MicroMux

Multiplexer

USER’S GUIDE

Disclaimer: The following document is provided to assist users with the installation, operation

and training in the use of our products. This document and our products are intended to be used

by technically qualified personnel. Contained herein is information that is proprietary to Canary

Systems and may not be reproduced or copied in any form, nor disclosed to outside parties by

any means whether directly or indirectly, without the written consent of Canary Systems. This

document is subject to change without notice and Canary Systems assumes no responsibility for

errors, omissions or misinterpretation. Furthermore Canary Systems makes no warranty as to the

suitability of this information and/or products for any given application or use.

Copyright2009-2010 Canary Systems, Inc. All Rights Reserved.

Micromux_usersguide.doc Revision A, 02-10

75 Newport Road, Suite 211

New London, NH 03257 USA

e-mail: support@canarysystems.com

web: www.canarysystems.com

Canary Systems, Inc.

Voice: (603) 526-9800

Fax: (603) 526-9004

Table of Contents

Section 1 Introduction

1.1 Overview........................................................................................ 3

1.2 Specifications................................................................................. 3

Section 2 MultiMux Operation and Installation

2.1 Operation Details ........................................................................... 4

2.2 Datalogger Connection .................................................................. 5

2.3 Instrument Connection................................................................... 5

2.4 MultiLogger Software Configuration ............................................... 5

2.5 CR10X Program Example.............................................................. 6

2.6 CR1000 Program Example ............................................................ 7

2.7 Using the MicroMux with the VW Comm Module............................ 7

2.8 Enclosure Installation..................................................................... 9

2.9 Input Protection.............................................................................. 9

Section 3 Troubleshooting

3.1 Troubleshooting Flowchart............................................................. 10

Section 1

-

Introduction

3

1.1 Overview

The MicroMux expands the number of instruments that may be read by most all types of 5v/12v

dataloggers to 4 channels by 4 wire, or 8 channels by two wire, depending on the internal switch settings

and the type of sensor being read. In addition the MicroMux provides integral lightning protection by

utilizing plasma surge arrestors on the control lines. The MicroMux is provided in a panel mount

enclosure.

The MicroMux utilizes advanced high-reliability components such as terminal blocks from Phoenix

Contact, Panasonic relays and a flash microcontroller from Microchip Devices to help insure years of

reliable and trouble-free operation in most any environment (components are rated to standard long term

temp range of at least -40°C to +85°C). The use of low contact resistance relays means almost universal

instrument support, a high degree of lightning protection on the control lines, and virtually infinite channel

isolation.

Warranty is applicable for 2 years from date of shipment. Warranty does not cover failure by improper

installation, misuse, or by nature including, but not limited to; flood, lightning (by improper grounding), fire,

or other catastrophe. Should you encounter problems with your MicroMux, see section 3.1 for the

troubleshooting flowchart.

A diagram of the MicroMux terminal connections is shown below.

1.2 Specifications

General

Power requirements: 9-16 VDC (unregulated)

Quiescent current: < 0.1 µA (Mux Not Enabled)

Channel activated current (2-wire): 42mA

Channel activated current (4-wire): 42mA

Standby Current 1.2mA (Mux stepped past maximum channel)

Control line input impedance: <10KΩ

Control line input levels: 5V through 12V (16V Maximum input)

Transient protection: TVS & Spark Gap

Operating temperature: -40 to +85° C (-40 to +185° F)

