Page 1

TRIGGER / JEKYLL

OWNER’S MANUAL SUPPLEMENT

ENGLISH

Read this supplement and your Cannondale Bicycle Owner’s Manual.

Both contain important safety information. Keep both for future reference.

Page 2

Page 3

ENGLISHTRIGGER/JEKYLL - OWNERS MANUAL SUPPLEMENT

Cannondale Supplements

This manual is a “supplement” to your Cannondale

Bicycle Owner’s Manual.

This supplement provides additional and important

model specic safety, maintenance, and technical

information. It may be one of several important

manuals/supplements for your bike; obtain and read all

of them.

Please contact your Authorized Cannondale Dealer

immediately if you need a manual or supplement, or

have a question about your bike. You may also contact

us using the appropriate country/region/location

information. See Contacting Cannondale in this

supplement.

You can download Adobe Acrobat PDF versions of any

manual/supplement from our website:

http://www.cannondale.com

Your Authorized

Cannondale Dealer

To make sure your bike is serviced and maintained

correctly, and that you protect applicable warranties,

please coordinate all service and maintenance through

your Authorized Cannondale Dealer.

NOTICE

Unauthorized service, maintenance, or repair parts

can result in serious damage and void your warranty.

CONTENTS

Safety Information ................................. 2

Technical Information .......................3-18

Maintenance ......................................... 19

Replacement Parts...........................2024

Intended Use

UNDERSTAND YOUR BIKE AND ITS INTENDED

USE. USING YOUR BIKE THE WRONG WAY IS

DANGEROUS.

Please read your Cannondale Bicycle Owner’s

Manual for more information about Intended Use

and Conditions 1-5.

Contacting Cannondale

Cannondale USA

Cycling Sports Group, Inc.

1 Cannondale Way, Wilton CT, 06897, USA

1-800-726-BIKE (2453)

Cycling Sports Group Europe B.V

Mail: Postbus 5100

Visits: Hanzepoort 27

7570 GC, OLDENZAAL, Netherlands

Tel: +41 61 551 14 80

Fax:+31 54 151 42 40

134910 Rev 1.

The intended use of all models

is ASTM CONDITION 4,

All-Mountain.

1

Page 4

‘

SAFETY INFORMATION

Important

Composites Message

Your bike (frame and components) is made from

composite materials also known as “carbon ber.”

All riders must understand a fundamental reality

of composites. Composite materials constructed

of carbon bers are strong and light, but when

crashed or overloaded, carbon bers do not bend,

they break.

For your safety, as you own and use the bike, you

must follow proper service, maintenance, and

inspection of all the composites (frame, stem, fork,

handlebar, seat post, etc.) Ask your Cannondale

Dealer for help.

We urge you to read PART II, Section D. “Inspect For

Safety” in your Cannondale Bicycle Owner’s Manual

BEFORE you ride.

YOU CAN BE SEVERELY INJURED, PARALYZED

OR KILLED IN AN ACCIDENT IF YOU IGNORE THIS

MESSAGE.

Inspection & Crash Damage Of

Carbon Frames/Forks

AFTER A CRASH OR IMPACT:

Inspect frame carefully for damage (See PART II,

Section D. Inspect For Safety in your Cannondale

Bicycle Owner’s Manual. )

Do not ride your bike if you see any sign of damage,

such as broken, splintered, or delaminated carbon

ber.

ANY OF THE FOLLOWING MAY INDICATE A

DELAMINATION OR DAMAGE:

– An unusual or strange feel to the frame

– Carbon which has a soft feel or altered shape

– Creaking or other unexplained noises,

– Visible cracks, a white or milky color present in

carbon ber section

CONTINUING TO RIDE A DAMAGED FRAME

INCREASES THE CHANCES OF FRAME FAILURE,

WITH THE POSSIBILITY OF INJURY OR DEATH OF

THE RIDER.

134910 Rev 1.

YOU CAN BE YOU SERIOUSLY INJURED,

PARALYZED OR KILLED

IF YOU IGNORE WARNINGS.

2

Page 5

TECHNICAL INFORMATION

Frame Specication

FRAME 148 x 12mm Ai

HEAD TUBE 1 1/8 - 1 1/2 Tapered

BOTTOM BRACKET PF30 83mm BB30 83mm

FRONT DERAILLEUR

SEAT POST DIA./BINDER 31.6 mm, 34.9 mm binder

MINIMUM SEAT POST INSERT 100 mm

TIRE SIZE/MAXIMUM WIDTH

MAXIMUM FORK LENGTH

INTENDED USE

REAR TRAVEL 145 mm 165mm

RECOMMENDED SAG 30%, 17 mm 30%, 18 mm

EYE-TO-EYE / STROKE 210 mm / 55 mm 230 mm / 60 mm

REAR BRAKE 160/180 Flat Mount

REAR AXLE 148 X 12 Maxle, 180 mm length

MAXIMUM WEIGHT LIMIT (Lbs/Kg) Total (rider+all equipment): 305lb / 138 Kg

TRIGGER CARBON JEKYLL CARBON JEKYLL ALLOY

Low Direct Mount,

Side Swing

(alloy CS only)

27.5” X 2.5”

545 mm 565 mm

ASTM CONDITION 4, All-Mountain

Please read your Cannondale Bicycle Owner’s Manual for more

information on specication marked with the safety alert symbol “

N/A

ENGLISHTRIGGER/JEKYLL - OWNERS MANUAL SUPPLEMENT

.”

