COPYRIGHT© 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

FEB.1999

FY8-13FJ-000

REVISION 0

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

COPYRIGHT © 1999 CANON INC.

Printed in Japan

Imprimé au Japon

Use of this manual should be strictly

supervised to avoid disclosure of confidential information.

IMPORTANT

THE INFORMATION CONTAINED HEREIN IS PUBLISHED BY CANON INC., JAPAN.

SPECIFICATIONS AND OTHER INFORMATION CONTAINED HEREIN MAY VARY SLIGHTLY

FROM ACTUAL MACHINE VALUES OR THOSE FOUND IN ADVERTISING AND OTHER PRINTED

MATTER.

ANY QUESTIONS REGARDING INFORMATION CONTAINED HEREIN SHOULD BE DIRECTED TO

THE COPIER SERVICE DEPARTMENT OF THE COMPANY.

Prepared by

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DEPARTMENT 3

OFFICE IMAGING PRODUCTS TECHNICAL SUPPORT DIVISION

CANON INC.

7-5-1, Hakusan, Toride-shi, Ibaraki 302-8501 Japan

Download free service manual at http://printer1.blogspot.com

This Service Manual contains basic data and figures on the color printer needed to

service the machine in the field.

This machine consists of the following system units:

1. Reader unit

2. Editor

3. Original holder

4. Printer unit

5. Duplexing unit

6. R cassette

7. PS/PCL board*

* Remains disabled when the printer unit is used in a copier mode.

For the reader unit, duplexing unit, R cassette, and PS/PCL board, refer to their

respective Service Manuals. This manual covers the printer unit, duplexing unit, and R

cassette, and consists of the following chapters:

Chapter 1 General Description introduces the machine’s features and specifications,

shows how to operate it, and explains how copies are made.

Chapter 2 Basic Operation provides outlines of the machine’s various mechanical

workings.

Chapter 3 Laser Exposure System discusses the principles of operation used for the

mechanical/electrical operations of the machine’s laser system. It also explains the timing at which the various units involved are operated, and shows how they may be disassembled/assembled and adjusted.

Chapter 4 Image Formation System discusses the principles of how images are

formed. It also explains the timing at which the various units involved in image formation

are operated, and shows how they may be disassembled/assembled and adjusted.

Chapter 5 Pick-Up/Feeding System discusses the principles of how the printer unit

picks up and moves paper inside it. It also explains the timing at which the various units

involv ed are operated, and sho ws how the y ma y be disassemb led/assembled and adjusted.

Chapter 6 Fixing System discusses the principles of how the printer unit fuses toner

images to paper.It also explains the timing at which the various units involved are operated, and shows how they may be disassembled/assembled and adjusted.

Chapter 7 Externals/Auxiliary Mechanisms shows the machine’s external par ts, and

explains the principles used for the machine’s various control mechanisms in view of the

functions of electrical and mechanical units and in relation to their timing of operation. It

also shows how these units may be disassembled/assembled and adjusted.

Chapter 8 Installation introduces requirements for the site of installation, and shows

how the printer unit may be installed using step-by-step instructions.

Chapter 9 Maintenance and Servicing provides tables of periodically replaced parts

and consumables/durables and scheduled servicing charts.

i

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

INTRODUCTION

Download free service manual at http://printer1.blogspot.com

Chapter 10 Troubleshooting provides tables of maintenance/inspection,

standards/adjustments, and problem identification (image fault/malfunction).

Appendix contains a general timing chart and general circuit diagrams.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the

relationship between electrical and mechanical systems with reference to the timing

of operation.

In the diagrams, represents the path of mechanical drive-where a signal name

accompanies the symbol →, the arrow indicates the direction of the electric signal.

In the digital circuits, ‘1’ is used to indicate that the voltage level of a given signal is

“High,” while ‘0’is used to indicate “Low.” (The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in “DRMD*” indicates that the DRMD signal goes on when ‘0’.

The expression “turn on the power” means flipping on the power switch, closing the

front door, and closing the delivery unit door, which results in supplying the machine

with power.

2. In practically all cases, the internal mechanisms of a microprocessor cannot be

checked in the field. Therefore, the operations of the microprocessors used in the

machines are not discussed: they are explained in terms of from sensors to the input

of the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and major changes will be communicated in the

form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this

Service Manual and all relevant Service Information bulletins and be able to identify and

isolate faults in the machine.

Reference:

Reader Unit Service Manual: FY8-13FH-000

PS/PCL Board Service Manual: FY8-13FK-000

ii

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download free service manual at http://printer1.blogspot.com

FOREWORD

System Configuration

This printer unit is designed to accommodate the following accessories:

• Upper 500 Sheet Cassette CS-82 A4R/A5R/B5R/LTRR*1

• Duplex Unit-A1 *1

• 1000-Sheet Paper Deck-D1 *2,3

• 2×500-Sheet Paper Deck-C1 *2,3

• 2000-Sheet Paper Deck-N1 *2,3

• ACC Controller-A1 *2,3

• ACC Interface Board-B1 *3

• ACC Interface Unit-B1 *3

(ACC controller-A1, ACC Interface Board-B1 and Plate)

• Sorter-H1 (requires the Attachment Kit for STR-H1 if the printer unit is mounted to

a Rack-A1) *2, *3

• Network Color PS/PCL Board-A1 *2

• Token Ring Board TB83

*1: Covered in this Service Manual

*2: Covered in a separate Service Manual.

*3:

If the printer unit is installed as a copier,

• Requires the ACC Interface Unit-B1,

• Requires the ACC Controller-A1.

If the printer unit is installed as a copier and a printer,

• Requires the ACC Controller-A1 and the ACC Interface Board-B1.

iii

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download free service manual at http://printer1.blogspot.com

Download free service manual at http://printer1.blogspot.com

v

CONTENTS

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES ..............................................1-1