Relays

Surge withstand between contacts and coil: 2500V

Breakdown voltage between contacts and coil: 1,500V

Initial contact resistance, max (By voltage drop 6V DC 1A): 75mΩ

Nominal switching capacity (resistive load): 2A 30V DC

Max switching current: 2A

Expected Mechanical Life (at 180cpm): 10

8

Cycles

Section 2

– Micro

Mux Operation and Installation

4

2

1

2

1

SELECTED

SELECTED

SELECTED

SELECTED

SELECTED

SELECTED

2.1 Operation Details

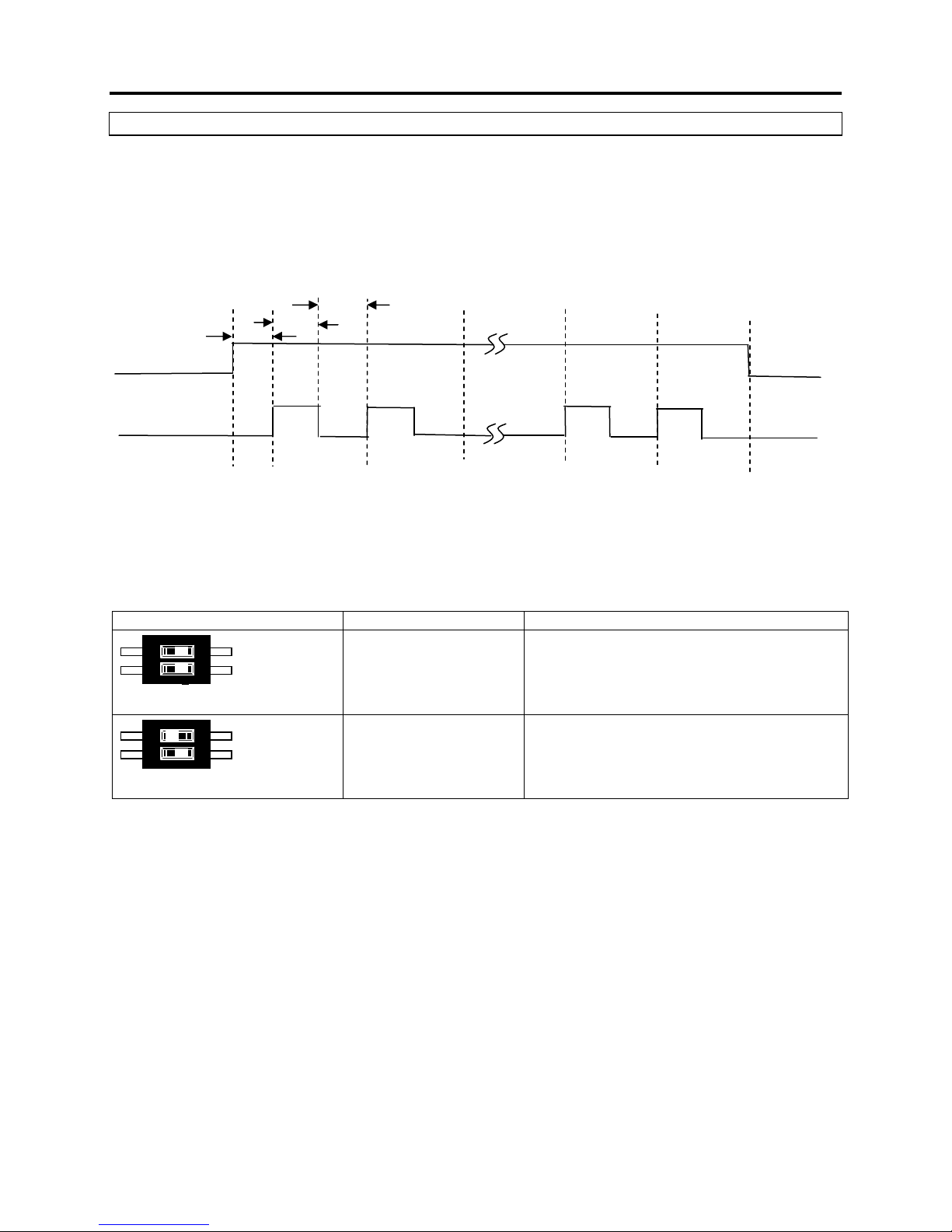

The MicroMux is controlled by the Datalogger Controller using 2 digital control signals. The operation of

the MicroMux is simple enough so that virtually any device capable of controlling 2 digital TTL/CMOS type

signals can be used to control the multiplexer. Generally speaking, the timing diagram depicted below

describes how the 2 digital signals are used to control the MicroMux.

NOTE: TIMING VALUES SHOWN ARE MINIMUM VALUES

2 mSec

50 mSec

2 mSec

ENABLE

CLOCK

NO CHANNEL

1

CHANNEL 1

2

CHANNEL 2

15

CHANNEL 15

16

CHANNEL 16

(DISABLED)

NO CHANNEL

In the case of the 4 or 8 channel modes, the maximum number of pulses to advance through all the

channels would be 4 and 8, respectively.

