Page 1

kitchen think

Instructions for Installation and Use

110cm Free Standing Gas Cooker

C110DPX

To the Installer

Before installation fill in the product details on the back cover this book.

The information can be found on the rating plate.

To the User

You must read the instructions prior to installing and using the appliance and

then retain them for future reference.

Page 2

Contents

Introduction 3

Installation 4

Burner and Nozzle Specifications 8

Safety Information 9

Features 11

Control Panel 12

Use of hotplates 13

The Cooking Modes in your Cooker (2nd OVEN) 14

The Cooking Modes in your Cooker (1st OVEN) 15

Electronic Clock & Automatic Cooking Feature 16

1st Oven - The Intelligent Cooking System 20

Care and Cleaning 24

Cooking Results Not Satisfactory? 25

Something Wrong With Your Cooker? 26

Technical Characteristics (1st OVEN) 27

Technical Characteristics (2nd OVEN) 28

Electric drawer 29

Troubleshooting 29

Key Contacts Back Cover

You must read these instructions prior to using your appliance and retain them for

future use.

2

Page 3

Introduction

Your new appliance is guaranteed* and will give lasting service. This guarantee is only applicable if the appliance

has been installed in accordance with the installation instructions detailed in this booklet.

To help make best use of your cooking equipment, please read this booklet carefully.

The cooker is designed specifically for domestic use and responsibility will not be accepted for use in any other

installation.

When the cooker is first used an odour may be emitted,

this will cease after a period of use.

When first using the cooker ensure that the room is well ventilated (e.g. open a window or use an extractor fan) and

that persons who may be sensitive to the odour avoid any fumes. It is suggested that any pets be removed from the

room until the smell has ceased. This odour is due to temporary finish on oven liners and elements and also any

moisture absorbed by the insulation.

* The guarantee is subject to the provisions that the appliance:

(a) Has been used solely in accordance with the Users Instruction Book.

(b) Has been properly connected to a suitable supply voltage as stated on the

rating plate attached to this equipment.

(c) Has not been subjected to misuse or accident or been modified or repaired by

any person other than the authorised employee or agent.

(d) Has been correctly installed.

1

This appliance is intended for nonprofessional use within the home.

2 These instructions are only for those countries whose symbols appear in the booklet and on the serial no. plate

of the appliance.

3 This owner’s manual is for a class 1 appliance (insulated) or class 2, subclass 1 appliances (installed

between two cabinets.

3

Page 4

Installation

The appliance must only be installed by a competent person. In the UK, CORGI registered installers undertake

to work to safe and satisfactory standards.

Before moving your cooker check that it is cool, and switch off at the cooker control unit. Movement of your cooker is

most easily achieved by lifting the front as follows:

Open the grill door sufficiently to allow a comfortable grip on the underside front edge of the oven roof, avoiding any

grill elements.

Note: Take care in moving the cooker as it is heavy. Take care to ensure that any floor covering is not damaged.

(FIG. C)

Splashplate optional, apply to Parts Department (see Back Cover for contact number.)

The following instructions should be read by a qualified technician to ensure that the appliance is installed,

regulated and technically serviced correctly in compliance with current regulations.

Important: remember to unplug the appliance from the mains before regulating the appliance or

carrying out any maintenance work.

Positioning

Important: this unit may be installed and used only in permanently ventilated rooms according to the British

Standards Codes Of Practice: B.S. 6172/B.S. 5440, Par. 2 and B.S. 6891 Current Editions. The following requirements

must be observed:

3

a) The cooker should not be installed in a bed sitting room with a volume of less than 20m

3

room of volume less than 5m

volume between 5m

3

and 10m3 a supplementary airvent area of 50cm2 is required, if the volume exceeds 11m

an air vent of effective area of 110cm2 is required, if it is installed in a room of

no airvent is required. However, if the room has a door or a window which opens directly to the outside no air

vent is required even when the volume is between 5m

3

and 11m3.

b) During prolonged use of the appliance you may consider it necessary to open a window to the outside to

improve ventilation.

c) If there are other fuel burning appliances in the same room, B.S.5440 Part 2 Current Edition, should, be

consulted to determine the requisite air vent requirements.

. If it is installed in a

3

Installation of the cooker

For a correct installation of the cooker the following precautions must be followed:

The height of the cooker can be adjusted by means of adjustable feet in the plinth (900mm - 915mm). Adjust the feet by

tilting the cooker from the side. Then install the product into position.

NOTE: This appliance must not be fitted on a platform.

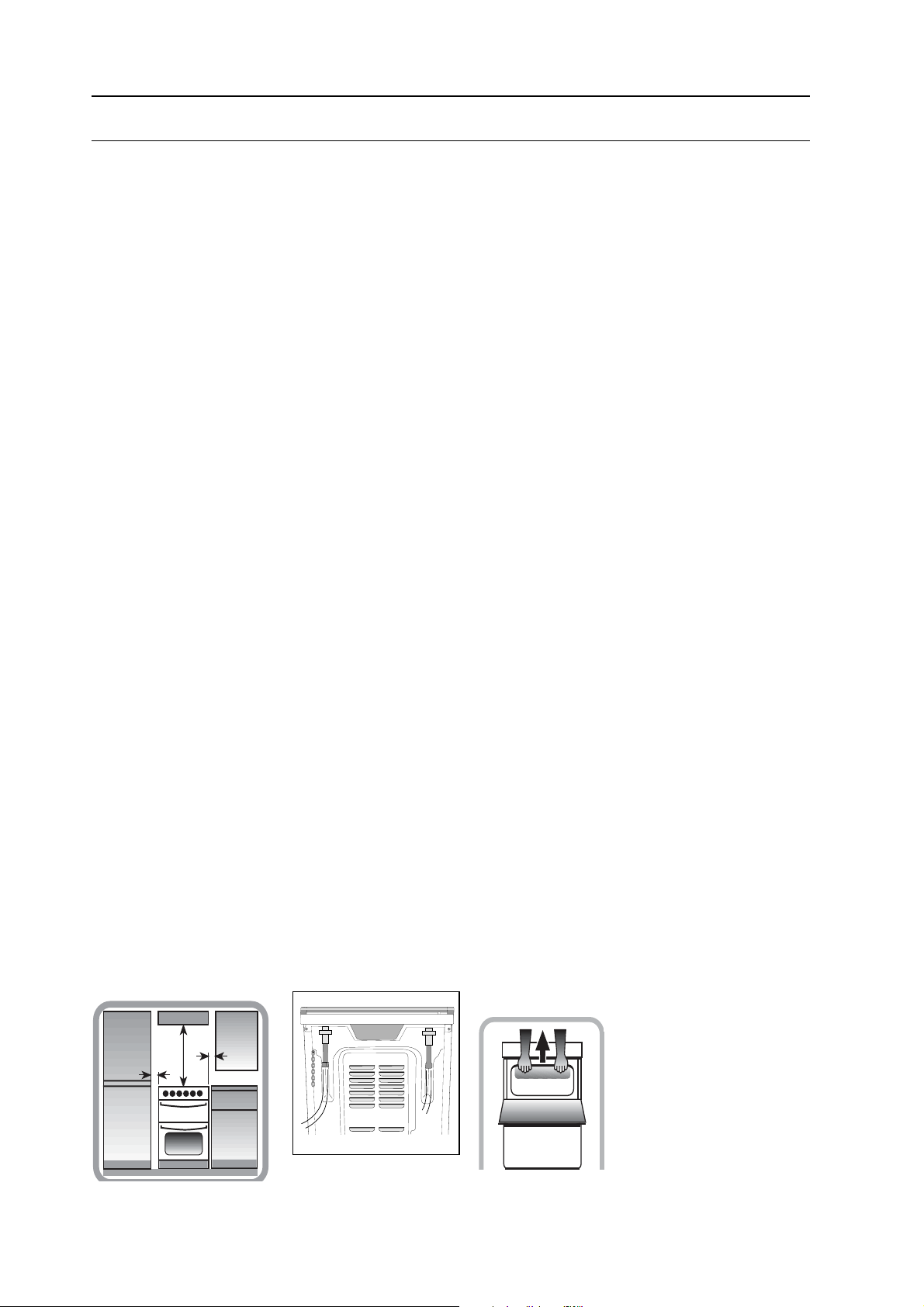

The cooker is designed to fit between kitchen cabinets spaced 500mm apart. The space either side need only be sufficient

to allow withdrawal of the cooker for servicing. It can be used with cabinets one side or both as well as in a corner setting.

