Page 1

MultiPASS C5000

SERVICE

MANUAL

Canon

Page 2

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation,

maintenance, and repair of products. This manual covers all localities where the products we sold. For this

reason, there may be information in this manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in

products. When changes occur in applicable products or in the content of this manual, Canon will release

technical information as the need arises. In the event of major

long or short period, Canon will issue a new editions of this manual.

changes

in the contents of this manual

over a

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product

individual companies.

names

and company names described in this manual are the registered trademarks of the

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be

copied, reproduced or translated into another language, in whole or in part, without the written consent of

Canon Inc..

Copyright 0 1997 by Canon Inc.

CANON INC.

Office Imaging Products Technical Support Dept. 2

5-1

Hakusan

DTP System

This

mnnunl

SUPER LASER SHOT

All graphics

All

documrwts

7-Chome,

was

were

and all page layouts

Toridecity, lbaraki 302, Japan

produced

produced with Macromedia FreeHand’.

on an Apple Macintosh” personal computer, final pages wer” printed on Canon

R406

PS.

were

created with

&arkXPress”.

Page 3

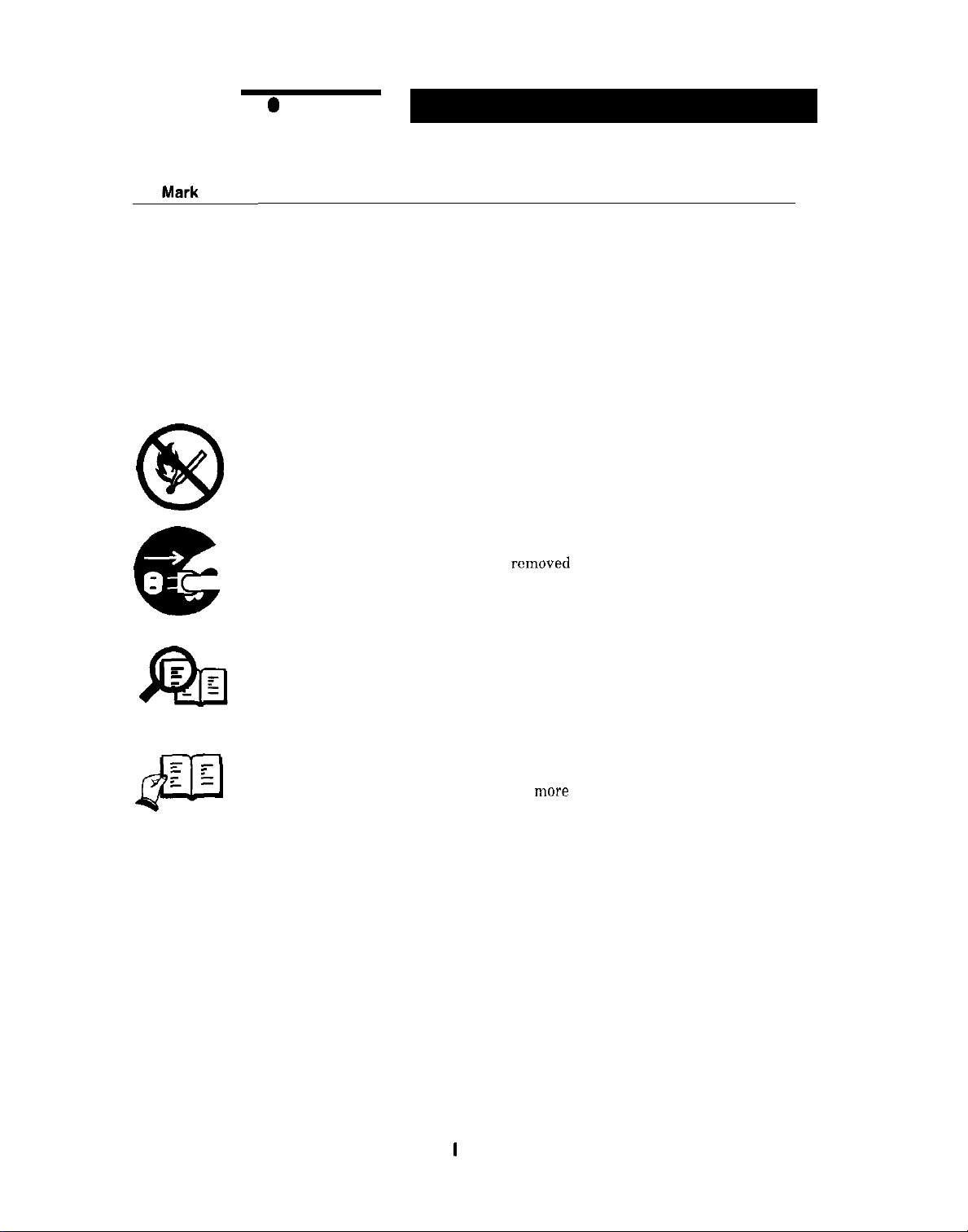

The marks used in this manual have the following meanings

Meaning

States a precaution to be taken to prevent danger to personnel, damage to

the product, or damage to electronic components by discharge of static

electricity. for example.

A

States a precaution to be taken to prevent damage to electronic components

by electrostatic discharge.

A

Informs you of fire-related cautions.

63

e

NOTE

REFERENCE

Informs you that the plug must be

starting an operation.

Gives useful information to understand descriptions.

Indicates sections to be read to obtain

removed

mere

from the power outlet before

detailed information.

I

Page 4

This manual is divided into

five

parts, and contains information required for servicing the

product.

Part

1: Facsimile

This section describes the facsimile function of the respective product.

Part 2: Printer

This section describes the printer function of the respective product.

Each of the above parts is further divided into the following four chapters:

Chapter 1: General Description

This part explains product specifications and the how to service the unit safely. It is very

important, so please read it.

Chapter 2: Technical Reference

This part explains the technical theory of the product

Chapter 3: Maintenance and Service

This part explains how to maintain the products for adjustment and troubleshooting and

service operations and service switches.

Chapter 4: Appendix

This part

explains

the informations of the optional products and user data flow.

z :

: -

0

REFERENCE

l

:

For more details of

of USER’S

l

Procedure for assembly/disassembly and greasing points are not given in this

GUIDE.

manual. See the illustrations in the separate volume of

l

Detailed description of each

except the new

See G3

Facsimile Service Data Handbook (supplied separately)

user

operations and

SSSW/parameter

SSSWslparameters

user

reports, see the separate volume

is not given in this manual

added to this model.

PARTS CATALOG.

for details

them.

l

See the G3 Facsimile Error

the error codes not shown in this

l

Detailed description of connector Locations and Signal Descriptions in not

Code

L~sf

(Rev. 1, supplied separate/y)

mnnual.

for details of

given in this manual.

See the Circuit

Diagram

for details

them.

II

Page 5

REVISION

I

CONTENT

0

I

Original

Page 6

fart 1: Facsimile

Page

1- 1

1- 1

l-2

l-2

1-2

l-3

l-5

l-7

l-6

1 -11

1 -11

1 -14

1

-16

1 -18

1 -20

1 -22

1 -23

1 -23

1

-25

1 -25

1 -26

1 -26

1 -26

1 -27

1 -27

1 -32

1 -40

1 -42

1 -42

1

-42

1 -43

1 -45

1 -45

1 -46

1 -47

1

-46

1 -49

1 -50

1 -52

Chapter 1: General Description

FEATURES

1.

1 .I Overview

SPECIFICATIONS

2.

General Specification

2.1

Communication Specification

2.2

Scanner Specification

2.3

2.4

Copy Specification

2.5

2.6 Function

OVERVIEW

3

3.1 External View

3.2 Operation Panel

3.3 Consumables

4

DIMENSIONS

SAFETY & PRECAUTIONS

5

5.1

5.2

5.3

5.4 Data-related precautions

Printer Specification

3.3.1

BJ cartridge and ink cartridge and BJ cartridge container

3.3.2 Print media

Personnel Hazards

5.1 .I Electrical shock

5.1.2 High-temperature parts

5.1.3 Fire hazards

5.1.4 Moving pads

5.1.5 Preventing ink stains

General Cautions

5.2.1 Unit cautions

5.2.2 BJ cartridge cautions

5.2.3 Ink cartridge cautions

Servicing Cautions

5.3.1 Damage from static charge

5.3.2 Scanner unit

5.3.3 Print assembly

5.3.4 Paper feed section

5.3.5 Control boards

5.3.6 Opening the upper Cover

5.4.1

Data in the image storage memory (DRAM)

5.4.2 Data in the control processing memory (SRAM)

5.4.3 Data in the EEPROM

5.4 4 SCNT board replacement precautions

IV

Page 7

1 -53

1

-54

1

-54

1 -54

1 -55

1 -55

1

-56

1 -56

1 -57

6. QUALIFICATION REQUIRED FOR INSTALLATION WORK

5.4.5 Data initialization through service operation

Protective Mechanism

5.5

55.1 Data battery backup function

5.5.2 BJ cartridge maintenance features

5.53 Heat protection mechanism

5.5.4 Overcurrent protection

5.5.5 Lightning protection

5.56 Power leakage protection

Chapter 2: Technical Reference

COMPONENT LAYOUT

2-

1

2-

3

2-

6

2 -11

2 -18

2 -18

2 -21

2 -23

2 -25

2 -25

2 -26

2 -29

2 -32

2 -32

2 -32

2 -32

2 -33

2 -33

. .

2 -33

2 -34

2 -34

2 -34

2 -35

1.

SCANNER MECHANISM

2.

PAPER SUPPLY MECHANISM

3.

4.

PRINTER SECTION

5.

BJ CARTRIDGE

5.1 Structure

5.2 BJ Head Driver Block Diagram

5.3 Printing Signal

ELECTRIC CIRCUIT

6.

6.1 Component Block Diagram

6.2 Circuit Board Components

6.3 Flow of Image Signals

COMMUNICATION SYSTEM OPERATIONS

7.1 FAX/TEL Switching

7.1 .l Settings

7.1.2 Parameters

7.2 Answering Machine Connection

7.2.1

Settings

7.2.2 Parameters

NEW FUNCTION

8.1 Color Scanning Ability

8.1 .I Contact sensor specifications

8.1.2

Reading color documents

3-

1

3- 1

3- 1

3-

2

3-

2

3-

2

3-

3

Chapter 3: Maintenance & Service

1.

MAINTENANCE LIST

1.1

Consumables

Cleaning

1.2

Periodic Inspection

1.3

1.4

Periodic

1.5

Adjustment Items

1.6

General Tools

Replacement Parts

V

Page 8

3-

3

3-

4

3-

4

3-

4

3-

4

3-

4

3-

4

3-

4

3-

4

3-

6

3-

6

3-

7

3 -10

3 -14

3 -14

3 -15

3 -15

3 -19

3 -26

3 -26

3 -27

3 -29

3 -31

3 -31

3 -31

3 -31

3 -32

3 -33

3 -40

3 -41

3 -43

3 -43

3 -43

3 -44

3 -44

3 -45

3 -46

3 -46

3 -47

3 -49

3 -52

3 -57

3 -57

1.7 Special Tools

2. HOW TO CLEAN PARTS

2.1 Main Unit Outer Covers

2.2 Separation Roller

2.3 Document Feed/Eject Roller

2.4 Separation Guide

2.5 Scanning Glass (Contact Sensor)

2.6 White Sheet

2.7 Printer Platen

3.

ADJUSTMENT

3.1 CS LED Lights-on Duration Adjustment

3.2 Vertical Alignment Correction

3.3 Head Gap Adjustment

4.

TROUBLESHOOTING

4.1 Troubleshooting Index

4.2 Errors Shown on the Display

4.2.1 User error message

4.2.2 Error codes

4.3 Errors not Shown on the Display

4.3.1 General errors

4.3.2 Printing problem

4.3.3 Scanning problem

5.

SERVICE SWITCHES

5.1 Hardware Switches

5.2 Service Data Sening

5.2.1 Service data overview

5.22 Service data registration/setting method

5.2.3 Service data setting

5.2.4 Explanation of service data

5.2.5 New SSSWslparameters added to this model

6.

TEST FUNCTIONS

6.1

User Test Print Functions

6.1 .l Nozzle check

6.2 Service Test Functions

6.2.1 Test mode overview

6.2.2 Test mode flowchart

6.2.3 D-RAM tests

6.2.4 CS tests

6.2.5 PRINT test

6.2.6 Modem and NCU tests

6.2.7 Faculty tests

7.

SERVICE REPORT

7.1 Report Output Function

VI

Page 9

3 -57

3 -59

3 -67

3 -67

3

-66

4-

1

4-

1

4- 1

4-

2

4-

2

4-

3

4- 6

4 -10

7.1 .I

User report output functions

7.1.2 Service report output functions

6.

WIRING DIAGRAM

6.1 Wiring Diagram

8.2 Connector Name and Signal Descriptions

Chapter 4: Appendix

1.