The channel switching mode is selected by configuring the DIP switch mounted on the MultiMux board.

The table shown below describes the 2 possible configurations.

DIP Settings Mode Description

4 Channel (Default)

(All set to “OFF”)

8 Channel

(SW1 set to “ON”)

8 CHANNEL

RESERVED

8 CHANNEL

RESERVED

O

N

O

N

Standard 4 channel mode for switching:

4-wire instruments (4 channel board)

8 channel mode for switching 2-wire

instruments

NOTE: Default Setting for MicroMux is 4 channel unless otherwise specified.

Section 2

– Micro

Mux Operation and Installation

5

2.2 Datalogger Connections

The MicroMux is connected to the Controller or MultiLogger Mux Terminal Board (or ML MUX TB) using

the screw terminals. The common screw terminal block is located on the left side of the terminal strip

The table below lists the connections for the screw terminal block:

MicroMux

4 Channel

MicroMux

8 Channel

Description 10-Pin

Bendix

(16/32

Mux Cable

(5 pair)

(4/8 board)

Mux Cable

(6 pair)

(48Ch board)

board)

1H 1H High side of CH1 A White Brown

1L 1L Low side of CH1 B White’s Black Brown’s Black

2H Not Used High side of CH2 C Red Red

2L Not Used Low side of CH2 D Red’s Black Red’s Black

S S Cable Shield K Shield Wires from

White & Red Pair

plus Overall

Shield Wires from

Brown & Red Pair

plus Overall

12V 12V Power F Yellow Yellow

G GND Ground G Yellow’s Black Yellow’s Black

EN EN Enable H Green Green

CLK CLK Clock J Green’s Black Green’s Black

2.3 Instrument Connection

The way instruments are connected to the MicroMux will vary slightly depending on the Mode selection

(section 2.1).

The following table illustrates typical connection techniques for each of the operating modes.

Mode Description Example

4 Channel

(4-wire)

INSTRUMENT #1

TEMPERATURE #1

H1

L1

H2

L2

H1

L1

H2

L2

8 Channel

(2-wire)

INSTRUMENT #2

2.4 MultiLogger Software Configuration

To configure MultiLogger to use the MicroMux select CAN

MicroMux as your multiplexer Model on the Configure |

Multiplexers form. Before the individual channels may be

edited you must select a Gage Type. Select either 4

Channels (default), 8 Channels to match the DIP switch

settings of the MicroMux.

If the VWDSP Interface is being used, be sure to select the

VWDSP Gage Type, as shown.

INSTRUMENT #1

H2

L2

H1

L1

H1

L1

H2

L2

Section 2

– Micro

Mux Operation and Installation

6

2.5 CR10X Program Example

The following example illustrates how to write custom programs for the CR10X to read instruments

connected to the MicroMux. The example assumes a 4 Channel Mode MultiMux reading 4 vibrating wire

gages and their respective thermistors.

The program example illustrates how measurements of instruments connected to the MicroMux are read,

it does not include instructions that would store the measurements for later retrieval. Consult the CR10X

Operators Manual for more information on storing measurements.

1: Set Port(s) (P20) ;Configure the control ports of the CR10/CR10X, C1=Enable, C8=Clock

1: 7999 C8..C5 = output/nc/nc/nc

2: 9994 C4..C1 = nc/nc/nc/10ms

2: Do (P86) ;Enable the MultiMux

1: 41 Set Port 1 High

3: Excitation with Delay (P22) ;50ms delay after enabling the MicroMux

1: 1 Ex Channel

2: 0 Delay W/Ex (units = 0.01 sec)

3: 5 Delay After Ex (units = 0.01 sec)

4: 0 mV Excitation

4: Beginning of Loop (P87)

1: 0 Delay

2: 4 Loop Count ;Total number of instruments

5: Do (P86) ;Advance the channel

1: 78 Pulse Port 8

6: Vibrating Wire (SE) (P28) ;Read the Vibrating Wire Gage

1: 1 Reps

2: 1 SE Channel

3: 1 Excite all reps w/Exchan 1

4: 20 Starting Freq. (units = 100 Hz)

5: 35 End Freq. (units = 100 Hz)

6: 250 No. of Cycles

7: 0 Rep Delay (units = 0.01 sec)