It can also be used free-standing.

Adjacent side walls which project above hob level, must not be nearer to the cooker than 150mm and should be protected

by heat resistant material. Any overhanging surface or cooker hood should not be nearer than 650mm. (Fig.A)

a) The cooker may be located in a kitchen, a kitonen/diner or bed sitting room, but not in a bathroom or

shower room.

b) The hoods must be installed according to the requirements in the hood handbook.

c) The wall in contact with the back of the cooker must be of flameproof material.

d) The cooker is fitted with a safety chain that must be attached to a hook, secured to the wall behind the

appliance.

Note: some models can have their gas connection inverted. It is important to make sure the safety chain

is always situated on the side which corresponds to the hose holder (Fig. B).

Moving the Cooker

150 mm

150 mm

650 mm

Fig. A Fig. B Fig. C

4

Page 5

Gas connection

The cooker should be connected to the gas-supply by a corgi registered installer. During installation of this

product it is essential to fit an approved gas tap to isolate the supply from the appliance for the convenience

of any subsequent removal or servicing. Connection of the appliance to the gas mains or liquid gas must be

carried out according to the prescribed regulation in force, and only after it is ascertained that it is adaptable

to the type of gas to be used. If not, follow the instructions indicated in the paragraph headed “Adaptation to

different gas types”. On some models the gas supply can be connected on the left or on the right, as

necessary; to change the connection, reverse the position of the hose holder with that of the cap and

replace the gasket (supplied with the appliance). In the case of connection to liquid gas, by tank, use

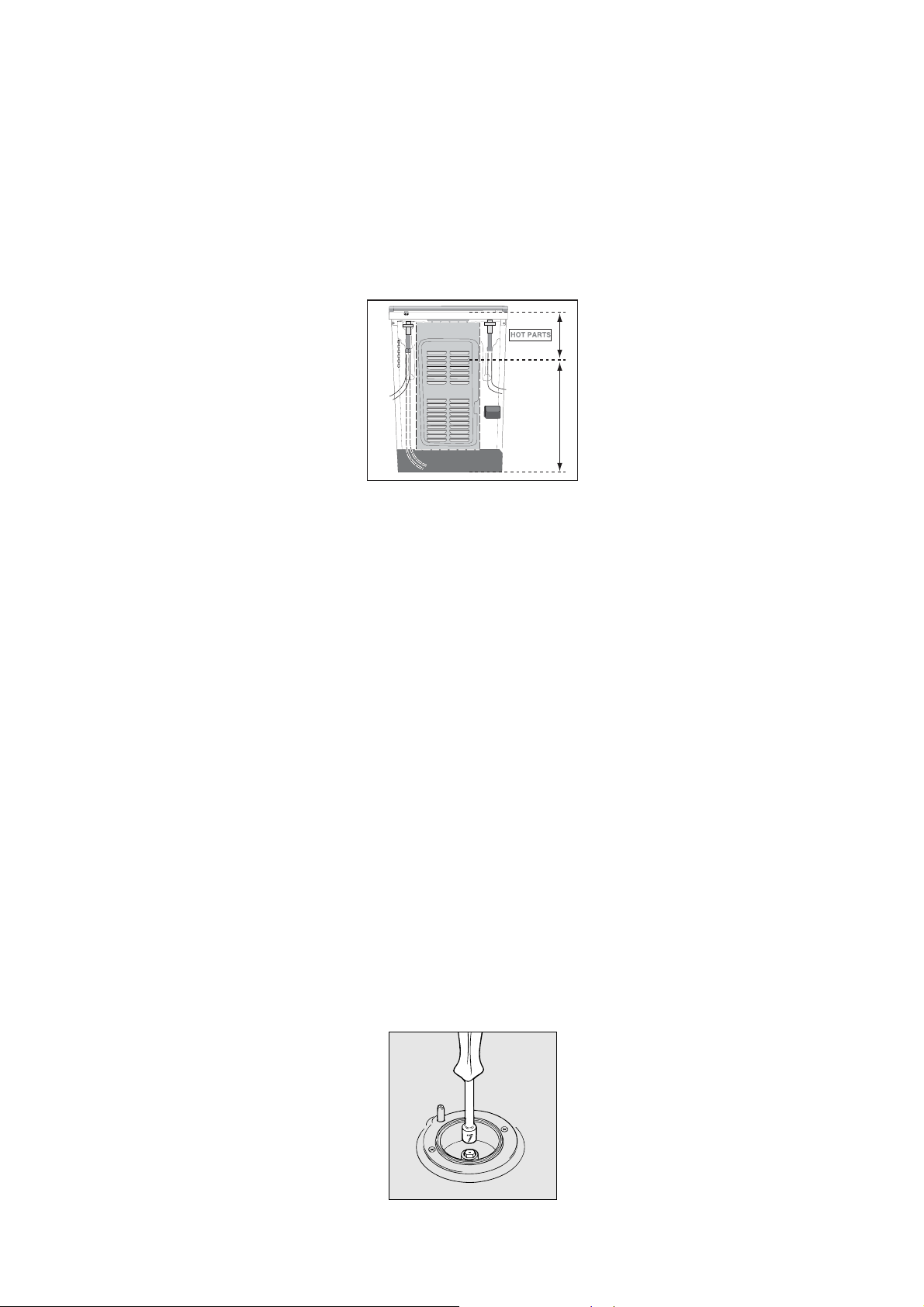

pressure regulators that conform to the regulation in force. The gas supply must be connected to the left of

the appliance. Be sure that the hose does not pass through the rear of the cooker touching hot parts.

HOT PARTS

600 mm

Important: make sure the supply pressure conforms with the values shown in the table entitled “Caracteristics of

the burners and nozzles”. When the cooker is installed between cabinets (recessed), the gas connection

must be effected by an approved flexible hose with bayonet fitting (BS 669 Current Edition). The gas inlet

for the cookers is a threaded G 1/2 gas female fitting.

Connecting the gas supply

To make the connection, a flexible hose should be used corresponding to the current gas regulations which are:

• the hose must never be at any point in its lenght in contact with the “hot” parts of the cooker;

• the hose must never be longer than 1,5 metre;

• the hose must not be subject to any tension or torsional stress and it must not have any excessively narrow

curves or bottlenecks;

• the hose must be easy to inspect along its entire length to check its condition;

• the hose must always be in good condition, never attempt to repair.

Important: the installation must comply with gas safety (installation and use) regulations 1984. In all cases for the

above, by low, a qualified, corgi approved engineer must be called for installation.

Disposing of the appliance

When disposing of the appliance please remove the plug by cutting the mains cable as close as possible to the

plug body and dispose of it as described above.

Adapting the cooker to different types of gas

In order to adapt the cooker to a different type of gas with respect to the gas for which it was produced

(indicated on the label attached to the lid), follow these steps:

a) replace the hose holder mounted on the appliance with that supplied in the bag of “cooker accessories”.

b) Replacing the burner nozzles on the hob:

• remove the grids and slide the burners from their housings;

• unscrew the nozzles using a 7 mm socket spanner, and replace them with nozzles for the new type of gas

(see table 1 “Burner and nozzle characteristics”).

• replace all the components by repeating the steps in reverse order.

