CANONET G-III 17

Similar models: Canonet QL 17/19

Battery: 1 ea. PX13

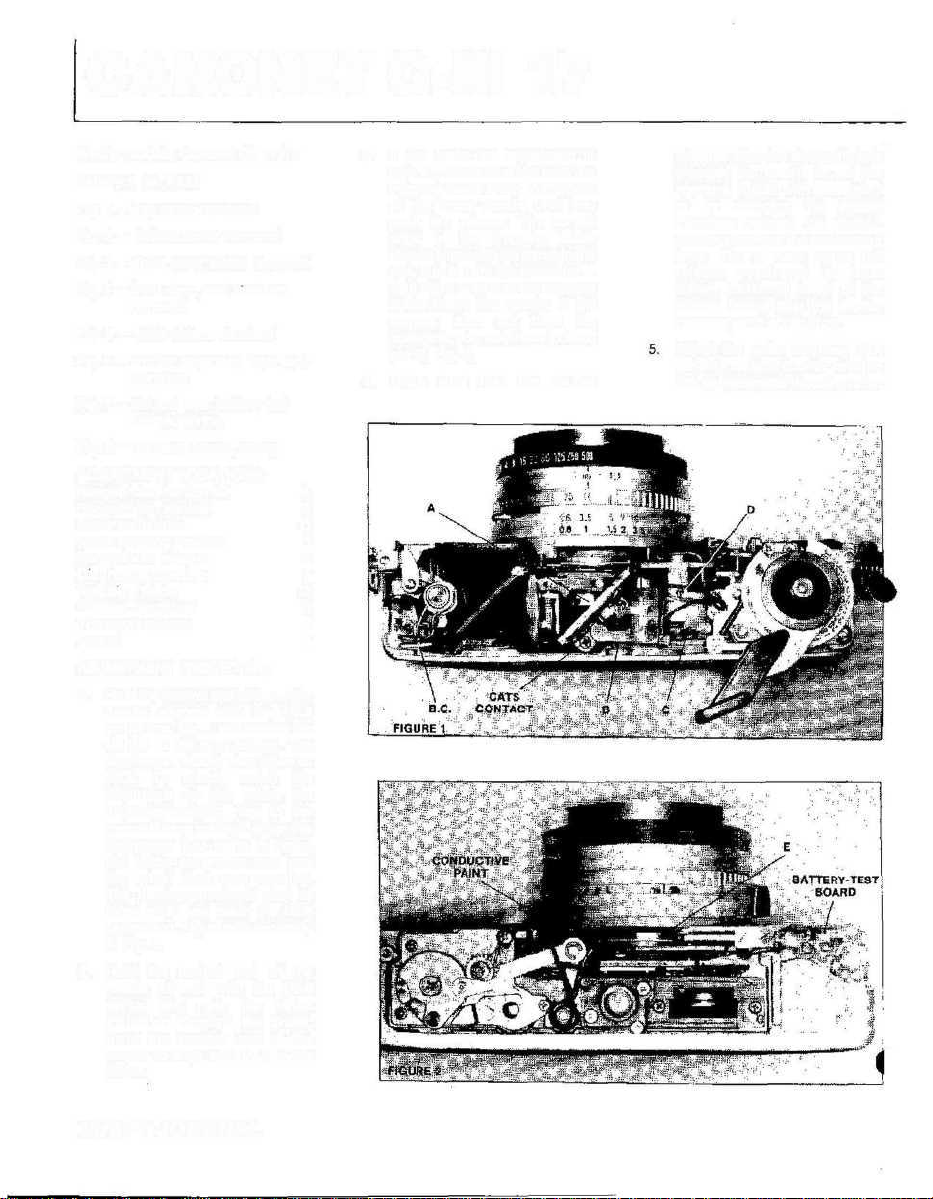

Fig. 1 — top cover removed

Fig, 2 — bottom cover removed

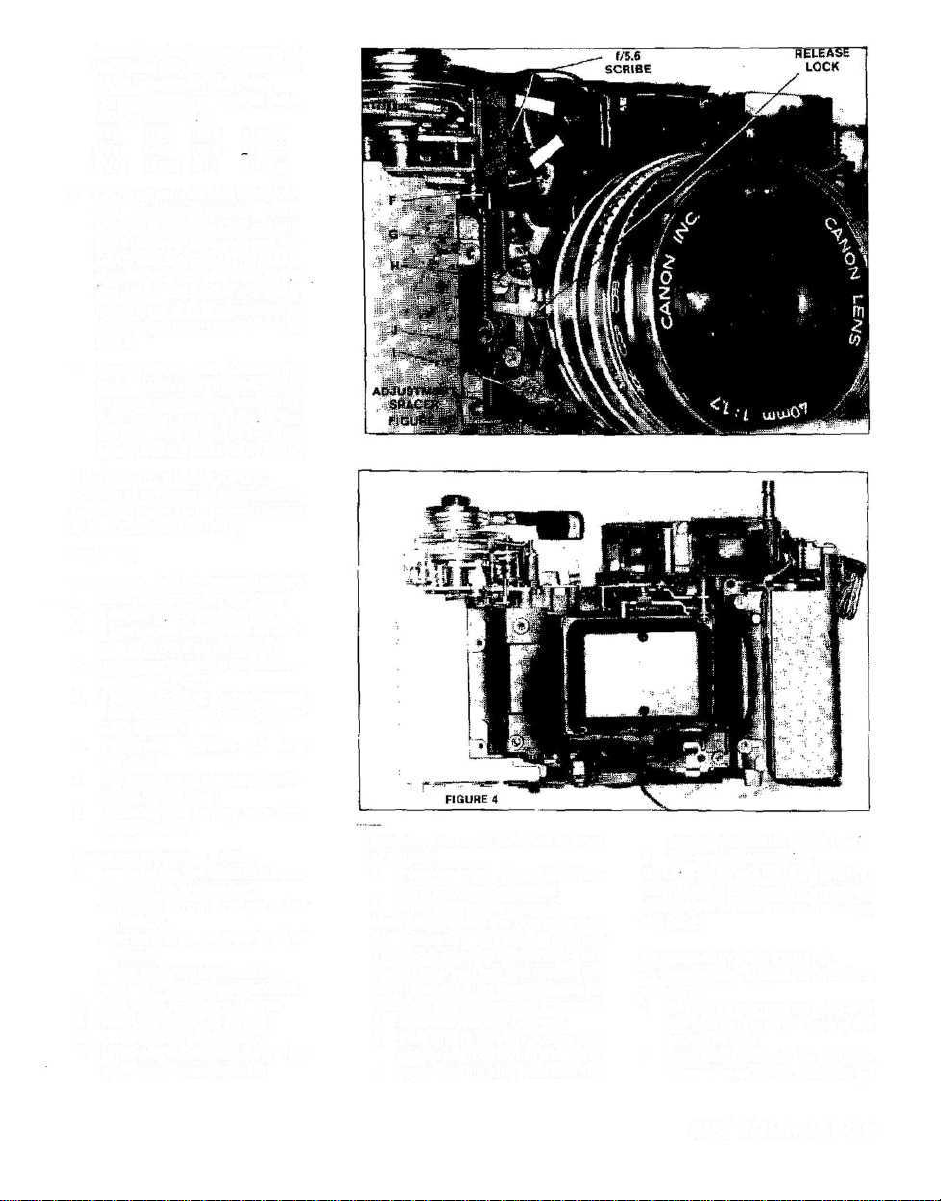

Fig. 3 — front cover plates removed

Fig. 4 — front view, lens standard

removed

Fig. 5 — back of lens standard

Fig. 6 — shutter separated from lens

standard

Fig. 7 — old and new battery-test

boards, wiring

Fig. 8 — terminal board, wiring

ADJUSTMENT LOCATIONS:

Rangefinder, horizontal A

Rangefinder, vertical B

Meter calibration C

Meter housing position D

Rangefinder resistor E

Diaphragm opening F

Trapping blade Q

Release over travel H

Transport release I

Focus J

ADJUSTMENT PROCEDURE:

1. Hold the control end of the meter

needle aligned with the f/5.6

scribe line, Fig. 3. and release the

shutter at the auto setting. The

diaphragm should stop down to

f/5.6. To check, watch the

diaphragm as you rotate the

diaphragm-setting ring to the

manual f/stop settings. When the

diaphragm just starts to open,

the f/stop calibration tells you

the actual diaphragm opening.

The diaphragm should start to

move when you reach the f/5.6

calibration. Adjust with eccentric

F, Fig. 3.

2. Hold the control end of the

needle aligned with the f/5.6

scribe and note the f/stop

indication through the finder.

Bend the readout end of the

needle to align with f/5.6 in the

finder.