8: 1 -- Loc [ VWGage_1 ]

9: 1000 Mult

10: 0 Offset

7: Excite-Delay (SE) (P4) ;Read the Thermistor

1: 1 Reps

2: 5 2500 mV Slow Range

3: 2 SE Channel

4: 1 Excite all reps w/Exchan 1

5: 5 Delay (units 0.01 sec)

6: 2500 mV Excitation

7: 17 -- Loc [ VWTemp_1 ]

8: .001 Mult

9: 0 Offset

8: Polynomial (P55) ;Convert thermistor voltage to °C

1: 1 Reps

2: 17 -- X Loc [ VWTemp_1 ]

3: 17 -- F(X) Loc [ VWTemp_1 ]

4: -104.78 C0

5: 378.11 C1

6: -611.59 C2

7: 544.27 C3

8: -240.91 C4

9: 43.089 C5

9: End (P95) ;End of measurement loop

Section 2

– Micro

Mux Operation and Installation

7

2.6 CR1000 Program Example

'Enable our multiplexer

PortSet (1,1)

'Wait 100mSec for multiplexer to power up

Delay(0,100,MSEC)

'Cycle through 4 channels

For Channel = 1 TO 4

'Set Clock port high to advance mux channel

PortSet(8,1)

'Wait 10mSec for 50% duty cycle

Delay(0,10,MSEC)

'Set Clock port low

PortSet(8,0)

'Wait 10mSec for channel to settle

Delay(0,10,MSEC)

'Read our vibrating wire gage

VibratingWire(MuxChannel(),1,mV7_5,2,VX1,600,3600,500,-1,20000,500,0,1,0)

'Read our YSI44005 type thermistor

BrHalf(ScratchLoc(1),1,mV2500,2,VX1,1,2500,0,1000,250,2.5,0.0)

ScratchLoc(2) = ScratchLoc(1) / 5000

ScratchLoc(3) = (2.5 - (ScratchLoc(2)*1000) - ScratchLoc(1))/ScratchLoc(2)

MuxChannelTemp() = 1/(.0014051 + (.0002369*Log(ScratchLoc(3))) +

(.0000001019*(Log(ScratchLoc(3))^3))) - 273.2

'End of measurement loop

Next

'Disable our multiplexer

PortSet (1,0)

2.7 Using the MicroMux with the VW Comm Module

The VW Comm has built in instructions to directly control the MicroMux, MultiMux, or MiniMux. There are

specific gage types in Multilogger Software to configure the VW Comm to be connected to 4 or 8 sensors

through the MIcroMux. The VW Comm can be used with a radio, and MicroMux as a remote node for 4 or

8 instruments.

'Read vibrating wire gage using a VW Comm at address 0 using Mux channel MicroMux'on a

Digi radio at address 0129. Radio network must match base station

ScratchLoc(1) = -99999

ScratchLoc(2) = -99999

ScratchLoc(3) = -99999

ScratchLoc(4) = -99999

ScratchLoc(5) = -99999

ScratchLoc(6) = -99999

ScratchLoc(7) = -99999

ScratchLoc(8) = -99999

ScratchLoc(9) = -99999

ScratchLoc(10) = -99999

ScratchLoc(11) = -99999

ScratchLoc(12) = -99999

'Open our port

SerialOpen (Com1,9600,0,100,255)

'open COM1 - C1&C2

Delay(0,1000,mSec) 'must wait 1 second before AT Command mode

'Transmit ===, Receive OK (wait up to 10 seconds)

SerialOut (Com1,"===","OK",2,5000)

Delay(0,1000,mSec) 'must wait 1 second after AT Command mode

Section 2

– Micro

Mux Operation and Installation

8

'Transmit ATDTnn (where nn = radio address), Receive OK (up to 10 seconds)

SerialOut (Com1,"ATDT0129"+Chr(13),"OK",1,1000)

Delay(0,1000,mSec)

'Transmit ATCN, Receive OK (wait up to 10 seconds)

SerialOut (Com1,"ATCN"+Chr(13),"OK",1,1000)

'Wake up the VW Comm - Try for 5 seconds

ScratchLoc(1) = SerialOut (Com1,"0!","0",50,100)

'Check for valid response

if ScratchLoc(1) <> 0 then

'Send Set Digital Outputs command (Switch to Gage 1)

