QY8-1360-000

REVISION 0

COPYRIGHT 1998 CANON INC. CANON BJC-7100 1098 AB 5.00-0 PRINTED IN JAPAN (IMPRIME AU JAPON)

OCT. 1998

1098 AB 5.00-0

Target Readers

This manual is published by Canon Inc. for qualified persons and contains the necessary technical

information for technical theory, installation, maintenance, and repair of products. This manual covers

all localities where the products are sold. For this reason, it may contain information that does not

apply to your locality.

Revisions

This manual may include technical inaccuracies or typographical errors due to improvements or

changes in the products. When amendments are made to the content of this manual, Canon will issue

technical information as the need arises. In the event of major alterations to the content of this manual

over a long or short period, Canon will publish a revised version of the manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with the local law.

Trademarks

The product names and company names appearing in this manual are the registered trademarks or

trademarks of the individual companies.

Copyright

This manual is copyrighted and all rights reserved. Under the copyright laws, this manual may not be

copied, reproduced, or translated into other languages, in whole or in part, without the express written

consent of Canon Inc. except in the case of internal business use.

Copyright 1998 by Canon Inc.

CANON INC.

BJ Products Quality Support Dept.

16-1, Shimonoge 3-chome, Takatsu-ku, Kawasaki, Kanagawa 213, Japan

This manual was produced on an Apple Macintosh Power Mac 7300/180 personal computer and Apple

LaserWriter II NTX-J laser beam printer; final pages were printed on Agfa SelectSet Avantra 25.

A YANO 640MO drive system NJ640MO with MITSUBISHI MO disk cartridge MR230M1 were used for

storing large volumes of page layout and graphic data for this manual.

All graphics were produced with MACROMEDIA FREEHAND 7.0J.

All documents and all page layouts were created with QuarkXPress 3.3J.

I

I. ABOUT THIS MANUAL

This manual is divided into five parts containing the information required for servicing the BJC7100 printer.

Part 1: Safety and Precautions

This part contains information on how to service the unit safely. It is very important, and

must be read.

Part 2: Product Specifications

This part outlines the product and its specifications.

Part 3: Operating Instructions

This part explains how to operate the unit properly, how it is installed, and how to use

the service mode.

Part 4: Technical Reference

This part outlines the unit operation giving a technically.

Part 5: Maintenance

This part explains maintenance of the unit. It includes details of disassembly/assembly,

adjustments required when assembling, troubleshooting procedures, and wiring/circuit

diagrams, etc.

This manual does not contain complete information required for

disassembling and assembling the BJC-5500 printer. Please also refer to the

separate Parts Catalog.

II. TABLE OF CONTENTS

Page

Part 1: SAFETY AND PRECAUTIONS

1 - 1 1. SAFETY PRECAUTIONS

1 - 1 1.1 Moving Parts

1 - 2 1.2 Front Cover

1 - 3 1.3 Ink Stains

1 - 3 1.3.1 Ink path

1 - 4 1.3.2 Ink mist

1 - 5 1.4 Live Parts

1 - 6 1.5 BJ Cartridge Metal Plate

1 - 7 2. MACHINE PRECAUTIONS

1 - 7 2.1 BJ Cartridge Handling

1 - 7 2.1.1 Unpacking the BJ cartridge

1 - 7 2.1.2 BJ cartridge protection

1 - 8 2.1.3 Power on/off

1 - 8 2.1.4 When not using the printer

1 - 9 2.1.5 Ink electroconductivity

1 - 9 2.2 Ink Tank Handling

1 - 9 2.2.1 Unpacking the ink tank

1 - 9 2.2.2 Preventing clogging

1 -10 2.3 Printer Handling

1 -10 2.3.1 Spurs

1 -10 2.3.2 Damage due to static electricity

1 -11 2.3.3 Ink Leakage and dry-out

1 -11 2.3.4 Carrying the printer

1 -12 3. NOTES ON SERVICING

1 -12 3.1 EEPROM Data

1 -13 3.2 Service Mode of Printer Driver

1 -13 3.3 Protecting the Power Supply

1 -14 3.4 Static Electricity

1 -15 3.5 Disassembly and Assembly

1 -15 3.5.1 Parts that cannot be disassembled

1 -15 3.5.2 Parts requiring careful attention during disassembly and assembly

1 -15 3.6 Self-Diagnosis

Part 2:

PRODUCT SPECIFICATIONS

2 - 1 1. PRODUCT OUTLINE

2 - 1 1.1 Outline

2 - 2 1.2 Features

2 - 3 1.3 BJ Cartridge

2 - 3 1.3.1 Black BJ cartridge (BC-60)

2 - 4 1.3.2 Photo BJ cartridge (BC-62e Photo)

2 - 5 1.3.3 Color BJ cartridge (BC-61)

2 - 5 1.3.4 BJ cartridge vs print mode

2 - 6 1.4 SB-60 BJ Cartridge Container

2 - 6 1.5 Consumables

2 - 6 1.5.1 BJ cartridge

2 - 6 1.5.2 Ink tank

2 - 7 2. SPECIFICATIONS

2 - 7 2.1 General Specifications

2 -10 2.2 Paper Specifications

2 -10 2.2.1 Paper types

II

Page

2 -11 2.2.2 Printing range

2 -12 2.3 Interface Specifications

Part 3: OPERATING INSTRUCTIONS

3 - 1 1. PRINTER SETUP

3 - 1 1.1 Unpacking

3 - 2 1.2 Installation Location

3 - 3 1.3 Installation

3 - 3 1.3.1 Connecting the interface cable

3 - 3 1.3.2 Connecting the power supply

3 - 4 1.3.3 Installing the BJ cartridge

3 - 6 1.3.4 Replacing the ink tanks

3 - 7 1.3.5 Cartridge container [SB-60]

3 - 8 1.4 Turning Printer Power On and Off

3 - 8 1.4.1 Turning the power on

3 - 8 1.4.2 Turning the power off

3 - 9 1.5 Loading Printer Paper

3 -10 1.6 Names of Parts and Their Functions

3 -12 2. TRANSPORTING THE PRINTER

3 -12 2.1 Transporting the Printer

3 -13 2.2 Manual Capping

3 -14 3. PRINTER SERVICING FUNCTIONS

3 -14 3.1 Error Indications

3 -14 3.1.1 Operator call errors

3 -15 3.1.2 Service calls

3 -16 3.2 Warning Indications

3 -17 3.3 Function Settings

3 -17 3.3.1 Items set by control function

3 -18 3.3.2 Service mode of printer driver

3 -19 3.4 EEPROM

3 -19 3.5 Cleaning the BJ Cartridge

3 -20 3.6 Test Printout

3 -20 3.7 Pickup Roller Cleaning Function (HR-101)

3 -21 3.8 Service Mode

3 -22 3.8.1 Final factory test pattern

3 -22 3.8.2 Resetting EEPROM data

3 -23 3.8.3 Printing EEPROM data

3 -23 3.8.4 Setting destination country

3 -24 3.8.5 Other Function

Part 4: TECHNICAL REFERENCE

4 - 1 1. OVERVIEW

4 - 1 1.1 Printer Block Diagram

4 - 2 1.2 Initial Flowchart

4 - 3 1.3 Print Signal Sequence

4 - 4 1.4 BJ Cartridge Drive

4 - 4 1.4.1 Print drive control

4 - 5 1.5 Power-Off Sequence Flowchart

4 - 6 2. FIRMWARE

4 - 6 2.1 Interface

4 - 6 2.1.1 Compatible mode

4 - 7 2.1.2 Nibble mode

4 - 7 2.1.3 ECP mode

III

Page

4 - 8 2.2 Print Modes

4 - 9 2.2.1 Plain paper optimized printing mode (P-POP)

4 - 9 2.2.2 Economy print mode (Draft mode)

4 - 9 2.2.3 Standard mode

4 - 9 2.2.4 High quality and fine mode

4 -10 2.2.5 Print mode settings

4 -11 2.3 Smoothing Function

4 -11 2.4 Print Optimization Controls

4 -11 2.4.1 Power monitor

4 -11 2.4.2 Head sticking prevention

4 -11 2.4.3 Ink smear prevention

4 -12 2.5 Head Overheat Protection

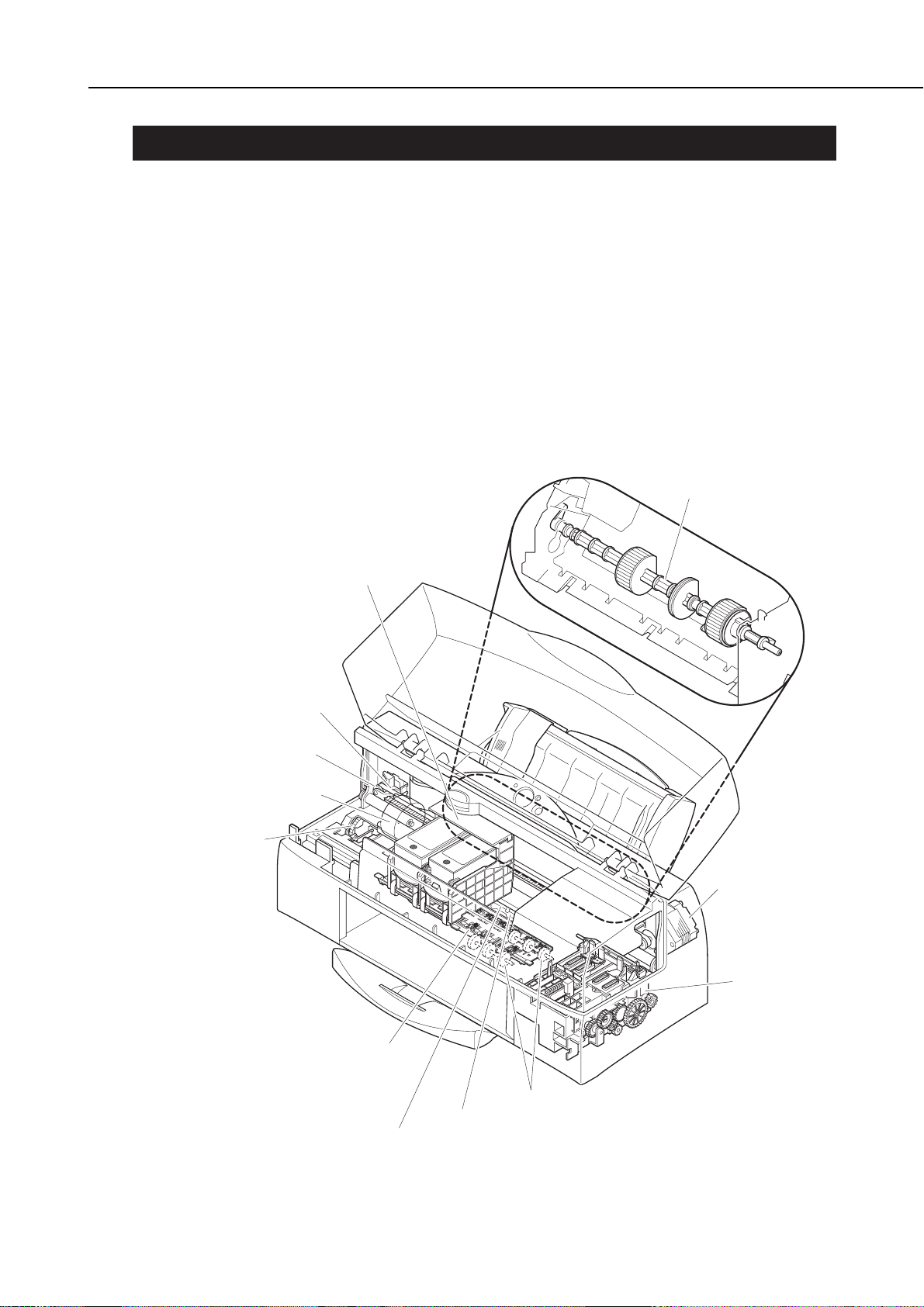

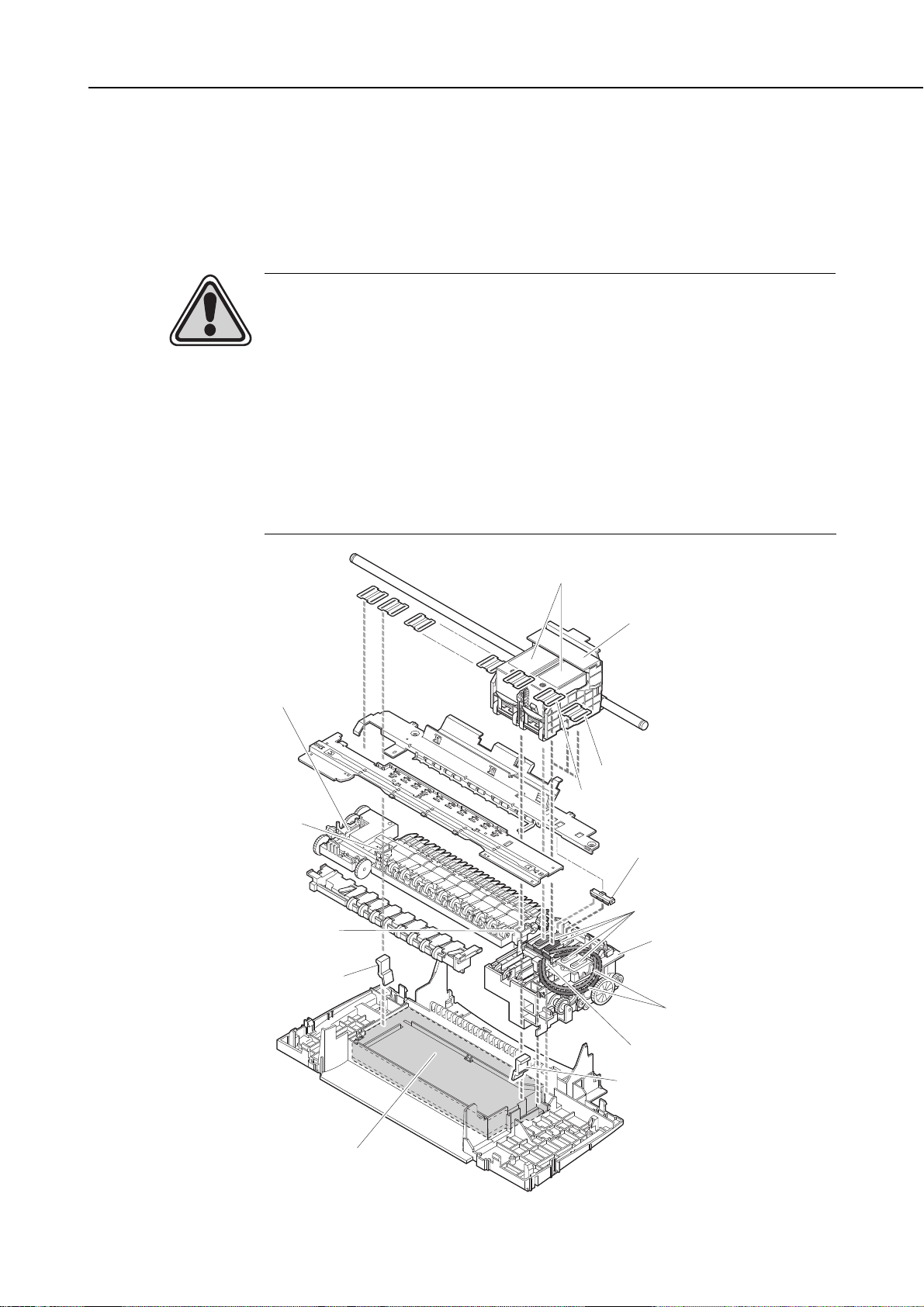

4 -13 3. PRINTER'S MECHANICAL SYSTEM

4 -13 3.1 Overview

4 -14 3.1.1 Structure of printer's mechanical system

4 -15 3.2 BJ Cartridge

4 -15 3.2.1 BJ Cartridge structure

4 -19 3.2.2 Structure of BJ head unit

4 -21 3.2.3 Nozzle arrays

4 -22 3.2.4 Signal contacts

4 -24 3.2.5 Drive circuit

4 -28 3.2.6 BJ cartridge detection

4 -29 3.3 Purge Unit

4 -29 3.3.1 Function of purge unit

4 -30 3.3.2 Structure of purge unit

4 -33 3.4 Carriage

4 -33 3.4.1 Carriage functions

4 -34 3.4.2 Carriage structure

4 -36 3.5 Paper Feed/Sheet Feeder Mechanism

4 -36 3.5.1 Paper feed/sheet feeder mechanism functions

4 -38 3.5.2 Paper feed/sheet feeder mechanism structure

4 -39 4. PRINTER ELECTRICAL SYSTEM

4 -39 4.1 Overview of Printer Electrical System

4 -40 4.2 Logic

4 -40 4.2.1 Logic block diagram

4 -41 4.2.2 Logic components

4 -45 4.3 Electrical System

4 -45 4.3.1 Input power supply (AC adaptor)