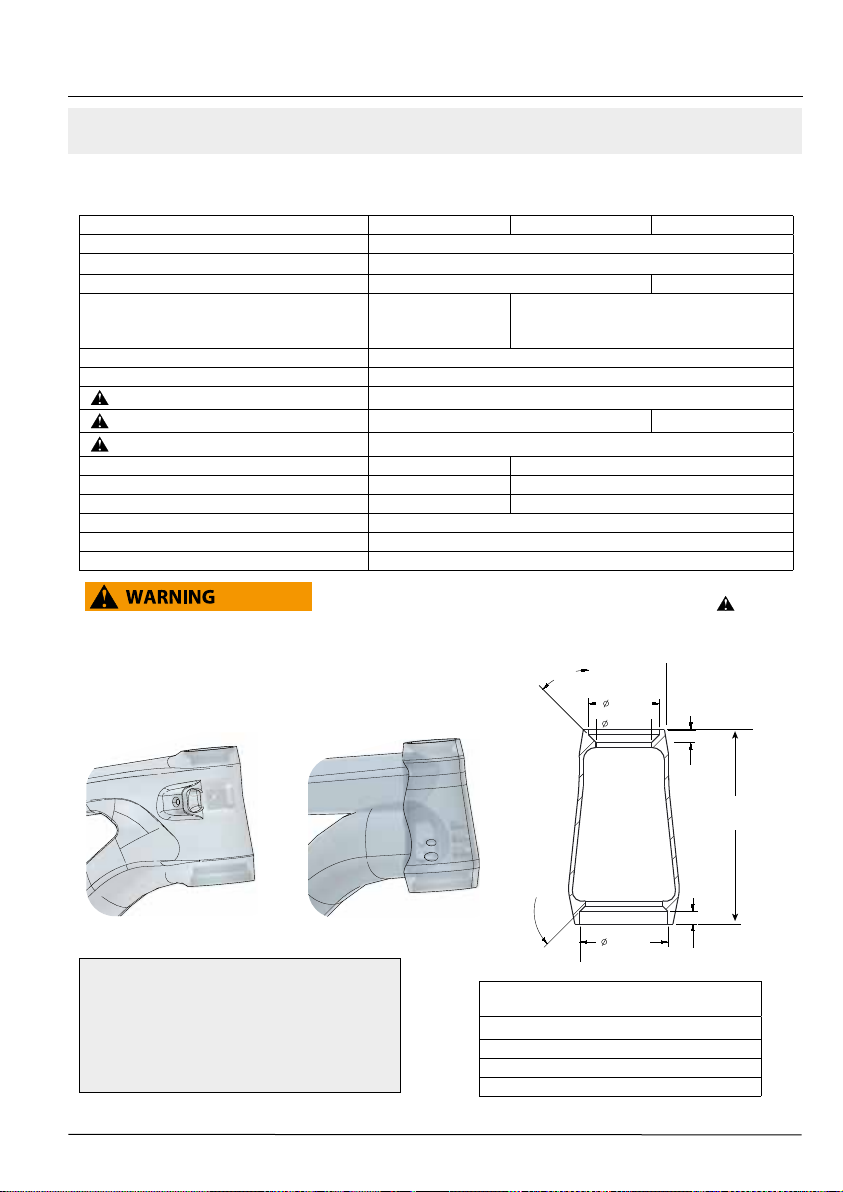

Headtube

(carbon) (alloy)

NOTICE

Do not face, surface, or cut the head tube bearing

cups. When removing adapters, bearings, or cup

from, extra care must be used so that the tool used

to drive out the bearing is not located on any part

a bonded cup.

134910 Rev 1.

45.0°

42.0 mm

33.0 mm

3.0 mm

X

45.0°

52.0 mm

FRAME SIZE

SM 102 mm

MD 115 mm

LARGE 122 mm

X-LARGE 134 mm

3

7.5 mm

HEADTUBE

LENGTH (X)

Page 6

‘

BOTTOM BRACKET PF30

Carbon frames have a 46 mm I.D. bottom bracket bearing system press interface. The shell width is 83mm.

Maintenance

In general, you should inspect the condition of the bearings annually (at a minimum) or anytime the crankset assembly is

disassembled , serviced, or if a problem is indicated.

To inspect, when the crankset is removed, rotate the inner bearing race of both bearings; rotation should be smooth, and

quiet. Execesssive play, roughness or corrossion indicates a damaged bearing.

Removal

To avoid serious damage to the frame, it is important to remove bearing systems very carefully using proper tools

indicated by the manufacture’s service instructions. Make sure the bearings(cup or adpater parts) are driven out squarely

and evenly from inside the shell!!! Do not pry components from shell.

Replacement

PressFit BB30 bearings are not removable from the adapters or cup systems that are pressed into the frame bottom

bracket shell. Therefore, damaged bearings must be removed and replaced as new entire sets. Before installing any new

bearing units into the shell, thoroughly clean the inside surface of the bottom bracket shell with a clean dry shop towel.

Also, make sure both bearing units and the BB shell surfaces are clean and dry. Do not apply grease to either.

Follow the manufacture’s instruction for assembly and installtion of the bearing system. Use a headset press such as Park

Tool HHP-2. See http://www.parktool.com/product/bearing-cup-press-HHP-2 Select appropriate press and adapters to

ensure that force is only applied to the cup and not the bearing inside. Press until the both cup anges are mated to the

BB shell edge.

