Page 1

Device manual

Encoder

with CANopen interface

RM7

RN7

UK

706362/02 11/2020

Page 2

CANopen encoder

Contents

1 Preliminary note � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�1 Symbols used� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

1�2 Warning signs used � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

2 Safety instructions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

3 General information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3�1 CANopen technology � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3�1�1 Supported operating modes� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

3�2 References � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

4 Functions and features � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5 Electrical connection� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

5�1 Bus connection� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

5�2 Setting the node number in the terminal cap � � � � � � � � � � � � � � � � � � � � � � � 8

5�3 Protocol definition � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

5�4 Baud rate setting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

6 Installation of the encoder� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

6�1 Settings of the encoder � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

6�2 Signal assignment � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

6�3 Setting of the node number � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

6�3�1 Setting of the node number via SDO objects� � � � � � � � � � � � � � � � � � 10

6�3�2 Setting of the baud rate via SDO objects� � � � � � � � � � � � � � � � � � � � � 10

6�3�3 Setting the node number and the baud rate via LSS� � � � � � � � � � � � 10

6�3�4 Bus termination � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

6�4 LED indications � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

7 Configuration � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

7�1 Operating modes � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

7�1�1 General information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

7�1�2 Preoperational mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �11

7�1�3 Start-operational mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

7�1�4 Start/stop mode � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

7�1�5 Reinitialisation of the encoder � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 12

7�2 Standard operation (CAN transmission modes)� � � � � � � � � � � � � � � � � � � � 12

7�3 Storing parameters� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

7�3�1 Object directory � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

7�3�2 Saving process � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 13

7�3�3 Storing without reset � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

7�3�4 Storing with reset � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

7�3�5 Restoring the parameters � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

7�3�6 Layer Setting Service (LSS)� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

8 Programmable parameters� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

8�1 Object directory � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

8�2 Programming example: preset value � � � � � � � � � � � � � � � � � � � � � � � � � � � � 15

2

Page 3

CANopen encoder

8�2�1 Set preset value (master to encoder with node number 1) � � � � � � � 15

8�3 Communication-specific objects of the DS301 from 1000h to 1FFFh

(communication profile DS301 V4�02) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 16

8�4 Manufacturer-specific objects from 2000h to 5FFFh � � � � � � � � � � � � � � � � 22

8�5 Device-profile-specific objects from 6000h to 9FFFF� � � � � � � � � � � � � � � � 26

9 Terms and abbreviations� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 33

UK

3

Page 4

CANopen encoder

1 Preliminary note

1.1 Symbols used

► Instruction

> Reaction, result

[…] Designation of pushbuttons, buttons or indications

→ Cross-reference

Important note

Non-compliance can result in malfunction or interference�

Information

Supplementary note

1.2 Warning signs used

NOTE

Warning of damage to property�

2 Safety instructions

These instructions are part of the device� They contain information and illustrations

about the correct handling of the device and must be read before installation or

use�

Observe the operating instructions�

Non-observance of the instructions, operation which is not in accordance with use

as prescribed below, wrong installation or incorrect handling can affect the safety

of operators and machinery�

The installation and connection must comply with the applicable national and

international standards� Responsibility lies with the person installing the unit�

Only the signals indicated in the technical data or on the device label may be

supplied to the connections or wires�

4

Page 5

CANopen encoder

3 General information

3.1 CANopen technology

The CANopen communication profile is based on the CAN Application Layer (CAL)

specification of the CiA organisation� CANopen is considered as a robust fieldbus

with highly flexible configuration options� It is used in many various applications

which are based on different application profiles� CANopen comprises a concept to

configure and communicate real-time data using synchronous and asynchronous

messages� Four message types (objects) are distinguished�

1� Administration messages (layer management, network management and

identifier distribution)

2� Service Data Objects (SDO)

3� Process Data Objects (PDO)

4� Predefined Objects (synchronisation, time stamp, emergency)

For further information please refer to the CiA-CAN specification (CiA 406 encoders, CiA 301 - CANopen)�

3.1.1 Supported operating modes

Encoders with CANopen interface support the following operating modes:

● RTR (request)

The position value is only given to the bus on request�

● EVENT time

The position value is given to the bus cyclically (interval can be set)�

● Cyclical-synchronous

When the sync telegram has been received by the host, the absolute encoder

transmits the current process value� A sync counter can be programmed so that

the encoder does not send before a defined number of sync telegrams�

In addition other functions can be configured (direction of rotation, resolution etc�)�

UK

3.2 References

http://www�can-cia�org

CAN Application Layer, DS 201 …207 CiA

LSS profile DS305 CiA

CAL-based communication profile, DS 301 CiA

Device profile for encoders DS 406 CiA

CAN specification version 2�0 A Robert Bosch GmbH

CANary CAN controller Atmel

5

Page 6

CANopen encoder

4 Functions and features

● There are 1 SDO server and 2 default value PDOs according to CiA DS 301�

The PDO mapping can be changed (dynamic PDO mapping)� The default value

identifiers have been assigned according to the "predefined connection set" in

the CANopen specification�

● The COB IDs of the PDOs and their baud rate can be configured�

● The module expects a sync object� The CAN identifier of the sync object can

be configured�

● The module supports "node guarding" and "heartbeat"�

● The module supports an emergency object� The COB ID of the EMCY object

can be configured�

● The module stores the last error� The error code of the corresponding

emergency object is stored�

● The module supports the load command (reset function to restore the factory

settings)�

● Alarms and warnings are not displayed�

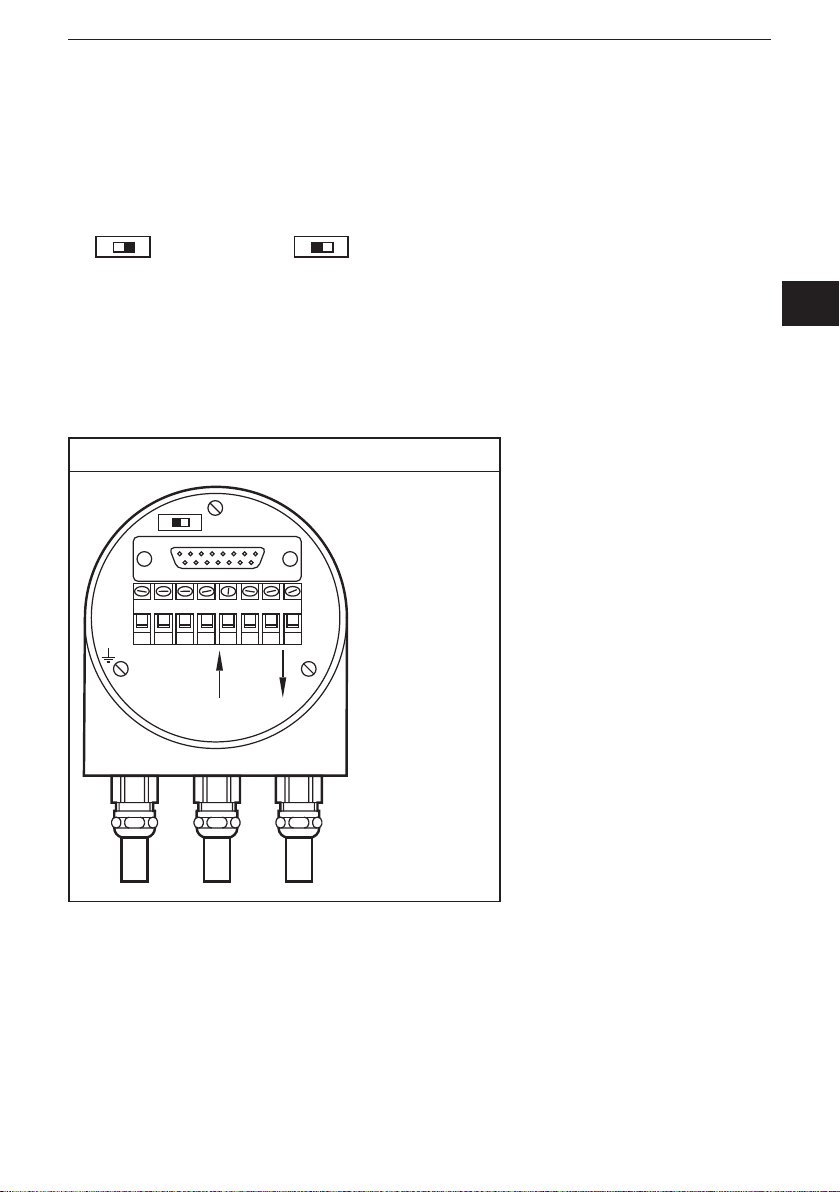

5 Electrical connection

The encoder is connected with two or three cables depending on whether the

power supply is integrated into the bus cable or connected separately� If the power

supply is integrated into the bus cable, one of the cable glands can be fitted with a

plug� The cable glands are suitable for cable diameters from 6�5 up to 9 mm�

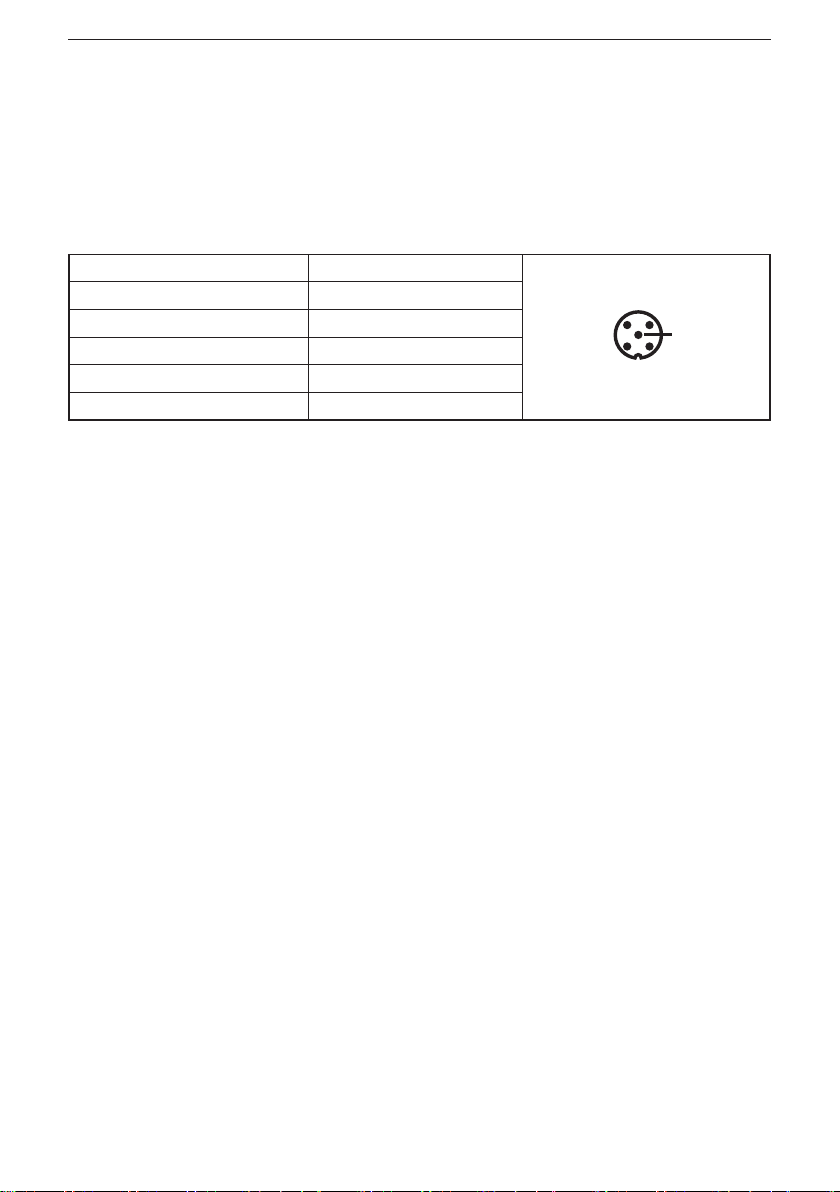

Terminal Description

┴ Ground

+ 24 V voltage supply

- 0 V voltage supply

G CAN Ground

L CAN low

H CAN high

G* CAN Ground

L* CAN low

H* CAN high

* are not connected, if the terminal resistor is

ON

6

On

R

0

1

9

2

8

3

7

4

6

5

Bd x1x10

T

LG H G HL+ -

0

0

1

1

9

9

2

2

8

8

3

3

7

7

4

4

6

6

5

5

Page 7

CANopen encoder

The terminal cap contains a resistor which can be activated as terminating resistor

if necessary� The resistor is to be switched to ON at the ends of the bus line in the

device�

Participant X Last participant

R

On

T

R

On

T

Terminating resistor RT (resistor termination)