4 -45 4.3.2 Output voltages

4 -46 5. DETECTION FUNCTIONS

4 -46 5.1 Sensor-based Detection Functions

4 -48 5.2 Miscellaneous Detection Functions

4 -48 5.2.1 Waste-ink amount detection

4 -48 5.2.2 BJ cartridge detection

4 -48 5.2.3 Ink-out detection

Part 5: MAINTENANCE

5 - 1 1. MAINTENANCE

5 - 1 1.1 Parts for Periodic Replacement

5 - 1 1.2 Consumable Parts

5 - 1 1.3 Consumables

5 - 1 1.4 Periodic Maintenance

5 - 2 2. SERVICING TOOLS

IV

Page

5 - 2 2.1 List of Tools

5 - 3 3. APPLYING GREASE

5 - 4 4. DISASSEMBLY AND REASSEMBLY

5 - 4 4.1 Disassembly and Reassembly

5 - 4 4.2 Notes on Disassembly and Reassembly

5 - 4 4.2.1 Main cover

5 - 4 4.2.2 Carriage unit

5 - 5 4.2.3 Bearings at ends of support shaft

5 - 5 4.2.4 Purge unit and bottom case assembly

5 - 5 4.2.5 Securing idler pulley assembly screw

5 - 6 4.3 Waste Ink Absorbers

5 - 7 4.4 Assembling the Chassis

5 - 8 5. ADJUSTMENTS

5 - 8 5.1 Adjustment Locations

5 - 8 5.1.1 Adjusting registration

5 - 8 5.1.2 Checking and adjusting the head gap

5 -13 6. TROUBLESHOOTING

5 -13 6.1 Troubleshooting Overview

5 -13 6.1.1 Overview

5 -13 6.1.2 Troubleshooting cautions

5 -14 6.2 Diagnosis

5 -14 6.2.1 Diagnostic flow

5 -16 6.2.2 Action

5 -37 7. CONNECTOR LAYOUT AND SIGNAL ASSIGNMENT

5 -37 7.1 Logic Board

5 -39 7.2 Carriage Board

5 -44 8. CIRCUIT DIAGRAMS

5 -44 8.1 Parts Layout

5 -44 8.1.1 Logic board

5 -45 8.1.2 Carriage board

5 -47 8.2 Circuit Diagrams

5 -47 8.2.1 Logic board

V

III. ILLUSTRATION INDEX

Page

Part 1: SAFETY AND PRECAUTIONS

1 - 1 Figure 1 - 1 The Printer's Moving Parts

1 - 2 Figure 1 - 2 Front Cover

1 - 3 Figure 1 - 3 Ink Path

1 - 4 Figure 1 - 4 BC-62e Photo and BC-61

1 - 4 Figure 1 - 5 Ink Mist

1 - 5 Figure 1 - 6 AC Adapter

1 - 6 Figure 1 - 7 BJ Cartridge Metal Plate

1 - 7 Figure 1 - 8 Removing the BJ Cartridge Cap and Tape

1 - 8 Figure 1 - 9 BJ Cartridges

1 - 9 Figure 1 -10 Removing the Ink Tank Cap

1 - 9 Figure 1 -11 The Ink Outlets on Ink Tank

1 -10 Figure 1 -12 Spurs

1 -10 Figure 1 -13 Contacts

1 -11 Figure 1 -14 Capping Position

1 -11 Figure 1 -15 Carrying the Printer

1 -13 Figure 1 -16 Protecting the Power Supply

1 -14 Figure 1 -17 Electrical System of Printer

1 -15 Figure 1 -18 Parts that Cannot be Disassembled

Part 2: PRODUCT SPECIFICATIONS

2 - 1 Figure 2 - 1 Printer Appearance

2 - 3 Figure 2 - 2 Black BJ Cartridge (BC-60)

2 - 4 Figure 2 - 3 Photo BJ Cartridge (BC-62e Photo)

2 - 5 Figure 2 - 4 Color BJ Cartridge (BC-61)

2 - 6 Figure 2 - 5 BJ Cartridge (SB-60)

2 - 6 Figure 2 - 6 Ink Tanks

2 -11 Figure 2 - 7 Printing Area

2 -18 Figure 2 - 8 Compatible Mode

2 -18 Figure 2 - 9 Nibble Mode

2 -18 Figure 2 -10 ECP Mode

Part 3: OPERATING INSTRUCTIONS

3 - 1 Figure 3 - 1 Packaging

3 - 2 Figure 3 - 2 Printer Dimensions

3 - 3 Figure 3 - 3 Connecting the Interface Cable

3 - 3 Figure 3 - 4 Connecting the Power Supply

3 - 4 Figure 3 - 5 Removing Cap and Tape from BJ Cartridge

3 - 4 Figure 3 - 6 Installing BJ Cartridges

3 - 5 Figure 3 - 7 Checking Print Head Alignment

3 - 6 Figure 3 - 8 Replacing the Ink Tank

3 - 6 Figure 3 - 9 Removing Protective Cap from Ink Tank

3 - 7 Figure 3 -10 Cartridge Container SB-60

3 - 8 Figure 3 -11 Incorrect Method of Powering Off

3 - 9 Figure 3 -12 Paper Settings

3 -10 Figure 3 -13 Names of Parts and Their Functions (1)

3 -11 Figure 3 -14 Names of Parts and Their Functions (2)

3 -12 Figure 3 -15 Transporting the Printer

3 -13 Figure 3 -16 Manual Capping Method

3 -14 Figure 3 -17 Control Panel

3 -17 Figure 3 -18 Windows 95 Driver Control Sheet (Sample)

VI

Page

3 -18 Figure 3 -19 Hidden Control Sheet (Sample)

3 -20 Figure 3 -20 Nozzle Check Pattern (Sample)

3 -22 Figure 3 -21 Service Mode Test Print (Sample)

3 -23 Figure 3 -22 EEPROM Data Print (Sample)

Part 4: TECHNICAL REFERENCE

4 - 1 Figure 4 - 1 Printer Block Diagram

4 - 2 Figure 4 - 2 Flowchart of Initialization Sequence

4 - 3 Figure 4 - 3 Print Signal Sequence

4 - 5 Figure 4 - 4 Power-Off Sequence Flowchart

4 - 6 Figure 4 - 5 Bidirectional Centronics Specifications Selection Sequence

4 - 6 Figure 4 - 6 Interface Timing (Compatible Mode)

4 - 7 Figure 4 - 7 Interface Timing (Nibble Mode)

4 - 7 Figure 4 - 8 Interface Timing (ECP Mode)

4 - 9 Figure 4 - 9 Photo Print Mode (Image)

4 -10 Figure 4 -10 Print Mode Main Sheet (Sample)

4 -11 Figure 4 -11 Print Mode Detail Quality Sheet (Sample)

4 -13 Figure 4 -12 Printer's Mechanical System

4 -15 Figure 4 -13 Structure of BC-60

4 -16 Figure 4 -14 Structure of BC-61

4 -17 Figure 4 -15 Structure of BC-62e Photo

4 -19 Figure 4 -16 Structure of BC-60 BJ Head Unit

4 -19 Figure 4 -17 Structure of BC-61 BJ Head Unit

4 -20 Figure 4 -18 Structure of BC-62e Photo BJ Head Unit

4 -21 Figure 4 -19 Nozzle Arrays

4 -22 Figure 4 -20 Signal Contacts

4 -24 Figure 4 -21 Block Diagram of BC-60 Drive Circuit

4 -25 Figure 4 -22 Block Diagram of BC-61/BC-62e Photo Drive Circuit

4 -32 Figure 4 -23 Purge Unit

4 -33 Figure 4 -24 Carriage

4 -35 Figure 4 -25 Paper Feed Motor Drive Switching

4 -36 Figure 4 -26 Auto Platen-Head Gap Adjustment

4 -37 Figure 4 -27 Paper Feed Mechanism

4 -38 Figure 4 -28 Paper Separator

4 -39 Figure 4 -29 Printer Electrical System

4 -40 Figure 4 -30 Logic Board Block Diagram

4 -43 Figure 4 -31 Printer Block Diagram

4 -44 Figure 4 -32 Motor Drive Circuit

4 -45 Figure 4 -33 AC Adaptor Output Voltages

4 -46 Figure 4 -34 Sensor Positions

Part 5: MAINTENANCE

5 - 3 Figure 5 - 1 Grease Points

5 - 4 Figure 5 - 2 Main Cover and Connector Cover

5 - 4 Figure 5 - 3 Releasing the Carriage Lock

5 - 5 Figure 5 - 4 Bearings at Ends of Support shaft

5 - 5 Figure 5 - 5 Purge Unit and Bottom Case Assembly

5 - 5 Figure 5 - 6 Tightening Idler Pulley Assembly Screw

5 - 6 Figure 5 - 7 Maintenance Jet and Waste Ink Absorbers

5 - 7 Figure 5 - 8 Tightening the Chassis Fixing Screws

5 - 8 Figure 5 - 9 Screws Influencing Head Gap

5 - 9 Figure 5 -10 Measuring Sheet Setting 1

5 - 9 Figure 5 -11 Measuring Sheet Setting 2

VII

Page

5 -10 Figure 5 -12 Thickness Gauge Setting

5 -10 Figure 5 -13 Check the Head Gap

5 -11 Figure 5 -14 Adjust the Head Gap 1

5 -12 Figure 5 -15 Adjust the Head Gap 2

5 -37 Figure 5 -16 Logic Board

5 -39 Figure 5 -17 Carriage Board

5 -44 Figure 5 -18 Logic Board (Face)

5 -44 Figure 5 -19 Component Board (Back)

5 -45 Figure 5 -20 Carriage Board (Face)

5 -45 Figure 5 -21 Carriage Board (Back)

VIII

IV. TABLE INDEX

Page

Part 2: PRODUCT SPECIFICATIONS

2 - 5 Table 2- 1 BJ Cartridge vs Print Mode

2 -10 Table 2- 2 Paper Specifications

2 -12 Table 2- 3 IO Signals Compatible Mode

2 -13 Table 2- 4 IO Signals in Nibble Mode

2 -13 Table 2- 5 IO Signals in ECP Mode

Part 3: OPERATING INSTRUCTIONS

3 - 9 Table 3- 1 Printer Paper Settings

3 -14 Table 3- 2 Operator Calls

3 -15 Table 3- 3 Service Calls

3 -21 Table 3- 4 Service Mode

Part 4: TECHNICAL REFERENCE

4 - 8 Table 4- 1 Number of Passes vs Number of Operational Head Nozzles

4 -10 Table 4- 2 Main Default Print Mode Settings

4 -22 Table 4- 3 BJ Head Input and Output Signals

4 -27 Table 4- 4 AND Gate Contacts and IDATA Order

4 -27 Table 4- 5 Electrode Connection Pins

4 -28 Table 4- 6 Index Connections

4 -28 Table 4- 7 Index Sensor Signals and BJ Cartridge Detection

4 -30 Table 4- 8 Cleaning Conditions and Ink Consumption (Average)

4 -48 Table 4- 9 Ink-out Detection Timing

Part 5: MAINTENANCE

5 -39 Table 5- 1 Contacts (DARK COL and LIGHT COL)

IX

Part 1

SAFETY AND

PRECAUTIONS

Page

1 - 1 1. SAFETY PRECAUTIONS

1 - 1 1.1 Moving Parts

1 - 2 1.2 Front Cover

1 - 3 1.3 Ink Stains

1 - 5 1.4 Live Parts

1 - 6 1.5 BJ Cartridge Metal Plate

1 - 7 2. MACHINE PRECAUTIONS

1 - 7 2.1 BJ Cartridge Handling

1 - 9 2.2 Ink Tank Handling

1 -10 2.3 Printer Handling

1 -12 3. NOTES ON SERVICING

1 -12 3.1 EEPROM Data

1 -13 3.2 Service Mode of Printer Driver

1 -13 3.3 Protecting the Power Supply

1 -14 3.4 Static Electricity

1 -15 3.5 Disassembly and Assembly

1 -15 3.6 Self-Diagnosis

1. SAFETY PRECAUTIONS

1.1 Moving Parts

Be careful not to let your fingers, hair, clothing, accessories, etc., become caught up in

the moving parts of the printer.

There are moving parts associated with the carriage motor and paper feed motor.

Carriage motor

Carriage belt, idler pulleys, and carriage

Paper feed motor

Paper feed roller, pressure rollers, spurs, pick-up roller, slow down gear, paper output

guide, and purge unit.

Be sure that the front cover is closed so that there is no risk of contacting the moving

parts, except when checking operation during servicing.

Note that the spurs are made of metal with a sharp edge. Be careful not to touch the

spurs with your bare hands.

