Page 1

2002 X440s OWNER'S MANUAL

P/N 951-5002032

Page 2

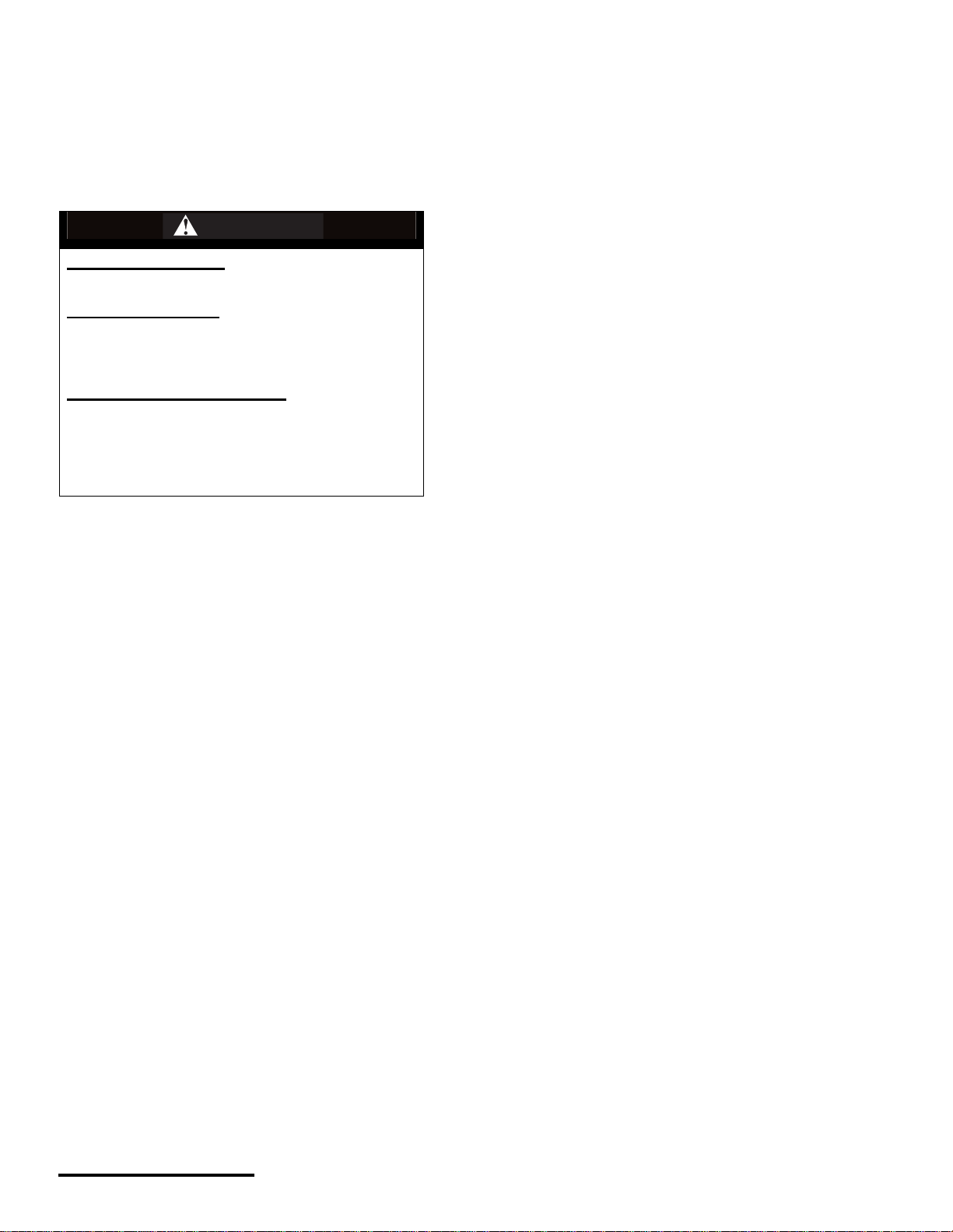

S a fe ty A le rts

• FAILURE TO FOLLOW THE WARNINGS CONTAINED IN THIS MANUAL CAN RESULT IN SERIOUS INJURY OR

DEATH.

• Keep this Owner’s Manual in a safe place.

MESSAGES WITH THE SAFETY ALERT SYMBOL

• Pay special attention to all messages preceded by the Safety Alert Symbol.

It means: ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED.

Indicates that severe personal injury or

DANGER

death WILL result if instructions are not

followed.

WARNING

CAUTION

Indicates a potential hazard could resul t in vehicle dam age if instructi ons are not follo wed .

NOTE : Provides helpful information

Indicates a potential hazard that COULD

result in serious injury or death.

1

P/N 951-05002032

Printed : 8/13/01

Page 3

Contents

Safety Alerts . . . . . . . . . . . . . . . . . 1

Contents . . . . . . . . . . . . . . . . . . . . 2

Important Information . . . . . . . . .3

Pre-Ride Inspection . . . . . . . . . . . 6

Component Locations . . . . . . . . . 7

Controls . . . . . . . . . . . . . . . . . . . . 8

Operating . . . . . . . . . . . . . . . . . . . 11

Fluids. . . . . . . . . . . . . . . . . . . . . . . 14

Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . 18

Transmission oil . . . . . . . . . . . . . . . . . . . 23

Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Maintenance and Adjustments . .27

Break-in . . . . . . . . . . . . . . . . . . . . . . . . . 27

Panels. . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Brakes. . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Exhaust. . . . . . . . . . . . . . . . . . . . . . . . . . 46

Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Electrical. . . . . . . . . . . . . . . . . . . . . . . . . 56

Steering . . . . . . . . . . . . . . . . . . . . . . . . . 65

Suspension. . . . . . . . . . . . . . . . . . . . . . . 66

Rear shock . . . . . . . . . . . . . . . . . . . . . . . 69

Tires & Wheels. . . . . . . . . . . . . . . . . . . . 73

Frame, Sub-frame, Swingarm. . . . . . . . . 75

Lubrication . . . . . . . . . . . . . . . . . . . . . . . 76

Cleaning and Storage . . . . . . . . . 83

X440s Model Specifications . . . . 85

X440s Service Specifications . . .86

X440s Torques . . . . . . . . . . . . . . . 87

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

2

Page 4

Imp or ta nt

In fo r ma tion

available at the time of publication. Cannondale Corporation

reserves the right to make changes at any time, without

notice.

This vehicle has U.S. and Internation al patents pending.

Cannondale Motorspo rts

Cannondale Corporat ion

We strongly suggest that you do the following before

operating the vehicle:

• READ and UNDERSTAND this Owner’s Manual.

• Perform the Pre-Ride Inspection found in this

manual.

• Wear appropriate protective gear - approved full

faced helmet, gloves, boots, long-sleeve shirt,

pants). Consider specially designed protective offroad vehic le riding apparel.

ABOUT THIS MANUAL

The purpose of this manual is to provide the owner with

important safety, service, maintenance, and tuning

information, and s hou ld be thoroughly read before operating

or working on the vehicle.

This manual is divided into sections which contain easy-tofollow procedures which are reasonably straight-forward.

Anyone with the mechanical ability and the proper tools

should be able to perform them. Each procedure is

accompanied by illustrations and photos to aid in proper

vehicle operation, basic maintenance, tuning, etc.

• Read and understand the entire procedure before

performing an y work. If you are unfamiliar with or

doubt your o wn abilities to co mplete a pro cedure as

described, have an authori zed Cannondale

motorsports dealer service y our vehicle.

Please keep your Owner's Manual in a safe and convenient

place, and consider it an integral part of your vehicle.

For detailed servicing information refer to the Service

Manual for your vehicle or contact an authorized

Cannondale motorsports dealer for a list of available

publications. If this manual is lost or damaged, contact an

authorized Cannondale motorsports dealer for a

replacement.

LIMITATIONS

EXPERIENCED RIDERS ONLY

• This vehicle is not f or b egin ner s.

All Cannondale motorsports products are designed for use

by trained and experienced riders only. All are very high

performance, competition sport machines and should only

be operated by licensed competition riders in excellent

physical condition, who are well-trained and experienced in

the operation of high perform an ce competition vehicles.

GOOD JUDGEMENT

There is always a risk involved when riding a vehicle;

however, making sure you and the vehicle are in the best

condition possible w il l ens ure a gre at riding ex pe rien ce. Use

sound judgement wh en ridi ng.

Never ride under the influence of alcohol, medication, or

drugs. Doing so will greatly reduce your ability to properly

operate this vehicle and could lead to an accident, injury,

and/or death. If you are taking medications prescribed by

your doctor, consult him/her before riding.

MODIFICATIONS

We recommend that you do not substitute parts, change or

modify your vehicle. Such changes could seriously impair

your vehicle’s handling, stability, and braking, making it

unsafe to ride and causing serious injury and/or vehicle

damage.

NO PASSENGERS

Do not overload this vehicle or carry passengers. Doing so

could seriously impair your vehicle’s handling, stability, and

braking, making it unsafe to ride which could result in

damage to the vehicle or serious injury or death to the

operator and/or passenger.

Meticulous engineering and aggressive product designs

represent the spirit of innovation - always a driving force at

Cannondale. All information, illustrations, and specifications

in this manual are based on the latest product information

3

P/N 951-05002032

Printed : 8/13/01

Page 5

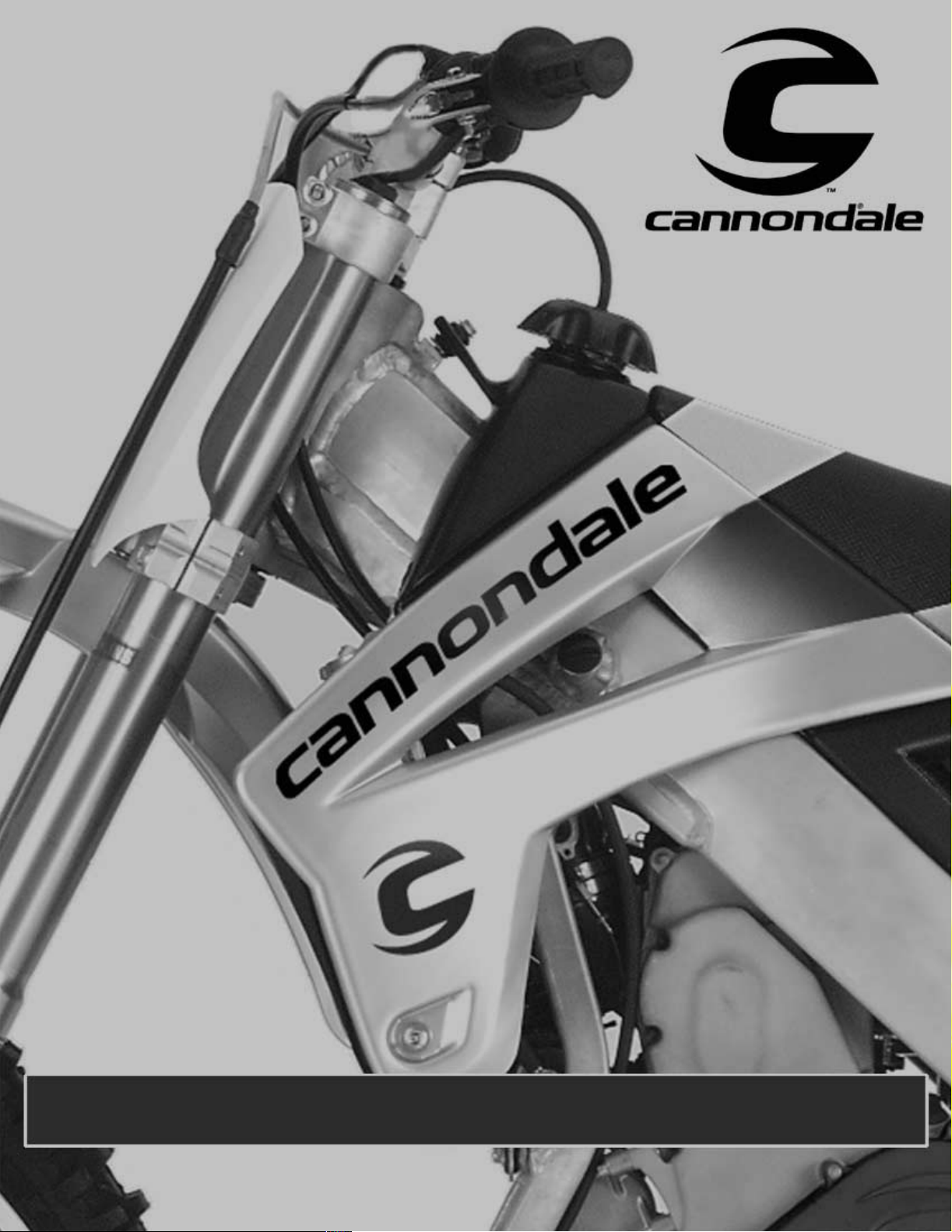

V EHICLE IDENTIFICATION NUMBER (VIN)

XXXXXXXXXXXX

XXXXXX

XXXXXX

The vehicle identification number ( VIN) is located on the left

side of the steering head.

XXXXXXXXXXXX

Record your vehicle’s ID number here:

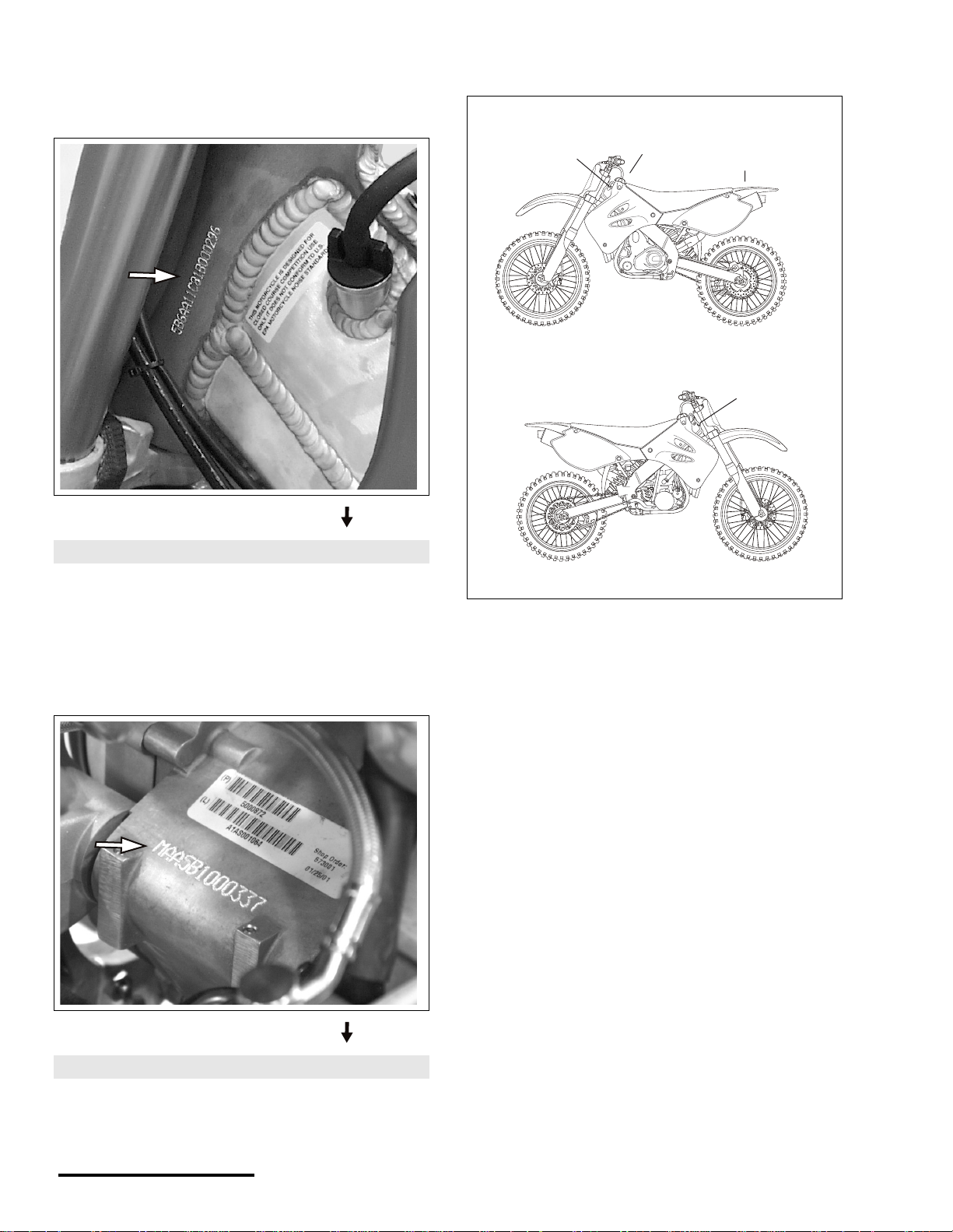

LABEL LOCATIONS

3

2

1

4

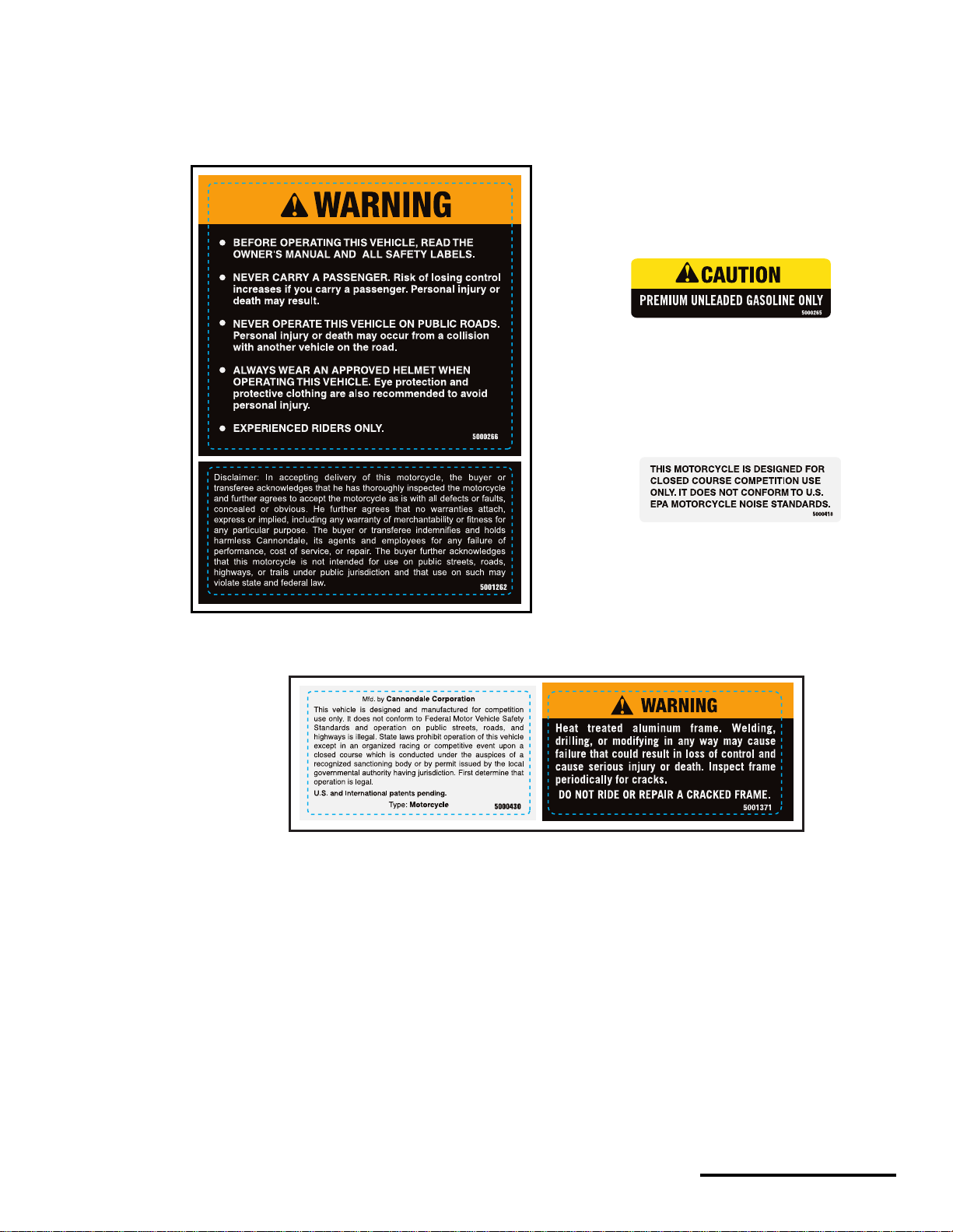

ENGINE SERIAL NUMBER

The engine serial numb er i s etche d/s tam pe d into th e eng ine

crankcase.

XXXXXXXXXXXX

Record your vehicle’s ID number here:

See illustration on following page for examples of the

numbered labels abov e.

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

4

Page 6

LABELS

(1)

(2)

(3)

1. General

2. Fuel

3. EPA noise

4. Frame

(4)

5

P/N 951-05002032

Printed : 8/13/01

Page 7

Pre-Ride

Inspection

WARNING

POTENTIAL HAZARD

Failure to inspect vehicle before operating.

WHAT CAN HAPPEN

Increases the possibility of equipment failure

resulting in a accident where you can be seriously

injured or killed.

HOW TO AVOID THE HAZARD

Always inspect before operating.

Always follow the inspection and maintenance

procedures found in this Owner’s Manual.

Have an authorized Cannondale Motorsports Dealer

inspect your veh ic le at le ast e very 25 ho urs of ridin g.

SUSPENSION

fork legs . . . . . . . . . . . (wear, damage,settings, oil leaks)

rear shock. . . . . . . . . .(wear, damage, settings, oil leaks)

WHEELS

wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (damage)

spokes . . . . . . . . . . . . . . . . . . (correct tension, damage)

TIRES

physical. . . . (tread conditions, wear, damage, punctures,

tears)

pressure . . . . . . . . . . . . . .(correct, regulate if necessary)

BODY PANELS

seat . . . . . . . . . . . . . . . . . . (damage, installed correctly)

plastics . . . . . . . . . . . . . . . . . . . . . . . . .(secure, damage)

FASTENERS

bolts, fasteners . . . . . . (tightened to the specified torque)

PRE-RIDE CHECKLIST

FLUIDS

brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . (level correct)

coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . (level correct)

engine oil . . . . . . . . . . . . . . . . . . . . . . . . . .(level correct)

transmission oil. . . . . . . . . . . . . . . . . . . . . .(level correct)

Fuel cap tightened securely

Inspect vehicle for leaks and repair if necessary.

BRAKES

Front/rear brakes . . . . . . . . . . . . . . . . . .(proper function)

Front/rear pads . . . . . . . . . . . . . . . . . . . . (damage, wear)

Front/rear discs. . . . . . . . . . . . . . . . . . . . (damage, wear)

THROTTLE

lev e r freepl ay. . . . .(as specified in all steering positions ))

proper operation . . . (smooth and returns to idle (clos ed)

position across the entire

steering range)

CLUTCH

clutch lever freeplay . . . . . . . . . . . . . . . . . . (as specified)

actuating arm . . . . . . . . . . . . . . . . . . . . (correct position)

DRIVE

sprocket conditions. . . . . . . . . . . . . . . . . (damage, wear)

chain condition . . . . . . . . . . (damage, wear, stretch limit)

chain sag . . . . . . . . . . . . . . . . . . . . . . . . . . (as specified)

clean and lubricate the chain

chain rollers . (cracks, excessive wear, or other damage)

chain guide block . . . . .(cracks, excessive wear, or other

damage)

swingarm buffer . . . . . .(cracks, excessive wear, or other

damage)

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

6

Page 8

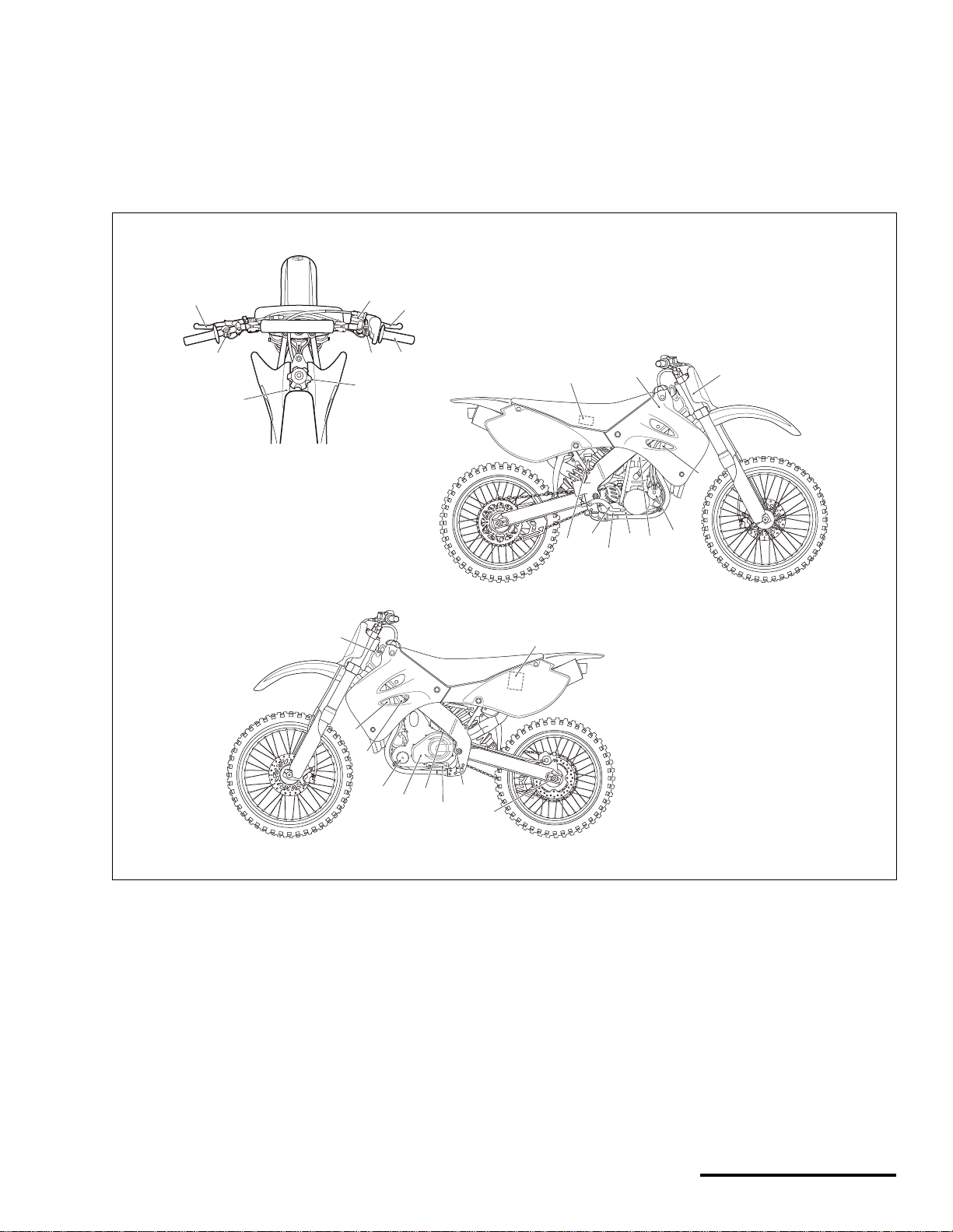

Component

Locations

1

2

3

5

6

4

7

19

20

21

8

22

25

24

23

27

28

26

9

10

18

17

1. Clutch lever

2. Engine stop button

3. Front brake master cylinder

4. Engine start button

5. Front brake lever

6. Throttle

7. Fuel tank cap

8. Fuel tank

9. Engine oil fill

10. Battery

11. Drive chain adjusters

12. Engine oil drain (frame)

14

13

12

11

7

16

15

13. Shift lever

14. Transmission oil fill

15. Clutch

16. Engine oil filter

17. Idle adjusting screw

18. Radiator

19. Engine Control Module (ECM)

20. Airbox filter

21. Main air filter

22. Fuel injectors

23. Starter clutch cover

24. Water pump

25. Engine oil crankcase drain

26. Transmission oil drain

27. Brake pedal

28. Rear brake reservoir

P/N 951-05002032

Printed : 8/13/01

Page 9

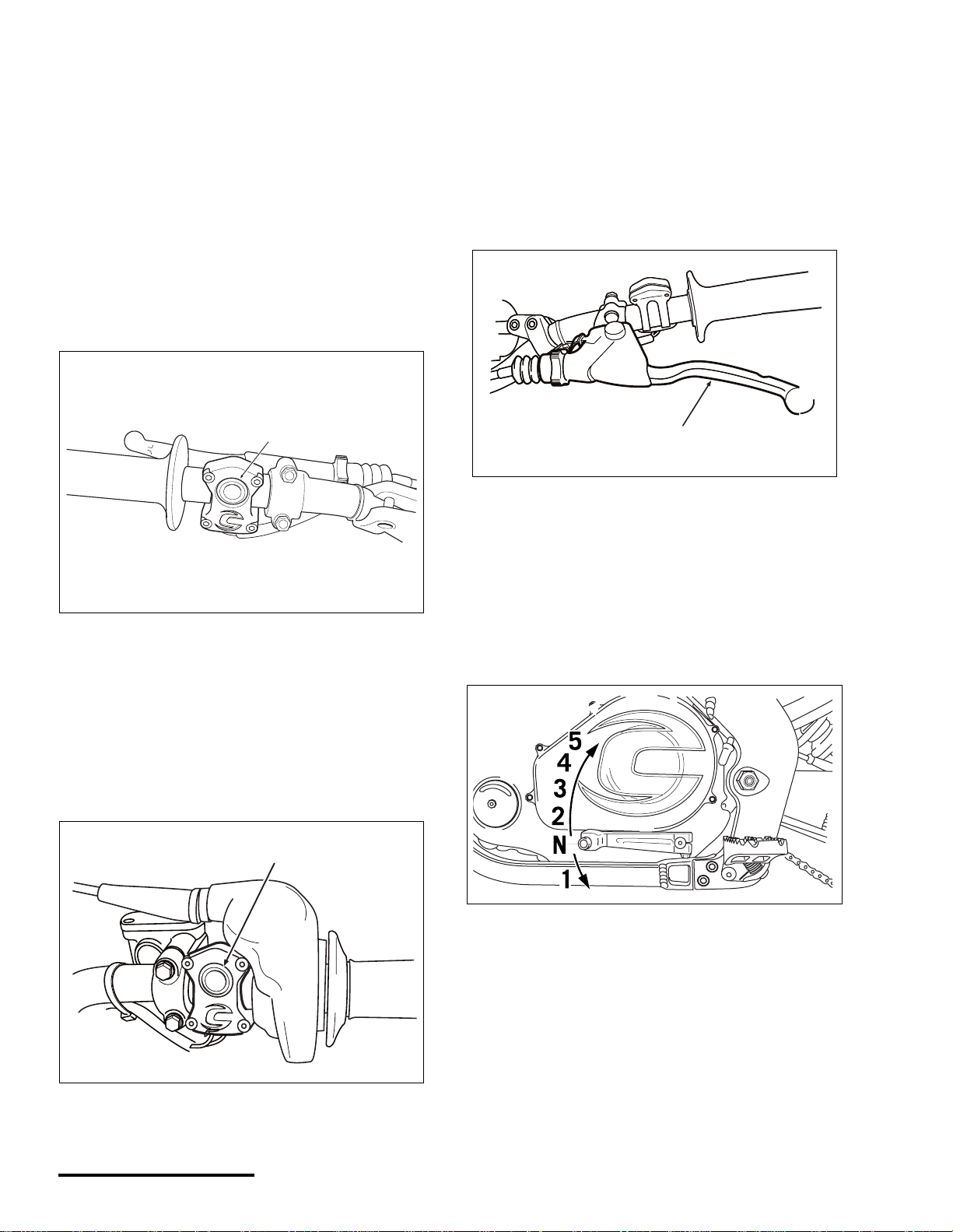

Controls

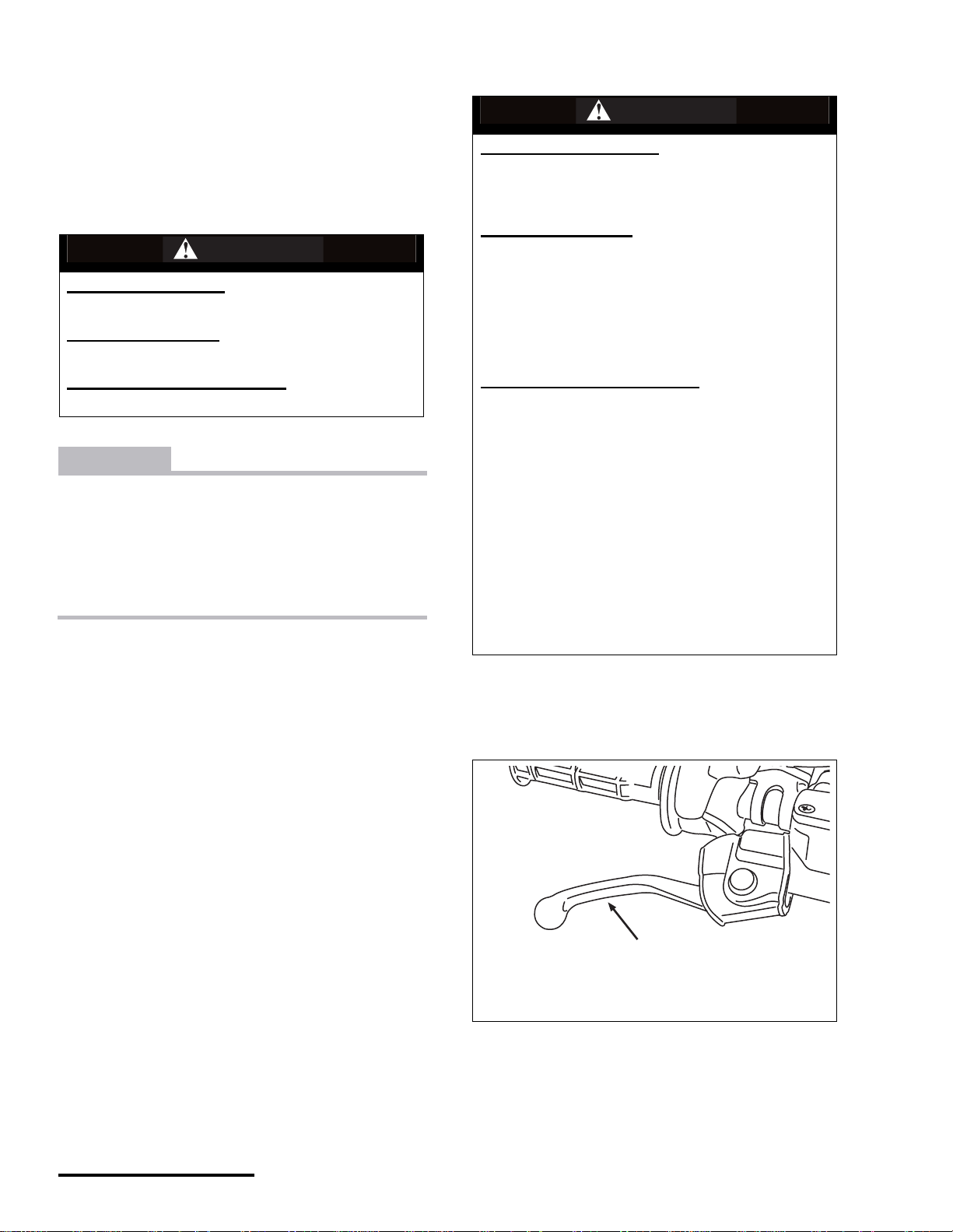

CLUTCH LEVER

The clutch lever is located on the left handlebar. Pull the

lever to disengage the clutch. Release the lever to engage

the clutch. The lever should be pulled quickly when

disengaging and slo wly when engaging.

