side piping work (Knock out hole)

5 Front side piping work

6 Piping work

7 Stop Valve

8 Removing Direction for Service Cover

C A U T I O N

Notes to open/close the service cover:

• Remove the screws following the instructions

to the above fi gure.

• Slowly press down the cover.

NOTE

Hold the cover with a hand to remove screws as the

cover may fall down.

36 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Service cover

Hook (three places): two fans

Hook (two places): one fan

(picture as example)

For the front and side piping

Front piping hole

Side piping hole

To use racking or conduit tubes, check the size and

remove part following the slit.

N O T E

Place insulation (fi eld supplied) to protect cables and

pipes from being damaged by plate edges

For the downward piping

Cables

Liquid piping

Gas piping

Knock-out hole

Bottom base

N O T E

Cables shall not contact directly to the pipes.

For the rear side piping

Rear Cover

N O T E

Remove the rear pipe cover under the rear cover and

remove

part following the slit.

2 Mount the piping cover in order to avoid water

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 37

entering into the unit. Seal the holes where pipes

and wires are inserted, by using a insulation (fi eld-

supplied).

3 If the fi

eld-supplied piping is connected with

stop valves di- rectly, it is recommended use a tube

bender.

4 Check to ensure that the stop valves are closed

completely before connecting pipes.

5 Connect the fi eld supplied refrigerant pipes to

the indoor unit and outdoor unit. Apply the oil thinly at

the seat fl are nut and pipe before tightening.

The required tightening torque is as follows:

Pipe Size

Tightening Torque (Nm)