5

Page 6

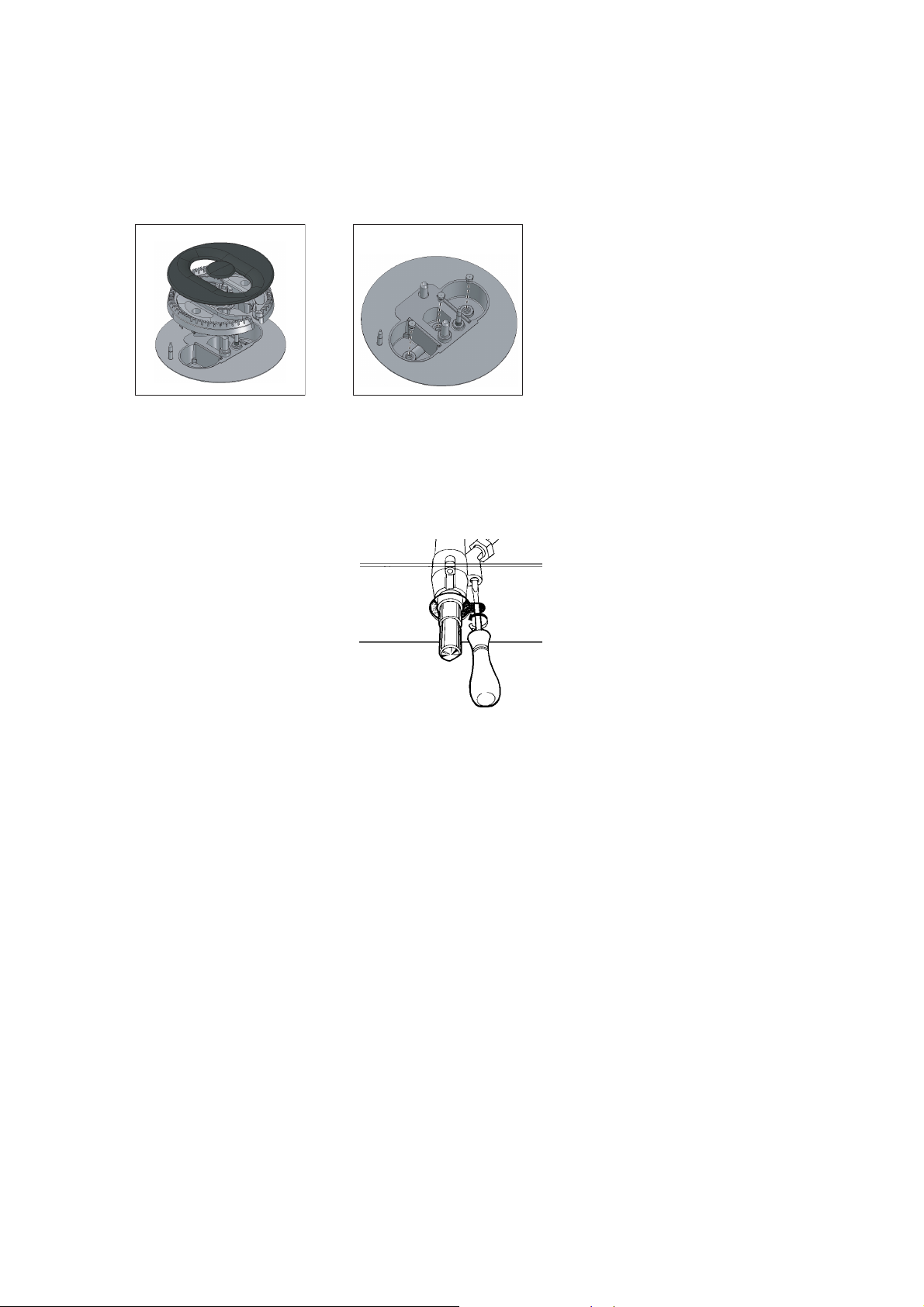

c) Replacing the nozzles on separate “double flame “ burners:

• remove the grids and slide the burners from their housings. The burner consists of 2 separate parts (

);

figure

• unscrew the burers with a 7 mm wrench spanner. The internal burner has a nozzle, the external burner has

two (of the same size). Replace the nozzle with models suited to the new type of gas (see table 1).

• replace all the components by repeating the steps in reverse order.

d) Minimum regulation of the hob burners:

•

turn the tap to minimum;

• remove the knob and adjust the regulation screw, which is positioned in or next to the tap pin, until the

flame is small but steady.

N.B.: in the case of liquid gas, the regulation screw must be screwed in to the bottom.

• check that the flame does not turn off when you turn the tap quickly from high to low.

see

e) Regulating the primary air of the burners:

The primary air of the burners requires no regulation.

Important

On completion of the operation, replace the old rating sticker with one indicating the new type of gas used.

This sticker is available from our Service Centres.

Note

Should the pressure of the gas used be different (or vary) from the recommended pressure, it is necessary to

fit a suitable pressure regulator onto the inlet pipe in compliance with current National Regulations relative to

“regulators for channelled gas”.

6

Page 7

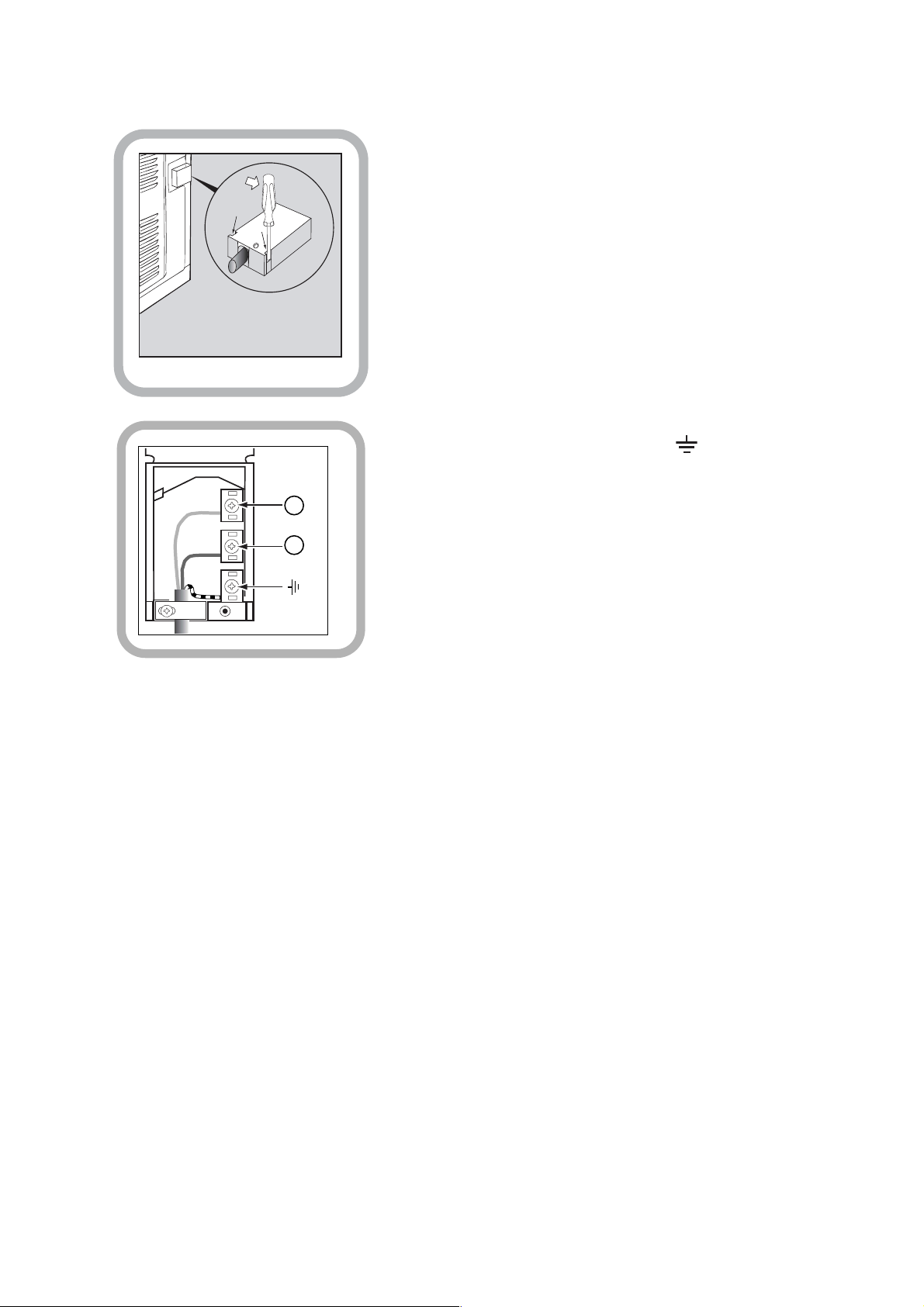

WARNING – THIS APPLIANCE MUST BE EARTHED.

