Canon imageRUNNER ADVANCE C7580i II, imageRUNNER ADVANCE C7565i II, imageRUNNER ADVANCE C7570i II Advance Maintenance Manual

Preventative Maintenance Procedure

Last update 04/27/2018

Pre-Visit

Service

History Check

Common

Process

(Before)

Maintenance

Process

Common

Process

(After)

Purpose

Increase following items.

FCFR

Uptime

MCBV

Customer Satisfaction

How to use

This document was developed by Canon USA Engineering Services and Solutions to

perform consistent, effective and efficient maintenance on all Canon products.

FCFR, MCBV,

Uptime

Parts Cost

Visits, Labor

Implementation of the Preventative Maintenance Procedure

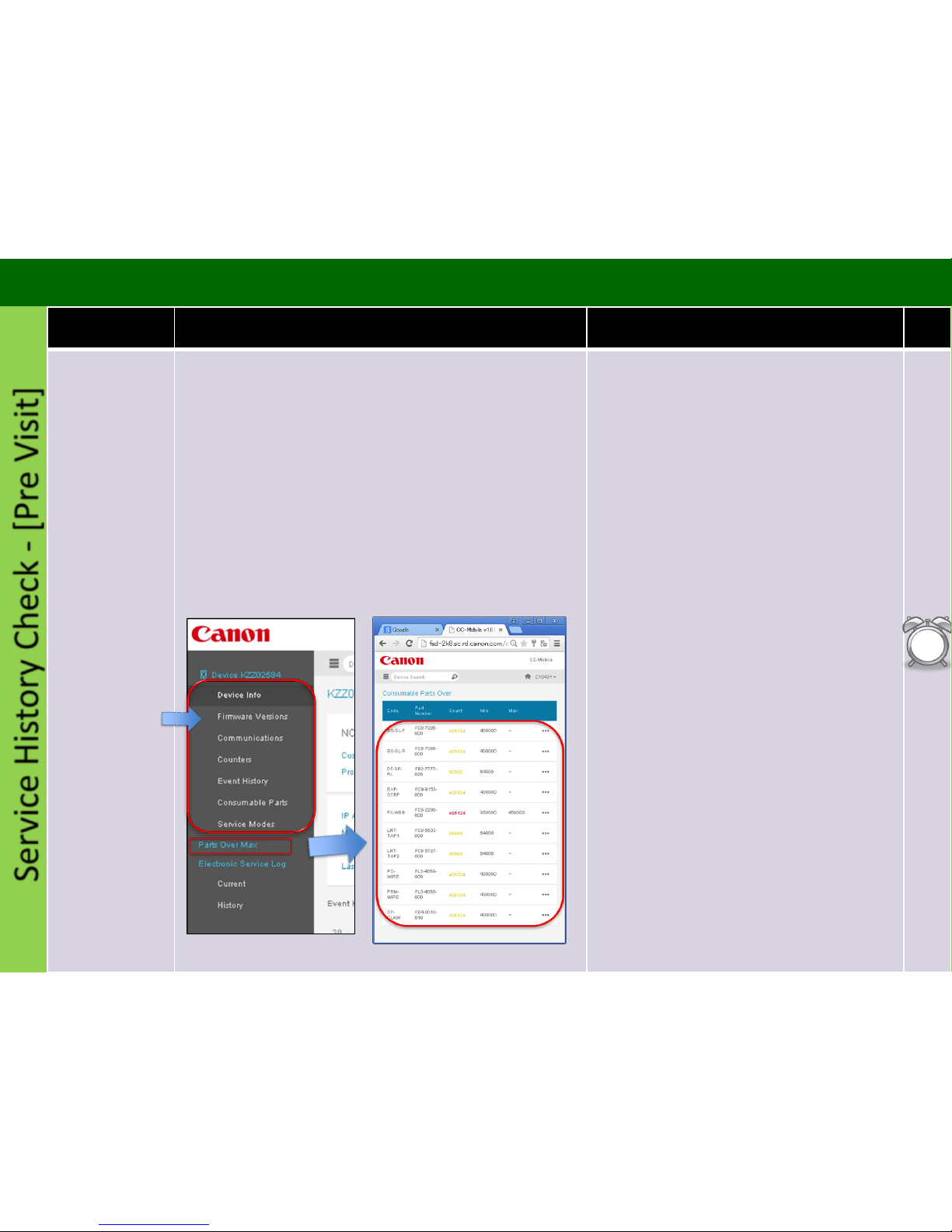

Service History Check - [Pre Visit]