Ø 6.35 mm (1/4) 20

Ø 9.53 mm (3/8) 40

Ø 12.70 mm (1/2) 60

Ø 15.88 mm (5/8) 80

Ø 19.05 mm (3/4) 100

6 After connecting the refrigerant piping, seal the

open space between knockout hole and refrigerant

pipes by using insula- tion material

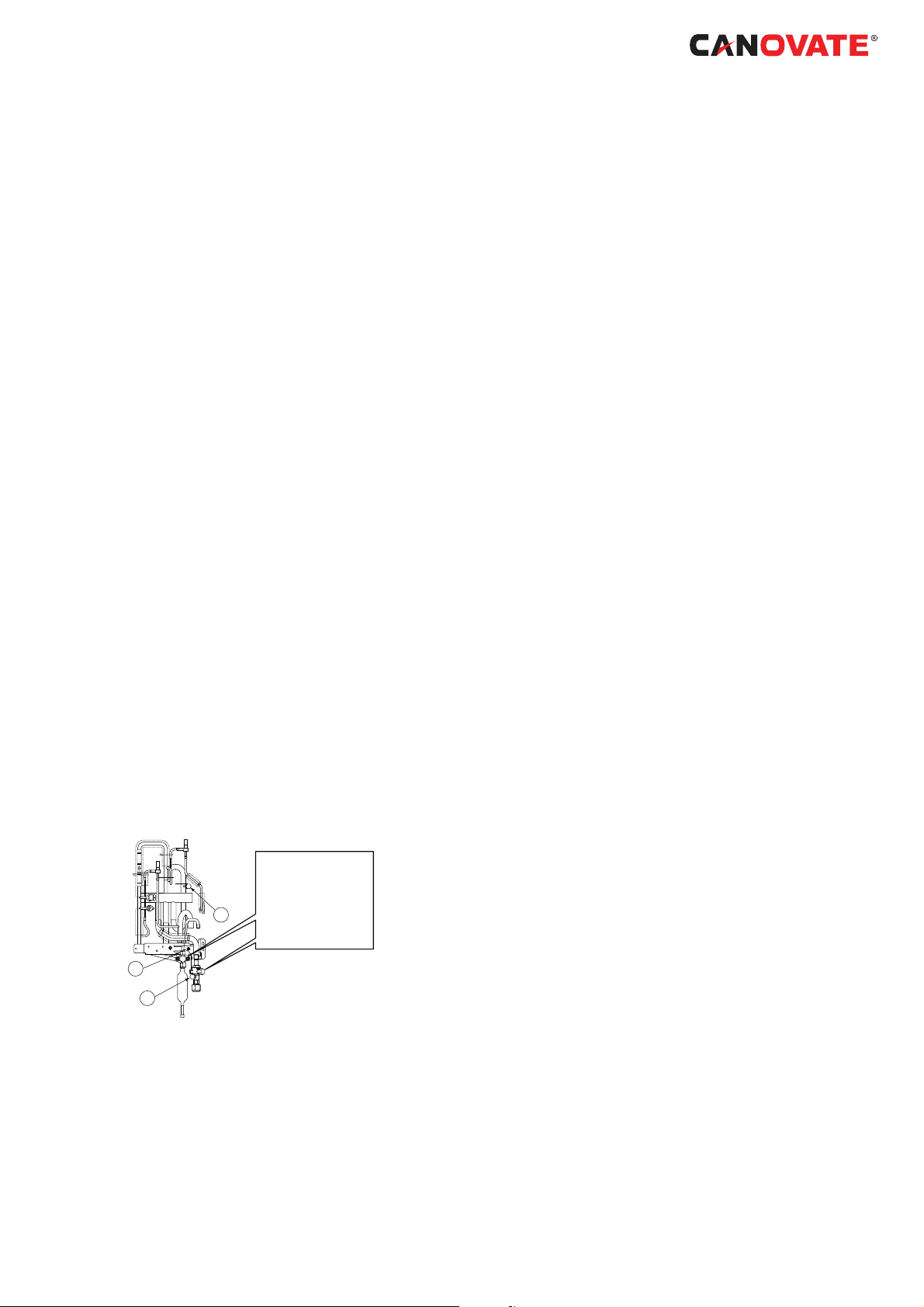

Description

Insulation Material

Insulation Material

Field Supplied

Insulation Material

Unit

Side

Nº

1

2

3

4

7 Operation of stop valve should be performed

according to the fi gure

below.

Close before shipment

Outdoor unit stop valve

Spindle T

38 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW www.canovate.com l info@canovate.com l P. +90 216 484 2222

ype

8-14 kW

1

2

3

4

Tightening Torque (Nm)

12 34

Liquid valve 7-9

Gas valve 9-11

40

10HP: 60

80

8/10HP: 100

Spindle Type Ball Type

Nº Description Remarks

Cap

1

Allen wrench Hex 4 mm

2

Refrigerant Piping Field Supplied

3

Flare nut

4

Refrigerant Pressure To Outdoor Unit

5

Seat Surface Fully closed position

6

Check Joint Only the charging those can be connected

7

Charge port cap

8

O-Ring Rubber

9

Spindle valve

10

Shaft

11

Pin

12

Stopper

13

Closed

(a)

Opened

(b)

Do not apply two spanners

at this position. If applied,

leakage will occur.

Open – Counterclockwise

Close – Clockwise

This valve is opened or closed with rotating 90

degrees at the ball valve part. Rotate the shaft

until the pin touches the stopper. Do not apply the

extra force. Use a slotted screwdriver to control

the shaft. Do not leave the ball valve partly ope

33-42

3HP: 33-42

4/5/6HP:

P=20-25

S/C=33-42

8/10HP:20-25

Stop valve

(Spindle type)

Flare nut

14-18

(a) (b)

n

Use two spanners

here for pipe connection

Don not apply

two spanners

work here

Do not work with

two spanners

here.

Refrigerant

leakage shall

Position to apply

spanners

occur

Spindle type Ball type

C A U T I O N

At the test run, fully open the spindle and ball stop

valve. If not fully opened, the devices will be damaged.

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 39

Do not attempt to turn service valve rod beyond its

stop.

Do not loosen the stop ring. If the stop ring is loosened,

it is dan- gerous since the spindle will hop out.

An excess or a shortage of refrigerant is the main

cause of trouble to the units. Charge the correct

refrigerant quantity according to the description of

label at the inside of service cover.

Check for refrigerant leakage in detail. If a large

refrigerant leakage occurs, it will cause diffi culty with

breathing or harmful gases would occur if a fi re was

being used in the room.

Evacuation and refrigerant charge

- Connect the gauge manifold using charging

hoses with a vacuum pump or a nitrogen cylinder to

the check joints of the liquid line and the gas line stop

valve.

- Check for any gas leakage at the fl are nut connection,

by using nitrogen gas to increase the pressure at

4.15 MPa for outdoor units inside of the fi eld-supplied

piping.

- Operate the vacuum pump for 1 to 2 hours until the

pres- sure decreases lower than a pressure of 756

mmHg in vacuum.

- For charging refrigerant, connect the gauge manifold

us- ing charging hoses with a refrigerant charging

cylinder to the check joint of the liquid line stop valve.

- Charge the proper quantity of refrigerant according

to the piping length (Calculate the quantity of the

refrigerant charge).

- Fully open the gas line stop valve, and slightly open

the liquid line stop valve.

- Charge refrigerant by opening the gauge manifold

valve.

- Charge the required refrigerant within the difference

range of ±0.5kg by operating the system in cooling.

- Fully open the liquid line stop valve after completing

refrig- erant charge.

- Continue cooling operation for more than 10 minutes

to circulate the refrigerant.