3. If you make the adjustment in

step #1, check to make sure the

trapping blade is not in the path

of the meter needle until you

push the release. The curved

edge of the trapping blade

should align with the curve in the

slot, Fig. 3. Turn the eccentric —

G in Fig. 3 —so that the trapping

blade clears the needle. If the

camera does not have the

eccentric, you may have to bend

pin G, Fig. 4.

4. Make sure that the shutter

releases after the stepped blade

engages the needle to set the

aperture. Adjust with eccentric I

or by changing the spacer

thickness between the shutterrelease plate and the connecting

lever, Fig. 3. Also adjust the

release over travel (at least

0,4mm additional travel of the

release button after the shutter

releases) with eccentric I.

Adjust the meter accuracy with

variable resistor C or by rotating

the galvanometer housing after

18/SPT JOURNAL

loosening the locking screw. If

you rotate the housing, check the

CATS adjustment (step #6).

Proper needle readings at ASA

100. K-factor 17 5:

EV8 1/30 f/2.8 ±1 stop

EV11 1/60 f/5.6 +1 stop

EV14 1/125 f/11 +-1 Stop

6. CATS adjustment. Set auto, ASA

100, and the 2-meter focus

position. Cover the CdS ceil and

short between ground and the

CATS contact, Fig. 1. The needle

should indicate between f/5 6

and f/8. If not, rotate the meter

housing or shift the position of

the rangefinder-resistor band,

Fig. 2.