Electrical connection

Electric cookers come without a power supply cable. The cooker is designed

to operate on an electricity supply which conforms to the electrical data

shown on the Rating Plate. The cooker can be connected to the mains only

after removing the back panel of the cooker itself with a screwdriver.

N.B.: the following installation procedure must be carried out by a qualified

electrician. The electrical installation must comply with the IEE Regulations,

Building & local By-Lays.

For the installation of the feeding cable carry out the following operations:

l Using a screwdriver, prise on the side tabs of the terminal board

cover (see fig. A);

l Pull and open the junction blok lid

Important: the wires in the mains lead are coloured in accordance with the

following code:

Fig. A

L

2

Green & Yellow Earth

Blue Neutral

Brown Live

As the colours of the wires in the mains lead may not correspond with the

coloured markings identifying the terminals in your plug, proceed as follows:

Green & Yellow wire to terminal marked “E” or

Green & Yellow.

Brown wire to terminal marked “L” or coloured Red.

Blue wire to terminal marked “N” or coloured Black (see fig. B).

l fix the feeding cable in the special cable stop and close the cover.

N

4

N.B.: the power supply cable must have these minimum requirements:

Type: H05RR-F

Section: 3x4 mm

or coloured Green or

2

Fig. B

Ensure that the mains cable is routed away from any brackets affixed to the

rear panel and is not trapped to the rear wall when pushing the cooker into

position between cabinets.

7

Page 8

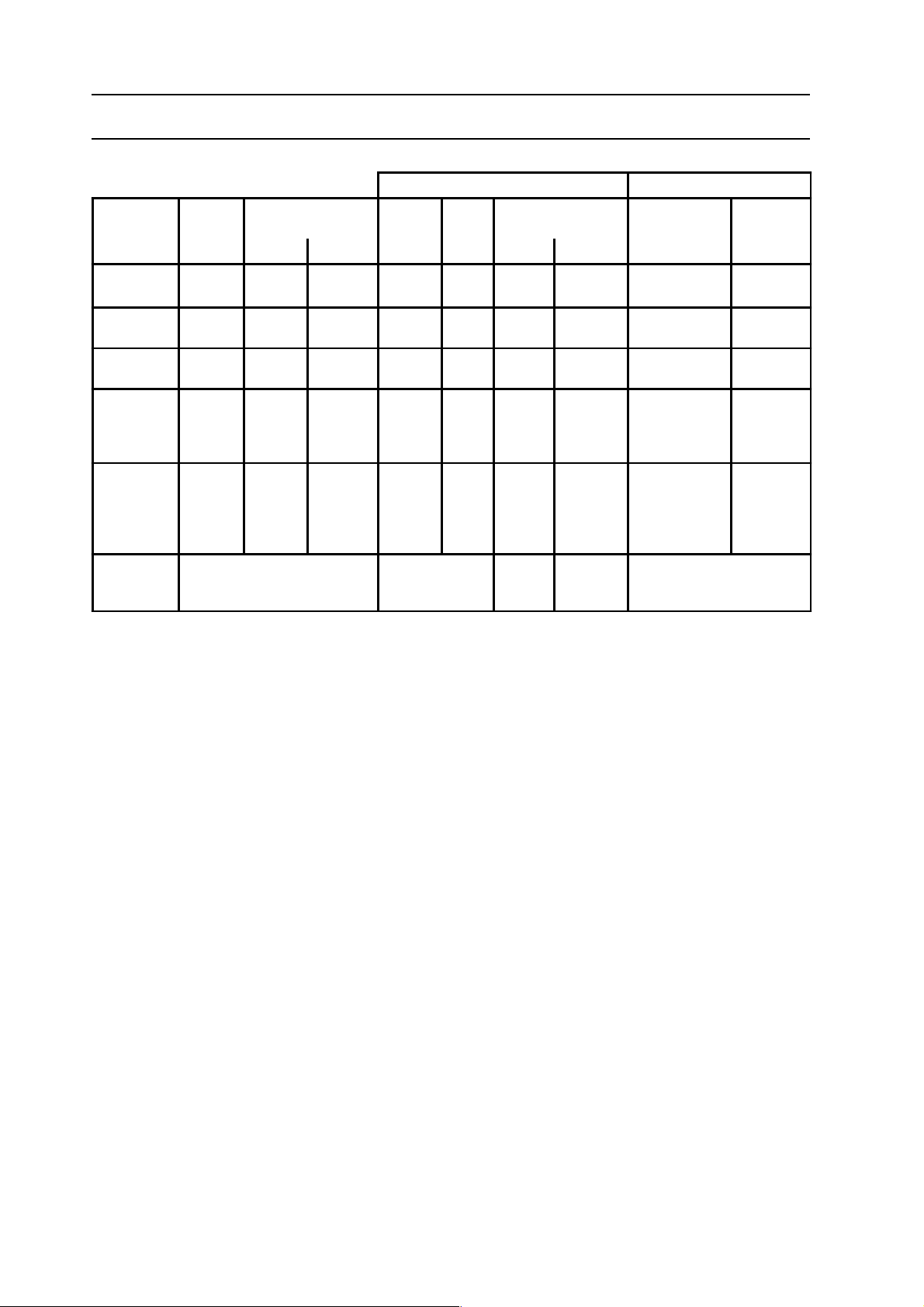

Burner and Nozzle Specifications

Table 1 Liquid Gas Natural Gas

Burner Diameter

(mm)

Thermal Power

kW (p.c.s.*)

Nominal Reduced (mm) (mm) *** ** (mm)

By-Pass

1/100

Nozzle

1/100

Flow*

g/h

Nozzle

1/100

Flow*

l/h

Fast

(Large)(R)

Semi Fast

(Medium)(S)

Auxiliary

(Small)(A)

Double

flame

(DCDR

internal)

Double

flame

(DCDR

external)

2 nozzle

Supply

Pressures

100 3,00 0,7 40 86 218 214 116 286

75 1,65 0,4 30 64 120 118 96 157

55 1,00 0,4 30 50 73 71 71 95

30 0,90 0,40 30 44 65 64 74 86

130 4,10 1,30 57 70 298 293 110 390

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

* At 15°C and 1013 mbar- dry gas

** Propane P.C.S. = 50,37 MJ/Kg

*** Butane P.C.S. = 49,47 MJ/Kg

Natural P.C.S. = 37,78 MJ/m

28-30

20

35

3

37

25

45

20

17

25

8

Page 9

Safety Information

When used properly your appliance is completely safe but as with any electrical product there are certain

precautions that must be observed.

PLEASE READ THE PRECAUTIONS BELOW BEFORE USING YOUR APPLIANCE.

