I

CAPPA ASPIRANTE - Istruzioni per l'uso

D

DUNSTABZUGSHAUBE - Gebrauchsanweisung

E

CAMPANA EXTRACTORA - Manual de utilización

F

HOTTE DE CUISINE - Notice d'utilisation

GB

COOKER HOOD - User instructions

NL

AFZUIGKAP - Gebruiksaanwijzing

P

COIFA ASPIRANTE - Manual do usuário

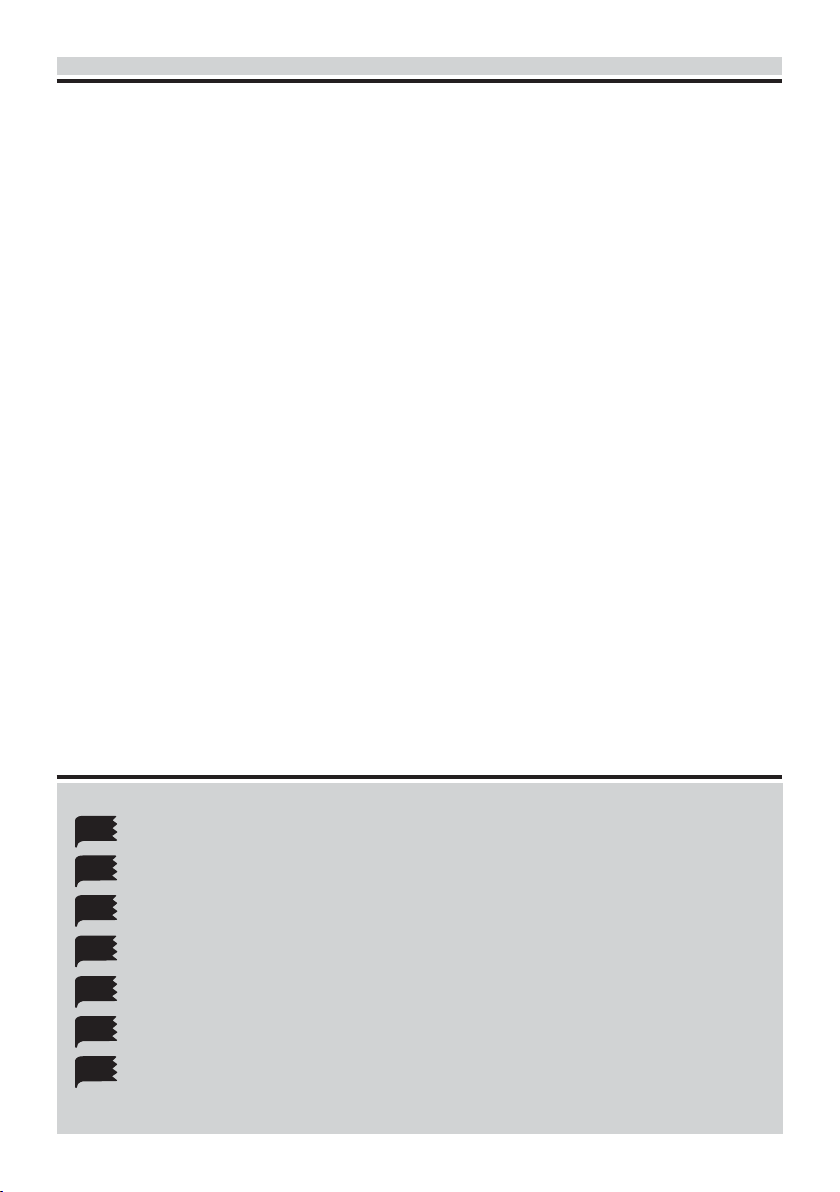

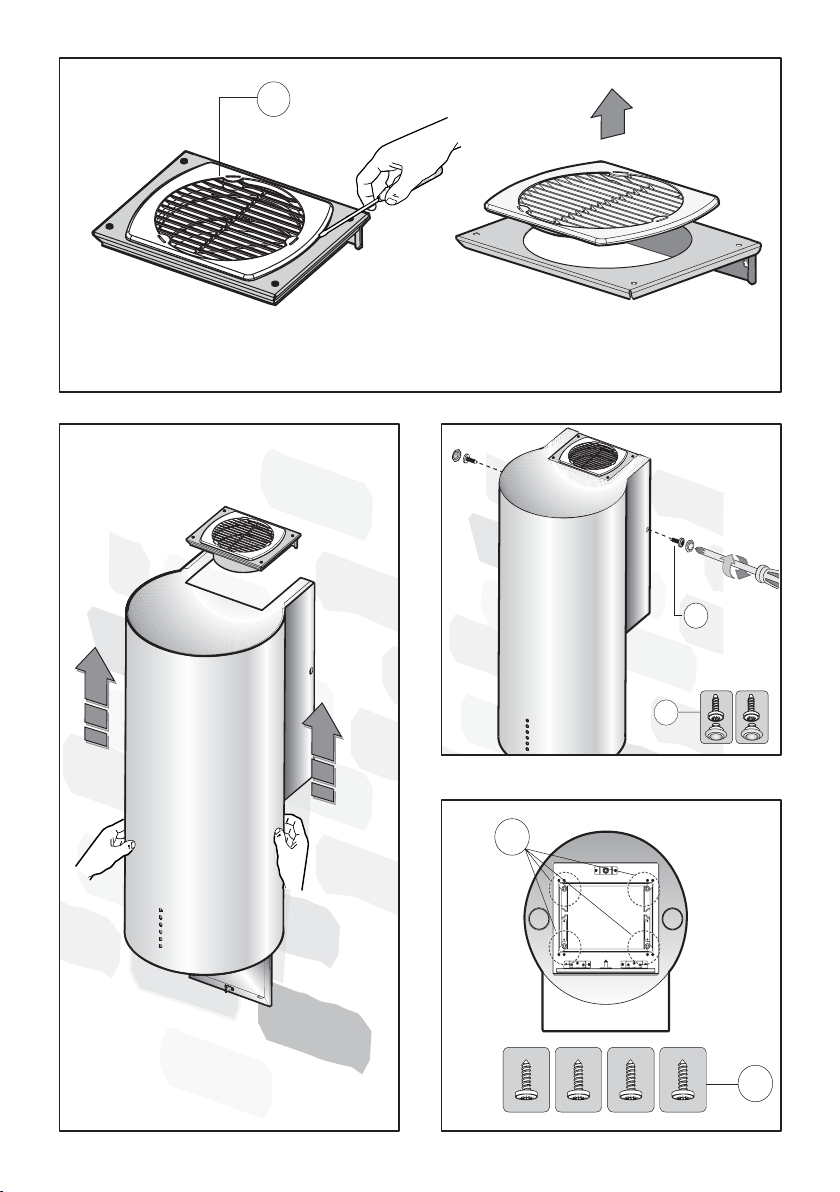

Fig.1

AB

max 90 cm

a

c

b

d

Fig.2

Fig.3

A

A

B

Fig.4 Fig.5

- 4 -

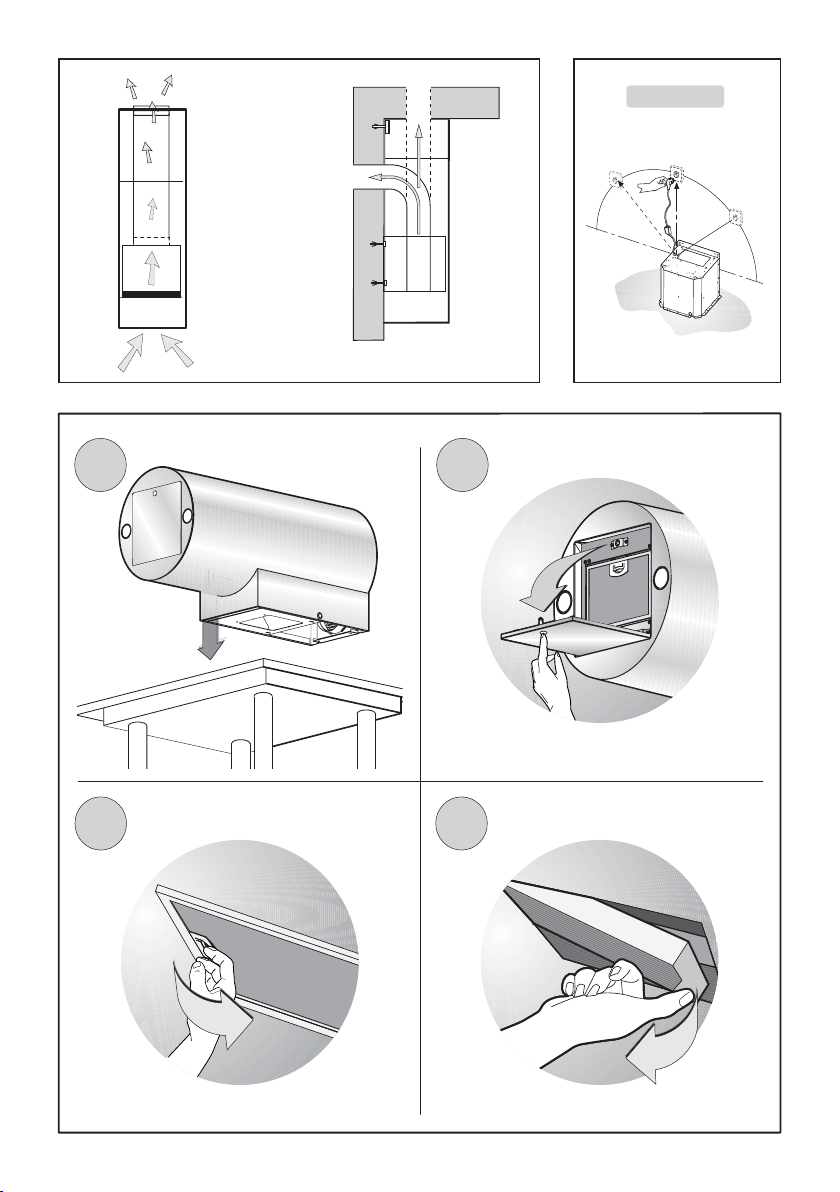

C

C

D

E

Y

X

Fig.6

Fig.8

E

C

D

- 5 -

Fig.7

Fig.9

E

C

D

C

D

Fig.10

F

A

Fig.11

A

Fig.12

A

A

Fig.13

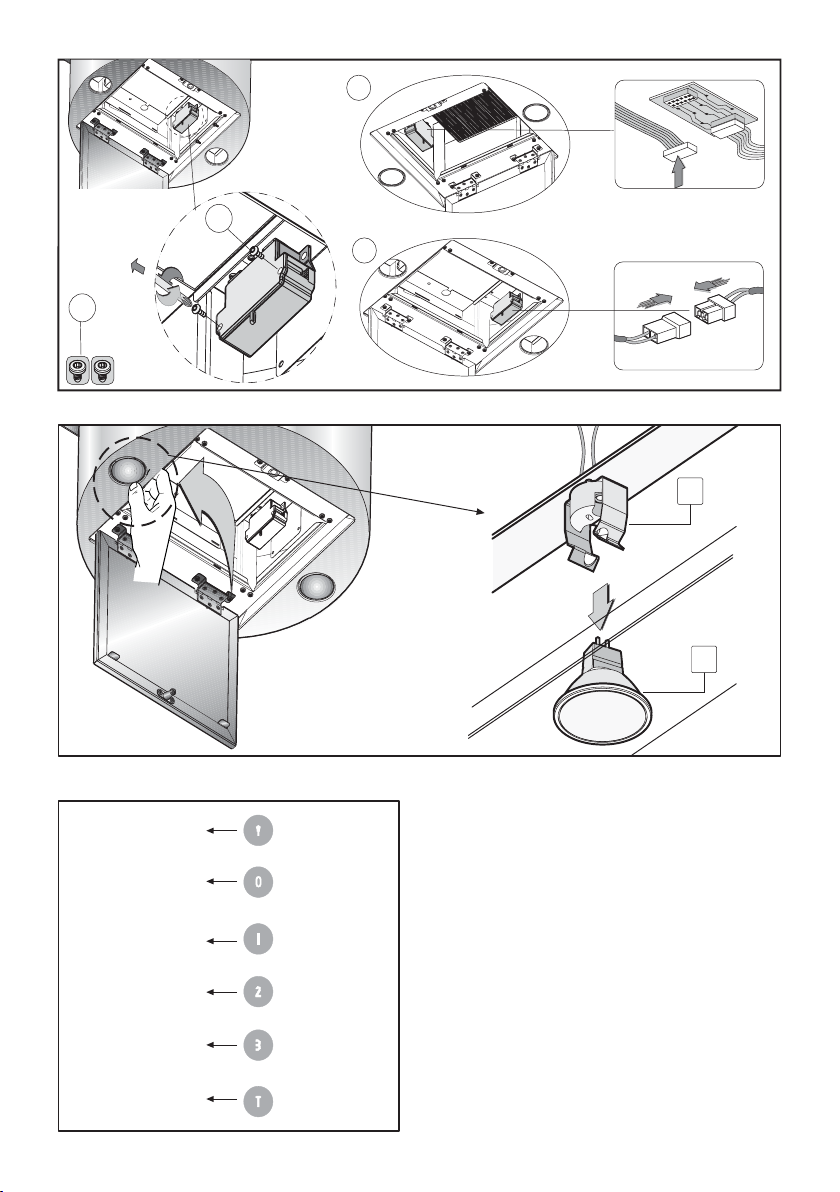

- 6 -

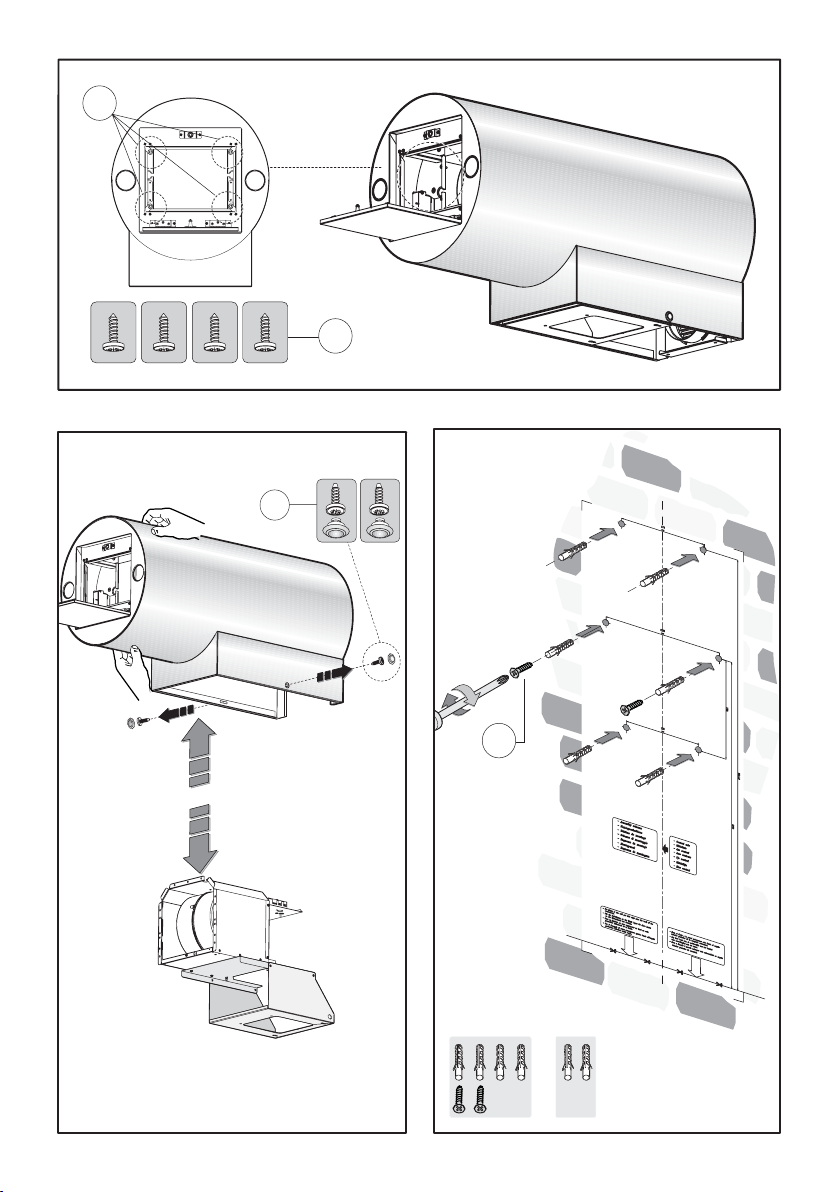

D

Fig.14

A

A

D

B

B

A

D

Fig.15

Fig.16

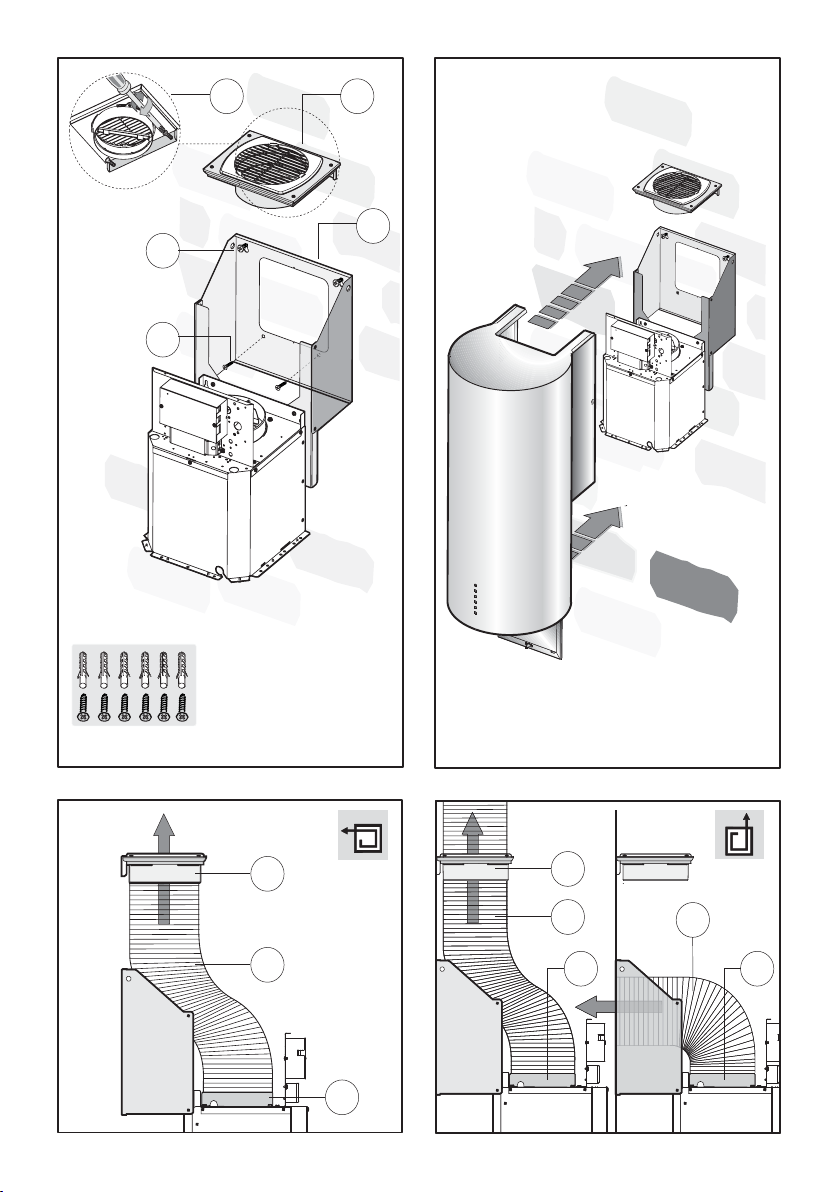

A

B

C

D

E

F

- 7 -

ITALIANO

I

GENERALITA'

Leggere attentamente il contenuto del presente

libretto in quanto fornisce importanti indicazioni

riguardanti la sicurezza di installazione, d'uso e di

manutenzione. Conservare il libretto per ogni ulteriore

consultazione. L'apparecchio è stato progettato per

uso in versione aspirante (evacuazione aria

all'esterno - Fig.1B) o filtrante (riciclo aria all'interno

- Fig.1A).

AVVERTENZE PER LA SICUREZZA

1. Fare attenzione se funzionano

contemporaneamente una cappa aspirante e un

bruciatore o un focolare dipendenti dall'aria

dell'ambiente ed alimentati da un'energia diversa da

quella elettrica, in quanto la cappa aspirando toglie

all'ambiente l'aria di cui il bruciatore o il focolare

necessita per la combustione. La pressione negativa

nel locale non deve superare i 4 Pa (4x10-5 bar). Per

un funzionamento sicuro, provvedere quindi ad

un'opportuna ventilazione del locale. Per

l'evacuazione esterna attenersi alle disposizioni

vigenti nel vostro paese.

Prima di allacciare il modello alla rete elettrica:

- controllare la targa dati (posta all’interno dell’

apperecchio) per accettarsi che la tensione e potenza siano corrispondenti a quella della rete e la presa