Thermal insulation

Gas line

Outdoor unit

Manifold

gauge

Vacuum cylinder

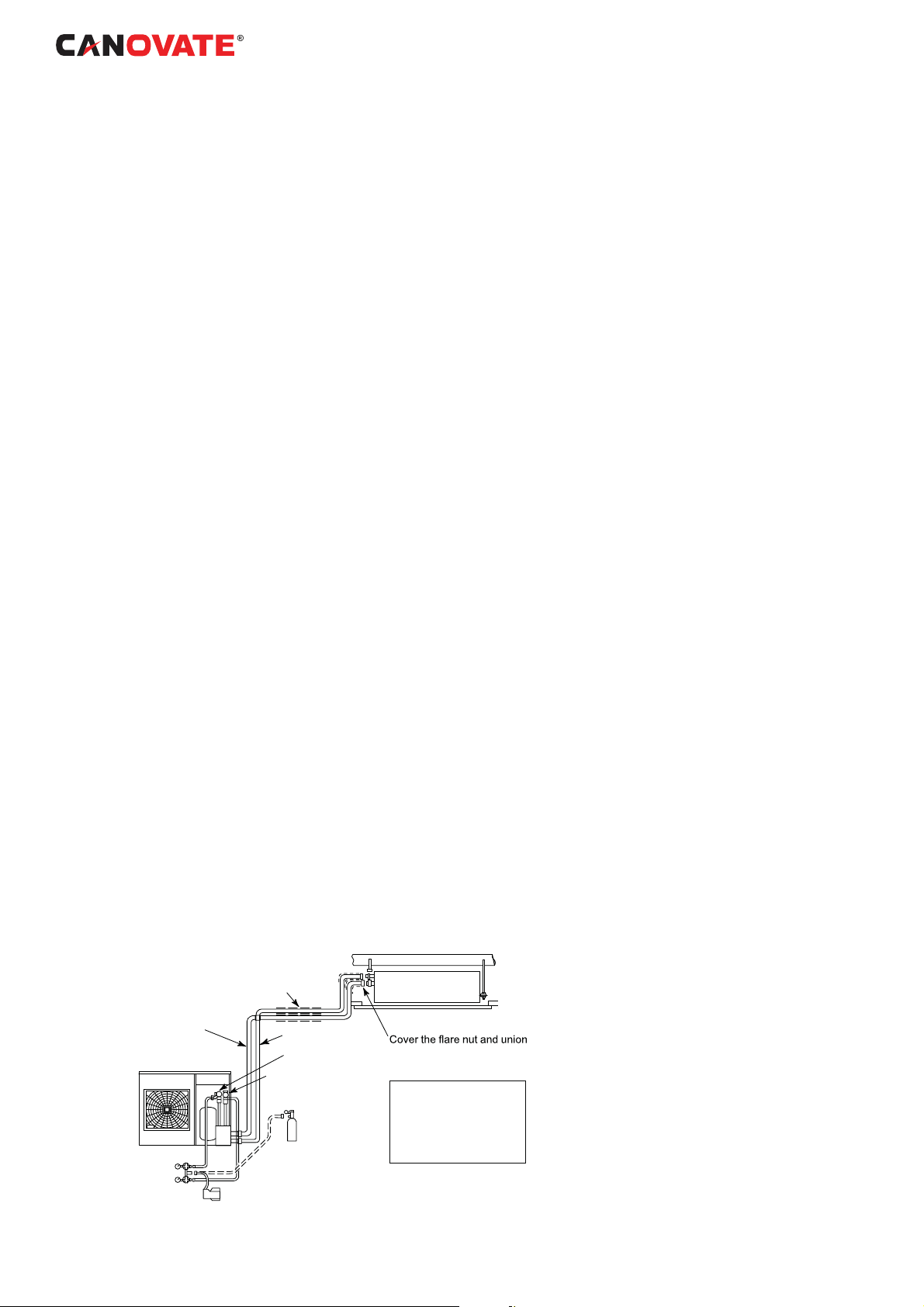

Example of Evacuation and Refrigerant Charge.

40 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

Liquid line

Liquid stop valve

Gas stop valve

Nitrogen tank

(For air Tight test

& Nitrogen blow

during brazing)

of the piping connection with

thermal insulation

Insulate the liquid pipe for

prevention of the capacity

decrease according to the

ambient air conditions and

the dewing on the pipe surface by the low pressure

www.canovate.com l info@canovate.com l P. +90 216 484 2222

18.4 Refrigerant charge

CAUTION

Do not charge OXYGEN, ACETYLENE, or other

fl ammable and poisonous gases into the refrigerant

because an explosion can occur. It is recommended

that oxygen free nitrogen be charged for these types

of tests cycle when performing a leakage test or an

airtight test. These types of gases are extremely

dangerous, Insulate the unions and fl are-nuts at the

piping connection part completely.

Insulate the liquid piping completely to avoid a

decrease of performance;

if not, it will cause sweating on the surface of the pipe.

Charge refrigerant correctly. Overcharging or

insuffi cient charging could cause a compressor

failure.

Check for refrigerant leakage in detail. If a large

refrigerant leakage occurred, it would cause diffi culty

with breathing or harmful gases would occur if a fi re

were being used in the room.

If the fl are nut is tigthened too hard, the fl are nut may

crack after a long time and cause refrigerant leakage.

18.5 Caution of the pressure by check

joint

When the pressure is measured, use the check joint

of gas stop valve (A), and use the check joint of liquid

piping (B) in the fi gure below.

At that time, connect the pressure gauge according to

the following table because of high pressure side and

low pressure side changes by operation mode.

NOTE

Be careful that refrigerant and oil do not splash to the

electrical parts at removing the charge hoses.

The gas stayed at O-ring

screw part is opened

and may make sound

B

However, it is not gas

leakage.