5.1 Bus connection

The terminal cap fulfils the function of a T-coupler� From there the wiring must be

done according to the drawing on the left side�

► Observe the assignment of the incoming and outgoing bus signals�

Terminal cap bus In and bus Out

R

T

On

LG H G HL+ -

UK

Bus In Bus Out

7

Page 8

CANopen encoder

5.2 Setting the node number in the terminal cap

► To set the node number remove the terminal cap for the installation�

► Loosen both screws on the back of the encoder�

► Do not damage the seal since otherwise the protection rating will be lost�

The setting is done via coding switches: 0��9 (x1) or 10��90 (x10)�

0

1

9

8

7

2

3

4

6

5

0

1

9

8

7

2

3

4

6

5

0

1

9

8

7

2

3

4

6

5

Bd x1x10

Internally, 1 is always added to the node number to avoid setting of the node

number 0�

Example: The node number 10 has to be set via the coding switch with 0 9�

BCD-coded encoder (binary coded decimal number)

Device address 0���89

x1 Set the CAN-node number

x10 Address reserved 90…99

xBd Set the baud rate

5.3 Protocol definition

x1 Device address 97

x10 Address reserved

x1 Device address 98

x10 Protocol selection according to DS301-V3

x1 Device address 99

x10 Protocol selection according to DS301-V4

8

Page 9

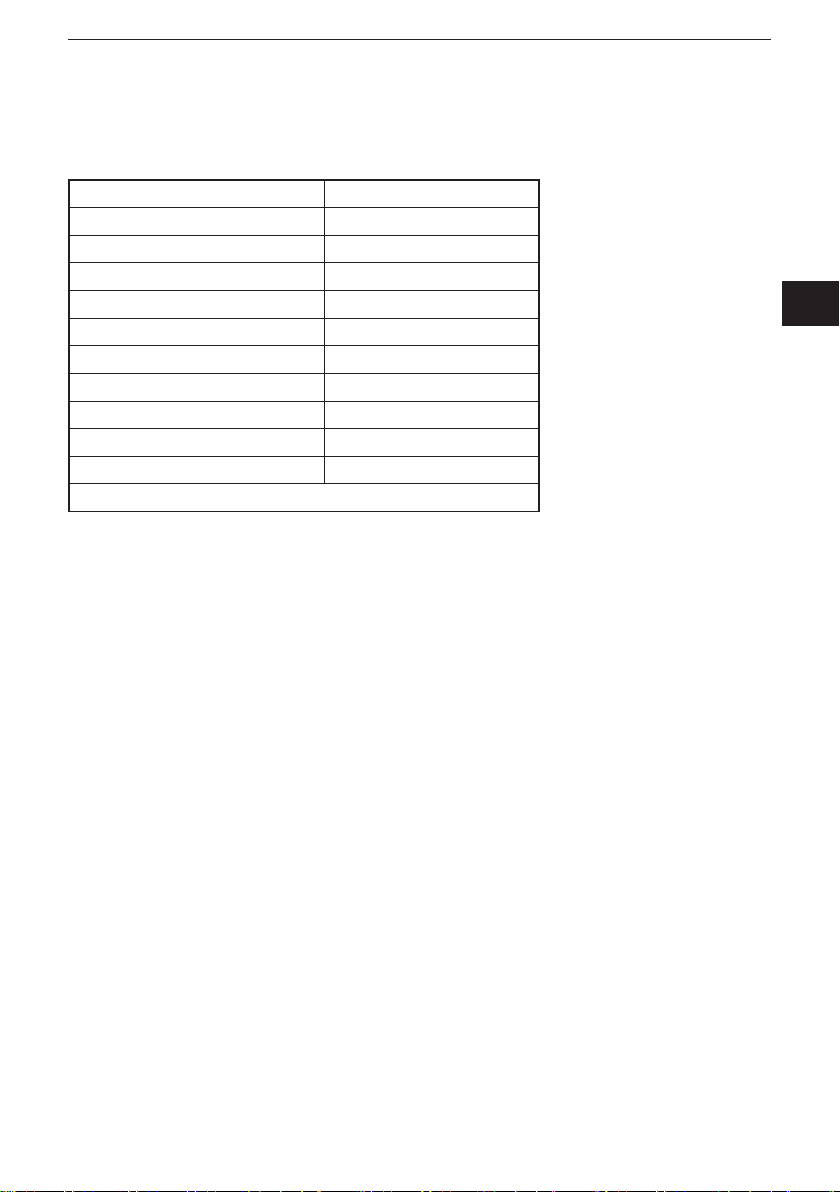

5.4 Baud rate setting

Setting is done via baud rate switch (Bd)�

The following baud rates are adjustable:

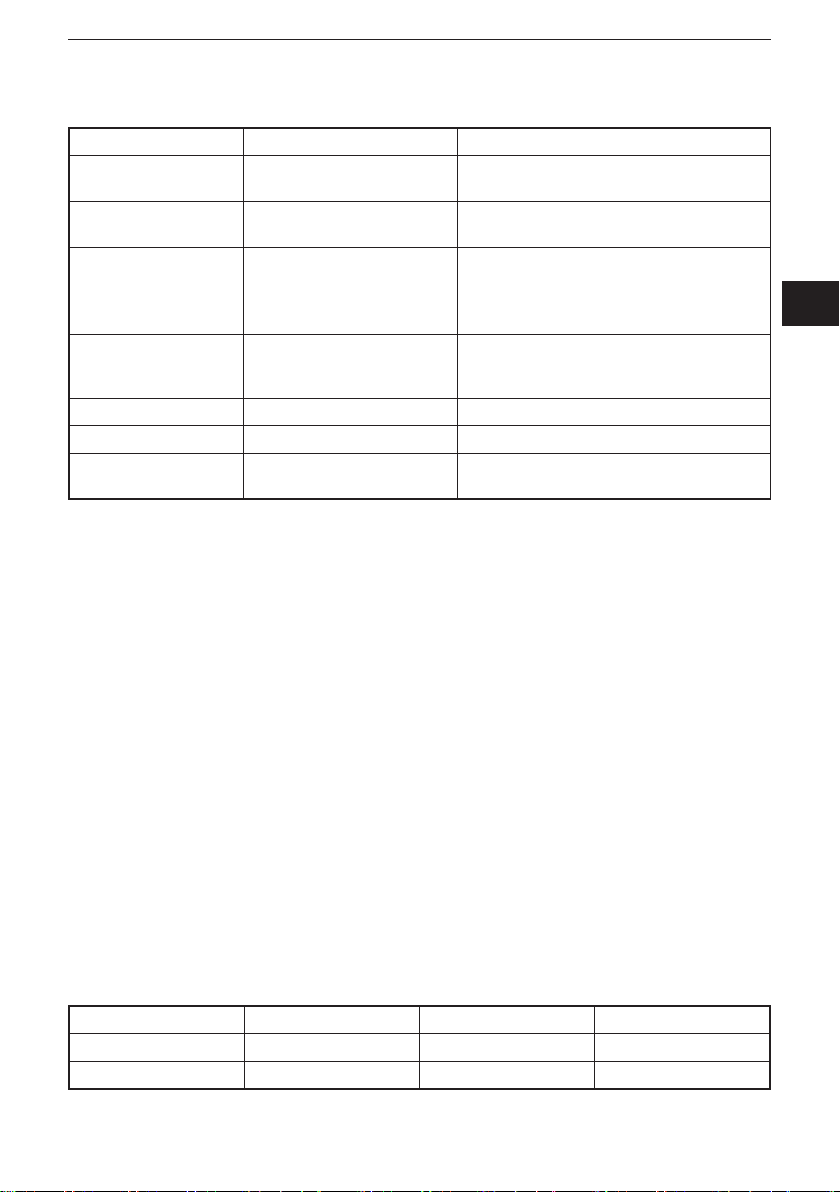

Baud rate in kBit/s BCD rotary switch

20 0

50 1

100 2

125 3

250 4

500 5

800 6

1000 7

Reserved 8

Sets the SDO mode* 9

* SCO service data objects

CANopen encoder

UK

9

Page 10

CANopen encoder

6 Installation of the encoder

6.1 Settings of the encoder

► Set the node address of the encoder, the baud rate and the bus termination

before set-up of the device via software�

6.2 Signal assignment

Signal 5-pole M12 connector

CAN GND pin 1

24 V supply voltage pin 2

GND (PE) pin 3

CAN high pin 4

CAN low pin 5

► Use screened cable�

6.3 Setting of the node number

6.3.1 Setting of the node number via SDO objects

For devices without terminal cap the address can only be set via SDO objects� The

address of an encoder without terminal cap is set to 32 as standard� Details on

changing the node number → chapter 7.4.

6.3.2 Setting of the baud rate via SDO objects.

For devices without terminal cap the baud rate can only be changed via SDO

objects� The baud rate is set to 125 Kbits/s as default value� Details on changing

the baud rate → chapter 7.4.

6.3.3 Setting the node number and the baud rate via LSS

Another possibility of how to set the node number and the baud rate for encoders

is Layer Setting Services. Further information → chapter 6.3.6.

6.3.4 Bus termination

If the encoder is the last participant, an external terminating resistor or a

terminating T connector has to be used�

10

Page 11

CANopen encoder

6.4 LED indications

LED Status Description

red flashes, 1 Hz operating voltage OK,

red lights "BUS OFF" caused e�g� by short circuit, wire

green flashes, 2�5 Hz master failure,

green/red green flashing, 2�5 Hz

green flashes, 1 Hz bus stopped

green lights operating voltage OK, bus connection OK

green/red green lights/

and red flashing 1x at each 3rd

pulse of the green LED

red flashing, 2�5 Hz

faulty bus connection

break, faulty connector

encoder remains in the preoperational

operating status

> guard and heartbeat error are not indicated

guarding error, either node guard or heartbeat

non reproducible indication (no clear

description of the indication)

7 Configuration

This chapter describes the configuration of the parameters of an absolute encoder

with CANopen interface�

UK

7.1 Operating modes

7.1.1 General information

In the preoperational mode the encoder replies to the CAN bus after sending its

boot up message�

Boot up message: 700 hex + node number (further details in the Communication

Profile chapter 7�3�)

► Change parameters only in the preoperational mode�

This mode decreases the bus load and simplifies the control of the messages sent

and received� It is not possible to send or receive PDO messages in this mode�

7.1.2 Preoperational mode

To set the encoder to the preoperational mode, the master must send the following

message:

Identifier Byte 0 Byte 1 Description

0 h 80 h 00 NMT PreOp, all nodes

0 h 80 h NN NMT PreOp, NN

NN: node number

11

Page 12

CANopen encoder

It is possible to set all nodes (byte 1 = 0) or individual nodes (byte 1 NN) to the

preoperational mode�

7.1.3 Start-operational mode

To set the encoder to the operational mode, the master must send the following

message:

Identifier Byte 0 Byte 1 Description

0 h 01 h 00 NMT start, all nodes

0 h 01 h NN NMT start, NN

NN: node number

It is possible to set all nodes (byte 1 = 0) or individual nodes (byte 1 NN) to the

operational mode�

7.1.4 Start/stop mode

To set the encoder to the stop mode, the master must send the following message:

Identifier Byte 0 Byte 1 Description

0 h 02 h 00 NMT stop, all nodes

0 h 02 h NN NMT stop, NN

NN: node number

It is possible to set all nodes (byte 1 = 0) or individual nodes (byte 1 NN) to the

stop mode�

7.1.5 Reinitialisation of the encoder

► Carry out reinitialisation in the event of incorrect function�

Identifier Byte 0 Byte 1 Description

0 h 81 h 00 reset all nodes

0 h 81 h NN reset node

NN: node number

It is possible to reset all nodes (byte 1 = 0) or individual nodes (byte 1 NN)� After

reinitialisation the device replies again in the preoperational mode�

7.2 Standard operation (CAN transmission modes)

RTR mode The connected host requests the current position value via a remote

EVENT time The absolute encoder cyclically sends the current position value -

12

transmission request telegram� The encoder reads the current position,

sets off set parameters (if applicable) and returns the position value via

the same CAN identifier�

without any request by the host� The cycle time can be programmed in

milliseconds for values between 1 ms and 65536 ms�

Page 13

CANopen encoder

Sync Mode When the sync telegram has been received by the host, the encoder

transmits the current process value� If several nodes reply to the sync

telegram, the individual nodes report one after the other according to

their CAN identifier� The programming of an offset time is not necessary�

A sync counter can be programmed so that the encoder does not send

before a defined number of sync telegrams�

7.3 Storing parameters

7.3.1 Object directory

Object Index Object description

1005h COB ID Sync

100Ch guard time

100Dh life time factor

1016h consumer heartbeat time

1017h producer heartbeat time

1020h verify configuration

1800h communication parameter PDO 1

1801h communication parameter PDO 2

1A00h transmit PDO1 mapping parameter

1A01h transmit PDO2 mapping parameter

2100h operating parameters

2101h resolution per revolution

2102h total resolution

2103h preset value

2104h limit switch, min�

2105h limit switch, max�

2160h customer storage

2200h cyclic timer

3000h node number (NN)

3001h baud rate

6000h operating parameter

6001h steps per revolution

6002h total resolution

6003h preset value

6200h EVENT

UK

7.3.2 Saving process

The parameters are stored in a non-volatile EEPROM� The changes made are

stored in the working memory of the encoder� Once all parameters have been

checked, they can be transferred to the EEPROM in a write cycle�

13

Page 14

CANopen encoder

The stored parameters are activated after a reset (power on, NMT reset)�

7.3.3 Storing without reset

Once the saving process is completed by using the object 1010, there will be no

automatic reset to activate the parameters�

7.3.4 Storing with reset

The object 2300 from the manufacturer-specific directory carries out storage via an

automatic reset� The parameters become active at once� This has to be taken into

account when the node number or the baud rate are changed since there may be

interference on the bus�

7.3.5 Restoring the parameters

The factory-set parameters can be restored� The settings stored in the EEPROM

are not overwritten� Only after the storage command has been sent again will the

default settings be stored in the EEPROM non-volatilely� The restored parameters

are identical for each CANopen encoder of this type and may possibly not

correspond to the original parameters� Please check the restored parameters with

regard to their validity before you perform the storage process again�

7.3.6 Layer Setting Service (LSS)

To configure the encoder via LSS, the encoder is handled like a slave� The

controller must have LSS master functionality� The LSS master device requests

the data of the encoder� The LSS master enquires the LSS information (vendor ID;

product code, revision number, serial number) of the slave� In this case the slave

is unambiguously recognised and the settings, node number and baud rate can be

set�

8 Programmable parameters

The objects are based on the device profile CiA 406 DS V3�2: CANopen profile for

encoders (www�can-cia�org)

Detailed description of the command byte

Command Data length Data type

43h 4 bytes unsigned 32

47h byte 3 unsigned 24

4Bh byte 2 unsigned 16

4Fh 1 byte unsigned 8

23h 4 bytes unsigned 32

27h byte 3 unsigned 24

14

Page 15

CANopen encoder

Command Data length Data type

2Bh byte 2 unsigned 16

2Fh 1 byte unsigned 8

8.1 Object directory

Data is transferred according to CAL exclusively via object-oriented message

telegrams� These objects are classified into groups via an index register� Each

index entry can be further subdivided via a sub index� The complete overview of

the standard object directory is shown in the following table�

Index (hex) Object

0000 not used

0001-001F static data types

0020-003F complex data types

0040-005F manufacturer-specific data types

0060-0FFF reserved

1000-1FFF area of the communication profile

2000-5FFF manufacturer-specific area

6000-9FFF device-specific area

A000-FFFF reserved

UK

8.2 Programming example: preset value

The receipt of the SDO answer is to be monitored in the program since the request

is sent permanently without confirmation of receipt�

If a CANopen device is connected to the bus and configured with correct baud rate

and node number, it replies to the bus with a boot up message�

8.2.1 Set preset value (master to encoder with node number 1)

Set preset value (value 1000)