di collegamento sia idonea. In caso di dubbio interpellare un elettricista qualificato.

- Se il cavo di alimentazione è danneggiato, esso

deve essere sostituito da un cavo o un assieme speciali disponibile presso il costruttore o il suo servizio

assistenza tecnica.

2. ATTENZIONE !

In determinate circostanze gli elettrodomestici

possono essere pericolosi.

A) Non cercare di controllare i filtri con la cappa

in funzione

B) Non toccare le lampade e le zone adiacenti,

durante e subito dopo l’uso prolungato

dell'impianto di illuminazione.

C) E' vietato cuocere cibi alla fiamma sotto la

cappa

D) Evitare la fiamma libera, perchè dannosa per

i filtri e pericolosa per gli incendi

E) Controllare costantemente i cibi fritti per

evitare che l'olio surriscaldato prenda fuoco

F) Prima di effettuare qualsiasi manutenzione,

disinserire la cappa dalla rete elettrica.

G) Questo apparecchio non è destinato

all'utilizzo da parte di bambini o persone che

necessitano di supervisione.

H) Controllare che i bambini non giochino con

l'apparecchio.

Questo apparecchio è contrassegnato in conformità

alla Direttiva Europea 2002/96/EC, Waste Electrical

and Electronic Equipment (WEEE). Assicurandosi

che questo prodotto sia smaltito in modo corretto,

l’utente contribuisce a prevenire le potenziali

conseguenze negative per l’ambiente e la salute.

Il simbolo sul prodotto o sulla documentazione di

accompagnamento indica che questo prodotto non

deve essere trattato come rifiuto domestico ma deve

essere consegnato presso l’idoneo punto di raccolta

per il riciclaggio di apparecchiature elettriche ed

elettroniche.

Disfarsene seguendo le normative locali per lo

smaltimento dei rifiuti. Per ulteriori informazioni sul

trattamento, recupero e riciclaggio di questo prodotto,

contattare l’idoneo ufficio locale, il servizio di raccolta

dei rifiuti domestici o il negozio presso il quale il

prodotto è stato acquistato.

ISTRUZIONI PER L'INSTALLAZIONE

Le operazioni di montaggio e collegamento

elettrico devono essere effettuate da personale

specializzato.