NOTICE

Consult with your Cannondale Dealer on the quality and compatibilty of any proposed replacement

component.

Make sure the PRESSFIT BB30 system is intended for use with with a 46 mm I.D. BB shell. Conrm acutal

part dimensions with a micrometer.

Do not use chemical solvents to clean. Do not remove frame material or use surfacing tools on bottom

bracket shell.

Frame damage, caused by improper components, component installation or removal is not covered by your

warranty.

134910 Rev 1.

4

Page 7

BOTTOM BRACKET – BB30

The bottom bracket shell is compatible with the BB30 Standard. See http://www.bb30standard.com/ .

Maintenance

Inspect bearing condition annually (at a minimum) and anytime the crankset assembly is disassembled or serviced.

With the crankset removed, rotate the inner bearing race of both bearings; rotation should be smooth. No play or

movement inside the shell. If the bearing is damaged, replace both bearings with new ones.

Bearing Removal

Remove the old bearings with the bearing removal tool KT011/.

Bearing Installation

To install bearings, use a headset press and Cannondale tool KT010/ . Clean inside of shell apply a high-quality

bicycle bearing grease to the inside surface. Press bearing one at a time. Press each bearing until seated. Following

installation, apply a light coating of a high-quality bicycle bearing grease to both sides of each bearing to help repel

moisture.

Do not re-use removed bearings. Install both bearings as a new set.

NOTICE

BEARINGS - Frequent or routine renewal of undamaged bearings is not recommended. Repeated removal

and reinstallation can damage the inside BB shell surfaces resulting in poor bearing t. Do not face, mill

or machine the bottom bracket shell for any reason. Doing so can result in serious damage and possibly a

ruined bike frame.

Do not cut, face, or use abrasives to clean the inside if the BB shell.

We strongly recommend that these procedures be performed by an Authorized Cannondale Dealer.

Damage caused by improper installation/removal is not covered under your warranty.

ENGLISHTRIGGER/JEKYLL - OWNERS MANUAL SUPPLEMENT

134910 Rev 1.

5

Page 8

‘

TRIGGER Geometry

A

SEAT TUBE LENGTH

B

TOP TUBE HORIZONTAL

C

TOP TUBE ACTUAL

D

HEAD TUBE ANGLE

E

SEAT TUBE ANGLE EFFECTIVE

F

STANDOVER

G

HEAD TUBE LENGTH

H

WHEELBASE

I

FRONT CENTER

J

CHAIN STAY LENGTH

K

BOTTOM BRACKET DROP

L

BOTTOM BRACKET HEIGHT

M

FORK RAKE

N

TRAIL

O

STACK

P

REACH

Dimensions = (centimeter/inches)

MENS WOMENS

SIZE

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

S M L XL S M

40.0/15.7 43.0/16.9 46.0/18.1 52.0/20.5 40.0/15.7 43.0/16.9

57.6/22.7 60.2/23.7 62.7/24.7 65.5/25.8 57.6/22.7 60.2/23.7

N/A N/A N/A N/A N/A N/A

66°

74.5°

74.9/29.5 76.1/30.0 76.7/30.2 79.6/31.3 74.9/29.5 76.1/30.0

10.2/4.0 11.5/4.5 12.7/5.0 14.0/5.5 10.2/4.0 11.5/4.5

113.0/44.5 115.8/45.6 118.5/46.7 121.5/47.8 113.0/44.5 115.8/45.6

71.1/28.0 73.9/29.1 76.5/30.1 79.5/31.3 71.1/28.0 73.9/29.1

42.0/16.5

1.2/0.5

34.5/13.6

4.4/1.7

10.7/4.2

58.3/23.0 59.5/23.4 60.6/23.9 61.8/24.3 58.3/23.0 59.5/23.4

41.4/16.3 43.7/17.2 45.9/18.1 48.4/19.0 41.4/16.3 43.7/17.2

A

J

H H H

H H H

H H H

H H H

H H H

H H H

H H H

B

P

75 mm

C

E

K

L

H

66°

74.5°

42.0/16.5

1.2/0.5

34.5/13.6

4.4/1.7

10.7/4.2

G

O

F

D

I

M

N

H

H

H

H

H

H

H

All Specifications subject to change without notice.

H - Indicates same.