ENGINE STOP BUTT ON

The engine stop button is located on the left handlebar. The

button is (RED) in color. Push it to stop the engine. Make

sure this button functions properly before you begin riding.

NOTE : The stop button is normally a closed circuit switch.

If the stop switc h is damag ed or the wires a r e fray ed or torn,

(circuit open) the engine may not sta r t.

1

1. Engine stop button

NOTE : When starting it is recommended that you shift the

transmission into neutral and pull in the clutch lever to

increase the starte r’s efficiency.

1

1. Clutch lever

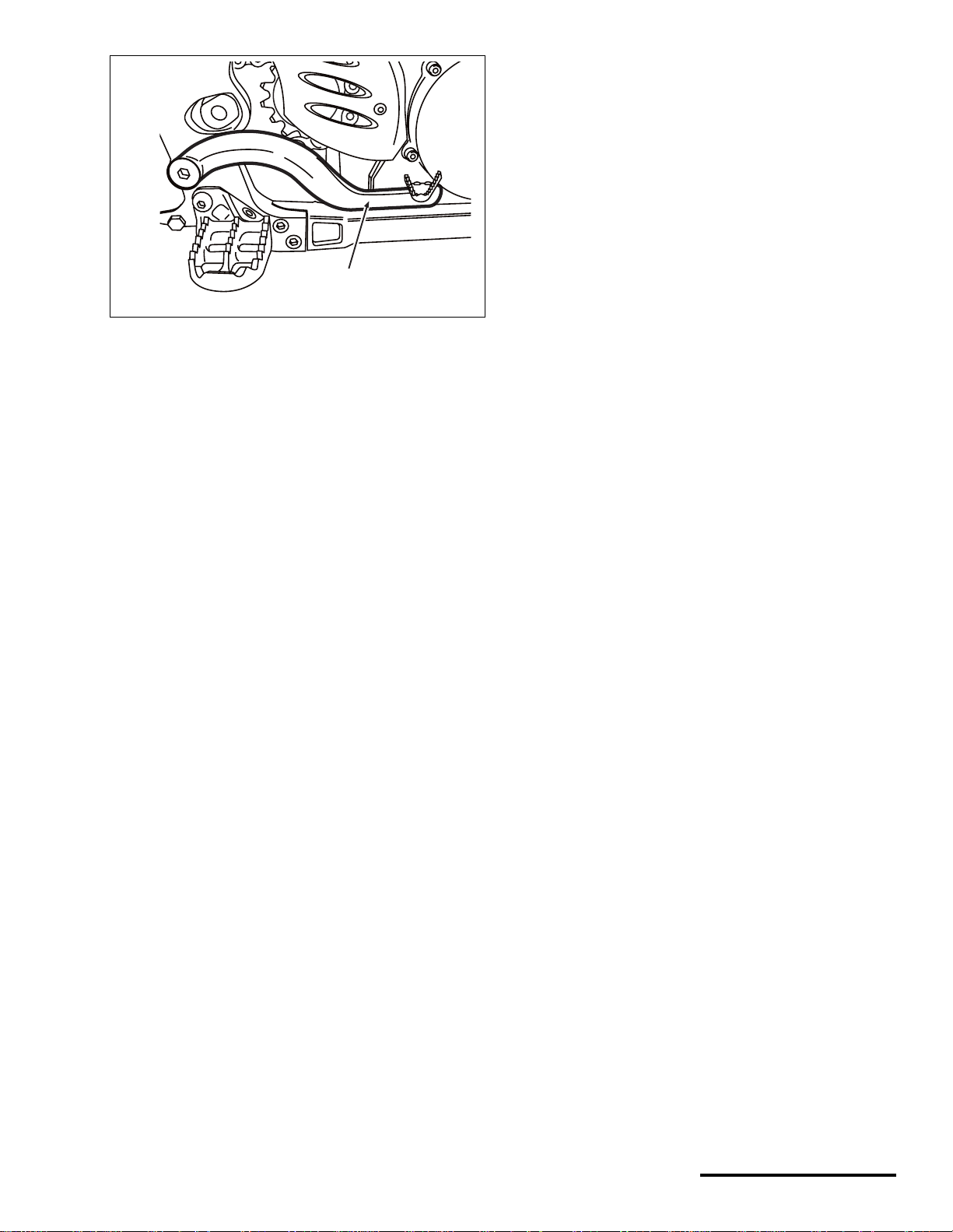

SHIFT LEVER

The shift lever is located on the left side of the engine.

NOTE : The tra n smission is commonly referred to as a “one

down, four up” transmission. Neutral is located between first

and second gears.

ENGINE START BUTTON

The engine start button i s locat ed on the rig ht handl ebar and

is (GREEN) in color. Pressing it activates the starter motor.

NOTE : When using the button, hold it for no more than 2-3

seconds at a time.

1

1. Engine start button

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

8

Page 10

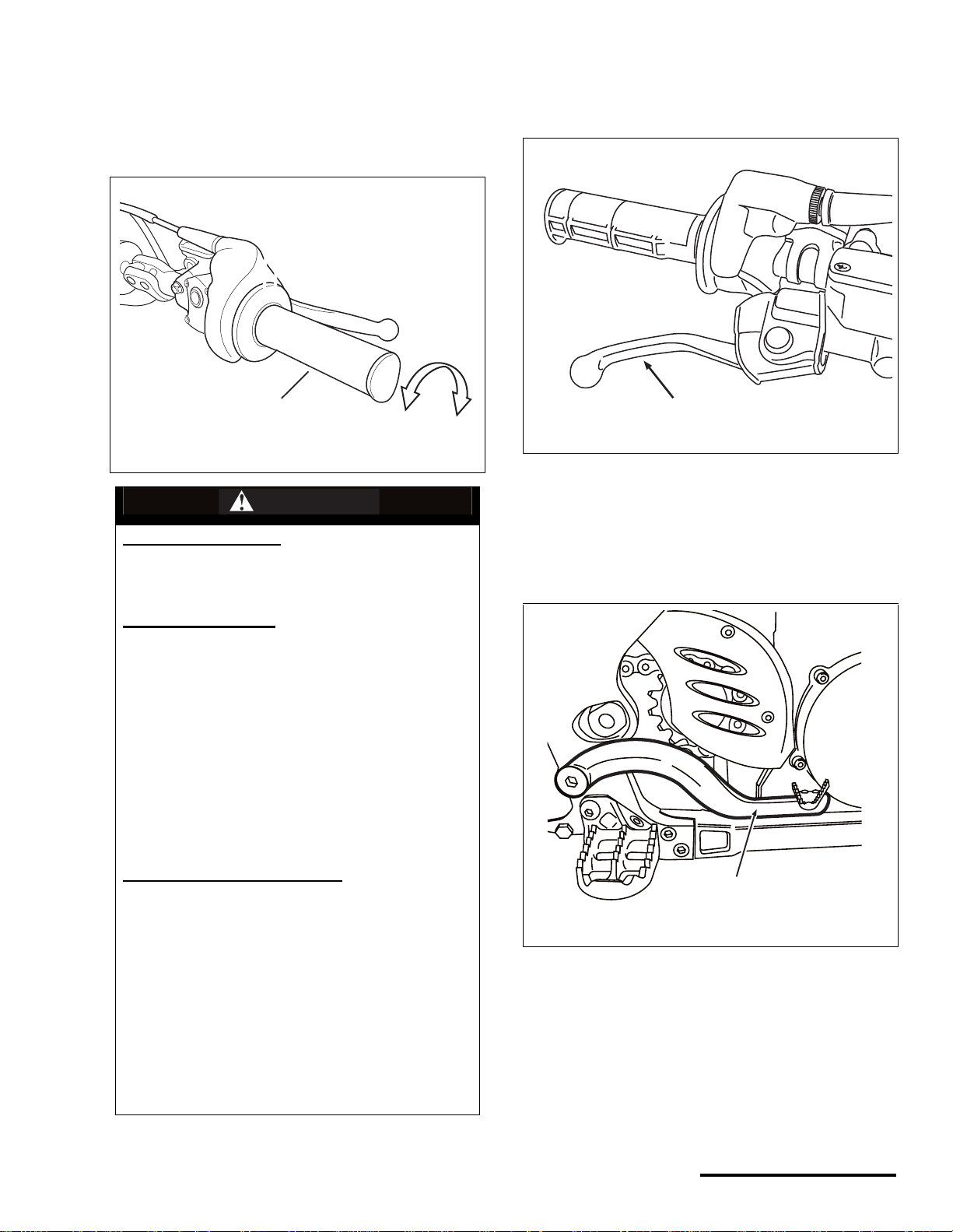

THROTTLE

1

FRONT BRAKE LEVER

The throttle lever is located on the right handlebaand

controls acceleration and deceleration of the engine. To

accelerate, turn the grip toward you. To decelerate, turn the

grip away from you.T

1

a

b

WARNING

POTENTIAL HAZARD

(1) Malfunctioning throttle

(2) Incorrect freeplay

The front brake lever is located on the right handlebar. Pull

the lever toward you to activate the front brake.

1

1. Front brake lever

REAR BRAKE PEDAL

The rear brake pedal is located on the right side of the

vehicle. Press it firmly to apply the rear brake.

WHAT CAN HAPPEN

(1) The throttle must return to to the closed position

when you release it. If it sticks you can lose the

ability to accelerate and decelerate the engine

which could result in an accident where you could

be seriously injured or killed.

(2) The throttle freeplay must be maintained as

specified, otherwise the engine speed could

increase when the handlebars are turned or when

the throttle is slightly grasped. Either situation

could result in an unexpected acceleration of the

engine where you could be seriously injured or

killed.

HOW TO AVOID THE HAZARD

(1) Test the operation of the throttle before each ride.

Make sure it operates smoothly (with no sticking or

binding) in all steering positions. It should return

automatically to the closed position when relea se d.

(2) Make sure the throttle freeplay is adjusted as

specified. See “throttle Freeplay” starting on

page 38.

(1 & 2) If the throttle malfunctions or you can not

adjust the throttle to the specified freeplay, do not

ride the vehicle. Contact an authorized Cannondale

motorsports for servicing.

1. Rear brake pedal

9

P/N 951-05002032

Printed : 8/13/01

Page 11

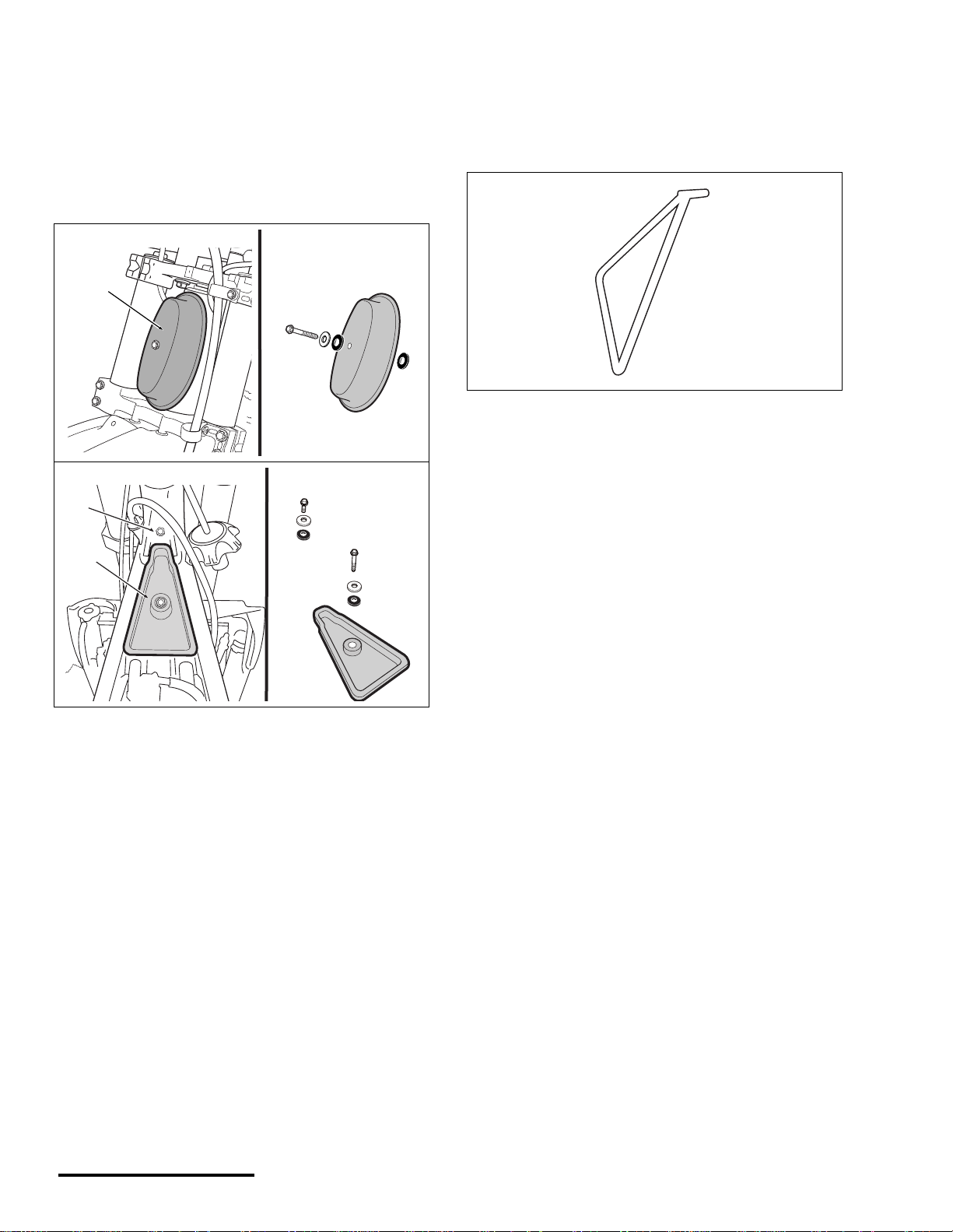

AIR FILTER CLEANING PLUGS

SIDE STAND

The air filt er cleaning plugs ar e provided with yo ur vehicle

and must be installed when washing/cleaning the

motorcycle. These plugs will help guard against water and

other contaminants entering the engine. Make sure the

sealing foam on the plug is in good condition. See the

cleaning section of this manual for how to install the plugs

properly.

1

2

The side stand is used to support the vehicle when not in

use. It is only designed to support the weight of the vehicle;

do not apply extra weight when using it (e.g., leaning on the

bike) Be sure to remove it before starting out.

3

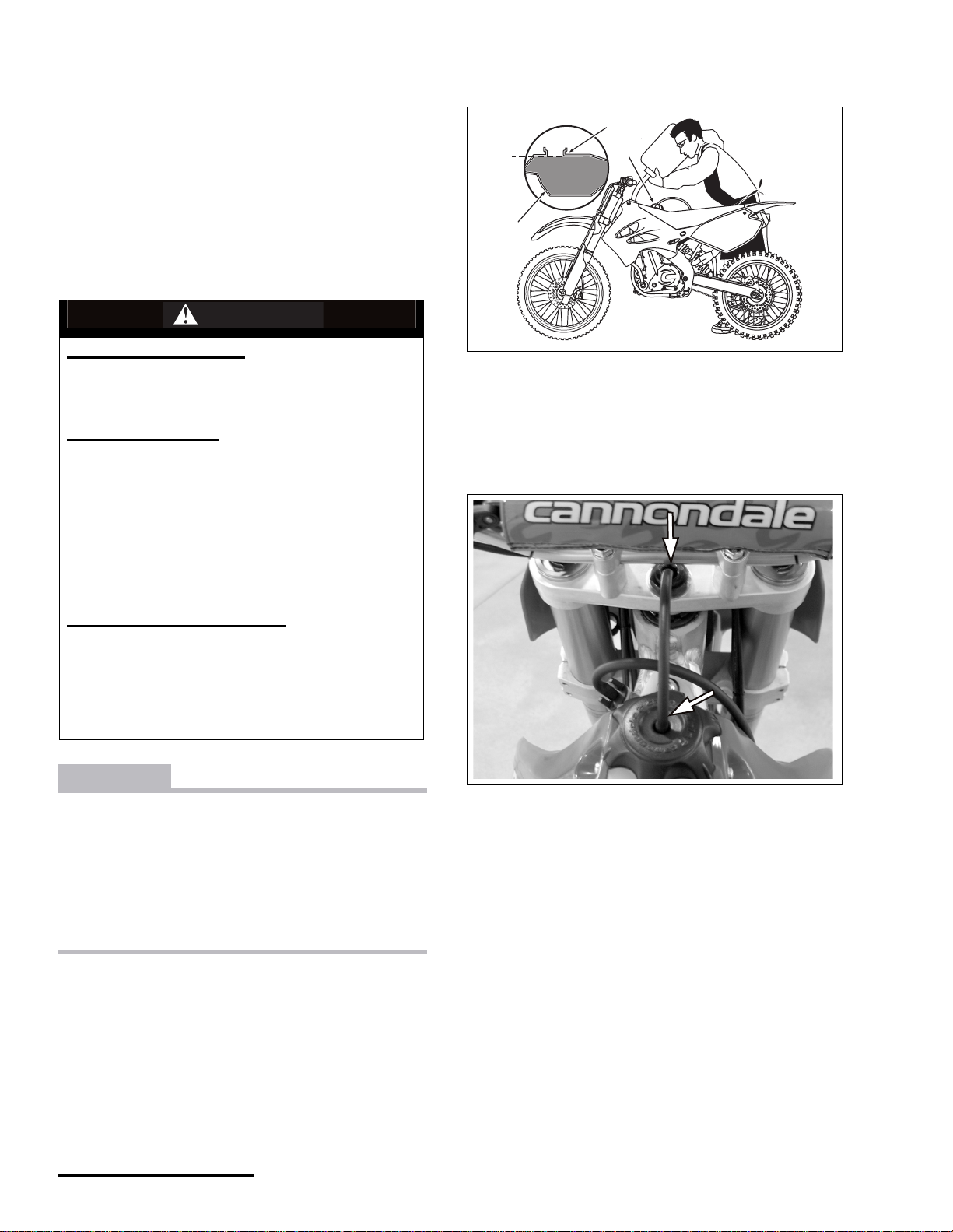

1. Steering head plug

2. Fuel tank bolt hole plug

3. Airbox plug

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

10

Page 12

Operating

This section explains basic operating and riding methods

(i.e., starting, stopping, and shifting). If after reading this

manual or at anytime you hav e any q uestio ns rega rding ho w

to operate the vehicle, contact an authorized Cannondale

motorsports dealer for assistance.