• Collegamento elettrico

L'apparecchio è costruito in classe II, perciò nessun

cavo deve essere collegato alla presa di terra.

L'allacciamento alla rete elettrica deve essere

eseguito come segue:

MARRONE = L linea

BLU = N neutro

Se non prevista, montare sul cavo una spina

normalizzata per il carico indicato nella etichetta

caratteristiche. Se provvista di spina, fare in modo

che sia facilmente accessibile dopo l’installazione

dell’apparecchio.

Nel caso di collegamento diretto alla rete elettrica è

necessario interporre tra l'apparecchio e la rete un

interruttore onnipolare con apertura minima tra i

contatti 3 mm, dimensionato al carico e rispondente

alle norme vigenti.

• La distanza minima fra la superficie di supporto

dei recipienti di cottura sul dispositivo di cottura e la

parte più bassa della cappa da cucina deve essere

di almeno 65 cm. Se dovesse essere usato un tubo

di connessione composto di due o più parti, la parte

superiore deve essere all'esterno di quella inferiore.

Non collegare lo scarico della cappa ad un condotto

in cui circoli aria calda o utilizzato per evacuare fumi

degli apparecchi alimentati da un'energia diversa da

quella elettrica. Prima di procedere alle operazioni

- 8 -

di montaggio, per una più facile manovrabilità

dell’apparecchio disinserire i filtro/i antigrasso

(Fig.2c).

Nel caso di montaggio dell’apparecchio in versione

aspirante predisporre il foro di evacuazione aria.

• Si consiglia l’utilizzo di un tubo evacuazione aria

con diametro 150. L’utilizzo di una riduzione potrebbe diminuire le prestazioni del prodotto ed aumentare la rumorosità.

all’interno della staffa uscita aria E fig. 9.

- Collegare il tubo flessibile C alla bocca uscita aria

D, che a sua volta sarà collegato al foro di

evaquazione aria predisposto in precedenza.

- Posizionare la scocca A sulla parete ( fig. 7) e allinearla alla struttura spingendola verso l’alto ( fig. 11).

- Fissare, prima le viti laterali D della scocca collegate alla struttura sottostante, indicate nella fig. 12, poi

le viti A della parte inferiore della cappa indicate nella fig.13.

Nota !

- Per l’installazione di questo prodotto si consiglia

l’aiuto di una seconda persona.

Attenzione!

• Prima di procedere con l’operazione di montaggio,

per una più facile manovralità della cappa, aprire

l’imballo , prendere la cappa e appoggiarla su un

piano comodo (fig.2a).

Aprire il pannello facendo pressione nel punto

indicato in fig. 2b.

Togliere il pannello in alluminio tirarando la maniglia

come indicato in fig. 2c. Se il prodotto è fornito di filtri

al carbone attivo, rimuoverli tirando verso l’esterno

la leva, come indicato in fig. 2d.

• MONTAGGIO DELLA CAPPA

Il prodotto viene fornito assemblato. Per effettuare il

montaggio, eseguire le seguenti fasi:

- Togliere le quattro viti A come indicato in fig. 3.

- Separare la scocca dalla struttura, togliendo i tappi

e poi le viti B indicate nella fig. 4.

• Fissaggio a parete

- Posizionare la dima di fissaggio sulla parete ( tenendo conto della distanza minima dal piano di cottura ).

Segnare ed eseguire i fori di fissaggio.

- Fissare le 2 viti C senza avvitarle completamente e

tasselli ad espansione ( fig. 6 ).

- A regolazione avvenuta, fissare il gruppo motore X

definitivamente tramite le 2 viti D (fig.6).

- Fissare la staffa uscita aria Y al muro con le 2 viti E

(fig.6).

- Posizionare il gruppo motore X al muro, allinearlo

in posizione orizzontale e avvitare le viti C (fig. 6).

- Per i vari montaggi utilizzare viti e tasselli ad espansione idonei al tipo di muro (es. cemento armato,

cartongesso, ecc).

- Nel caso in cui le viti e i tasselli siano forniti in dotazione con il prodotto accertarsi che siano idonei per

il tipo di parete in cui deve essere fissata la cappa.

- Se il vostro modello è in versione filtrante, prima

di fissare la scocca alla struttura, fissare il tubo flessibile C ( non fornito) alla bocca di uscita aria D della

cappa e della flangia uscita aria E (fig.8).

- Se il vostro modello è in versione aspirante, to-

gliere la griglia F ( fig. 10 ) solo nel caso in cui si ha

la necessità di far passare il tubo evaquazione aria

- Collegamento elettrico

Prima di effettuare il collegamento, svitare le 4 viti D

delle due scatole e aprire i coperchi (Fig.14)

- Effettuare le connessioni elettriche tra il corpo cappa e il gruppo motore (Fig.14 A e B).

USO E MANUTENZIONE

• Si raccomanda di mettere in funzione l'apparecchio

prima di procedere alla cottura di un qualsiasi

alimento. Si raccamanda di lasciar funzionare

l'apparecchio per 15 minuti dopo aver terminato la

cottura dei cibi, per un'evacuazione completa dell'aria

viziata.

Il buon funzionamento della cappa è condizionato da

una corretta e costante manutenzione; una particolare

attenzione deve essere data al filtro antigrasso e al

filtro al carbone attivo.

• Il filtro antigrasso ha il compito di trattenere le

particelle grasse in sospensione nell’aria, pertanto è

soggetto ad intasarsi in tempi variabili relativamente

all’uso dell’apparecchio.

Il filtro acrilico, che si trova appoggiato alla griglia, va

sostituito quando le scritte, visibili attraverso la griglia,

cambiano colore e l'inchiostro si espande; il nuovo

filtro deve essere applicato in modo tale che le scritte

siano visibili attraverso la griglia dall'esterno della

cappa.

Nel caso in cui i filtri acrilici non abbiano le scritte,

oppure siano presenti filtri metallici o a pannello in

alluminio, per prevenire il pericolo di eventuali incendi,

al massimo ogni 2 mesi è necessario lavare i filtri

eseguendo le seguenti operazioni:

- togliere il filtro dalla griglia e lavarlo con una

soluzione di acqua e detergente liquido neutro

lasciando rinvenire lo sporco.

- Sciacquare abbondantemente con acqua tiepida e

lasciare asciugare.

I filtri metallici e/o pannello in alluminio possono

essere lavati anche in lavastoviglie. Dopo alcuni

lavaggi, se i filtri sono in alluminio o pannello in

alluminio, si possono verificare delle alterazioni del

colore. Questo fatto non dà diritto a reclamo per

l'eventuale loro sostituzione.

In caso di inadempienza delle istruzioni di sostituzione

e di lavaggio si può verificare il rischio di incendio dei

filtri antigrasso.

• I filtri al carbone attivo servono per depurare l'aria

che viene rimessa nell'ambiente. I filtri non sono

- 9 -

lavabili o rigenerabili e devono essere sostituiti ogni

quattro mesi al massimo. La saturazione del carbone

attivo dipende dall'uso più o meno prolungato

dell'apparecchio, dal tipo di cucina e dalla regolarità

con cui viene effettuata la pulizia del filtro antigrasso

• Pulire frequentemente tutti i depositi sul ventilatore

e sulle altre superfici, usando un panno inumidito con

alcool denaturato o detersivi liquidi neutri non abrasivi.

• L’ impianto di illuminazione è progettato per l’uso

durante la cottura e non per l’uso prolungato di illuminazione generale dell’ambiente. L’uso prolungato

dell’illuminazione diminuisce notevolmete la durata

media delle lampade.

• Sostituzione delle lampade alogene (Fig.15).

Per sostituire le lampade alogene B dall’interno della cappa spingere verso il basso con due dita come

è raffigurato in fig.15.

Sostituire con lampade dello stesso tipo.

• COMANDI:(Fig.16) LUMINOSI Ia simbologia è di

seguito

riportata:

A= tasto ILLUMINAZIONE

B= tasto OFF

C= tasto PRIMA VELOCITA’

D= tasto SECONDA VELOCITA’

E= tasto TERZA VELOCITA’

F= tastoTIMER ARRESTO AUTOMATICO 15 minuti

• Se il vostro apprecchio è provvisto della funzione

velocità INTENSIVA, tenere premuto per 2 secondi

circa il tasto E e questa verrà attivata per 10 minuti

dopo di che ritornerà alla velocità precedentemente

impostata.

Quando la funzione è attiva il LED lampeggia. Per

interromperla prima dei 10 minuti premere di nuovo

il tasto E

0,5 sec. i filtri carbone devono essere sostituiti.

Una volta ricollocato il filtro pulito bisogna resettare

la memoria elettronica premendo il tasto A per circa

5 sec. fino a che termina di lampeggiare.

SI DECLINA OGNI RESPONSABILITA’ PER

EVENTUALI DANNI PROVOCATI DALLA

INOSSERVANZA DELLE SUDDETTE

AVVERTENZE

Premendo il tasto F per 2 secondi (a cappa spenta)

si attiva la funzione “clean air”. Questa funzione fa

accendere il motore per 10 minuti ogni ora alla prima

velocità. Appena attivata la funzione, il motore parte alla 1° velocità per la durata di 10 minuti durante i

quali devono lampeggiare contemporaneamente il

tasto F e il tasto C. Trascorso questo tempo il motore

si spegne ed il led del tasto F rimane acceso di luce

fissa fino a quando dopo altri 50 minuti riparte il motore alla prima velocità e i led F e C ricominciano a

lampeggiare per 10 minuti e così via. Premendo qualsiasi tasto ad esclusione delle luci la cappa torna al

suo funzionamento normale immediatamente (es. se

premo il tasto D si disattiva la funzione “clean air” e

il motore va subito alla 2° velocità; premendo il tasto

B la funzione si disattiva).

• Saturazione filtri antigrasso/carbone attivo:

- Quando il tasto A lampeggia con una frequenza di

2 sec. i filtri antigrasso devono essere lavati.

- Quando il tasto A lampeggia con una frequenza di

- 10 -

DEUTSCH

D

ALLGEMEINES

Diese Anleitung bitte aufmerksam durchlesen, da sie

wichtige Sicherheitshinweise zur Installation, zum

Gebrauch und zur Wartung enthält. Die Anleitung für

eventuelle zukünftige Konsultationen aufbewahren.

Das Gerät ist zur Verwendung in der Abluftversion

(Abluft ins Freie - Abb. 1B) oder Umluftversion

(interner Umluftbetrieb - Abb. 1A) konzipiert.

SICHERHEITSHINWEISE

1. Vorsicht ist geboten, wenn gleichzeitig eine

Abzugshaube und ein raumluftabhängiger Boiler oder

ein offenes Feuer in Betrieb sind, die von einer

anderen Energiequelle als Strom versorgt werden,

da die Küchenhaube die Raumluft absaugt, die auch

der Boiler oder das Feuer zur Verbrennung benötigen.

Der Unterdruck im Raum darf den Wert von 4 Pa

(4x10-5 bar) nicht übersteigen. Um einen sicheren

Betrieb der Abzugshaube zu gewährleisten, ist daher

immer auf eine ausreichende Belüftung des Raumes

zu achten. Bei der Ableitung der Luft nach aussen

müssen die nationalen Vorschriften eingehalten

werden.

Vor Anschluss des Modells an das Stromnetz :

- kontrollieren Sie das Typenschild an der Geräteinnenseite um sich zu vergewissern, ob Spannung

und Stromstärke der des Stromnetzes entsprechen

und die Steckdose geeignet ist. Im Zweifelsfall

wenden Sie sich bitte an einen qualifizierten

Elektriker.

- Sollte das Speisekabel beschädigt sein, ist es durch

ein anderes - beim Hersteller oder dessen

Kundendienst erhältliches - Kabel oder mit einem

speziellen Bausatz - zu ersetzen.