Identifier DLC Command Index Sub index Service data

NN 1 download 6003h byte 4 byte 5 byte 6 byte 7

601 8 23h 03h 60h 00h 00h 10h 00h 00h

Response from the encoder

Identifier DLC Command Index Sub index Service data

NN 1 download 6003h byte 4 byte 5 byte 6 byte 7

581 8 60h 03h 60h 00h 00h 00h 00h 00h

15

Page 16

CANopen encoder

Read preset value from the encoder

Identifier DLC Command Index Subindex Service data

NN 1 download 6003h byte 4 byte 5 byte 6 byte 7

601 8 40h 03h 60h 00h 00h 00h 00h 00h

Response from the encoder

Identifier DLC Command Index Sub index Service data

NN 1 download 6003h byte 4 byte 5 byte 6 byte 7

581 8 43h 03h 60h 00h 00h 10h 00h 00h

Non-volatile storage of the preset value

Identifier DLC Command Index Sub index Service data

NN 1 download 1010h byte 4 byte 5 byte 6 byte 7

601 8 23h 10h 10h 01h 73h 61h 76h 65h

Response from the encoder

Identifier DLC Command Index Sub index Service data

NN 1 download 6003h byte 4 byte 5 byte 6 byte 7

581 8 60h 10h 10h 00h 00h 00h 00h 00h

8.3 Communication-specific objects of the DS301 from 1000h to 1FFFh (communication profile DS301 V4.02)

Index S-Idx Name Type,

1000 0 Device type u32, ro N/A Device type and device profile

1001 0 Error register u8, ro N/A Indication internal device error

1003 0 Pre-defined

error field

1���10 Error history u32, ro S-Idx 1 last error

1005 0 COB ID sync

object

16

access

u8, ro 0 An error list with 10 entries is supported

u32, rw 80h The object contains the identifier for the

default value Description

0b 0000 0000 generic error

S-Idx 2 second but last error

����������

Deleting the error memory

The error memory is deleted by writing a

zero to the sub index 0�

SYNC object�

Page 17

CANopen encoder

Index S-Idx Name Type,

1006 0 Com cycle

period

1007 0 Synchronous

window length

1008 0 Manufacturer

device name

1009 0 Manufacturer

hardware

version

100A 0 Manufacturer

software

version

100C 0 Guard time u16, rw 0 This object contains the 'guard time' in

100D 0 Life time factor u8, rw 0 This object contains the life time factor

1010 Store

parameters

0 Number of sub

indices

1 Store all

parameters

access

u32, rw 0h The object defines the communication

u32, rw 0h The object contains the sync windows

str, ro RM9000 Device designation

str, ro x�x Hardware version

str, ro x�x Software version

u8, ro 1

u32, rw "save" To write the parameters to the non-

default value Description

cycle (SYNC producer) in μs (max. time

between 2 sync objects)�

length for synchronous PDOs in μs.

milliseconds�

parameter� The life time factor multiplied

with the guard time results in the life time

for the guarding protocol�

This object is used to write the

parameters to the non-volatile memory�

volatile memory the word "save" has to

be sent to the corresponding node�

UK

ASCII e v a s

Hex value 65h 76h 61h 73h

1011 Restore

parameters

0 Number of sub

indices

1 Restore all

parameters

Most significant word Least significant word

The object is used to restore the factory

settings�

u8, ro 1

u32, rw "load" To restore the factory settings the

word "load" has to be sent to the

corresponding node� When the

parameters have been restored, please

check the parameters before the store

command is executed again� The

restored parameters only become active

after a reset or power up�

17

Page 18

CANopen encoder

Index S-Idx Name Type,

ASCII d a o l

Hex value 64h 61h 6Fh 6Ch

Index S-Idx Name Type,

1012 0 COB ID time

stamp object

1013 0 High resolution

time stamp

1014 0 COB ID

emergency

object

1016 Consumer

heartbeat time

0 Number of sub

indices

1 Consumer

heartbeat time

The contents of the sub index 1 is composed as follows:

Bit 31 to 24 23 to 16 15 to 0

value 0h (reserved) address of the

access

Most significant word Least significant word

access

u32, rw 100h The object contains the COB ID of the

u32, rw 0 The object contains a time stamp with a

u32, rw 80h + node ID The object contains the EMCY

u8, ro 1

u32, rw 0

default value Description

default value Description

time stamp object�

resolution of 1 µs�

emergency message identifier�

The consumer heartbeat time defines the

heartbeat cycle time to be expected in

ms� The encoder can only monitor one

device� When the time is set to zero, this

service is not activated� The set time

must be higher than the corresponding

time (object 1017) of the device to be

monitored�

device to be

monitored

monitoring time

(ms)

1017 0 Producer

heartbeat time

18

u16, rw 0 This object contains the time interval in

milliseconds during which it has to send

the message�

Page 19

CANopen encoder

Index S-Idx Name Type,

1018 Identity object This object contains the device

0 Number of

entries

1 Vendor ID u32, ro 0x0069666D

2 Product code u32, ro 0x43 0x41

3 Revision

number

4 Serial number u32, ro see type label

1020 Verify

configuration

0h Number of

entries

1h Configuration

date

2h Configuration

time

1029 Error behaviour The object shows the error behaviour�

0h Number of

entries

1h Communication

error

1800 1st transmit

PDO

communication

parameter

0 Number of sub

indices

1 COB ID u32, rw 180h +

2 Transmission

mode

3 Inhibit time u32, rw 0

4 not available

5 Event timer u32, rw 0x64 or 0

access

u8, ro 1

u32, ro 0x10000

u8, ro 2h

u32, rw 0x0

u32, rw 0x0

u8, ro 1h

u8, rw 0x0

u8, ro 5

u8, rw FE

default value Description

information

The object indexes the loaded

configuration, date and time�

This object contains the communication

parameters of the first transmit PDO�

node number

UK

19

Page 20

CANopen encoder

Index S-Idx Name Type,

1801 2nd transmit

PDO

communication

parameter

0 Number of sub

indices

1 COB ID u32, rw 280h

2 Transmission

mode

3 Transmission

mode

4 not available

5 Event timer u32, rw 1

The transmission mode is set and configured as follows:

Value

(decimal)

0 x x Transmit PDO to first

1���240 x x Transmit PDO every xth

241���251 reserved

252 x x Receive SYNC message

253 x Data update and transmit

254, 255 x Transmit PDO with event

Cyclical Acyclical Synchro-

access

u8, ro 5

u8, rw 1

u32, rw 0

default value Description

node number

Transmission mode

nous

The object contains the communication

parameters of the second transmit PDO�

Please note! This object is only activated

with C6 CANopen encoders�

Asynchronous

Only

RTR

Description

sync messsage after an

event

sync message

and transmit PDO on

remote request

PDO on remote request

Inhibit time

For "transmit PDOs"� The "inhibit time" for PDO transmissions can be set as a

16-bit value� If data changes, the PDO checks if the inhibit time has elapsed since

its last data transmission� Another data transmission is only possible once the

inhibit time has elapsed� It is useful to set a time with asynchronous transmission

(transmission modes 254 and 255) to avoid overlaods on the bus�

Event time

The "event timer" only works in asynchronous transmission modes (transmission

modes 254 and 255)� If the data changes before the event timer elapses, a

temporary telegram is sent� If the value of the timer is >0, the data will be sent