1-1

BJC-7100

Part 1: Safety and Precautions

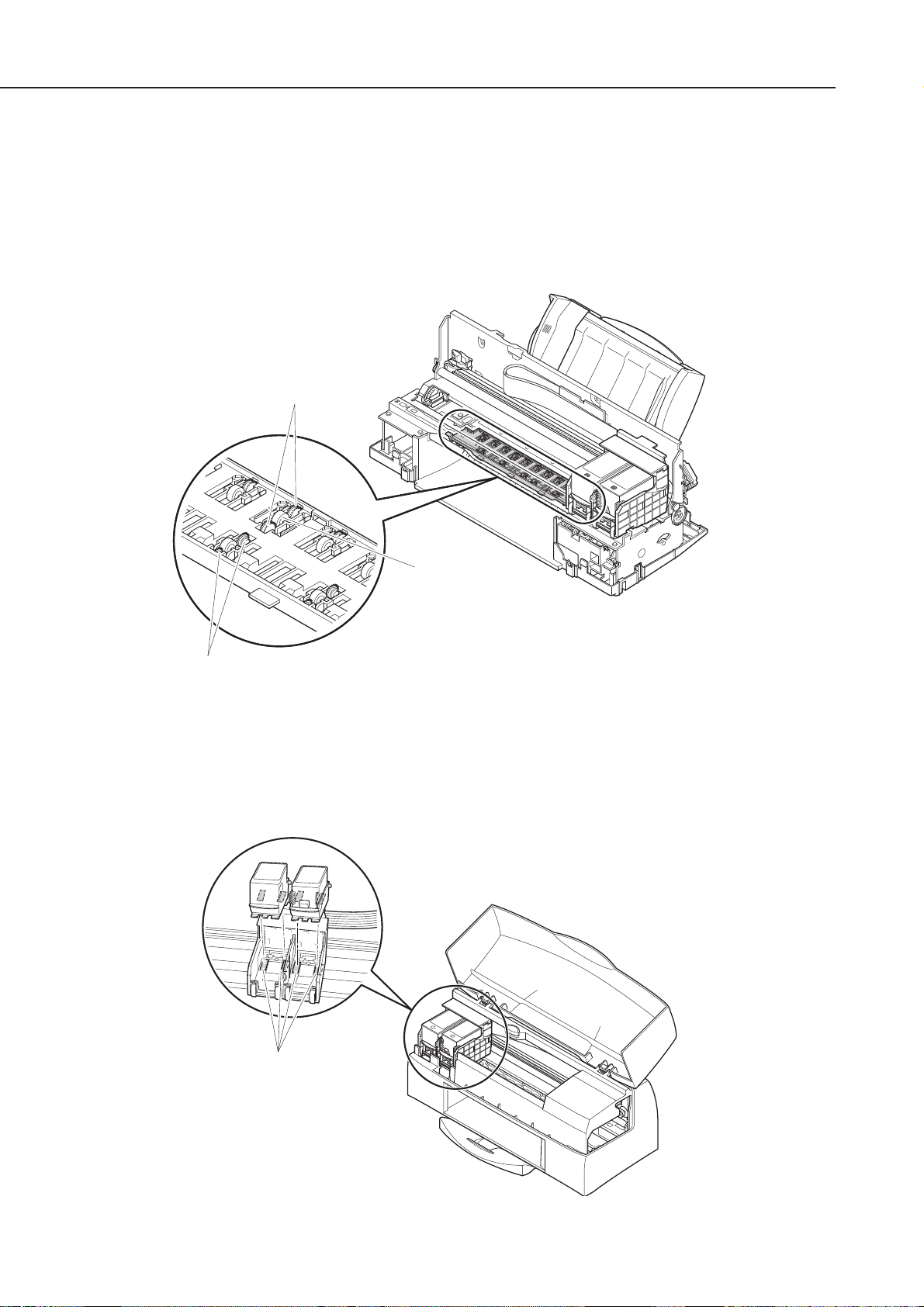

Figure 1-1 The Printer's Moving Parts

Pickup Roller

Carriage Belt

Idler Pulley

Paper Feed Motor

Slow Down Gear

Carriage

Carriage Motor

Purge Unit

Spur Unit

Page Eject Roller

Feed Roller

Pressure Roller

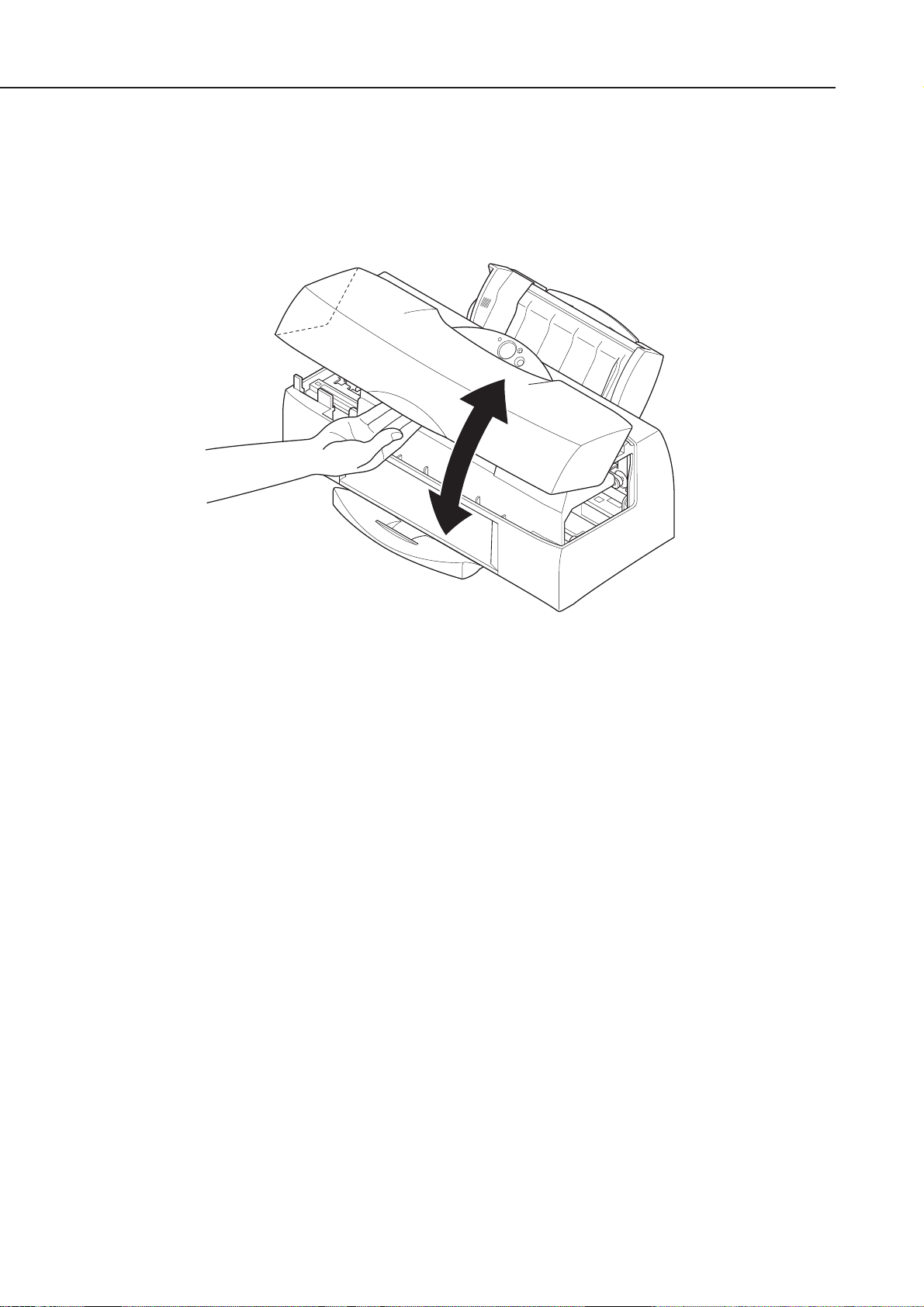

1.2 Front Cover

Hold the front part of the front cover to open and close the cover.

Be careful not to pinch your fingers between the front and main cover when closing the

front cover.

Part 1: Safety and Precautions

BJC-7100

1-2

Figure 1-2 Front Cover

1.3 Ink Stains

1.3.1 Ink path

Be careful not to touch the ink path as it may stain your hands, clothes, printer, work

table etc., during servicing.

The ink path consists of the BJ cartridge nozzles, head cap, waste ink tube, head

wiper, cleaner unit, maintenance jet receiving section, and waste ink absorber.

CAUTION

Although the ink and ink optimizer for plain paper are not harmful to the

human body, they contain organic solvents indicated on the package.

Avoid getting the ink into your mouth and eyes, and store out of reach of

children.

If ink does get into your eyes, wash with plenty of water and consult a

doctor. If for some reason a large amount of ink is swallowed, consult a

doctor immediately.

Give the doctor the information on the BJ cartridge package.

This ink contains dyes, that cannot be removed from clothing, etc.

1-3

BJC-7100

Part 1: Safety and Precautions

Figure 1-3 Ink Path

Wiper for Plain Paper

Ink Optimizer

Maintenance Jet Receiving

Section for Plain Paper

Ink Optimizer

Maintenance Jet

Receiving Section

for Ink

Maintenance Jet Absorber

for Plain Paper Ink Optimizer

BJ Cartridge

Carriage

Color: Photo Head (Nozzles)

Black: Ink Optimizer Head (Nozzles)

Cleaner Unit

Head Cap

Purge Unit

Waste Ink Tube

Waste Ink & Waste Ink Optimizer Absorber

Head Wiper

Maintenance Jet

Absorber for Ink

The joints and ink outlets of the respective ink tanks of the photo BJ cartridge [BC62e Photo] and color BJ cartridge [BC-61] are also part of the ink path and must be

handled with care.

Unless absolutely necessary, do not remove the ink tanks from a BJ cartridge, since

air may enter the ink path and have a negative effect on print quality.

The BJC-7100 uses a variety of inks and an ink optimizer for printing on

plain paper. The ink optimizer is an almost colorless, transparent fluid.

We will refer to the ink optimizer for plain paper simply as ink optimizer or

just optimizer for simplicity purposes. We will also refer to the various

colored inks and the ink optimizer for plain paper simply as "inks".

1.3.2 Ink mist

The BJ cartridge ejects ink onto the paper. After prolonged or heavy-duty use of the

printer, a small amount of ink mist splattered during printing can dirty the printer

such as the platen.

Turn off the power, open the front cover, and clean the dirty parts with a soft moist

cloth. This is to prevent dirtying the paper, your hands, and clothing from touching

these parts.

Part 1: Safety and Precautions

BJC-7100

1-4

Figure 1-4 BC-62e Photo and BC-61

Figure 1-5 Ink Mist

Ink Outlets

Joints

Head (Nozzles)

Ink Outlets

Joints

Head (Nozzles)

BC-62e Photo BC-61

Front Cover

Platen

Paper Output

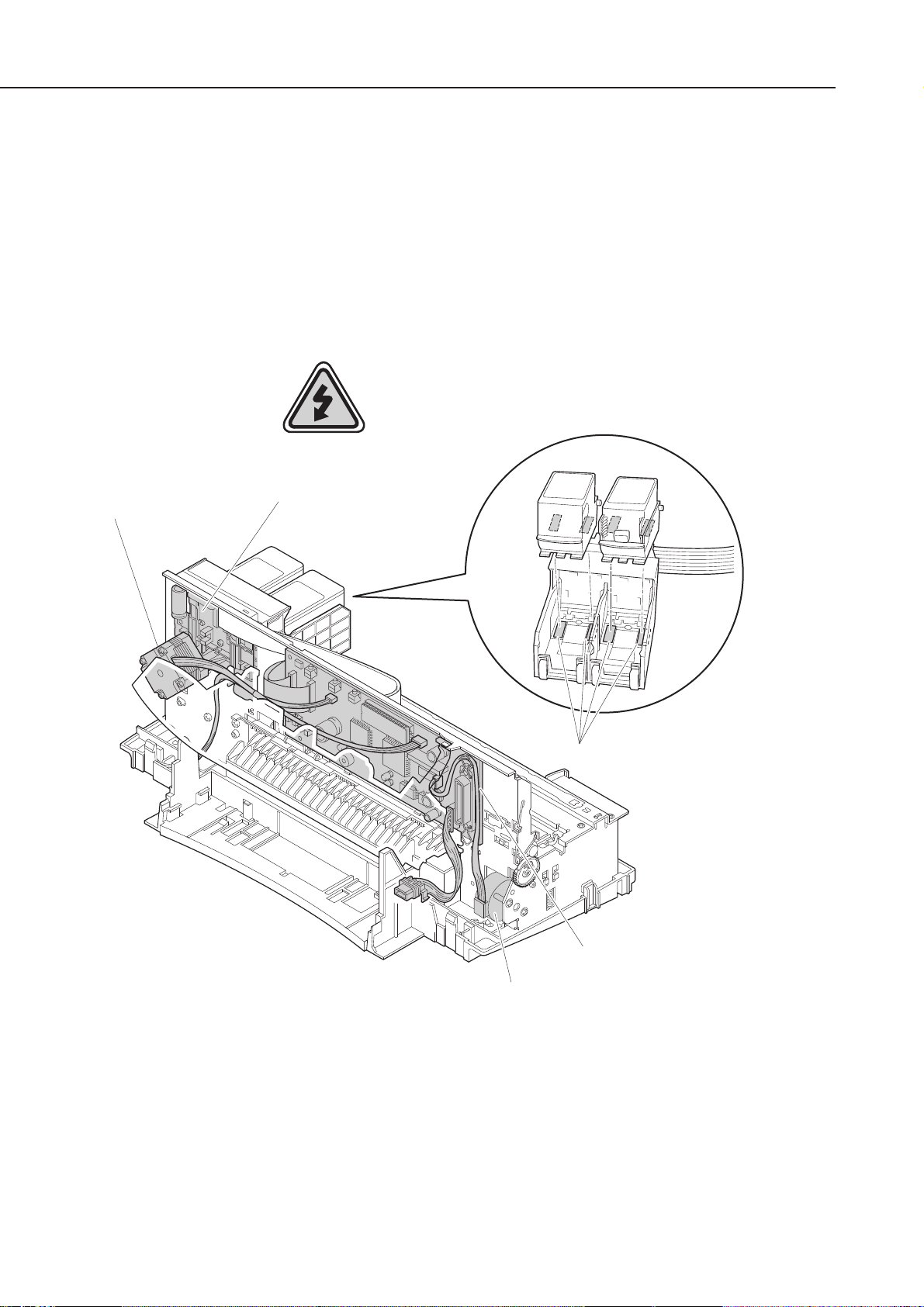

1.4 Live Parts

When the plug of the printer's AC adapter is plugged into a live power outlet, the power

supply unit of the printer is live regardless of the power being set to ON or OFF using

the

POWER

button.

Be careful not to get on electric shock if you are checking the printer operation with the

covers off.

CAUTION

Do not attempt to dismantle the AC adapter. The mains AC voltage is

supplied to the primary side of the AC adapter. To prevent risk of electric

shock, do not attempt to dismantle the AC adapter to check its operation,

etc.

If faulty, the AC adapter must be replaced as one unit (service part). The

structural components, including the case, are not available individually

as service parts. Do not attempt to dismantle the AC adapter.

1-5

BJC-7100

Part 1: Safety and Precautions

Figure 1-6 AC Adapter

1.5 BJ Cartridge Metal Plate

Do not touch the BJ cartridge's metal plate as it may be very hot. The metal plate

heats up during printing and becomes particularly hot during heavy duty printing.

CAUTION

Danger! High Temperature!

Do not touch.

The printer has the following protective mechanisms to detect overheating:

1. Overheat detection when replacing cartridge

If overheating is detected, a beeper sounds four times and the carriage

does not return to the replacement position. This is to prevent the user

from touching the BJ cartridge's metal plate.

Resume the cartridge replacement after leaving the cartridge to cool for

several minutes.

2. Overheat detection during normal printing

The carriage movement and the paper eject operation are continued

while the printing is stopped. Depending on the outcome of the ink-out

detection after completion of printing a page, a beeper sounds to

indicate the status of the error.

Ink available: BJ cartridge overheat error (beeper sounds 7 times)

Ink out: Ink-out error (beeper sounds 3 or 4 times)

When a BJ cartridge overheat error occurs, leave the cartridge to cool

for several minutes then press the

RESUME

button.

These protective mechanisms are based on the temperatures detected by

the sensors in the BJ head.

If the protective mechanism is activated and normal operation cannot be

resumed after cooling the head for several minutes, see

"Part 5: 6.

TROUBLESHOOTING" (page 5-13)

.

For details of ink-out detection, see

"Part 4: 5.2.3 Ink-out detection" (page 4-48)

.