II. SPECIFICATIONS....................................1-2

A. Pr inter Unit.........................................1-2

III. SAFETY OF LASER LIGHT.....................1-6

IV. NAMES OF PARTS..................................1-7

A. External View.....................................1-7

B. Cross Section ...................................1-11

V. USING THE CONTROL PANEL.............1-13

VI. NOTES T O THE USER..........................1-15

VII. NOTES TO THE SERVICE PERSON....1-16

A. Stor ing the Drum Cartridge and the

Toner Cartridges ..............................1-16

B. Points to Note When Handling the

Drum Cartr idge and the Toner

Cartridges ........................................1-18

VIII. IMAGE FORMATION .............................1-20

A. Outline..............................................1-20

B. Latent Static Image Formation

Block ................................................1-22

C. Development Block ..........................1-25

D. Transfer Block ..................................1-27

E. ITD (inter mediate transfer drum)

Cleaning Block.................................1-31

F. Photosensitive Drum Cleaning.........1-33

G. Fixing Block......................................1-34

CHAPTER 2 BASIC OPERATION

I. BASIC OPERATIONS ..............................2-1

A. Functional Constr uction .....................2-1

B. Electr ical Circuitr y..............................2-2

C. Inputs to and Outputs of the Major

PCBs..................................................2-3

D. Basic Sequence of Operations (used as

a printer)...........................................2-14

E. Controlling the Main Motor ...............2-19

CHAPTER 3 LASER EXPOSURE SYSTEM

I. OUTLINE..................................................3-1

II. LASER CONTROL CIRCUIT...................3-3

A. Outline................................................3-3

B. Image Signal Processing ...................3-5

C. Controlling the Laser Intensity...........3-6

D. Horizontal Sync Control.....................3-7

E. Controlling the Laser Diode

Emission ............................................3-8

III. LASER SCANNER MOTOR.....................3-9

A. Controlling the Laser Scanner

Motor..................................................3-9

IV. FAULT IN THE LASER SCANNER........3-11

V. DISASSEMBLY/ASSEMBLY ..................3-12

A. Pr inter Unit Exter nal Covers............3-13

B. Door Switch Actuator .......................3-22

C. Laser/Scanner Assembly.................3-25

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

vi

CHAPTER 5 PICK-UP/FEEDING SYSTEM

I. OUTLINE..................................................5-1

A. Outline................................................5-1

II. PICK-UP ASSEMBLY ...............................5-3

A. Pick-Up from the Cassette.................5-3

B. Pick-Up from the Multifeeder Tray ....5-16

C. Controlling the Pick-Up Motor ..........5-19

III. FEEDING/DELIVERY ASSEMBLY.........5-21

A. Outline..............................................5-21

IV. DUPLEXING UNIT.................................5-22

A. Outline..............................................5-22

B. Reversing Operation........................5-25

C. Horizontal Registration

Adjustment.......................................5-26

D. Re-Pickup.........................................5-28

V. DETECTING JAMS................................5-29

A. Detecting Jams in the Printer Unit...5-29

B. Detecting Jams in the Duplexing

Unit...................................................5-32

VI. DISASSEMBLY/ASSEMBLY ..................5-34

A. Pick-Up Assembly............................5-35

B. Delivery Assembly ...........................5-39

C. Feeding Assembly............................5-40

D. Registration Roller Assembly...........5-40

E. Multifeeder Pick-Up Assembly.........5-42

F. Multifeeder Tray Pick-Up Roller........5-44

G. Multifeeder Tray Separation Pad......5-45

H. Cassette Pick-UP, Feeding, and

Separation Rollers ...........................5-45

I. PCBs................................................5-46

CHAPTER 4 IMAGE FORMATION SYSTEM

I. OUTLINE..................................................4-1

A. Constr uction.......................................4-1

B. Operations..........................................4-2

II. FORMING LATENT STATIC IMAGES......4-5

A. Outline................................................4-5

B. Dr um Car tr idge Memor y....................4-6

C. Checking the Life of the Photosensitive

Drum ..................................................4-8

D. Monitoring the Waste Toner Case......4-9

III. DEVELOPMENT....................................4-10

A. Outline..............................................4-10

B. Controlling the Developing Rotary...4-12

C. Locking the Developing Rotary........4-14

D. Detecting the Absence of the Toner

Cartridges ........................................4-14

E. Detecting the Level of Color Toner...4-16

F. Checking the Presence/Absence of a

Color Toner Cartridge.......................4-17

G. Checking the Level of Black Toner and

the Presence/Absence of the Black

Toner Cartridge................................4-17

IV. TRANSFER ............................................4-18

A. Outline..............................................4-18

B. Locking the Secondary Transfer

Belt...................................................4-19

C. Controlling the ITD Cleaning

Roller................................................4-20

V. IMAGE STABILIZATION CORRECTION

CONTROL..............................................4-21

A. Environmental Changes Correction

Control .............................................4-21

B. Image Density Correction Control (maxi-

mum density control)........................4-21

C. Image Gradation Correction Control

(requires a PS/PCL Board)..............4-22

D. Detecting the Density.......................4-23

VI. HIGH-VOLTAGE POWER SUPPLY

CIRCUIT.................................................4-24

A. Outline..............................................4-24

B. High-Voltage PCB 1.........................4-26

C. High-Voltage PCB 2.........................4-30

D. Separation Static Eliminating Bias

PCB..................................................4-33

VII. OTHER CONTROL MECHANISMS.......4-34

A. Developing Rotary Motor Control ....4-34

B. Controlling the Cartridge Motor .......4-36

C. Controlling the Drum Motor..............4-37

VIII. DISASSEMBLY/ASSEMBLY ..................4-38

A. Dr ive System....................................4-39

B. Charging, Developing, and

Cleaning...........................................4-45

C. PCBs................................................4-53

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

vii

CHAPTER 6 FIXING SYSTEM

I. OUTLINE..................................................6-1

II. FIXING CONTROL CIRCUIT ...................6-2

A. Controlling the Fixing Temperature....6-2

B. Preventing Rush Current ...................6-3

C. Protecting the Fixing Assembly .........6-4

D. Detecting a Fault in the Fixing

Assembly............................................6-4

III. DISASSEMBLY/ASSEMBLY ....................6-9

A. Fixing Assembly...............................6-10

CHAPTER 7 EXTERNALS/AUXILIARY MECHANISMS

I. CONTROL PANEL ...................................7-1

A. Outline................................................7-1

B. Operations..........................................7-1

II. FANS........................................................7-2

III. POWER SUPPLY.....................................7-4

A. Power Supply.....................................7-4

B. Remote Switch...................................7-6

C. Protective Mechanisms ......................7-7

D. Power Save Mode ..............................7-8

IV. DISASSEMBLY/ASSEMBLY ....................7-9

A. Fans .................................................7-10

B. Power Supply Assembly ..................7-13

CHAPTER 8 INSTALLATION

I. SELECTING THE SITE............................8-1

II. UNPACKING AND INSTALLATION ..........8-3

A. Unpacking the Printer Unit.................8-3

B. Installing the Pr inter Unit....................8-4

C. Making Settings and Checking Images

and Operations ................................8-11

D. Selecting the Type of Message for

the Printer Unit.................................8-14

III. RELOCATING THE MACHINE...............8-16

IV. INSTALLING THE DUPLEXING UNIT...8-17

V. INSTALLING THE VERTICAL FEED

CASSETTE (A4R, LTRR, B5R, A5R) ....8-20

CHAPTER 9 MAINTENANCE AND SERVICING

I. PERIODICALLY REPLACED PARTS.......9-1

II. CONSUMABLES AND DURABLES ........9-1

III. BASIC SERVICING CHART ....................9-2

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

viii

APPENDIX

A. GENERAL TIMING CHART.....................A-1

B. SIGNALS AND ABBREVIATIONS...........A-7

C. GENERAL CIRCUIT DIAGRAM............A-15

D . SPECIAL TOOLS...................................A-17

E. SOLVENTS AND OILS..........................A-18

CHAPTER 10 TROUBLESHOOTING

I. STANDARDS AND ADJUSTMENTS .....10-1

A. Electr ical System .............................10-1

II. TROUBLESHOOTING IMAGE

FAULTS ................................................10-10

A. Making Initial Checks.....................10-10

B. Guide to Test Pr ints for the Printer

Unit.................................................10-12

C. Troubleshooting Image Faults........10-14

III. TROUBLESHOOTING

MALFUNCTIONS .................................10-28

A. Error Codes ....................................10-29

B. Faults Not Identified by Error

Codes.............................................10-45

IV. TROUBLESHOOTING FEEDING

PROBLEMS.........................................10-58

A. Paper Jams....................................10-58

B. Faulty Feeding ...............................10-66

V. ARRANGEMENT AND FUNCTIONS OF

ELECTRICAL PARTS ..........................10-69

A. Sensors..........................................10-70

B. Ther mistors, Lamps, and Heaters .10-72

C. Clutches and Solenoids.................10-74

D. Fans and Motors............................10-75

E. PCBs..............................................10-76

F. Duplexing Unit ................................10-78

G. Var iable Resistors (VR), Light-Emitting

Diodes, and Check Pins PCB........10-79

VI. SERVICE MODE..................................10-83

A. Enter ing the Ser vice Mode ............10-83

B. Menu Structure and Key

Assignment ....................................10-83

C. Main Menu.....................................10-85

VII. TEST PAGE PRINT MODE..................10-93

A. Generating the Test Page ..............10-93

B. Test Pattern....................................10-93

VIII. SELF DIAGNOSIS...............................10-99

A. Pr inter unit......................................10-99

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

This chapter provides specifications of the machine, instructions on how to operate

the machine, and an outline of reproduction process.

CHAPTER 1

GENERAL DESCRIPTION

I. FEATURES ..............................................1-1

II. SPECIFICATIONS....................................1-2

A. Pr inter Unit.........................................1-2

III. SAFETY OF LASER LIGHT.....................1-6

IV. NAMES OF PARTS..................................1-7

A. External View.....................................1-7

B. Cross Section ...................................1-11

V. USING THE CONTROL PANEL.............1-13

VI. NOTES T O THE USER..........................1-15

VII. NOTES TO THE SERVICE PERSON....1-16

A. Stor ing the Drum Cartridge and the

Toner Cartridges ..............................1-16

B. Points to Note When Handling the

Drum Cartr idge and the Toner

Cartridges ........................................1-18

VIII. IMAGE FORMATION .............................1-20

A. Outline..............................................1-20

B. Latent Static Image Formation

Block ................................................1-22

C. Development Block ..........................1-25

D. Transfer Block ..................................1-27

E. ITD (inter mediate transfer drum)

Cleaning Block.................................1-31

F. Photosensitive Drum Cleaning.........1-33

G. Fixing Block......................................1-34

Download free service manual at http://printer1.blogspot.com

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

I. FEATURES

1. Oil-Free Fixing Assembly

The fixing assembly is free of oil, allowing replacement without soiling hands.Further,

since the fixing assembly is fixed in place without a screw, it may be removed by simply shifting the releasing lever.

2. Quick Replacement of Toner Cartridges

The Y, M, and C toner cartr idges are designed as a 3-color rotary development construction so that they, including the black toner cartridge, ma y be replaced b y the user

without effort.

The black toner cartridge is a large-capacity cartr idge—suitable for business uses,

which require large volumes of black-and-white printing work.

3. Auto Duplexing Mechanism

The installation of a duplexing unit (accessory) will enable making double-sided prints

(through-path configuration).

4. Reader Unit

The installation of the reader unit (accessory in some areas) will generate sharp

prints at a resolution of 600 dpi x 600 lpi.

CHAPTER 1 GENERAL DESCRIPTION

1-1

Download free service manual at http://printer1.blogspot.com

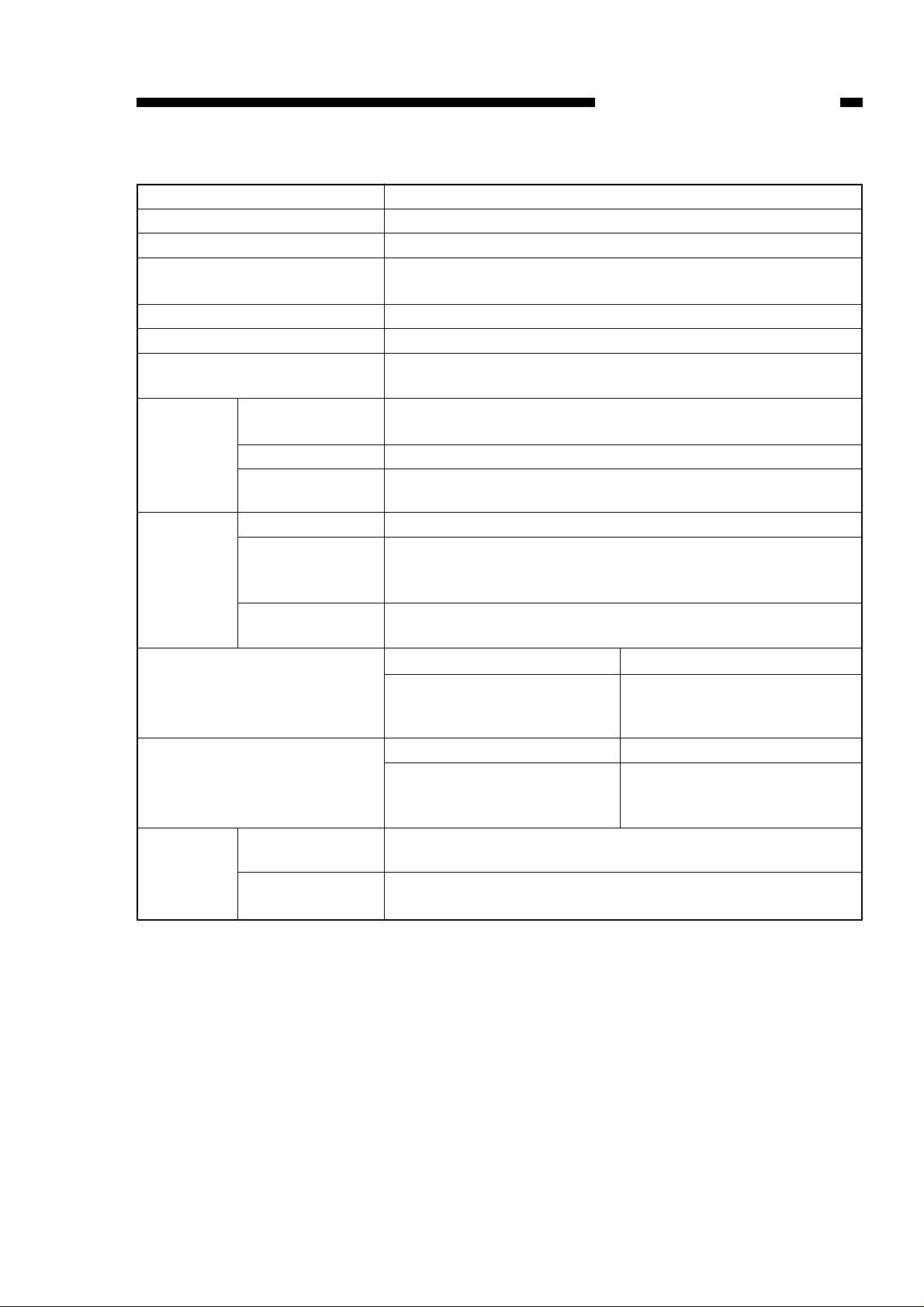

II. SPECIFICATIONS

A. Printer Unit

1. Type

Printing Laser beam indirect photostatic reproduction (using an inter-

mediate transfer drum)

Laser Semiconductor laser

Scanning system Scanning by 6-facet mirror

Charging Roller charging

Exposure Laser beam

Contrast adjustment Auto

Development Toner projection

Toner Non-magnetic, single-component dr y toner (Y, M, C)

Magnetic, single-component dry toner (Bk)

Toner supply By replacement of Y, M, C, and Bk toner cartridges

Pick-up Special front cassette (2 holders), multifeeder

Transfer Primary transfer: rubber blade

Intermediate transfer drum: cleaning roller

Fixing Heat roller (top: 595 W; bottom: 595 W (100/120 V))

(top: 550 W; bottom: 550 W (220/240 V))

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

1-2

Body Desk-top page printer (console when installed to a paper

deck)

Photosensitive medium OPC drum (62-mm dia.)

2. System

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

1-3

Wait time 5 min or less

First print time See Table 1-201.

Printing speed See Table 1-202.