WARNING

POTENTIAL HAZARD

Failure to inspect vehicle before operating.

WHAT CAN HAPPEN

Increases the possibility of equipment failure

resulting in a accident where you can be seriously

injured or killed.

STARTING

DANGER

POTENTIAL HAZARD

Running the engine indoors.

Breathing exhaust gases

WHAT CAN HAPPEN

Running the engine indoors will expose you to

dangerous exhaust gases. Breathing carbon

monoxide gas leads to poisoning, asphyxiation, and

death. This will happen rapidly and without notice.

HOW TO AVOID THE HAZARD

Never operate the vehicle indoors even for brief

periods.

BATTERY (FULLY CHARGED)

HOW TO AVOID THE HAZARD

Always ins pec t before operating.

Always follow the inspection and maintenance

procedures found in this Owner’s Manual.

Have an authorized Cannondale Motorsports Dealer

inspect your vehicle at least after every 25 hours of

use.

CAUTION

Allow the engine to reach operating temperature

before riding.

This vehicle does not have a cooling fan. Airflow

across the radiator is maintained during riding. If

the vehicle runs without airflow, the engine can

overheat and be severely damaged. The time it

would take to overheat will depend on the weather

conditions. Do not allow your vehicle to idle for

more than 3 minutes without airflow across the radiator.

• Make sure the battery is at full charge. Why? If the

battery voltage dr ops wh ile you are using the

starter motor, the v olta ge could drop and the power

relay of the ECU will shut the ECU off. When this

happens, the engine will turn over but not start.

COLD STARTING - (MC1000 )

NOTE : MC1000 equipped unit utilize an idle air control

valve which automatically adjust throttle air bypass for cold

starts. Do not open the throttle when cold starting.

1. Shift transmission into NEUTRAL and pull-in and hold

in the clutch lever.

2. Press and hold the engine start button for no more

than 2 to 3 seconds at a time.

When the engine fires release the button and slowly

release the clutch lever.

11

P/N 951-05002032

Printed : 8/13/01

Page 13

STARTING A WARM ENGINE

BRAKING

When starting an engine after it has reached operating

temperature, do not open th e th rottl e. This wi ll m ak e s tart ing

very difficult a nd pos si bly foul the spark plug.

SHIFTING GEARS

WARNING

POTENTIAL HAZARD

Shifting to a lower gear at high speeds.

WHAT CAN HAPPEN

Tires can lose traction and cause an accident.

HOW TO AVOID THE HAZARD

Do not down shift at high speeds.

CAUTION

When shifting gears, press the shift lever firmly to

make sure the gears engagement is complete.

Careless shifting can result in incomplete gear

engagement and can cause the transmission to

jump out of gear. This can severely damage the

engine.

1. To engage first gear from NEUTRAL, pull in the clutch

lever and push down on the shift lever.

2. Release the shift lever.

3. Open the throttle a little and slowly let out the clutch

lever.

WARNING

POTENTIAL HAZARD(S)

(1) Using the brakes improperly.

(2) Wet brake system (e.g. discs, pads)

WHAT CAN HAPPEN

(1) If you apply the brakes too quickly or suddenly

the wheels may slide or skid possibly causing you to

lose control resulting in an accident where you

could be seriously injured or killed.

(2)Wet brakes do not provide the stopping power

needed and therefore are extremely dangerous.

HOW TO AVOID THE HAZARD

(1) Apply the front and rear brakes evenly and

gradually. Always consider the surface of the terrain

you are riding on and how it will affect your braking

ability. Concentrate on applyin g both brakes as har d

as possible without skidding. Shift down or fully

disengage the clutch as necessary to keep the

engine from stalling.

(2) In wet conditions test the brake operation

frequently. When riding in wet conditions, ride the

vehicle at sl ow spe eds an d ap ply th e b rake s seve ral

times until they are dry and at full power. Before

riding the vehicle m ake su re the b rakes an d controls

(e.g., brake lever, brake pedal, clutch lever, engine

stop switch, and throttle) operate properly.

To brake, close the throttle completely with the clutch

engaged (except when shifting gears) so the engine will

help slow down the vehicle. Apply the front and rear brakes

evenly.

4. To shift into a higher gear, pull in the clutch lever, push

the shift lever up to the next gear, release the shift

lever, then release the clutch lever.

5. To shift into a lower gear, pull in the clutch lever, push

down on the shift lever and release - then release the

clutch lever.

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

1

1. Front brake lever

12

Page 14

1. Rear brake pedal

1

STOPPING

When stopping the vehicle, pull in the clutch lever while

completely closing the throttle, shift the transmission into

neutral, and press the en gin e stop switch with your thumb.

AFTER YOU RIDE

1. After riding the vehicle, clean it thoroughly and allow it

to dry , and th en inspect th e entire veh icle for da mage or

loose fasteners.

2. Repair or tighten any damaged or loose comp onents

and lubricate the vehicle .

3. If the vehicle is damaged, it is recommended that you

put tape over the start button to remind you to not

start the vehicle. Also, attach a piece of paper to the

handlebar with the problem written on it.

13

P/N 951-05002032

Printed : 8/13/01

Page 15

Fluids

BRAKE

SERVICE : Brake, fluid type, DOT #4

CAUTION

Avoid spilling brake fluid on painted, plastic or rubber parts; damage can result. Place a shop towel or

rag over these parts when servicing the brake system. Any wipe up spills immediat ely.

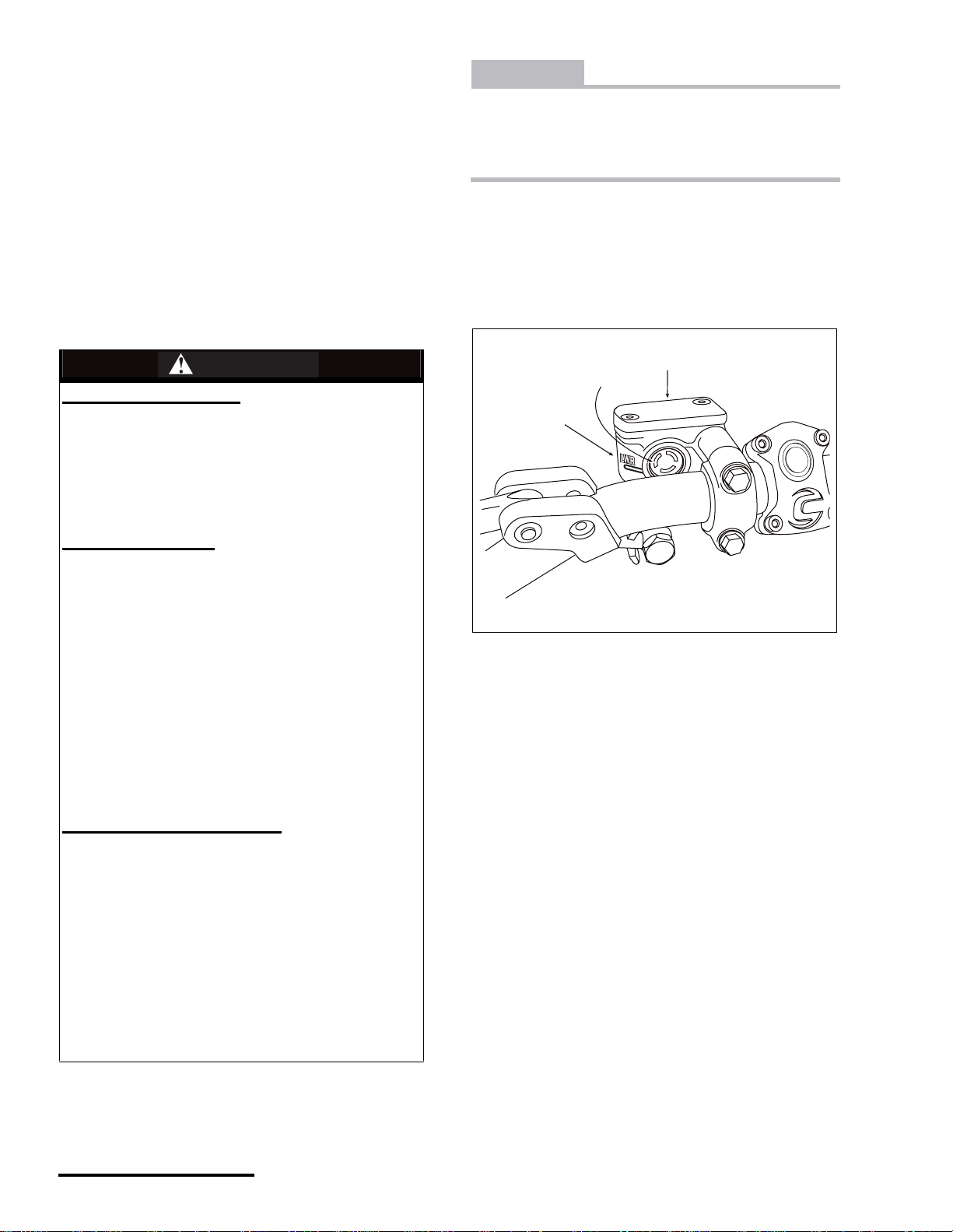

FRONT BRAKE

1. T o ch ec k the front system, start by leveling the top of

the master cylinder (mounted on the right handlebar).

WARNING

POTENTIAL HAZARD(S)

(1) Eye and skin injury, death if swallowed.

(2) Not using the specified, mixing different types (or

brands) of, and using unsealed containers of brake

fluid.

(3) Inadequate brake fluid levels.

WHAT CAN HAPPEN

(1) Brake fluid is a hazar dous substance. It can cause

injury to your ey es or skin if you touch it. If swallo we d

it can cause death.

(2) Using unspecified brake fluid can damage the

brake system leaving you without brakes. A container

of brake fluid once unsealed can begin to absorb

moisture from the atmosphere - if used in the brake

system, the moisture will reduce braking force. You

could lose your brakes an d hav e an accide nt resulting

in injury or death.

(3) Low brake fluid can allow air to enter the system

and this will reduce braking power. Again, you could

have an accident and be serio usly injured or killed.

HOW TO AVOID THE HAZARD

(1) Always wear eye and hand protection when

working with brake fluid. Keep brake fluid out of the

reach of children and animals. If ingested contact

contact a doctor immediately.

2

1

3

CLEAN BEFORE OPENING!

1. Master cylinder

2. Site window

3. ‘LWR’ mark

2. Inspect the fluid level through the site glass. If the

fluid level is below the ‘LWR’ mark, add the specified

brake fluid until the fluid is at the top of the window.

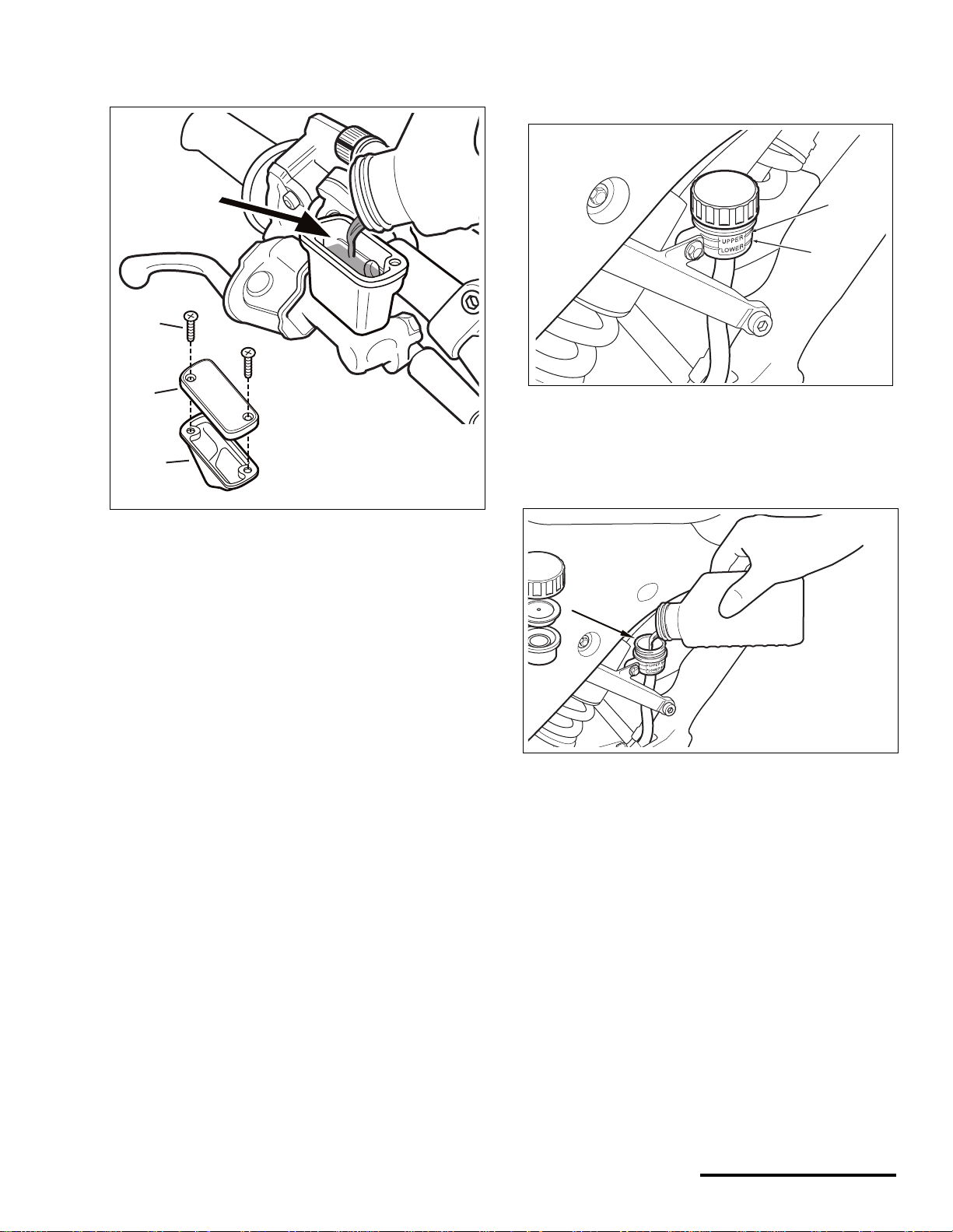

3. To add fluid, remove the screws, cover and

diaphragm from the master cylinder. Pour DOT#4

brake fluid from a sealed container into the resevoir.

Pour only until the fluid level rises to the top of the site

window and no higher. If you fill above the window

(2) Always use DOT 4 brake fluid from a sealed

container. Don’t mix fluids or use opened fluids.

Have the system drained and refilled by an authorized

Cannonadale Motorsports dealer if you suspect fluids

have been mixed acciden tally .

(3) Check for proper brake operation and fluid level

before riding the vehicle.

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

14

Page 16

fluid will spill when you re-install the diaphram and

4

cover.

POUR TO

TOP OF

WINDOW

DOT

1

2. If the fluid level is below the ‘UPPER’ mark, add

specified brake fluid until it reaches the ‘UPPER’

mark.

2

1

2

3

1. Front brake master cylinder cover screws

2. Front brake master cylinder cover

3. Diaphragm

4. Reinstall the front brake master cylinder diaphragm

and cover. Tighten front master cyli nd er cove r scre ws

to the specified torque.

TORQUE : Brake, master cylinder, front, cover screws

1.9 N•m (1.4 lbf•ft)

REAR BRAKE

1. To check the rear system, level the rear brake master

cylinder reservoir. The fluid level should be above the

‘LOWER’ mark.

1. ‘LOWER’ mark

2. ‘UPPER’ mark

NOTE : Do not fill the brake master cylinder above the

‘UPPER’ mark or the fluid will overflow when the diaphragm

is installed.

DOT 4

1. Reservoir cap

2. Diaphragm plate

3. Diaphragm

3. Install reservoir diaphrag m, diaphragm plate and cap.

15

P/N 951-05002032

Printed : 8/13/01

Page 17

COOLANT LEVEL

COOLANT

SERVICE : Coolant, type

Anti-freeze Ethylene glyc ol with corrosion

inhibitors fo r alumin um en gines

SERVICE : Coolant, mixture ratio

1:1 (coolant/distilled water)

WARNING

POTENTIAL HAZARD(S)

(1) Scalding coolant sprayed onto YOU

(2) Serious eye or skin injury

WHAT CAN HAPPEN

(1) You can be severely burned by coolant sprayed

out from under high pressure if the bottle is

opened while the system is hot.

(2) Coolant is poisonous. If it gets in your eyes or

contacts your skin the fluid can cause irritation or

severe injury.

1. To check the level, make sure the engine and radiator

are cold.