Always

l Remove all packing from inside the oven and grill compartments before switching on for the first time.

l Understand the controls prior to using the appliance.

l Keep children away from the appliance when grilling as the surfaces will get extremely hot during and after

use.

l Turn controls off when you have finished cooking and when not in use.

l Stand back when opening an oven door to allow any build up of steam or heat to disperse.

l Use dry good quality oven gloves when removing items from the oven/grill.

l Place pans centrally over the hotplate making sure handles are kept away from the edge of the hob and cannot

become heated by other hotplate/pans.

l Take care to avoid heat/steam burns when operating the controls.

l Turn off the electricity supply at the wall switch before cleaning and allow the appliance to cool.

l Make sure the shelves are in the correct position before switching on the oven.

l Keep the oven and grill doors closed when the appliance is not in use.

l Take care when removing items from the grill when the lower oven is on as the contents will be hot.

l Keep the appliance clean, as a build up of grease or fat from cooking can cause a fire.

l Follow the basic principles of food handling and hygiene to prevent the possibility of bacterial growth.

l Keep ventilation slots clear of obstructions.

l Refer servicing to a qualified appliance service engineer.

l Take care to avoid touching heating elements inside the oven, as during use the oven becomes hot.

l Before operating the product, remove all plastic film from the sides of the appliance.

9

Page 10

Safety Information

Never

l Never line the interior of the oven with foil as this may cause the appliance to overheat.

l Never leave children unsupervised where a cooking appliance is installed as all surfaces will be hot during

and after its use.

l Do not allow children or persons who are not familiar with the appliance to use it, without supervision.

l Never allow anyone to sit or stand on any part of the appliance.

l Never store items above the appliance that children may attempt to reach.

l Never leave anything on the hob surface when unattended and not in use.

l Never remove the oven shelves whilst the oven is hot.

l Never heat up unopened food containers as pressure can build up causing the container to burst.

l Never store chemicals/food stuffs, pressurised container in or on the appliance, or in cabinets immediately

above or next to the appliance.

l Never place flammable or plastic items on or near the hob.

l Never fill a deep fat frying pan more than 1/3 full of oil, or use a lid.

DO NOT LEAVE UNATTENDED WHILE COOKING.

l Never operate the grill with the grill door closed as this will cause the appliance to overheat.

l Never use the appliance as a room heater.

l Never use the grill to warm plates.

l Never dry any items on either the hob or oven doors.

l Never install the appliance next to curtains or other soft furnishings.

l Never use steam cleaners.

SAFETY ADVICE IN CASE OF A CHIP-PAN FIRE

In the event of a chip pan fire or any other pan fire.

1. TURN OFF THE COOKER APPLIANCE AT THE WALL SWITCH.

2. COVER THE PAN WITH A FIRE BLANKET OR DAMP CLOTH, this will smother the flames and extinguish the

fire.

3. LEAVE THE PAN TO COOL FOR AT LEAST 60 MINUTES BEFORE MOVING IT. Injuries are often caused by

picking up a hot pan and rushing outside with it.

NEVER USE A FIRE EXTINGUISHER TO PUT OUT A PAN FIRE as the force

of the extinguisher is likely to tip the pan over.

Never use water to extinguish oil or fat fires.

10

Page 11

Features

1650W

4100W

+900W

3000W

1650W

CONTROL

PANEL

1000W

2nd OVEN

Compartement

opening

1nd OVEN

Adjustable

feet

11

Page 12

Control Panel

1st Oven 2nd Oven

1

1

22

33

44

Selector

Knob (2nd Oven)

Gas Hob

Controls

Gas Hob Controls

1˚ Oven:

- Reccommended

Shelf Position

and

- Preheat

Temperature Indicator

1st Oven

Light

+/- Control

Knob

2.TRADIZIONAL

1.FAN

OVEN

4.ROAST

CHICKEN

3.ROAST

MEAT

Thermostat

Knob (1st Oven)

Knob (1st Oven)

6.BREAD

5.FISH 7.CAKES

Minute

Minder

Cooking

Duration

Time /

Mode

1˚ OVEN FUNCTIONS (1-7)

OVEN

End

Time

Selector

Set

Time

Thermostat

Knob (2nd Oven)

Thermostat indicator

light (2nd Oven)

Push in and turn the control knob anti-clockwise to the large flame symbol. Continue to push in the

control until the sparks light the gas.

Turn the control knob anti-clockwise to reduce the heat input.

Only turn the control between the large flame symbol and the small flame symbol when adjusting the

setting.

To turn off, turn the control knob fully clockwise to the symbol “O”, its off position.

1st Oven

Light

Cooling Fan

1st Oven

Control

The 1st Oven

Cooking Functions

Adjusting the

1st Oven

Temperature

12

The 1st oven light can be switched on, when the oven is not in use, by pressing the oven light button

on the display. The oven light will also operate whenever the 1st oven door is opened.

NOTE: The oven light can be switched off when the door is opened by pressing the oven light button

on the display, or by closing the door.

The cooling fan operates with the ovens and grill. The fan will operate at full speed for a few seconds

and then reduce to a lower speed. The cooling fan will only increase to full speed if the temperature

inside the cooker reaches above a certain limit.

This control switches on the top and rear heating elements at various times in the 1st oven, dependent

on which mode has been set. The temperature of the 1st oven can be set anywhere between 80°C and

230°C in cooking modes 1 - 5.

The 1st oven preheat temperature indicator (

The 1st oven preheat temperature indicator (

symbol) will be on the display (middle, left hand side).

symbol) will switch OFF and an audible tone will sound

when the 1st oven has reached the required temperature.

The 1st oven has eight cooking functions. Use the 1st oven control to select the cooking mode you

require. The display will show the function you have selected, across the top (1 - 7) with the eighth

function being shown on the clock display as “(RISE)”

When a program is set (position 1 - 5), the display will automatically suggest a cooking temperature. If

you wish you can use the +/- control knob to change the suggested temperature to one of your own

choice, within a range which is suitable for the particular cooking mode.

Page 13

Use of Hotplates

Practical Advice on Using the Burners

To use the burners as efficiently as possible, some basic guidelines should be followed:

• Use cookware that is the right size for each burner (see table) in order to prevent the flame from spreading

beyond the bottom of the cookware.

• Only use cookware with flat bottoms.

• As soon as the boiling point is reached, turn the knob to the lowest setting.

• Always use lids with pots and pans.

Burner ø Cookware diameter (cm)

Rapid (R) 24 - 26

Semi-Rapid (S) 16 - 22

Auxilliary (A) 10 - 14

Double flame (DCDR

internal)

Double flame (DCDR

external)

1. Push in and turn the control knob of the chosen burner anti-clockwise to the large flame

symbol. Continue to push in the control knob until the sparks light the gas.

2. Turn the control knob anti-clockwise to reduce the heat input. Only turn the control knob

between the large flame symbol and the small flame symbol when adjusting the setting.

3. To turn off, turn the control knob fully clockwise to the symbol O.

DO NOT use the hotplate unless all pan supports are in position.

DO NOT use mis-shapen pans which may be unstable.

DO NOT use round base woks directly on the pan supports.

Each burner is fitted with a spark ignitor for lighting the gas. To ensure rapid lighting of the burners every time they

are used, the ignitors must be kept clean and dry. Remove any food spillage or cleaning materials from the

electrode using a small nylon brush such as a tooth brush. Access to the electrode can be achieved by lifting off the

loose burner parts carefully when the burners are cool.

When the hotplate burner bodies and caps are removed for cleaning, be careful not to drop any food particles or

cleaning materials into the burner bases, to avoid the possibility of blocking the gas jets.

If aluminium based pans are used, a silvery deposit may appear on the top edge of the pan support fingers. See

'Care and Cleaning' section for cleaning information.