INSTALLATION

1

.I Setting Up

1.2 Checking Operations

2. USER DATA FLOW

2.1

USER DATA FLOW (by Operation Panel)

2.2 USER DATA FLOW (by

2.3 SPECIAL MODE FLOW (by Operation Panel)

3. MAKER CODE

MultiPASS

Desktop Manager)

INDEX

VII

Page 10

Part 2: Printer

Chapter 1: General Description

I-

1

l-2

l-2

1- 5

1 -10

1 -10

1 -11

1 -12

1 -12

1 -12

1 -12

1 -12

1 -12

1 -13

1.

FEATURES

2.

SPECIFICATIONS

2.1 Basic Specifications

2.2 Interface Specifications

3.

OVERVIEW

3.1 Interface Connector

3.2 Printer Operation Panel

4. SAFETY & PRECAUTIONS

4.1 Personnel Hazards

4.2 General Cautions

5.

RESTRICTIONS

Chapter 2: Technical Reference

1,

2-

1

2-

1

2-

2

2-

3

2-

4

2-

5

2-

5

2-

7

2-

7

2-

7

2-

a

2-

a

2-

a

2-10

2 -10

2 -11

2 -11

2 -12

THEORY OF OPERATIONS

2.1 Outline

2.2 Mechanical Overview

2.3 Data Flow

2.4 Printing

2.5 Circuit Overview

2.6 720 dpi Printing/Smoothing

2.7 Printing Modes

2.6 Optimum Printing Direction Control

2.9 Ink Smear Control

2.10 Bi-Centronics Interface

4.2.1 Connecting the interface cable

4.2.2 Data lost when power cord is pulled out

4.2.3 Data reset

2.51

Printer circuit

Feature

2.6.1 Canon extension mode

2.6.2 Emulation mode

2.7.1 Printing mode

2.7.2 Photoprint mode

2.10.1 Functions

2.10.2Structure

Chapter 3: Maintenance & Service

1.

3-

1

3-

1

3-

1

3-

2

3-

2

MAINTENANCE LIST

2. HOW TO CLEAN PARTS

3.

ADJUSTMENT

4.

TROUBLESHOOTING

4.1

Errors Shown on the Display

VIII

Page 11

3-

2

3-

2

3-

3

3-

5

3-

5

3-

5

3-

5

3-

5

3-

6

3-

7

3-

7

3-

7

3-

4- 1

4-

4-

7

2

3

4.1 .I User error message

4.1.2

Error codes

4.2 Errors not Shown on the Display

5. SERVICE OPERATION FUNCTION

5.1 Report Output Function

5.2 Service Data

5.3 Test Functions

5.3.1 User test functions

5.3.2 Hexadecimal dump list

6. WIRING DIAGRAM

6.1 Wiring Diagram

6.2 Connector Location and Signal Description

6.2.1 SCNT board

Chapter 4: Appendix

1,

INSTALLATION

1.1

Choosing a Location for the Printer

1.2

Connecting the Printer to the Computer

IX

Page 12

.,,.

Part 1: Facsimile

Page

1-4

1- 6

1 -11

1 -12

1 -14

1 -15

1 -16

1 -17

1 -16

1 -19

1 -20

1 -21

1

-22

1 -23

1

-24

1 -38

1 -39

1 -40

1 -41

1

-43

1 -46

1

-47

1 -51

1

-53

Chapter I: General Description

Figure 1- 1

Figure l- 2

Figure l- 3

Figure l- 4

Figure l- 5

Figure l- 6

Figure l- 7

Figure I- 6

Figure I- 9

Figure

Figure

Figure l-12

Figure l-13

Figure I- 14

Figure l-15

Figure l-16

Figure

Figure

Figure l-19

Figure l-20

Figure

Figure l-22

Figure l-23

Figure 1-24

Scanning Range

Printing Range

External View

External View (2)

Operation Panel

Operation Panel (2)

Operation Panel (3)

Operation Panel (4)

Consumables

Consumables (2)

l-10

Print Media (1)

l-11

Print Media (2)

Dimensions

Personnel Hazards

Personnel Hazards (2)

Unpacking the BJ Cartridge

Ink Path Cartridge

l-17

Removing Cartridge Cap

l-16

Ink Outlet

Print Assembly Precautions

Opening the Upper Cover

l-21

Memory IC and Backed up Devices

Waste Ink Absorber

All Clear

(1)

(1)

(1)

(1)

2-

1

2-

2

2-

3

2-

6

2-

6

2-

9

2 -11

2-13

2 -13

2 -16

2 -19

2 -19

2 -20

Chapter 2:

Figure 2Figure 2- 2

Figure 2- 3

Figure 2- 4

Figure 2- 5

Figure 2- 6

Figure 2- 7

Figure 2Figure 2- 9

Figure 2Figure 2- 11

Figure 2- 12

Figure 2- 13

10

Technical Reference

Mechanical Layout

1

Electrical System Layout

Document Feed Section

Paper Feed Section

Paper Feed Motor Drive Switching

Paper Separation Mechanism

Printer Section

Purge Unit

6

Pump Operation State Detection

Ink Empty Detection

Nozzle Arrangement

Black BJ Cartridge Structure

Color BJ Cartridge Structure

X

Page 13

2 -20

2 -22

2 -22

2 -23

2 -24

2 -25

2 -29

2 -30

2 -31

2 -35

3-

5

3-

6

3-

7

3-

7

3-

6

3- 0

3-

9

3 -10

3 -11

3 -12

3 -13

3 -19

3 -27

3 -26

3 -32

3 -33

3 -34

3 -35

3 -37

3 -38

3 -39

3 -40

3 -40

3 -43

3 -45

3 -46

3 -47

3 -46

3 -51

3 -53

3 -55

Figure 2- 14 Photo BJ Cartridge Structure

Figure 2- 15 BJ Head Driver Block Diagram (Black BJ Cartridge)

Figure 2- 16 BJ Head Driver Block Diagram (Color BJ Cartridge)

Figure

Figure 2- 16 Printing Signals (HQ Mode)

Figure 2- 19 Block Diagram

Figure

Figure 2-21 G3 Reception Image Signal Flow

Figure 2-22 Color Copy Image Signal Flow

Figure 2-23 Contact Sensor

Z-17

Printing Sequence (Black BJ Cartridge/HQ Mode)

Z-20

G3 Transmission Image Signal Flow

Chapter 3: Maintenance & Service

Figure 3-

Figure 3- 2 CS LED Lights-on Duration Adjustment Operation

Figure 3-

Figure

Figure 3-

Figure 3- 6 Sample Test Pattern with Vertical Misalignment

Figure 3- 7 Vertical Line Misalignment Correction Procedure

Figure 3-6Headgap

Figure 3-9Adjustment Preparation

Figure3-10

Figure3-11

Figure3-12

Figure 3-13 Paper Feed Motor/Carriage Motor/Document Feed Motor Connector

Figure3-14

Figure3-15

Figure 3-16 Service Data (page 1)

Figure3-17

Figure

Figure3-19

Figure 3-20 Service Data (page 5)

Figure 3-21 Service Data (page 6)

Figure 3-22 Bit Switch Display

Figure 3-23 How to Read Bit Switch Tables

Figure 3-24 Nozzle Check Pattern

Figure 3-25 Test Mode

Figure 3-26 D-RAM Test

Figure 3-27 Print Test Pattern Check

Figure 3-26 Print Pattern Sample

Figure 3-29 CNG and DTMF Signal Reception Tests

Figure 3-30 Sensor Tests

Figure 3-31 Operation Panel

1

Cleaning Location

3

Printing the Test Pattern

3-4Test Pattern Sample

5

Correct Test Pattern

Head Gap Adjustment

Head Gap Adjustment (2)

Service Error Code Display

Defective Pattern (Sample)

Service Data Setting Method

Service Data (page 2)

3- 16

Service Data (page 3)

Service Data (page 4)

(1)

XI

Page 14

3 -58

3 -60

3 -61

3 -62

3 -64

3 -65

3 -66

3 -67

4-

2

4-

3

4-

4

4-

5

4-

6

4-

7

4-

8

4 -10

Figure 3-32 Memory Clear List

Figure 3-33 System Data List (page 1 - page 4)

Figure 3-34 System Data List (page 5 - page 6)

Figure 3-35 System Dump List (112)

Figure 3-36 System Dump List

Figure 3-37 Service Error TX Report

Figure 3-38 Service Error Activity Report (receiving)

Figure 3-39 Wiring Diagram

(2/2)

Chapter4:Appendix

Figure 4-1

Figure 4-2

Figure 4-3

Figure 4-4

Figure 4-5

Figure

Figure 4-7

Figure 4-8

User Menu Settings (116)

User Menu Settings

User Menu Settings

User Menu Settings

User Menu Settings

4- 6

User Menu Settings

Special Mode Settings

Maker Code

(2/6)

(316)

(4/6)

(5/6)

(616)

XII

Page 15

Part 2:

Page

l-4

l-6

I-

9

1 -10

2- 1

2-

3

2-

4

2-

5

2-

7

2 -13

3-

6

3-

7

4-

2

4-

3

Printer

Chapter 1: General Description

Figure I- 1 Printing Range

Figure l- 2 Signal Circuits

Figure I- 3 Interface Timing

Figure l- 4 Interface Connector

Chapter 2: Technical Reference

Figure

Figure

Figure

Figure

Figure 2-5720 dpi Printing/Smoothing Feature

Figure 2- 6 Nibble Mode Facsimile to Host Data Transfer

2-1Printer Outline

2-2Data Flow (image)

2-3Character Printing

2-4Printer Circuit Block Diagram

Chapter 3: Maintenance & Service

Figure3-1

Figure3-2

Hexadecimal Dump Print (Sample)

SCNT Board

Chapter 4: Appendix

Figure 4- 1 Location for the Printer

Figure 4- 2 Connecting the Interface Cable

XIII

Page 16

Chapter 1: General Description

1 .l Overview

This product is a G3 transreceiving facsimile based on the ITU-T recommendation. It can

be used in telephone networks.

*: This mark indicates new function.

Excellent print quality

The high-performance print head offers 360 x 360 dot per inch (dpi) resolution for text and

graphics.

Automatic switching between fax and voice calls

Fax/telephone switching allows you to receive fax messages and normal phone calls on a

single line.

BJ

cartridge

The BC-20 and BC-21 BJ cartridges provide excellent print quality for crisp, clean-looking

documents.

REFER TO PAGE 2-16.

Convenient paper handling

The paper tray holds up to 100 sheets of plain letter, legal, or A4 paper, and the automatic

document feeder can hold up to 20 letter-size, A4-size or 10 legal-size pages.

Simple maintenance

The replaceable ink cartridge contains the ink and the print head. When it runs out of ink,

simply replace it.

Ink detection function

This model has a new ink detection function. After each received page is printed, ink is

ejected in front of a photosensor, so that the machine can detect whether there is ink

remaining or not.

REFER TO PAGE 2-16.

Copy function

This machine can make up to 99 black and white (including halftones) copies of a document

at a time, at a rate of up to three copies per minute.

It can also make one color copy at n time at a rate of ten minutes per copy.

Full-color and

By using the settings in the MultiPASS Desktop Manager software, you can scan photos in

full color or with 256

photos are reproduced as clearly as

possible.

256-level

gray-scale (for PC) REFER TO PAGE 2-34.

lcvcls

of gray, rather than just in black and white, ensuring that

High-resolution scanning

This machine

electro~cnh~nced

can

scan docum~nls at true resolutions of 30 - 300 dpi,

rrsolulions

or

of 301 - 600 dpi.