134910 Rev 1.

6

Page 9

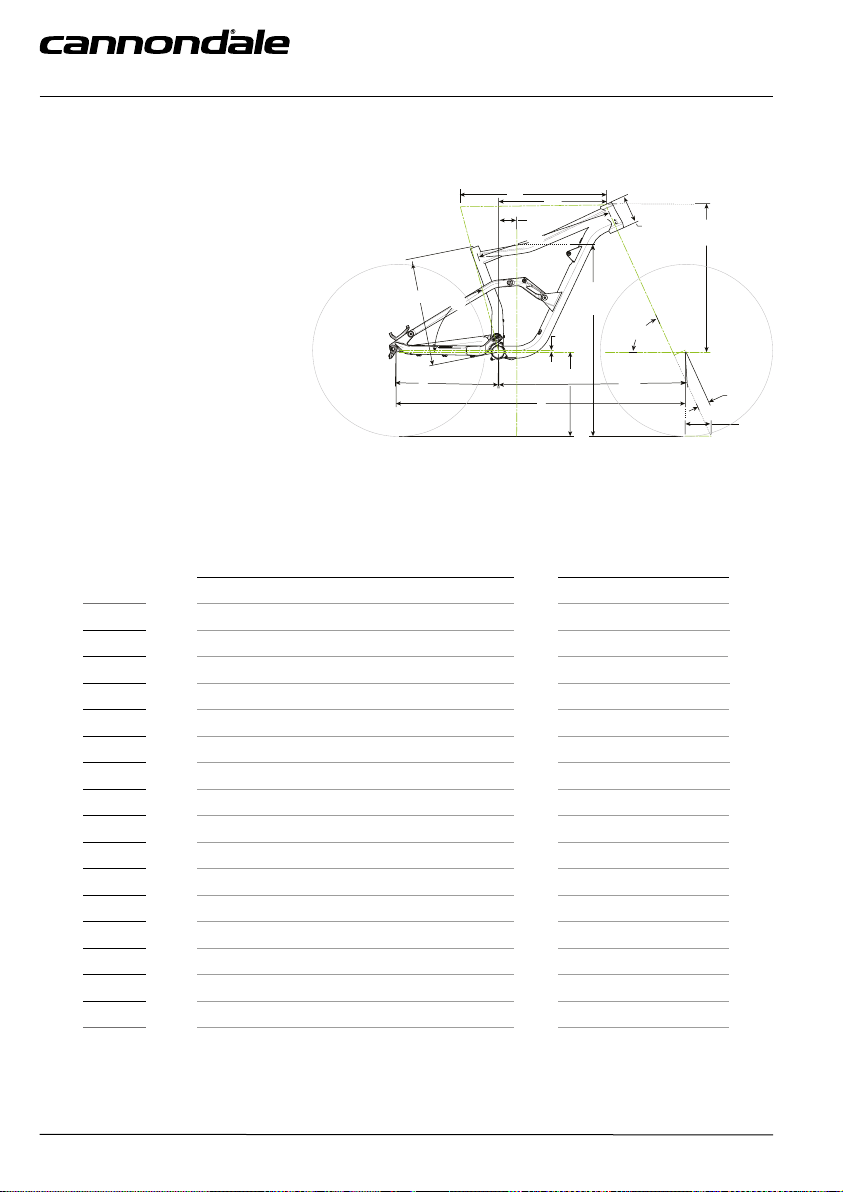

JEKYLL Geometry

A

SEAT TUBE LENGTH

B

TOP TUBE HORIZONTAL

C

TOP TUBE ACTUAL

D

HEAD TUBE ANGLE

E

SEAT TUBE ANGLE EFFECTIVE

F

STANDOVER

G

HEAD TUBE LENGTH

H

WHEELBASE

I

FRONT CENTER

J

CHAIN STAY LENGTH

K

BOTTOM BRACKET DROP

L

BOTTOM BRACKET HEIGHT

M

FORK RAKE

N

TRAIL

O

STACK

P

REACH

Dimensions = (centimeter/inches)

ENGLISHTRIGGER/JEKYLL - OWNERS MANUAL SUPPLEMENT

B

P

75mm

C

A

E

K

J

H

G

O

F

D

L

I

M

N

All Specifications subject to change without notice.

H - Indicates same.

134910 Rev 1.

SIZE

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

S M L XL

40.0/15.7 43.0/16.9 46.0/18.1 52.0/20.5

58.4/23.0 60.9/24.0 63.4/25.0 66.2/26.1

53.7/21.1 56.2/22.1 58.7/23.1 62.1/24.5

65°

75.0°

75.0/29.5 75.8/29.8 76.7/30.2 77.5/30.5

10.2/4.0 11.5/4.5 12.7/5.0 14.0/5.5

116.0/45.7 118.7/46.7 121.4/47.8 124.4/49.0

74.0/29.1 76.7/30.2 79.4/31.3 82.4/32.5

42.0/16.5

0.8/0.3

34.9/13.7

4.4/1.7

11.4/4.5

59.2/23.3 60.4/23.8 61.5/24.2 62.6/24.7

42.5/16.7 44.7/17.6 46.9/18.5 49.4/19.5

H H H

H H H

H H H

H H H

H H H

H H H

H H H

7

Page 10

‘

Dropout

6 Nm

Loctite 242 (blue)

small end

Maintenance

The condition of the bearings, pivot axles, and spacers

should be inspected periodically. These are normal wear

parts so plan to have them renewed as they wear-out.

Inspection frequency should be based upon how and

where you ride. Evidence of damage would be excessive

play, visible wear, or perhaps corrosion of bearings.

If you nd any damage to the parts, discontinue riding

until all the parts (bearings, pivot axles, spacers) can be

renewed. This will help prevent damage elsewhere.

See the kits list in the back of this supplement for

renewal kits.

KP169/

Key Information:

A special service tool KP169/ contains parts necessary

to service the assembly. The parts of this tool are shown

shaded above.

When connecting the seat stays to the dropouts, always

insert the small end of pivot spacers into the dropout

bearings . The at side of the spacers should face out,

as shown.

When tightening the axles, insert the 5 mm hex key

completely into the axle to prevent damage when

turning the bolt. Always tighten with a torque wrench

to the specied torque.

134910 Rev 1.

8

Page 11

Asymmetric Integration - Ai

Rear Wheel- 3 mm Oset

The Ai rear hub is oset 3 mm to the drive side. This both aligns the

cassette with the Ai frame’s 55mm chainline, and aligns the rim/tire

with frame’s centerline for correct tire clearance.