C

A

.pac eht gnivomer nehw

18.6 Refrigerant Charging Quantity

Outdoor Units has been charged with refrigerant for

30m of actual piping length. An additional refrigerant

charged is required in systems with actual piping

length longer than 30m.

www.canovate.com l info@canovate.com l P. +90 216 484 2222

1

Determine an additional refrigerant quantity

according to the following procedure, and charge it

into the system.

2 Record the additional refrigerant quantity to facilitate

service activities thereafter.

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 41

CAUTION

When charging refrigerant accurately measure

refrigerant to be charged.

Overcharging or undercharging of refrigerant can

cause compressor trouble

In case of actual piping length less than 5 m, consult

your distributor

.

18.7

ELECTRICAL WIRING CONNECTION

FOR OUTDOOR UNITS

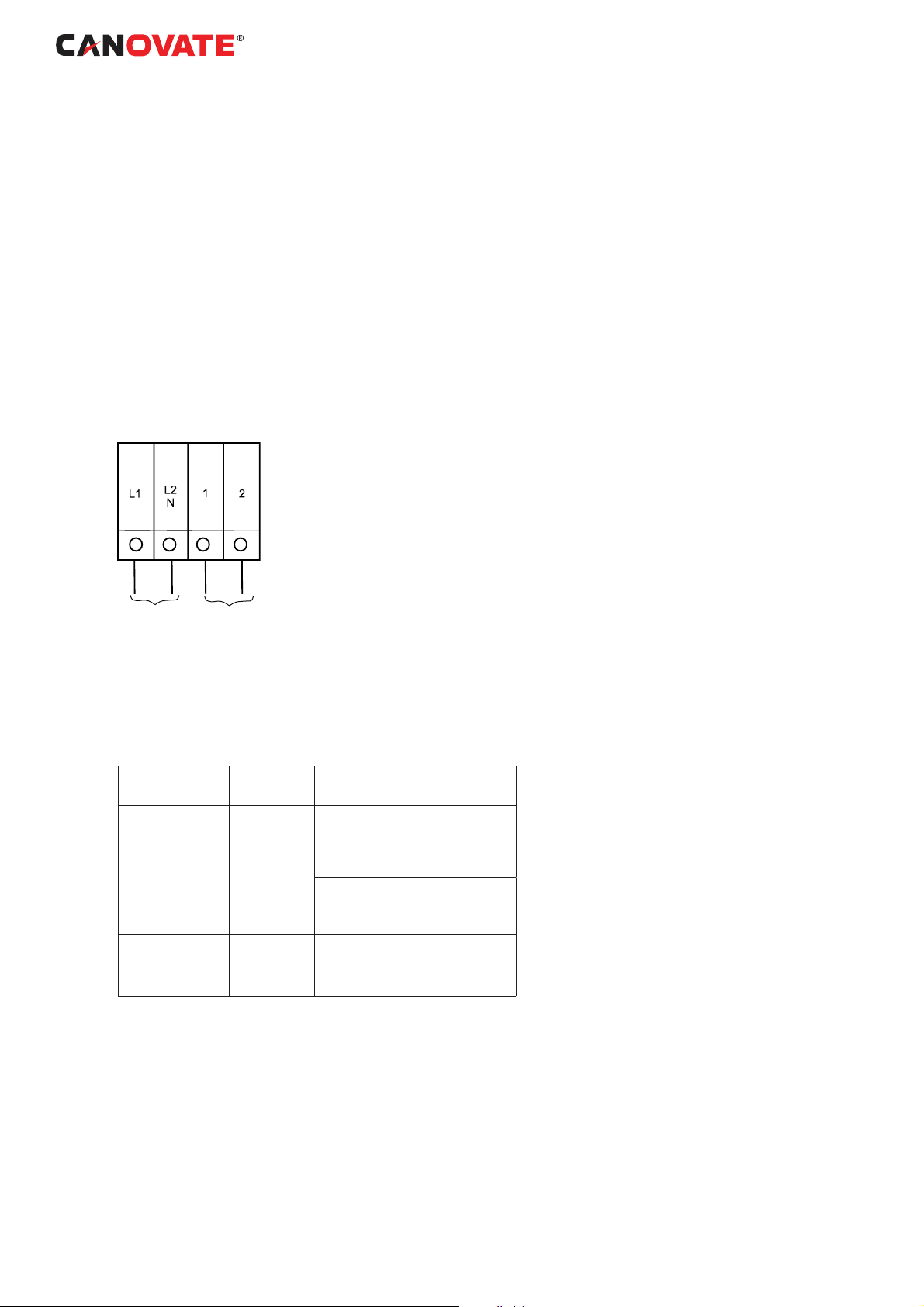

The electrical wiring connection for the outdoor unit is

shown in fi gure

8-14 kW

1~ 230V

Power supply

below:

Control cable (5V)

able for Terminal Connection between units

T

Wiring

Power Supply DC inverter O.U. to O.U.

Operating DC inverter O.U. to I.U. or I.U. toI.U. 1 to1,

Remote Control DC inverter I.U. to I.U. A to A, B to B

System Units type Connection of

terminals

L1 to L1, L2 to L2, L3 to L3,

N to N

I.U. to I.U.