l-l

Page 17

Part 1: Facsimile

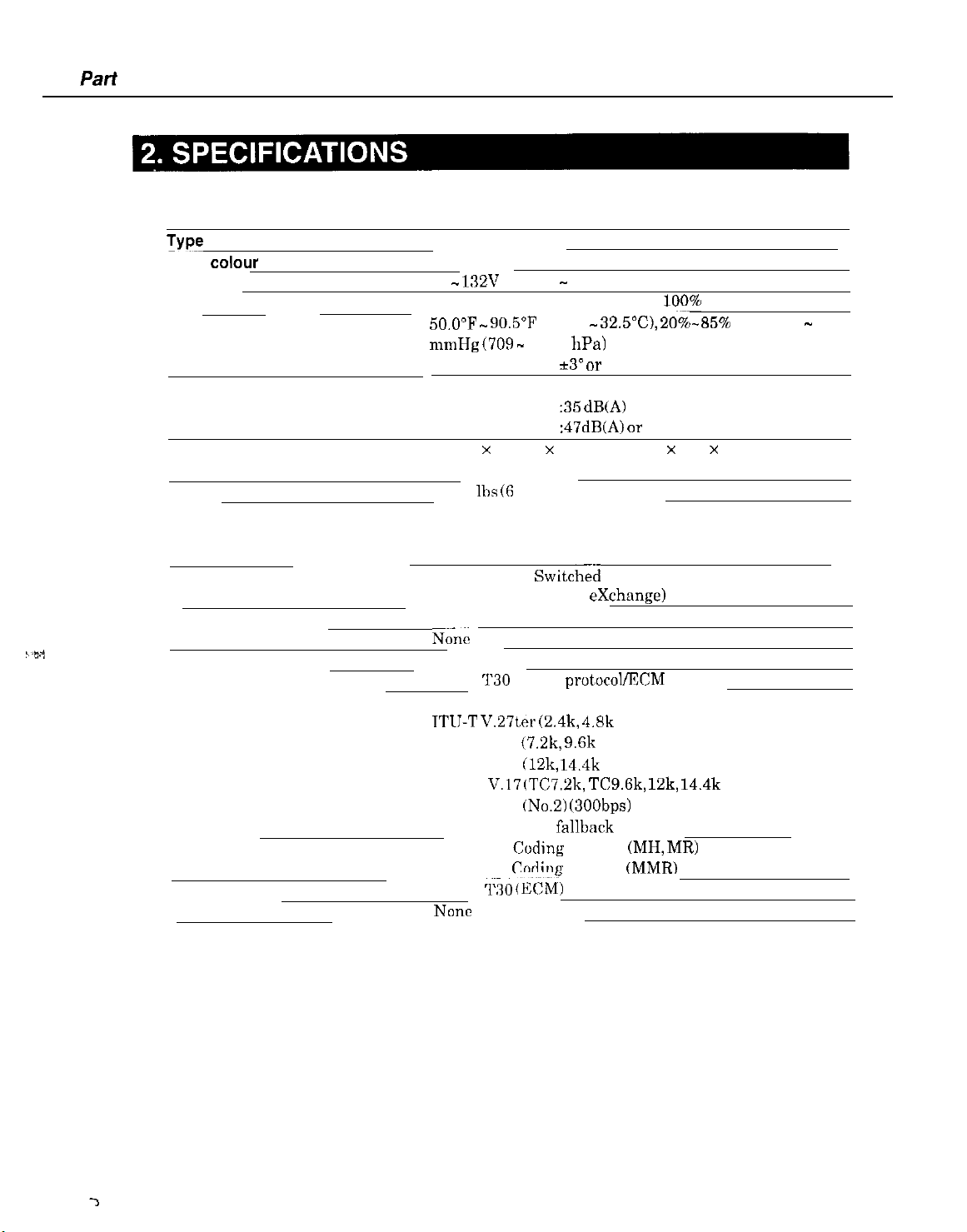

2.1 General Specification

TYPT

Body colour

Power source

Power consumption

Usage environment.

Operating noise

Dimensions (W X D X H)

Weight

Desktop

Art gray

98 - 132V AC, 48 - 62 Hz,

standby 9 W/Max. 49 W (when

50,O”F mmHg (709 - 1013 hPa)

Horizontal

Measured in accordance with IS0 standards

Standby

Operating

15.75” x 14.37” x 8.07” (400 mm x 365 x 205 mm)

(Not including Trays)

13.23

2.2 Communication Specification

Applicable lines

_

Applicable Services

Handset

Transmission method

Transmission control protocol

Modulation method

G3 image signals

G3 procedure signals

Coding

Error correction

Canon express protocol (CEP)

PSTN (Public Switch&l Telephone Network)

PBX (Private Branch

_

DRPD

N&c

Half-duplex

ITU-T

TTIJ-T

ITU-T V.29 (7.2k, 9.6k bps)

ITU-T V.33

ITU-T V.17 (TC7.2k,

ITU-T V.21 (No.2) (300bps)

(With automatic fallback function)

ITU-T T.4

ITU-T T.6

ITU-T T30

NOllC

90.5”F (10°C - 32.5”C),

*3” or less

:35

dB(A) or less

:47dB(A) OT less

111s (6

0 kg) Including trays

exchange)

‘~30

binary protocol/ECM protocol

V.27ter (2.4k, 4.8k bps)

(12k,

14.4k bps)

TCS.Gk, 12k,

C:oding

method (MH, MR)

&dine

method (MMR)

(E&j

100%

black copy)

20%-85%

14.4k bps)

_

RH, 532 - 760

1-2

Page 18

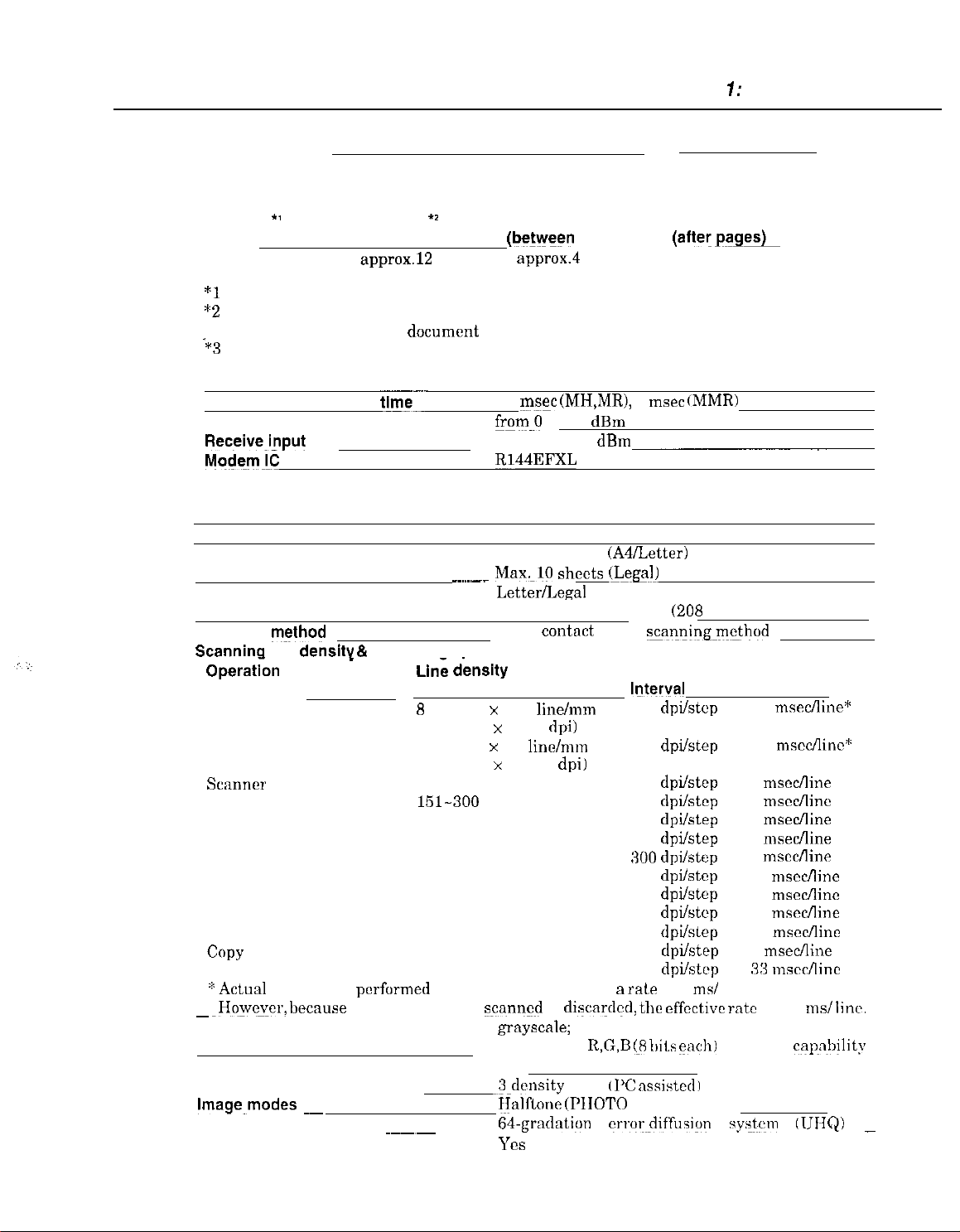

Time required for transmission protocol

Chapter 7: General Description

Pre-message

Protocol

Mode

Stand&/Fine

*l

Time from when other facsimile is connected to the line until image transmission begins.

*2

Post-message (between pages): Time from nftcr one document has been sent until

‘*3

Post-message (after last pages): Time from after image transmission is completed until

Minimum transmission

Transmission output level

Receive_i_nput

Mo&m!C

2.3

Scanner Specification

Type

ADF capacity

Effective scanning width

Scanning

Scanninq

Opera&n Mode

FAX

COPY

*Actual

~

~Howc~cr,

Scanner gradations

TWAIN

Scanning density adjustment

lmage_modes ~~

Halftone (fax and copy)

Prescan

‘1

transmission of the next

line is switched from facsimile to telephone.

level

method

line dens@ & Scanning speed

Standard

Fine

Text (Binary)

Gray scale

Full color

B&W

Full color

scanning is

becnuse

Protocol

approx.12

_

performed

1 of every 3 lines

*I

sec.

document

tim_e--

__..___ Max,10 sheets

Line dknslty

8

dot/mm x 3.85

(203.2 dpi x 97.79 dpi)

8 dot/nun x 7.7

(203.2 dpi x 195.58 dpi)