2. ACHTUNG !

Elektrogeräte können unter gewissen Umständen

gefährlich sein!

A) Niemals die Filter kontrollieren, wenn die

Küchenhaube in Betrieb ist.

B) Die Lampen und den umliegenden Bereich

nicht während oder nach längerer Benützung

der Beleuchtungskörper berühren.

C) Es ist verboten, Speisen unter der

Abzugshaube zu flambieren.

D) Offene Flammen sind unbedingt zu vermeiden,

da diese die Filter beschädigen und einen

Brand verursachen können.

E) Beim Frittieren sind die Speisen ständig zu

kontrollieren, um die Entzündung des Öls zu

vermeiden.

F) Wird das Netzkabel dieser Haube beschädigt,

muss es in einer vom Hersteller zugelassenen

Werkstatt ersetzt werden, da hierzu

Spezialwerkzeug benöetigt wird.

G) Das Gerät ist nicht für den Gebrauch durch

unbeaufsichtigte Kinder oder unfähige

Personen konzipiert.

H) Achten Sie bitte darauf, dass Kinder nicht mit

dem Gerät spielen.

I) Vor jeglichen Wartungsarbeiten unbedingt den

Netzstecker aus der Steckdose entfernen.

Dieses Gerät ist gemäß der EU-Richtlinie 2002/96/

EC, Waste Electrical Electronic Equipment (WEEE)

gekennzeichnet. Sorgen Sie bitte dafür, dass das

Gerät korrekt entsorgt wird, der Benutzer trägt dazu

bei, den potentiellen negativen Folgen für Umwelt und

Gesundheit vorzubeugen.

Das auf dem Produkt oder auf den Begleitpapieren

befindliche Symbol sagt aus, dass dieses Produkt

nicht wie normaler Hausmüll behandelt werden darf,

sondern dass es einer geeigneten Sammelstelle für

das Recycling der elektrischen und elektronischen

Geräteteile zugeführt werden muss. Entsorgen Sie

bitte das Altgerät gemäß der lokalen Richtlinien. Für

weitere Informationen hinsichtlich der Behandlung,

der Wiederverwertung und des Recycling des

Produkts wenden Sie sich bitte an die zuständige

lokale Stelle, an die Sammelstelle für Hausmüll, oder

an den Händler, bei dem Sie das Gerät erworben

haben.

INSTALLATIONSANLEITUNG

Montage und Anschluss müssen von einem

Fachmann durchgeführt werden.

• Elektroanschluss

Die Küchenhaube gehört zur Geräteklasse II, daher

muss keine der Leitungen geerdet werden. Der

Anschluss an das Stromnetz ist folgendermassen

durchzuführen:

BRAUN = L Leitung

BLAU = Neutrale Linie

Falls nicht vorhanden, muss ein Normstecker mit den

auf dem Typenschild angegebenen Werten an das

Kabel angeschlossen werden. Wenn die

Küchenhaube mit einem Netzstecker ausgestattet ist,

muss diese so installiert werden, dass der Stecker

gut zugänglich ist.

Beim Direktanschluss an das Stromnetz muss

zwischen Gerät und Netz ein der Netzlast und den

geltenden Vorschriften entsprechender

Mehrpolstecker mit einer Mindestöffnung von 3 mm

zwischen den Kontakten installiert werden.

• Der Mindestabstand zwischen der Stellfläche für

die Kochbehälter auf der Kochvorrichtung und dem

- 11 -

unteren Teil der Abzugshaube muss mindestens 65

cm betragen.

Falls ein Verbindungsrohr verwendet wird, das aus

zwei oder mehr Teilen zusammengesetzt ist, muss

der obere Teil über den unteren gestülpt werden. Auf

keinen Fall darf das Abluftrohr der Küchenhaube an

ein Rohr angeschlossen werden, in dem Warmluft

zirkuliert oder das zur Entlüftung von Geräten

verwendet wird, die an eine andere Energiequelle als

an Strom angeschlossen sind. Vor der Durchführung

der Montagevorgänge, den/die Fettfilter entfernen,

damit sich das Gerät leichter handhaben läßt

(Abb.2c). Sollte das Gerät mit Abzugsvorrichtung

montiert werden, bereiten Sie eine Luftabzugsöffnung

vor.

• Es empfiehlt sich der Einsatz eines Abluftrohres,

das einen Durchmesser von 150 mm aufweist. Die

Verwendung eines Reduzierstücks könnte die

Leistungen des Erzeugnisses beeinträchtigen und

das Betriebsgeräusch erhöhen.

Anmerkung!

- Zur Installation dieses Produkts empfiehlt sich der

Einsatz einer zweiten Person.

Achtung!

• Bevor Sie mit der Montage beginnen, öffnen Sie

zur einfacheren Handhabung der Dunstabzugshaube

die Verpackung, entnehmen Sie die

Dunstabzugshaube und legen Sie sie auf einer

bequemen Fläche ab (Abb. 2a).

Öffnen Sie das Paneel, indem Sie auf die in der Abb.

2b gezeigte Stelle drücken.

Entfernen Sie das Aluminiumpaneel, indem Sie am

Griff, wie in der Abb. 2c dargestellt, ziehen. Wenn

das Gerät mit Aktivkohlefiltern ausgestattet ist,

entfernen Sie diese, indem Sie den Hebel nach außen

ziehen (siehe Abb. 2d).

• Montage der Abzugshaube

Das Produkt wird fertig zusammengebaut geliefert. Zur

Montage gehen Sie wie nachfolgend beschrieben vor:

- Entfernen Sie die vier Schrauben A, wie in der Abb.

3 dargestellt.

- Trennen Sie das Gerätegehäuse von der Struktur,

indem Sie die Stopfen und dann die Schrauben B

entsprechend der Abb. 4 entfernen.

• Befestigung an der Wand

- Legen Sie die Befestigungsschablone an der Wand

an. (Achten Sie hierbei auf den Mindestabstand

zwischen Kochfeld und Dunstabzugshaube.)

Markieren und bohren Sie die Befestigungslöcher.

- Befestigen Sie die 2 Schrauben C, ohne sie vollständig

anzuziehen, sowie die Spreizdübel (Abb. 6).

- Nach erfolgter Ausrichtung befestigen Sie die

Motoreneinheit X endgültig mittels der 2 Schrauben

D (Abb. 6).

- Bringen Sie die Halterung Y des Luftabzugs mit Hilfe

der 2 Schrauben E an der Wand an (Abb. 6).

- Positionieren Sie die Motoreneinheit X an der Wand,

richten Sie sie waagrecht aus und drehen Sie die

Schrauben C ein (Abb. 6).

- Verwenden Sie zur Geräteinstallation Schrauben

und Spreizdübel, die für die jeweilige Wandart (zum

Beispiel: Stahlbetonwände, Wände aus Gipspappe

usw.) geeignet sind.

- Sollten die Schrauben und Dübel als

Geräteausstattung mitgeliefert werden, stellen Sie

bitte sicher, dass sie sich für die Art von Wand, an

der das Gerät montiert werden soll, eignen.

- Ist Ihr Modell ein Umluftgerät, bringen Sie den

Schlauch C (nicht mitgeliefert) an der

Luftabzugsöffnung D der Dunstabzugshaube und des

Luftabzugsflansches E an (Abb. 8), bevor Sie das

Gerätegehäuse an der Struktur befestigen.

- Ist Ihr Modell ein Abluftgerät, entfernen Sie das

Gitter F (Abb. 10) nur, falls die Abluftleitung durch

die Halterung E des Luftabzugs (Abb. 9) geführt

werden muss.

- Schließen Sie den Schlauch C an der

Luftabzugsöffnung D an, die wiederum mit dem zuvor

vorgesehenen Ausschnitt für die Luftableitung

verbunden wird.

- Positionieren Sie das Gerätegehäuse A an der

Wand (Abb. 7) und richten Sie es an der Struktur aus,

indem Sie es nach oben schieben (Abb. 11).

- Bringen Sie zuerst die seitlichen Schrauben D des

Gerätegehäuses an, die mit der darunter befindlichen

Struktur verbunden werden (siehe Abb. 12), und

drehen Sie dann die Schrauben A im unteren Teil

der Dunstabzugshaube gemäß der Abb.13 ein.

- Elektrischer Anschluss

Schrauben Sie vor dem elektrischen Anschluss die

4 Schrauben D der beiden Gehäuse heraus und

öffnen Sie die Abdeckungen (Abb.14).

- Stellen Sie die elektrische Verbindung zwischen

dem Haubenkörper und der Motoreneinheit her

(siehe Abb. 14 A und B).

BENUTZUNG UND WARTUNG

• Es wird empfohlen, die Dunstabzugshaube schon

vor Kochbeginn der Speisen einzuschalten. Es wird

weiterhin empfohlen, das Gerät nach Beendigung des

Kochvorgangs noch 15 Minuten weiterlaufen zu

lassen, um den vollständigen Abzug der Kochdünste

zu gewährleisten.

Die Leistungsfähigkeit der Dunstabzugshaube hängt

entscheidend von der Sorgfalt und Regelmäßigkeit

der Wartung ab, insbesondere die des Fettfilters und

die des Aktivkohlefilters.

• Der Fettfilter hat die Aufgabe, die in den

Kochdünsten enthaltenen Fettpartikel

zurückzuhalten. Er ist demnach der Verschmutzung

besonders ausgesetzt und sollte, je nach Gebrauch

und Kochgewohnheiten, in mehr oder weniger langen

- 12 -

Zeitabschnitten gereinigt werden.

Der auf dem Gitter befindliche Acrylfilter ist jedes Mal

dann auszutauschen, wenn die durch das Gitter

sichtbaren Aufschriften Farbveränderungen

aufweisen und die Tinte ausläuft. Der neue Filter ist

so einzulegen, dass die Aufschriften durch das Gitter

hindurch vom Äußeren der Dunstabzugshaube her

sichtbar sind.

Im Falle von Acrylfiltern ohne Schriften, Metallfiltern

oder Filtern in Form von Alupaneelen muss die

Reinigung spätestens alle 2 Monate erfolgen, um

Brandgefahr vorzubeugen. Gehen Sie hierzu wie folgt

vor:

- Filter vom Gitter abnehmen und in einer milden

Spüllauge reinigen, eventuell etwas einweichen

lassen.

- Abschließend gründlich lauwarm abspülen und

trocknen lassen.

Die Metallfilter und/oder Alupaneele können auch im

Geschirrspüler gereinigt werden. Nach mehrmaligem

Reinigen der Filter (bei Alufiltern oder -paneelen)

könnten Farbveränderungen auftreten. Hieraus

resultiert jedoch kein Anspruch auf kostenlosen

Ersatz derselben.

Durch Nichteinhaltung der Vorgaben hinsichtlich des

Austauschs und der Reinigung der Fettfilter kann

Brand verursacht werden.

• Die Aktivkohlefilter dienen dazu, die Luft zu reinigen,

die wieder in den Raum zurückgeführt wird. Die Filter

sind weder waschbar noch wiederverwertbar und

müssen spätestens alle vier Monate ausgewechselt

werden. Die Sättigung der Aktivkohle hängt von der

mehr oder minder langen Benutzungsdauer der

Dunstabzugshaube, von der Art der zubereiteten

Speisen und von der mehr oder weniger häufigen

Reinigung des Fettfilters ab.

• Alle auf dem Lüftergehäuse und den anderen Teilen

der Haube angesammelten Rückstände sind

regelmäßig mit Spiritus oder einem neutralen

Flüssigreiniger ohne Scheuermittel zu entfernen.

• Die Beleuchtung der Dunstabzugshaube ist dazu

geplant, während des Kochvorgangs eingesetzt zu

werden. Durch einen verlängerten Einsatz der

Beleuchtung wird die durchschnittliche Lebensdauer

der Leuchten erheblich gemindert.