Part 1: Safety and Precautions

BJC-7100

1-6

Metal Plate

Figure 1-7 BJ Cartridge Metal Plate

2. MACHINE PRECAUTIONS

2.1 BJ Cartridge Handling

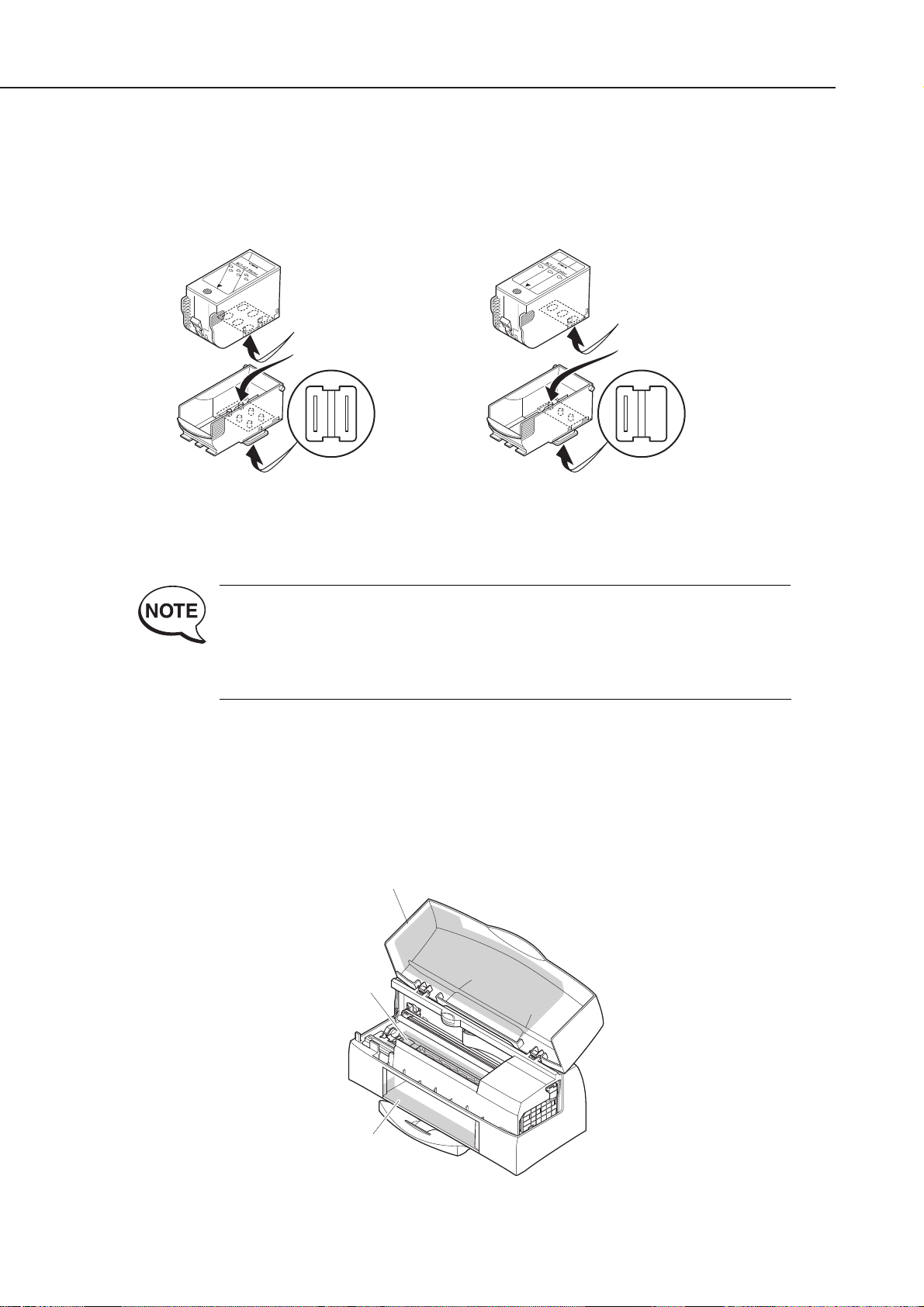

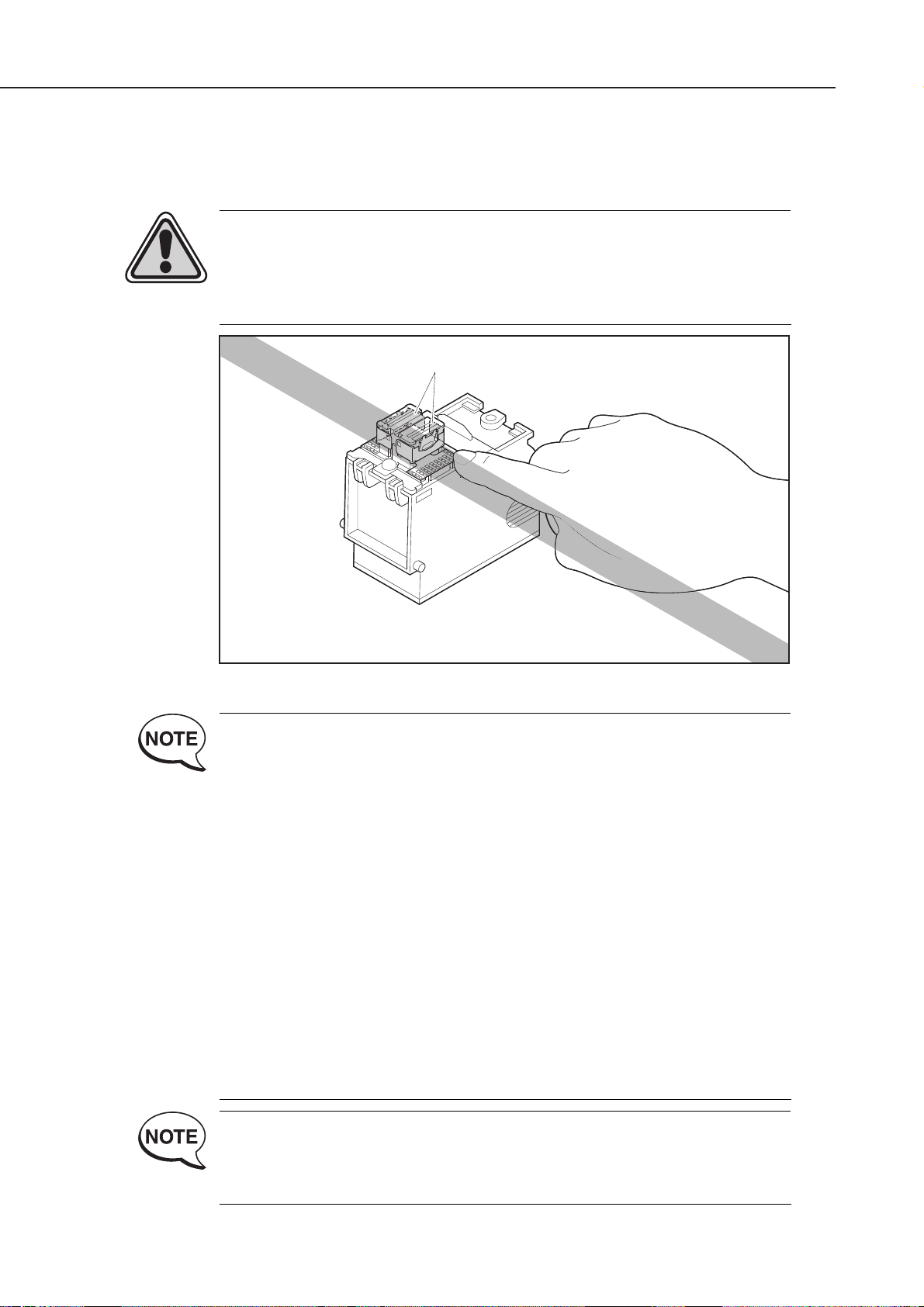

2.1.1 Unpacking the BJ cartridge

Do not unpack the BJ cartridge until you are ready to use it.

Before installing the BJ cartridge in the printer, remove the cap protecting the nozzles

and gently peel off the protective tape.

Do not attempt to reuse the cap or the tape after they have been removed, as doing so

may cause faulty printing.

If you replace the cap on the color BJ cartridge or photo BJ cartridge, the

sponge in the cap may cause the colors to bleed into each other. The

nozzles may also become clogged.

Always move the carriage to the BJ cartridge replacement position before

attempting to remove or install a cartridge. Failure to do so may result in

damage to the BJ cartridge.

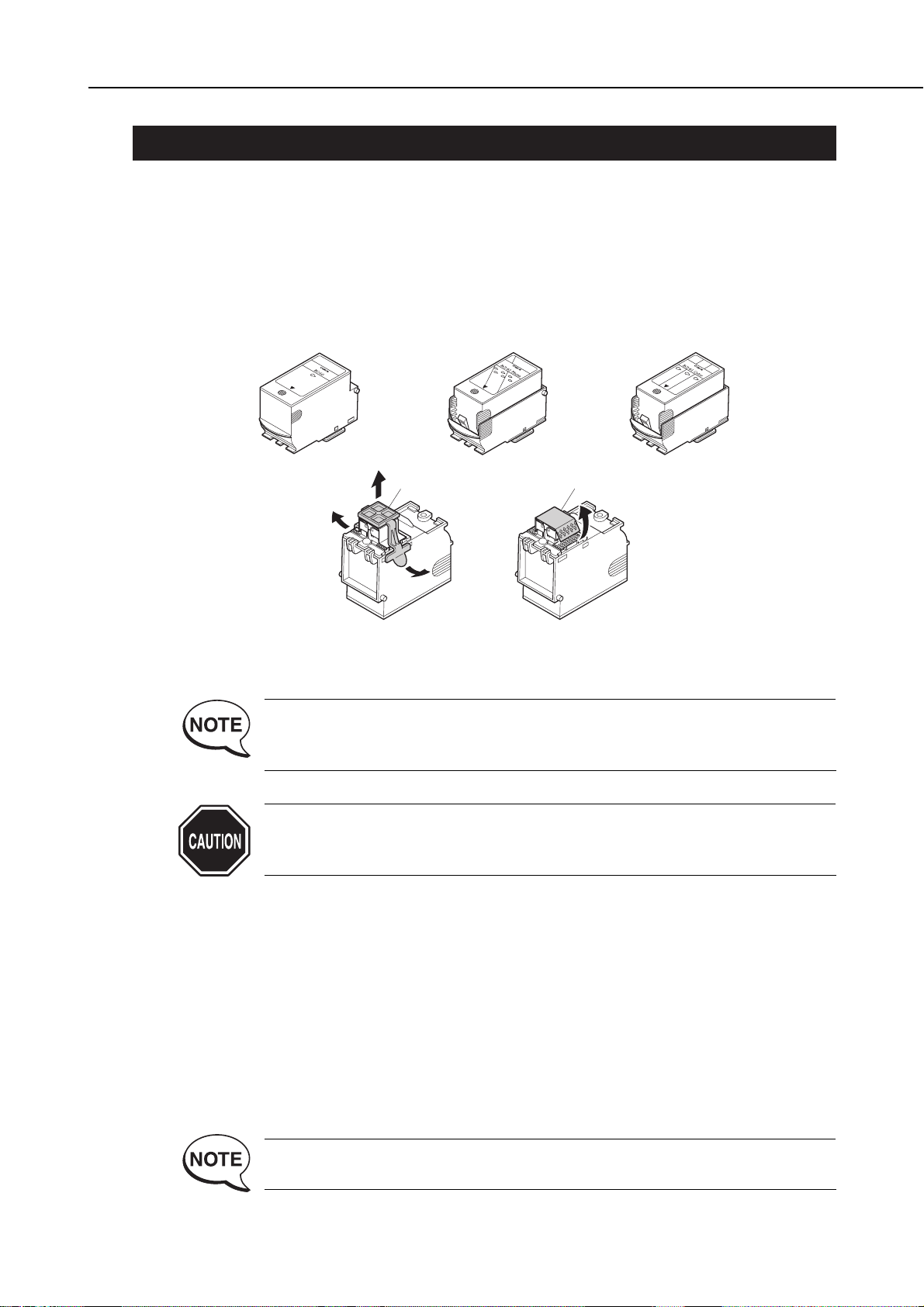

2.1.2 BJ cartridge protection

To prevent the nozzles from clogging, never touch or wipe the nozzles, joint pipes, or

ink tank outlets with your bare hands or with tissue paper, etc. After removing the

cap and peeling off the protective tape from a BJ cartridge, promptly install the

cartridge in the printer or store it in the cartridge holder. If the BJ cartridge is not

capped or stored in the cartridge holder, the nozzles may clog due to dried out ink or

dust, etc.

Do not attempt to leave color BJ cartridges or photo BJ cartridges with their ink tanks

removed.

BJ cartridges cannot be disassembled, reassembled, or washed.

Clogged nozzles cause faulty printing. If this problem persists even after

the nozzles are cleaned, replace the BJ cartridge.

1-7

BJC-7100

Part 1: Safety and Precautions

Figure 1-8 Removing the BJ Cartridge Cap and Tape

BC-60

BC-62e Photo

Head Cap

Protective Tape

BC-61

2.1.3 Power on/off

When the printer is turned off with the

POWER

button, the printer automatically caps

the BJ cartridge's nozzles for protection and to prevent ink leakage.

If the AC adapter is unplugged before the printer is turned off with the

POWER

button, the nozzles may not be capped. In this case, plug the AC adapter again, start

up the printer and turn off the printer with the

POWER

button before unplugging the

power cord. Note that, if you unplug the power during the recovery operation and

then leave the printer, the purge unit may be damaged.

If the nozzles are not capped, the ink might dry out and clog the nozzles or

leak from the cartridge.

2.1.4 When not using the printer

Keep the BC-60 BJ cartridge installed in the printer even when the printer is not in

use. The BC-62e Photo and BC-61 BJ cartridges can be left installed in the printer or

stored in the cartridge holder. This also applies when carrying, transporting, or

storing the printer.

If the BJ cartridge is taken out of the printer, dried ink or dust may clog

the nozzles, resulting in inconsistent printing.

If the printer is moved or transported with no cartridge installed, ink may

leak from the cap mechanism.

Part 1: Safety and Precautions

BJC-7100

1-8

Figure 1-9 BJ Cartridges

BC-60 BC-62e Photo

Ink Outlets

Joints

BC-61

Ink Outlets

Joints

2.1.5 Ink electroconductivity

The ink used in the BJ cartridge can conduct electricity. If any ink leaks into the

printer's mechanical parts, use paper towels, etc., to wipe clean. If the ink leaks onto

the printer's electrical components, use tissue paper, etc., to wipe clean. If the ink

gets to the IC chips on the PCB, or if it is too difficult to thoroughly clean off the ink,

replace the respective parts.

Never connect the printer's power cord if ink has leaked inside the printer.

It may damage the circuitry.