150 dpi or less

151-300

301-600 dpi

150 dpi or less

151-300 dpi

301-600 dpi

150 dpi or less

151-300 dpi

301-600 dpi

360 dpi

360 dpi

in 150 dpi increments at B

~~~~

Post-message Post-message

Protocol l I

(be@een

approx.4

starts if several pages are transmitted.

10 msec (MH,MR), 0 msec

from.0 to -15

from -3 to -43 dBm

B144EFXL

Sheets

Max. 20 sheets

Letter/Legal

A4

Color

dpi

scanned

grayscale;

___ color;

YCS

-3-density

~Jalflor~e

Wgrndiltion crror&ffusign yy$em

Yes

pages)

sec.

dBm

contnct

line/mm

linclmm

is discardccl,

sensor

8 bit, 256 gradations

R,G,B (8

level tl’C

(PIIOTO mode)

(A4/Letter)

(Legal)

8.42” (214 mm)

8.19”

scanningm$hod

Motor step

lfiterval

150

dpiktcp

150

dpi/step

150

dpiktcp

300

dpikcp

600

dpilstep

150

dpikep

300

dpiktep

600

dpikcp

150

dpi/step

300

dpiktcp

600

dpilslep

600

dpiktep

600

dpiktup

rate

of 5 ms/ line

the

effective

bits

nssistedl

(aftewg*

approx.3.5 sec.

(MMR)

_

(208

mm)

rntc

each) full color

Scanning speed

7.5 msecAine”

7.5 mscc/linc“:

5

msccfline

5

msccflinc

5 msecAine

7

msecfline

7

mscclline

11 msccAine

21 msccAine

21

ms&line

33 msccAinc

5

mseclline

:13 “xccllinc

is 7.5

IIJNQ)

ms/ linr.

capnbility

_

l-3

Page 19

Pari

1: Facsimile

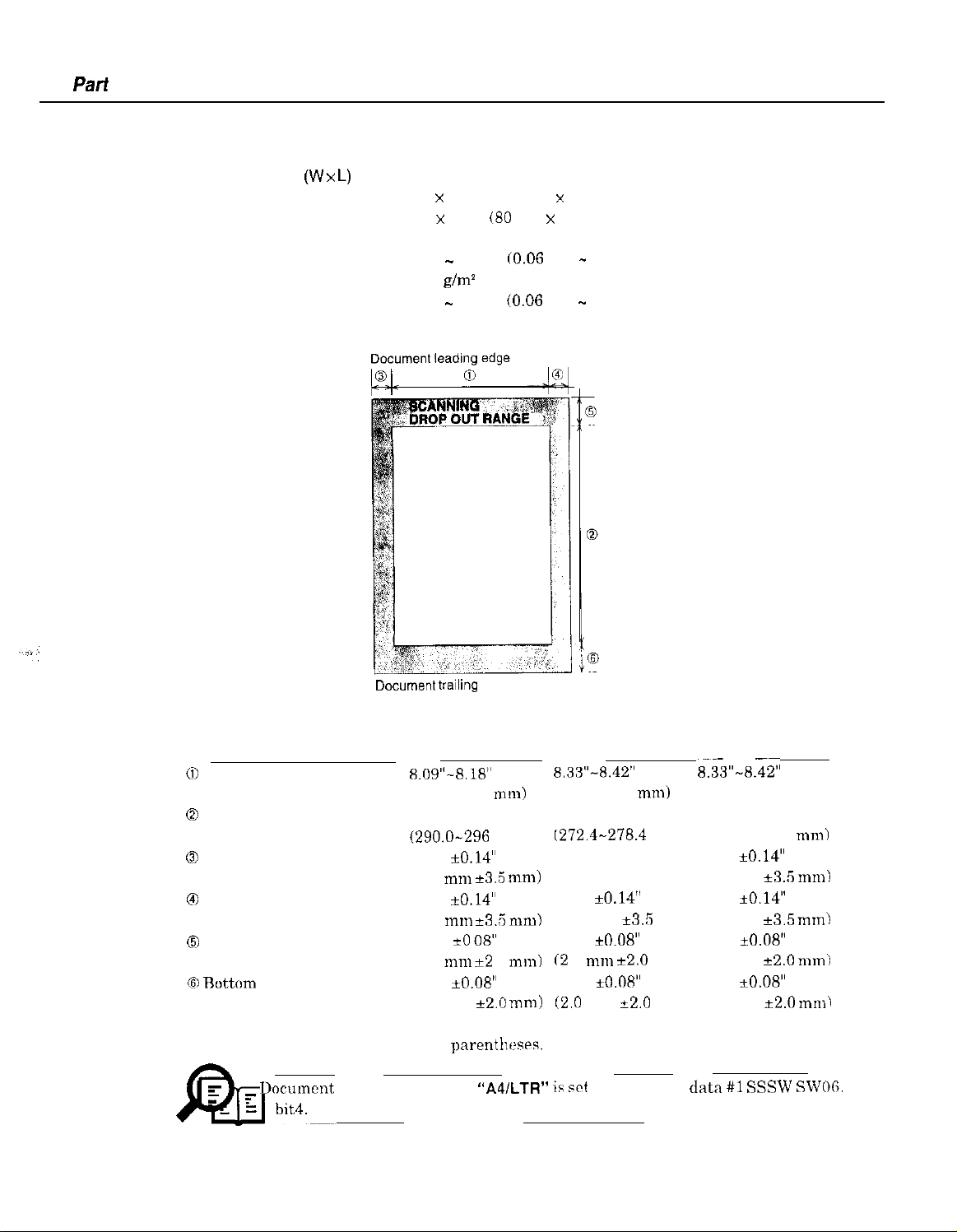

Scanning range

Sheet dimensions (W x

Maximum

Minimum

Thickness

multiple pages:

single page:

L)

8.50” x 39.3” (216 mm x 1000 mm)

3.15” x 1.77”

0.002” - 0.005”

40-90

0.002” - 0.017” (0.06 mm - 0.43 mm)

40-340 g/m’

SCANNING RANGE

g/m2

(80

mm x 45 mm)

CO.06

mm - 0.13 mm)

Document

Figure l-l Scanning Range

Item

0)

Effective scanning width

0

Effective scanning length

0

Left margin 0.04” *0.14”

0

Right margin

0

Top margin

(6)

Ruttom margin

Units arc inches with mm shown in

E- Documet~t

NOTE

scanning width

A4

8.09”-8.18”

(205.5-208 mm)

11.54”

(290.0-296

(1.0

0.04”

(1.0 I”“1

0.08” *O

(2.0

0.08” iO.08”

(2.0 mm

trailing

edge

mm)

,““I

*3.5

zkO.14”

*3.R

08”

“11”

*2 0 mm)

k2.0

parenth~~srs.

“A4/LTR

mn1)

mm)

mm)

Letter_

8.33”-8.42”

(211.5-214 mm)

10.84”

I272.4-278.4

0.08” k0.14”

(2.0 mm e3.5 mm) (2.0 mm

0.04” *0.14”

(1.0 mm

0.08” *0.08” 0.08” +0.08”

(2

0

“ll”

0.08” iO.08” 0.08” ~0.08”

(2.C

mm

” ii wt

in service data #l SSSW

mm) (348.6-354.6 mm)

*3.R

k2.0 mm) (2.0 mm e2.0 mm)

+2.0

Legal

8.33”-8.42”

(211.5-214 mm)

13.84”

0.08” +0.14”

0.04” iO.14”

mm) (1.0 mm k3.5 mm)

mm) (2.0 mm

*3.5

*2.0

_

mm)

“II”~

SWOG.

1-4

Page 20

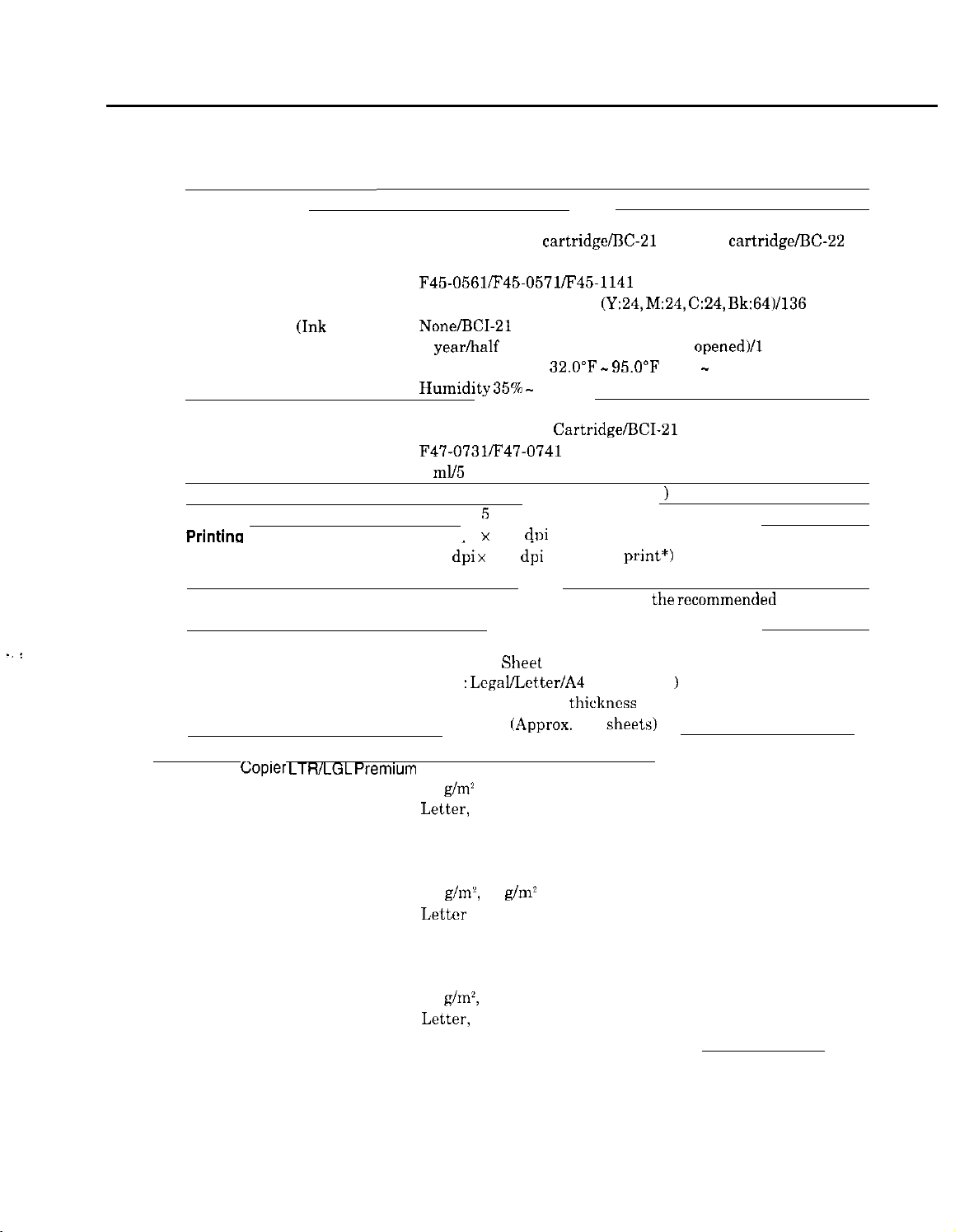

2.4 Printer Specification

Chapter 1: General Description

Printing method

BJ Cartridge

Products name

Product code

Print head

Ink cartridge

Valid period

Storage conditions

Ink Cartridge

Products name

Product code

Ink contains

Ink detection

Printlng speed

Printina

Paper output tray stacking

. .

:

Paper tray

Recommended paper

Canon

resolution

*Printing in a checkered pattern without printing vertical and horizontal adjacent dots.

Paper supply method

Number of paper tray

Paper capacity

Copier LTRlLGL Premium

Wright

Paper size

Manufactured by

(Ink

tank)

Bubble-jet ink on-demand

BC-20 Black BJ

Photo Color BJ cartridge

F45-0561/F45-0571/F45-1141

128 nozzles/136 nozzles

None/BCI-21

1 year/half a year (since the seal was

Temperature

Humidity35% -

BCI-21 Black Ink

F47-0731/F47-0741

9

ml/5

ml each of YMC

Yes

(Directly detects ink ejection

Approx. 5 pages/minute (in case of character print)

360 dpi x 360

180

d;i x

180

Approx. 50 sheets (when using

Approx. 20 sheets (when raised output guides)

ASF (Auto

ltray :

Lcgal/Lctter/A4

Max. 0.40” (10 mm)

plain paper

Paper

75

g/ma

Letter,

Legal

BOISE CASCADE

cartridge/BC:-21

(Y:24, M:24, C:24,

Color or BCI-21 Black/None

32.O”F - 95.O”F

65% RH

Cartridge/BCI-21

dpi

(Normal print)

dpi

(Economy

Sheet

Feeder)

(Universal

thickness

(Approx.

100

Color BJ cartridge/BC-22

opened)/1

(0°C - 35°C)

Color Ink Cartridge

1

print*)

the recommended

)

sheets)

Bk:64)/136 nozzles

year

paper)

PLOVERBOND

Weight

Paper size

Manufactured by

XEROX 4024

Weight

Paper size

Manufactured by

75

g/m’,

90

g/m2

Letter

FOX RIVER

75

g/m~,

90 g/m’

Letter,

Legal

XEROX

1-5

Page 21

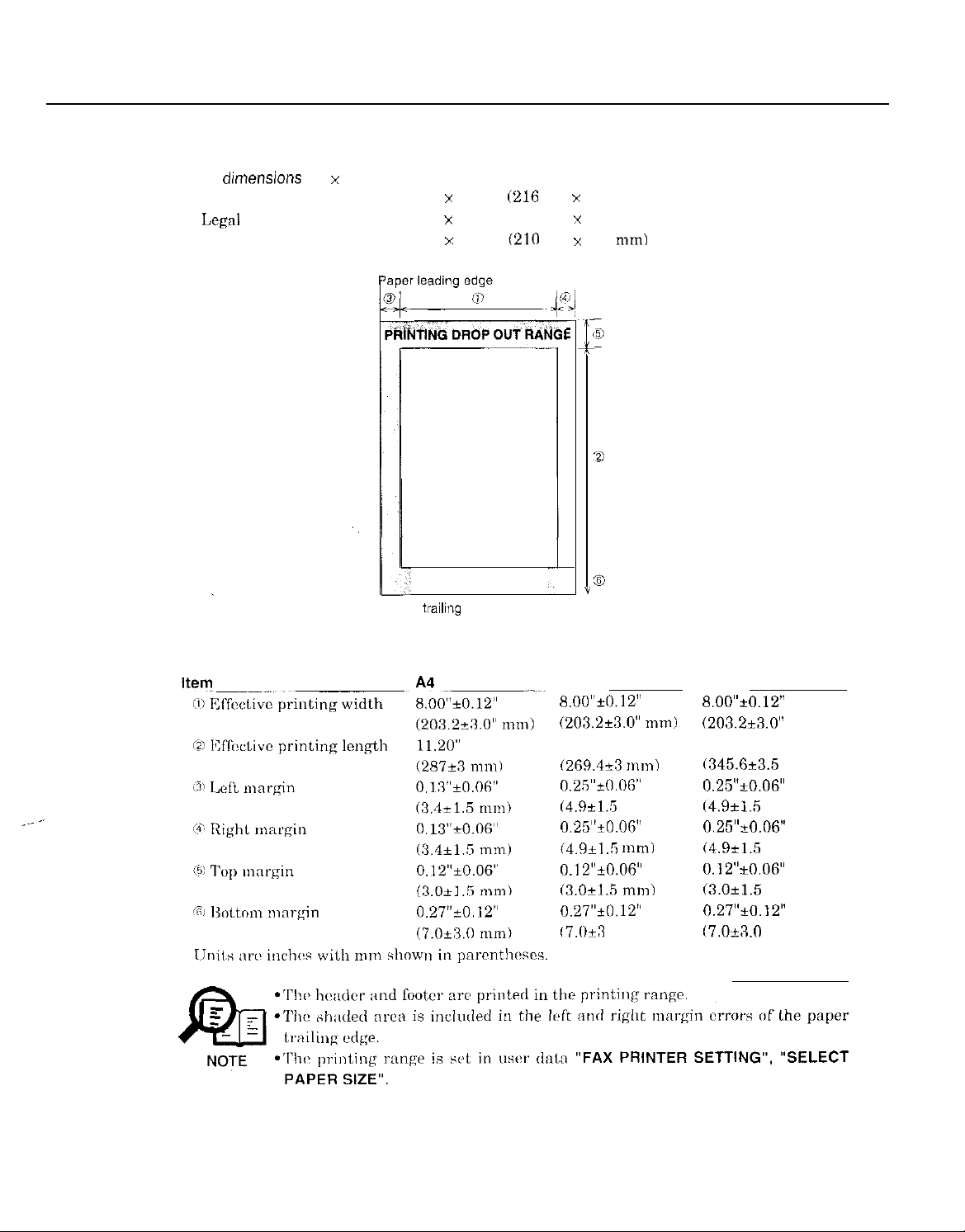

Part 1: Facsimile

Printing range

Paper

Letter

Legal

A4

dunensions

(W x L)

8.50” x 10.98”

8.50” x 14.02” (216 mm x 356 mm)

8.27” x 11.69”

(216

mm x 279 mm)

(210

mm x 297 mm)

z_

i

(

1

PRINTING RANGE

Y

Paper trailing edge

Figure 1-2 Printing Range

Letter

8.00”t0.12”

(203.2+3.0” mm)

10.51”

(269.4+3 mm)

0.25”+0.06”

(4.9k1.5 mm)

0.25”+0.OF” 0.25”+0.06”

(4.9+1 .R tn111~

0.12”&06”

(3.0+1.5 mm)

0.27”+0.12”

17.0&l 0 mm)

Legal

8.00”~0.12”

(203.2i3.0”

13.47”

(345.6t3.5

0.25”kO.O6”

(4.9*15

(4.9k1.5 mm)

0.12”iO.O6”

(3.Ok1.5

0.27”*0.12”

17.0+X0

mm)

mm)

mm)

mm)

mm)

l-6

Page 22

2.5 Copy Specification

Chapter 7: General Description

Color copy

Multiple copy

YCS

99 copies (Black

Copy mode

Black & white B&W TEXT, B&W PHOTO

Color

Copy resolution

Scanning

Printing

Copy magnification ratio

&

white mode only)

COLOR FINE, COLOR STANDARD, COLOR SNAPSHOT

Black & white 360 dpi x 360 dpi (direct copy)

8 dot/mm x 7.7 line/mm (memory COPY)

Color 360 dpi x 360 dpi (FINE or SNAPSHOT)

180 dpi x 360 dpi (STANDARD)

360 dpi x 360 dpi

loo’%,

90’%,

807q 70%

1-7

Page 23

Part 1: Facsimile

2.6 Function

Dialling

Manual dialling Numeric button

Auto dialing Max. 120 digits

Group dial Max.55 locations

Redial

Transmission

Broadcast transmission

Delayed transmission Yes (PC Assisted)

Confidential

Relay broadcasting originating None

Relay broadcasting

Reception

Dual Access

FAX/TEL switching

Method

MiSage

Pseudo CI

Pseudo ring

Pseudo

TX/RX

ringback

__

tone

~.~_

One-touch:B, Coded speed:50, Numeric

Numeric button

Max.

57 locations

button:

N0Ile

NOIE

1)

redial

function (Max. 120 digits)

(One-touch:6,

Coded

Y‘.ZS

Yes

CNG,

ROT(Rr-Order

NOIX

NOW

Yes

YE3

Tone) detection

button:1

speed:50,

Numeric

Reduction settings for reception

Automatic reduction of reception images

Built-in Answering machine

Answering machine connection

Remote reception

Memory lock reception

Reception printing in reverse order

Polling

Polling transmission

Polling reception

Yes

Yes (1007&70%)

NOW?

Yes (Telephone answering priority type)

Yes (Remote ID method)

NOW

1-8

Page 24

Chapter 1: General Description

Others

Closed network

Direct mail prevention

Reception printing In reverse order

Memory box

Memory backup

Backup contents

Backup IC

Backup device

Battery life

Image data backup

Activity management

a) User report

Activity management report (Every 20 transactions : always transmission and reception

together)

Activity report (sending/receiving)

One-touch speed dialling list

Coded speed dialling list (by SPECIAL MODE)

Group dialling list

Memory clear list

User’s data list

Multi activity report

b) Service report

System data list

System dump list

Error list

N0ne

NOIE

Nona

N0na

Dial registration data, User data, Service data,

Time

256 kbit SRAM for control

Lithium battery

Approx. 5 years

Nona

Yes

(by SPECIAL MODE)

(by SPECIAL MODE)

(by SPECIAL MODE)

3.OV DC/600 mAh

1-9

Page 25

Part

7: Facsimile

Transmitting terminal identification

Time

Management data

Precision

Display

Completion stamp

Program key

Telephone exchange function

Speaker phone

Demo print function

HELP function

Ye.3

Year/month/date/day/hour/minute (24 hour

display)

?r90 set

NOIE

NOIW

NOFX

NOlIe

NCJne

NOIE

lrow x

per month

16 digits

l-10

Page 26

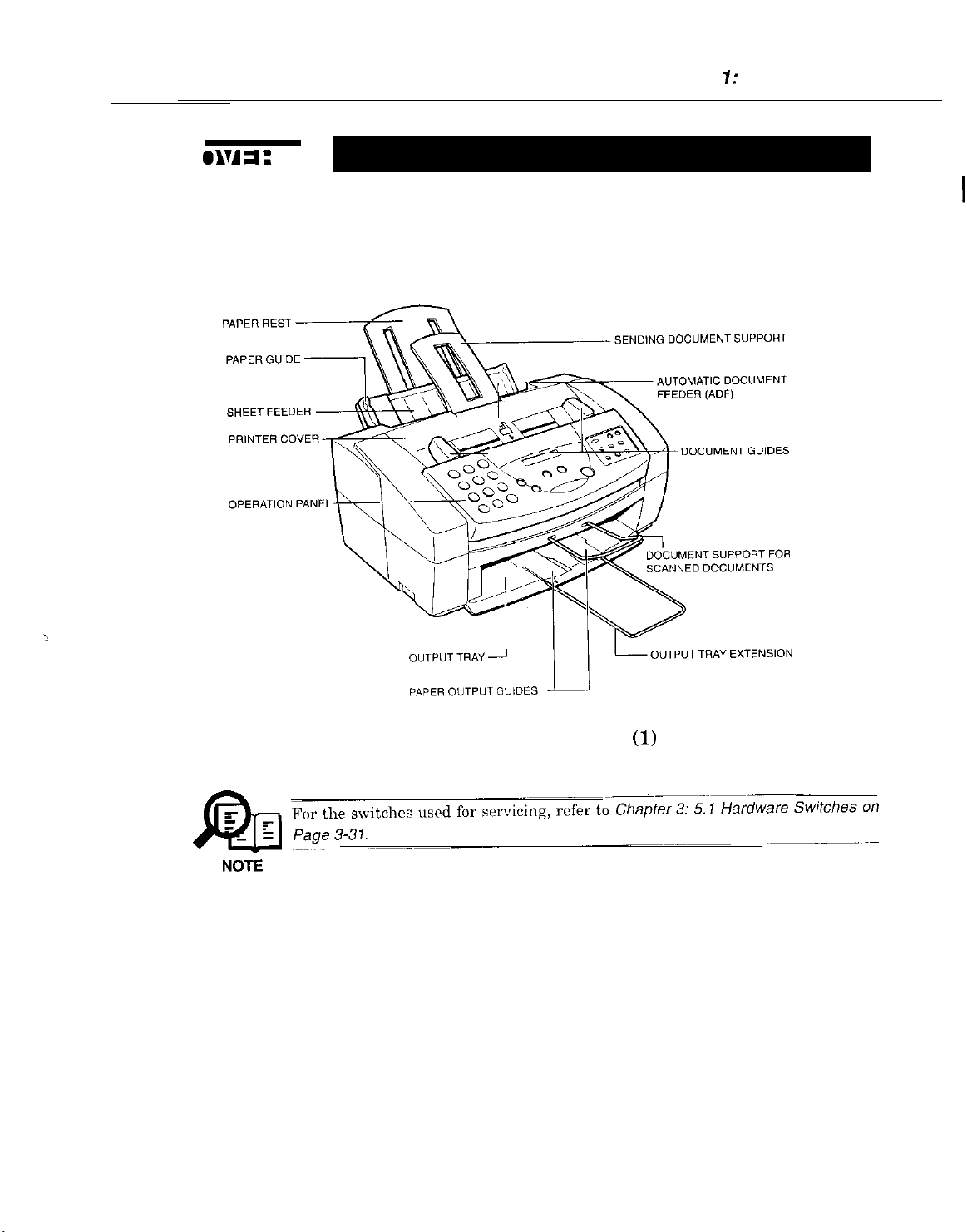

3.1

External View

Front View

Chapter 7: General Description

Figure 1-3 External View

l-11

(1)

Page 27

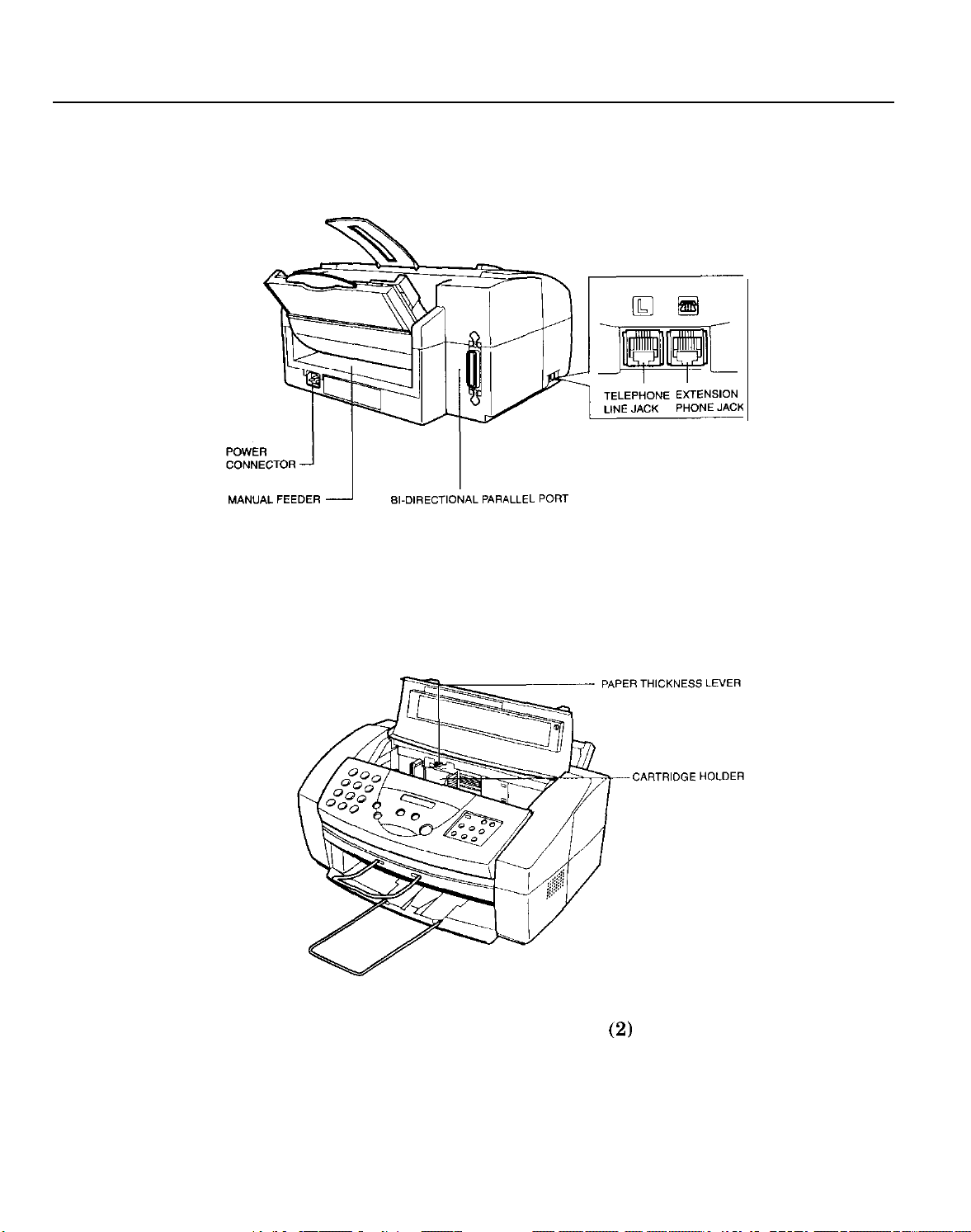

Part 1: Facsimile

Rear View

Inside the Printer Cover

Figure 1-4 External View

(2)

1-12

Page 28

Part 7: Facsimile

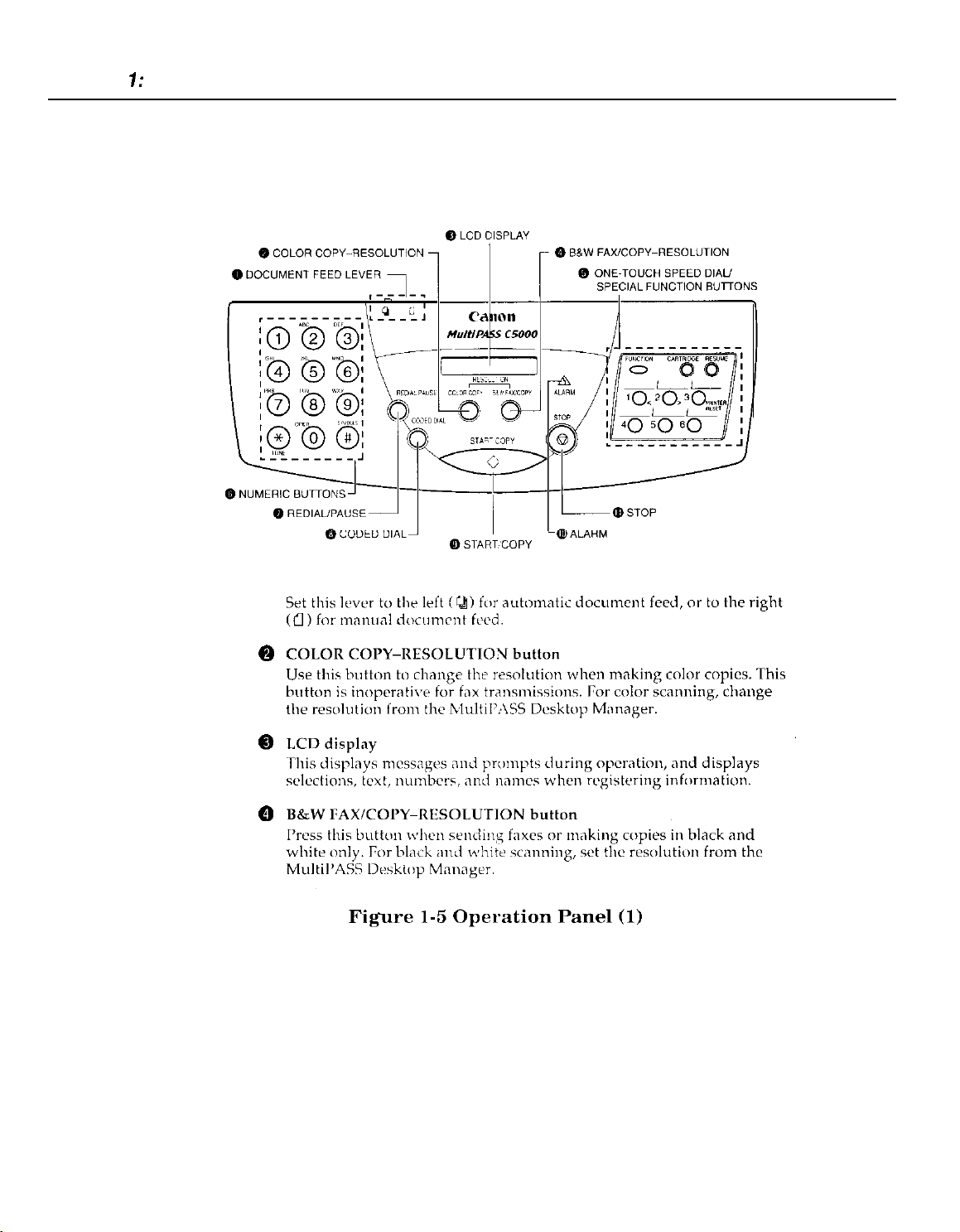

3.2

Operation Panel

The Operation Panel

Document feed lever

0

0

0

0

1-14

Page 29

Chapter 7: General Description

@

One-Touch Speed Dial/Special Function buttons