SerialOut (Com1,"0MM00!","00045",5,50)

'Send Set Up VW Start Freq, End Freq, command

SerialOut (Com1,"0M110400350002550500!","00045",5,50)

ScratchLoc(4)= FormatFloat(Channel, "%2g")

'Send Set Digital Outputs command (Switch to Gage 1)

SerialOut (Com1,"0MM0"+ScratchLoc(4)+"!","00045",5,50)

'Send Take Reading command

SerialOut (Com1,"0M!","00045",5,50)

SerialFlush(com1)

Delay(0,1500,mSec)

'Send Get Readings command

SerialOut (Com1,"0D0!","0",5,50)

'Receive response

SerialIn(sInBuf,Com1,100,CHR(13),75)

'Get length of response buffer

ScratchLoc(3) = Len(sInBuf)

if Len(sInBuf) >= 9 then

'Split out response values

Splitstr(ScratchLoc(4),sInBuf,"",12,0)

'Convert to reading - may be in Digits, Freq, or Period

mlReading=ScratchLoc(4)

Else

'No valid response

mlReading = -99999

EndIf

'Send Set Digital Outputs command (Switch back to Gage 1)

SerialOut (Com1,"0M6000!","00045",5,250)

Else

'No valid response

mlReading = -99998

EndIf

'Close our serial port

SerialClose(Com1)

Section 2

–

MultiMux Operation and Installation

9

2.8 Enclosure Installation

The MicroMux can be attached to any surface with 4 mounting 6-32 screws.

The placement of the mounting holes is depicted in the illustration below.

6 inches

www.canarysystems.com

Made in the U.S.A.

2 inches

CURRENT LIMIT: 2A 30VDC MAX

H1

6 inches = 15.2cm

2 inches = 5.1cm

COMMON

L1

H2

CHANNEL

VW

Gage

S

G

CLK

12V

L2

1H1

EN

CHANNEL

VW

Gage

1

2H1

1L1

1H2

1L2

CHANNEL

VW

Gage

2

3H1

2H2

2L2

2L1

Note: The Micromux can be installed

upside down, vertically, or horizontally.

CHANNEL

VW

VW

Gage

3

3L1

3H2

3L2

Gage

4

SHIELD

4H1

4L1

4H2

4L2

S

2.9 Input Protection

The MicroMux is equipped with lightning protection components on the control signals. As a result, care

must be exercised in the installation to maximize their effectiveness. Specifically, an effective earth

ground must be attached to the MicroMux shield (S) for proper protection. Most Vibrating wire instruments

also have lightning protection components.

The Enable and Clock inputs can be connected to 12 volts directly without damaging the MicroMux. The

connections to the datalogger should be disconnected and insulated from contacting other electrical

connections. The 12V tolerant inputs allow the MicroMux to be field tested without the need for a

datalogger connection. The enable can be wired to the 12V input while the clock input can be touched to

12V. This action will cause the MicroMux to step channels for each touch to 12 volts.

MicroMux4

Section 3

–

Troubleshooting

10

wiring correct for the

wiring?

water or other

3.1 Troubleshooting Flowchart

If you cannot obtain readings using the MicroMux or the readings are unstable then see the

troubleshooting flowchart below for help in determining the nature of the problem.

Start

Does the MicroMux

advance through the

channels?

Yes

Are the switched leads

connected?

Yes

Is the

sensor leads?

Yes

Do the

software settings match

the sensor type and

No

No

No

No

Connect the leads

Adjust the wiring for the

type of sensor used

Note: See the MultiSensor

Interface User's Guide or

MultiLogger Software

User's Guide for wiring

diagrams.

Adjust the software

settings

Is 12V and G

connected to the

MicroMux?

Yes

Are the Enable and

Clock lines connected

to the control ports?

Yes

Do the software

settings for the Enable

and Clock lines match

the connections?

No

No

No

Attach 12V and G

Attach Enable & Clock

Match software and digital

I/O connections

lines

Yes

Is there a source of

electrical noise nearby?

No

Do the

circuit boards show

contamination?

No

Call Canary Systems for

further assistance

Yes

Yes

Remove the noise source

or move the MicroMux

Clean the circuit boards

Yes

Loading...

Loading...