• Austausch der Halogenlampen (Abb. 15).

Zum Austausch der Halogenlampen B drücken Sie

die Lampen mit zwei Fingern aus dem Inneren der

Dunstabzugshaube nach unten, wie in der Abbildung

15 zu sehen ist.

Tauschen Sie die Lampe durch eine desselben Typs

aus.

E = Taste DRITTE GESCHWINDIGKEIT

F = TIMER AUTOMATISCHES ANHALTEN nach 15

Minuten

• Wenn Ihr Gerät mit der Funktion INTENSIVE

Geschwindigkeit ausgestattet ist, etwa zwei

Sekunden lang die Taste E drücken, dann wird diese

aktiviert (dann wird diese) 10 Minuten lang aktiviert,

danach kehrt es zu der zuvor eingestellten

Geschwindigkeit zurück.

Wenn die Funktion aktiv ist, blinkt die LED. Um sie

vor Ablauf der 10 Minuten zu unterbrechen, wieder

die Taste E drücken.

• Wenn die Taste F zwei Sekunden lang gedrückt wird

(bei ausgeschalteter Haube), wird die Funktion

“clean air” aktiviert. Diese Funktion bewirkt das

Anschalten des Motors für 10 Minuten pro Stunde

mit der ersten Geschwindigkeit. Sofort nach der

Aktivierung der Funktion startet der Motor mit der 1.

Geschwindigkeit für die Dauer von 10 Minuten,

während dieser Zeit müssen die Taste F und die Taste

C gleichzeitig blinken. Nach Ablaufen dieser Zeit geht

der Motor aus, und die Led der Taste F leuchtet fest

weiter, bis der Motor nach weiteren 50 Minuten mit

der ersten Geschwindigkeit neu startet und die Leds

F und C wieder anfangen, 10 Minuten lang zu blinken, und so weiter. Durch Drücken jeder beliebigen

Taste außer den Lichtern kehrt die Haube sofort zu

ihrem normalen Funktionieren zurück (Beispiel: Wenn

ich die Taste D drücke, wird die Funktion “clean air”

deaktiviert, und der Motor geht sofort in die 2.

Geschwindigkeit; wenn die Taste B gedrückt wird, wird

die Funktion deaktiviert)

• Sättigung der Fett- und Aktivkohlefilter:

- Leuchtet die Taste A alle 2 Sek. auf, müssen die

Fettfilter gereinigt werden.

- Leuchtet die Taste A alle 0,5 Sek. auf, müssen die

Kohlefilter ausgetauscht werden.

Nachdem der gesäuberte Filter wieder eingesetzt

wurde, muss der elektronische Speicher neu aktiviert

werden, indem man die Taste A für circa 5 Sek.

gedrückt hält bis diese aufhört zu blinken.

FÜR SCHÄDEN, DIE AUF DIE NICHTBEACHTUNG

DER OBEN GENANNTEN ANWEISUNGEN ZURUCKZUFÜHREN SIND, WIRD KEINERLEI

VERANTWORTUNG ÜBERNOMMEN.

• BEDIENUNG: (Abb.16) DER BELEUCHTUNG die

SimboLbezeichnungen sind folgend wiedergegeben:

A = Taste BELEUCHTUNG

B = Taste OFF

C = Taste ERSTE GESCHWINDIGKEIT

D = Taste ZWEITE GESCHWINDIGKEIT

- 13 -

ESPAÑOL

GENERALIDADES

Lea atentamente el contenido del presente libro de

instrucciones pues contiene indicaciones importantes

para la seguridad en la instalación, el uso y el

mantenimiento (Consérvelo para un posible consulta

posterior). El aparato ha sido proyectado para ser

utilizado en la versión aspirante (evacuación del aire

al exterior - Fig. 1B) o filtrante (recirculación del aire

en el interior - Fig. 1A).

SUGERENCIAS PARA LA SEGURIDAD

1.Preste atención si funcionan contemporáneamente

una campana aspirante y un quemador o una

chimenea que toman el aire del ambiente y están

alimentados por energía que no sea eléctrica, pues

la campana aspirante toma del ambiente el aire que

el quemador o la chimenea necesitan para la

combustión. La presión negativa del local no debe

superar los 4 Pa (4x10-5 bares). Para un

funcionamiento seguro, realice primero una

adecuada ventilación del local. Para la evacuación

externa, aténgase a las disposiciones vigentes en

su país.

Antes de enchufar el modelo a la corriente

eléctrica:

- controlar los datos de matrícula (que se encuentran

en el interior del aparato) para constatar que la

tensión y la potencia correspondan a la de la red y el

enchufe de conexión sea idóneo. En caso de dudas,

recurra a un electricista calificado.

- Si el cable de alimentación está dañado, se debe

cambiar con un cable o conjunto especial de cables

que puede suministrar tanto el fabricante como el

servicio de asistencia técnica.

2. ¡ ATENCIÓN !!

En determinadas circunstancias los

electrodomésticos pueden ser peligrosos.

A) No intente controlar los filtros cuando la

campana esté funcionando.

B) No tocar las lámparas y las zonas adyacentes,

durante e inmediatamente después del uso

prolongado del equipo de iluminación.

C) Está prohibido cocinar alimentos a la llama

debajo de la campana.

D) Evite las llamas libres, pues resultan perjudiciales para los filtros y pueden provocar

incendios.

E) Controle en todo momento los alimentos fritos

para evitar que el aceite caliente prenda fuego.

F) Antes de realizar cualquier operación de mantenimiento desconecte la campana de la corriente

eléctrica.

G) El aparato no ha sido diseñado para ser

E

utilizado por niños o personas incapaces sin

vigilancia.

H) Controle que los niños no jueguen con el

aparato.

Este aparato está fabricado en conformidad con la

Norma Europea 2002/96/EC, Waste Electrical and

Electronic Equipment (WEEE). Controlando que este

producto sea eliminado de modo correcto, el usuario

contribuye a prevenir consecuencias negativas para

el ambiente y la salud.

El símbolo en el producto o en la documentación

adjunta, indica que este producto no debe ser tratado

como residuo doméstico sino que debe ser entregado

a un punto de recolección para reciclar aparatos

eléctricos y electrónicos. Elimínelo siguiendo las

normas locales para la eliminación de desechos. Para

mayor información sobre el tratamiento, recuperación

o reciclaje de este producto, llame a la oficina local

encargada, al servicio de recolección de desechos

domésticos o al negocio en el cual ha comprado el

producto.

INSTRUCCIONES PARA LA INSTALACIÓN

Las operaciones de montaje y conexión eléctrica

deben ser efectuadas por personal especializado.

• Instalación eléctrica

El aparato está construido en clase II, por lo tanto

no se debe e conectar ningún cable a la toma de

tierra.

La conexión a la corriente eléctrica debe realizarse

de la siguiente manera:

MARRÓN = L línea.

AZUL = N neutro.

Si no está incluido, monte en el cable un enchufe

normalizado para la carga indicada en la etiqueta

de las caracteristicas. Si está provista de

enchufe,coloque la campana de tal manera que el

enchufe quede en un sitio accesible. En caso de

conexión directa a la corriente eléctrica, es necesario

interponer entre el aparato y la red un interruptor

omnipolar con abertura mínima de 3mm, adecuado

a la carga y que responda a las normas vigentes.

• La distancia mínima entre la superficie de soporte

de los recipientes de cocción en el dispositivo de

cocción y la parte más baja de la campana de cocina

debe de al menos 65 cm.

Si debe usarse un tubo de conexión compuesto de

dos o más partes, la parte superior debe estar fuera

de la parte inferior. No conecte la descarga de la

campana a un conducto en el que circúle airecaliente

o que sea utilizado para evacuar los humos de

aparatos alimentados por una energía que no sea

eléctrica.

- 14 -

Antes de efectuar las operaciones de montaje, para

una más fácil maniobrabilidad del aparato, extraer

el/los filtro/s antigrasa (Fig.2c).

En el caso de montaje del aparato en la versión

aspirante, predisponer el orificio de evacuación aire.

• Se aconseja el uso de un tubo de evacuación de

aire con un diámetro de 150. El uso de una reducción

podría disminuir las prestaciones del producto y

aumentar el ruido.

Nota:

- Para la instalación de este producto se aconseja

solicitar la ayuda de una segunda persona.

¡Atención!

• Para maniobrar más fácilmente la campana, antes

de proceder con el montaje, abra el embalaje, tome

la campana y apóyela sobre una superficie cómoda

(fig. 2a).

Abra el panel haciendo presión en el punto indicado

en la fig. 2b.

Quite el panel de aluminio, tirando de la manija, como

se indica en la fig. 2c. Si el producto posee filtros de

carbón activo, quítelos tirando hacia el exterior la

palanca, como se indica en la fig. 2d.

• Montaje de la campana

El producto se suministra ensamblado. Para realizar

el montaje, ejecute las siguientes fases:

- Quite los cuatro tornillos A como se indica en la fig. 3.

- Separe el armazón de la estructura quitando los

tapones y luego los tornillos B indicados en la fig. 4.

• Fijación a la pared

- Coloque la plantilla de fijación en la pared (teniendo

en cuenta la distancia mínima de la encimera).

Realice una marca y luego los orificios de fijación.

- Fije los 2 tornillos C y las espigas para pared (fig.

6). Los tornillos no deben ser enroscados

completamente.

- Una realizada la regulación, fije el grupo motor X

definitivamente con los 2 tornillos D (fig. 6).

- Fije la abrazadera de salida de aire Y a la pared

con los 2 tornillos E (fig. 6).

- Coloque el grupo motor X en la pared, en posición

horizontal y enrosque los tornillos C (fig. 6).

- En los distintos montajes utilice tornillos y espigas

adecuados para el tipo de pared (por ej. cemento

armado, cartón de yeso, etc.).

- Cuando los tornillos y las espigas se suministren

con el producto, controle que sean los adecuados

para el tipo de pared a la que se debe fijar la

campana.

- Si su modelo funciona en versión filtrante, antes

de fijar el armazón a la estructura, fije el tubo flexible

C (no se suministra) a la boca de salida de aire D de

la campana y de la brida de salida de aire E (fig. 8).

- Si su modelo funciona en versión aspirante, quite

la rejilla F (fig. 10) sólo en el caso en que sea

necesario hacer pasar el tubo de evacuación de aire

dentro de la abrazadera de salida de aire E fig. 9.

- Conecte el tubo flexible C a la boca de salida de

aire D y también al orificio de evacuación de aire

preparado precedentemente.

- Coloque el armazón A en la pared (fig. 7) y proceda

a alinearlo con la estructura empujándolo hacia arriba

(fig. 11).

- Fije primero los tornillos laterales D del armazón,

conectados a la estructura que está debajo, indicados

en la fig. 12, luego los tornillos A de la parte inferior

de la campana indicados en la fig. 13.

- Conexión eléctrica

Antes de realizar la conexión, desenrosque los 4

tornillos D de las dos cajas y abra las tapas (Fig. 14).

- Realice las conexiones eléctricas entre el cuerpo

de la campana y el grupo motor (Fig.14 A y B).

USO Y MANTENIMIENTO

• Se recomienda poner en funcionamiento el aparato

antes de proceder a la cocción de un alimento

cualquiera. Se recomienda también, dejar funcionar

el aparato durante 15 minutos después de haber

finalizado la cocción para lograr una evacuación

completa del aire viciado.

El buen funcionamiento de la campana depende de

la realización de un correcto y constante

mantenimiento; se debe prestar una atención

particular al filtro antigrasa y al filtro de carbón activo.

• El filtro antigrasa cumple la función de retener las

partículas de grasa en suspensión en el aire, por lo

tanto, puede atascarse en distintos momentos que

dependen del uso del aparato.