Use these buttons for one-touch speed dialing, entering user

information,

print head. For more information on the special function buttons.

@

Numeric buttons

Use

thcsr

information,

for automatic dialing.

prmting

buttons to type numbers and names when entering

and

documents stored in memory, and cleaning the

to dial fax/telephone numbers that

are

not

registrred

@ REDIALPAUSE

Press this button to

number buttons, or to enter pauses between digits when dialing fax

numbers.

@

CODED DIAL button

Press this button (followed by entering a two-digit code with the

numeric buttons) to dial a fax number that you have registered for

coded speed

@

START/COPY button

Press this button to

operations, or to select functions when registering information.

@I

ALARM lamp

This

lamp

is

out

of paper or ink.

@

STOP button

Prtx

this button to cancel sending, receiving, or any other

button

redial

the last number that was dialed using the

dialing.

begin

sending, receiving, scanning, or other

flashes when an

error

occurs, or when the

Figure 1-6 Operation Panel

MultiPASS

(2)

C5000

oprration.

1-15

Page 30

Part 1: Facsimile

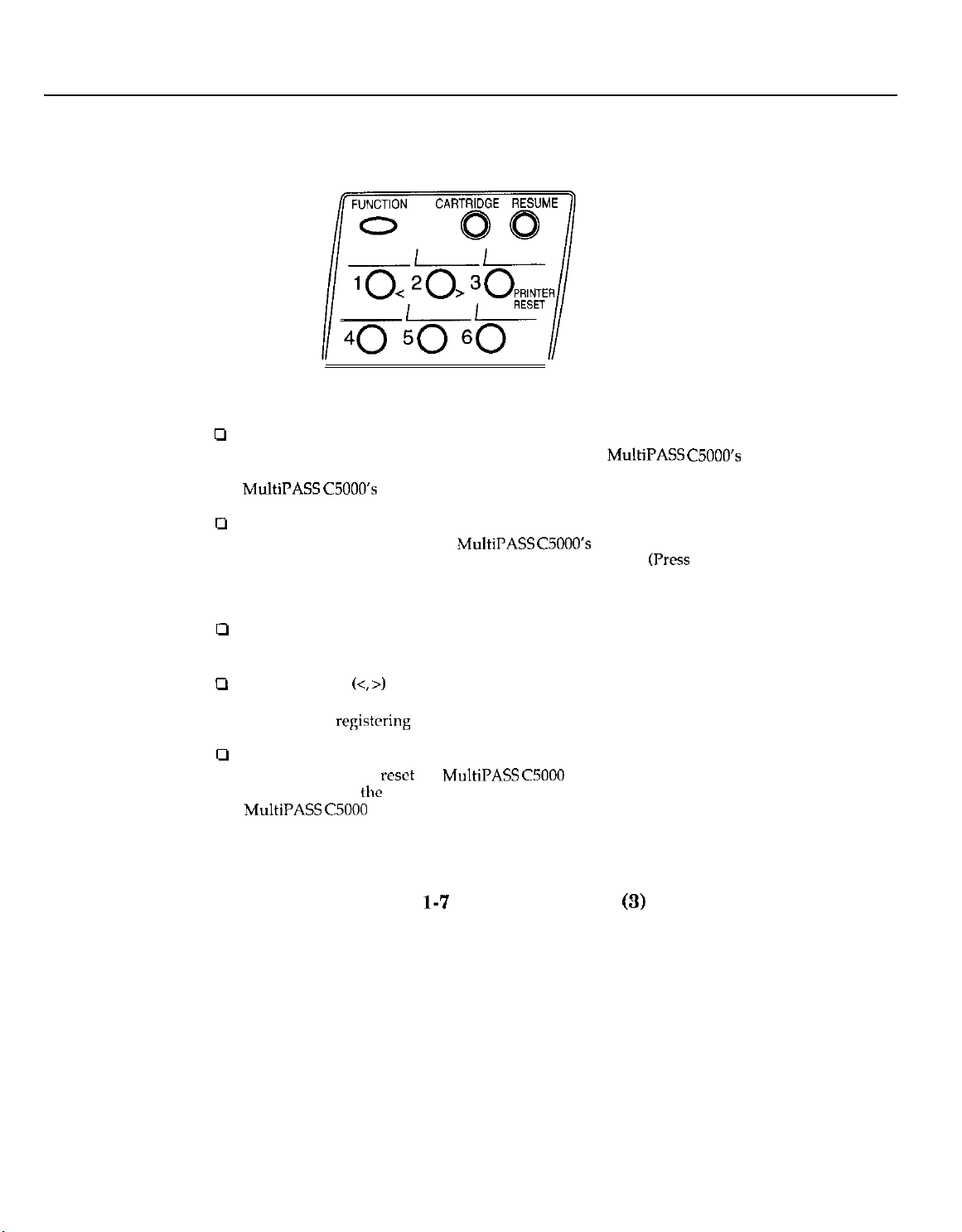

0

0

Special Function Buttons

FUNCTION button

Use this button to enter user information, to run the

self-cleaning process, check the nozzles, or to print faxes stored in the

MultiPASS C5OOO’s

CARTRIDGE button

Press this button to release the

its center position for installing or replacing the cartridge.

after installing the cartridge to return the cartridge holder back to its

home position.)

memory.

MultiPASS C5OOO’s

MultiPASS C5OOO’s

BJ cartridge holder to

(Press

again

u

RESUME button

Press this button when you want to form-feed paper when printing

cl

Arrow buttons

Use these buttons to scroll through menu selections or to move the

cursor when

cl

PRINTER RESET button 3

Press this button to

will maintain all

MultiPASS

(<, >)

1 and 2

registering

C5000 to reset the unit or the faxes in memory will be lost.

Figure

data.

reset

the

MultiPASS CSOOO

the

faxes currently in memory. Do not unplug the

l-7

Operation Panel

if your PC crashes. This

(3)

1-16

Page 31

Chapter 7: General Description

Entering a Name

When

entering

a number and a group of uppercase

The chart below shows which number to press for each character.

a

name

(such as “Unit Name”), each numeric button has

and

lowercase letters assigned to it.

Button

1

2

3

4

6

7

8

9

0

#

Figure

Characters

1

ARCabc2

DEFdrf3

GHIehi4

MNOmnoh

I’QRSpqrs7

TLJVtuv8

WXYZwxyz9

0

-.‘#!“,;:“‘_=/ I’?$Q%&+oIloo

l-8

Operation Panel

(4)

1-17

Page 32

Part 1: Facsimile

3.3 Consumables

3.3.1 BJ cartridge and ink cartridge and BJ cartridge container

Choosing the Best Cartridge

a

Note

Canon offers several BJ print cartridges and ink tanks for use in

MultiPASS

while BJ ink tanks contain only ink.) Use

decide which type of cartridge best suits your particular needs.

To avoid printing problems, use only the BC-21/21e BJ cartridge for

normal printing (or the separately sold UC-20 Black BJ cartridge, if

rarely print color). The BC-22/22r Photo Color BJ Cartridge (sold

separately) is for printing photo-realistic color images. Other cartridges

can produce unsatisfactory results. In addition, use only

and BCI-21 Color ink tanks in the BC-21/21e Color BJ cartridge.

BC-21/21e

The BC-21/21e incorporates a UJ pnnt head

and two replaceable ink tanks (a BCI-21

Black and a BCI-21 Color). Use this cartridge

for

nonml

C5lKtO.

(BJ print cartridges contain the BJ print head and ink,

Color BJ Cartridge

printing.

the

following

dcscriptims

BCI-21

the

to

you

Black

EC-21 /21e

Color BJ cartridge

1-18

Page 33

Chapter 1: General Description

BC-W22e

Includes the print head

single unit. Use this cartridge for printing

photo-realistic color images.

BC-29F Fluorescent BJ Cartridge

Includes the print head and

single unit. Use this cartridge for printing

bright, attractive fluorescent colors. For

optimum print quality, use High Resolution

Paper HR-101.

The

the

feature: because the

have ink tanks that can be replaced separately), using them to print

faxes will use the black ink faster, using up the cartridges while they still

have a considerable amount of

SB-21 BJ Cartridge Container

Use the 58-21 to store an

in a

from drying out.

Photo Color BJ Cartridge

MultiPASS

BC-22/22e

convenient

C20 cannot print incoming

or BC-29F cartridge is installed. This is an ink-saving

BC-22/22e

location, Tvhile keeping it

and

color ink in a

colour

and

colour

extra BJ

ink in a

K-2YF

ink remaining.

cartridge

faxes

or make copies while

are single units (and do not

Your

MultiPASS

Cartridge (which incorporates the IICI-21 Black and

tanks) and an additional

ink, or if you wish to

above, you can purchase them from your Canon dealer.

C5000 unit comes with a BC-21 or

BCIL21

Black ink tank. When you

11s~ ,my

other Canon BJ cartridges mentioned

Figure l-10 Consumables

BC-2Ic

BCI-21

(2)

1-19

Color BJ

Color ink

run

out of

Page 34

Part 1: Facsimile

Page 35

Chapter 1: General Description

Canon Glossy Photo Paper GP-201

Canon Glossy Photo I’aper (;I’-201 is a high gloss, thicker paper that

produces the look

22/22e Photo BJ

printer. (Select Glossy Paper in thr printer driver when you have this

paper loaded.)

and feel (If ,I ph<~tograph

Cnrtridgtz tu pmducc

Use this paper with

photo-realistic prints from your

the

BC

Canon High-Gloss Film

This is a high-grade,

and mcm vivid color output than is possible with coated paper. This

film provides the

cartridge. Use this film fw

presentations,

Fabric Sheets FS-101

These legal-size, white, cutton fabric sheets are specifically designed for

Canon BJ Color printers,

cross stitch, pillows, holiday stockings, and other craft

T-Shirt Transfers TR-IO1

bet

and

Figure l-12 Print Media

HG-101

letter-4/e

color t,rint quality for the BC-21/21e Color BJ

whrn

gloss film that lets you create sharper

trxlr

show displays or other special

p~intmg

~IKI

at 720 x 360 dpi resolution.

enable you to print your own designs for

prqects.

(2)

1-21

Page 36

Part 7: Facsimile

r

w

Units

: mm

Figure l-13 Dimensions

--

0

,-r

400

~-

--

-

l-22

Page 37

5.1

Personnel Hazards

Electrical Shock and High-Temperature Parts

Chapter 1: General Description

Power

supply

Page

l-25

Paper feed motor

Page l-25

BJ cartridge

(Alminlum plate)

PAGE l-25

(-132 F)

(-212~F)

’ -

‘SCNTb&

Page l-25

Carriage motor

Document feed

motor

(-145.2~F)

(-

113 F)

Figure 1-14 Personnel Hazards

l-23

(1)

Page 38

Part 1: Facsimile

Moving parts

01’

Page1 -26

1

Preventing ink stains m

Pagel-

Figure

l-15

Personnel Hazards (2)

Purge unit

/

Carriage belt

l-24

Page 39

5.1.1 Electrical shock

Chapter 7: Genera/ Description

Electrical shock hazard

*To

prevent electrical shock, be sure to disconnect the power cord and modular jack

_

e

c

_

RIJ

A

@n

NOTE

5.1.2 High-temperature parts

c

- -

NOTE

before disassembly.

*Remove grounding wrist straps before servicing this unit while the FAX’s power is

on. Otherwise, electrical shock may occur.

bower supply unit

r

When power is supplied to this unit, 120 VAC

-5

Telephone

If a telephone line is connected to this unit, 48 VDC will be supplied by this line.

When a call signal is received, a voltage of 90 VAC

High-temperature warning

To prevent skin burns, disconnect the

10

minutes to allow hot parts to cool.

How

Heat of about 122°F or more causes burns. Also, the longer the contact, the mow

c

severe the burn.

When treating a burn, the first minute after receiving the burn is

important. Cool the burn immediately with cold running water. In

serious burn, seek medical attention immediately.

line

to treat burns

I

will be supplied to the primary side.

Vrms

____~

powcr

cord and let this unit stand for at least

_.

will be supplied.

the

case

most

of a

.

nn

r

- -

NOTE

The parts which get hot during operation are indicated. For the location of

in

parts, refer to

(Ambient

Document

Paper feed motor (approx. - 132°F

Carriage motor (approx. - 145.2-F