Cassette Universal cassette: about 500 sheets of 80 g/m

2

R cassette (accessory):about 500 sheets of 80 g/m

2

Multifeeder tray about 10 mm in height (about 100 sheets of 80 g/m2)

Duplexing unit Through-path (accessory)

Delivery tray Face-down: about 300 sheets (80 g/m

2

paper), w/ limit sensor

Face-up:about 100 sheets (80 g/m

2

paper)

Print size Cassette 1 Universal cassette: LGL, B4, LTR, A4

Special cassette (accessory): LTRR, A4R, B5R, A5R

Cassette 2 Universal cassette: 11×17, A3, LGL, B4, LTR, A4

Multifeeder Envelope, A3 (11×17) to A5 (if B5 and A5, horizontal only);

12×18.5

Print paper Cassette Plain paper (60 to 105 g/m

2

), colored paper, recycled paper

Multifeeder Plain paper (60 to 105 g/m

2

), transparency (special), thick

paper (106 to 135 g/m

2

), label sheet (special), envelope, col-

ored paper, recycled paper

Double-sided Duplexing unit (if installed) : A3 to B5R plain paper (60 to

printing 105 g/m

2

)

Image margin Single-sided Double-sided

Leading edge: 5.0 ±2.0 mm Leading edge:5.0 ±2.0 mm

Trailing edge: 5.0 ±2.0 mm Trailing edge: 5.0 ±2.0 mm

Left/right: 5.0 ±2.0 mm Left/right: 5.0 ±2.0 mm

Non-image width Single-sided Double-sided

Leading edge: 5.0 ±2.0 mm Leading edge:5.0 ±2.0 mm

Trailing edge: 5.0 ±2.0 mm Trailing edge: 5.0 ±2.0 mm

Left/right: 5.0 ±2.0 mm Left/right: 5.0 ±2.0 mm

Resolution Main scanning 600 dpi (dots per inch)

direction

Sub scanning 600 lpi (lines per inch)

direction

3. Functions

Download free service manual at http://printer1.blogspot.com

Operating environment See p.8-1.

Power supply (rated voltage ±10%) Power supply Serial No.

120V (USA) NLQ xxxxx

120V (TWN) NLX xxxxx

230V (KOR) PLC xxxxx

230V (Others) PLF xxxxx

230V (CA)

230V (UK) ULL xxxxx

230V (FRN)

230V (GER)

230V (AMS)

230V (ITA)

Weight (printer unit only) 91.6 kg (including drum cartr idge weighing about 2.3

kg; black toner cartridge, about 1.5 kg; each color

toner cartridge, about 1.2 kg)

The duplexing unit weighs about 3.5 kg.

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

1-4

4. Others

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

1-5

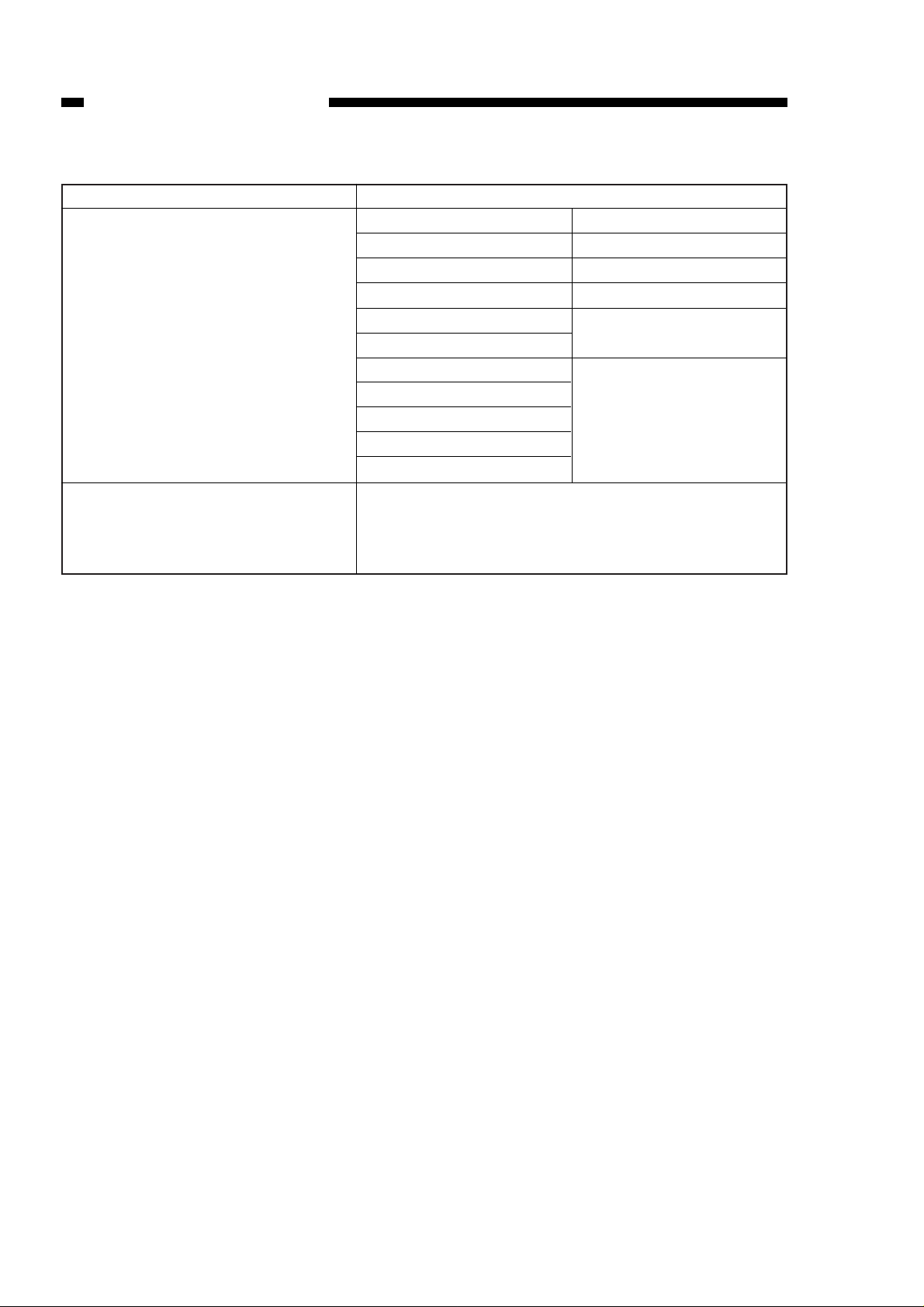

Plain paper

Thick paper

Transparency

A4/LTR

A4/LTR

A4/LTR

4-color

34

50

57

Mono-color

(YMCK)

18

35

41

Table 1-201 First Print Time

*A4, Direct, cassette 1, face-up delivery, no pre-scanning if face-down delivery, add

3 sec for plain paper, 6 sec for thick paper, and 7 sec for transparency.

(unit: sec or less)*

Source

Cassette

Multifeeder

Multifeeder

Multifeeder

Plain paper

Thick paper

Transparency

Size

A3/B4/A4R/B5/A5R/

11×17/LGL/LTRR

A4/LTR

A3/11×17

A4/LTR

A4/LTR

4-color

3

6

1.2

2.4

2.1

Mono-color

(YMCK)

12

24

1.7

3.4

2.8

Table 1-202 Printing Speed

(copies/min)

The above specifications are subject to change for product improvement.

Download free service manual at http://printer1.blogspot.com

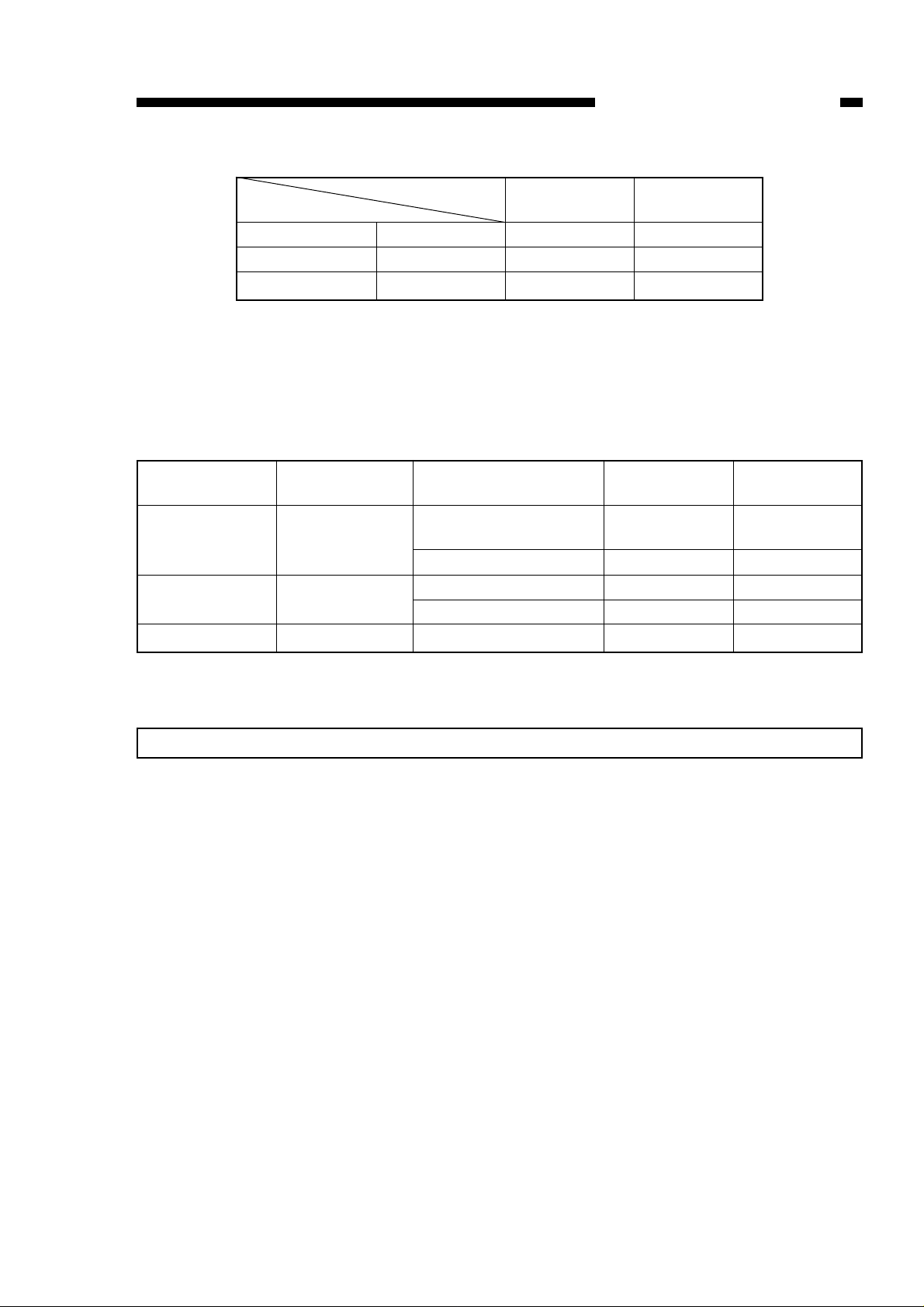

III. SAFETY OF LASER LIGHT

Radiation of laser light can be hazardous to human beings. To ensure safety, the

machine’s laser scanning system is sealed inside a protective housing and external covers, preventing leakage of laser light to the outside so that the user cannot be exposed

to the machine’s laser light as long as the printer unit is used normally.