El filtro de acrílico que se encuentra apoyado en la

rejilla, se debe sustituir cuando las letras que se

observan a través de la rejilla, cambian de color y la

tinta se expande; el nuevo filtro se debe aplicar de

modo tal que las letras se puedan observar a través

de la rejilla desde el exterior de la campana.

Si los filtros de acrílico no tienen estas letras o en su

lugar hay filtros metálicos o de panel de aluminio,

para prevenir el peligro de incendios, es necesario

lavar los filtros cada 2 meses como máximo,

realizando las siguientes operaciones:

- quite el filtro de la rejilla y lávelo con una solución

de agua y detergente líquido neutro.

- Enjuague con abundante agua tibia y deje secar.

Los filtros metálicos y/o de panel de aluminio se

pueden también lavar en lavavajillas. Después de

algunos lavados, si los filtros son de aluminio o panel

de aluminio, se pueden producir alteraciones del

color. Si esto sucede, no constituye motivo de

reclamo para su sustitución.

Si no se cumplen las instrucciones de sustitución o

de lavado, existe el riesgo de incendio de los filtros

antigrasa.

• Los filtros de carbón activo sirven para depurar el

aire que se devuelve al ambiente. Los filtros no se

- 15 -

pueden lavar o regenerar y deben ser sustituidos

cada cuatro meses como máximo. La saturación del

carbón activo depende del uso más o menos

prolongado del aparato, del tipo de cocina y de la

regularidad con la que se realiza la limpieza del filtro

antigrasa.

• Limpie frecuentemente todos los depósitos en el

ventilador y en otras superficies, usando un paño

humedecido con alcohol de quemar y detergentes

líquidos neutros no abrasivos.

• La instalación de iluminación ha sido proyectada

para ser utilizada durante la cocción y no para su

uso prolongado como iluminación general del

ambiente. El uso prolongado de la iluminación

disminuye notablemente la duración media de las

lámparas.

• Sustitución de las lámparas halógenas (Fig.15).

Para sustituir las lámparas halógenas B, desde el

interior de la campana empuje hacia abajo con dos

dedos, como se indica en la fig. 15.

Sustitúyalas con lámparas del mismo tipo.

• MANDOS: (Fig.16) Luminosos la simbología es

la siguiente:

A= botón ILUMINACION.

B= botón OFF

C= botón PRIMERA VELOCIDAD.

D= botón SEGUENDA VELOCIDAD.

E= botón TERCERA VELOCIDAD.

F= botón TIMER PARADA AUTOMáTICA 15

MINUTOS.

• Saturación de los filtros antigrasa/carbón activo:

- Cuando el botón A centellea con una frecuencia de

2 seg., los filtros antigrasa deben ser lavados.

- Cuando el botón A centellea con una frecuencia de

0,5 seg., los filtros de carbón deben ser sustituidos.

Después que se vuelve a colocar el filtro limpio, es

necesario reiniciar la memoria electrónica

presionando el botón A durante 5 seg. hasta que

deje de centellear.

EL FABRICANTE NO SE HACE RESPONSABLE DE

LOS DAÑOS PRODUCIDOS POR EL

INCUMPLIMIENTO DE ESTAS ADVERTENCIAS.

• Si su aparato está equipado con la función velocidad

INTENSIVA, tener el botón E presionado por casi 2

segundos para activar esta función por 10 minutos,

pasado este tiempo regresará a la velocidad

precedentemente programada.

Cuando la función es activa el LED relampagea. Para

interrumpirla antes de los 10 minutos presione la tecla

E de nuevo.

Presionando el botón F por dos segundos (con la

campana apagada) se activa la función “clean air”.

Esta función enciende el motor por 10 minutos cada

hora en la primera velocidad. Apenas sea activada

la función, el motor parte con la 1° velocidad por un

período de 10 minutos, durante los cuales deben

relampagear los botones F y C contemporaneamente.

Terminado este período el motor se apaga y el led

del botón F se mantiene encendido con una luz fija

por 50 minutos. En ese momento el motor reparte en

la primera velocidad, los leds F y C recomienzan a

relampagear por 10 minutos y se repite el ciclo.

Presionando cualquier botón, a excepción de las

luces, la campana inmediatamente regresa a su

funcionamiento normal (ej. presionando el botón D

se desactiva la función “clean air” y el motor cambia

a la 2° velocidad; presionando el botón B la función

se desactiva).

- 16 -

FRANÇAIS

F

GÉNERALITÉS

Lire attentivement le contenu du mode d'emploi

puisqu'il fournit des indications importantes

concernant la sécurité d'installation, d'emploi et

d'entretien. Le conserver pour d' ultérieures

consultations. Cet appareil a été conçu pour utilisation

en version à évacuation extérieure (Fig.1B) ou

recyclage (Fig.1A).

CONSEILS POUR LA SÉCURITÉ

1. Attention, lorsque dans la même pièce vous utilisez

simultanément la hotte à évacuation avec un brûleur

ou une cheminée alimentés par une énergie autre

que l'électricité, vous pouvez créer un problème

"d'inversion de flux".

Dans ce cas la hotte aspire l'air nécessaire à leur

combustion.

La dépression dans le local ne doit pas dépasser les

4 Pa (4x10-5 bar). Pour un fonctionnement en toute

sécurité, n'oubliez pas de prévoir une ventilation

suffisante du local.

Pour l'évacuation vers l'extérieur, veuillez vous référer

aux dispositions en vigueur dans votre pays.

Avant de brancher la hotte au réseau de

distribution électrique:

- lire les données reportées sur la plaquette d’identification (appliquée à l’intérieur de la hotte) pour

vérifier si le voltage et la puissance correspondent à

ceux du réseau.

Contrôler aussi si la prise est adaptée. En cas de

doutes, contacter un électricien qualifié.

- Si le câble d'alimentation est abîmé, il faut le

remplacer par un autre câble ou par un ensemble,

spécialement prévus, que vous pouvez commander

au fabricant ou à un de ses services d'assistance

technique.

2. ATTENTION !

Dans des circonstances déterminées les électroménagers peuvent être dangereux.

A)Ne pas controler les filtres pendant que la hotte

est en fonctionnement

B) Ne pas toucher les lames et les zones

adjacentes, pendant et immediatement apres

l’utilisation prolonge du systeme d’eclairage.

C)Il est interdit de cuire les aliments à la flamme

sous la hotte

D)Eviter la flamme libre, parcequ'elle est nuisible

pour les filtres et dangereuse pour les incendies

E)Controler constamment les aliments frits pour

éviter que l'huile surchauffée/ne prenne feu

F)Avant d'effectuer n'importe quel entretien déconnecter la hotte du réseau électrique.

G) Cet appareil n'a pas été conçu pour être utilisé

par des enfants ou par des personnes inaptes

sans surveillance.

H) Veiller à ce que les enfants ne jouent pas avec

l'appareil.

Cet appareil est marqué conformément à la Directive

européenne 2002/96/CE sur les déchets

d'équipements électriques et électroniques (DEEE).

Assurez-vous que cet appareil soit mis au rebus selon

la réglementation en vigueur, vous éviterez ainsi des

conséquences néfastes sur l'environnement et la

santé.

Le symbole appliqué sur le produit ou sur la

documentation jointe rappelle que cet appareil ne doit

pas être traité comme un déchet domestique mais

faire l'objet d'une collecte sélective dans une

déchetterie spécialisée dans le recyclage des

appareils électriques et électroniques.

Conformez-vous aux réglementations locales sur la

collecte et l'élimination des déchets.

Pour tout autre renseignement sur le traitement, la

récupération et le recyclage de cet appareil, veuillez

contacter le bureau concerné de votre ville, le service

de collecte des déchets domestiques ou le magasin

où vous avez acheté votre appareil.

INSTRUCTIONS POUR L'INSTALLATION

Le montage et le branchement électrique doivent être

effectués par un personnel spécialisé.

• Connexion électrique

L'appareil est construit en classe II, pour cela aucun

cable ne doit être connecté avec la prise terre.

La connection avec le réseau électrique doit être

éxécutée comme suit:

MARRON = L ligne

BLEU = N neutre

Si elle n'a pas été prévue, monter sur le cable une

fiche normalisée pour la charge indiquée sur

l'etiquette des caractéristiques. Si elle est dotée d'une

fiche, la hotte doit être installée en sorte que la fiche

soit accessible.

En cas de connection directe avec le réseau

électrique, il est nécessaire d'interposer entre

l'appareil et le réseau un interrupteur omnipolaire

avec une ouverture minimale entre les contacts de 3

mm, proportionnel à la charge et correspondant aux

normes en vigueur.

• La distance minimum entre la surface de support

des récipients de cuisson sur le dispositif de cuisson

et la partie la plus basse de la hotte pour cuisine doit

être de 65 cm au moins.

S'il doit être utilisé un tuyau de connection composé

- 17 -

de deux ou plusieurs parties, la partie superieure

doit être à l'exterieur de celle inférieure.

Ne pas relier le tuyau d'échappement de la hotte à

un conduit dans lequel circule de l'air chaud ou

employé pour évacuer les fumées des appareils

alimentés par une énergie differente de celle

électrique.

En vue d’une manœuvrabilité de l’appareil plus facile,

avant d’exécuter les opérations de montage, déconnecter le filtre/les filtres anti-graisse (Fig.2c).

S’il s’agit d’une hotte aspirante, il faudra prévoir une

ouverture pour l’évacuation de l’air.

• Nous conseillons d’utiliser un tuyau d’évacuation

de l’air diamètre 150.

L’utilisation d’une réduction pourrait diminuer les

performances du produit et augmenter le niveau

sonore

Remarque !

- Pour installer l'appareil, il est conseillé de se faire

aider par une autre personne.

Attention!

• Avant de procéder aux opérations d'installation de

l'appareil, ouvrez l'emballage, sortez la hotte et

posez-la sur un plan pratique pour pouvoir la manier

plus facilement (fig.2a).

Ouvrez le panneau en exerçant une pression à

l'endroit indiqué (fig. 2b).

Otez le panneau en aluminium en tirant sur la poignée

comme illustré (fig. 2c). Si le produit est équipé de

filtres à charbon actif, retirez-les en tirant le levier

vers l'extérieur, comme illustré (fig. 2d).

• Montage de la hotte

Le produit est fourni déjà assemblé. Pour procéder à

son montage, effectuez les opérations suivantes :

- Retirez les quatre vis A comme illustré (fig. 3).

- Séparez la hotte de la structure, retirez les bouchons

puis les vis B comme illustré fig. 4.

• Fixation murale

- Positionnez le gabarit de perçage contre le mur (en

respectant bien la distance minimale de sécurité du

plan de cuisson).

Repérez et percez les trous de fixation

- Fixez les 2 vis C sans serrer à fond et les chevilles

expansives (fig. 6).

- Une fois le réglage effectué, fixez définitivement le

groupe moteur X à l'aide des 2 vis D (fig.6).

- Fixez au mur la bride de l'évacuation de l'air Y à

l'aide des 2 vis E (fig.6).

- Accrochez le groupe moteur X au mur, alignez-le à

l'horizontale et vissez les vis C (fig. 6).

- Pour les opérations de montage, utilisez des vis et

des chevilles expansives adaptées à la nature du mur

(béton armé par ex. ou placoplâtre, etc.).

- Si les vis et les chevilles sont fournies avec

l'appareil, assurez-vous qu'elles soient bien adaptées

à la nature du mur qui supportera la hotte.

- S'il s'agit d'un modèle de hotte version recyclage,

avant de fixer la hotte à la structure, fixez le tuyau

flexible C (non fourni) à l'orifice de sortie de l'air D de

la hotte et à la bride de l'évacuation de l'air E (fig.8).