Power supply unit (Max. - 185°F

PCNT board

BJ cartridge (nmx. -

the

figures.

temperature

feed motor (approx. -

assrmbly

95°F

(approx. -

212°F

(35°C)

continuous copy

113.9”F (45.5”C))

(55.6”C))

(62.9”C))

(85.2%))

173.1”F (78.4”C))

(100°C))

l-25

operation)

thcsc

Page 40

Part 1: Facsimile

5.1.3 Fire hazards

5.1.4 Moving parts

e

Do not dispose in fire.

Do not dispose of lithium batteries in fire. Doing so may rupture the battery

and expose flammable materials.

Follow applicable local

assembly’s lithium battery.

Fire hazard

When using

internal electronic circuits can ignite the solvent. Before using such solvents,

be

sure

parts cool. Use the solvent in a well-ventilated area.

Moving parts

To prevent mishaps due to moving or rotating parts during servicing, be

to disconnect the power cord before disassembly.

Since the this unit does not have a

and

rollers

operation. If the printer cover must be opened during printing,

moving parts.

Figure l-14 shows the driving s&ion’s location.

IPA

or other solvents during servicing, heat or sparks from

to turn off the power source and wait until the

will not stop even if the printer cover is opened during a printing

regulations

when disposing of the the SCNT board

high-temperature

sensor

on

the

printer cover, the carriage

bewnrr

of the

sure

5.1.5 Preventing ink stains

Avoid touching the BJ cartridge ink nozzles, ink pad, head cap, head wiper,

absorbers. The ink can stain your hands,

is

permanmt

c

- -

&

NOTE

nnd will permanently stain clothing, ptr.

Although the ink is not toxic, it

67-63-O). If the ink enters the

L

water and

immediately and

see a doctor. If the ink is

giw thr informntion

clothes,

etc. Although the ink is

contnms

eyw accidentally,

an organic solvent (isopropyl nlcohol

swallowrd

printed on the

watrr soluble,

flush the eyes with running

accidentally, see a doctor

B.J cnrtridgo

lnbcl.

and

ink

it

l-26

Page 41

5.2

General Cautions

5.2.1 Unit cautions

Safety Instructions

Chapter 1: General Description

A

Caution

Read these safety instructions thoroughly before using your

C5000, and keep them handy in case you need to refer to them later.

Except as specifically described in this manual, do not attempt to service

the

MultiPASS

opening and removing its interior covers will expose you to dangerous

voltages and other risks. For all service, contact your local authorized

Canon dealer or service center.

Cl

Always follow all warnings and

MultiPASS

U Use the

the

U Do not use the

into the unit, unplug it immediately and call your local authorized

Canon dealer or

0

The back and bottom of the

openings for ventilation. To keep the

overheating (which

fire risk), take

operate the unit on a bed, sofa, rug, or

near a radiator or other heat source. Du not

C5000 in a

ventilation is available See “Choosing a

MultiPASS

the unit needs for ventilation

0

Operate

indicated on the unit’s label. If

available

0

The

third pin is a grounding pin) that fits only into

outlets.

the correct type, contact an

2

&pter,

purpose.

C5000 yourself. Never attempt to disassemble the unit:

instru tions

C5000.

MultiPASS

MultiPASS

closet

C5000” on

the MultiPASS C.iOOi)

from your xvall outlets, contact your

MultiPASS

This is a safety feature. If the outlet you intend to

as this

C5000 only on n sturdy, stable, level surface. If

C5000 falls, it could be seriously damaged.

MultiPASS GO00

service

center.

can

cause it to operate abnormally

cart

not to block or

or cabinet or on

page

C5000 has a three-prong, grounding-type plug (the

defeats

the three-pronged plug’s grounding

near water. If you spill liquid on

MultiI’ASS

cover

shelves

2-3 for

guidclincs

Only from

you are

elrctri&n

marked on the

C5000 include slots

MultiPASS

these openings. Do not

other

unless adequate

I.ocation

not

to

rcplacr

C5000 from

similar soft surface, or

place

the

for Your

on how much space

the type

suw

of the type of power

Irxal

gr<>undiIlg-type

it: do not

MultiPASS

and

and

create a

MultiPASS

of

power sowx

power company.

use

is not

use

a X-to-

or

1-27

181-11

Page 42

Part 7: Facsimile

U

Do not allow anything to rest un the

MultiPASS CSOOO

cord is not knotted or kinked.

0

Do not insert objects of any kind into the slots or openings on the

MultiPASS C5OOO’s

points or short out parts, and result in fire or electric shock.

3 Do not allow small objects (such as pins,

fall into the

the unit immediately and call your local authorized Canon dealer or

service center.

Ll

Always unplug the

0

Whenever you unplug the

seconds before you plug it back in.

0

Keep the

damage it. If you have to place it near a window, install heavy

curtains or blinds.

0

Do

fluctuations. Install the unit in H

range 5LI~90.5°F

3 Always unplug the

a

I3rfore

c1

Always lift the

sheet

MultiPASS

not expose the

you transport the

feeder

where the cord will bc walked on Make

cabinet, as they could touch dangerous voltage

MultiI’ASS GO00

MultiPASS C5OOO

MultiPASS

C5000 away from direct sunlight, as this can

MultiPASS C5tlOO

(lo”-323°C)

MultlPASS C.5000

MultiPASS CSOOO,

MultiPASS

or document supports.

C5000 as shown below.

power

paper

If something

before moving or cleaning it.

C5000, wait at

to extreme

plnce

with temperatures in the

during thunderstorms.

cord or place the

clips, or staples) to

does

fall into it, unplug

Irast

five

temperature

remove its

Ncvcr

L3J

cartridge.

lift it by its

swc

the

IBl-12

l-28

Page 43

Chapter 1: General Description

0

Unplug

Canon dealer or

l

l

l

l

l If the

l If the

FCC rules governing the use of fax equipment, require that you register

your fax number, your

in

the MultiPASS

User Information in the

the MulWASS

If

the

power cord or plug is damaged or frayed.

service

C5000 and

center in

co&+ct

your local authorized

any

of these situations:

If liquid spills into the unit, or if it is otherwise exposed to rain

liquids.

If you notice smoke or unusu~~l noises or odors coming from it.

If the

MulWASS

C5000 does not operate normally when you

follow the operating instructions. Adjust only those controls that

are covered by the operating instructions in this user’s guide,

or

you can damage the unit and require extensive repair work.

MultiPASS

M&PASS CSOOO

C5000 is dropped or

its

cabinet damaged.

begins performing poorly, and you

cannot correct the problem by using the procedures in Chapter 6,

“Trouhleshootinr.”

name or

C5000 before using it.

company name, and the date and time

For

instructions, see “Entering

MultiPASS

C5000”.

or

/

Ml-13

1-29

Page 44

Part 1: Facsimile

Choosing a Location for Your

MultiPASS

c5000

A

CaUtlon

Before unpacking your MultiPASS

choose the best location for it.

Please review the information provided in “Safety Instructions”, to

make sure you are installing your MultiPASS

Put the MultiPASS GO00 in a cool, dry, clean, well ventilated place:

0

l Make sure the area is free from dust.

.

Make sure the location is not affected by extreme

changes, and always stays between 50” and

32.5”C).

.

Make sure the area’s relative humidity is

and 90%.

Keep the MultiPASS

0

If possible, put the MultiPASS

0

outlet, to avoid the expense of installing a new one.

Place the MultIPASS GO00

0

A three-prong, grounded plug,

IIz) power. (This is standard for U.S. outlets; if you

contact an electrician to check the power for you.)

Place the MultiI’ASS GO00

0

Make sure you

fax machine, copier, scanner, and telephone.

Do not plug the MultiI’ASS

0

sppliancc

or copier. Such devices generate electrical noise that can interfere

with your MultiPASS

Set the MultiPASS

0

is strong enough to support its Ivcight (about 12.3

Make sure the locntian you choose provides

3

the MultiPASS

flow freely into and out of the unit. The figure below shows the

minimum space

such as an air conditioner, electric typewriter, television,

C5000

can

reach it easily, as

C5000’5

C5OOl)

C5000 tar adqtwte

required

C5000,

follow these guidelines to

C5OOO

away from

C5000 near

near

md that

war

CWOO

‘tbility to send or receive