SAFETY REQUIREMENTS FOR DEEP FAT FRYING

10 -14

26 - 28

1. Never fill chip pans more than one third full with oil or fat.

2. Never leave oil or fat unattended during the heating or cooling period.

3. Never heat fat or fry with a lid on the pan.

4. Always dry food thoroughly before frying, and lower it slowly into the hot oil or fat. Frozen foods in

particular will cause frothing and spitting if added too quickly.

5. Always keep the outside of the pan clean and free from streaks of oil or fat.

HOW TO DEAL WITH A FAT FIRE

1. Do not move the pan.

2. Turn off the hotplate burners.

3. Smother the flames with a fire blanket or damp cloth to extinguish the fire. Do not use water or a fire

extinguisher as the force of it may spread the burning fat or oil over the edge of the pan.

4. Leave the pan for at least 60 minutes before moving it.

13

Page 14

The Cooking Modes in your Cooker (2nd OVEN)

NOTE: A temperature value can be set for all cooking modes between 50°C and Max, except for the following

modes

• MAXI-GRILL / MINI-GRILL (recommended: set only to MAX power level)

Starting the oven

1. Select the desired cooking mode by turning the SELECTOR knob.

2. Select the recommended temperature for the cooking mode or the desired temperature by turning the

THERMOSTAT knob.

A list detailing cooking modes and suggested cooking temperatures can be found in the relevant table.

During cooking it is always possible to:

• Change the cooking mode by turning the SELECTOR knob.

• Change the temperature by turning the THERMOSTAT knob.

• Set the total cooking time and the cooking end time (see below).

• Stop cooking by turning the SELECTOR knob to the “0” position.

NOTE: Never put objects directly on the bottom of the oven; this will avoid the enamel coating being damaged. Only

use position 1 in the oven when cooking with the rotisserie spit.

NOTE: Always place cookware on the rack(s) provided.

THERMOSTAT indicator light

When this is illuminated, the oven is generating heat. It switches off when the inside of the oven reaches the

selected temperature. At this point the light illuminates and switches off alternately, indicating that the thermostat is

working and is maintaining the temperature at a constant level.

Oven light

This is switched on by turning the SELECTOR knob to any position other than “0”. It remains lit as long as the oven

is operating.

TRADITIONAL OVEN mode

Both the top and bottom heating elements will come on. When using this traditional cooking mode, it is best to use

one cooking rack only. If more than one rack is used, the heat will be distributed in an uneven manner.

PASTRY Mode

The bottom heating element comes on.

This mode is ideal for baking and cooking delicate foods - especially cakes that need to rise because the heat

coming from the bottom helps the leavening process.

Please note that it takes a considerable amount of time for the higher temperatures to be reached, therefore we

recommend you use the “Convection Mode” in these cases.

MINI GRILL

The top central heating element comes on.

The extremely high and direct temperature of the grill makes it possible to brown the surface of meats and roasts

while locking in the juices to keep them tender. The grill is also highly recommended for dishes that require a high

temperature on the surface: beef steaks, veal, rib steak, filets, hamburgers etc...

MAXI GRILL

The top heating element comes on.

This mode can be used to brown food at the end of cooking.

14

GRILLING MUST BE DONE WITH THE GRILL DOOR SHUT.

CONTROL KNOBS MAY BECOME HOT DURING GRILLING.

CAUTION: ACCESSIBLE PARTS WILL BECOME HOT WHEN THE GRILL

IS USED - CHILDREN SHOULD BE KEPT AWAY.

Page 15

The Cooking Modes in your Cooker (1st OVEN)

Your new cooker is equipped with a number of different cooking modes:

Fan Oven

- the fan oven operates by constantly blowing heated air, from an element wrapped around the fan, into the oven.

This gives improved efficiency and in general, enables the use of lower temperatures for cooking. It also means that

there is less need to be particular about shelf positions and that you can bake at more than one level

simultaneously (Batch Baking).

Traditional

- the upper and rear heating elements are switched on in this position. The traditional oven brings an outstanding

level of temperature distribution and reduced consumption. In traditional cooking use only one rack to ensure good

heat distribution. By using the various shelf positions available you can balance the quantity of heat between the

upper and lower part. If cooking requires more heat from below or above, use the lower or higher shelves

respectively.

Roast Meat

- specially created for cooking joints of meat. This mode raises the temperature in the oven to a very high heat for

the first part of the cooking cycle, to seal the outside of the joint and retain the juices of the meat throughout cooking.

After this the temperature is reduced to the set temperature using each heating element in turn to guarantee a

homogeneous temperature for the cooking period. A temperature is suggested on this mode but this can be altered

using the ‘+/-’ control knob.

Roast Chicken

- specially created for cooking excellent roast poultry. This mode can be used to roast chickens, duck, turkey and

other poultry to perfection. Each heating element is used in the cycle to guarantee a homogeneous temperature

within the oven. A temperature is suggested on this mode but this can be altered using the ‘+/-’ control knob.

Rising

- this mode heats and holds the oven at 40¢ªC. It is ideal for proving bread and yeast based dough mixtures. When

this mode is selected a cooking duration of 14 minutes is automatically set, this can be altered by pressing the ‘time/

mode’ button until the cooking duration icon flashes. Then use the ‘+/-’ control knob to adjust the cooking duration.

Cake cycle - Auto

- this mode is fully automatic and lasts for 1 hour. When this mode is selected the time and temperature cannot be

adjusted. it is suitable for baking sponge based cakes that take between 30 minutes and 1 hour to cook. Some

recipe ideas are included in the recipe book supplied with the cooker.

Bread cycle - Auto

- this mode is fully automatic and lasts for 1 hour. When this mode is selected the time and temperature cannot be

adjusted. It is suitable for baking bread weighing up to 1.5kg, either in a tin or on a baking tray. This mode includes a

proving cycle and a baking cycle. If an initial proving cycle is needed this can be done using the RISE mode (8).

Some recipe ideas are included in the recipe book supplied with the cooker.

Fish

- this mode provides gently pulsing top and rear heat to lightly poach fish dishes without overcooking or drying out.

A temperature is suggested on this mode but this can be altered using the ‘+/-’ control knob.

15

Page 16

Electronic Clock & Automatic Cooking Feature

When you first switch on the appliance you will be prompted to set the “Time of Day” on

the display. You must ensure you have done this before attempting to use the automatic

cooking feature.

AUTOMATIC

COOKING

HINTS ON

AUTOMATIC

COOKING

SETTING THE

TIME OF DAY:

The 1st oven can be controlled automatically.

- Select food which will require the same cooking time and temperature.

- To ensure food does not cool down and require reheating, set the end time so the food is ready when

you require it.

- Always ensure that meat and poultry is defrosted before placing in the oven.

- Whenever possible, take food out of the refrigerator and keep it as cool as possible.

- If cooking food that requires frying before placing in the oven for automatic cooking, keep the delay

time to a minimum.

- Never place hot or warm food in the oven for delayed start cooking as it could cause the oven to be

warm and produce harmful bacteria in the food.

- We advise that dishes containing left-over cooked poultry and meat, eg. shepherds pie, should not be

cooked automatically if there is to be a delay period.

- Ensure that delay start times are kept to a minimum to prevent bacterial growth in food.

- Wine or beer may ferment and cream may curdle during the delay period, so it is best to add these

ingredients just before serving.

- Foods which discolour should be protected by coating in fat or tossing in water to which lemon juice

has been added, prior to placing food in the oven.

- Dishes containing liquid should not be filled too full to prevent boiling over.

- Food should be well sealed (but not airtight) in a container to prevent the loss of liquid during cooking.

Aluminium foil gives a good seal.

- Always ensure that food is piping hot and cooked thoroughly before serving.

- Only reheat food once.

16

STEP 1. Check the electricity supply to the cooker is turned on.

STEP 2. When switched on the display will show both 00:00 and the “set time” symbol flashing. Wait

until these stop flashing.

STEP 3. Press the Time/Mode button once, so that the “Set Time” symbol and the display are flashing.