The printer unit is certified as a Class I product under 1040.10 of Title 21 of the Code

of Federal Regulations (USA) and a Class 1 laser product under IEC825.

Figure 1-301 shows the label attached to products certified to comply with the foregoing standards (120-V model).

The eye, if exposed to laser light, can suffer permanent damage.

The machine’s laser light is a visible light. However, the following label is attached to

covers that may reflect laser light. Pay special attention whene ver servicing areas behind

such covers.

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

1-6

Do not insert a screwdriver or other tools with a high reflectance into the laser path

when servicing areas around the laser scanning system.

Be sure to remove watches, rings, and the like before starting to service the machine.

Warning:

This label is attached to those covers of the machine’ s laser scanning system which

are used to protect against laser light.

Figure 1-301

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

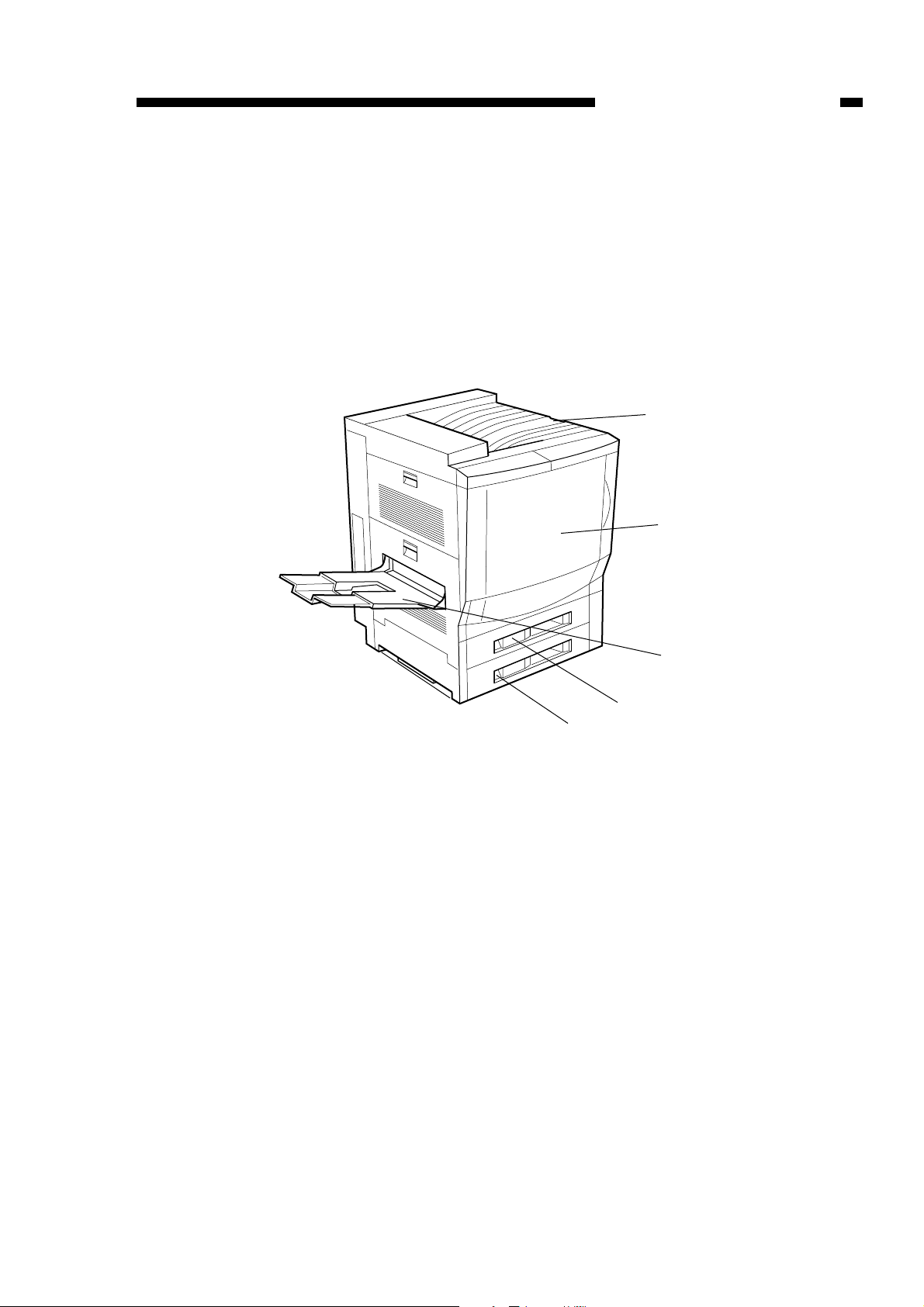

IV.NAMES OF PARTS

A. External Vie w

• Front View

CHAPTER 1 GENERAL DESCRIPTION

1-7

Figure 1-401

q

w

q Face-down tray

w Front cover

e Face-up tray

e

r

t

r Cassette 1

t Cassette 2

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

1-8

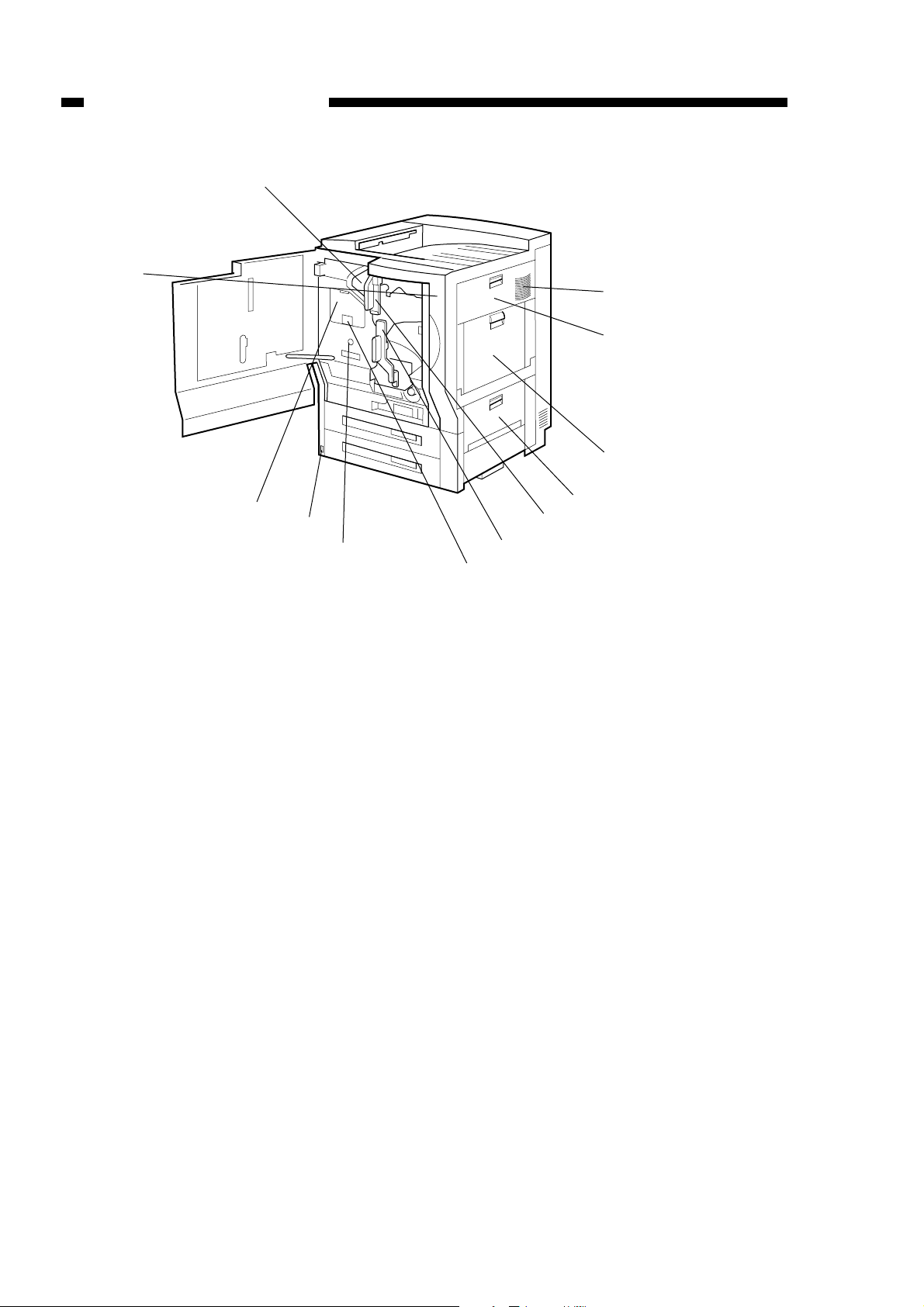

Figure 1-402

q

!1

w

e

r

!0

!2

q Black toner cartridge slot

w Exhaust vent

e Right cover

r Multifeeder

t Pick-up cassette cover

y Top releasing lever

t

y

o

u

i

u Bottom releasing lever

i Toner cartridge color check window

o Color cartridge replacement turret button

!0 Color cartridge cover

!1 Front right cover

!2 Printer unit power switch

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

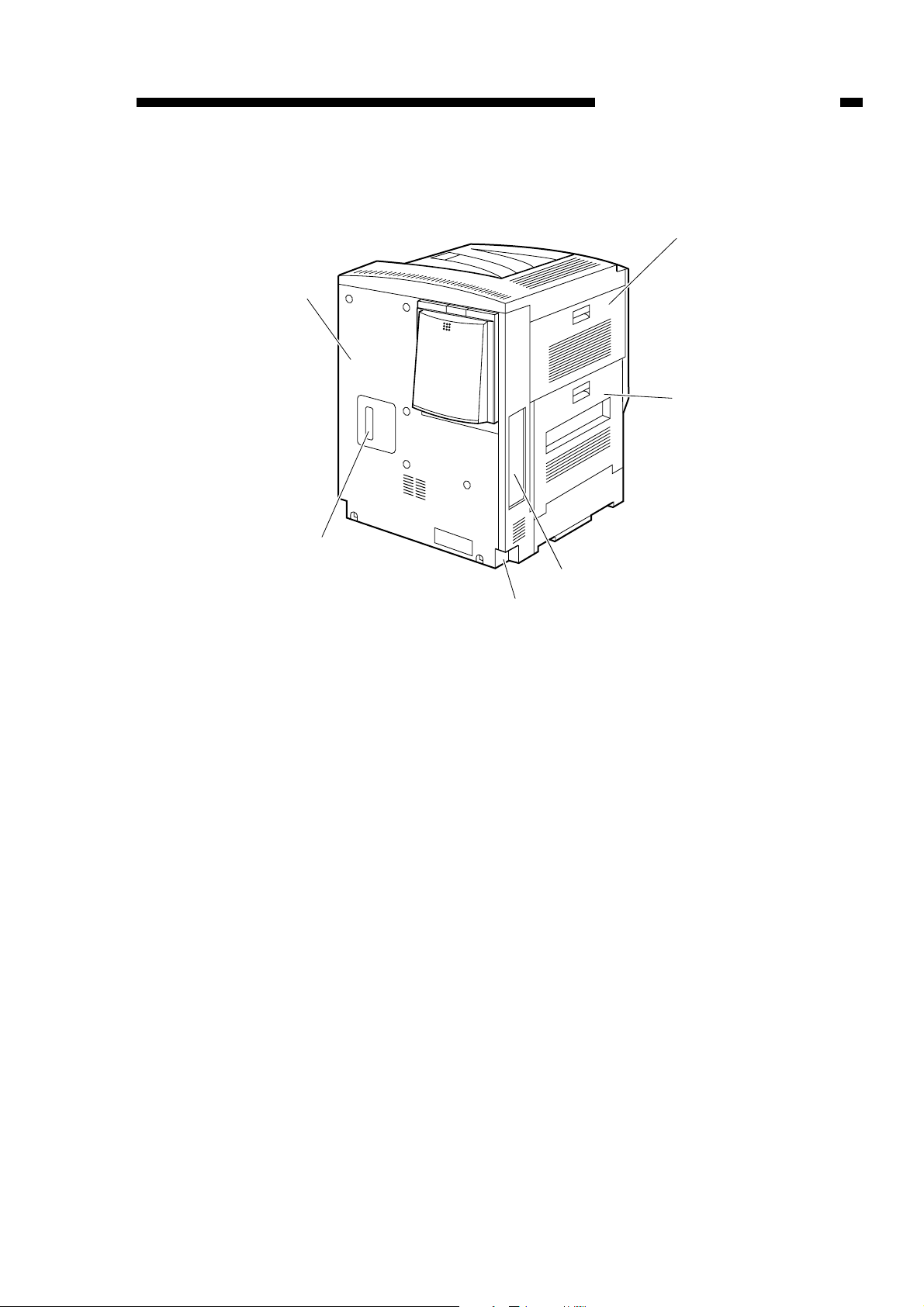

• Back

CHAPTER 1 GENERAL DESCRIPTION

1-9

Figure 1-403

q

y

w

t

q Upper left cover

w Delivery cover

e Video controller cover

e

r

r Power supply cord connector (printer unit)

t Interface cable (for connection

to the reader unit)