on a flat, stable, vibration-free surface that

for the unit.

direct

an existing telephone

an electrical wall outlet that accepts

provides 120.volt AC

the PC you will be connecting it to.

you

will bc using it as a printer,

into the same circuit as an

ventilation, and to allow

for safe use.

Y0.5”F (10”

always

between 10%

sunlight.

have

lbs/5.6

enough

space around

temperature

and

(60

any doubts,

faxes.

kg).

paper

to

IB2-3

l-30

Page 45

Powering Up

Chapter 7: General Description

A

Ca”tlon o

Follow these guidelines when connecting your

power source:

The

MultiPASS CSOOO

only and requires 120 V AC. Do not use it outside the U.S. or

Canada.

Plug

the

0

prong grounded outlet.

Use only

0

cord or extension cord can cause the

malfunction.

Unplug the unit only by pulling on the plug itself.

0

cord.

Do not plug the

0

appliance such as an air conditioner, computer,

or copier. These devices generate electrical noise, which can

interfere with the

Make sure nothing is

0

cannot be walked on or tripped over.

Do not overload the electrical outlet. Make sure the total amperage

0

used by all

ampere rating of the outlet’s circuit

Make

0

properly closed, and that there are no documents in this

MultiPASS

the power

the

machines plugged into the outlet does not exceed

sure

that the operation

is intended for use in the U.S. and Canada

GOtlO only into a

cord that

MultiPASS

MultIPASS C5OOO’s

laying on

came

with the unit. Using a longer

C5000 into an outlet shared with an

the power cord, and that the cord

paw1

of the

MultiPASS

120-v&

MultiPASS C.5000

operation.

breaker.

AC, 60-H&

Never

elfctric

MultiPASS

C5000 to a

to

typewriter,

C5000 is

threc-

pull on the

the

arm

1-31

182-22

Page 46

Part

1:

Facsimile

5.2.2 BJ cartridge cautions

a) General cautions

Selecting and Installing a BJ Cartridge

Canon offers a number of Bubble Jet

of printing requirements. (The

BC-2.1 or

the best BJ cartridge for your needs, as well as how to install and

maintain

BC-2le

the

cartridge.

Color BJ cartridge.) This section describes how to

(BJ)

MultiPASS

cartridges to meet a wide range

C5000 comes with one

select

Guidelines for Using and Maintaining BJ Cartridges

The most important thing you can do to ensure the best possible print

quality, as well as extend the life of your

care of the

M&PASS C5OOo’s

Store cartridges at

Keep

cartridges in their staled containers until you are ready to

them.

Install the cartridge immediately after removing its print head cap

and protective tape.

Always use the cartridge within

When changing cartridges, always

SB-21 BJ cartridge container that

Do not remove the cartridge from the

necessary.

room

BJ cartridges following these guidelines:

temperature.

-

The ink in the BJ cartridges is difficult to

spilling ink, always bc

the

cartridges:

0

Do not attempt to

IL!

Do not shake or drop the cartridge, or tip the print head downward.

0

Kwp

BJ

cxtridgcs

sure

to follo~v these

dis,lswnblc or refill lhe

out of

~h~ldrcv~‘s

MultiPASS

one

year of unpacking it.

store

the unused cartridge in

comes

with the

MultiPASS

clenn

prccnutions when

reach

C5000, is to take

up if spilled. To avoid

cartridge.

MultiPASS

C5000 unless

C5000.

handling

USC

the

lB2-24

l-32

Page 47

Chapter 7: General Description

Hold the BJ cartridge by its

sharp edges around the print head, the silver plate on the bottom of the

cartridge, or the silver metal or circuit area on its

0

Make

sure

the BJ cartridge holder is in its home position (on the

right side of the unit) when you are not using the

If it is not in its home position, press the CARTRIDGE button.

Leaving it out of its home position will dry out the print head on the

cartridge.

0

Clean the print head when print quality is no

“Cleaning and Testing the BJ Cartridge Print Head” for instructions.

If

the print quality does not improve after five consecutive

cleanings, replace the ink tank or BJ cartridge.

0

Do not use a

tanks missing. Doing so can cause it to clog.

Cl

Do not remove the ink tanks from the

unnecessarily, or the ink in

n

Never attempt to refill an

BC-21/21e

sides

only. Do not touch the print head, the

side.

MultiPASS

longer

satisfactory. See

Color BJ cartridge with either of its ink

BC-21/21c

them

may clog.

empty cartridge.

Color BJ cartridge

C5000.

1-33

182-25

Page 48

Part 1: Facsimile

Maintaining BJ Cartridges

Cleaning and Testing the BJ Cartridge Print Head

One of the most important elements in maintaining your MultiPASS

C5OOO’s

regularly, and to replace the BJ ink cartridges and

needed.

The print head in the BJ print cartridge contains nozzles through which

ink is propelled onto the paper. To maintain the best possible print

quality, these nozzles need to be rleaned from time to time. Your

MultiPASS C5000 is equipped with a print head cleaning function that

does this.

If your printouts become faint or streaked, or if their quality otherwise

decreases, clean the print head as

If your printing is faded, you can often correct the problem by adjusting

the print density (contrast) and printing speed. (For instructions, see

MultiPASS

cleaning the print head.

excellent print

Drsktop Mmqcrfor Wirtdows” USEI’S Guide.)

quality

is to clean the

dcscribcd

BJ

below.

cartridge’s print head

tanks

promptly when

Try this hefore

the

Cleaning the print

significantly reduces

when necessary.

1.

2. Press

‘0<20> ..

‘3

head

uses a small amount of ink. Cleaning too often

the

amount of ink in the cartridge, so clean only

Make sure the MultiPASS

IWNCTION.

I’ress

< or > tu

s&<~t

CLEANING

(‘LEANING

C.3100

is plugged in.

187-7

l-34

Page 49

5.

Chrck

whether cleaning corrected the problem by printing

copying a document.

6.

If necessary, repeat this procedure up to four more times (giving five

cleanings in all). If the problem persists after this, install a new BJ

cartridge.

When to Replace the BJ Cartridge

Chapter 1: General Description

01

How frequently you need to replace your

cartridge or one of its ink tanks depends on how you use your

MultiPASS

grayscales, you will need to replace the cartridge more often than if you

print mainly text.

To

help ensure the maximum

guidelines for cartridge maintenance given in “Guidelines for Using and

Maintaining BJ Cartridges”.

In general, you will need to replace the

situations:

C5000. If you print a good deal of graphics, halftones, or

life for your cartridges, always follow the

If you have been using a UC-21/21e Color BJ cartridge for over six

months or the BC-20 Black BJ cartridge for over a year.

If your printed output is not crisp and clrnr or has gaps in the

characters (missing dots),

five times as described above.

If your color printouts appear to bc missing n color,

have cleaned the print head five times as described above.

even a&r

MultiPASS C5OOO’s

13J

cartridge in the following

you have cleaned the print head

cvcn

BJ

after you

.

1-35

IB7-8

Page 50

Part 7: facsimile

Cl

If you are using the BC-21/21e Color BJ cartridge and your output is

blank, one of the ink tanks is probably empty and needs to be

replaced. Print the NOZZLE CHECK test pattern to check whether

the BJ cartridge needs replacing or not.

0

If the

mcssagr

Cl IANGE CARTRIDGE appears in the LCD display,

the BJ cartridge may have run out of ink. This message also appears

if the MultiPASS C5000 has to store a fax in its memory because the

cartridge is out of ink.

If this message appears, do the following:

1.

Press START/COPY to print any faxes in memory.

l If the printout appears normal, you do not need to replace

the BJ cartridge. (Sometimes cleaning the print head or re-

installing the cartridge will clear up the problem.)

l If the print is light or shows gaps, go to step 2.

2.

If there was no fax in memory, or if the fax’s print was light,

blank, or showed gaps, print or copy a document to make sure

the problem is not with the machine that sent the fax.

3.

If

the

document is light, blank, or shows gaps, clean the printing

area. If this doesn’t work, replace the cartridge.

Althou+