L1 to L1, N to N)

2 to 2

42 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW www.canovate.com l info@canovate.com l P. +90 216 484 2222

18.7.3

Setting of DIP Switches for Outdoor

Unit

Quantity and Position of DIP

is as follows:

Switches. The location

DSW1: For T

Factory setting

est Run

DSW2: Optional Function Setting

Factory setting

3LSLQJOHQJWKP

3LSLQJOHQJKWP

Optional function setting

Optional function setting

ON

1 2 4 6

([WHUQDOLQSXWRXWSXWVHWWLQJPRGH

www.canovate.com l info@canovate.com l P. +90 216 484 2222 Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 43

DSW3: Capacity

Factory setting

8 kW

ON

1 2 3 4 5 6

8 kW

ON

1 2 3 4 5 6

DSW5: T

ransmission Setting of End Terminal

14 kW

ON

1 2 3 4 5 6

14 kW

ON

1 2 3 4 5 6

Resistance

Factory setting

Cancellation

In the case that the outdoor units quantity in the same

H-LINK is 2 or more, set No. 1 pin of DSW5 at “OFF”

side from the 2nd refrigerant group outdoor unit. If

only one outdoor unit is used, no setting is required.

Refrigerant Cycle No. Setting

DSW6: Optional function setting (IVX series only)

For individual operation

(factory setting position)

For IVX series

For simultaneous operation

DSW4

Factory setting

(Setting for the ten digit).

DSW6: Not available for ES series

tpmEy

Factory setting

or

RSW1

44 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW www.canovate.com l info@canovate.com l P. +90 216 484 2222

Factory setting

(Setting for the last digit).