y Rear cover

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

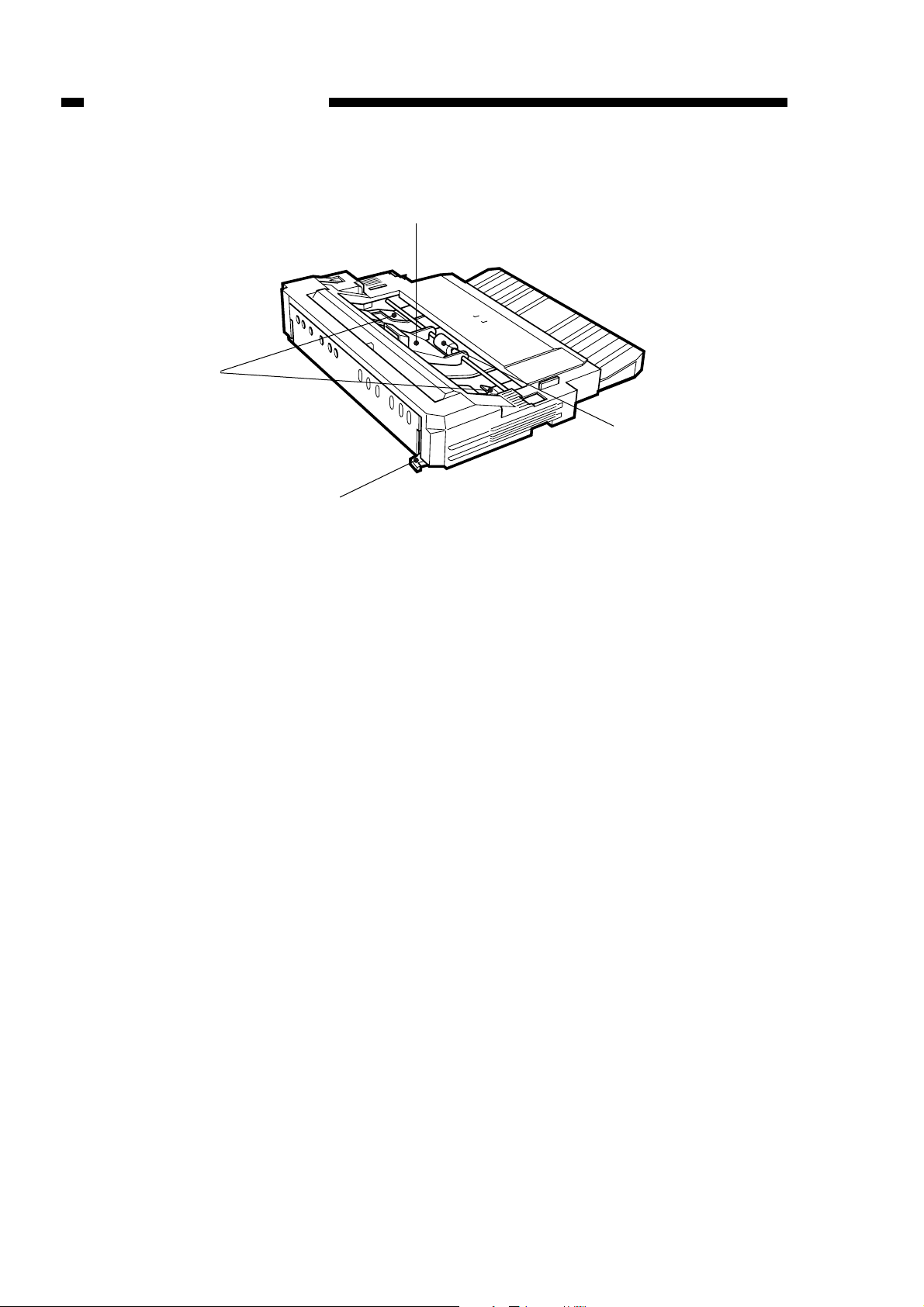

• Duplexing Unit

CHAPTER 1 GENERAL DESCRIPTION

1-10

Figure 1-404

q

w

e

r

q Horizontal registration guide

w Pick-up guide plate

e Duplexing feeding roller 1

r Duplexing releasing lever

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

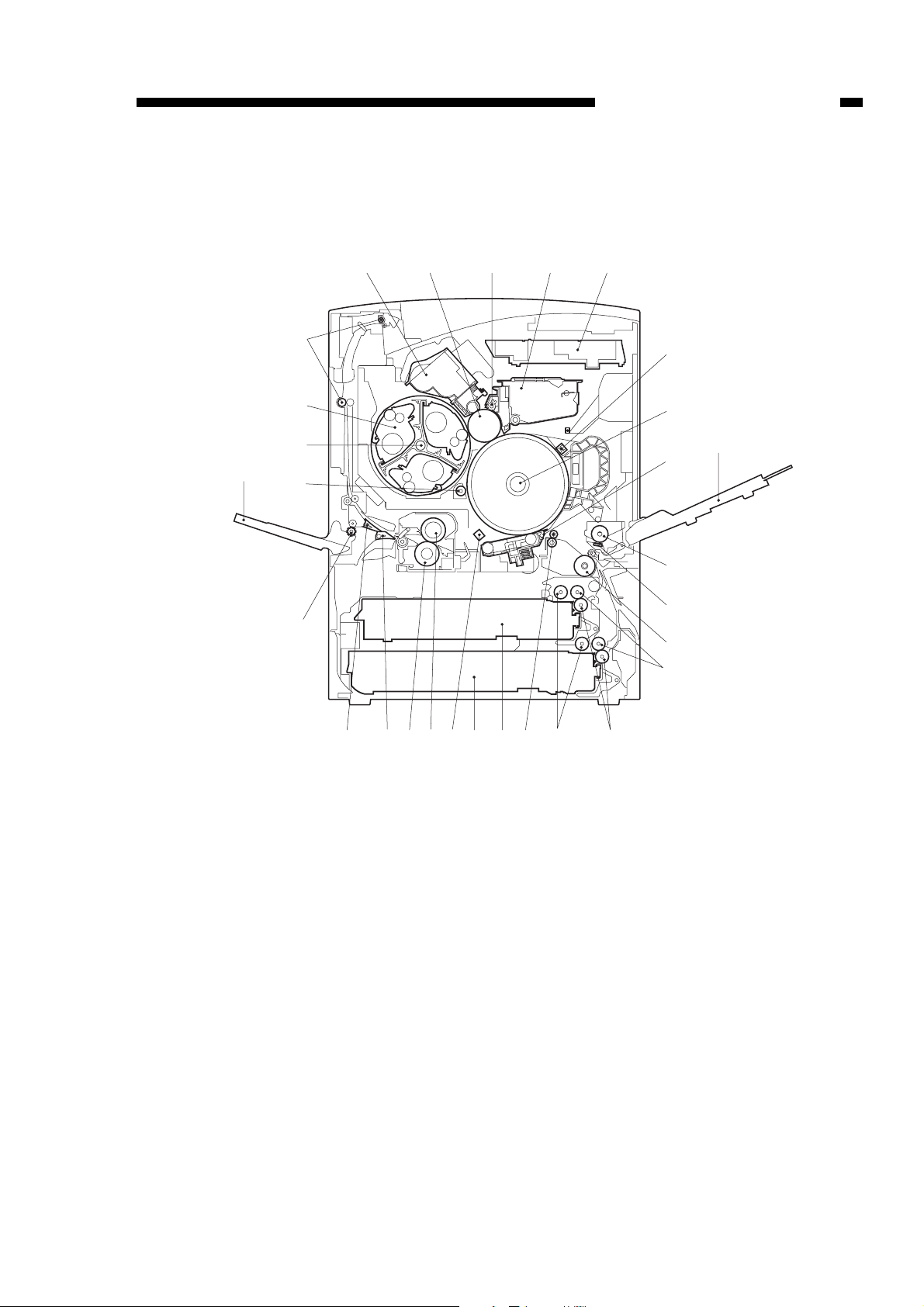

B. Cross Section

• Printer Unit

CHAPTER 1 GENERAL DESCRIPTION

1-11

Figure 1-405

@4

@8

@7

@6

@5

@3

qw

e

r

t

y

u

o

i

!0

!1

!2

!3

!9 @9

@1

@2

q Black toner cartridge

w Photosensitive drum

e Primary charging roller

r Photosensitive drum cartridge

t Laser/scanner assembly

y

Secondary pre-transfer charging assembly

u Intermediate transfer drum

i Secondary transfer belt

o Multifeeder tray

!0 Multifeeder pickup roller

!1 Separation pad

!2 Feeding roller 2

!3 Feeding roller 1

!4 Separation roller

!5 Pick-up roller

@0

!8

!7 !6

!5

!6 Registration roller

!7 Cassette 1

!8 Cassette 2

!9 Upper fixing roller

@0 Lower fixing roller

@1 Duplexing flapper

@2 Face-up flapper

@3 Face-up delivery roller

@4 Face-up tray

@5

@6 Color developing rotary

@7 Color toner cartridge

@8 Delivery roller

@9 Separation static eliminator

!4

Intermediate transfer drum (ITD) cleaning roller