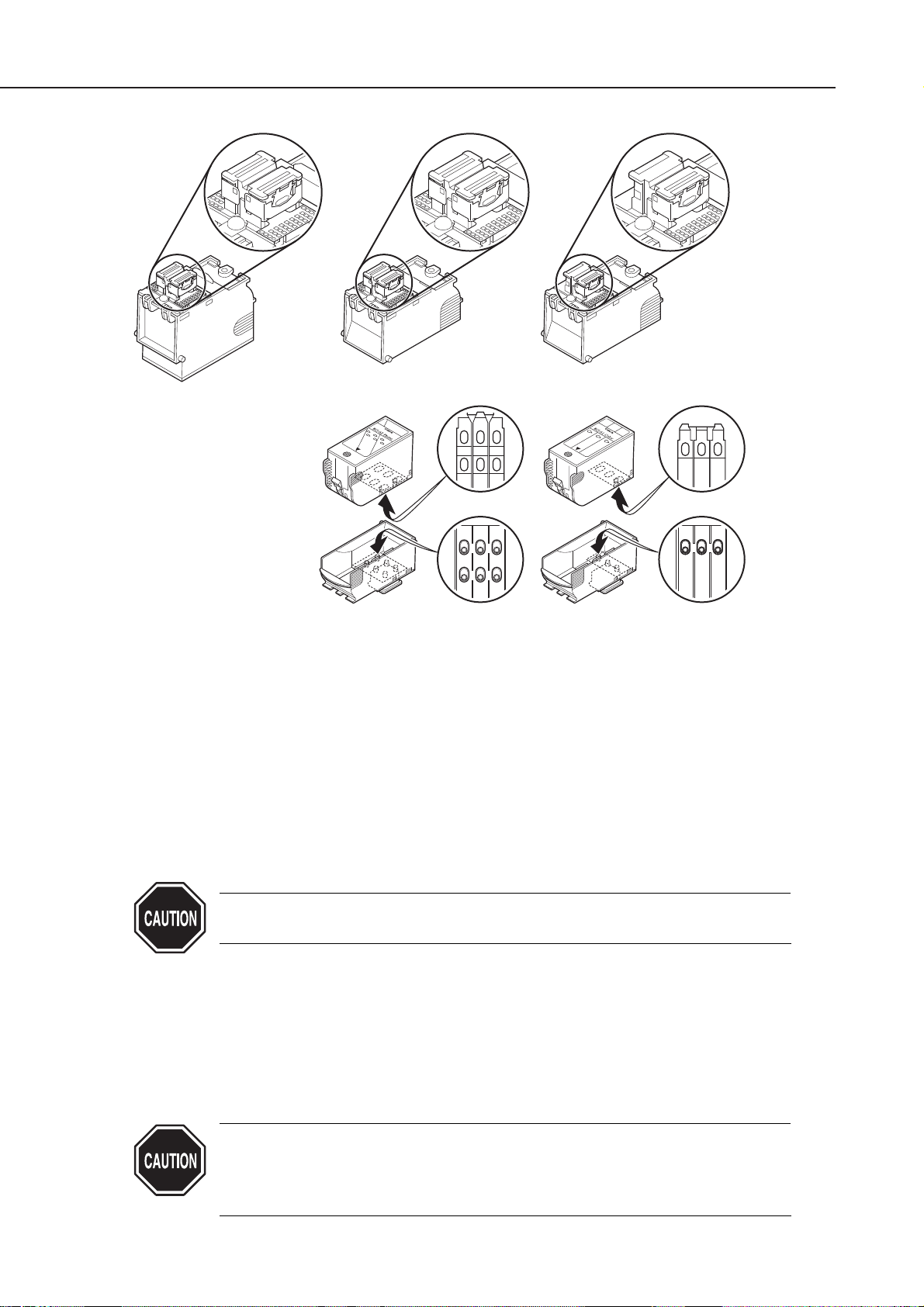

2.2 Ink Tank Handling

2.2.1 Unpacking the ink tank

Do not unpack the ink tank until you are ready to use it.

Before installing it in the color BJ cartridge, remove the cap covering the ink outlets.

2.2.2 Preventing clogging

To prevent poor ink suction due to clogging of the joints in the BJ cartridge, never

touch the ink tank's ink outlets. After removing the cap from the ink tank, promptly

install the ink tank in the BJ cartridge to prevent the nozzles from clogging due to

dried-out ink, dust, etc. Do not remove an ink tank from a BJ cartridge unless you

are replacing it.

1-9

BJC-7100

Part 1: Safety and Precautions

Figure 1-10 Removing the Ink Tank Cap

Figure 1-11 The Ink Outlets on Ink Tank

BCI-62 Photo

Photo Cyan Ink Outlet

Photo Magenta Ink Outlet

Photo Yellow Ink Outlet

Yellow Ink Outlet

Magenta Ink Outlet

Cyan Ink Outlet

BCI-61 Color

Cyan Ink Outlet

Magenta Ink Outlet

Yellow Ink Outlet

2.3 Printer Handling

2.3.1 Spurs

Take care not to bend the tips of the spurs.

The spurs that transport and eject the paper after printing are very small and can

easily be deformed.

If a spur is deformed, its contacting surface with the printed paper increases, creating

a dotted line.

2.3.2 Damage due to static electricity

The static charge accumulated by your body from clothing can damage electrical

components and alter their electrical characteristics.

Never touch the carriage contacts or BJ cartridge contacts.

Part 1: Safety and Precautions

BJC-7100

1-10

Figure 1-12 Spurs

Figure 1-13 Contacts

Double Spurs

Spur Cleaner

Spurs

Contacts

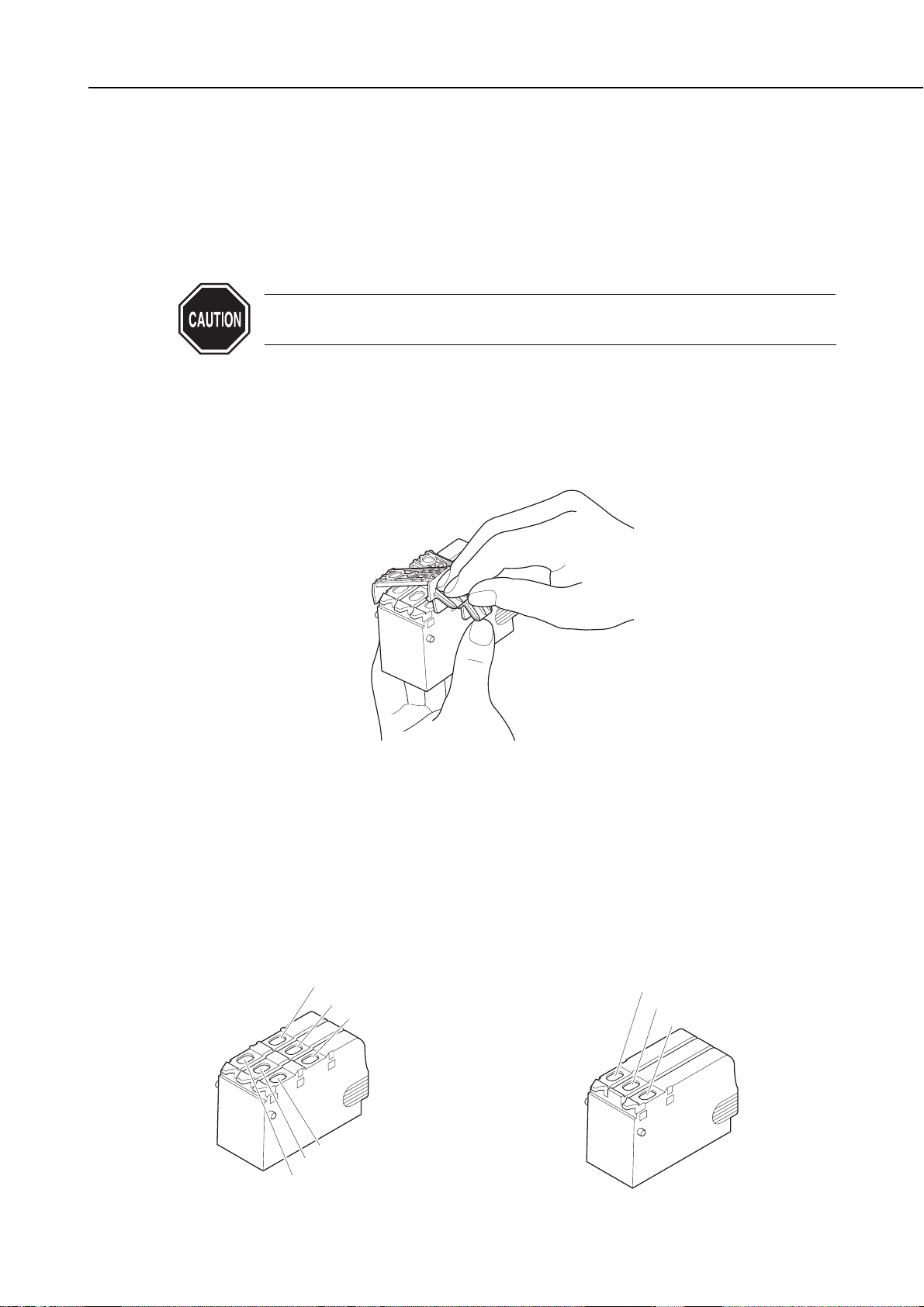

2.3.3 Ink leakage and dry-out

Make sure a BJ cartridge is installed before turning off the power, using the

POWER

button.

When you turn off the printer using the

POWER

button, the printer automatically

performs the following operations:

Cleaning

Any ink left in the purge unit or in the nozzles of the BJ cartridge is removed.

Capping

To prevent ink dry-out, the BJ cartridge's nozzles are capped automatically and the

carriage is locked in position.

If you unplug the AC adapter by mistake, plug the power cord again, turn the power

on and then off again using the

POWER

button, then unplug the AC adapter.

If you turn the power off or unplug the AC adapter when the BJ cartridge has been

removed, the nozzles will not be automatically capped or the carriage locked in

position, and hence there is a risk of ink leaking or dry-out.

If the power cannot be turned on due to some failure, manually move the

carriage belt or the carriage itself to the capping position. For details, see

"Part 3: 2.2 Manual Capping" (page 3-13).

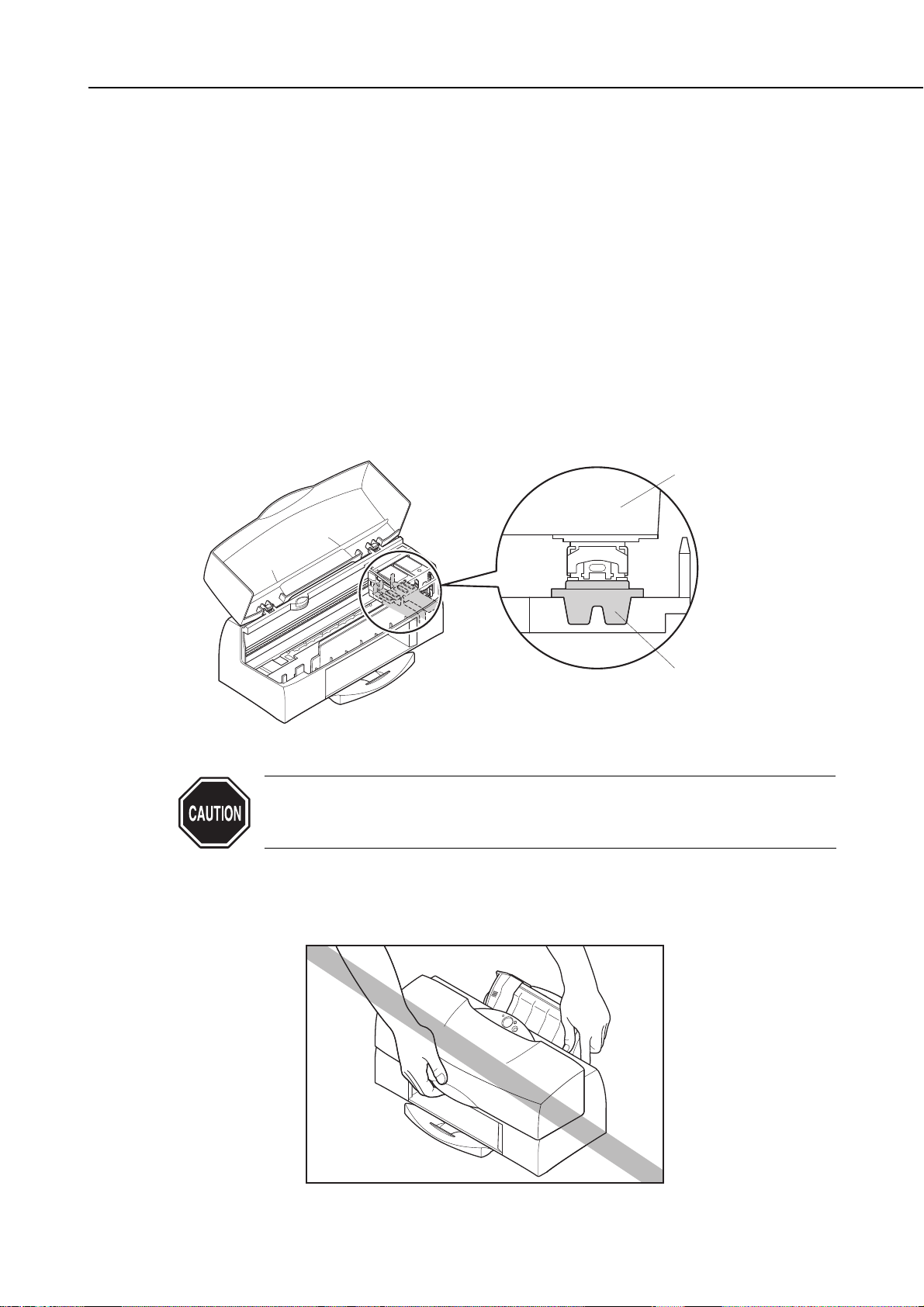

2.3.4 Carrying the printer

Hold both sides of the bottom of the printer to carry it. Note that inserting your hand

into the paper outlet may dislodge or damage the paper guides.

1-11

BJC-7100

Part 1: Safety and Precautions

Figure 1-14 Capping Position

Figure 1-15 Carrying the Printer

BJ Cartridge

Head Cap

3. NOTES ON SERVICING

3.1 EEPROM Data

The printer stores the function settings and keeps track of various information

including the total sheets printed, the number of cartridge replacements, the total

waste ink amount, and the head position adjustment values. The data is stored in the

EEPROM on the logic board.

Note the following precautions during servicing:

1) Before servicing

You can check the EEPROM data with a test print. The total sheets printed can give

you an idea of how much the printer has been used.

2) During logic board replacement

Always replace the waste ink absorber when replacing the EEPROM.

If you do not replace the waste ink absorber, the data on waste ink amount will differ

from the amount of ink that can be absorbed by the waste ink absorber. There is

therefore a risk of ink leaking.

When replacing the logic board, be sure to reset all the data. Because the data on

new EEPROMs is undefined, they cannot be used until they are reset. For details of

handling EEPROMs, see

"Part 3: 3.4 EEPROM" (page 3-19)

.

3) After waste ink absorber replacement

After replacing full waste ink absorbers, reset the EEPROM's waste ink counter.

4) If you accidentally reset the EEPROM's waste ink amount data or all data

Once reset, the EEPROM data cannot be restored. If you accidentally reset the

EEPROM, you must take the same steps as when replacing the logic board.

After the EEPROM is reset, the data it contained cannot be printed out

with a test print. If you want to check the stored data, be sure to make a

test print before resetting the EEPROM.

Note that you cannot reenter the data from the printer's control panel or

by using a computer.

If the EEPROM is faulty, or all data is reset, all data is lost. Whenever

possible, restore all data such as the head alignment to the user's

settings.

During operation, the waste ink amount (EEPROM data) is automatically

updated. An error message is displayed and operation halted when the

waste ink absorber is nearly full. If this occurs, refer to

"Part 5: 6.

TROUBLESHOOTING" (page 5-13)

.

See

"Part 3: 3.8.3 Printing EEPROM data" (page 3-23)

for how to make a test

print of the stored data.

You can choose to either reset the waste ink counter or all data. See

"Part

3: 3.8.2 Resetting EEPROM data" (page 3-22)

for details.

Part 1: Safety and Precautions

BJC-7100

1-12

3.2 Service Mode of Printer Driver

There are certain printer driver control functions, described below, that are, in

principle, hidden from the end user. These service mode functions, which must be

used with caution, are provided for service purposes only.

See

"Part 3: 3.3.2 Service mode of printer driver" (page 3-18)

for details.