0

1

9

2

8

3

7

4

6

5

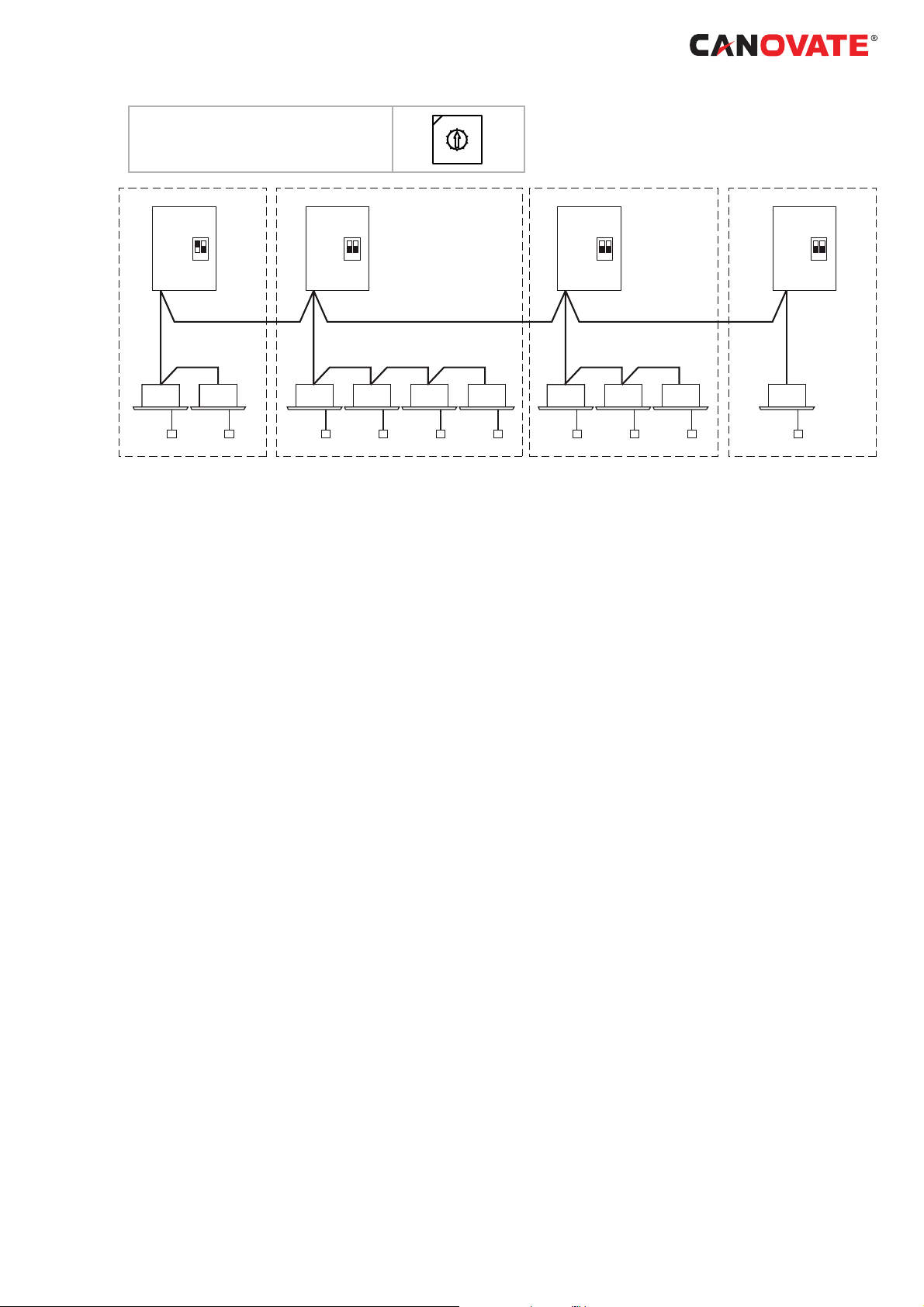

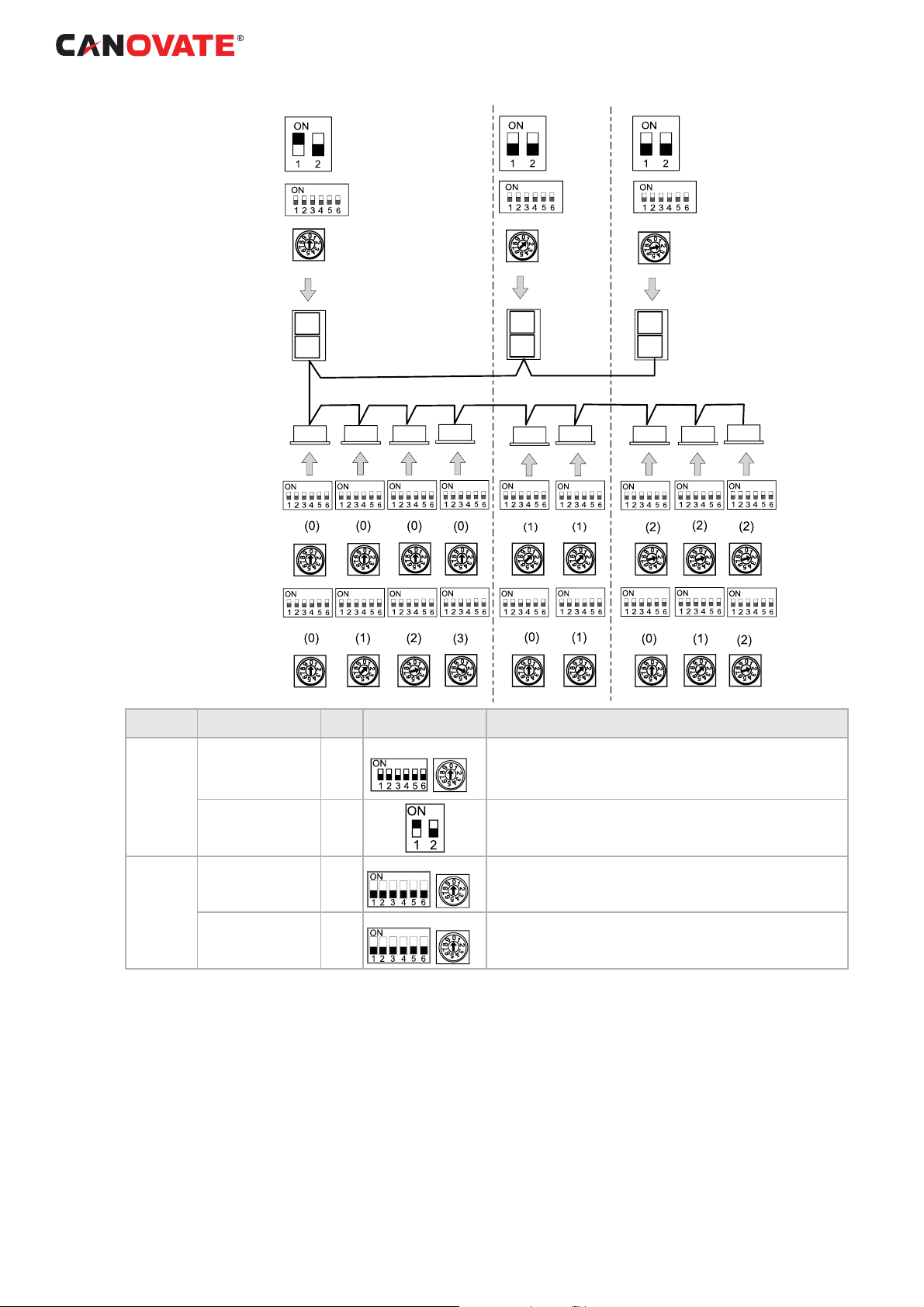

18.7.4

System installation DIP Switch

DSW5

12

H-LINK) ( H-LINK)

(

DSW5

12

Setting

Dip Switch Setting of Indoor PCB and Outdoor PCB

for H-LINK II

It is required to set dip switches of every indoor unit

and outdoor unit and match of the transmission circuit

impedance.