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

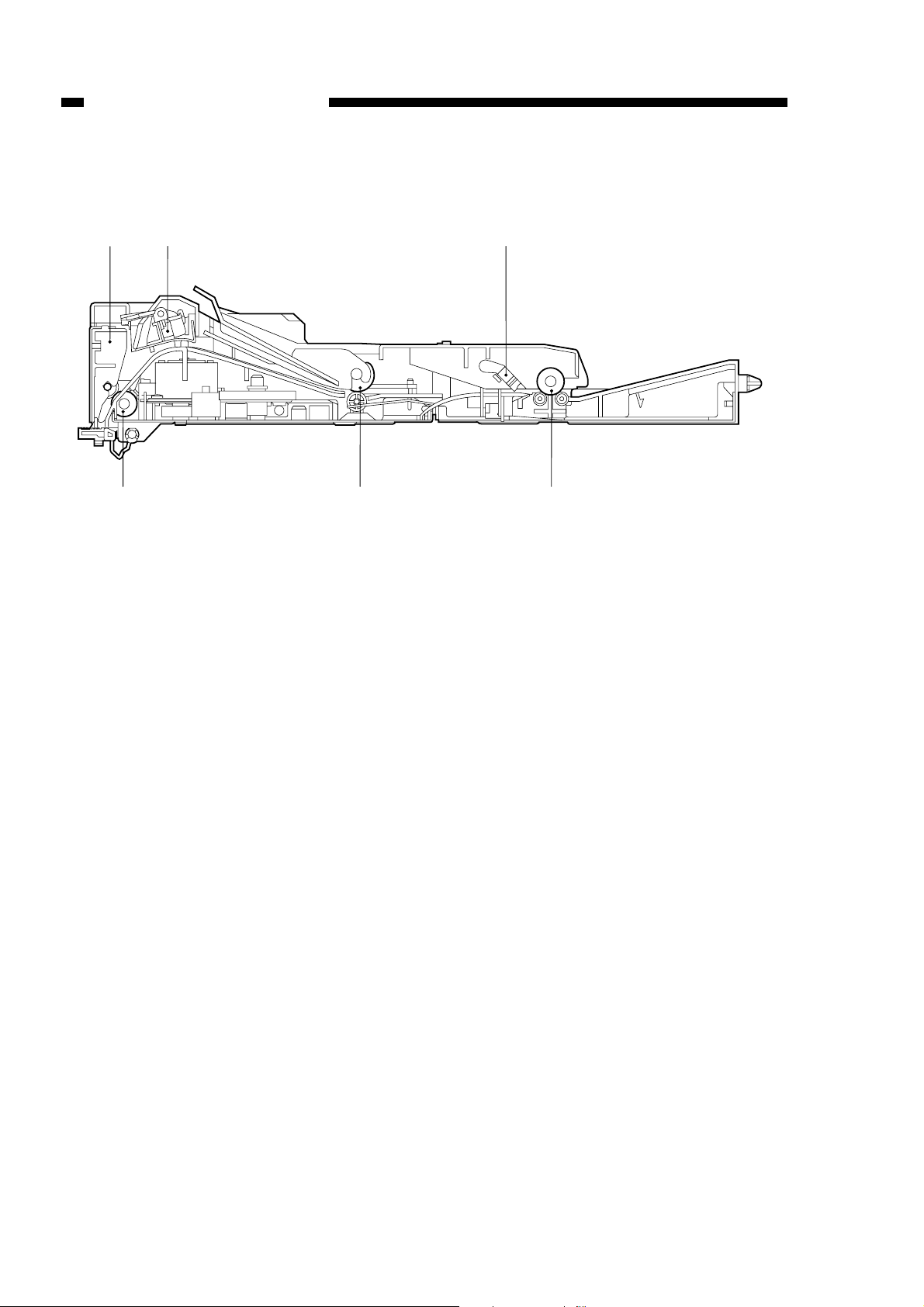

• Duplexing Unit

CHAPTER 1 GENERAL DESCRIPTION

1-12

Figure 1-406

q

we

ytr

q Reversing roller releasing plate

w Reversal paper sensor

e Re-pick up sensor lever

r Duplexing feeding roller 2

t Duplexing feeding roller 1

y Reversing roller

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

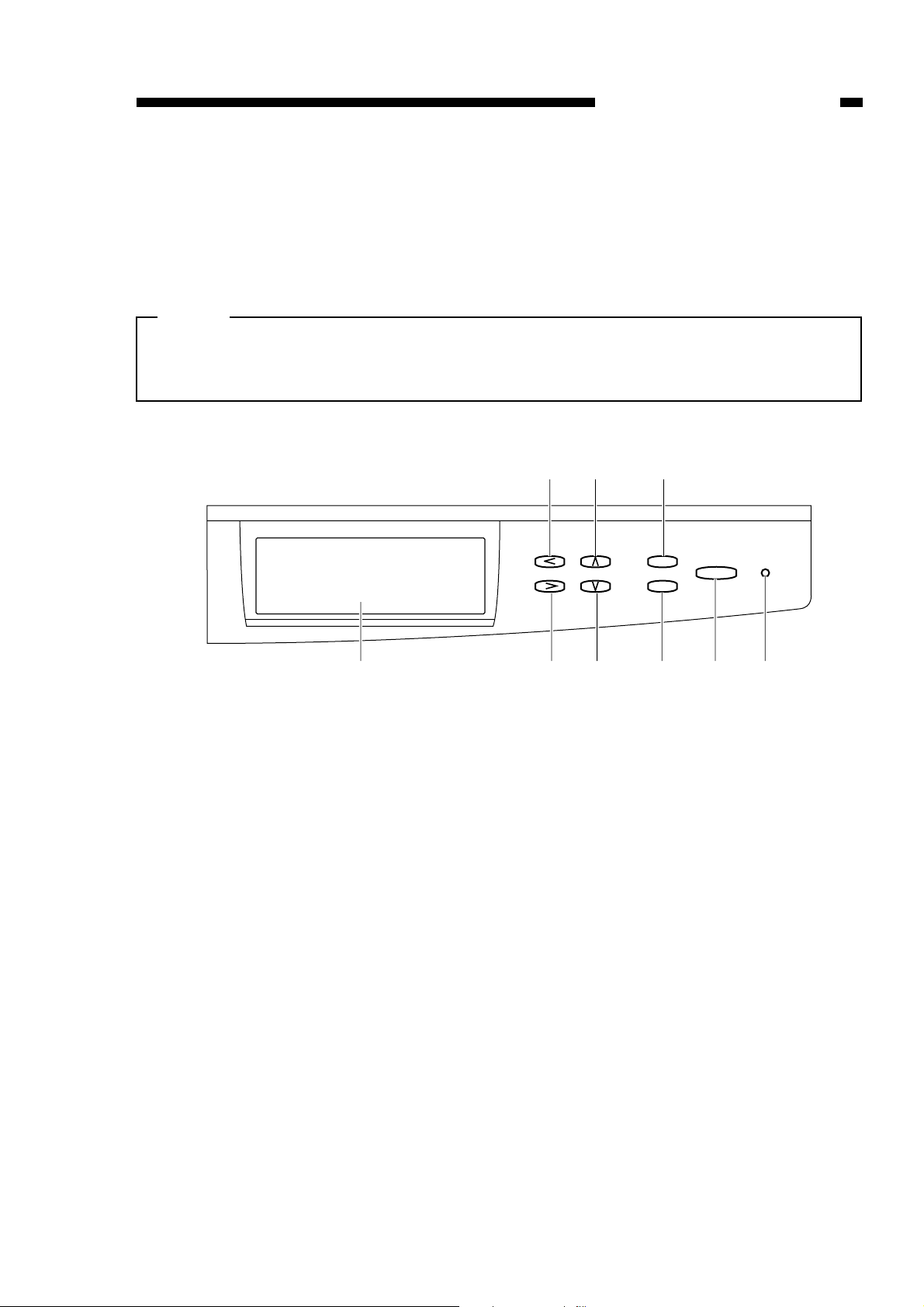

V. USING THE CONTROL PANEL

The control panel on the top of the printer enables you to set options and view the

status of the printer and print jobs.

For details, see the PS/PCL Board Service Manual.

CHAPTER 1 GENERAL DESCRIPTION

1-13

This control panel is available only when the printer unit is used as a printer after

equipping it with a printer board, and is not available if the printer unit is used as a

copier.

Caution:

t

ey

Cancel

Menu

qwoiu

r

Enter/Online

Message

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

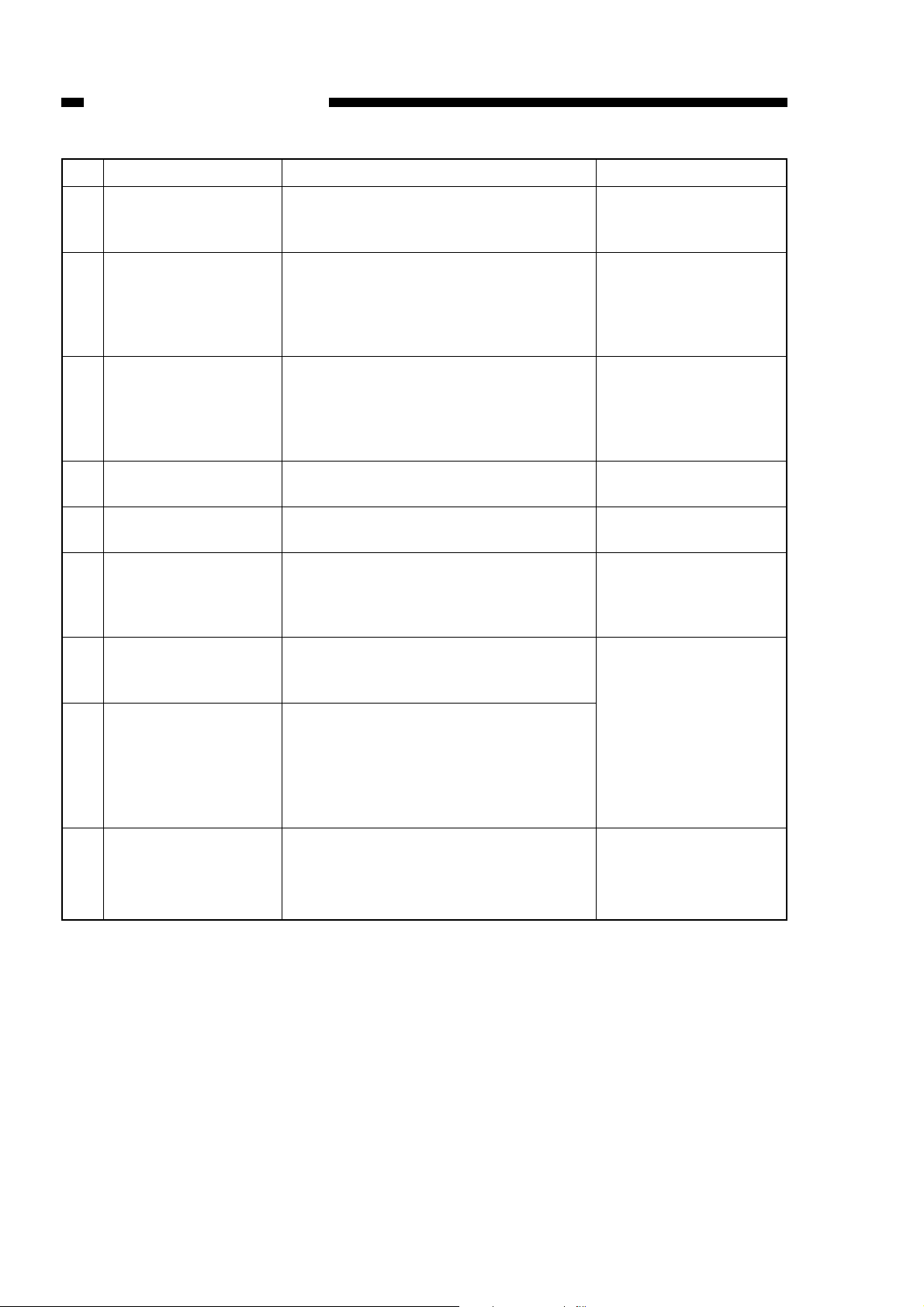

1-14

Name

Display window

Down arrow button

Up arrow button

Right arrow button

Left arrow button

Cancel button

Menu button/LED

Enter/Online

button/LED

Message LED

q

w

e

r

t

y

u

i

o

Operation/function

The LCD window on the control panel

displays status messages and a

graphical representation of the printer.