Procedure Detail Note Time

Action Prior to

Customer Visit:

Whenever

possible,

Check Snapshot

for :

6

min

Check

1. Log into Snapshot :

• Enter the machine Serial Number to check the

following:

1. Firmware Version – Prepare Firmware if necessary

2. Communications

3. Counters – Machine Usage

4. Event History – Check History for Errors, Alarms

and Jams

5. Consumable Part Counters -

Prepare Consumable and Durable

Parts

6. Service Modes

ITB Belt Position [disp_misc ITB-POS]

• Firmware Version

• Event History

• Part Counters

• Service Mode Settings

iRADV C7580i/C7570i/C7565i Advance Maintenance Guide

1. Understand the machine's current condition

(jams and error, needed consumable parts) before

visiting EM call or PM-Call.

2. Prepare all consumable parts that exceeded

Target and replace them on a PM-call, replace any

parts that exceeded life you have now at the EM

call.

3. Take the necessary actions for the jamming and

errors.

Common Process (Before)

Procedure Detail Note Time

Verify Customers’

Concern

Ask the customer about the condition of the machine

and validate any issues they have.

Ask Questions to find out if there are any following

issues on the machine?

1.Copy Quality

2.Jamming

3.ERROR

4.Other issues (Copier Only)

5.No Problem

Point:

- To perform efficient maintenance, we need to

ask the customer about machine condition.

Check the Serial

Number

Ensure the serial number on the machine matches the

serial number that you are dispatched to.

Point:

- If the serial number is incorrect and there is

more than one machine at the account that is

down please notify dispatch.