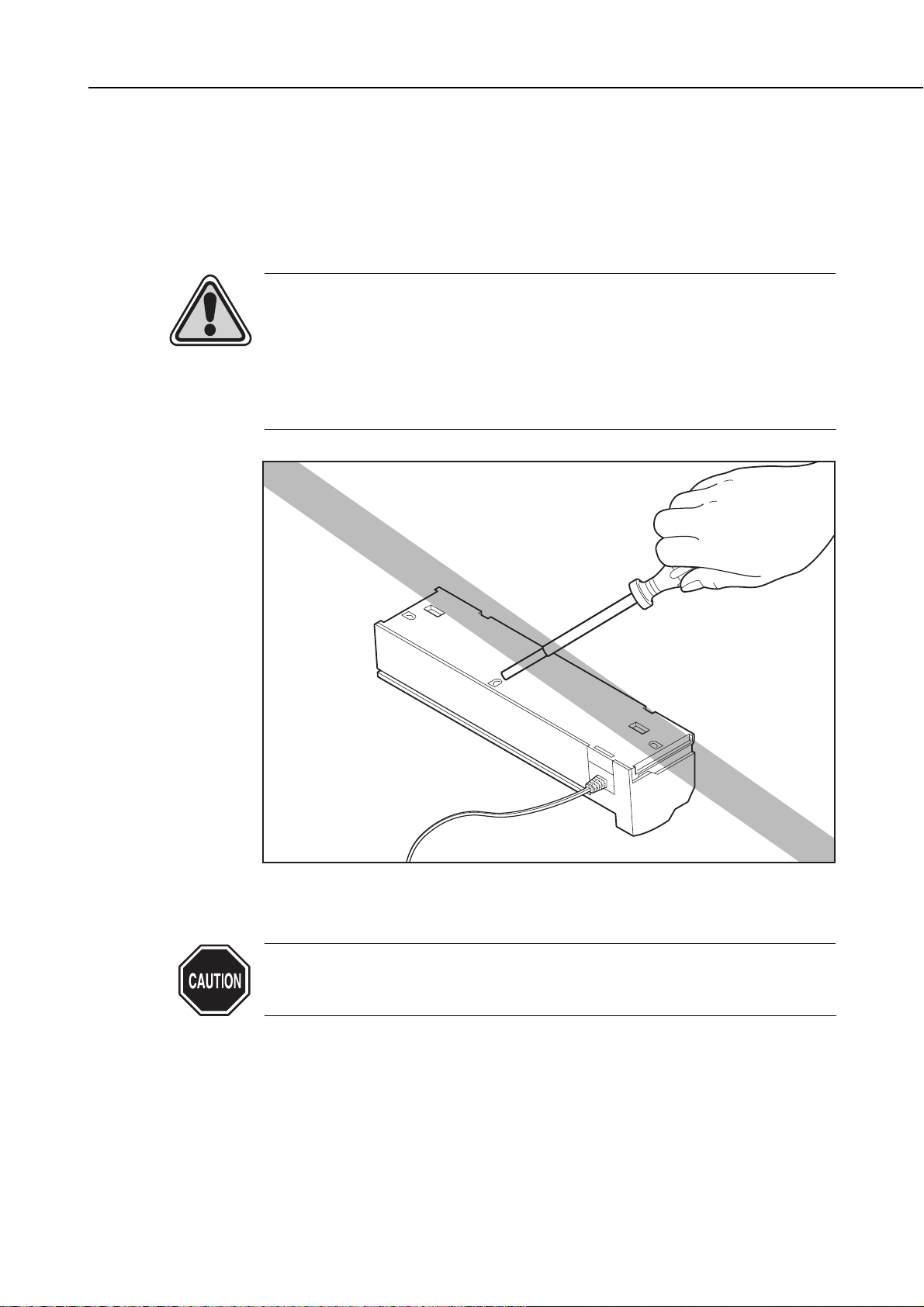

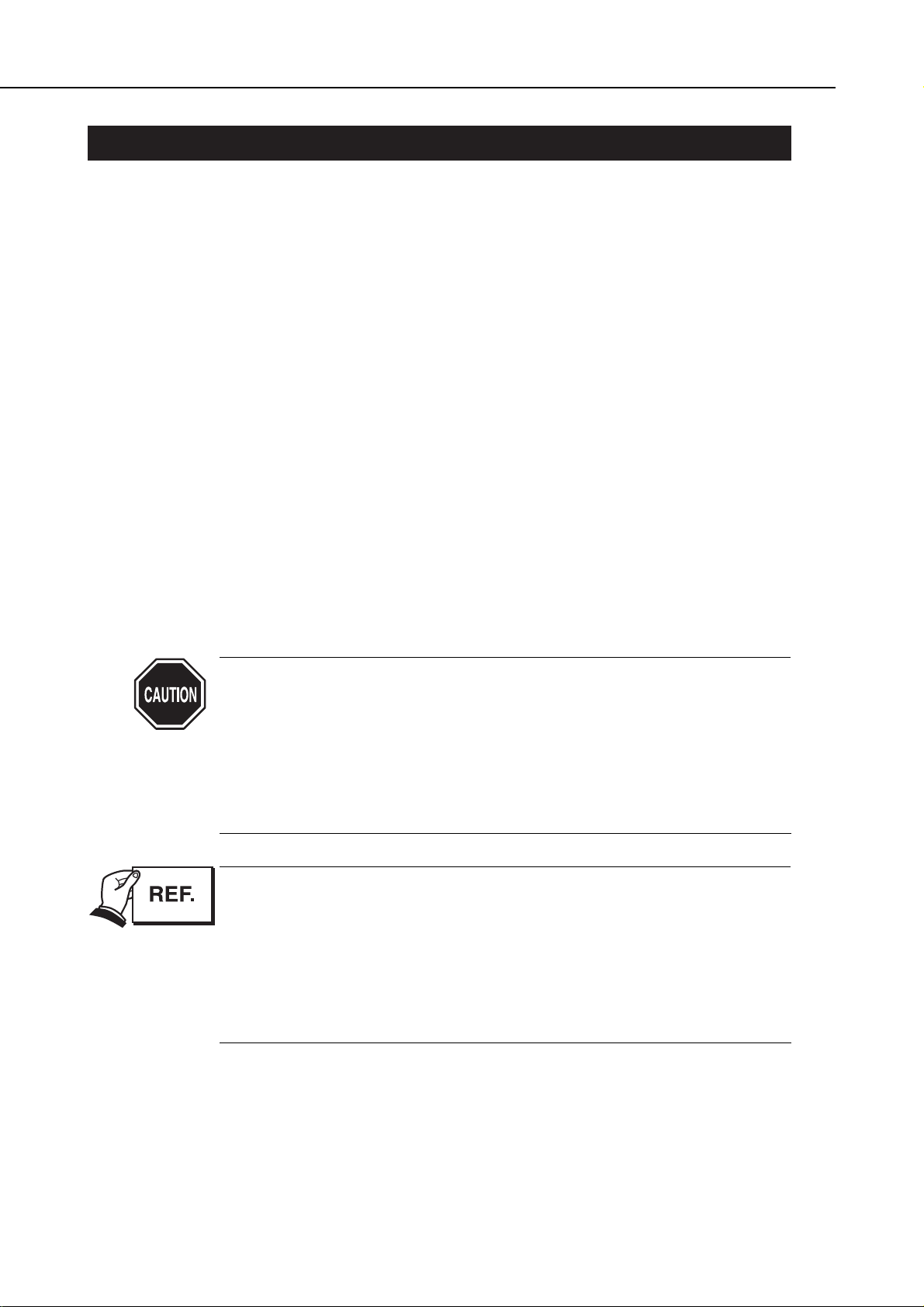

3.3 Protecting the Power Supply

The power supply for the BJC-7100 printer consists of an AC adapter and a power supply

circuit on the logic board. Provided the AC supply is connected, the printer power supply

is live whether or not the power is set ON or OFF using the

POWER

button.

Always unplug the AC adapter from the power outlet before connecting it to or

disconnecting it from the printer. Ignoring this warning can result in damage and

failure of the printer power supply.

When moving the carriage by hand when, for example, manually capping the

ink nozzles or releasing the carriage lock, do so slowly while paying attention

to the operation of the carriage motor; the back electromotive force generated

by moving the carriage horizontally may damage the motor control board.

If it is necessary to move the carriage horizontally fairly frequently, such

as when replacing or adjusting the carriage, temporarily disconnect the

carriage motor connector from the control board.

1-13

BJC-7100

Part 1: Safety and Precautions

Figure 1-16 Protecting the Power Supply

STEP 1-1

USA Only

or

STEP 2

STEP 1-2

3.4 Static Electricity

The electrostatic charge accumulated in clothing can damage electrical components

and alter their electrical characteristics.

Before disassembling the printer to service it, use a wriststrap or other grounded metal

object to discharge the static electricity. The following parts must not be touched

before you have discharged the static electricity from your body:

• Logic board, carriage board

• Motor control board

• Cable connectors and contacts

• BJ cartridge signal contacts

Part 1: Safety and Precautions

BJC-7100

1-14

Figure 1-17 Electrical System of Printer

Static Damage!

Carriage Motor

Carriage Board

BJ Cartridge Signal Contacts

Logic Board

Paper Feed Motor

3.5 Disassembly and Assembly

3.5.1 Parts that cannot be disassembled

Do not disassemble the ribbon cable to the head on the carriage unit. The position in

relation to the contacts with the BJ cartridge is factory adjusted, and cannot be

readjusted during printer servicing.

In addition, do not attempt to disassemble the AC adapter, BJ cartridge, or ink tanks.

In principle, do not loosen any of the screws painted red in the printer mechanism

(except when adjusting the head gap using the jig). The red screws hold the adjustable

plate that determines the gap between the nozzles of the BJ cartridge and the platen.

This gap is adjusted to the optimal value when the printer leaves the factory.

In addition to the above, do not attempt to disassemble any parts not

shown disassembled in the exploded diagrams in the parts catalog.

Failure to observe this warning may result in those parts not functioning

as originally intended after they are reassembled.

3.5.2 Parts requiring careful attention during disassembly and assembly

The printer has many parts that can be damaged during disassembly and assembly.

For details, see

"Part 5: 4. DISASSEMBLY AND REASSEMBLY" (page 5-4)

. Please read

this section carefully before attempting to disassemble and assemble the printer.

The printer also has many plastic parts. When disassembling the printer, take care

not to break or bend the plastic hooks.

Some plastic parts contain glass fibers for extra rigidity and precision, but

since their viscosity is low, the plastic hooks can break easily when

excessive force is used. Do not pull a plastic hook with excessive force

while unhooking it.

3.6 Self-Diagnosis

The printer has a self-diagnosis feature to detect hardware defects. The results of the

self-diagnosis are indicated on the LED on the control panel, and by the beeper. For

details, see

"Part 3: 3.1 Error Indications" (page 3-14).

1-15

BJC-7100

Part 1: Safety and Precautions

Figure 1-18 Parts that Cannot be Disassembled

Head AlignmentAdjuster Plate

AC Adapter

Red Screw

Carriage Unit

BJ Cartridge

Ink Tank

Red Screw

Head AlignmentAdjuster Plate

Part 1: Safety and Precautions

BJC-7100

1-16

This page intentionally left blank

Part 2

PRODUCT

SPECIFICATIONS

Page

2 - 1 1. PRODUCT OUTLINE

2 - 1 1.1 Outline

2 - 2 1.2 Features

2 - 3 1.3 BJ Cartridge

2 - 6 1.4 SB-60 BJ Cartridge Container

2 - 6 1.5 Consumables

2 - 7 2. SPECIFICATIONS

2 - 7 2.1 General Specifications

2 -10 2.2 Paper Specifications

2 -12 2.3 Interface Specifications

1. PRODUCT OUTLINE

1.1 Outline

The BJC-7100 is a personal desktop color bubble-jet printer that uses a new 600dpi BJ

cartridge and technology to achieve outstanding print quality and photographic

realism. The printing process uses an ink optimizer to enable water resistance printing

on plain paper.

The BJC-7100 printer uses new accurate photo BJ cartridge BC-62e Photo and new

paper eject mechanisum to achieve high speed printing with high quality print.

The BJC-7100 printer, which is easy to operate under Microsoft Windows, and is

compatible with the Internet and multimedia tools such as digital cameras, is targeted

at a wide range of users in the small-office and personal-computer environments who

require high-quality full color printing.

The ink optimizer is an almost colorless, transparent fluid. For simplicity

in this manual, we refer to the ink optimizer for plain paper simply as ink

optimizer or just optimizer. We also refer to the various colored inks and

the ink optimizer for plain paper simply as "inks".

2-1

BJC-7100

Part 2: Product Specifications

Figure 2-1 Printer Appearance

REPLACE

Button

POWER

Indicator

ERROR

POWER

BJ Cartridge Container

Indicator

RESUME

Button

Cover

Button

Paper Guide

Paper Rest

Auto Sheet Feeder

Paper Output Tray

Manual Feed Guide

Manual Feed Slot

AC Adapter

1.2 Features

1. The new 600dpi BJ cartridge provides high-resolution printing at up to 1200 (H) ×

600 (V) dpi when using the exclusive printer driver.

There are three types of new BJ cartridge: BC-60, BC-62e Photo, and BC-61. (Note

that the BJ cartridge configuration differs according to the country.)

2. The printer is equipped with two BJ cartridges.

The BC-60 is normally installed in the printer and either the BC-62e Photo or BC-61

is installed as required for the type of printing to be carried out.

3. The print process uses an ink optimizer to enable maximum water resistance when

printing on plain paper (and envelopes).

In this new printing process, the surface of the paper is coated with the ink optimizer

prior to being printed. The ink optimizer is discharged from the special BJ head of

the BC-60.

4. The straight manual insertion path allows printing on a wide variety of papers.

In addition, the automatic platen-head adjustment mechanism obviates the need for

levers for selecting papers and platen-head gap.

5. The printer performs high speed print; HQ: 5.8ppm, HS: 7.6ppm (BK; PC magazine)

6. The printer is equipped with an ink-out detection function based on the conduction

of static electricity.

An electrical signal is input to the ink path in the BJ cartridge. This signal is picked

up by the electrode on the carriage, and the signal level is used to determine the

existence or absence of ink.

7. The printer is equipped with an IEEE1284-compatible bidirectional parallel interface.

This interface is compatible with nibble mode and ECP mode.

8. The built-in control mode is the Canon extended mode.

The host computer sends print signals in Canon extended mode, generated by the

special printer driver.

9. The printer is supplied with Windows 3.1, Windows 95 and Windows 98 special

printer driver.

10. The printer is powered by an AC adaptor, installed by manufucturing.

The ink optimizer printing process can be used in both monochrome and

color printing when the printer driver is set to plain paper (including

postcards and envelopes) in all but Draft mode. It cannot be used if the

driver is set to other than plain paper (special papers and film, etc.).

The ink-out detection mechanism confirms that the BJ cartridge is out of

ink. The mechanism does not measure the amount of ink remaining in

the cartridge and therefore does not necessarily indicate an error at the

point where print quality deteriorates as the ink runs out.

Part 2: Product Specifications

BJC-7100

2-2

1.3 BJ Cartridge

1.3.1 Black BJ cartridge (BC-60)

The BC-60 BJ cartridge is used for monochrome printing and for printing using the

ink optimizer. It is a head and ink tank integrated type, disposable BJ cartridge

consisting of a unified BJ head and ink tanks for black ink and ink optimizer.

There are two parallel BJ heads, each with 304 nozzles. One head supplies ink while

the other supplies the ink optimizer.

Replace the BJ cartridge if either the black ink or ink optimizer runs out, or if

satisfactory printing cannot be achieved even after the stipulated cleaning operations

have been performed. Also replace the cartridge if more than 12 months has elapsed

after the seal is broken.

The BC-60 BJ cartridge will print approximately 870 pages of a standard 1500character print pattern (Default setting of Text mode).

2-3

BJC-7100

Part 2: Product Specifications

Figure 2-2 Black BJ Cartridge (BC-60)

1

N.C.

2

4

3 5

,

8

7 9 6

121011

14 15 13

17 16 18

2021 22 19

,

24 23

25

27 26

N.C.

View

2726

N.C.

2423

25

20212219

171618

141513

12 10 11

,

8796

,

435

12

N.C.

1.3.2 Photo BJ cartridge (BC-62e Photo)

The BJ head for the BC-62e Photo has been modified to considerably improve the ink

jet emission precision.

The BC-62e Photo BJ cartridge is used for photo-realism (super photo mode) (when

printing photographs with substantial numbers of half-tones and light colors). The

cartridge consists of a main unit that separates the BJ heads, and disposable ink

tanks (BCI-62 photo).