7. Focus adjustment. Loosen the

three setscrews on the outer

circumference of the focus ring.

Also loosen screw J, Fig 3. Set

the focus ring to infinity and slide

screw J for the best infinity focus.

DISASSEMBLY HIGHLIGHTS:

Position of left-hand threads: shutterretaining ring in G-lll (normal thread

in Now Canonet QL 17/19)

Sequence:

1. top and bottom cavers (battery

cover and cover spring loose)

2. 2 sections, front leatherette

3. 2 front-cover plates, one on each

side of lens (2 screws each)

4. unsolder red wire from batterytest board, Fig. 7

5. 2 screws holding shutter-release

plate to connecting lever (adjust-

ment spacer loose)

6. 4 screws, corners of lens

standard

7. lift aside lens standard (view-

finder mask loose)

8. unsolder blue battery wire from

terminal board

Sequence to remove shutter:

1. unsolder the five wires that come

through the shutter port:

—yellow from rangefinder

resistor

—white and purple from terminal

board

—red from variable resistor

—black from hot-shoe contact

2. free wires from wire clamps

3. rear light shield (2 screws)

4. unscrew rear lens group

5. unscrew shutter-retaining ring

(left-hand thread in G-lll)

Sequence to reach switches at front

of shutter:

1. front-retaining ring, identification ring, photocell mask

2. unscrew front lens group

Note: Unscrewing the complete lens

cell requires a special spanner

T0630-13-9246-1T. Without the

special tool, you can first remove the

front element. It's then possible to

reach the spanner notches in the cell.

3. 2 screws holding CdS cell

4. filter ring (3screws) — pass CdS

cell through cutout in filter ring

5. speed-setting ring (tab on ring

passes into slot in speed cam)

6. film-speed setting ring

Note. To reach the shutter

mechanism, disassemble from the

back of the shutter rather than from

the front.

REASSEMBLY HIGHLIGHTS:

To mount the shutter to the lens

standard:

1. Seat the intermediate ring and

the charge ring on the back of the

shutter, Fig. 6.

2. Push the end of the shutterrelease lever as far as it will go

SPT JOURNAL/19

toward the lens opening.

3. Seat the lens standard over the

shutter, making sure that the tab

on the charge ring passes

through the slot in the shuttercharge lever and that the

aperture-connecting pin passes

above the aperture-connecting

lever.

METER TESTS:

1. Check the CdS cell between the

yellow wire connected to the

rangefinder resistor and ground.

2. Check the galvanometer between the red wire at the variable

resistor and the blue wire at the

terminal board. Approximate coil

resistance: 1.6K.

3. At the auto setting, the needle

deflection should change as you

change the film-speed setting,

shutter-speed setting, and light

level. No deflection — check the

CdS cell, the galvanometer, the

battery connections, and the

brush contacts at the front of the

shutter.

4. At the guide-number settings,

the needle deflection should

change as you change the focus

setting and the light level. No

change at the different focus

settings — check the rangefinder

resistor and the switch at the

front of the shutter. Check the

switch between the white lead

from the rangefinder resistor and

ground: you should measure

direct continuity at the guidenumber settings and no

continuity at auto.

5. The meter should turn off at the

manual f/stop setting (switch at

front of shutter).

6. At auto, the lock on the release

plate, Fig. 3, should prevent the

shutter from releasing if the

needle is in one of the red areas

at either end of the viewfinder

scale (underexposure or overexposure). The shutter should

always release at the manual

I/stop settings.

BATTERY-CHECKER TESTS:

1. The battery-test lamp should

turn on when you short B.C., Fig.

2, to ground.

2. The battery-test lamp should

turn on with 1V connected

directly between its leads.

3. If the battery-test lamp does not

turn on with a good battery,

check the voltage at the

transistor base, Fig. 7. If you

measure the proper base bias

(D.8V), the transistor is the

problem. If you do not measure

the base bias, there's an open in

the bias path (one of the resistors

on the underside of the batterytest board or the thermistor).

OTHER COMMENTS;

1. You can reach the rangefincder

adjustments without removing

the top cover. Slide off the

accessory-shoe cover to reach

the horizontal adjustment:

unscrew the cover screw at the

back of the top cover to reach the

vertical adjustments.

The rangefinder resistor comes

in two parts —• the carbon

resistor and a contact strip, Fig.

2. If you replace either part, apply

conductive paint such as Silver

Print between the contact strip

and the resistance bend as

shown in Fig. 2.

20/SPT JOURNAL

BLACK (LAMP)

BLACK (LAMP)

PINK (SWITCH)

B

TR

RED (-BATTERY)

BLACK (LAMP)

BLACK (LAMP)

B

TR

RED (-BATTERY)

FIGURE 7

OLD

PINK (SWITCH)

NEW

FIGURE 8

SPT JOURNAL/21

Loading...

Loading...