- S'il s'agit d'un modèle de hotte version évacuation

extérieure, ne retirez la grille F (fig. 10) que s'il vous

faut faire passer le tuyau d'évacuation de l'air à

l'intérieur de la bride de sortie de l'air E fig. 9.

- Raccordez le tuyau flexible C à l'orifice de sortie de

l'air D qui sera, à son tour, raccordé au trou

d'évacuation de l'air préparé au préalable.

- Positionnez la hotte A contre le mur ( fig. 7) et

alignez-la à la structure en la poussant vers le haut

(fig. 11).

- Fixez d'abord les vis latérales D (indiquées fig. 12)

qui fixent la hotte à la structure support, et ensuite

les vis A (indiquées fig. 13) situées dans la partie

inférieure de la hotte.

- Raccordement électrique

Avant de procéder au raccordement, dévissez les 4

vis D des deux boîtiers et ouvrez les couvercles

(Fig.14)

- Procédez aux connexions électriques voulues entre

le corps de la hotte et le groupe moteur. (Fig. 14 A et

B).

EMPLOI ET ENTRETIEN

• Il est conseillé de mettre en service la hotte

quelques minutes avant de commencer à cuisiner.

De même il est conseillé de l'arrêter 15 minutes après

avoir terminé la cuisson pour éliminer au maximum

les odeurs et évacuer l'air vicié.

Le bon fonctionnement de la hotte est lié à la

fréquence des opérations d'entretien et, plus

particulièrement, à l'entretien du filtre anti-graisse et

du filtre à charbon actif.

• Le filtre anti-graisse a pour rôle de retenir les

particules grasses en suspension dans l'air. Il peut

donc se boucher plus ou moins rapidement selon la

fréquence d'utilisation de la hotte.

Le filtre acrylique, posé sur la grille, signale par un

changement de couleur de ses inscriptions, visibles

à travers la grille, et par l'encre qui s'étend qu'il est

temps de procéder à son remplacement. Il faut

installer le nouveau filtre de manière à ce que les

inscriptions soient visibles de l'extérieur de la hotte.

Si les filtres acryliques sont dépourvus d'inscriptions,

ou en cas de présence de filtres métalliques ou de

panneau en aluminium, pour éviter tout risque

d'incendie, il est nécessaire de laver les filtres au

moins tous les deux mois en procédant comme suit :

- retirer le filtre de la hotte et le laver avec de l'eau et

un détergent liquide neutre, laisser la saleté se

décoller.

- Rincer abondamment à l'eau tiède et laisser sécher.

Les filtres métalliques et/ou le panneau en aluminium

sont lavables au lave-vaisselle. Après plusieurs

- 18 -

lavages, les filtres ou le panneau en aluminium

peuvent changer de couleur. Ceci ne donne pas droit

à réclamation ni droit, par conséquent, à leur

remplacement.

Le non-respect des consignes de remplacement et

de lavage peut entraîner un risque d'incendie des

filtres anti-graisse.

• Les filtres à charbon actif servent à filtrer l'air qui

est ensuite renvoyé dans la pièce. Les filtres ne sont

ni lavables ni régénérables, il faut par conséquent

les changer au moins tous les quatre mois. La

saturation du charbon actif dépend de l'utilisation plus

ou moins prolongée de l'appareil, du type de cuisine

pratiquée et de la régularité du nettoyage du filtre

anti-graisse.

• Nettoyer fréquemment tous les dépôts sur le

ventilateur et les autres surfaces à l'aide d'un chiffon

imbibé d'alcool dénaturé ou de détergents liquides

neutres non abrasifs.

• N'utiliser l'éclairage de la hotte que pendant la

cuisson, ce dernier n'est en effet pas conçu pour un

éclairage général prolongé de la pièce. Une utilisation

prolongée de l'éclairage diminue considérablement

la durée de vie moyenne des lampes.

• Remplacement des lampes halogènes (Fig. 15).

Pour changer les lampes halogènes B, poussez vers

le bas, de l'intérieur de la hotte, en vous servant de

deux doigts comme illustré (fig.15).

Remplacez-les par des lampes de même type.

• COMMANDES: (Fig.16) Lumineux le symbole sont

le suivant:

A = touche ECLAIRAGE

B = touche OFF

C = touche PREMIERE VITESSE

D = touche DEUXIEME VITESSE

E = touche TROISIEME VITESSE

F = touche MINUTEUR ARRET AUTOMATIQUE 15

minutes

électroluminescentes F et C recommencent à cligno-

ter pendant 10 minutes et ainsi de suite. En appuyant

sur n’importe quelle touche à l’exception des touches

de lumière, la hotte retourne immédiatement à son

fonctionnement normal (ex. en appuyant sur le bouton D la fonction « clean air » se désactive et le

moteur passe directement à la 2

ème

vitesse ; en

appuyant sur le bouton B la fonction se désactive)

• Saturation filtres anti-gras/charbon actif :

- Quand la touche A se met à clignoter par intervalles

de 2 secondes, il est temps de laver les filtres anti-

gras.

- Quand la touche A se met à clignoter par intervalles

de 0,5 secondes, il est temps de changer les filtres

à charbon.

Après avoir remis le filtre propre à sa place, procéder

à une remise à zéro la mémoire électronique en

appuyant 5 secondes de suite sur la touche A jusqu'à

ce que cette dernière cesse de clignoter.

NOUS DECLINOS TOUTE RESPONSABILI TE POUR LES

EVENTUELS DÉGATS PROVOQUÉS PAR L'INOBSERVATION DES SUSDITES INSTRUCTIONS.

• Si votre appareil possède la fonction vitesse

INTENSE, maintenir appuyé pendant environ 2

secondes le bouton E pour activer la fonction pendant

10 minutes, après quoi elle retournera à la vitesse

établie en précédence.

Quand la fonction est active, la LED clignote. Pour

l’interrompre avant les 10 minutes, presser de

nouveau sur la touche E.

• En appuyant sur le bouton F pendant 2 secondes

(lorsque la hotte est allumée), la fonction « clean

air » s’active. Cette fonction démarre le moteur pour

10 minutes par heure à la première vitesse.

Dès que la fonction est activée, le moteur démarre

ère

en 1

vitesse pour 10 minutes pendant lesquelles

les boutons F et C doivent clignoter en même temps.

A la fin de ce temps, le moteur s’arrête et la diode

électroluminescente du bouton F reste allumée sans

clignoter jusqu’à ce que le moteur reparte en 1

vitesse 50 minutes plus tard. Les diodes

ère

- 19 -

ENGLISH

GENERAL

Carefully read the following important information regarding installation safety and maintenance. Keep this

information booklet accessible for further

consultations.

The appliance has been designed for use as a ducted

version (air exhaust to the outside - Fig. 1B), or a

filter version (air circulation on the inside - Fig. 1A).

SAFETY PRECAUTION

1. Take care when the cooker hood is operating si-

multaneously with an open fireplace or burner that

depend on the air in the environment and are supplied

by other than electrical energy, as the cooker hood

removes the air from the environment which a burner

or fireplace need for combustion. The negative

pressure in the environment must not exceed 4Pa

(4x10-5 bar). Provide adequate ventilation in the environment for a safe operation of the cooker hood.

Follow the local laws applicable for external air evacuation.

Before connecting the model to the electricity network:

- control the data plate (positioned inside the

appliance) to ascertain that the voltage and power

correspond to the network and the socket is suitable.

If in doubt ask a qualified electrician.

- If the power supply cable is damaged, it must be

replaced with another cable or a special assembly,

which may be obtained direct from the manufacturer

or from the Technical Assistance Centre.

2. WARNING !

In certain circumstances electrical appliances

may be a danger hazard.

A) Do not check the status of the filters while the

cooker hood is operating

B) Do not touch bulbs or adjacent areas, during

or straight after prolonged use of the lighting

installation.

C) Flambè cooking is prohibited underneath the

cooker hood

D) Avoid free flame, as it is damaging for the filters

and a fire hazard

E) Constantly check food frying to avoid that the

overheated oil may become a fire hazard

F) Disconnect the electrical plug prior to any

maintenance.

G) This appliance is not intended for use by young

children or infirm persons without supervision

H) Young children should be supervised to

ensure they do not play with the appliance

I) There shall be adequate ventilation of the room

when the rangehood is used at the same time as

GB

appliances burning gas or other fuels

L) There is a risk of fire if cleaning is not carried

out in accordance with the instructions

This appliance conforms to the European Directive

EC/2002/96, Waste Electrical and Electronic

Equipment (WEEE). By making sure that this

appliance is disposed of in a suitable manner, the

user is helping to prevent potential damage to the

environment or to public health.

The symbol on the product or on the

accompanying

paperwork indicates that the appliance should not

be treated as domestic waste, but should be delivered

to a suitable electric and electronic appliance

recycling collection point. Follow local guidelines

when disposing of waste. For more information on

the treatment, re-use and recycling of this product,

please contact your local authority, domestic waste

collection service or the shop where the appliance

was purchased.

INSTALLATION INSTRUCTIONS

Assembly and electrical connections must be

carried out by specialised personnel.

• Electric Connection

The appliance has been manufactured as a class II,

therefore no earth cable is necessary.

The connection to the mains is carried out as follows:

BROWN = L line

BLUE = N neutral

If not provided, connect a plug for the electrical load

indicated on the description label. Where a plug is

provided, the cooker hood must be installed in order

that the plug is easily accessible.

An omnipolar switch with a minimum opening of 3mm

between contacts, in line with the electrical load and

local standards, must be placed between the

appliance and the network in the case of direct

connection to the electrical network.

• The minimum distance between the support

surfaces of the cooking pots on the cooker top and

the lowest part of the cooker hood must be at least

65 cm.

If a connection tube composed of two parts is used,

the upper part must be placed outside the lower part.

Do not connect the cooker hood exhaust to the same

conductor used to circulate hot air or for evacuating

fumes from other appliances generated by other than

an electrical source.

Before proceeding with the assembly operations, remove the anti-grease filter(s) (Fig.2c) so that the unit

is easier to handle.

- 20 -

In the case of assembly of the appliance in the suction

version prepare the hole for evacuation of the air.

• We recommend the use of an air exhaust pipe with

a diameter of 150. If a pipe with a smaller diameter is

used, the efficiency of the product may be reduced

and its operation may become noisier

Note!

- When installing this product we recommend you

seek the help of another individual.

Please note:

• Before beginning the assembly procedure, for

easier cooker hood handling, open the packaging,

remove the cooker hood and place it on a convenient

surface (Fig. 2a).

Open the panel by pressing the point indicated in

Fig. 2b.

Remove the aluminium panel by pulling the handle

as indicated in Fig. 2c. If the product is supplied with

active charcoal filters, remove them by pulling the

lever outwards as indicated in Fig. 2d.

• Hood assembly

The product is supplied pre-assembled. To install it,

proceed as follows:

- Remove the four screws A as indicated in Fig. 3.

- Separate the bodywork from the frame, removing

the plugs and then the screws B as indicated in Fig. 4.

• Fixing the appliance to a wall

- Position the fixing template on the wall (taking the

minimum distance from the hob into account).

Mark fixing holes and cut them into the material.

- Fix the 2 screws C and the screw anchors (Fig. 6),

without tightening them completely.

- After the necessary adjustments have been made,

fix the motor assembly X in place using the 2 screws

D (Fig. 6).

- Fix the air outlet bracket Y to the wall using the 2

screws E (Fig. 6).

- Position the motor assembly X against the wall,

make sure it is in a horizontal position and tighten

the screws C (Fig. 6).

- When carrying out the fixing procedures, use only

screws and screw anchors which are suited to the

type of wall (e.g. reinforced concrete, plasterboard

etc.).

- If the screws and screw anchors are supplied with

the appliance, make sure that they are suited to the

type of wall to which the hood must be fixed.