•

Dip Switch Setting Example:

DSW5

12

DSW5

12

( H-LINK)

www.canovate.com l info@canovate.com l P. +90 216 484 2222 Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 45

DSW5

Terminating Resistance

DSW4

Refrigerant Cycle Nº

(Setting for ten digit)

RSW1

Refrigerant Cycle Nº

(Setting for last digit)

Outdoor units

Indoor units

DSW5

Refrigerant Cycle Nº

(Setting for ten digit)

RSW2

Refrigerant Cycle Nº

(Setting for last digit)

DSW6

Indoor unit Address

(Setting for ten digit)

Cycle nº 0

Cycle nº 1

Cycle nº 2

RSW1

Indoor unit Address

(Setting for last digit)

Unit Name of Dip Switch Mark

Refrigerant Cycle

Outdoor Unit

Terminating Resistance DSW5

Refrigerant Cycle

Indoor Unit

Indoor Unit Address

DSW4

RSW1

DSW5

RSW2

DSW6

RSW1

Setting Before

Shipment

DSW4 RSW1

DSW5 RSW2

DSW6 RSW1

Function

For setting refrigerant cycle address of Outdoor Unit. Set the DSW4

and RSW1 not to overlap the setting of other Outdoor units in the same

H-LINK system

For matching impedance of transmission circuit, set the DSW5 according to the quantity of outdoor units in the H-LINK system.

For setting refrigerant cycle address of indoor units. Set the DSW5 and

RSW2 corresponding to the address of outdoor unit in the same refrigerant cycle.

For setting indoor unit address. Set the DSW6 and RSW1 not to overlap

the setting of other indoor units in the same refrigerant cycle. (If not set,

the automatic address function is performed).

46 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW

www.canovate.com l info@canovate.com l P. +90 216 484 2222

19. TEST RUNNING

When installation is completed, perform test run

according to the following procedure, and hand

over the system to the customer. Perform test run

regarding indoor units one by one in order, and

confi rm that the electrical wiring and the refrigerant

piping are correctly connected.

Test run should be performed according to the Test

Run Proce- dure on next page.

C A U T I O N

Do not operate the system until all the check points

have been cleared:

• Check to ensure that the electrical resistance

is more than 1 MΩ, by measuring the resistance

between ground and the terminal of the electrical

parts. If not, do not operate the sys- tem until the

electrical leakage is found and repaired. Do not

impress the voltage on the terminals for transmission

1 and 2.

• Check to ensure that the stop valves of the

outdoor unit are fully opened, and then start the

system.

• Check to ensure that the switch on the main

power source has been ON for more than 12 hours,

to warm the compressor oil by the oil heater

Pay attention to the following items while the system

is running:

• Do not touch any of the parts by hand at the

discharge gas side, since the compressor chamber

and the pipes at the dis- charge side are heated

higher than 90°C.

• DO NOT PUSH THE BUTTON OF THE

MAGNETIC SWITCH(ES), it will cause a serious

accident.

• Do not touch any electrical components for

more than three minutes after turning OFF the main

switch

• Confi rm that the gas line stop valve and the

liquid line stop valve are fully open.

• Confi rm that the leakage of the refrigerant does

not exist. The fl are nuts are sometimes loosened by

vibration during trans- portation.

• Check that the refrigerant piping and the

electrical wiring con- form to the same system.

• Confi rm that the dip switch setting on the

printed circuit board of the indoor units and the

outdoor units are correct.

• Check whether or not the electrical wiring of

the indoor units and the outdoor units are connected

as shown in the chapter Electrical Wiring.

www.canovate.com l info@canovate.com l P. +90 216 484 2222

Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW l 47

A U T I O N

C

Confi rm that fi eld-supplied electrical components

(main switch fuse, fuse-free breaker, earth leakage

breakers, wires, conduit connectors and wire

terminals) have been properly selected ac- cording

to the electrical data given in the Technical Catalog of

the unit and ensure that the components comply with

national and local codes.

N O T E

• For more reference check Troubleshooting

chapter on Opera- tion Part.

• For twin, triple and quad check the indoor unit

outlet air tem- perature at test run. If the temperature

difference is large (aprox. 10 deg. or more (cooling)

20 deg. or more (heating) recheck the refrigerant

piping, Installation may have some problem.

• In the case of anual cooling optional function,

cut JP1 out and set the DSW6-1 to OFF. (Individual

control is not available when anual cooling is

selected).

48 l Can BREEZE Operating and Maintenance Cooling Unit Instructions 8-14 kW www.canovate.com l info@canovate.com l P. +90 216 484 2222