20

Page 21

CANopen encoder

after the timer has elapsed� The value of the timer is written in subindex 5 of the

respective PDO� The data is also transferred without any changes to the data� The

value range is between 1-65536 ms�

Index S-Idx Name Type,

1A00 1st transmit

PDO mapping

parameter

0 Number of sub

indices

1 1st mapped

object

1A01 2nd transmit

PDO mapping

parameter

0 Number of sub

indices

1 2nd mapped

object

1F50 Download

program area

0h Number of sub

indices

1h Domain,

1F51 Program

Control

0h Number of

program control

entries

1h u32, rw The sub index 1h and higher verifies

access

u8, ro 2

u32, rw -

u8, ro 2

u32, rw -

u8, ro 2h

wo

u8, ro

default value Description

The object contains the mapping

parameters of the 1st transmit PDO

The object contains the mapping

parameters of the 2nd transmit PDO�

This is a special object for the boot

loader functionality�

Use this entry to read the Intel hex file

with the program data� For detailed

information about the domain download

and the block transfer see CiA Draft

Standard 301 application layer and

communication profile�

This is a special bootloader object to

update the firmware�

This data area controls the program in

the index 0X1F50�

the storage block functionality� They can

have the following values:

write:

1 - start downloading the program

4 - delete flash memory

UK

21

Page 22

CANopen encoder

8.4 Manufacturer-specific objects from 2000h to 5FFFh

Index S-Idx Name Type,

2000 0 Position value u32, ro

2100 0 Operating

parameters

access

u16, rw 0h The counting direction of the encoder as

default value Description

an operating parameter can be changed

and the two limit switches can be switched

on or off�

The parameter counting direction

(complement) determines the counting

direction of the encoder� With the same

direction of rotation the value can be

indicated either adding or substracting�

The counting direction is set by bit 0 of the

object to 2100h� In addition the two limit

switches can be switched on or off� Bit 1

and bit 2 are used for this purpose�

Note: The counting direction is always

seen looking at the shaft� With clockwise

direction of the shaft (CW) the counting

direction is increasing�

Calculation example:

Goal: encoder with counting direction

decreasing (CCW) and both limit switches

off

Bit matrix:

bit 0 = 1 direction decreasing (CCW)

bit 1 = 0 limit switch min� disabled

bit 2 = 0 limit switch max�disabled

result = 01h

2101 0 Resolution per

revolution

0 Resolution per

revolution

22

u16, rw Requested steps per revolution

(single turn resolution up to 13 bits)

u32, rw Requested steps per revolution

(single turn resolution > 13 bits)

If the requested resolution per revolution

exceeds the physical resolution, the set

value is not transmitted�

► Set correct resolution�

Page 23

CANopen encoder

Index S-Idx Name Type,

2102 0 Total

2103 0 Preset value u32, rw 0 The preset value is a position value which

2104 0 Limit switch,

The limit switch (min) sets bit 30 = 1 with the next telegram transmitted when the set position value

has been reached or fallen below�

resolution

min�

access

u32, rw 0x1000000 Total resolution of the encoder

u32, rw 0 Two position vaues can be programmed as

default value Description

This parameter is used to set the

requested total resolution� The parameter

must not exceed the physical measuring

range of the encoder� The total resolution

and the resolution per revolution must be

entered using the following formula:

GA = (PGA x AU) / PAU

PGA

total physical resolution of the encoder

(see type label)

PAU

physical resolution per revolution of the

enocder (see type label)

GA

total resolution (customer-specific)

AU

resolution per revolution (customerspecific)

If the requested total resolution is lower

than the total physical resolution, the total

resolution parameter must be a multiple of

the physical resolution per revolution�

is to be indicated at a certain physical

position of the axis� The preset value must

not exceed the total physical resolution to

avoid runtime errors�

limit switch positions� When one of these

values has been reached, one of the 32-bit

position values is set� Both values must not

exceed the total physical resolution of the

encoder to avoid runtime errors�

UK

Function Status bit Process value

Bit 31 30 29 28 27 26 25�����0

0 1 X X X X X

23

Page 24

CANopen encoder

Index S-Idx Name Type,

2105 0 Limit switch,

max�

The limit switch (max) sets bit 31 = 1 with the next telegram transmitted when the set position

value has been reached or fallen below�

Function Status bit Process value

Bit 31 30 29 28 27 26 25�����0

1 0 X X X X X

2160 Customer

storage

0h Number of sub

indices

1h Customer

storage 1

2h Customer

storage 2

3h Customer

storage 3

4h Customer

storage 4

2200 0 Cyclic timer

PDO

2300 0 Save

parameter with

reset

3000 0 Node number u8, rw - The object contains the node number of

3001 0 Baud rate u8, rw 0x3 The object contains the baud rate of the

access

u32, rw 0 Two position vaues can be programmed as

u8, rw 4h The object enables the user to store any

u32, rw 0x0

u32, rw 0x0

u32, rw 0x0

u32, rw 0x0

u32, rw 0x0

u16, ro 0 The object contains the value of the event

u32, wo 55AAAA55h With this object the set parameters can be

default value Description

limit switch positions� When one of these

values has been reached, one of the 32-bit

position values is set� Both values must not

exceed the total physical resolution of the

encoder to avoid runtime errors�

value�

timer in ms�

written to the non-volatile memory� After

successful transmission of the access code

a reset will be made�

the device�

The node number must be ≠ 0.

► Always add a 1 to the node number�

Example: 1Fh+1h = 20h = 32 (dec)

device�

24

Page 25

CANopen encoder

Index S-Idx Name Type,

Eight different baud rates are supported� Only one byte is used to set the baud rate�

Baud rate

[kbits/s]

20 0x00

50 0x01

100 0x02

125 0x03

250 0x04

500 0x05

800 0x06

1000 0x07

3010 Speed control Speed measurement, the measurement is

0h Number of sub

indices

1h Enable speed u8, rw 0h

2h Speed mode u8, rw 0h Via this sub-index the filter interval

access

Byte

u8, ro 2h

default value Description

switched off in the factory setting�

and thus the latency time of the speed

measurement can be set� There are three

setting options:

Setting Speed

mode

0 5

1 50

2 500

Delay time

[ms]

UK

3011 0h Speed value u8, romap Speed value [dig/s]