Turn the +/- control knob until the correct hour is set.

STEP 4. Press the Time/Mode button once, so that the “Set Time” symbol and the display are flashing.

Turn the +/- control knob until the correct minutes are set. Press the Time/Mode button again.

TIME OF DAY IS NOW SET.

To alter the time of day after the first setting, simply press the Time/Mode button.

The “Set Time” symbol and the display will flash. Repeat STEPS 3 and 4.

Page 17

Electronic Clock & Automatic Cooking Feature

SETTING THE

TIME MINUTE

MINDER:

STEP 1. Press the Time/Mode button, until the “bell” symbol is flashing.

STEP 2. Turn the +/- control knob to set the duration in minute increments until the required time is set.

After a few seconds the “bell” symbol will stop flashing and the time will count down.

THE MINUTE MINDER IS NOW SET.

At the end of the set time an audible tone will be heard and the “bell” symbol will go out. After a few

seconds the audible tone will stop and after a few seconds the display will revert back to the time of

day.

The minute minder can be cancelled at any time by following

STEPS 1 and 2, setting the time period to zero using the +/- control knob.

The display will revert back to the time of day. The display shows HOURS and MINUTES

eg. 1 hour 38 minutes

17

Page 18

Electronic Clock & Automatic Cooking Feature

AUTO COOKIN TIMER

There are two Auto Cooking programmes for the 1st oven, that can be selected using the display:

(a) To set the 1st oven to switch ON immediately and OFF automatically after a time of your choice.

(b) To set the 1st oven to switch ON and OFF automatically, at the times of your choice.

(a) To set the 1st oven to switch ON immediately and OFF automatically:

This allows you to cook for a specified duration, after which the oven will automatically switch off.

STEP 1. Check that the correct time of day is set, if not follow instructions for setting the time of

day.

STEP 2. Place food to be cooked on shelf in the oven.

STEP 3. Switch the 1st oven control to the desired mode. The display will automatically

suggest a cooking temperature. This can be changed by turning the +/- control knob. (The

oven will start).

STEP 4. Press the Time/Mode button, until the “cooking duration” symbol is flashing.

STEP 5. Turn the +/- control knob to set the cooking duration you require. After a few seconds

the “cooking duration” symbol will stop flashing and the display will show the temperature that

has been set. This will change every few seconds when the display will show the cooking

duration re1sting.

THE COOKING DURATION IS NOW SET.

At the end of the set cooking duration, “End” will show in the display and an audible tone will

be heard for a few seconds.

Turn the 1st oven control to “O”, the OFF position to switch the oven off. The display will revert

back to the time of day.

To cancel the automatic mode at any time turn the 1st oven control to “O”, the OFF position.

Note: During the cooking period the cooking duration will be shown in the display for a

few seconds and then revert to the temperature set.

18

Page 19

Electronic Clock & Automatic Cooking Feature

(b) To set the 1st oven to switch ON and OFF automatically:

This allows you to cook for a specified duration and additionally choose the time you wish the cooking

cycle to finish. From this information the system works out when the cooking cycle will need to start and

automatically switches the oven on at the required time.

- Follow STEPS 1 to 5 in the previous section (a) entitled: “To set the 1st oven to switch ON immediately and

OFF automatically”, then continue as below:

STEP 6. Press the Time/Mode button, until the “end time” symbol is flashing. The display will

show a default cooking end time (this will be the current time plus the cooking duration you

set in STEP 5). The “end time” symbol will flash.

STEP 7. Turn the +/- control knob to set the time you wish the cooking to end. After a few

seconds the display the temperature, cooking duration and end time in turn.

THE COOKING DURATION AND END TIME IS NOW SET.

The display will show the temperature and cooking duration when the programme has

started.

At the end of the cooking duration, “End” and the “cooking duration” symbol will show in the

display and an audible tone will be heard for a few seconds.

Turn the 1st oven control to “O”, the OFF position to switch the oven off. The display will revert

back to the time of day.

To cancel the automatic mode at any time turn the 1st oven control to “O”, the OFF position.

Note: At any time up to the start of cooking, the cooking end time, cooking duration and

the temperature will be shown in the display.

19

Page 20

1st Oven - The Intelligent Cooking System

The main oven of your new cooker is equipped with an intelligent electronic cooking system

that gives you additional cooking performance, flexibility and features over traditional cooking

products.

See cooking charts for temperatures and shelf positioning

Cooking

temperature

ranges

The intelligent cooking system will automatically suggest a suitable cooking temperature for several

cooking modes. It is possible however to modify the suggested temperature within a range specific to

each cooking mode.

20

Page 21

1st Oven - The Intelligent Cooking System

21

Page 22

1st Oven - The Intelligent Cooking System

22

Page 23

1st Oven - The Intelligent Cooking System

23

Page 24

Care and Cleaning

Grill

Control Panel

Decorative Trims

Doors

Remove the grill pan and the wire grid food support, it is best to wash these items immediately after

use to prevent stains from being burnt on when used again. Wipe out the Grill compartment, use a fine

steel wool soap pad to remove stubborn stains from the grill runners and the floor of the compartment.

Wipe over the control panel with a damp cloth and polish with a dry cloth.

Do not use cream cleaners, oven cleaners or aerosols, scouring pads or abrasive powder for

cleaning the plastic knobs as damage will occur.

It is advisable to clean the decorative trims regularly to prevent any build up of soiling. The

recommended method of cleaning is to wipe over the trims with a soft cloth wrung out in warm water or

mild non-abrasive cleaner. (If in doubt try the cleaner on a small area of trim which is not noticeable in

normal use). Then, after wiping with a cloth wrung out in clear water, dry with a soft clean cloth.

Wipe over the outer door glass panels with a cloth wrung out in warm soapy water, then after wiping

with a cloth wrung out in clear water, dry with a soft clean cloth. Ensure that glass doors are not

subjected to any sharp mechanical blows.

Glass Inner Door Panel (where fitted) – open the door fully and unscrew the two screws securing

the glass panel, taking care not to allow the glass to fall. The glass panel may now be washed at the

sink. Stubborn stains can be removed by using a fine steel wool soap pad. Ensure the glass panel is

not subjected to any sharp mechanical blows. Take particular care not to damage the inner

surface which is coated with a heat reflective layer. After cleaning, rinse and dry with a soft cloth. For

slight soiling the inner glass panel may be cleaned, while still warm, without removing it from the door.

Warning: Oven must not be operated with inner door glass removed.

Take care during cleaning not to damage or distort the door seals. Do not lift the door seal from the

oven chassis, if necessary remove the seal by carefully unhooking the corner clips.

Take care that the rating label edges are not lifted during cleaning, and furthermore that the lettering is

not blurred or removed.

Ovens

Oven Shelf

Supports

Oven Lamp

Replacement

Remove the rod shelves and grill pan. Use a fine steel wool soap pad to remove stubborn stains from

the rod shelves, grill pan and the floor of the oven.

sponge and a non-abrasive cleaning product, then dry thoroughly with a soft cloth. Do not use rough

abrasive material or sharp metal scrapers as these could scratch the surface and cause the glass to

crack.

The shelf supports are removable and dishwasher safe.

To remove hold the support at the front and pull away from the oven side, this can then be cleaned in

a sink or a dishwasher. When removed it allows access to the oven side, which can be cleaned with

warm soapy water.

To refit the support, insert the longer leg into the rear fixing hole and push in the front leg.

Open the oven door and remove the rod shelves. Using a suitable cloth to protect the fingers grip the

light glass dome, unscrew anti-clockwise and lift. Reach into the aperture with fingers, and unscrew the

lamp anticlockwise. Fit replacement lamp (25W 300°C rated SES), refit dome.

WARNING: To avoid electric shocks - please ensure that the electricity supply to the appliance

is switched off and the appliance is fully cold, before removing the lamp lens.