There are two parallel BJ heads, each with 240 nozzles. One head supplies color inks

while the other supplies photo inks. Both BJ heads have three vertical rows of 80

nozzles each for yellow, magenta, and cyan.

The total 6 ink tanks for color and photo inks are integrated.

The BC-62e Photo BJ cartridge works by layering the photo inks, which are about

1/3rd the density of the color inks, thereby enabling pale colors and halftones to be

printed. The color inks are used to print denser colors and fill larger areas with one

color.

Replace the ink tanks if any of the 6 inks runs out, or if satisfactory printing cannot

be achieved even after the stipulated cleaning operations have been performed. If you

still cannot obtain satisfactory print quality, replace the BJ cartridge. Also replace the

cartridge if more than 12 months has elapsed after the seal is broken. (Replace the

ink tank 6 months after the seal is broken.)

The BC-62e Photo BJ cartridge will print approximately 90 pages per tank of a

standard photo print pattern (Reference data).

Part 2: Product Specifications

BJC-7100

2-4

Figure 2-3 Photo BJ Cartridge (BC-62e Photo)

1

N.C.

4

8

7 9 6

,

14 15 13

17 16 18

2021 22 19

,

24 23

2

3 5

121011

25

27 26

N.C.

N.C.

2726

2423

25

20212219

,

171618

141513

12 10 11

8796

,

435

12

N.C.

View

1.3.3 Color BJ cartridge (BC-61)

The BC-61 BJ cartridge is used for color printing (denser colors and filling larger

areas with color). The cartridge consists of a main unit that separates the BJ heads,

and disposable ink tanks (BCI-61 Color).

The BJ head has 240 nozzles supplying the color inks. There are three vertical rows

of 80 nozzles each for yellow, magenta, and cyan. The 3 ink tanks are integrated.

Replace the ink tanks if any of the 3 inks runs out, or if satisfactory printing cannot

be achieved even after the stipulated cleaning operations have been performed. If you

still cannot obtain satisfactory print quality, replace the BJ cartridge. Also replace the

cartridge if more than 12 months has elapsed after the seal is broken. (Replace the

ink tank 6 months after the seal is broken.) The BC-61 BJ cartridge will print

approximately 275 pages per tank of a standard color print pattern.

1.3.4 BJ cartridge vs print mode

The inks are used in different ways according to the selected print mode, as shown in

the table below.

●●: Used ▲▲: Used only for plain paper, envelopes ✕: Not used

When you use the BC-62e Photo BJ cartridge to print in color using only the normal

color inks and not the photo inks, the normal color inks will run out and the ink

tanks will have to be replaced before the photo inks are used up.

The estimated print quantity for the BC-60 (approximately 870 pages in

monochrome) is for printing only in monochrome and assumes that the

ink optimizer is not used up by color printing. If the ink optimizer is used

in color printing, the cartridge may not print as many pages and it may be

necessary to replace the BC-60 even if you do not print in monochrome at all.

When handling BJ cartridges and ink tanks, observe the notes in

"Part 1:

2.1 BJ Cartridge Handling" (page 1-7)

.

2-5

BJC-7100

Part 2: Product Specifications

Figure 2-4 Color BJ Cartridge (BC-61)

TABLE 2-1 BJ CARTRIDGE VS PRINT MODE

Print Mode

Fast

Standard (Fast)

Standard (High Quality)

High Quality

Fine

Black Ink

●●

●●

●●

●●

●●

Ink Optimizer

✕

▲▲

▲▲

▲▲

▲▲

Color Ink

●●

●●

●●

●●

●●

Photo Ink

✕

✕

✕

●●

●●

Color Ink

●●

●●

●●

●●

●●

BC-60 BC-62e Photo BC-61

1

N.C.

2

4

3 5

8

7 9 6

,

121011

14 15 13

17 16 18

2021 22 19

,

24 23

25

27 26

N.C.

View

1.4 SB-60 BJ Cartridge Container

The SB-60 cartridge container is for storing the BC-62e Photo or BC-61 BJ cartridge—

whichever is not currently being used.

The SB-60 cartridge container is supplied with the printer, and can also be bought as

optional equipment.

After placing a cartridge in the holder, be sure to close the lid securely. Failure to do so

may result in the nozzles clogging due to dried ink.

The SB-60 cartridge container can be used to store either the BC-62e Photo or BC-61

BJ cartridge. Store either of the cartridges in the holder if you have removed the

protective caps and tape.

The cartridge container can be installed on the printer.

Note that the BC-60 cartridge cannot be stored in the SB-60 cartridge

container, and is always installed in the printer.

1.5 Consumables

1.5.1 BJ cartridge

The BJ cartridges (BC-60, BC-62e Photo, and BC-61) used in the BJC-7100 printer

are supplied as consumables. Except for the packaging, these consumables are

identical to the BJ cartridges supplied with the new printer.

The BC-62 Photo used in the BJC-700J Printer cannot be used on this printer. If the

BC-62 Photo is installed on BJC-7100, printing is carried out, however, print quality

may deteriorate drastically.

1.5.2 Ink tank

The BCI-62 Photo ink tank for the BC-62e Photo cartridge, and the BCI-61 Color ink

tank for the BC-61 cartridge are both supplied as consumables.

Always replace the ink tanks if one of the colors runs out, or satisfactory print quality

cannot be achieved even after the stipulated cleaning operations. If, after replacing

the ink tanks, you still cannot obtain satisfactory print quality, replace the BJ

cartridge. Note that the ink tanks can only be used for 6 months after the seal is

broken.

Part 2: Product Specifications

BJC-7100

2-6

Figure 2-5 BJ Cartridge (SB-60)

Figure 2-6 Ink Tanks

BCI-62 Photo BCI-61 Color

2. SPECIFICATIONS

2.1 General Specifications

1. Type

Desktop serial color bubblejet printer

2. Operating mode

Canon extended mode

3. Print resolution

1200 (H) × 600 (V) dpi max.

4. Printing speed

Burst (BC-60 monochrome)

HQ: 480cps, HS: 720cps

Throughput

Monochrome printing: HQ: Approx. 5.8ppm, HS: Approx. 7.6ppm

Color printing: HQ: Approx. 0.5 to 2.1ppm, HS: Approx. 1.3 to 4.4ppm,

FINE: Approx. 0.26 to 0.9ppm

HQ: Default setting of Text mode

HS: Default setting of Draft mode

FINE: Default setting of Auto mode

5. Printing width

218mm max. (Maximum print width when Letter+ size is selected)

6. Line pitch

n/600inch (where n is programmable)

7. Print direction

Select either of Unidirectional or BIdirectional as the printing mode. (See

"Part 4: 2.2

Print Mode" (page 4-8)

)

8. Bit image printing

Data matrix: Canon extended mode: Raster image format

Resolution: Canon extended mode: 300, 600, and 1200dpi

9. Buffer

256KB

10. Interface

IEEE1284-compatible parallel interface

11. Interface cable

Material: AWG28 or thicker

Type: Twisted pair shielded cable

Length: 2.0m max.

12. Interface connectors

Printer: Amphenol 57-40360 or equivalent

Cable: Amphenol 57-30360 or equivalent

2-7

BJC-7100

Part 2: Product Specifications

13. Paper Feeding method

ASF and manual feed: Plain paper, high-resolution paper, envelopes,

transparencies, back print film, glossy photo paper,

fabric sheets, high-gloss photo film and T-shirts transfer

Manual feed only: Other papers

14. Sheet feeder capacity

Plain paper: 130 max.

High-resolution paper: 100 max.

Envelopes: 15 max.

Transparencies: 30 max.

Back print film: 10 max.

Glossy photo card: 10 max.

Glossy photo paper: 1

High-gloss photo film: 1

Fabric sheets: 1

T-shirts transfer 1

15. Paper sizes

Cut sheets: Size: A4, B5, A5, Letter, Legal, A4+, Letter+

Weight: 64g/m2to 105g/m2[17 to 28 lbs] (auto sheet

feeder),

64g/m2to 550g/m2[17 to 146 lbs] (manual feed)

Thickness: 0.8mm max. (manual feed)

Envelopes: COM#10 and DL-size

Recommended plain paper: Canon bubble jet paper LC-301

High-resolution paper: High-resolution paper for color BJ HR-101

Glossy photo paper: Glossy photo paper for color BJ GP-301

High-gloss photo film: High-gloss photo film for color BJ HG-201

Glossy photo card: Glossy photo card for color BJ FM-101

Transparencies: Transparencies for color BJ CF-102

Back print film: Back print film for color BJ BF-102

Fabric sheets: Fabric sheets for color BJ FS-101

T-shirts transfer: T-shirts transfer for color BJ TR-201

16. BJ cartridge

Black BJ cartridge BC-60

Nozzles: Two rows of 304 nozzles × 1 color

Ink colors: Black ink and ink optimizer (semi-transparent)

Service life: Approx. 870 pages per cartridge (when printing standard

1500-character pattern)

Photo BJ Cartridge BC-62e Photo

Nozzles: Two rows of 80 nozzles × 3 colors

Ink colors: Yellow, magenta, and cyan

Photo yellow, photo magenta, and photo cyan

Service life (Reference data): Approx. 90 pages per tank (when printing standard

photo pattern)

Head service life: Approx. 2000 pages (when printing standard photo pattern)

Part 2: Product Specifications

BJC-7100

2-8

Color BJ cartridge BC-61

Nozzles: One row of 80 nozzles × 3 colors

Ink colors: Yellow, magenta, and cyan

Service life: Approx. 275 pages per tank (when printing standard color pattern

at 7.5% duty per color)

Head service life: Approx. 2000 pages (when printing standard color pattern at 7.5%

duty per color)

17. Acoustic noise level

Approx. 48dB (based on ISO9296 sound pressure level)

18. Operating environment

During operation: Temperature: 5°C to 35°C

Humidity: 10% to 90% (no condensation)

During storage: Temperature: 0°C to 35°C

Humidity: 5% to 90% (no condensation)

19. Power supply

USA/Canada: 120VAC, 60Hz

UK/Australia: 240VAC, 50Hz

Europe/China: 220VAC, 50Hz

20. Power consumption

During soft-power off mode: Approx. 7W max.

During idle: Approx. 8W max.

During printing: Approx. 45W max.

21. External dimensions

467mm (w) × 313mm (d) × 218mm (h)

(with paper output tray in storage position)

22. Weight

Approx. 6.4kg (with AC adaptor installed)

23. Sensor functions

Paper out detection: Yes

BJ cartridge installation detection: Yes

Waste ink amount detection: Yes

Paper width detection: No

BJ cartridge identification: Yes

Ink-out detection: Yes

2-9

BJC-7100

Part 2: Product Specifications

2.2 Paper Specifications

2.2.1 Paper types

●● : OK ✕: NG

*1: A4+ size paper is a Canon original size paper that, measuring 222.7 × 355.6mm, is

slightly larger than A4 size paper. The A4+size paper allows you to print to the full A4

size. The LTR+ size, measuring 228.6 × 337.8mm, similarly allows you to print to the

full LTR size.

Part 2: Product Specifications

BJC-7100

2-10

Plain paper

Type

Class 1

Class 2

Name

Canon PB (NSK)

Canon PB (NDK)

Canon NP (Kangas)

Canon NP (Neusiedler)

Canon NP (BoiseCascade)

Canon BJ Paper LC-301

Xerox 4024 (75g/m2)

Xerox 4024 (95g/m2)

Plover Bond

Size

A4, B5, A5

A4, B5, A5

A4, B5, A5

A4, B5, A5

LTR, LGL

A4, B5, LTR, LGL

LTR, LGL

LTR, LGL

LTR, LGL

Sheet Feeder

●●

●●

●●

●●

●●

●●

●●

●●

●●

Manual Feed

●●

●●

●●

●●

●●

●●

●●

●●

●●

Special Papers

Type

Coated Paper

High-Resolution Paper

Transparency

BPF

Glossy Photo Paper

High-Gloss Photo Film

Envelopes

Fabric Sheets

Other Paper

T-Shirts transfer

Name

LC-301

HR-101

CF-102

BF-102

GP-301

HG-201

COM#10

DL

FS-101

TR-201

Size

A4, LTR

A4, LTR

A4, LTR

A4, LTR

A4, LTR, A4+*1, LTR+*

1

A4, LTR

241 × 105mm

220 × 110mm

241 × 356mm

A4, A3

Sheet Feeder

●●

●●

●●

●●

●●

●●

●●

●●

●●

✕

●●

Manual Feed

●●

●●

●●

●●

●●

●●

●●

●●

●●

●●

●●

TABLE 2-2 PAPER SPECIFICATIONS

2.2.2 Printing range

2-11

BJC-7100

Part 2: Product Specifications

Figure 2-7 Printing Area

3mm

7.0mm

A4, A5 and B5 Sizes

3.4mm

3.4mm

A4+and Letter (LTR+) Sizes

(1) 12.0mm

(2) 21.0mm

(1) 22.6mm

(2) 21.6mm

29.3mm

Letter (LTR) and Legal (LGL) Sizes

3mm

7.0mm

6.4mm 6.4mm

Fabric Sheets

(1) 12.0mm

(2) 21.0mm

(1) 22.6mm

(2) 21.6mm

25.4mm

5.1mm

A4+ 5.9mm

Letter+ 5.1mm

: Recommended Printing Area

: Printable Area

(1) Monochrome Printing

(2) Color or Photo Printing

28.0mm

3.0mm

7.0mm

6.4mm

Envelopes

6.4mm

43.6mm

31.4mm

(1) 12.0mm

(2) 21.0mm

(1) 22.6mm

(2) 21.6mm

COM#10: 31.4mm

DLsize: 10.4mm

2.3 Interface Specifications

1) Interface type

Bidirectional parallel interface (IEEE1284 compatible)

2) Signal level

Input

TTL level: Input signals other than to data bus

"Low" level: +0.0V to +0.6V "High" level: +2.4V to +5.0V

TTL level: Data bus

"Low" level: +0.0V to +0.8V "High" level: +2.2V to +5.0V

Output

"Low" level: +0.0V to +0.4V

"High" level: +2.4V to +5.25V

3) IO

Each signal is pulled up to +5V.

4) Interface cable

Material: AWG No. 28 or thicker (American Wire Gauge)

Type: Shielded twisted pair cable

Length: 2.0m max.

5) Interface connectors

Printer: Amphenol 36-pin 57-40360 or equivalent

Cable: Amphenol 36-pin 57-30360 or equivalent

6) IO signals and pin configuration

*1: N.C.: No Connection *2: -RET are All Connected to Gnd.

*3: Connected to +5.0V Through 390 Resistance.

*4: Connected to +5.0V Through 3.3k Resistance.

Part 2: Product Specifications

BJC-7100

2-12

TABLE 2-3 IO SIGNALS IN COMPATIBLE MODE

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Signal

Date-Strobe

Data 1

Data 2

Data 3

Data 4

Data 5

Data 6

Data 7

Data 8

Acknlg

Busy

PE

Select

Auto Feed XT

N.C.*

1

Gnd

Gnd

Peripheral Logic High

*

3

I/O

IN

IN

IN

IN

IN

IN

IN

IN

IN

OUT

OUT

OUT

OUT

IN

...

...

...

...

Signal

Data Strobe-RET*

2

Data 1-RET

Data 2-RET

Data 3-RET

Data 4-RET

Data 5-RET

Data 6-RET

Data 7-RET

Data 8-RET

Acknig-RET

Busy-RET

PE-RET

Init

Fault

Gnd

N.C.*

1

Peripheral Logic High

*

4

Select in

I/O

...

...

...

...

...

...

...

...

...

...

...

...

IN

OUT

...

...

...

IN

Pin No.