- If your model is a filter version, before fixing the

bodywork to the structure, fix the flexible hose C (not

supplied) to the air outlet opening D on the hood and

the air outlet flange E (Fig. 8).

- If your model is a ducted version, remove the grille

F (Fig. 10) only if the air exhaust tube must be passed

through the inside of the air outlet bracket E (Fig. 9).

- Connect the flexible hose C to the air outlet D, which

in turn will be connected to the air exhaust hole made

previously.

- Position the bodywork A against the wall (Fig. 7) and

align it with the frame, pushing it upwards (Fig. 11).

- First, fix the side screws D on the bodywork in place

(these are connected to the frame underneath) as

indicated in Fig. 12, then tighten the screws A on the

lower part of the cooker hood as indicated in Fig. 13.

- Electrical connection

Before performing this connection, loosen the 4

screws D on the two boxes and open the cover panels

(Fig. 14).

- Perform the necessary electrical connections

between the cooker hood body and the motor

assembly (Fig. 14A and B).

USE AND MAINTENANCE

• We recommend that the cooker hood is switched

on before any food is cooked. We also recommend

that the appliance is left running for 15 minutes after

the food is cooked, in order to thoroughly eliminate

all contaminated air.

The effective performance of the cooker hood

depends on constant maintenance; the anti-grease

filter and the active carbon filter both require special

attention.

• The anti-grease filter is used to trap any grease

particles suspended in the air, therefore is subject to

saturation (the time it takes for the filter to become

saturated depends on the way in which the appliance

is used).

The acrylic filter, which is found resting on the grille,

should be replaced when the text, visible through the

grille, changes colour and the ink spreads; the new

filter should be fitted in such a way that the text can

be seen through the grille from outside the cooker

hood.

If the filters do not have any text on them, or if metal

filters or aluminium panel filters are used, they should

be washed every 2 months in order to prevent the

risk of fire. To wash the filters, proceed as follows:

- Remove the filter from the grille and wash it using a

solution of water and neutral liquid detergent, leaving

the dirt to soften.

- Rinse thoroughly with warm water and leave to dry.

The metal filters and/or aluminium panel are also

dishwasher safe. If the filters are made using

aluminium, or if an aluminium panel is used, after a

few washes the colour may change. This does not

mean they have to be replaced.

If the replacement and washing instructions are not

followed, the anti-grease filters may present a fire

hazard.

• The active carbon filters are used to purify the air

which is released back into the room. The filters are

not washable or re-usable and must be replaced at

least once every four months. The active carbon filter

- 21 -

saturation level depends on the frequency with which

the appliance is used, the type of cooking performed

and the regularity with which the anti-grease filters

are cleaned.

• Remove build-up from the fan and other surfaces of

the cooker hood regularly using a cloth moistened

with denatured alcohol or non-abrasive neutral liquid

detergent.

• The light on the cooker hood is designed for use

during cooking and not for general room illumination.

Extended use of the light reduces the average

duration of the bulb.

• Replacing halogen light bulbs (Fig. 15).

To replace the halogen lamps B, from the inside of

the cooker hood press downwards with two fingers

as shown in Fig. 15.

Replace the bulbs with new ones of the same type.

• COMMANDS: (Fig.16) LUMINOUS the key symbols

are explained below:

A = LIGHT

B = OFF

C = SPEED I

D = SPEED II

E = SPEED III

F = AUTOMATIC STOP TIMER - 15 minutes

• If your appliance does not have the INTENSIVE

speed function, press key E for two seconds and it

will be activated for 10 minutes after which it will return

to the previously set speed.

When the function is active the LED flashes. To interrupt it before the 10 minutes have expired press

key E again.

After the clean filter has been replaced, the electronic

memory must be reset by pressing button A for

approximately 5 seconds, until the light on the button

stops flashing.

THE MANUFACTURER DECLINES ALL

RESPONSIBILITY FOR EVENTUAL DAMAGES

CAUSED BY BREACHING THE ABOVE

WARNINGS.

• By pressing key F for two seconds (with the hood

switched off) the “clean air” function is activated. This

function switches the appliance on for ten minutes

every hour at the first speed. As soon as this function

is activated the motor starts up at the first speed for

ten minutes, During this time key F and key C must

flash at the same time.

After ten minutes the motor switches off and the LED

of key F remains switched on with a fixed light until

the motor starts up again at the first speed after fifty

minutes and keys F and C start to flash again for ten

minutes and so on.

By pressing any key for the exclusion of the hood

light the hood will return immediately to its normal

functioning (e.g. if key D is pressed the “clean air”

function is deactivated and the motor moves to the

2nd speed straight away. By pressing key B the

function is deactivated).

• Active carbon/grease filter saturation:

- When button A flashes at a frequency of 2 seconds,

the grease filters must be cleaned.

- When button A flashes at a frequency of 0.5

seconds, the carbon filters must be replaced.

- 22 -

NEDERLANDS

NL

ALGEMEEN

De inhoud van dit boekje grondig doorlezen, daar

het belangrijke informatie bevat voor veilige installatie,

gebruik en onderhoud.Het boekje bewaren voor

verdere raadpleging.Het apparaat is ontworpen als

afzuigkap (Iuchtafvoer naar buiten, waarbij gezorgd

moet worden voor voldoende luchttoevoer naar de

keuken) of als filter (Iuchtrecirculatie binnen). Het

apparaat is ontwikkeld om te worden gebruikt in de

afzuigversie (afvoer lucht naar buiten toe - Afb. 1B)

of in de filterversie (hercirculatie lucht aan de

binnenkant - Afb. 1A).

VEILIGHEIDSVOORSCHRIFTEN

Opletten indien tegelijkertijd een afzuigkap en een

brander of haard functioneren die afhankelijk zijn van

de omgevingslucht en gevoed worden door een

andere energiebron dan de elektrische energie. De

afzuigkap kan de lucht die de brander of haard nodig

heeft voor de verbranding aan de omgeving

onttrekken. De negatieve druk in de omgeving mag

niet boven de 4 Pa (4x10-5 bar) liggen. Voor een

veilige werking dient u te zorgen voor een goede

ventilatie van de ruimte. Voor de afvoer naar buiten

moet u zich houden aan de geldende voorschriften

die van toepassing zijn in uw land.

Voordat u het model op het elektriciteitsnet

aansluit:

- controleer op het gegevensplaatje (aan de

binnenkant van het apparaat) of de spanning en het

vermogen overeenkomen met die van het net, en of

de stekker geschikt is voor de aansluiting. Neem in

geval van twijfel contact op met een gekwalificeerde

elektricien.

- Als de voedingskabel beschadigd is dient deze te

worden vervangen door een andere kabel of een

speciale kabelcombinatie, beschikbaar bij de

fabrikant of de technische servicedienst.

2. WAARSCHUWING !

Onder bepaalde omstandigheden kunnen huishoudelijke apparaten gevaarlijk zijn.

A) Probeer de filters niet te controleren als de

afzuigkap in werking is

B) Onmiddellijk na en tijdens de langdurige

werking van de verlichtingsinstallatie de lampen

en aangrenzende zones niet aanraken.

C) Het is verboden om onder de afzuigkap gerechten

te flamberen

D) Laat de branders niet open en bloot branden,

omdat dit schadelijk is voor de filters en gevaarlijk

is met het oog op brand.

E) Tijdens frituren constant opletten, om te

voorkomen dat de olie door oververhitting vlam

zou vatten

F) Alvorens onderhoudswerkzaamheden aan het

apparaat te verrichten, de stroom uitschakelen.

G) Het apparaat is niet geschikt om zonder

toezicht te worden gebruikt door kinderen of door

onkundige personen.

H) Controleer dat kinderen niet met het apparaat

spelen.

Dit apparaat is voorzien van het keurmerk Waste

Electrical and Electronic Equipment (WEEE), zoals

vastgesteld door de Europese Norm 2002/96/EC.

Door te zorgen dat de afvalverwijdering van dit

product correct wordt uitgevoerd, werkt de gebruiker

mee aan het voorkomen van potentiële negatieve

consequenties voor omgeving en gezondheid.

Het symbool op het product of op het bijgeleverde

documentatiemateriaal geeft aan dat het niet moet

worden behandeld als normaal huisvuil, maar dat het

moet worden ingeleverd bij een speciaal

verzamelpunt voor het recyclen van elektrische en

elektronische apparatuur. De afvalverwijdering moet

plaatsvinden in het respect van de gemeentelijke

normen. Voor meer informatie over het onderhoud

en het recyclen van dit product kunt u contact

opnemen met uw gemeente, de locale

reinigingsdienst, of de winkel waar u het product heeft

aangeschaft.

INSTALLATIE INSTRUCTIES

De werkzaamheden m.b.t de montage en de elektrische aansluiting dienen verricht te worden door gespecialiseerd personeel.

ELEKTRISCHE AANSLUITING

Het apparaat is gemaakt in klasse II (dubbel

geïsoleerd), het snoer hoeft derhalve niet op een

geaard stopcontact aangesloten te worden.

De aansluiting op het elektriciteitsnet moet als volgt

uitgevoerd worden:

BRUIN = L fase

BLAUW = N nulleiding

Als deze niet reeds voorzien is moet u een stekker

op het snoer aansluiten die genormaliseerd is voor

de belasting die op het typeplaatje is aangegeven.

Indien van stekker voorzien moet de afzuigkap

zodanig geïnstalleerd worden dat de stekker

bereikbaar is.

In het geval van een rechtstreekse aansluiting op het

elektriciteitsnet moet u tussen het apparaat en het

net een meerpolige schakelaar plaatsen met een

minimale opening tussen de contacten van 3 mm.

Deze schakelaar moet berekend zijn op de belasting

vermeld op het typeplaatje en moet aan de geldende

voorschriften voldoen.

- 23 -

• De minimumafstand tussen het oppervlak dat de

pannen op het fornuis ondersteunt en de onderkant

van de afzuigkap moet minstens 65 cm bedragen

Indien een verbindingsbuis bestaande uit twee of

meer delen gebruikt wordt, dan moet het bovenste

gedeelte aan de buitenkant van het onderste gedeelte

zitten.

Sluit de afvoer van de afzuigkap niet aan op een

leiding waardoor warme lucht circuleert of die gebruikt

wordt voor de afvoer van rook van apparaten die door

een andere energiebron dan elektrische energie gevoed worden.

Voordat u verder gaat met de montage dient u, om

het apparaat makkelijker te kunnen verplaatsen, de

anti-vetfilter(s) te verwijderen (Afb.2c).

Bij montage van het apparaat in de afzuigversie dient

u voor een gat voor de luchtafvoer te zorgen.

• We raden u aan een luchtafvoerbuis te gebruiken

met een diameter van 150. Het gebruik van een

reduceerelement zou de prestaties van het product

kunnen beperken en het lawaai kunnen doen

toeneme

Opmerking!

- Men raadt aan om iemand anders te vragen om

mee te helpen met de installatie van dit product.

Attentie!

• Voor u overgaat tot de montagehandelingen en om

de afzuigkap tevens beter te kunnen bedienen, opent

u de verpakking, pakt u de afzuigkap op en plaatst u

hem op een geschikt draagvlak (afb. 2a).

Open het paneel door druk uit te oefenen op het punt

aangegeven in afb. 2b.

Verwijder het aluminium paneel door aan het handvat

te trekken zoals aangegeven in afb. 2c. Als het

product is voorzien van actieve koolstoffilters

verwijdert u ze door de hendel naar buiten te trekken,

zoals aangegeven in afb. 2d.

• Montage van de kap

Het product wordt geassembleerd geleverd. Om het

te monteren volgt u de volgende handelingen uit:

- Verwijder de vier schroeven A, zoals aangegeven

in afb. 3.

- Scheid de draagstructuur van de romp door de