2. Place a thick towel over the radiator cap.

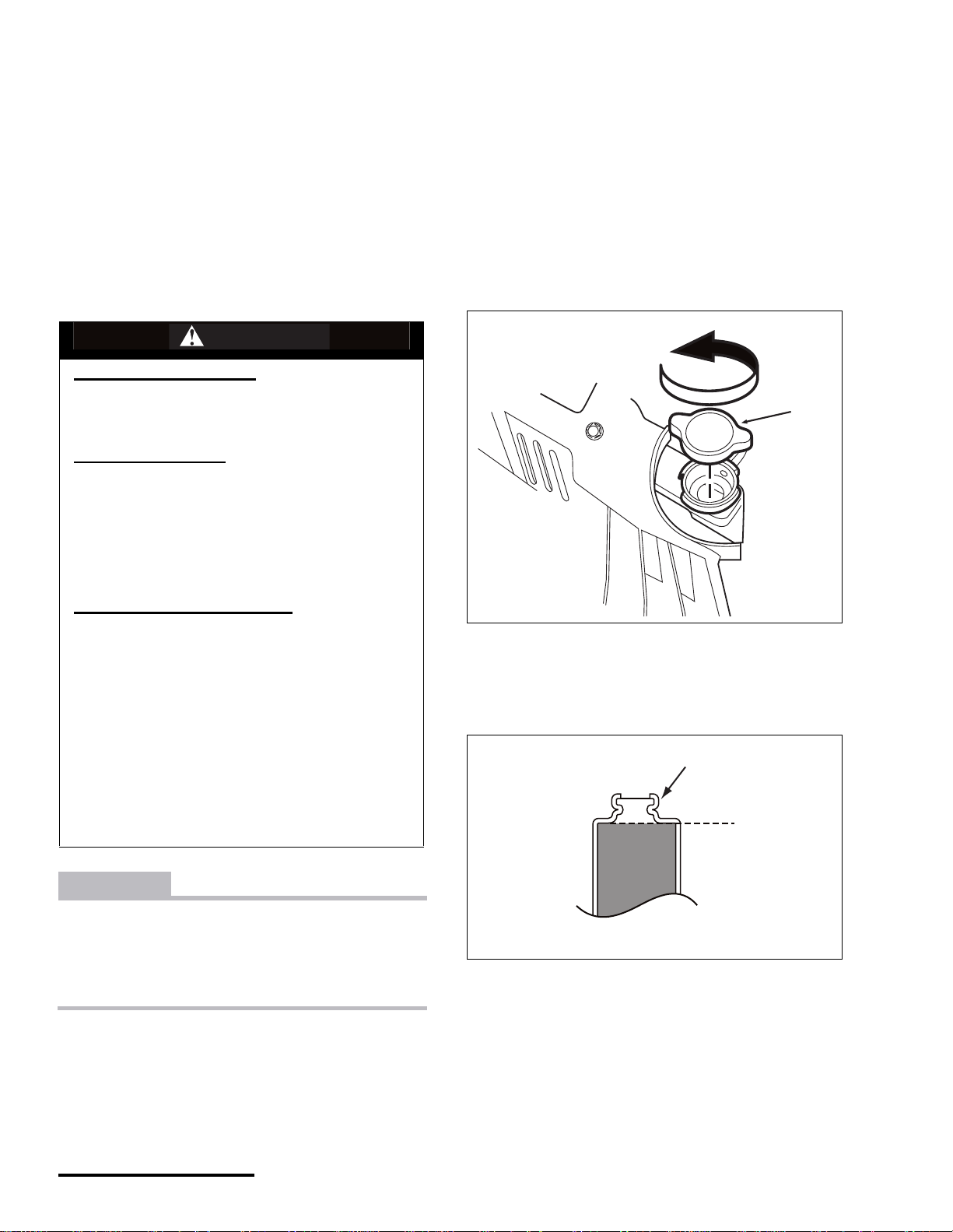

3. Slowly turn the cap in direction (a) until you feel the

cap reach the detent; this will allow any residual

pressure to escape. Allow all pressure to escape

before continuing.

Press down on the cap and keep turning it until it can

be removed.

a

1

HOW TO AVOID THE HAZARD

(1) Wait for engine to cool before removing the cap

or servicing the coolant system. Be sure to wear

eye protection, a long-sleeve shirt, and hand

protection (e.g. rubber gloves) when working with

coolant.

(2) Always wear eye protection and protective

clothing when working with any components of

the cooling system. Keep coolant away from

children and pets. Call a doctor immediately if

coolant is swallowed and induce vomiting. Flush

eyes and skin with water if coolant gets in eyes or

comes into contact with skin.

CAUTION

Operating the vehicle with a leaky or faulty cooling

system can result in severe engine damage. Always

use the specified coolant.

If the coolant level drops significantly, bleed the system after adding.

NOTE : We recommend that you bleed the coolant system

each time you add fluid.

1. Radiator cap

a. Loosening direction

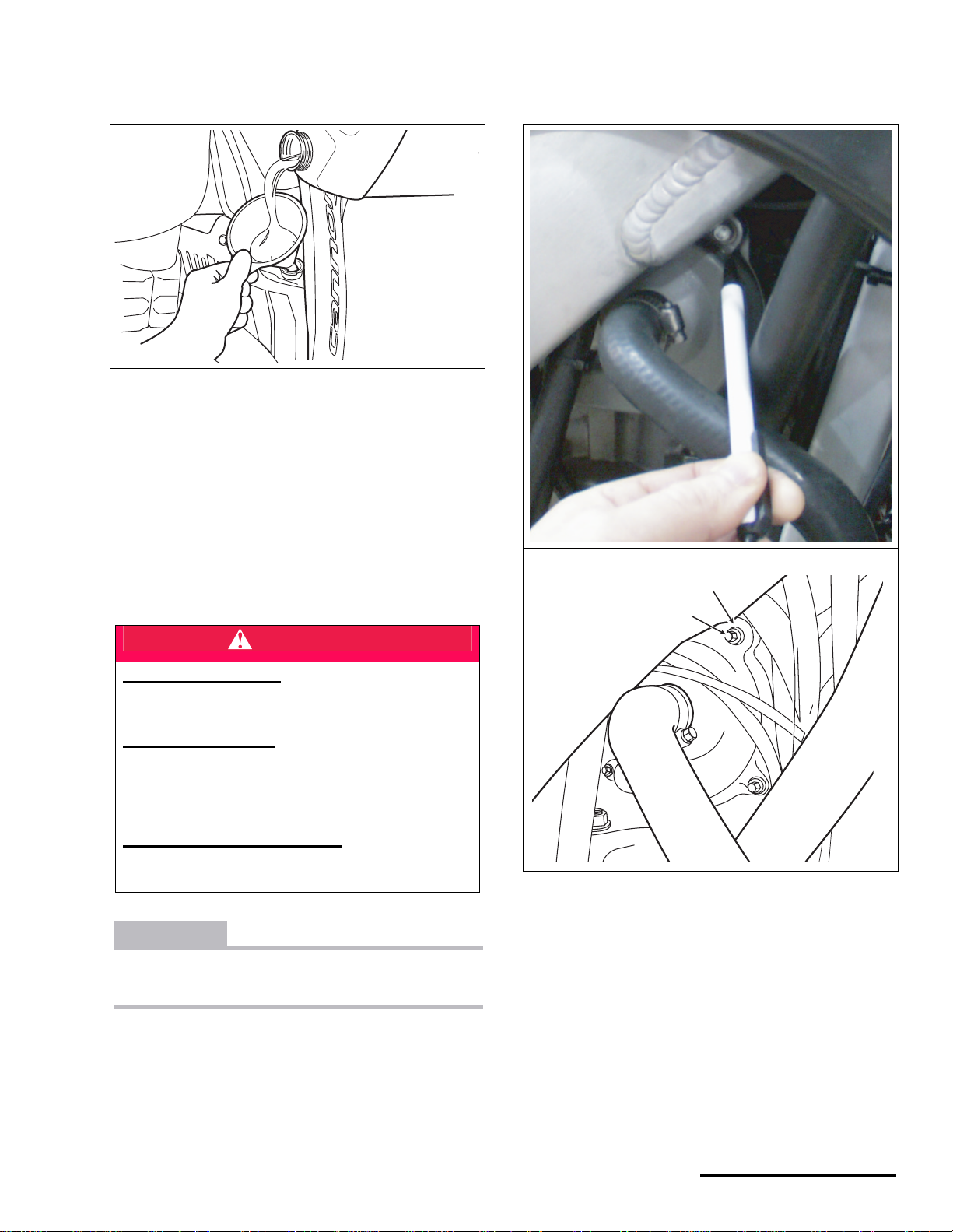

4. Coolant level should be at the bottom of the filler

neck. Add if necessary.

1

1. Filler neck

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

16

Page 18

5. To add, add the specified coolant at the radiator filler

hole using a clean funnel. Wipe up any spill ed cool ant

with a clean shop towel.

6. Reinstall the radiator cap.

7. Check the entire cooli ng system for le aks.

8. If the coolant level drops after adding and no leaks

are found, contact an authorized Cannondale

Motorsports dealer for servicing.

4. Loosen the bleed bolt on the water pump cover and

allow any trapped air to escape. It is not necessary to

remove the bolt.

BLEEDING THE COOLANT SYSTEM

DANGER

POTENTIAL HAZARD

Running the engine indoors.

Breathing exhaust gases

WHAT CAN HAPPEN

Running the engine indoors will expose you to

dangerous exhaust gases. Breathing carbon

monoxide gas leads to poisoning, asphyxiation, and

death. This will happen rapidly and without notice.

HOW TO AVOID THE HAZARD

Never operate the vehicle indoors even for brief

periods.

CAUTION

Do not over-tighten the bleed bolt and check the

condition of the sealing washer. If it leaks, replace it.

1

2

1. Sealing washer

2. Bleed bolt

5. When no more air is coming out of the bolt hole; only

coolant, tighten the bleed bolt. Add coolant at the

radiator to bring to proper level if necessary.

6. Reinstall the radiator cap.

1. Make sure the engine and coolant system are cold.

2. Place vehicle on a stand.

3. Remove radiator cap.

17

7. Start engine and allow to idle for three minutes and

briefly touch the radiator. If the radiator is warm, the

cooling system was ble d properly . If the radiator is still

cool, stop the engine. Repeat the bleed procedure

and check again.

P/N 951-05002032

Printed : 8/13/01

Page 19

ENGINE OIL

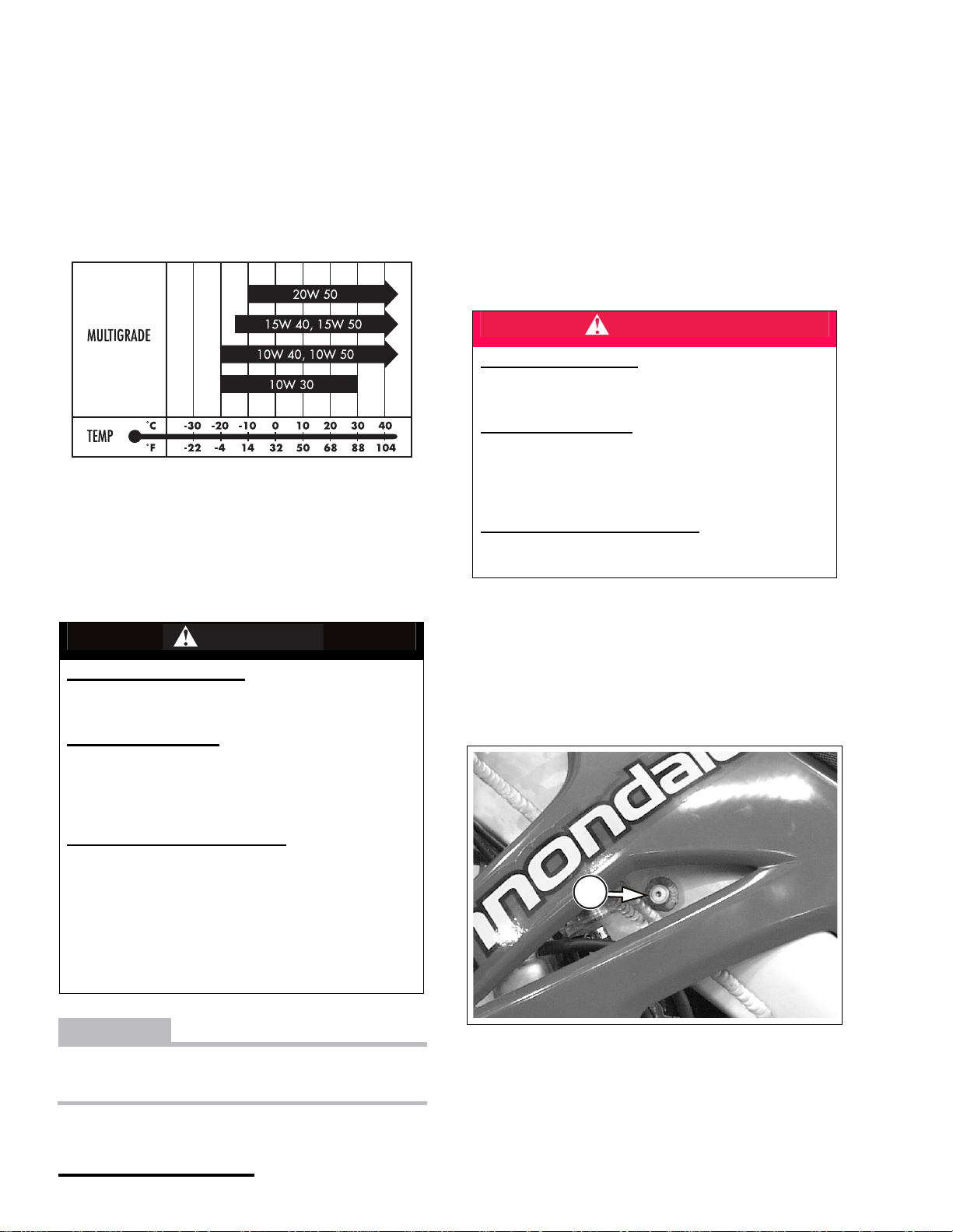

SERVICE : Engine, oil recommended

Synthetic or semi-synthetic, 10W-40.

SERVICE : Engine, oil, total quantity,

1.3 US qt. (1.2 L)

SERVICE : Engine, oil, change, quantity (* see note

below)

1 US quart (0.9 L)

NOTE : * When adding engine oil following a change (i.e.

drain of the spars, crankcase, filters removal and cleaning),

small volumes of oil can remain within the spar reservoirs.

Keep this fact in mind and be careful not to over fill the

system. The change quantity specified here provides

sufficient oil to operate engine safely so that level may be

checked in the spar.

Be careful not to overfill the engine oil. Pour small amounts

rechecking the le ve l b etw e en pours. Place vehicle on a level

surface.

CHECKING T H E EN GI NE OI L

DANGER

POTENTIAL HAZARD

Running the engine indoors.

Breathing exhaust gase s

WHAT CAN HAPPEN

Running the engine indoors will expose you to

dangerous exhaust gases. Breathing carbon

monoxide gas leads to poisoning, asphyxiation, and

death. This will happen rapidly and without notice.

HOW TO AVOID THE HAZARD

Never operate the vehicle indoors even for brief

periods.

1. T o check, place the vehicle on a stan d so it is le ve l.

WARNING

POTENTIAL HAZARD(S)

Serious injury or irritation to the skin or eyes.

Death if swallowed.

WHAT CAN HAPPEN

Engine oil is a hazardous substance. If it comes into

contact with your skin or eyes you can suffer

serious injury or irritation. If it is swallowed it can

cause death.

HOW TO AVOID THE HAZARD

Wear hand protection and safety glasses when

working with engine oil.

If you touch engine oil, wash it off immediately with

soap and water.

Clean clothes or rags contaminated with engine oil.

If swallowed seek immediate medical attention.

KEEP ENGINE OIL AWAY FROM CHILDREN AND

ANIMALS.

CAUTION

The correct oil level can only be checked after the

engine has run for a 1 minute.

2. Shift the transmission into NEUTRAL and start the

vehicle. Allow to run for 1 minute at idle speed, then

turn the engine off.

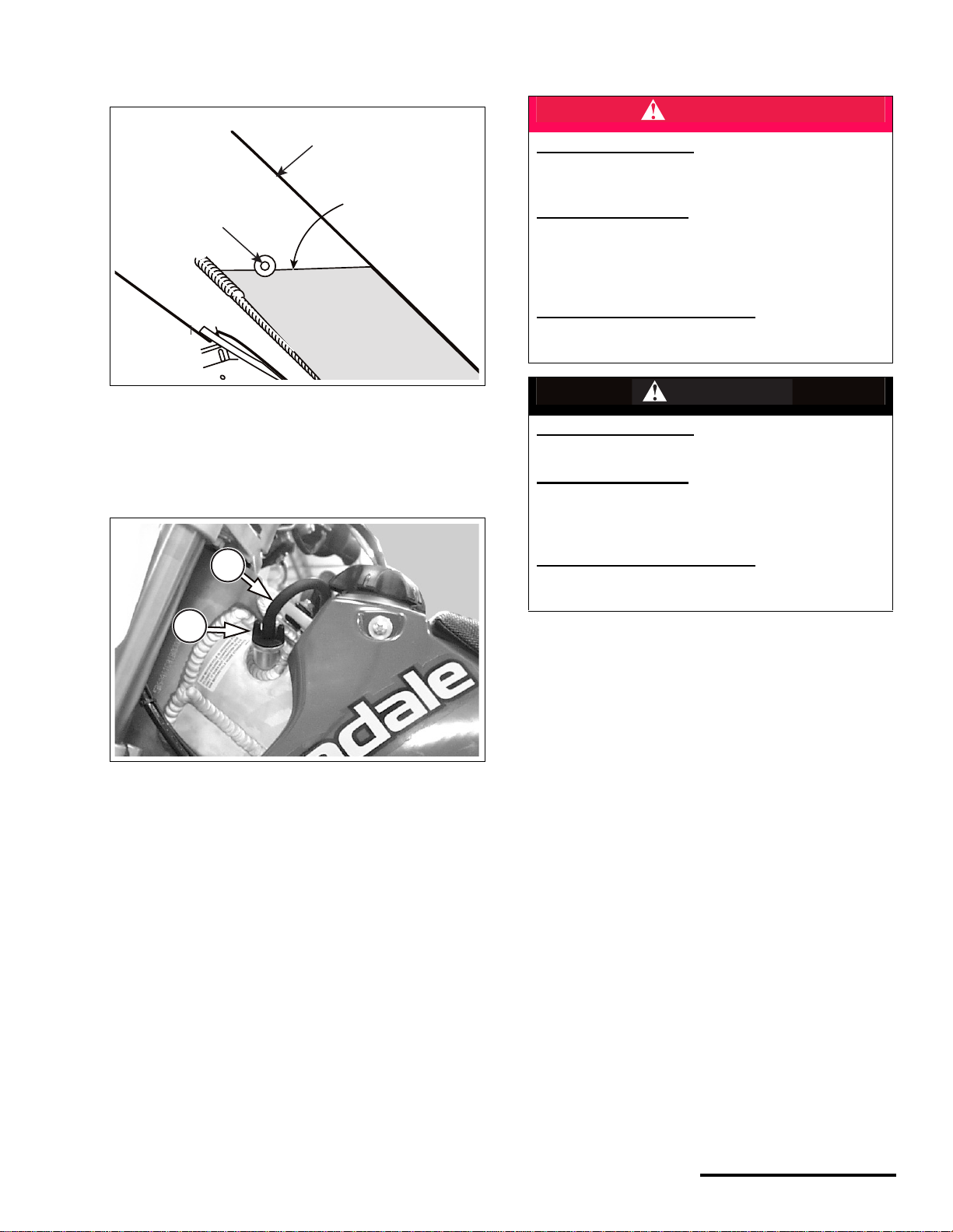

3. Remove the engine oil level check bolt.

1

1. Engine oil level check bolt (left frame spar)

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

18

Page 20

4. The engine oil level should be even with the bo ttom of

the check hole. Add if necessary.