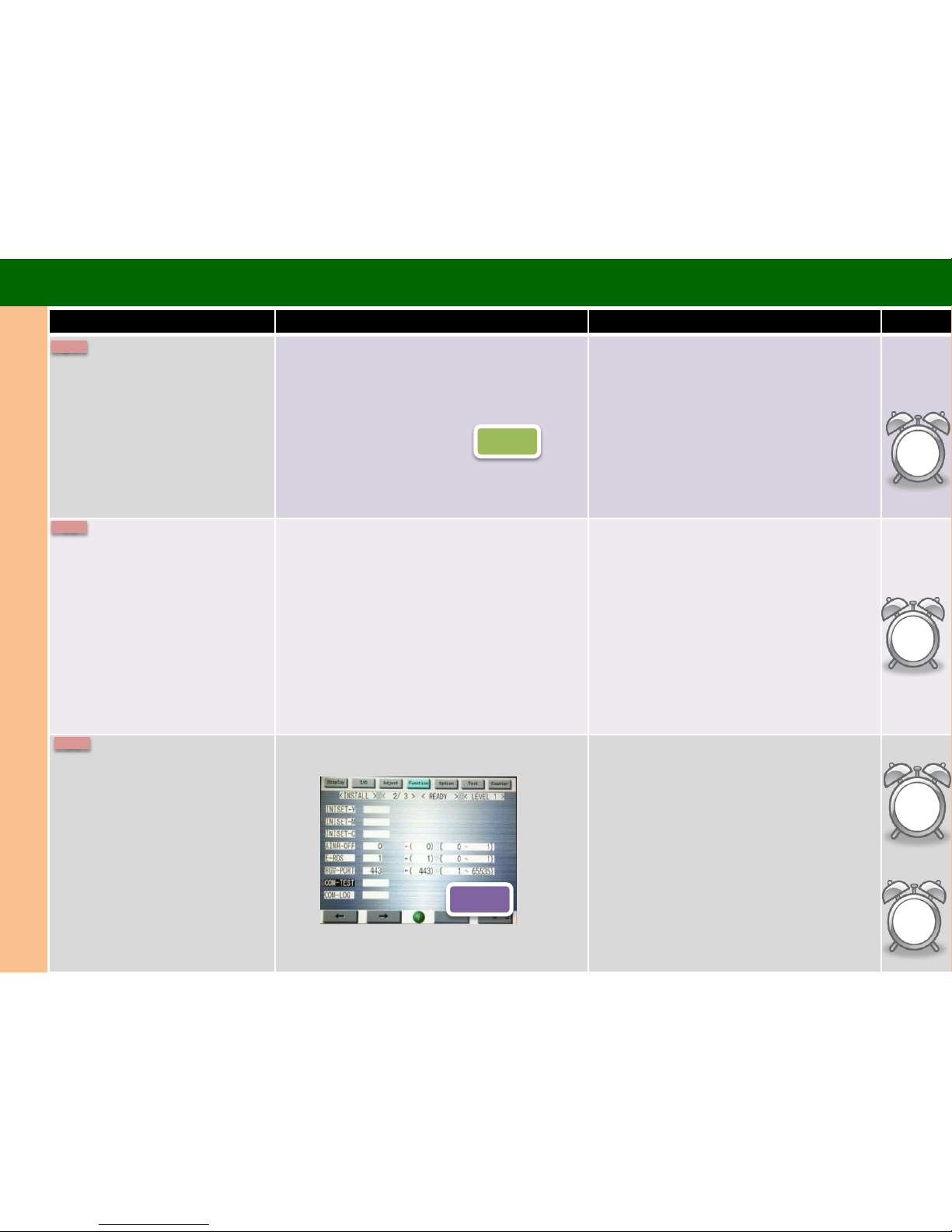

Perform COM-TEST

COPIER > Function > INSTALL>COM-TEST If COM-TEST is NG, fix this issue at first. If you can’t

fix this issue please insure the issue is resolved

prior to leaving the account.

C1

1

min

Check

1

min

Scan

Check

COM TEST

1

min

Check

1

min

COM TEST

C2

C3

iRADV C7580i/C7570i/C7565i Advance Maintenance Guide

Procedure Detail Note Time

Check Service Log

1. Check Service Log Point:

1. Check the log to see if there is any reoccurring

issues. If you see the same issues listed on the

log, then the root cause hasn’t been fixed.

2. Check what parts were replaced recently. These

parts should not be replaced again for the same

issue.

3. If the problem seems to be related to the

previous call, check what the previous tech did.

Check Service History

1. Check ERR/JAM/ALARM history

Address all Error and Jams.

Check

COPIER>DISPLAY>ERR

COPIER>DISPLAY>JAM

COPIER>DISPLAY>ALARM

Visual Check

Visual Check

Check

Update

1

min

20

min

1

min

1

min

Check System

Software Version

Check System Software Version

COPIER>DISPLAY>VERSION

Check for latest version on e-support and

recommend to update the system software to

latest version.

Point

Check

Update

Check

The latest firmware version should be installed on the

machine. Please visit e-Support for the latest version.

Common Process (Before)