In a fixed-length list, takes you to the

next item in the list.When entering

numbers or text, increments to the

previous number or character. Hold

down the button to increment rapidly.

In a fixed-length list, takes you to the

previous item in the list. When entering numbers or text, increments to the

previous number or character. Hold

down the button to increment rapidly.

When entering numbers or text,

advances the cursor.

When entering number or text, backspaces and deletes.

In setup menus, exits menus entirely,

returning to ready. While printing, cancels printing or processing the current

job.

Accepts an option and advances to

the next choice. When the printer is in

ready mode, takes the printer offline.

From ready or power saver mode,

enters the setup menus. In setup

menus, advances from one menu to

the next. From a setup menu option,

returns to the previous setup menu.

On when the printer requires a service

call. Blinking when the pr inter requires

operator intervention (e.g., load

paper).

Remarks

On when the printer is

online (ready to

accept and process

new jobs), blinking

when receiving, processing or printing

data, and off when the

printer is offline or the

power is off.

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

VI. NO TES TO THE USER

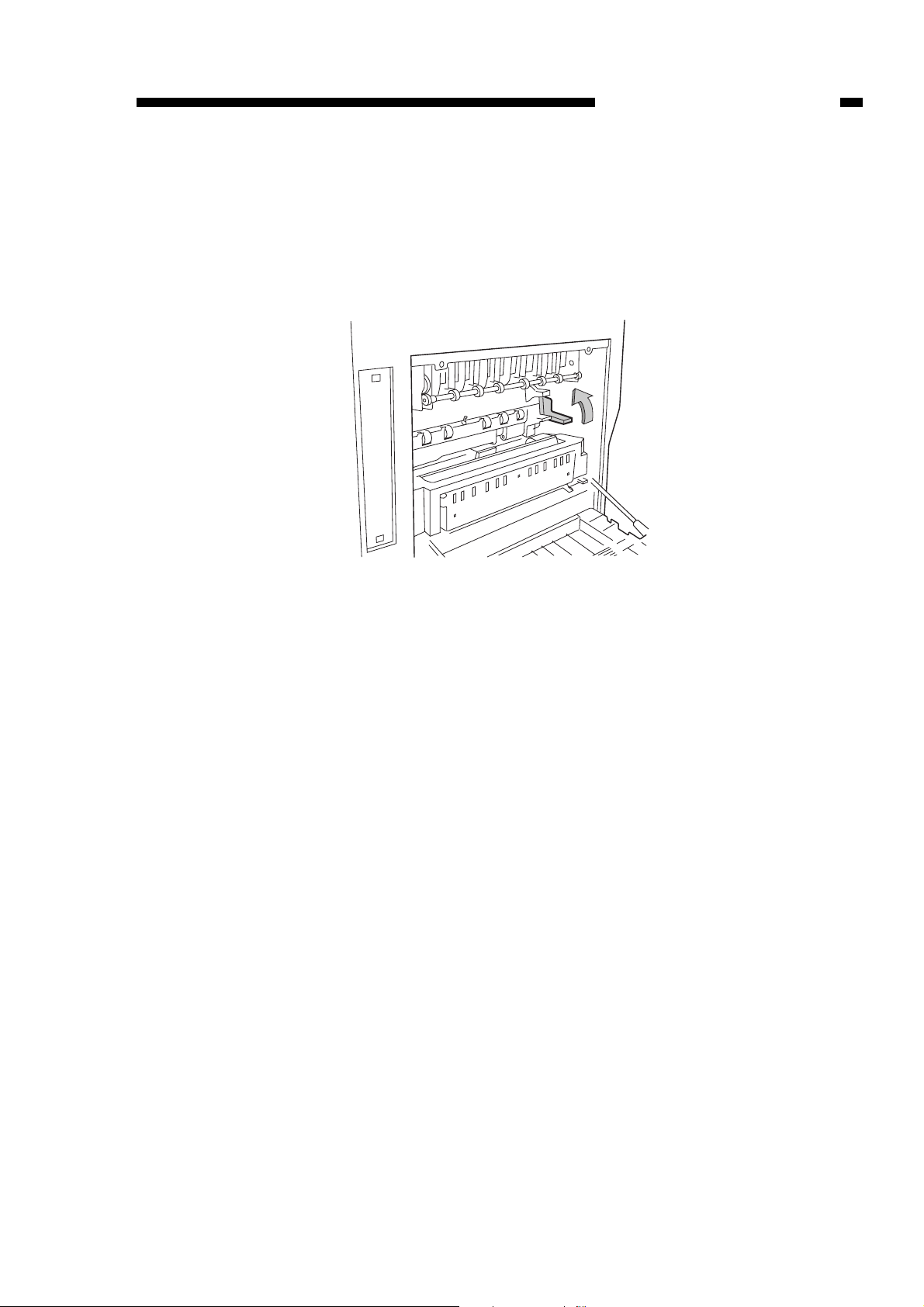

If the printer unit is expected to remain out of use for a long time (e.g., holidays), be

sure to shift up the fixing assembly releasing lever as shown to unlock the upper and

lower rollers of the fixing assembly.

CHAPTER 1 GENERAL DESCRIPTION

1-15

Figure 1-601 Fixing Assembly Releasing Lever

Download free service manual at http://printer1.blogspot.com

VII. NO TES TO THE SERVICE PERSON

A. Storing the Drum Cartridge and the Toner Cartridges

Regardless of whether they have been opened or not, the cartr idges (Y, M, and C

toner cartridges, black toner cartridge, and drum car tridge) remain subject to the influences of the environment, and their characteristics change over time. (This is also true

regardless of how many copies/prints they have processed.)

The speed of change, however, is dependent on the conditions of the site and maintenance and, therefore, it is important to take full care when storing or handling them.(Be

sure to instruct the user to be careful when storing and handling the toner car tr idges.)

1. Before Opening the Package

When storing the cartr idges (Y, M, and C toner cartridges, black toner cartridge, and

drum cartr idge) in a storeroom or a workshop, be sure that the place complies with the

conditions in Table 1-601; in addition,

1) Avoid direct sunshine;

2) Avoid an area subject to appreciable vibration; and

3) Avoid subjecting them to impact by hitting or dropping.