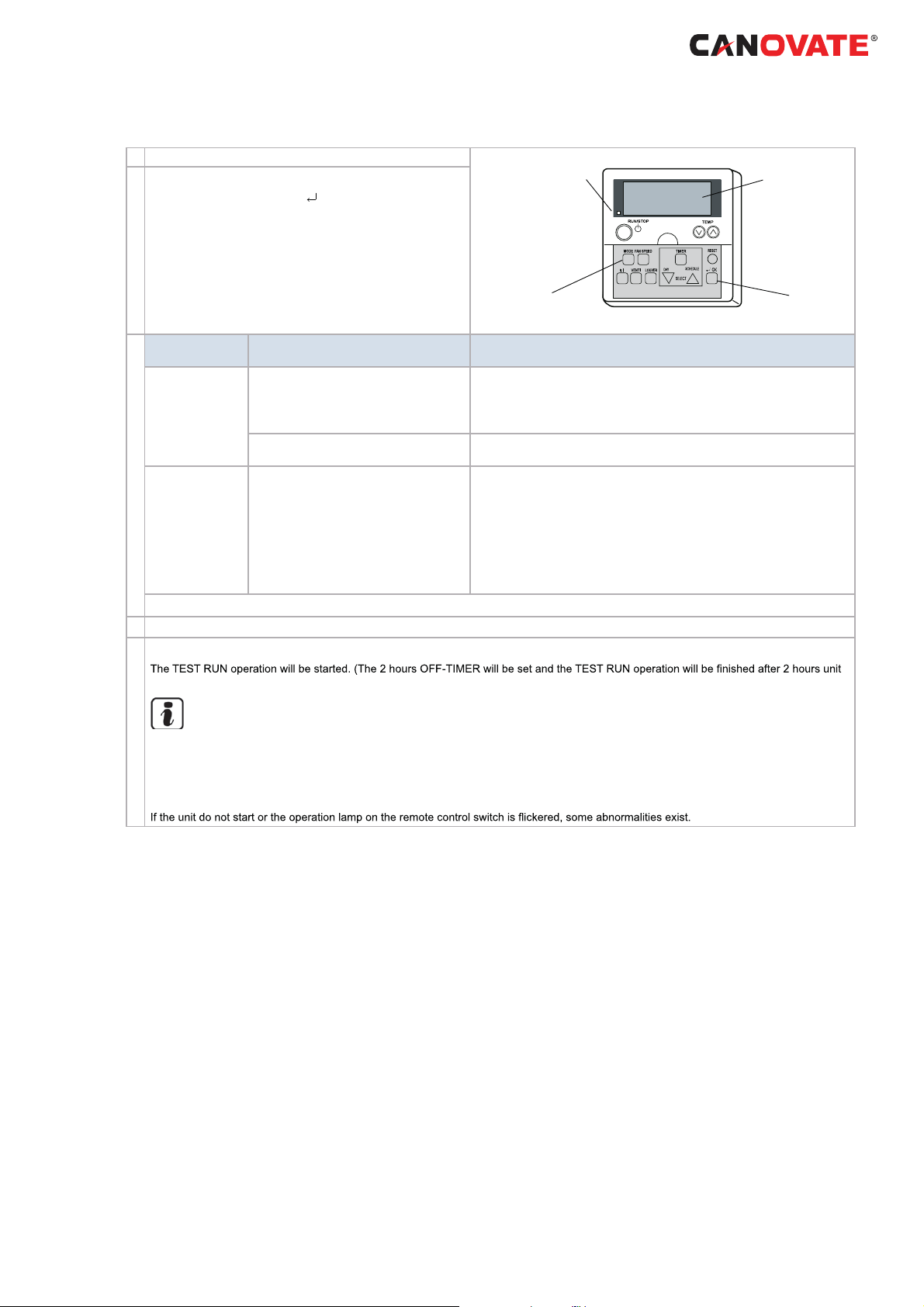

19.1 TEST RUN PROCEDURE BY REMOTE

CONTROL SWITCH (PC-ART EXAMPLE)

Turn ON the power source of the Indoor and Outdoor Units

Ƒ

Set the TEST RUN mode by remote control switch.

Depress the “MODE” and the “

for more than 3 seconds.

If “TEST RUN” and the counting number of the connect-

a.

Ƒ

Ƒ

Ƒ

ed units to the remote control switch (for example

are indicated on the remote control switch, the connec-

tion of remote control cable is correct.ĺGo to

If no indication appear or the number of the units indicat-

b.

ed is smaller than the actual number of the units, some

abnormalities exist.ĺGo to

Remote Control

Switch Indication

The power source of Outdoor Unit is not

turned ON.

No indication

Counting number

of connected units

is incorrect

Back to

Ƒ after checking

Select TEST RUNNING MODE by depressing MODE Switch (COOL OR HEAT)

Depress RUN/STOP switch.

The connection of the remote control cable

is incorrect.

The connecting wires of power supply line

are incorrect or loosened.

The power source of Outdoor Unit is not

turned ON.

The operating line wiring between indoor

unit and outdoor unit is not connected.

The connection of control cables between

each indoor units are incorrect. (When

one remote control switch controls multiple

units)

OK” switches simultaneously

“05”)

Ƒ

Ƒ

Wrong Portions Inspection Points after Power Source OFF

1

Connecting Points of Remote Control Cable terminal board of Remote

Control switch and indoor unit.

Contact of Terminals of Remote Control Cable

2

3

Connection Order of each Terminal Board

Screw Fastening of each Terminal Boards.

4

5

Dip Switch Setting on Printed Circuit Board

Connecting on the PCB

6

7

This is the same as item Ƒ 1, 2 , and 3.

Operation lamp

05

Counting

number of

connected

units

operation or by depressing the RUN/STOP switch again).

Ƒ

NOTE

TEST RUN operation ignores the temperature limitation and ambient temperature during heating operation to have a continuous