Ai wheels have equal spoke angles and tension on both sides (nondished wheel) which improves wheel stiness, strength.

• The 3mm oset is for 148 X 12mm spacing only!

• Other Ai equipped bike with 142mm or 135mm rear

spacing use a 6mm oset.

NOTICE

USE ONLY 3mm “Ai” OFFSET REAR WHEELS. Incorrect wheel

oset can damage your frame.

Standard wheel assembled on this frame will result in

insucient tire clearance leading to rubbing and serious frame

damage. This kind of damage is not covered by the Cannondale

Limited Warranty.

Building/Truing a Wheel

If you chose to build, or true the wheel, make sure the 3 mm

oset is present. Consult with your Cannondale Dealer if you

have any questions.

ENGLISHTRIGGER/JEKYLL - OWNERS MANUAL SUPPLEMENT

NON-DRIVE DRIVE

3mm

Main Pivot Bearing Tool - CK9017U00OS

Install

134910 Rev 1.

9

148mm

Remove

Page 12

‘

LOCK’R AXLES

1 N-m

134910 Rev 1.

5 N-m

1 N-m

5 N-m

10

Page 13

NGLI-2

ENGLISHTRIGGER/JEKYLL - OWNERS MANUAL SUPPLEMENT

T25

1.

5.0 N-m

4.

M5

3.

M6

1.0 N-m

A

Eastwing.com

12oz/340g

Removal

The axle removal technique is shown removed from for

clarity. See inset A.

Steps:

A. Loosen the screw (4) 4-6 turns using a T25 Torx key.

B. Tap head of M4 screw (4) to un-seat threaded

wedge (2).

Remove M4 screw (4) and threaded wedge (2) from

the axle (1).

C. Insert a 5mm hex key to twist the wedge (3) free

and remove it (shown). If stuck, insert the long side

of a 6mm HEX key (non-ball end) from the threaded

end of axle and tap it out.

D. Insert a 6mm hex key into the axle and turn

counter-clockwise until it can be removed.

2.

a

5mm

Installation

Be sure to inspect the parts for any burrs, scratches or

other damage before assembly. Replace the complete

axle assembly if any damage is found.

• Apply a high-quality bearing grease to all the

parts of the assembly before installing into

the linkage. Be sure to coat all threads, wedge

surfaces and expansion areas.

• Be sure to use the correct length axle and screw

for the specic location. See above.

• Insert the axle (1) into the link from the non-drive

side. and tighten it with an 6mm hex to 1.0Nm.

Do not over-tighten.

• Insert the threaded wedge (2) into the drive side

of the axle and insert the other wedge (3) and

screw (4) opposite and tighten screw with a T25

Torx to 5.0Nm.

134910 Rev 1.

11

Page 14

‘

Tightening Torques

Correct tightening torque for the fasteners (bolts, screws, nuts) on your bicycle is very important to your safety , durability,

and performance of your bicycle.

We urge you to have your dealer correctly torque all fasteners using a torque wrench. If you decide to tighten fasteners

yourself always use a good torque wrench!

Loctite 242 (blue)

6 Nm

Loctite 242 (blue)

2 Nm

Loctite 242 (blue)

pgs.....13

6 Nm

1.5 Nm

NLGI-2

2 Nm

NLGI-2

pgs.....14

6 Nm

Loctite 242 (blue)

pgs.....8

1 Nm

pgs.....15

12 Nm

Loctite 242 (blue)

5 Nm

pgs.....10-11

134910 Rev 1.

12

Page 15

Rear Derailleur Hanger - CK3257U00OS

2.

1.

ENGLISHTRIGGER/JEKYLL - OWNERS MANUAL SUPPLEMENT

2.

M3X12

Hanger Replacement

Hanger replacement kit is available as Cannondale kit

- CK3257U00OS.

The kit includes the hanger (1) and a new pivot bolt

(3). Before installing a new hanger, be sure to clean

any dirt or debris on the dropout with a nylon brush

(old toothbrush). Inspect the area for any damage.

Lightly grease the dropout surface. Apply Loctite 242

(blue) to the pivot bolt (4). Align the hanger on the

opposite side of the dropout and tighten the bolt to

the specied torque.

134910 Rev 1.

3.

5 Nm

Loctite 232

13

Page 16

2 N-m

M5x25

‘

Shimano Di2 Battery

A

(a)

(b)

1.

The rubber grommets

are pressed into the

frame holes when no

battery is installed.

5.

B 2.

3.

5.

Battery Installation

For Di2, use the seat post type battery

(Shimano SM-BTR2)

1. Remove fork and headset from the frame.

2. Attach mounting plate (1) included in Cannondale

kit K32027/ to the battery (2) using two 3mm nylon

ties (3). Make sure the plate lip (a) is aligned with

the case groove on the battery nearer the cable

connection (b). See inset A.

3. Tie a thin dental string (5) to the battery plate

4. Plug in Di2 wire (to junction B) into the battery

5. Use a shift cable inserted into the top tube hole

and out the lower head tube to guide.

Apply light

grease to

threads.

6. Attached the end of the dental thread to the shift

cable and draw the dental thread through and out

the top tube hole.

7. Insert the battery and plate in the bottom of the

head tube and use the dental thread to guide the

battery and plate into position. 5. With the battery

in position as shown, holding the string (5) taught,

apply grease to the screw (6) and tighten to 2 Nm.