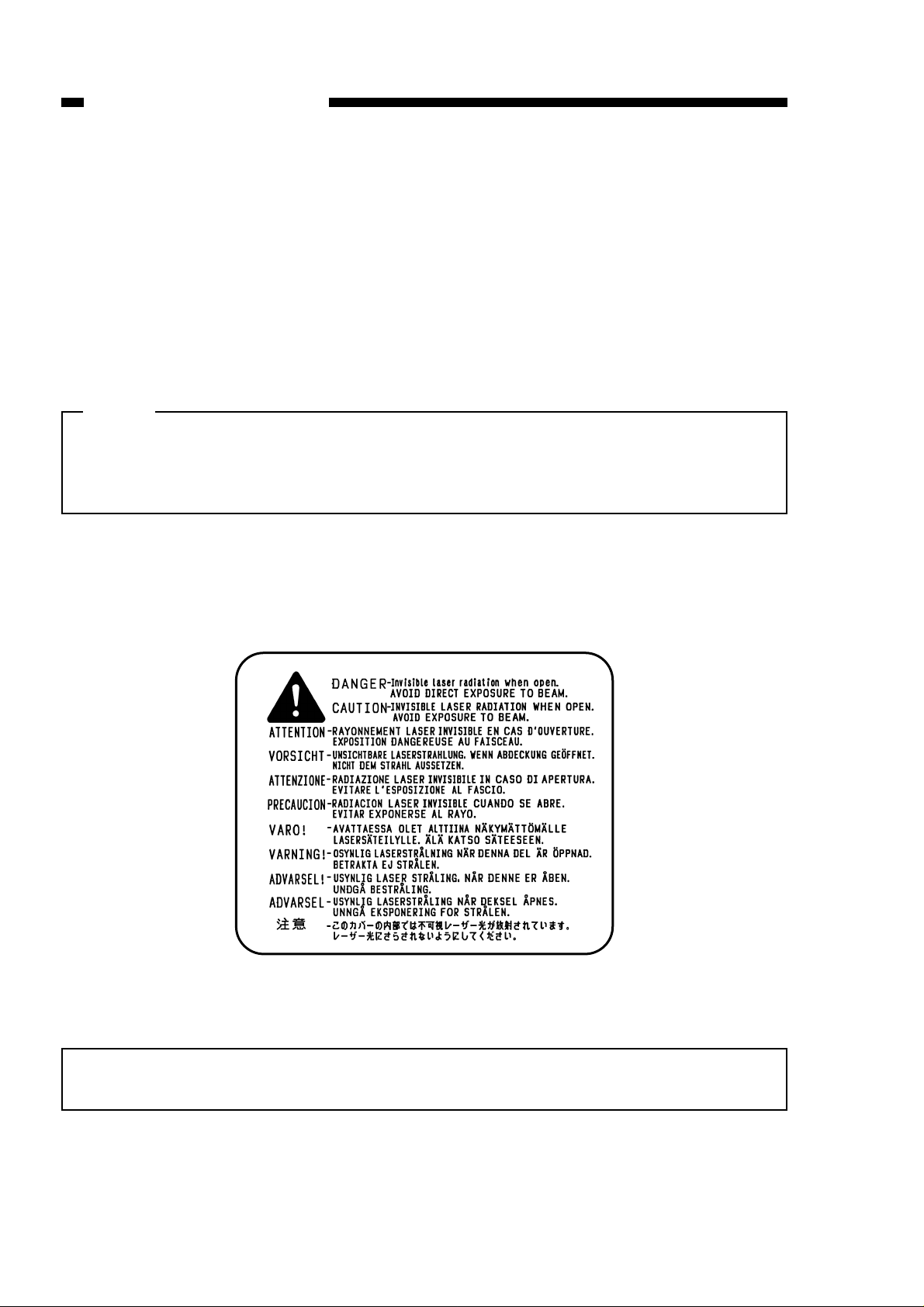

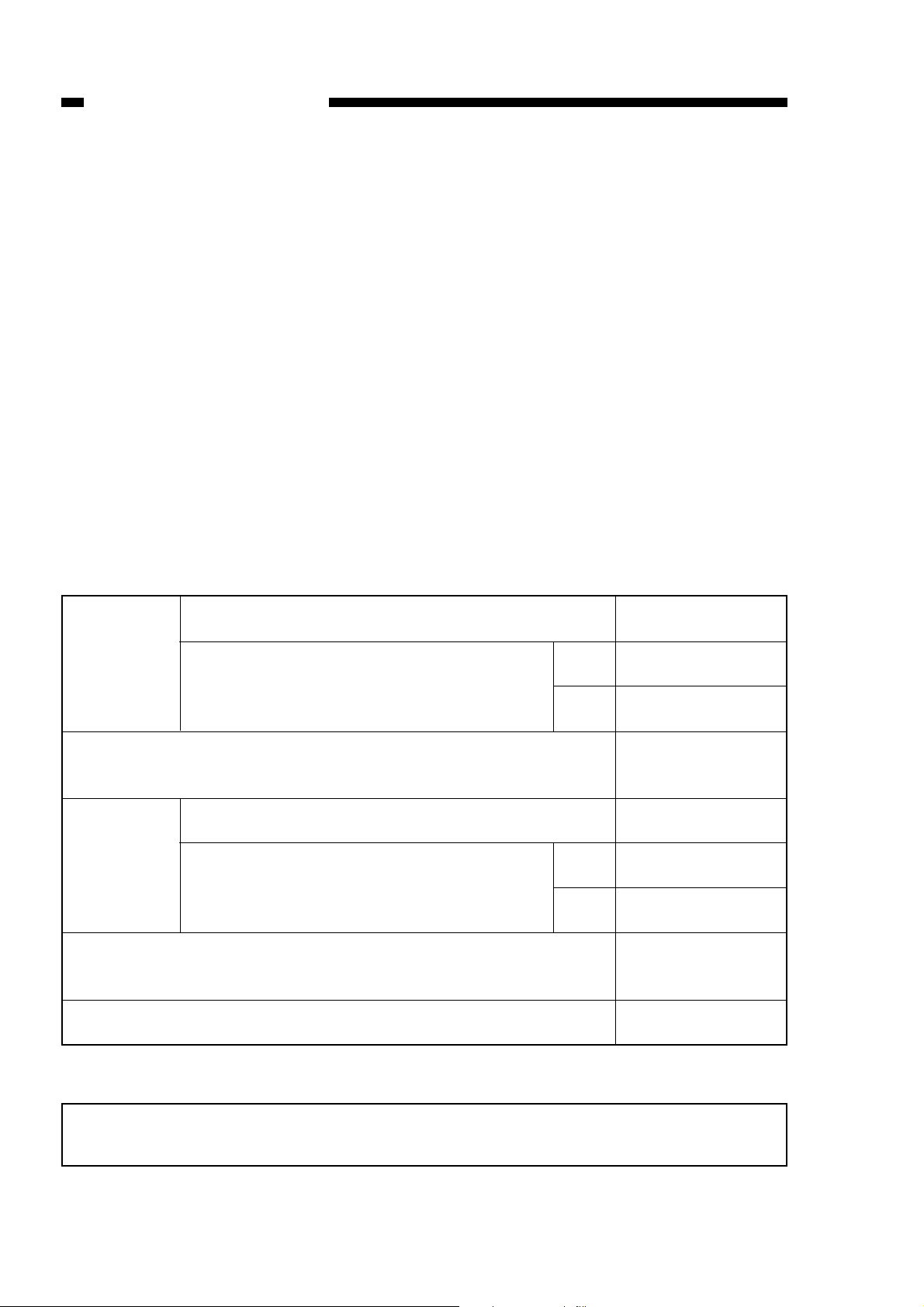

Temperature

Humidity

0 to 35°C

35 to 40°C

–20 to 0°C

40°C → 15°C

–20°C → 25°C

35 to 85%

85 to 95%

85 to 95%

613 to 1013 hPa

(608 to 760 mmHg)

1 yr

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

CHAPTER 1 GENERAL DESCRIPTION

1-16

Note: The term “entire storage period” means a per iod of one year form the date

of manufacture indicated on the cartridge package.

Table 1-701

Normal (9/10 or more of entire storage period)

Severe (1/10 or less of entire storage period) High

Low

Changes in temperature (within 3-min period)

Normal (9/10 or more of entire storage period)

Severe (1/10 or less of entire storage period) High

Low

Atmospheric temperature

Entire storage period

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

2. After Opening the Package

The photosensitive drum is an organic photoconductor (OPC), and would deteriorate

if subjected to strong light.The toner cartridges, on the other hand, contains toner, requiring care by the user for storing and handling after they have been opened.

3. Storage Environment (after opening)

1) Keep it in a protective bag.

2) Avoid direct sunshine. Avoid bright areas (e.g., near windows). Do not leave them

inside a car for a long time, as the inside can become extremely hot.

3) Avoid high-temperature, high-humidity, low-temperature, or low-humidity areas and

areas in which temperature or humidity change rapidly.

4) Avoid areas subject to corrosive gas (e.g., insecticide) or briny air.

5) Make sure the cartridges are kept between 0° and 35°C.

6) Do not place the cartridges near a CRT screen, disk drive, or floppy disks.

7) Keep the car tridges out of reach of children.

4. Service Life

The service life of a cartridge is 2.5 years from the date of manufacture, indicated by

means of an abbreviation on the cartridges.

For the user, a “service life,” obtained by adding 2.5 years to the date of manufacture,

is indicated on the package and the cartridge itself.

Prints made using a cartr idge older than its service life may have low image quality,

making it important to use up each car tr idge before the end of its service life.

CHAPTER 1 GENERAL DESCRIPTION

1-17

Download free service manual at http://printer1.blogspot.com

COPYRIGHT © 1999 CANON INC. CANON 660/2100 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

B. Points to Note When Handling the Drum Cartridge and the

Toner Car tridges

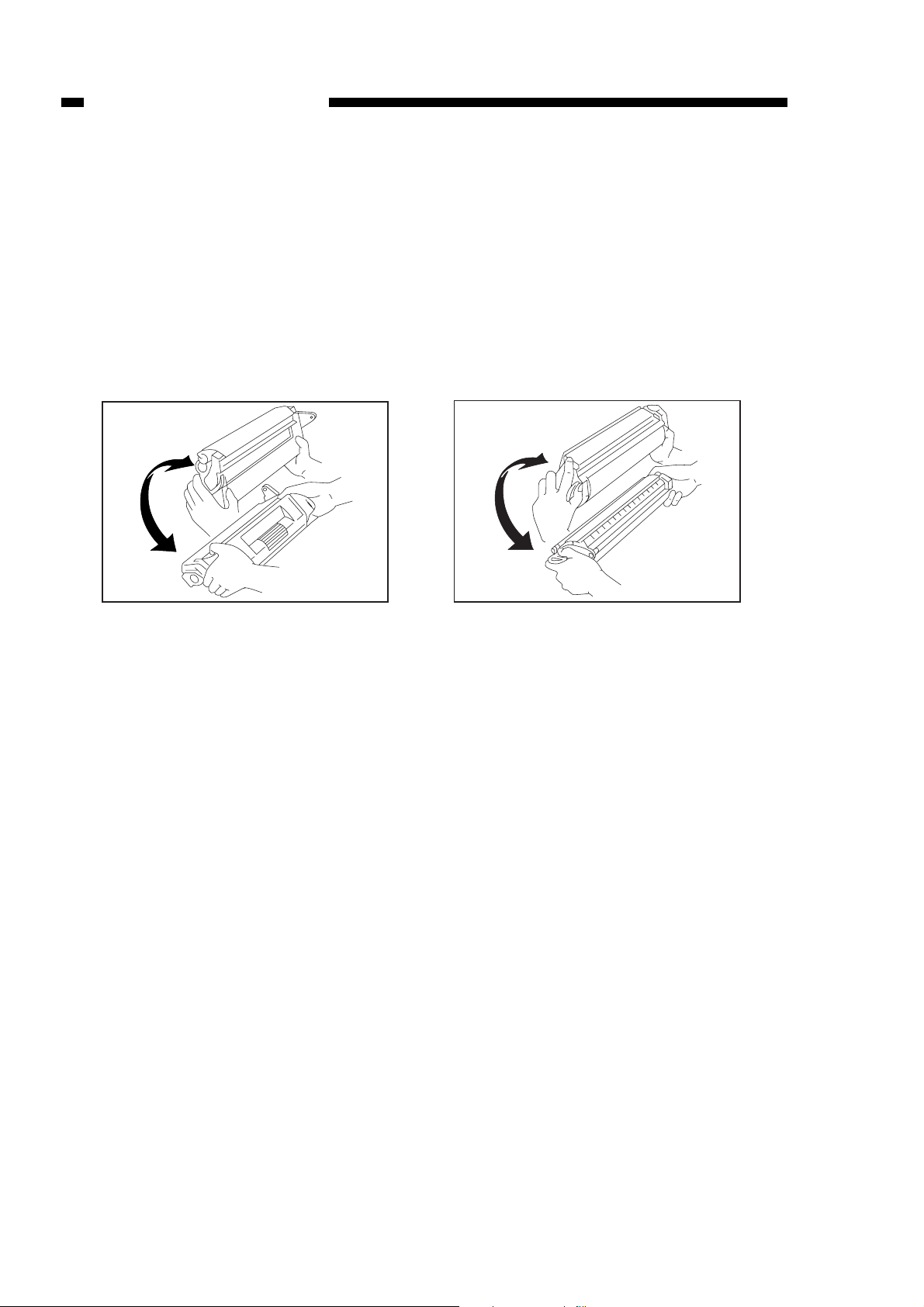

1) When setting a new toner cartridge (Y/M/C toner car tridge, black toner cartridge) in

the printer unit or if white spots occur on output prints because of uneven toner inside

a cartridge, hold the cartridge horizontal and rotate it slowly up and down (about 45°)

five to six times to even out the toner. (Instruct the user to observe this. In addition,

inform the user that handling a toner cartridge other than the foregoing method can

cause leakage of toner from the developing cylinder.)

2) Remove all car tridges if the pr inter unit must be moved.

In the case of the drum cartr idge, put the special protective cover (MF4-0106-000)

after taking it out of the printer unit, and put it in a protective bag or wrap it in a thick

cloth to prevent exposure to light.

3) Do not place the black toner car tr idge near a CRT screen, disk drive, or floppy disks.

The magnetic field it generates can damage the data.

4) Do not expose the drum cartridge to direct sunshine or strong light. Doing so could

affect print images.

5) Do not touch the surface of the photosensitive drum of the drum car tr idge.

6) Do not place the cartridge on its side or turned over.Be sure that the label side faces

up.

7) Do not disassemble the cartridges.

CHAPTER 1 GENERAL DESCRIPTION

1-18

Figure 1-701

Black toner cartridge Y/M/C toner cartridge

Download free service manual at http://printer1.blogspot.com

Loading...

Loading...