LEFT FRAME

SPAR

CORRECT

CHECK BOLT

HOLE

OIL LEVEL

AFTER 1 MINUTE

CHANGING THE ENGINE OIL

DANGER

POTENTIAL HAZARD

Running the engine indoors.

Breathing exhaust gases

WHAT CAN HAPPEN

Running the engine indoors will expose you to

dangerous exhaust gases. Breathing carbon

monoxide gas leads to poisoning, asphyxiation, and

death. This will happen rapidly and without notice.

HOW TO AVOID THE HAZARD

Never operate the vehicle indoors even for brief

periods.

WARNING

5. To add, remove the filler ca p on the left frame spar

and pour the specified engine oil until the level

reaches the bottom of the check hole. Pour slowly to

allow the oil to flow throughout the spar.

2

1

1. Engine oil filler cap (left frame spar)

2. Vent hose

6. Reinstall the check bolt.

TORQUE : Frame, engine oil spar check bolt

15.0 lbf•ft (20.3 N•m.

POTENTIAL HAZARD

Blindness, eye injury,

WHAT CAN HAPPEN

When cleaning the oil filters, objects propelled by

compressed air can strike your eyes and cause

serious injury or blindness.

HOW TO AVOID THE HAZARD

Wear safety glasses when working with compressed

air.

1. Place the vehicle on a stand.

2. Start engine and allow to reach normal operating

temperature 158°F (70°C).

3. Turn the engine off.

4. Place an oil pan under the left frame spar drain bo lt.

5. Connect a clear plastic hose to the engine oil drain

bolt and loosen it

6. Allow the contents of the spar to drain completely into

an oil pan.

19

P/N 951-05002032

Printed : 8/13/01

Page 21

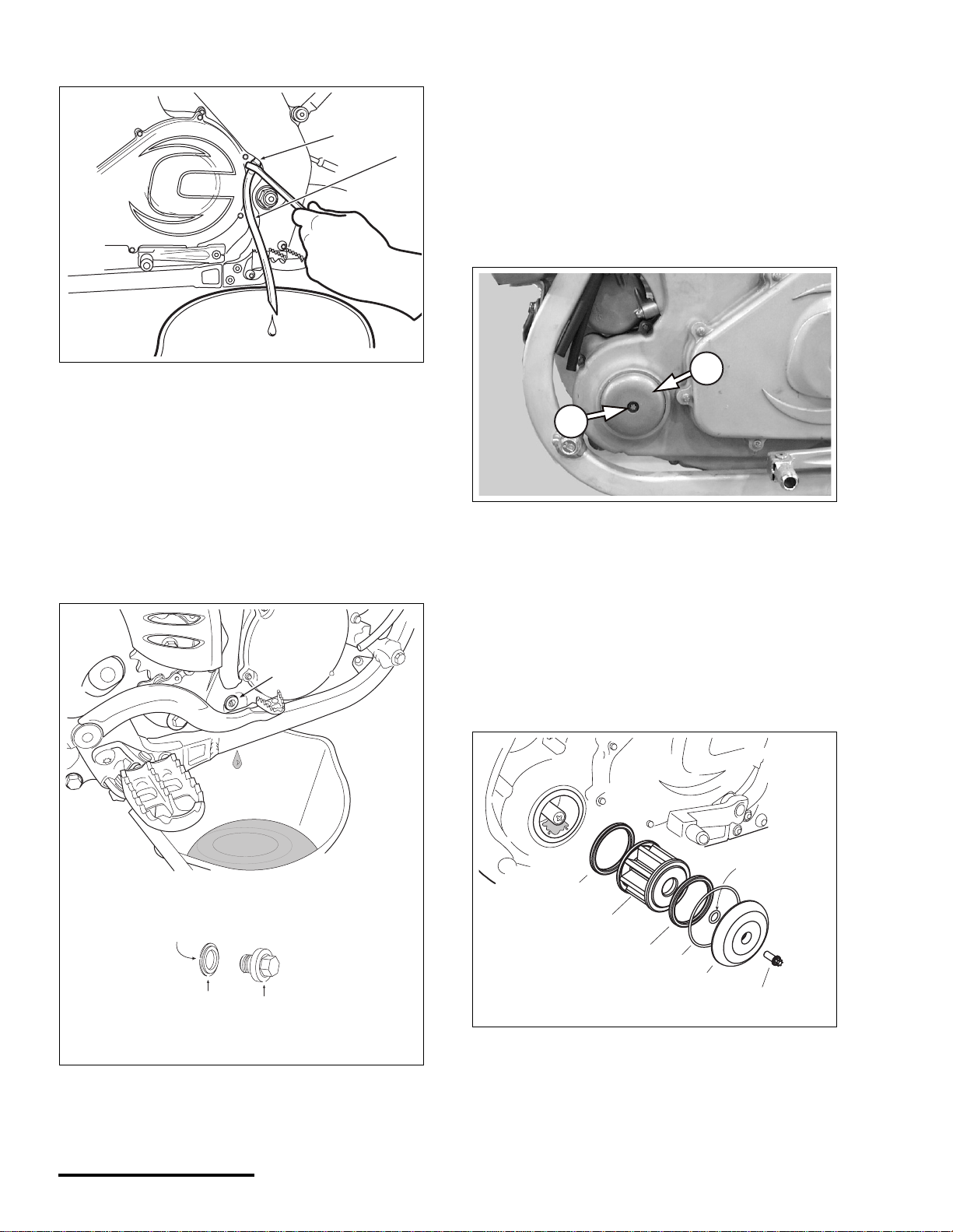

NOTE : Remove the spar oil filler cap to facilitate draining.

1

2

that the flat side faces the crankcase and install.

Tighten to the spe ci fie d torqu e.

TORQUE : Engine, engine oil drain bolt (crankcase)

6.0 lbf•ft (8.1 N•m)

10. Now, place a container under engine oil filter cover

and remove bolt and engine oil filter cover.

NOTE : Be sure to note the two cover O-rings as you

remove the cove r.

1. Engine oil drain plug (left spar)

2. Clear hose

7. Tighten the bolt.

TORQUE : Engine, engine oil drain bolt (left spar)

15.0 lbf•ft (20.3 N•m)

8. Place a container under engine oil crankcase drain

bolt located on the right side of the engine and

remove it and the sealing washer. Allow the oil to

drain completely.

1

2

1

1. Filter cover bolt

2. Filter cover

11. Remove the seal, filter (screen) and seal from the

filter housing.

12. Clean the filter using compressed air and clean the

the filter housing cavity with a clean shop towel.

13. Inspect the seals and filter element for tears, cracks,

and other damage. Replace new if damaged.

FLAT SIDE

SEALING

BOLT

WASHER

1. Bolt

2. Sealing washer

9. Apply anti-seize compo und to t he threa ds of th e drain

bolt. Then install the sealing washer onto the bolt so

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

1. Bolt

2. Cover

3. O-ring (2-011)

4. O-ring (2-033)

5. Filter seal

6. Filter (screen)

20

3

5

6

5

4

2

1

Page 22

14. Apply a light coat of O-ring grease to the large and

small cover O-rings and insert them back into the

cover.

15. Use some O-ring grease to “stick” the filter seals s o

that they are centered on the filter. This will help

assure that the seals remain in place when you insert

the filter into the housing.

16. Install the cover and cover bolt.

CAUTION

Do not over-tighten the cover bolt. You will damage

the threads of the filter housing. If the cover leaks,

you may need to replace the cover O-rings or

inspect the cover and housing mating surfaces for

damage.

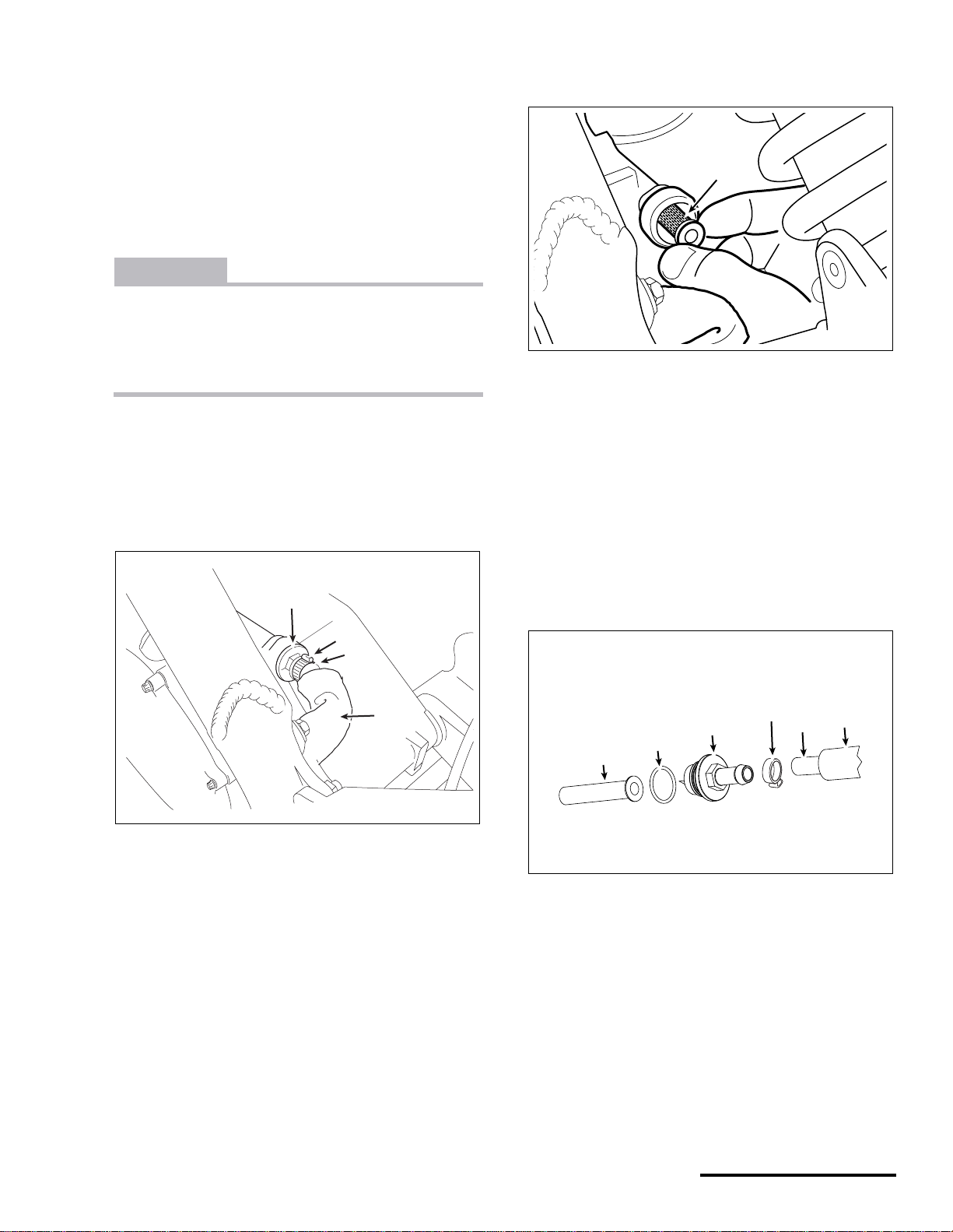

18. Loosen and remove the inlet fitting. Then, remove the

inlet filter (screen) from the crankcase hole.

1

1. Inlet filter (screen)

19. Clean the screen using compressed air.

TORQUE : Engine, engine oil, filter cover bolt

3.3 lbf•ft (4.5 N•m)

17. Now, carefully work the heat shield back to expose

the left spar return hose and clamp. Then, remove the

clamp and the hose from the engine oil inlet fitting.

4

3

2

1

1. Heat shield

2. Spar return hose

3. Clamp

4. Inlet fitting

20. Inspect the inlet fitting, 0-ring, and inlet screen for

tears, cracks, and other damage. Replace any

damaged part with a new one.

21. Reinstall the filter into the crankcase. Inspect the

fitting O-ring and replace it with a new one if

necessary.

22. Apply light coat of clean engine oil to the fitting O-ring

install the fitting. Tighten it to the specified torque.

3

4

6

5

2

1

1. Screen

2. O-ring

3. Inlet fitting

4. Clamp

5. Spar return hose

6. Heat shield

21

TORQUE : Engine, engine oil inlet fitting

18.0 lbf•ft (25.0 N•m)

23. Reinstall the engine oil inlet hose and clamp onto the

fitting.

24. Re-position the heat shield up to the cl amp.

P/N 951-05002032

Printed : 8/13/01

Page 23

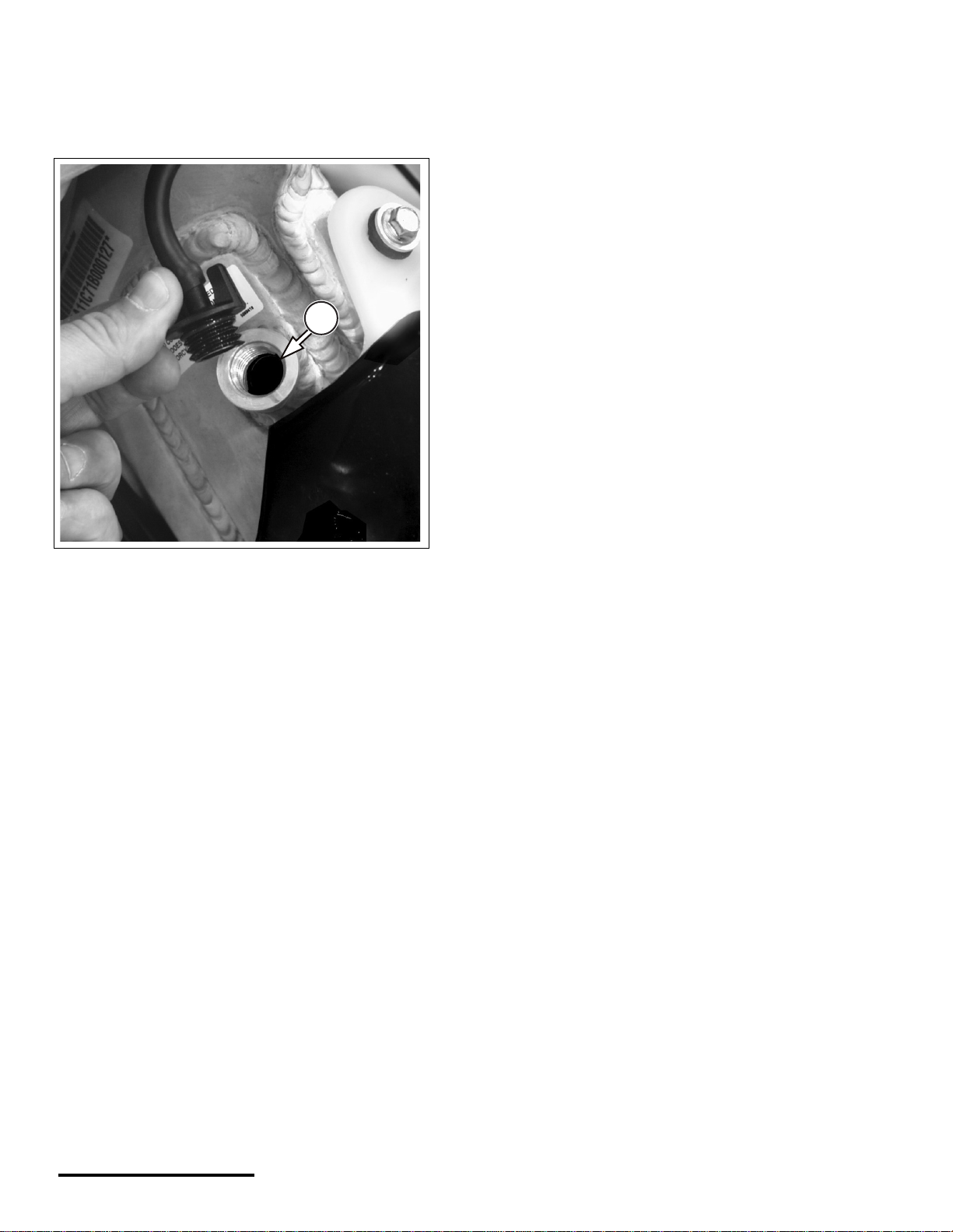

25. Now, remove the left spar oil filler cap and add the

specified “engine oil change quantity” using a clean

funnel.

Pour slowly allowing the oil to flow throughout the

spar.

1

1. Engine oil filler hole (left frame spar)

26. Reinstall cap and run engine for 1 minute at idle

speed to circulate the new oil.

27. Recheck the level as described in the engine oil

checking procedure. Add oil as required to bring level

to the bottom of the c hec k bol t hole.

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

22

Page 24

TRANSMISSION OIL

SERVICE : Transmission, oil, recommended type

80W or 85W

SERVICE : Transmission, oil, total quantity (dry fill)

0.74 US quart (0.7 L)

WARNING

POTENTIAL HAZARD(S)

Serious injury or irritation to the skin or eyes.

Death if swallowed.

and add small amounts slowly at the filler hole and

recheck the level.