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

*1: N.C.: No connection

*1: N.C.: No connection

2-13

BJC-7100

Part 2: Product Specifications

TABLE 2-4 IO SIGNALS IN NIBBLE MODE

TABLE 2-5 IO SIGNALS IN ECP MODE

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Signal

HostClk

Data 1

Data 2

Data 3

Data 4

Data 5

Data 6

Data 7

Data 8

PtrClk

PtrBusy

AckDataReq

Xflag

HostBusy

N.C.*

1

Gnd

Gnd

Vcc

Symbol on

Circuit Diagram

[STROBE]

[DATA 1]

[DATA 2]

[DATA 3]

[DATA 4]

[DATA 5]

[DATA 6]

[DATA 7]

[DATA 8]

[ACK]

[BUSY]

[PE]

[SELECT]

[AFXT]

[N.C.]

[GND]

[GND]

[

Peripheral Logic High

]

I/O

IN

IN/OUT

IN/OUT

IN/OUT

IN/OUT

IN/OUT

IN/OUT

IN/OUT

IN/OUT

OUT

OUT

OUT

OUT

IN

...

...

...

...

Pin No.

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Signal

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Init

DataAvail

N.C.*

1

N.C.*

1

N.C.*

1

1284 Active

Symbol on

Circuit Diagram

[GND]

[GND]

[GND]

[GND]

[GND]

[GND]

[GND]

[GND]

[GND]

[GND]

[GND]

[GND]

[INIT]

[FAULT]

[GND]

[N.C.]

[

Peripheral Logic High

]

[SELECT IN]

I/O

...

...

...

...

...

...

...

...

...

...

...

...

IN

OUT

...

...

...

IN

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Signal

HostClk

Data 1

Data 2

Data 3

Data 4

Data 5

Data 6

Data 7

Data 8

PeriphClk

PeriphAck

AckReverse

Xflag

HostAck

N.C.*

1

Gnd

Gnd

Vcc

Symbol on

Circuit Diagram

[STROBE]

[DATA 1]

[DATA 2]

[DATA 3]

[DATA 4]

[DATA 5]

[DATA 6]

[DATA 7]

[DATA 8]

[ACK]

[BUSY]

[PE]

[SELECT]

[AFXT]

[N.C.]

[GND]

[GND]

[

Peripheral Logic High

]

I/O

IN

IN/OUT

IN/OUT

IN/OUT

IN/OUT

IN/OUT

IN/OUT

IN/OUT

IN/OUT

OUT

OUT

OUT

OUT

IN

...

...

...

...

Pin No.

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Signal

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

Signal Gnd

ReverseReq

PeriphReq

N.C.*

1

N.C.*

1

N.C.*

1

1284 Active

Symbol on

Circuit Diagram

[GND]

[GND]

[GND]

[GND]

[GND]

[GND]

[GND]

[GND]

[GND]

[GND]

[GND]

[GND]

[INIT]

[FAULT]

[GND]

[N.C.]

[

Peripheral Logic High

]

[SELECT IN]

I/O

...

...

...

...

...

...

...

...

...

...

...

...

IN

OUT

...

...

...

IN

7) Description of input/output signals

Compatible Mode

Data Strobe [Input]

This signal is used to read DATA1 to DATA8. The signal becomes valid after the

BUSY signal goes Low and the printer outputs an ACKNLG signal. This signal is

normally High. After it goes Low, the printer receives data. When the signal

remains Low, the printer does not operate until it goes High.

Data1 to 8 [Input]

The printer receives data with the DATA STROBE signal.

The state of each bit of the signal must be maintained for at least 0.5µs from the

rising edge of the DATA STROBE signal.

Acknlg [Output]

This signal is a response signal to the DATA STROBE signal.

The host computer does not send the next DATA STROBE signal until this signal is

sent.

When the power is turned on or the BUSY signal goes Low for the input of the INIT

signal, this signal is sent regardless of the DATA STROBE signal.

Busy [Output]

When this signal is High, the printer is BUSY; when Low, the printer is READY.

The printer receives data at least 1 Byte when Data Stobe signal is input in the case

Busy signal goes to "H" regardless of receiving data.

The signal is High in the following cases:

• When receiving data

• When input buffer is full

• When INIT signal is input

• When carriage is in cartridge replacement position

• During manual cleaning

• When an error occurs (paper-out, paper jam, etc.)

• During soft power on/off sequence

• During internal initialization

PE [Output]

This signal goes High when the printer cannot feed paper. The BUSY signal goes

High and the SELECT and FAULT signals go Low.

This signal goes Low when the reset key was pressed and paper is loaded and fed.

The FAULT and SELECT signals then go from Low to High.

If paper is not ejected (paper jam) after an eject operation, this signal and the BUSY

signal go High, and the SELECT and FAULT signals go Low. In this case, the signals

do not change even if the paper is removed manually.

Select [Output]

The printer is READY when this signal is High.

This signal goes Low when an error occurs (paper-out, paper jam, etc.) or when the

carriage is in the cartridge replacement position.

Fault signal goes to low 50ms after Busy signal goes to high.

Auto Feed XT [Input]

This signal is only used for the transition from compatible mode to negotiation mode.

Part 2: Product Specifications

BJC-7100

2-14

Init [Input]

When it changes to Low, this signal sets the printer in the BUSY state, then resets

the printer by changing from Low to High.

The pules width of this signal is requiired longer than 5 micro seconds.

On completion of initialization, the head retreats to the home position and the

default print mode is selected.

Fault [Output]

This signal changes to Low when the printer detects an error and when the carriage

is in the cartridge replacement position to inform the host computer of the error

state.

Select in [Input]

This signal is only used for the transition from compatible mode to negotiation mode.

Nibble Mode

HostClk [Input]

This is the STROBE signal to read DATA 1 to DATA 8. When in negotiation phase

this is the trigger signal to send the protocol confirmation to the printer.

In nibble mode, this signal is always High so that the printer does not fetch data.

Data 1 to 8 [Input]

The data bus is not used in nibble mode.

Ptr Clk [Output]

The printer requests the host computer to read the data by making the Ptr Clk

signal Low in the reverse data transmission phase. After finishing reading, the host

computer notifies the printer of completion of data receiving by making the Host

Busy AUTO FEED XT signal High.

Ptr Busy [Output]

This signal outputs the data to be sent to the host computer in the reverse data

transmission phase. First, bit 3 of the transmission byte data is output, followed by

bit 7.

Ack Data Req [Output]

This signal outputs the data to be sent to the host computer in the reverse data

transmission phase. First, bit 2 of the transmission byte data is output, followed by

bit 6.

This signal is used as the trigger signal to inform the host computer of the printer’s

condition in the negotiation phase.

Xflag [Output]

This signal outputs the data to be sent to the host computer in the reverse data

transmission phase. First, bit 1 of the transmission data is output, followed by bit

5.

This signal informs the host computer whether the printer supports nibble mode in

the negotiation phase.

The printer supports nibble mode when this signal level changes to Low at the same

time the Ack Data Req (PE) signal rises.

2-15

BJC-7100

Part 2: Product Specifications

Host Busy [Input]

Indicates that the host is ready to receive the data from the printer by making the

Host Busy signal Low in the reverse data transmission phase. After that, it goes

High when data is received from the printer to verify receiving data.

This signal changes to High in response to the PtrClk (ACKING) signal changing to

Low to change to the reverse data transmission phase.

Init

This signal is not used in nibble mode.

DataAvail [Output]

This signal outputs the data to be sent to the host computer in the reverse data

transmission phase. First, bit 0 of the transmission data is output, followed by bit

4.

Informs the host computer if there is reverse transmission data or not in the

negotiation phase. If data is ready to be sent to the host computer, this signal

changes to Low.

1284 Active (Input)

This signal confirms that the printer is an IEEE 1284-compatible device. This signal

goes High at the start of the negotiation phase and remains High in nibble mode to

indicate that the printer is operating in bidirectional mode. It changes to Low in the

termination phase.

ECP mode

HostClk [Input]

This is the signal used in handshaking with PeriphAck (BUSY) signal when data is

sent from the host computer to the printer.

This signal changes to Low when data has been output to the data bus (Data1 to 8)

This signal changes to High in response to the PeriphAck (BUSY) signal rising. It

remains High in the reverse data transmission phase.

Data 1 to 8 [Input/Output]

These are input data signals when data is sent from the host computer to the

printer.

In the reverse data transmission phase, these are output signals, and the printer

outputs data to the host computer using this data bus.

Periph Clk [Output]

This signal is always High when data is sent from the host computer to the printer.

In the reverse data transmission phase, this signal changes to Low to indicate that

data is output to the host computer. This signal changes to High in response to the

HostAck (AUTO FEED XT) signal changing to High.

Periph Ack [Output]

When data is sent from the host computer to the printer, this signal changes to Low

when the printer is ready to receive data.

When the data has been received from the host computer, this signal changes to

High.

In the reverse data transmission phase, this signal indicates if the information

output from the printer to the data bus is command information or data (Low:

Command information; High: data).

Part 2: Product Specifications

BJC-7100

2-16

Ack Reverse [Output]

This signal remains High when data is sent from the host computer to the printer. It

remains Low in the reverse data transmission phase.

When switching from the forward to reverse data transmission phase, this signal

changes to Low, to indicate that a request to switch modes has been received, in

response to the fall of the Reverse Request (INIT) signal, which is sent by the host

computer to request the switch.

This signal changes to High, to indicate that the request to switch modes has been

received, when the Reverse Request (INIT) signal rises.

Xflag [Output]

This signal is always High in ECP mode.

Host Ack [Input]

When data is sent from the host computer to the printer, this signal indicates

whether the signal information on the data bus is data or command information

(Low: Command information; High: data).

In reverse data transmission, this signal is used for handshaking with the Periph

Clk (ACKNLG) signal.

When the host is ready to receive data from the printer, this signal changes to Low,

then changes to High when the data has been received.

Reverse Req [Input]

This signal changes to Low during the recovery phase (resending data) when data is

sent from the host computer to the printer.

This signal changes to High in response to the lowered Ack Reverse (PE) signal.

This signal changes to Low on transition from the idle state in the forward data

transmission phase to the reverse data transmission phase (when data is sent from

the printer to the host computer).

When Low, this signal indicates reverse data transmission.

The signal changes to High on transition from reverse data transmission to forward

data transmission.

Periph Req [Output]

This signal changes to Low when, during forward data transmission, the printer

requests reverse data transmission.

When the host computer changes from forward data transmission to reverse data

transmission, this signal changes to High at the same time as the Ack Reverse (PE)

signal in response to the fall in the Reverse Request (INIT) signal, which requests the

switch in modes by the host computer.

1284 Active (Input)

This signal goes High at the start of the negotiation phase and remains High in ECP

mode to indicate that the printer is operating in bidirectional mode. It changes to

Low in the termination phase on exiting ECP mode.

2-17

BJC-7100

Part 2: Product Specifications

Part 2: Product Specifications

BJC-7100

2-18

Figure 2-8 Compatible Mode

Figure 2-9 Nibble Mode

Figure 2-10 ECP Mode

Data 1-8

STROBE

BUSY

ACKNLG

1284 Active

0.5µs

0.5µs

0.5µs

Min.

Min.

Min.

4µs (When HS mode is invalid)

Min.0.8µs

Ack Data Req

Data (1 to 8)

Host Busy

Host Clk

Ptr Clk

Ptr Busy

nData Avail

Xflag

1284 Active

nAck Reverse

Data (1 to 8)

Host Ack

Host Clk

0000 0000

Printer Busy

Ptr Host

With data

Nibble mode

Support

Invalid

0001 0000

Bit2 Bit6

Bit3 Bit7

Bit0 Bit4

Bit1 Bit5

TP TP TP

Byte0

nCmd nCmd

Byte1

TP: minimum set up

Periph Clk

Periph Ack

nPeriph Req

Xflag

ECP mode Support

TP

TP

TP

TP

TP: minimum set up

Part 3

OPERATING

INSTRUCTIONS

Page

3 - 1 1. PRINTER SETUP

3 - 1 1.1 Unpacking

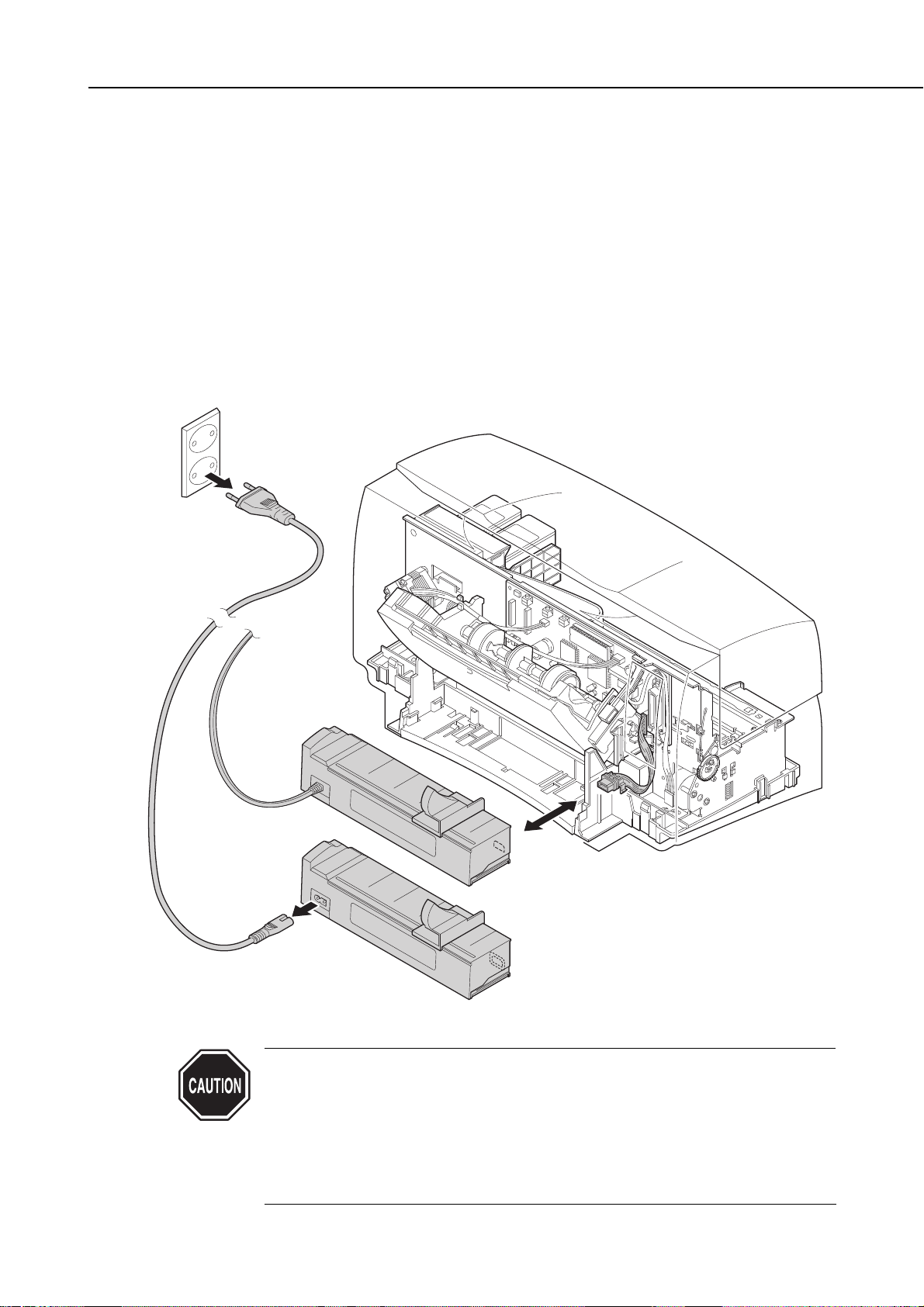

3 - 2 1.2 Installation Location