Canon makes numerous BJ cartridges, the BC-21/21e Color BJ

cartridge, the BC-20 Black BJ cartridge, the BC-22/22e Color Photo BJ

cartridge, and the BC-29F Fluorescent BJ cartridge are designed

specifically for Canon’s color BJ printers, and are the only ones Canon

recommends.

Also, the

spccificnlly

C.1non

BCI-21

Color and

fc,r

tllc BC-21/21e Color BJ cartridge, and are the only

rcctlmmc!ld~ for the

BCI-21

Black ink tanks nrr designed

BC-2: /21e.

one’s

187-9

. l-36

Page 51

Storing BJ Cartridges

Once a BJ cartridge is unwrapped, its print head must be kept from

drying out, or it can clog and fail to work properly. A cartridge installed

in the

MultiPASS

moving to the home position at the right side of the unit and capping

itself.

If

you remove a partially used BJ cartridge from the

store it in the 33-21 BJ cartridge container that came with your unit.

1.

Insert the cartridge in the container with the cartridge’s label facing

forward, and the print head down.

C5000 is

protected

Chapter 1: General Description

from drying out by automatically

MultiPASS

C5000,

2.

Close the container lid, and

snap

it shut

182-33

1-37

Page 52

Part 1: Facsimile

b) Unpacking the BJ cartridge

Do not open the BJ cartridge packaging unless you are ready to install the new BJ

cartridge. Before installing the BJ cartridge, gently remove the orange head cap and the

orange protective tape from the nozzles.

NOTE

Storing an opened BJ cartridge

If the BJ cartridge packaging has been opened and the BJ cartridge is not

to be installed immediately, store the cartridge in the SB-21 cartridge

container, to prevent the printing

As much as possible, do not open the packaging until the BJ cartridge is to

be installed immediately.

._

bead

from drying out and clogging.

Photo BJ Cartridge

Figure 1-16 Unpacking the BJ Cartridge

1

Tape

1-38

Page 53

Chapter 7: General Description

c) Protecting the ink nozzles

Do not touch or wipe the ink nozzles with tissue paper, etc. Doing so can clog the nozzles.

If the head cap and

installed immediately, store the cartridge properly to prevent the nozzles from drying out

and clogging.

Do not disassemble the BJ cartridge. Also, the BJ cartridge contains electronic circuitry.

Do not wash it with water.

Black BJ Cartridge

protective

tape

have

been removed and the BJ cartridge is not to be

Color BJ Cartridge

Photo BJ Cartridge

Figure l-17 Ink Path Cartridge

d) Ink conductivity

The BJ cartridge ink can conduct electricity. If ink has leaked onto any mechanical parts,

wipe off with a damp paper towel.

paper and carefully wipe off the ink completely even at

Never

turn on the power while ink still remains on

so may damage the circuit?.

If ink has leaked onto the circuit board, use

the base

of

the

IC chips.

the

circuit board. Doing

tissue

A

1-39

Page 54

Part 1: Facsimile

5.2.3 Ink cartridge cautions

a)

General cautions

Refer to a) General cautions on Page

b) Unpacking the ink cartridge

Do not

cartridge. Before installing it in the RJ cartridge, remove the protective cap from the ink

inlet.

I-27.

open

the ink cartridge packaging unless you are ready to install the new ink

Cap

\

Figure 1-18 Removing Cartridge Cap

l-40

Page 55

Chapter 1: General Description

c) Preventing ink clogging

Do not touch the ink cartridge’s ink outlets. Doing so may introduce foreign matter into

the printing head’s joint pipes, causing poor ink suction. After removing the cap from the

ink cartridge, immediately install the ink cartridge in the printing head to prevent the ink

at the nozzles from drying out and clogging. Do not remove the ink cartridge except when

it is to be replaced.

Color Ink Cartridge

Yellow

Ink Outlet

Black Ink Cartridge

Cyan Ink Outlet

(Contact Section

of

the Joint Pipe)

NOTE

‘Black Ink Outlet

(Contact Section

of the Joint

Pope)

Figure 1-19 Ink Outlet

If the ink nozzles are clogged or if

have horizontal white stripes. If the cleaning operation

to norm;ll, replace the RJ cartridge.

the

ink suction is poor, the printout may

does

not restore it

1-41

Page 56

Part 1: Facsimile

5.3 Servicing Cautions

5.3.1 Damage from static charge

This unit contains contact

custom chips, etc.

charge.

When disassembling this unit, take care to prevent static charge.

sensors

Thrsc clrctronic

printed

and

components are susceptible to damage caused by

Static electricity

Static

chnmctcristics. F,vcn

can generate damaging static charge.

charge

damage

can

plastic tools and hands without grounding wrist straps

electronic components or alter their electrical

circuit boards equipped with ROM, RAM,

stalic

l-42

Page 57

5.3.3

Print assembly

Chapter 1: General Description

BJ

Cartridge _

Figure l-20 Print Assembly Precautions

l-43

Page 58

Part 1: Facsimile

a) General precautions

Head gap

The head gap is the distance between the BJ head and the platen. It has been

adjusted. If the carriage guide frame

head gap must be adjusted. This may affect the printing quality.

fastened

factory-

to the printer frame is repositioned, the

5 :

L

@

REFERENCE

Lubrication points

Do not touch the greased parts of the carriage guide frame, carriage shaft, idler roller

and

some

operation of the printer unit.

b

- -

&

NOTE

--

r

z -

&J

REFERENCE

spurs

During

spur tips

causing

Carriage

Dn mkgnr

disrupt the cable’s continuity and prevent the printing signals to be sent properly to the

cartridge.

If the printing quality has degraded due to a change in the head gap, see

%

Chapter

parts. Doing so will wipe off the grease which has been applied for the smooth

Do not apply grease to any unspecified parts and surfaces. If grease is on

z

the purge section’s rubber cap or the wiping assembly’s blade, it may cause

the BJ cartridge’s nozzles to clog, rendering the BJ cartridge unusable.

Also. do not use any

type of grease may dissolve or deform plastic parts.

r

I-

If you accidentally

PARTS CATALOG

servicing, be

are

deformed, the

vertical

ribbon cable assembly

3: 3.3

Head Gap Adjustment on Page

-.

car&l

not to

ax%

black stripes on

3-10

to adjust the head gap.

grease

other than the specified type. Using a different

touch n

(provided separately).

of

the

the

paper.

greased surface, reapply the grease. See the

damage

ribbon

or deform the spur assembly’s spur tips.

paper coming into contact after the printing increases,

cable more than is necessary. Doing so may

If the

Power off during printing

During servicing, do not

the cartridge is being replaced. Otherwise, the cartridge will stop at a position

the ink nozzles cannot be

the nozzles. During servicing, be sure

capping.

disconnect

protrct,ed

the

powcr

cord during a printing operation or while

by the rubber cap. The ink may then dry and clog

the

cartridge is properly positioned for nozzle

l-44

where

Page 59

Chapter 7: General Description

5.3.4

Paper feed section

a) General precautions

Setting the paper

For fax operations, the user sets the paper size with the

for Windows, The unit cannot detect the paper size automatically. Therefore, if the

paper size is altered during servicing, be sure to set it back to the user’s paper size

setting.

A

sire

MultiPASS

If the paper size setting does not match the size of the paper installed. One

of the following two operations will be executed:

(A)

If the paper size setting is the same or smaller than the actual size of

the paper installed. the following will be executed:

The document will be printed to

has been set.

Even if the paper size setting is smaller than the actual paper size,

printing will be executed and no error will result. Depending on the

document, large blank areas may result on the printout.

(B)

If the paper size setting is larger than the actual paper size, the

following will be executed:

As with

size that has been set. Since the actual paper size is shorter than the

paper size setting, the document’s contents would be broken up to fit

the paper size setting. “CHECK PAPER” will therefore be displayed

and printing will be canceled.

(A),

the document will be printed to fit the length of the paper

fit

the length of the paper size that