The screw threads should cut the string so it can be

removed.

NOTICE

Periodically, check for proper tightness of the

mounting screws. Use a torque wrench. Do not

over-tighten.

134910 Rev 1.

14

Page 17

Internal Guides - KP436/

1 Nm

5 mm

ENGLISHTRIGGER/JEKYLL - OWNERS MANUAL SUPPLEMENT

4mm

5 mm x 2

1 Nm

5 4mm

4mm

Internal Frame Guides:

Install plastic spiral wire wrap (5) over

Di2 wires (6) passing through internal

guide (7).

Use the 4mm guide opening for Di2 wire.

Use the guide inserts in open

locations.

1 Nm

5

4mm

4mm

5 mm

134910 Rev 1.

6

15

5mm

Page 18

‘

Rear Shock - Gemini

Both the TRIGGER and JEKYLL are equipped with FOX Float X or FOX Float DPS rear shocks. The shocks have “Gemini”

technology which allows the rider to switch between two modes on the y using a handlebar remote: Hustle and Flow.

This supplement contains shock specications and recommended settings for the both TRIGGER and JEKYLL. You’ll need

to see the FOX Owner’s Manual for adjustment and maintenance information: www.foxracingshocks.com.

TRIGGER JEKYLL

SAG 30%, 17mm 30%, 18 mm

1

SAG

12 Nm

12 Nm

Flow Mode

Flow mode uses the shock’s entire air chamber and is

ideal for descending and other situations where having

full shock travel is advantageous.

Set to Flow mode: press the black handlebar remote

button (a) releasing the silver button (b).

1.2 Nm

NOTICE

Mount shocks TRIGGER and JEKYLL

in orientation shown: controls

forward and facing up as shown.

Hustle Mode

This mode reduces the usable air volume in the shock

and provides a more supportive, progressive spring

rate for situations like out of the saddle sprinting and

climbing.

To switch the shock to Hustle mode, press the silver

button down until you feel a click and the silver

button remains depressed.

134910 Rev 1.

16

Page 19

ENGLISHTRIGGER/JEKYLL - OWNERS MANUAL SUPPLEMENT

(a)

(b)

To set air pressure:

1. Set handlebar remote to Flow mode: press the

black handlebar remote button (a) so that the

remote handlebar control is in the position shown

below.

2. Remove the Schrader valve cap (1) and pressurize

the shock with a shock pump according to your

riding weight (body weight, clothing and

equipment). Consult the table for your bike/shock.

3. Remove the shock pump.

4. Cycle the shock 10 times to allow the positive and

negative air pressures to equalize.

5. Thread the shock pump back onto the valve and

pump the shock back up the recommended

pressure again to compensate for any transferred air

pressure.

NOTE: Air pressure measured at the pump will

decrease after air has transferred from positive to

negative chambers.

5. Remove the shock pump from the shock valve.

6. Check sag to conrm your shock setup. Recommended seated sag with full riding gear is 30% (see

tables below)

7. If there is too much sag, add air pressure in 10

psi increments until correct sag is achieved. If

there is too little sag, reduce air pressure in 10 psi

increments until correct sag is achieved.

8. Install the Schrader valve cap onto the air valve.

9. Turn the red rebound adjuster clockwise towards

“slow” until it stops.

a. Float X - Insert a 2mm hex wrench into a cutout in

the red rebound knob located near the eyelet on

the frame side of the shock. Use the wrench to turn

the knob towards “slow” until it stops.

b. Float DPS - Turn the red rebound knob located

under the blue compression adjustment lever on

the frame side of the shock clockwise towards

“slow” until it stops.

10. Turn the red rebound knob counter-clockwise

towards “fast”, counting each detent click until you

reach the recommended number of clicks based on

the table below.

Gemini - FOX Float DPS

RIDER WT. AIR PRESSURE REBOUND

Lbs Kg PSI Bar Clicks*

100 45 105 7.2 13

110 50 118 8.1 13

120 55 131 9.0 12

130 59 144 9.9 11

140 64 157 10.8 10

150 68 170 11.7 10

160 73 184 12.7 9

170 77 197 13.6 8

180 82 210 14.5 7

190 86 223 15.4 6

200 91 236 16.3 5

210 95 249 17.2 5

220 100 262 18.1 4

* Fully close the rebound dial, turn clockwise until dial stops. To set count clicks turning counter-clockwise.

134910 Rev 1.

Gemini - FOX Float X (shown)

RIDER WT. AIR PRESSURE REBOUND

Lbs Kg PSI Bar Clicks*

100 45 130 9.0 21

110 50 144 9.9 20

120 55 158 10.9 19

130 59 172 11.9 18

140 64 186 12.9 17

150 68 200 13.8 16

160 73 215 14.8 15

170 77 229 15.8 14

180 82 243 16.7 13

190 86 257 17.7 12

200 91 271 18.7 11

210 95 285 19.6 10

220 100 299 20.6 9

17

Page 20

‘

Remote Cable Installation

1. Cut a piece of derailleur housing that ts from

Gemini’s housing stop to the Gemini remote

without interfering with the rotation of the handle

bars. Install a ferrule on one end of the housing.

2. Place the Gemini remote in Flow mode by pressing

the black button on the Gemini remote while

placing upward pressure on the silver button.

3. Insert a derailleur cable into the round hole below

the silver button on the Gemini remote. Feed the

cable through the remote until the cable head is

fully seated.