Clean the glass part of the oven door using a

24

Page 25

Cooking Results Not Satisfactory?

Problem Check

Fat splattering Ensure that the grill is not set to too high a temperature.

Oven Baking

Uneven rising of cake

Sinking of cakes The following may cause cakes to sink:

Over/Under cooking

Fast/Slow cooking

Uneven cooking of

cakes

Uneven rising of cake Ensure that the shelf is level (see above) and that the

Food is taking too long

to cook

Ensure that the oven shelves are level by using a spirit

level on the rod shelf and adjusting, using suitable

packing e.g. wood, under the feet of the appliance. This

should be checked both left to right and front to back.

Ensure that the food is positioned centrally in the oven.

1. Cooking at too high a temperature.

2. Using normal creaming method with soft margarine.

Refer to the cooking times and temperatures given in

the oven temperature charts, however, it may be

necessary to increase or decrease temperatures by

10°C to suit personal taste.

Do not use utensils greater than 2¼ ins in height.

1. Too large baking sheet used. (See 'Cookery Notes')

2. Over loading of oven and always ensure even air

gaps around baking tins.

food is positioned centrally in the oven.

Only cook one item at a time to avoid overloading the

oven.

25

Page 26

Something Wrong with your Cooker?

Before contacting your nearest Service Centre/Installer, check the problem guide below; there may be nothing wrong

with your cooker.

Problem Check

Ignition does not work

Hotplate Burner

Hob Top

Burner Ports Ignitor

If all burners fail to ignite:

Check that sparks appear at the bur ners;

A c li cki ng noi se shoul d be hear d.

If not

Check t hat t he pl ug i s plugged i n to a

13amp Electri c soc k et and the s upply

is switched on.

If all burners still fail to ignite

Check and replace if nec essary the 13am p fuse

If only one burner fails to ignite

Check that the burner is dry and that spill age of food or

cleaning fluid remains are not affecting the Ignitor or burner

ports.

Oven Temper atur e seems too

high or too low

Oven does not cook evenly.

Hotplates are slow to boil or will

not simmer

Odour or smoke when using your new cooker

Condensation / Steam in the Oven After Use

Condensation on the Wall at the Rear of the Cooker

Clean away any debris wi th a dry nyl on brush such as an

old dry toothbrush.

If a wire wool pad has been used for cl eaning around the

burner ensure the Igni tor is fr ee from any str ay str ands .

Any water on the burner s hould be dried wi th a cl oth or

kitchen towel.

On the hotplate make sure that all burner

parts are correctl y seated

Check that the temperature has been set i n accordance with

the temperature charts. It may be necessary to increase or

decrease the recommended temperature by 10 C to suit your

taste

Check the temperature and shelf position are as recommended

in the temperatur e c har ts

Check t hat t he Ut ensi l bei ng us ed i n the ov en al l ow suffi cient

air fl ow around them.

Check that the cooker is l evel.

Check t hat y our pans conform to the r ecommendations in

these instructions.

Thi s is norm al and should cease after a shor t period.

Condensation and s team i s a by pr oduct of c ooki ng food

with a water content.

To help minimi se always:

A) Try to avoid leaving food i n the oven to cool after being cooked

B) Us e a coved Utensi l wher ev er pos si ble

Steam and/or c ondensat i on m ay appear from the vent at the rear of

the appliance when us ing an oven, particularl y when cooking foods

with a high water content (Such as Oven Chips or Chicken).

Thi s is norm al and any exc es s shoul d be wi ped off

26

Page 27

Technical Characteristics (1st OVEN)

Oven dimensions

Volume

Voltage and Frequency

Burners:

Adaptable for use with all the types of gas indicated on the data plate.

ENERGY LABEL

Directive 2002/40/EC on the label of electric ovens. Standard EN 50304

(HxWxD): 33x38x54 cm

68 Litres

see data plate

Energy consumption for Natural convection – heating mode:

Declared energy consumption for Forced convection Class – heating mode: Cake

This appliance conforms with the following European Economic Community directives:

- 73/23/EEC of 19/02/73 (Low Voltage) and subsequent modifications;

- 89/336/EEC of 03/05/89 (Electromagnetic Compatibility) and subsequent modifications;

- 90/396/EEC of 29/06/90 (Gas) and subsequent modifications (only for models which use gas);

- 93/68/EEC of 22/07/93 and subsequent modifications.

- 2002/96/EC

The European Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE), requires that old

household electrical appliances must not be disposed of in the normal unsorted municipal waste stream. Old

appliances must be collected separately in order to optimise the recovery and recycling of the materials they

contain and reduce the impact on human health and the environment. The crossed out “wheeled bin” symbol

on the product reminds you of your obligation, that when you dispose of the appliance it must be separately

collected.

Consumers should contact their local authority or retailer for information concerning the correct disposal of

their old appliance.

Traditional mode

27

Page 28

Technical Characteristics (2st OVEN)

Oven dimensions

Volume

Voltage and Frequency

Burners:

Adaptable for use with all the types of gas indicated on the data plate.

ENERGY LABEL

Directive 2002/40/EC on the label of electric ovens. Standard EN 50304

Energy consumption for Natural convection – heating mode: Traditional mode

(HxWxD): 33.8x24.5x43.8 cm

36 Litres

see data plate

28

Page 29

Electric drawer

2

1

3

0

The heated compartment makes it possible to:

• Leaven dough and defrost food (position 1 on the selector knob).

• Reheat food and keep it warm (positions 2 and 3 on the selector knob).

• Heat up pans and crockery (position 1on the selector knob).

NOTE: The appliance only heats up if the compartment has been closed properly.

To activate the desired function:

1. Open the compartment by pressing gently on the front panel (push/push mechanism).

2. Place the crockery or the food to be leavened/defrosted/reheated inside.

3. Select a function using the SELECTOR knob. The OPERATION indicator light illuminates.

4. Close the compartment.

5. A heating element will be activated, thus enabling the selected programme to be performed.

SELECTOR

knob

OPERATION

indicator light

To stop the function, open the compartment and turn the SELECTOR knob to 0. The OPERATION indicator light will

switch off.

Troubleshooting

It may happen that the compartment does not function properly or even at all. Before calling the service centre for

assistance, check if anything can be done. First, check that there are no problems relating to the electricity supply.

Problem

The crockery or foods remain cold.

The crockery or foods do not heat up sufficiently.

The compartment does not close properly.

Possible causes / Solutions:

• The appliance has not been activated.

• There has been a dip in the electricity supply current.

• The compartment has not been closed properly.

• Keep the crockery or foods inside the compartment for a

longer period of time.

• The compartment has not been closed properly.

• Make sure that the compartment has been installed

correctly.

The OPERATION indicator light does not illuminate.

• Make sure that the SELECTOR knob is not in the 0

position.

29

Page 30

30

Page 31

31

Page 32

Key Contacts

After Sales Service

Over 1200 trained specialists, directly employed by us, ensure that you can have complete confidence in

both the appliances and services we offer.

Repair Service and Information Desk

UK: 08709 066 066

(Open 8 to 8 Mon - Fri, 8 to 6 Sat, 10 to 4 Sun & Bank Holidays)

www.cannonservice.co.uk

Republic of Ireland: 1850 302 200

Note: Our operators will require the following information:

Model number:

Serial number:

Extended Warranties

UK: 08709 088 088

(Open 8 to 8 Mon - Sun)

www.cannonservice.co.uk

Republic of Ireland: 1850 502 200

Genuine Parts and Accessories

UK: 08709 077 077

(Open 8-30 to 5-30 Mon - Fri & 9 to 12 Sat)

www.cannonservice.co.uk

Republic of Ireland: (01) 842 6836

www.cannoncooking.co.uk

Indesit Company UK LTD, Morley Way, Peterborough, PE2 9JB.

07/2007 - 19506021800

Loading...

Loading...