C6

C5

C4

iRADV C7580i/C7570i/C7565i Advance Maintenance Guide

If Snapshot was used

successfully, skip steps C5

through C8

If Snapshot was used

successfully, skip steps C5

through C8

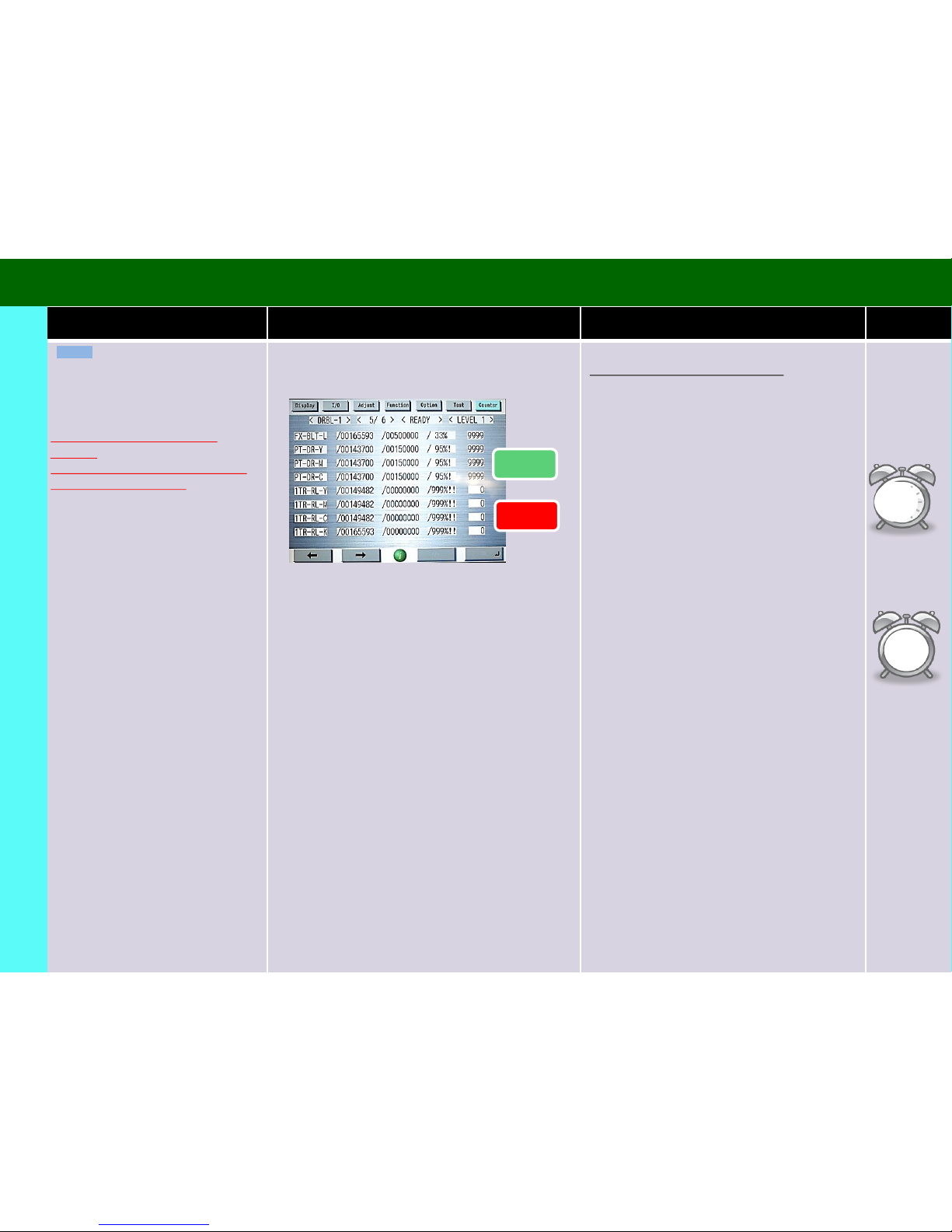

Procedure Detail Note Time

Check the Image

Formation Counters

*Reset the counters if parts are

replaced.

*Check that physical condition of the

part matches the counter

1. Check the Drum, Corona and Cleaning Blade

counters.

Point:

*Replace any parts at or above 100%

Drums and Developer may exceed rated life, change

based on counter, print quality and customer needs

Check the P/U Roller

Counters

*Reset the counters if parts are

replaced

*Check that physical condition of the

part matches the counter

Check the roller counters.