4. Insert the cable into the cable noodle end opposite

the barrel adjuster. Slide the cable noodle along the

cable until it is fully inserted into the remote.

5. Insert the derailleur cable into the Gemini cable

housing end with the ferrule and push it through

until the housing is fully seated in the barrel

adjuster on the cable noodle.

6. Insert the derailleur cable through the housing stop

on the Gemini shock, then pull the cable until the

housing is fully seated in the housing stop. There

should not be a housing ferrule on this side of the

Gemini housing.

7. Use a 2 mm hex wrench to loosen the set screw

located on the rear of the Gemini shock cam until

there are only 2 threads engaged.

8. Insert the cable between the set screw and Gemini

cam. Pull the cable so the cable and housing are

fully seated and tight.

9. Tighten the set screw to 1.2 Nm with a 2mm hex

wrench to secure the cable.

10. Function Test: Push on the remote’s silver Hustle

mode button, then press the black Flow mode

button.

a. Cable is too tight: the remote cannot stay in Hustle

mode. Reduce cable tension by turning barrel

adjuster clockwise. If problem persists, reduce cable

tension by loosening the set screw and resetting

cable tension as described in steps 7-9.

b. Cable is too loose: the cam will not turn as soon

as you engage the lever. Increase cable tension

by turning the barrel adjuster counter-clockwise.

If problem persists increase cable tension by

loosening the set screw and resetting cable tension

as described in steps 7-9.

SELECT ONLY COMPATIBLE SHOCKS AND FORKS

FOR YOUR BIKE. DO NOT MODIFY YOUR BIKE IN

ANY WAY TO MOUNT ONE. HAVE YOUR SHOCK

OR FORK INSTALLED BY A PROFESSIONAL BIKE

MECHANIC

• Riding with the wrong rear shock can damage

the frame. You could have a serious accident.

Make sure the total travel, eye-to-eye length,

and stroke length of the rear shock you select

meet the SPECIFICATIONS listed in this manual.

• When selecting dierent shocks or forks for

your bike, make sure that the shock or fork you

select is compatible with your bike’s design

and how you will use your bike.

YOU CAN BE YOU SERIOUSLY INJURED,

PARALYZED OR KILLED IF YOU IGNORE THESE

WARNINGS.

134910 Rev 1.

18

Page 21

MAINTENANCE

The following table lists only supplemental maintenance items. Please consult your Cannondale Bicycle Owner’s

Manual for more information on basic bike maintenance. Consult with your Authorized Cannondale Dealer to create

a complete maintenance program for your riding style, components, and conditions of use. Follow the maintenance

recommendations given by the component manufacturer’s for the various parts of your bike.

ITEM FREQUENCY

HOUSING AND CABLES - Your bike has been supplied with small adhesive

frame protectors - KF103/. Place this material on the the frame between where

cables and housing rub due to movement. Overtime, cable rubbing can wear

into the frame itself causing very serious frame damage.

NOTE: Damage to your bike caused by cable rubbing is not a condition

covered under your warranty. Also, adhesive frame guards are not a x for

incorrectly installed or routed cables or lines. If you nd that applied guards

are wearing out very quickly, consult with your Cannondale Dealer about the

routing on your bike.

DAMAGE INSPECTION - Clean and visually inspect entire bike frame/swing

arm/linkage assembly for cracks or damage. See “Inspect For Safety” in your

Cannondale Bicycle Owner’s Manual.

CHECK TIGHTENING TORQUES - In addition to other component specic

tightening torques for your bike. Tighten according to the “TIGHTENING

TORQUES” information listed in this supplement.

DISASSEMBLE, CLEAN, INSPECT, RE-GREASE, REPLACE WORN OR

DAMAGED PARTS IN THE FOLLOWING ASSEMBLIES:

• SHOCK LINK ASSEMBLY • PIVOT AXLES • FRAME PIVOT

BEARINGS

BEFORE FIRST RIDE

BEFORE AND AFTER EACH RIDE

EVERY FEW RIDES

IN WET, MUDDY, SANDY

CONDITIONS EVERY 25 HRS.

IN DRY, CONDITIONS

EVERY 50 HRS.

ENGLISHTRIGGER/JEKYLL - OWNERS MANUAL SUPPLEMENT

FORK and SHOCK: - Please consult the manufacturer’s owner’s manual for maintenance information.

ANY PART OF A POORLY MAINTAINED BIKE CAN BREAK OR MALFUNCTION LEADING TO AN ACCIDENT WHERE

YOU CAN BE KILLED, SEVERELY INJURED OR PARALYZED.

Please ask your Authorized Cannondale Dealer to help you develop a complete maintenance program, a program

which includes a list of the parts on your bike for YOU to check regularly. Frequent checks are necessary to identify the

problems that can lead to an accident.