1

WHAT CAN HAPPEN

Transmission oil is a hazardous substance. If it

comes into contact with your skin or eyes you can

suffer serious injury or irritation. If swallowed it can

cause death.

HOW TO AVOID THE HAZARD

Wear hand protection and safety glasses when

working with engine oil.

If you touch tran smissio n oil, wash it off imm ediatel y

with soap and water .

Clean clothes or rags contaminated with engine oil.

If swallowed seek immediate medical attention.

KEEP TRANSMISSION OIL AWAY FROM CHILDREN

AND ANIMALS.

CAUTION

A low transmission oil level may result in severe

engine damage. Check level before eve ry ride.

Always use the specified transmission oil.

Always use a clean funnel when adding transmission oil

1. Check bolt

4. Install t he transmission oil level check bolt.

TORQUE : Transmission, oil level check bolt

5.0 lbf•ft (6.8 N•m)

1

1. Transmission oil filler hole

1. To check, make sure the engine is cold.

2. Place the vehicle on a stand so it is level and wait a

few minutes until the tran sm ission oil settles.

3. Place a few rags under the transmission oil level

check bolt and remove it. The transmission oil level

should be even with the bottom of the check hole. If

the transmission oil level is low, install the check bolt,

23

P/N 951-05002032

Printed : 8/13/01

Page 25

CHANGING THE TRANSMISSION OIL

WARNING

POTENTIAL HAZARD

Blindness, eye injury,

WHAT CAN HAPPEN

When cleaning the oil filters, objects propelled by

compressed air can strike your eyes and cause

serious injury or blindness.

HOW TO AVOID THE HAZARD

Wear safety glasses when working with compressed

air.

CAUTION

When re-installing the transmission oil filter, be sure

to insert it into the drain bolt, then insert the pair

into the crankcase hole together. This helps assure

that the other end of the filter will locate into the

back of the transmission oil pump (rear of cartridge

plate inside gearbox cavity). If the filter does not

locate into the plate hole, unfiltered oil can enter and

damage the pump.

4. Lean the vehicle slightly to the right to ensure all oil is

drained.

5. If the fil ter did not com e out with the bo lt, remove it

carefully from the hole. Clean it using compressed

air.

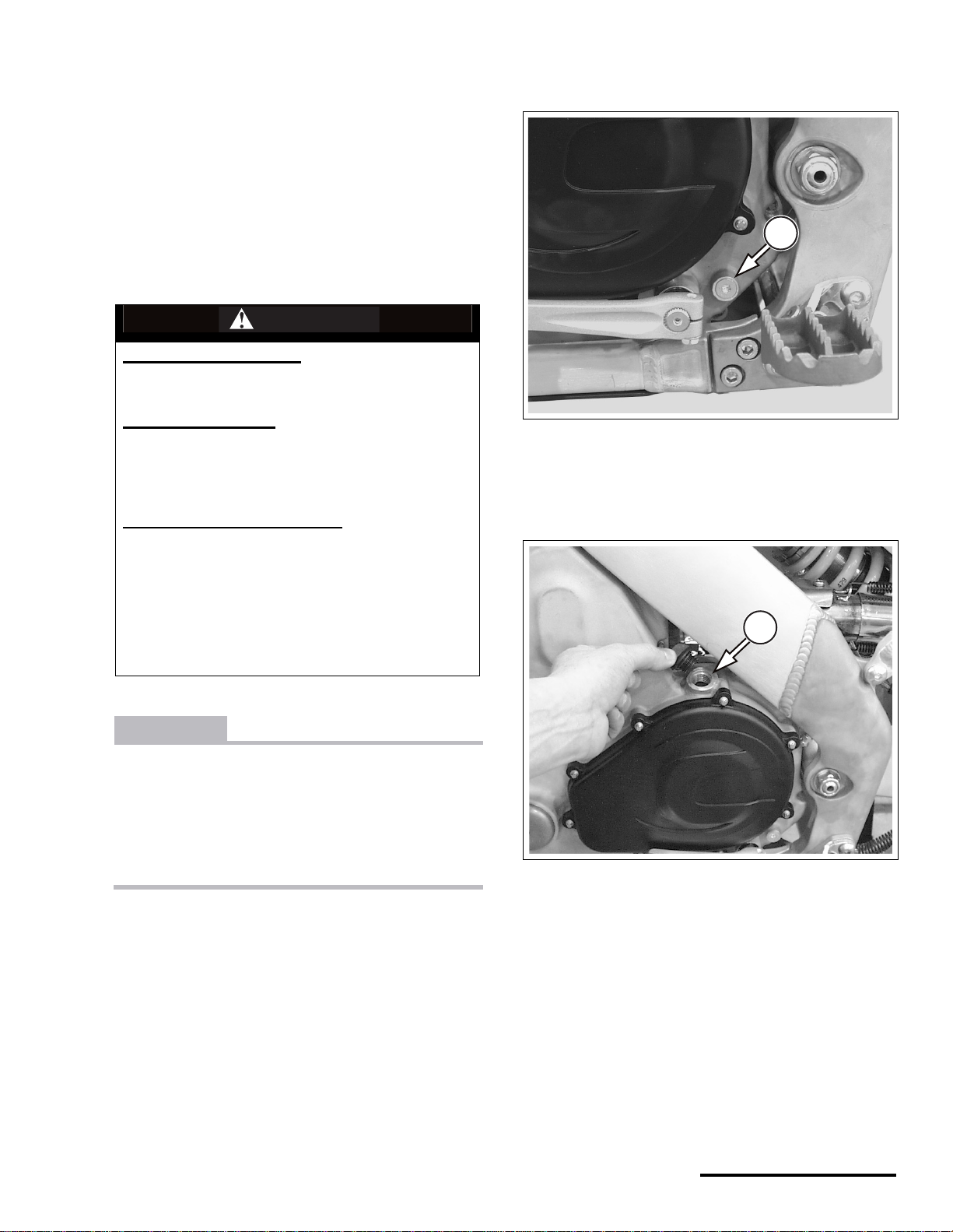

NOTE : The transmission drain bolt is located on the right

side of the engine. The filter (screen) may not come out with

the drain bolt. After the oil drains, use needle nose pliers to

gently remove it from within the drain hole.

Take notice of the sealing washer on the bolt when you

remove it.

1. Place vehicle on a level surface.

2. Place a suitable container under transmission drain

bolt and remove the bolt.

6. Inspect the filter for cracks, holes, tears, and other

damage. Replace new if damaged.

7. Make sure the threads of the bolt and crankcase are

clean.

8. Apply anti-seize compound to the threads of the

transmission drain bolt (1). Then install the sealing

washer (2) onto the bolt with the flat side (a) facing

3. Allow the transmission oil to drain completely.

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

24

Page 26

the case. Insert the filter into the bolt, and install into

the case.

3

a

2

1. Drain bolt

2. Sealing washer

3. Filter (screen)

a. Sealing washer flat side

1

9. Tighten the bolt to the specified torque.

TORQUE : Transmission, oil, drain bolt

6.0 lbf•ft (8.1 N•m)

10. Add the specified transmission oil at the filler cap until

oil level reaches the bottom of the check bolt hole.

Pour slowly and allow time for the oil to flow

throughout the case cavity.

11. Then, run the engine briefly (1-2 minutes) to circulate

newly added oil and recheck the level. Add if

necessary.

NOTE : The transmission oil level should always be at the

bottom of the check bolt hole.

25

P/N 951-05002032

Printed : 8/13/01

Page 27

3. After fueling, turn the fuel tank cap clockwise to

tighten.

FUEL

SERVICE : Fuel, recommended fuel

Premium unleaded gasoline

SERVICE : Fuel, fuel tank ca pac ity

2.1 US gal (8.0 L)

WARNING

POTENTIAL HAZARD(S)

(1) Fire or explosion

(2) Overfilling the fuel tank.

WHAT CAN HAPPEN

(1) Gasoline is extremely flammable. Handling it

inappropriately or near cigarettes, flame, sparks,

welders, or other sources of ignition can result in a

fire or explosion where you can be seriously injured

or killed.

(2) Fuel expands due to heat (e.g., engine, sun) and

may overflow if the tank is overfilled, resulting in a

fire

4

3

1

2

1. Fuel tank cap

2. Fuel tank

3. Fuel level

4. Filler neck

4. Make sure the fuel cap breather hose is routed

correctly.

HOW TO AVOID THE HAZARD

(1) Only handle gasoline outdoors and away from

cigarettes, flame, sparks, welders, or other sources

of ignition.

(2) Stop adding fuel when the fuel level reaches the

bottom of the filler neck

CAUTION

If engine “knocking” or pinging occurs, use a different brand of gasoline or a higher octane rating.

Never experiment by using fuels other than the recommended type in this vehicle. Other fuels or additives not designed specifically for this vehicle can

severely damage the eng ine a nd its sup porting com ponents (e.g. fuel system, sensor s, tank, hoses, etc. )

1. To add fuel, remove the fuel tank cap by turni ng it

counterclockwise.

2. Carefully fill the fuel tank with the recommended fuel

until the fuel level reaches the bottom of the filler

neck.

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

26

Page 28

Maint enance and

Adjustments

BREAK-IN

CAUTION

The break-in period for this vehicle is 1 hour.

If not used carefully during this period, the vehicle

may end up “broken down” instead of “broken in”.

Complete the Break-in column of the maintenance

schedule in this section.

RIDING WHEN BREAKING-IN

Ride two 10-minute segments using no more than 1/2

throttle and wait for the engine to cool after each segment.

Next, ride three 15 -mi nute segments using no more th an 3/4

throttle, again allowing the engine to cool between rides.

NOTE : During all rides, it is also important to shift gears

often so that high rpms are avoided and the engine is not

lugged.

SUSPENSION BREAK-IN

During the first hour, it is recommend ed to se t the ride height

(spring pre-load), but do not change the factory-set

suspension settings to allow the fork legs and rear shock

absorber to brea k-in , in or der to wor k freely with a m in imum

of friction.

NOTE : The initial suspension impression (or “feel”) could

be harsh or stiff, this will change after about 1 hour of use.

Therefore, do not change the initial suspension settings un til

after the vehicle has been ridden for 1 hour.

27

P/N 951-05002032

Printed : 8/13/01

Page 29

OWNER DEALER

Fuel

Transmission

Engine

Brakes

Coolant

Electrical

SCHEDULE

Fill to proper level

Replace inline filter

Adjust idling

Check throttle freeplay. Open the throttle fully and

check for proper retu rn to idle position.

Check transmissi on oil level

Change transmission oil and clean filter

Check engine oil level

Change engine oil and clean filters

Check valve clearan ce

Check fluid level

Pad wear (replace pads as a set)

Check brake lever freepla y.

Check brake discs

Check brake pedal height

Break-In

Pre-Ride

x

x

xx x

x

x

x

x

xx x x

(after 1 hour)

Every 5 hours

x

xx

xx

xx

Every 10 Hours

(

Every 25 Hours

x

x

Change brake fluid x

Check brake system rout ing

Check level

Inspect the cooling system (radiator, hoses, radiator

cap)

Inspect spark plug

Inspect vehicle for fluid leaks

Inspect all cable housings for wear or damage and

repair or replace if necessary.

xx

xx x

x

x

x

x

Once a year

Check all electrical wiring and connections for

correct routing, connections, and damage and

adjust, repair, or replace if necessary.

Visually inspect for loose or missing fasteners

Fasteners

Check all fasteners and tighten to the specified

torque

Check clutch lever freepl ay.

Clutch

Check clutch arm position

Air Clean air filters

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

x

x

xx

xx

xx

xx x

28

Page 30

OWNER DEALER

Drive chain

Exhaust

Frame

Steering

SCHEDULE

Check drive chain for wear, damage, stretch

Check the drive chain free pl ay

Clean and lubricate the drive chain

Inspect the drive sprockets for broken teeth, cracks,

excessive wear

Inspect the drive chain rollers, guide block, and

swingarm buffer for cracks, or excessive wear.

Inspect the e xhaust syst em for cra cks, hole s, leaks,

or other damage

Inspect the frame, subframe, and swingarm (and

bearings) for damage and repair or replace if

necessary.

Check the steering head beari ngs for co rrect prel oad

Check the steering head for correct rotation from left

to right steering stops and no interference from

cables, hoses, and wiring, and adjust if necessary.

Also, make sure the idle speed does not increase

when turning the steering head.

Break-In

Pre-Ride

xx x

x

x

xx

(after 1 hour)

Every 5 hours

x

Every 10 Hours

x

(

Every 25 Hours

x

x

x

Once a year

Suspension

Tires & wheels

Inspect the fork legs and rear shock absorber for

signs of oil leakage and repair if necessary. Make

sure the fork legs are evenly adjusted and adjust if

necessary.

Inspect the tires for cracks, tears, or other damage

and replace if necessary. Check the tire pressure

and regulate if necessary.

Inspect the wheels for damage

Check the spokes for correct tension or loose or

damaged spokes and rep lac e or tight en if nece ss ary

Check the wheel alignment and adjust if necessary.

xx

xx

xx

x

x

29

P/N 951-05002032

Printed : 8/13/01

Page 31

SEAT

PANELS

This section describes how to properly remove and install

the various panels of the vehicle.

After removing panels, inspect them for cracks, chips, or

other damage. If any panel is heavily damaged or interferes

with vehicle ope rati on (e.g., fork leg guard damage c aus es it

to interfere with the front suspension movement), replace

the damaged component with a new one.

SIDE NUMBER PANELS

To remove the side number panels, remove the bolts and

the panel.

1. To remove, first remove the side number panels.

2. Lift up the rear of the seat slightly, pulling it back and

away from the fuel tank.

WARNING

POTENTIAL HAZARD

Seat coming off while riding.

1

1. Bolts (left panel)

1

1. Bolts (right panel)

To install, place the panel in the original position and install

the bolts.

TORQUE : Panel, side number bolts

5.0 lbf•ft (6.8 N•m)

WHAT CAN HAPPEN

If you install the seat incorrectly or if it is damaged,

it can shift or come off while you are riding causing

you to lose con tro l. You could be seriously injured o r

killed.

HOW TO AVOID THE HAZARD

Make sure the seat is fastened securely and it is in

good condition. After installing the seat, pull the

front of the seat upwards to make sure it is locked

into position.

3. To install the seat, align retaining tabs located on the

fuel tank with the receivers on the underside of the

seat. Align the upper fuel tank tab first.

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

Align seat and tank tabs

30

Page 32

4. Use slight downward pressure at the mid section of

the seat while sliding the seat forward onto tabs.

5. Position the seat so the rear seat brackets are on the

outside of the subframe rails.

NOTE : Keep your hand under the front fender so the

fender nut does not fall when the lower bolt is removed

6. Install the side number panels.

FORK LEG GUARDS

Remove the brake line clamp bolts from the left fork guard.

Then, remove the fork leg bolts and guard.

1

2

1

2

1. Upper bolt

2. Lower bolt

To install, place the front fender and panel in the original

position and insta ll the bolts.

TORQUE : Panel, front number plate, lower bolt

5.0 lbf•ft (6.8 N•m)

3

1. Brake line clamp (left guard)

2. Guard

3. Bolts

To install, place the panel in the original position and install

the bolts.

TORQUE : Fork, leg gua r d, bolts

5.0 lbf•ft (6.8N•m)

TORQU E : Brake, f ork leg br ake line clamp, bolts

5.0 lbf•ft (6.8N•m)

To remove, remove the upper and lower (with fender nut)

number plate bolt.

31

P/N 951-05002032

Printed : 8/13/01

Page 33

FRONT FENDER

CAUTION

Be careful not to damage the radiator core during

removal.

Remove the front number plate, front fender bolts and

washers. Then, remove the fender.

1

6

3

RADIATOR SHROUDS

Place the vehicle on a stand and remove radiator shroud

bolts.

1

1. Left radiator shroud

2

1. Front number plate

2. Fender bolts

3. Front fender

To install, place the panel in the original position and install

the bolts.

TORQUE : Panel, front fender, mounting bolts

5.0 lbf•ft (6.8 N•m)

1

1. Right radiator shroud

To install, place the panel in the original position and install

the bolts.

TORQUE : Panel, radiator shroud, bolts

5.0 lbf•ft (6.8 N•m)

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

32

Page 34

RADIATOR GUARD

MUDFLAP

CAUTION

Do not damage the radiator core during removal .

1. Place the vehicle on a stand.

2. Remove front fender.

3. Remove side bolts, upper bolts, the radiator guard.

2

3

1

WARNING

POTENTIAL HAZARD

Electrical short-circuit or electrical fire.

WHAT CAN HAPPEN

You can short the battery to ground with a tool and

the vehicle frame. This can cause an electrical fire.

You can be burned severe ly or in jur ed by th e spa rks

themselves.

HOW TO AVOID THE HAZARD

When removing the mudflap use extra care to not

contact the 12V+ battery jump start terminal. Cover

this terminal with electrical tape to prevent an

accidental short to ground. (i.e., touching the

terminal with a tool that is grounded to the frame,

subframe, swingarm or exhaust system)

Remove mudflap bolts (1), retainer (2) and mudflap (3).

1

4

1

1. Side bolts

2. Upper bolts

3. Radiator guard

4. To install, place the panel in the original position and

install the bolts.

TORQUE : Panel, radiator guard, side bolts

5.0 lbf•ft (6.8 N•m)

TORQUE : Panel, radiator guard, upper bolts

5.0 lbf•ft (6.8 N•m)

2

3

1. Bolts

2. Retainer

3. Mudflap

4. (12V+ - Battery jump start terminal)

To install, place the panel in the original position and install

the bolts.

TORQUE : Panel, mudflap, mounting bolts

5.0 lbf•ft (6.8 N•m)

33

P/N 951-05002032

Printed : 8/13/01

Page 35

REAR FENDER

GLIDE PLATE

1. Remove the seat and the bolts (1).

1

1

1. Bolts

2. Remove th e fender nut and the rear fender.

1. Secure the vehicle in a wheel vice.

2. Remove the bolts, nuts, and glide plate (1).

1

1. Glide plate

2

NOTE : To prevent the nuts from spinning, hold them with a

thin-blade screwdriver while rem ov in g the bolts.