Point:

*Replace any rollers at or above 100%

Cassette 1,2,3,4, Bypass: COPIER>COUNTER>DRBL-1

C1/C2/C3/C4 - SP/FD/PU-RL

M-SP-RL

M-FD_RL

Multi Drawer Deck: COPIER>COUNTER>DRBL-2

PD-PU/SP/FD-RL (Upper Deck)

PD-PU/SP/FD-R2 (Middle Deck)

PD-PU/SP/FD-R3 (Lower Deck)

ADF: COPIER>COUNTER>DRBL-2

DF-PU-RL

DF-FD-RL

DF-SP-RL

LNT-TAP1

LNT-TAP2

COPIER>COUNTER>DRBL-1

COPIER>COUNTER>DRBL-2

Visual Check

1 min

Replace

10

min

Replace

10

min

Developer

COPIER>COUNTER

DRBL-1>DV-UNT-C

DRBL-1>DV-UNT-Y

DRBL-1>DV-UNT-M

DRBL-1>DV-UNT-K

Coronas

COPIER>COUNTER

PRDC-1 >PRM-WIRE

PRDC-1 >PRM-CLN

PRDC-1 >PRM-CLN2

PRDC-1 >PO-WIRE

PRDC-1 >PO-CLN

PRDC-1 >PO-CLN2

PRDC-1 >PRM-GRID

PRDC-1 >GRID-PAD

Drum

COPIER>COUNTER>LF

Y-DRM-LF = %

M-DRM-LF = %

C-DRM-LF = %

K-DRM-LF = %

Visual Check

1

min

Check

Replace

Replace

Check

Drum Cleaning

COPIER>COUNTER

DRBL-1 >CLN-BLD

SU-SHT-K

EDGE-F-K(2)

If Canon Snapshot tool was

used successfully, skip

steps C5 through C9

Common Process (Before)

C7

C8

iRADV C7580i/C7570i/C7565i Advance Maintenance Guide

If Snapshot was used

successfully, skip steps C5

through C8

Procedure Detail Note Time

Check Transfer, Fixing

and Filter Counters

*Reset the counters if parts are

replaced

*Check that physical condition of the

part matches the counter

1. See the Parts counter.

COPIER>COUNTER>DRBL-1

COPIER>COUNTER>PRDC-1

Point:

Replace any parts at or above 100%

COPIER>COUNTER>DRBL-1/PRDC-1

ITB/2nd Transfer

2TR-ROLL

TR-BLT

2TR-INRL

1TR-RL-Y

1TR-RL-M

1TR-RL-C

1TR-RL-K

TR-STC-H

ITB-BLD-1

ITB-SCRP

Fixing

FX-BLT-U

FIX-TH1

FIX-TH2

Replace

60

min

Visual Check

1

min

Check

Replace

Filters

TN-FIL1

OZ-FIL1

OZ-FIL2

If Snapshot tool was used

successfully, skip steps C5

through C9

FX-WEB ( 1 to 4)

FX-L

FX-UH-RL

C9

Common Process (Before)

iRADV C7580i/C7570i/C7565i Advance Maintenance Guide

Procedure Detail Note Time

Make Samples (Before

Sample)

Take following Print/Copy samples. Copy from ADF and

Copy Glass.

PG5(Y,M,C,K) PG10 CA-8

If you find following PCQ, check the ADV Topics.

Test Paper Feed

Take copies from All Cassette at least 5 each from ADF.

Take copies from following cassette.

Point:

Make following jobs.

1.Double sided

2.Staple

3.Hole punch

If the machine jams, find the cause and fix that

issue.

PCQ

If you find following PCQ

1. Lines when using ADF - See iRADV Topic 2012

Archive C5000 Topic 13- Paper Feed Lines When

Scanning Originals via DADF (White Lines)

1. Cassette 1

2. Cassette 2

3. Cassette 3

4. Cassette 4

5. Bypass Tray or Paper

Deck

Perform C10 and C11 at the same time to save time

Check

5

min

1. Black band on 2nd side

2. Light or missing image on

rear side from developing

roller coating failure

3. White band

4. White line

5. White spots (Y, M or C)

6. Color Displacement (Main

or Sub scanning direction)

Check

Check

Check

Make sample copies on

“12x18” or larger size paper if

the customer utilizes them to

check for CQ issues on the

front and rear ends on the

copies.

Common Process (Before)

C10

C11

iRADV C7580i/C7570i/C7565i Advance Maintenance Guide

Loading...

Loading...