134910 Rev 1.

19

Page 22

34.9 mm

M

L

‘

TRIGGER (Carbon)

CS-L

REPLACEMENT PARTS

H

M4

Loctite 242 (blue)

6 Nm

M2.5

Loctite 242 (blue)

2 Nm

CS-R

DT & SS

A

F

D

F

I

ID CODE DESCRIPTION

CK3147U00OS

A

B

C

D

E

F

CK3177U00OS

CK3227U00OS

CK3257U00OS

KP421/160

KP421/180

CK3237U00OS

Trigger Pivot Hardware

Trigger Pivot Bearings

Trigger Shock Bolts

Jekyll/Trigger Rear Der Hanger

Brake Mount Flat 160mm

Brake Mount Flat 180mm

Trigger CRB Cstay Protector

G CK3287U00OS Trigger CRB Cstay Guard

A

J

E

B

C

Loctite 242 (blue)

M4

Loctite 242 (blue)

6 Nm

G

12 Nm

A

K

A

ID CODE DESCRIPTION

K34068

H

I

J

K

K34058

CK3247U00OS

C22698M00L1

KP390/

Trigger CRB CS Heel Rub Grds

( Trigger 1)

Trigger ALLY CS Heel Rub Grds

(Trigger 2 and 3)

Trigger Al Chainstay Protector

27.5 M Trigger Crb Link

Mount F Der

134910 Rev 1.

20

Page 23

ENGLISHTRIGGER/JEKYLL - OWNERS MANUAL SUPPLEMENT

M

34.9 mm

A

1.5 N-m

B

L

Q

M2.5

1 N-m

N

M2.5

1 N-m

P

M2.5

C

M5

Loctite 242 (blue)

12 Nm

O

1 N-m

P

Q

Q

ID CODE DESCRIPTION

CK9017U00OS

L

M

KP197/SRM

KP388/

17x30 Bearing Tool

Kit Bearing BB-Presst 30 SRM

Seatbinder MTN 34.9

For rear shock parts and service:

www.foxracingshocks.com

134910 Rev 1.

ID CODE DESCRIPTION

K32027

N

Internal Di2 Battery Mount

0 CK3117U00SM Trigger Crb DT Protector SM

CK3117U00MD Trigger Crb DT Protector MD

CK3117U00LG Trigger Crb DT Protector LG

CK3117U00XL Trigger Crb DT Protector XL

CK3187U00OS

P

KP436/

M

Jekyll/Trigger Grommets

Cable Guides Scalpel Si

21

Page 24

Loctite 242 (blue)

12 Nm

A

N

‘

REPLACEMENT PARTS

JEKYLL (Carbon/Alloy)

F

C

Loctite 242 (blue)

12 Nm

1

2 N-m

M5x25

E

G

D

D

A

1

1.5 Nm

H

B

F

34.9 mm

I

= NLGI-2 Synthetic Grease

1

ID CODE DESCRIPTION CRB ALLY

CK3157U00OS

A

B

C

D

E

F

CK3167U00OS

CK3207U00OS

K36018

CK3187U00OS

KP388/

KP436/

KP197/SRM

KB6180/

QC616/

Jekyll Pivot Hardware X X

Jekyll Pivot Bearings X X

Jekyll Carbon Shock Bolts X

Jekyll Alloy Shock Bolts X

Jekyll/Trigger Grommets X X

Seatbinder MTN 34.9 X X

Cable Guides Scalpel Si X

Kit Bearing BB-Presst 30 SRM X

Bearing BB Si 2PCS BLU X

Circlips 2x BB Si X

134910 Rev 1.

ID CODE DESCRIPTION CRB ALLY

K32027

G

H

I

CK3107U00SM

CK3107U00MD

CK3107U00LG

CK3107U00XL

K34008

CK9017U00OS

Internal Di2 Battery Mount X

Jekyll Crb DT Protector SM X

Jekyll Crb DT Protector MD X

Jekyll Crb DT Protector LG X

Jekyll Crb DT Protector XL X

Jekyll Alloy DT Protector (all sizes) X

17x30 Bearing Tool X X

22

Page 25

ENGLISHTRIGGER/JEKYLL - OWNERS MANUAL SUPPLEMENT

Loctite 242 (blue)

12 Nm

A

C

A

Loctite 242 (blue)

N

M

5 Nm

K

L

For rear shock parts and service:

www.foxracingshocks.com

A

A

W

L

2 Nm

6 Nm

M5 X 18

A

CS-L

O

CS-R

DT & SS

P

Loctite 242 (blue)

6 Nm

B

ID CODE DESCRIPTION CRB ALLY

CK3257U00OS

J

K

L

M

N

O

P

CK3217U00OS

CK3197U00OS

K34078

C21698M00L1

K34068

K34058

KP421/160

KP421/180

Jekyll/Trigger Rear Der Hanger X X

Jekyll AL CSTAY Protector X

Jekyll CRB CSTAY Protector X

Jekyll CRB Chainsuck Protector X

27.5 M Jekyll CRB Link (w/bearings)

All sizes, both carbon and alloy

Jekyll CRB CS Heel Rub Grds (Jekyll 1) X

Jekyll/ ALLY CS Heel Rub Grds

(Jekyll 2, 3,4)

Brake Mount Flat 160mm X X

Brake Mount Flat 180mm X X

134910 Rev 1.

X X

X

23

Page 26

CANNONDALE USA

Cycling Sports Group, Inc.

1 Cannondale Way,

Wilton CT, 06897, USA

1-800-726-BIKE (2453)

CANNONDALE EUROPE

Cycling Sports Group Europe B.V

Mail: Postbus 5100

Visits: Hanzepoort 27

7570 GC, OLDENZAAL, Netherlands

Tel: +41 61 551 14 80

Fax:+31 54 151 42 40

WWW.CANNONDALE.COM

© 2017 Cycling Sports Group

TRIGGER/JEKYLL Owner’s

Manual Supplement - 134910 Rev 1

Loading...

Loading...