The nuts are not secured within frame rails. Be careful not to

lose them.

1

1

(12V+)

JUMP START

TERMINAL!

1. Fender nuts

2. Rear fender

3. To install, place the panel in the original position and

install the bolts.

TORQUE : Panel, rear fender bolts

5.0 lbf•ft (6.8 N•m)

1

3. To install, place the panel in the original position and

install the bolts.

TORQUE : Panel, glide plate bolts

5.0 lbf•ft (6.8 N•m)

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

34

Page 36

AIR

CLEANING THE AIRBOX FILTER

2. Remove the airbox filter bolt and the filter elements.

2

1

CAUTION

Be very careful not to allow any dirt or foreign matter

into the ai rbox when you have the filters remove d.

Severe engine damage will result if foreign matter or

dirt enter the combustion chamber via the airbox.

Use only high quality foam air filter specific oils on

the filters. Local operating conditions may require

different air filter oils. Consult your authorized Cannondale motorsports dealer for available oil brands.

The air filter must be completely dry before applying

the air filter oil.

Make sure the airbox filter fits properly in the frame

so there are no gaps around the mating surfaces.

Use a high quality water-proof grease on the filter

where it contacts the frame to help guard against

unfiltered air entering the system.

1. Remove the fuel tank. See “Fuel” the Maintenance &

Adjustment section of t his m anu al for how to pro perl y

remove the fuel tank .

3

4

APPLY A THIN LAYER OF

WATERPROOF GREASE

TO THE FILTER WHERE IT

MEETS THE FRAME

1. Bolt

2. Cover

3. Foam element

4. Screen

3. Spray the inside and outside of the filter elements

completely with a non-flammable or high-flash point

air-filter specific cleaning solvent. Do NOT use

gasoline!

4. Rinse elements with warm water, squeeze out any

excess water, and let the elements air dry thoroughly.

35

5. Inspect the airbox filter foam element, cover, and

screen for damage. Replace new if damaged.

6. Coat both sides of the air filter foam element evenly

with a high quality foam air-filter oil. Squeeze the

element a few times to ensure complete coverage.

7. Clean interior of airbox with contact cleaner and wipe

with a lint-free rag before installing.

8. Apply a thin layer of high quality water-proof grease to

the flange of the airbox filter mounting surfaceInstall

the airbox filter screen, foam element with the denser

P/N 951-05002032

Printed : 8/13/01

Page 37

(white/denser) foam side down, and cover into the

YES

NO

frame.

DENSER SIDE

OF THE FILTER

(WHITE) GOES

DOWN.

CLEANING T H E ST EER IN G HEA D F IL T ER

CAUTION

When re-installing the filter make s ure the i nner light

blue foam is not exposed. This will allow unfiltered

air to enter the system resulting in severe engine

damage.

Also, apply a layer of a high-quality waterproof

grease to the mating surface of the foam.

YES

9. Tighten the airbox filter bolt.

10. Reinstall the removed components.

NO

1. Correct

2. Incorrect

1. To remove and clean the steering head filter, first

remove the f ront number plate.

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

36

Page 38

2. Remove the bolt, washer , and filter assembly from the

steering head.

the element a few times to ensure even distribution of

the oil.

9. Carefully install the main air filter element onto the

cage.

1

2

1. Bolt and washer

2. Steering head filter

3. Separate the filter foam element from the cage.

2

10. Apply a thin layer of a high-quality waterproof grease

to the air filter mounting surface to help eliminate air

leakage.

1

11. Install the filter over the steering head opening.

12. Install the steering head filter bolt and washer.

TORQUE : Air, steering head filter, bolt

5.0 lbf•ft (6.8 N•m)

1. Foam element

2. Cage

4. To clean, spray a non-flammable or high-flash point

air filter specific cleaning solvent over the inside and

outside of the filter element and cage. Do NOT use

gasoline!

5. Allow it to soak then squeeze it a few times until all

the dirt has come off. Repeat if heavily soiled.

6. Rinse the filter with warm water and squeeze out

excess water.

CAUTION

Do not wring or twist the air filter.

7. Inspect steering head filter foam eleme nt and ca ge for

any damage. Replace ne w if damaged.

8. Apply a light, even coat of high-quality foam air-filter

oil over bo th sides of the a ir filter elem ent. Squeeze

37

P/N 951-05002032

Printed : 8/13/01

Page 39

FUEL

THROTTLE FREEPLAY

the throttle tube and c abl e; making su re it is pro perl y ro ute d.

If the throttle grip still does not operate properly, contact an

authorized Cannondale motorsports dealer for servicing.

To measure the freeplay, gently rotate the throttle grip until

the slack is ta ke n up , th en mea s ure ho w far th e gr i p move d .

If the measurement (a) is out of specification, adjustments

can be made at either the throttle grip or at the engine side

of the throttle cable

SERVICE : Fuel, throttle, freeplay

0.07-0.15 inches (2-4 mm)

WARNING

POTENTIAL HAZARD

Damaged throttle (e.g., sticking, cable frayed, or

improper freeplay)

WHAT CAN HAPPEN

While riding you could lose the ability to accelerate

or decelerate the engine with a subsequent loss of

vehicle control resulting in an accident where you

could be seriously injured or killed.

HOW TO AVOID THE HAZARD

Check the throttle for proper operation before each

ride. Make sure the throttle has the specified

freeplay.

If the throttle sticks open, immediately push and

hold down the stop button until the engine shuts off.

To check operation, with vehicle off, rotate the throttle grip

and make sure it moves e asi ly from fully closed to fully open

with the front wheel turned in all steering positions. The

throttle grip should return automatically from fully open to

fully closed when released.

If the throttle grip sticks, it is probably due to a cable

problem. Remove and lubricate the throttle cable, remove

and clean the throttle tube, and adjust the freeplay. Install

a

a. Throttle cable freeplay

ADJUSTING THROTTLE FREEPLAY (AT THE HANDLEBARS)

1. Pull the long rubber boot (1) down the throttle ca bl e so

the lockring (2) and throttle c abl e adju ster (3) are

visible.

2. Turn the lockring, using pliers, in direction (a) to

loosen it. Turn the adjuster in direction (a) to reduce

freeplay or direction (b) to increase freeplay. Tighten

the lockring secu rely.

2

1

3

a

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

b

1. Long rubber boot

2. Lockring

3. Cable adjuster

a. Loosen/decrease freeplay

b. Increase freeplay

3. If the throttle can not be adjusted further and the

freeplay is still out of specification, the cable will have

to be adjusted at the engine side.

38

Page 40

ADJUSTING THROTTLE FREEPLAY AT THE THROTTLE BODY

WARNING

POTENTIAL HAZARD

Crash resulting from a stuck throttle.

WHAT CAN HAPPEN

If the throttle cable locknut at the engine side of the

cable is not tightened securely the nu,t can loosen

and the cable can become dislodged. This could

result in a loss of engine throttle control and you

could be severely injured or killed in an accident.

HOW TO AVOID THE HAZARD

When adjusting throttle cable freeplay at the throttle

body side of the cable, make sure locknut is

tightened securely.

1. Adjust for maximum freeplay at the lever on the

handlebar.

2. Remo ve the front f ender, left ra diator s hroud and the

radiator guard.

3. Remove the upper radiator bolts and carefully move

the radiator forward.

4. Remove the upper, center, and lower bolts. Then

move the left frame rail so the throttle cable is

accessible.

CAUTION

Make sure the engine is properly supported to

relieve any undue stress after the left fram e rail bolts

are removed.

1

2

3

4

1. Upper bolt

2. Center bolt

3. Lower bolts

4. Left frame rail

5. Loosen the locknut. Turn the throttle cable adjuster in

direction (a) to increase freeplay or direction (b) to

reduce freeplay.

39

a

1

b

2

1. Locknut

2. Adjuster

a. Increases freeplay

b. Decreases freep lay

P/N 951-05002032

Printed : 8/13/01

Page 41

6. Tighten the locknut securely and install the left frame

rail. Tighten the rail bolts to the specified torque.

TORQUE : Frame, left frame rail upper bolt

25.0 lbf•ft (34.0 N•m)

TORQUE : Frame, left frame rail center bolt

35.0 lbf•ft 47.5 N•m)

TORQUE : Frame , left frame rail lower bolt

20 lbf•ft (27.0 N•m)

TORQUE : Coolant, upper radiator mounting bolt

5.0 lbf•ft (6.8 N•m)

7. Install the radiator and tighten the upper bolts to the

specified torque.

8. Install the radiator guard, left radiator shroud, and

front fender.

IDLE SPEED ADJUSTMENT

It is necessary to periodically adjust the idle speed for

optimum fuel efficie nc y and proper engine operation.

WARNING

POTENTIAL HAZARD

Severe burns to your hands or fingers.

WHAT CAN HAPPEN

The engine operates at e xt remel y high temperatu res.

If you touch the engine or surfaces around it, you

can be severely burned.

HOW TO AVOID THE HAZARD

1. Use extra caution when adjusting the idle speed.

2. Have an authorized Cannondale Motorsports

dealer adjust the idle speed.

CAUTION

The lower right radiator shroud bolt is supporting

the radiator (along with the coolant hoses), so do

not swing the radiat or out too far.

1. Allow the engine to reach operating te mp era ture 158°F

(70°C).

2. To achieve the smoothest idle speed, turn the idle

speed adjuster (1) in direction (a) to increase idle

speed or in direction (b) to decrea se id le speed.

a. Increase

b. Decrease

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

40

Page 42

FUEL TANK

WARNING

POTENTIAL HAZARD

Explosion or fire.

WHAT CAN HAPPEN

Gasoline is highly-flammable and an explosion can

occur if handled improperly or in areas where an

accidental spark or flame could ignite the gasoline.

You can be burned severely of even be killed if you

ignore this warning

HOW TO AVOID THE HAZARD

Always make sure the work area is free of possible

ignition sources (e.g., sparks, cigarettes, welders,

grinders, flames)

CAUTION

Press in the quick connect fitting tabs before reinstalling the quick connect hose fitting, or the Oringof the fittings can be damaged ( i.e., ripped, torn,

or dislodged).

3. Disconnect the fuel tank quick connect outlet (1)

located on the left side of the fuel tank by pressing on

connector tabs and carefully withdrawing the hose

fitting.

1

a

1. Fuel tank outlet (quick connect)

a. Tab

Always inspect the condition of the O-rings before

re-installing and replace if they are torn.

Apply a light coat of engine oil to thequick connect

fitting O-rings before re-stalling into the tank.

LUBRICATE

O-RING

BEFORE

INSERTING

4. Disconnect the fuel return quick connect located on

the right side of the fuel tank .

a

1

1. Fuel tank return (quick connect)

a. Tab

1. Remove the side number panels, seat and radiator

shrouds.

2. Remove the fuse (located under the se at).

41

P/N 951-05002032

Printed : 8/13/01

Page 43

5. Remove the fuel tank bolt and lift up the front of the

FLOW

fuel tank. Slide the tank forward slightly, and remove

it from the vehicle.

1

1. Fuel tank bolt

6. To install the fuel tank, align the tank onto the frame.

NOTE : Make sure the fuel tank buffers (1) align with the

notches (a) on both sides of the fuel tank.

REPLACING THE FUEL FILTER

NOTE : Accumulation of dirt in the fuel filter will restrict fuel

flow. Proper fuel flow and pressure is critical to the reliability

of the fuel injection system and level of vehicle performance.

Therefore, the fuel filter should be inspected frequently and

replaced if necessary.

1. Remove the tank outlet quick connect fitting. Press in

on the fitting tab before remov ing the fitting from the

tank valve.

2. Loosen the filter hose clamps and remove the filter.

3. Reinstall a new filter and make sure the hose clamps

are tightened securely. Be sure to observe any flow

indicator on the filter housing.

1

a

1

1. buffer

a. notch

7. Tighten the bolt to the specified torque

TORQUE : Fuel, fuel tank mounting bolt

5.0 lbf•ft (6.8 N•m)

8. Press in the quick connect tabs on the fuel valves.

FLOW

2

1. Outlet quick connect

2. Fuel filter

9. Apply a light coat of engine oil to the outlet O-rings.

Then, return the quick connects, and install them into

the fuel tank valves.

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

42

Page 44

4. Tighten the lo ck nut to the specified torque.

BRAKES

For safe motorcycle operation it is critical to have the brake

system performing at its best. Regular inspection of the

brake components and brake fluid level should become a

habit prior to riding the motorcycle.

FRONT BRAKE FREEPLAY ADJUSTMENT

1. Gently pull in the brake lever until the play is taken up,

then measure the freeplay (a) at the end of the brake

lever. Adjust if out of specification.

TORQUE : Brake, lever adjuster, front, locknut

4.3 lbf•ft (5.8 N•m)

FRONT BRAKE LEVER POSITION

The position of the brake lever can be adjusted so that

control is comfortable when seated and standing.

1. Loosen the bolts (1).

2. Rotate the brake lever to the desired position and

tighten the clamp bolts to the specified torque.

Tighten the top bo lt firs t, then the lowe r bolt.

TORQUE : Brake, front, master cylinder mounting bolts

5.0 lbf•ft (6.8 N•m)

TORQUE

UPPER

BOLT FIRST

1

a

a. Freeplay

SERVICE : Brake, lever, front, freeplay, maximum

0.8 inches (20 mm)

2.

To adjust, loosen the locknut (1).

3. Turn the brake lever adjuster (2) in direction (a)

decrease freeplay, in direction (b) to increase

freeplay,

a

b

a

b

2

1

1

1. Front brake master cylinder mounting bolts

1. Locknut

2. Brake lever adjuster

a. Decrease freeplay

b. Increase f reeplay

43

P/N 951-05002032

Printed : 8/13/01

Page 45

FRONT BRAKE PADS INSPECTION

a

b

1

2

Worn brake pads can damage the brake disc, adversely

affecting brake performance and possibly causing an

accident. Never ride the motorcycle with worn or damaged

brake pads.

Each brake pad has wear indicator marks (1) and grooves

(2). If either brake pad is worn to the minimum thickness

indicator (3) or beyond the minimum thi ckness (a), the brake

pads need to be replaced with a new set.

Contact an authorized Cannondale Motorsports delaer for

replacement.

a

1

a

2

3

3. Turning the hex in direction (a) will lower the brake

pedal and turning the hex in direction (b) will raise the

pedal.

1. Locknut

2. Hex

a. Lowers the brake pedal

a. Raises the brake pedal

1. Wear indicator marks

2. Minimum thickness indicator

3. Wear indicator grooves

a. Minimum thickness

SERVICE : Brake, pad thickness, front, minimum

0.04 inches (1.0 mm)

REAR BRAKE PEDAL HEIGHT ADJUSTMENT

The rear brake pedal height can be adjusted for comfort as

well as proper operation.

1. To adjust, loosen the locknut on the master cylinder

pushrod.

2. Turn the hex on top of the pushrod until the brake

pedal is at the correct height.

4. Tighten the lo ck nut to the specified torque.

TORQUE : Brake, rear brake m aster cylinder pushrod,

locknut

13.0 lbf•ft (17.6 N•m)

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

44

Page 46

When adjusting the brake pedal, make sure that clearance

Check brake operation be fore riding the motorcycle. Failu re to follow this warning can lead to a serio us accident with subsequen t serious injury or death.

(a) between the lower end of the pushrod (1) and the brake

pedal is within specification.

When raising the br ak e p eda l (2 ), do not allow the lower end

of the pushrod thread (3) to enter into the brake pedal joint

(4).

1

a

4

2

1. Pushrod lower end

2. Brake pedal

3. Pushrod thread

4. Brake pedal joint

a. Clearance

SERVICE : Brake, rear, master cylinder pushrod,

clearance

0.04 in (1mm)

REAR BRAKE PADS INSPECTION

Each brake pad has wear indicator grooves (1). If either

brake pad is worn to the minimum thickness indicator (2) (or

beyond the minimum thickness (a)), the brake pads need to

be replaced with new ones as a set. Contact an authorized

Cannondale Motorsports dealer for replacement.

1

a

CHECK BOTH

PADS!

1. Wear limit indicators

a. Minimum thickness

SERVICE : Brake, pad thickness, rear, minimum

0.04 inches (1.0 mm)

45

P/N 951-05002032

Printed : 8/13/01

Page 47

EXHAUST

The primary functions of the exhaust system are to deliver

the burned combustion gases to the atmosphere, reduce

exhaust noise to an acceptable level, and to route the

exhaust gases away from the rider.

INSPECTING THE EXHAUST SYSTEM

Inspect the exhaust pipe and silencer for cracks, dents, rust

or other damage. If any damage is found, contact an

authorized Cannondale dealer for servicing.

NOTE : The exhaust system is shown removed from the

vehicle for clarity.

TORQUE : Exhaust pipe bolt

5.0 lbf-ft (6.8 N•m)

TORQUE : Silencer mounting bolt

15.0 lbf-ft (20.3 N•m)

X440s Owner's Manual.fm

© 2001 Cannondale Corporation - All Rights Reserved

46

Page 48

CLUTCH LEVER FREEPLAY

CLUTCH

CLUTCH LEVER POSITION

The clutch lever position can be adjusted so it can be used

comfortably while sitting or standing.

1. Loosen the clutch lever clamp bol ts (1).

1

1

1. Clutch lever clamp bolts

SERVICE : Clutch, lever, freeplay

0.08 - 0.16 inches (2 - 4 mm)

a

TAKE UP

SLACK

IN CABLE

a. Clutch lever freeplay

CAUTION

Check the clutch actuating arm position following

any adjustment to the lever.

2. Rotate the clutch lever to the desired position and

tighten the clamp bolts to the specif ied torque.

3. Tighten the upper clamp bolt first, then the lower

clamp bolt.

TORQUE : Clutch, lever clamp, bolts

5.0 lbf•ft (6.8 N•m)

NOTE : Adjust clutch lever freeplay at the lever first. If the

specified freeplay cannot be achieved, adjust for more

available freeplay at the inline adjuster.

LEVER

1. To adjust the lever, the quick adjuster until the specified

freeplay is reached.

a

1