25

Page 26

CANopen encoder

Index S-Idx Name Type,

4000 0h Bootloader

control

access

u32, wo The object controls the bootloader

default value Description

functionality� If the security code is

written to the object, the EEprom and

the information in the flash memory

are deleted� Furthermore the device is

subjected to a reset� After another set-up,

the bootloader verifies the user application

and does not find any other information�

The bootloader starts with a predefined

CANopen node number (0x1) and a fixed

baud rate of 125 Kbits�

Activation of the bootloader entails an

erasing process� Afterwards only a small

number of objects are available� The

encoder is waiting for new programming�

Due to this behaviour the security code for

prevention is not published in this manual

but is only available from ifm on request�

8.5 Device-profile-specific objects from 6000h to 9FFFF

Index S-Idx Name Type,

6000 Operating

parameters

Scaling function:

Using the scaling function the position value provided can be adapted to the requirements of

the application via the software� The objects 6001 and 6002 of the device profile are scaling

parameters� When the scaling bit has been set to zero, scaling is switched off�

Bit structure

access

u16, rw 1h The object sets the counting direction,

default value Description

the diagnostic function and the scaling

function�

Note: The counting direction is always

seen looking at the shaft� With clockwise

direction of the shaft (CW) the counting

direction is increasing�

26

Bit 15 14 13 12 11���4 3 2 1 0

Description MS MS MS MS R MD SFC CD CS

Abbreviations:

MS = manufacturer-specific function (not available)

R = reserved

MD = measurement direction (not available)

SFC = scaling function (0 = off, 1 = on)

CD = commissioning diagnostic control (not available)

CS = counting direction 0 = CW (clockwise); 1 = CCW (counter-clockwise)

Page 27

CANopen encoder

Index S-Idx Name Type,

6001 0 Measuring

units per

revolution

6002 0 Total

measuring

range in

measuring

units

6003 0 Preset value u32, rw 0 Setting the preset value for the encoder

6004 0 Position value u32,

6030 Speed value

0h Number of sub

indices

1h Speed value

channel 1

6200 0 Event time u16, rw 0x64 This object contains the value of the

6300 Cam state

register

0h Number of sub

indices

1h Cam state

channel 1

6301 Cam enable

register

0h Number of sub

indices

1h Cam enable

channel 1

6302 Cam polarity

register

0h Number of sub

indices

1h Cam polarity

channel 1

access

u32, rw see

u32, rw see

romap

u8, ro 1h

integer

16, romap

u8, ro 1h

u8, romap 4h

u8, ro 1h

u8, rw

u8, ro 1h

u8, rw 0h

default value Description

type label

type label

- The object gets the position value

-

Setting steps per revolution

Setting the total resolution of the

measuring range

If the max� possible value is exceeded,

the value stops there� The user can use

the object 3010 (32 bits)�

event timer of the corresponding PDOs�

The value can be set between 1 and

65538 ms�

The object describes the cam state

register� The object contains the current

position of the cam from 1 to 8�

The object describes the cam state�

The object describes the cam behaviour�

UK

27

Page 28

CANopen encoder

List of cam objects

6310h Cam 1 low limit

0h VAR Highest sub-index supported u32 ro 0x1

1h VAR Cam 1 low limit channel 1 u32 rw 0x0

6311h Cam 2 low limit

0h VAR Highest sub-index supported u32 ro 0x1

1h VAR Cam 2 low limit channel 1 u32 rw 0x0

6312h Cam 3 low limit

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 3 low limit channel 1 u32 rw 0x0

6313h Cam 4 low limit

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 4 low limit channel 1 u32 rw 0x0

6314h Cam 5 low limit

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 5 low limit channel 1 u32 rw 0x0

6315h Cam 6 low limit

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 6 low limit channel 1 u32 rw 0x0

6316h Cam 7 low limit

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 7 low limit channel 1 u32 rw 0x0

6317h Cam 8 low limit

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 8 low limit channel 1 u32 rw 0x0

6320h Cam 1 high limit

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 1 high limit channel 1 u32 rw 0x0

6321h Cam 2 high limit

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 2 high limit channel 1 u32 rw 0x0

6322h Cam 3 high limit

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 3 high limit channel 1 u32 rw 0x0

6323h Cam 4 high limit

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 4 high limit channel 1 u32 rw 0x0

28

Page 29

6324h Cam 5 high limit

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 5 high limit channel 1 u32 rw 0x0

6325h Cam 6 high limit

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 6 high limit channel 1 u32 rw 0x0

6326h Cam 7 high limit

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 7 high limit channel 1 u32 rw 0x0

6327h Cam 8 high limit

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 8 high limit channel 1 u32 rw 0x0

6330h Cam 1 hysteresis

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 1 hysteresis channel 1 u32 rw 0x0

6331h Cam 2 hysteresis

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 2 hysteresis channel 1 u32 rw 0x0

6332h Cam 3 hysteresis

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 3 hysteresis channel 1 u32 rw 0x0

6333h Cam 4 hysteresis

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 4 hysteresis channel 1 u32 rw 0x0

6334h Cam 5 hysteresis

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 5 hysteresis channel 1 u32 rw 0x0

6335h Cam 6 hysteresis

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 6 hysteresis channel 1 u32 rw 0x0

6336h Cam 7 hysteresis

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 7 hysteresis channel 1 u32 rw 0x0

6337h Cam 8 hysteresis

0h VAR Highest sub-index supported u8 ro 0x1

1h VAR Cam 8 hysteresis channel 1 u32 rw 0x0

CANopen encoder

UK

29

Page 30

CANopen encoder

Index S-Idx Name Type,

6400 Area state

register

0h Measuring

units per

revolution

1h Total

measuring

range in

measuring

units

Bit structure

7 6 5 4 3 2 1 0

R r r r r Range

MSB LSB

Signal Value Definition

Out of range 0 Position between low and high limit

Range overflow 0 No range overflow

Range underflow 0 No range underflow

r 0 reserved

access

u8, ro 1h

u8, romap -

default value Description

The object describes the area state

register�

In this object the status of the encoder

value is indicated in the area defined

before�

underflow

1 Position out of range (refer to module

identification object, 650Ah) is reached

1 Position is lower than the position value set

in object 6402h "work area low limit“

1 Position is higher than the position value set

in object 6401h "work area high limit“

Range

overflow

Out of

range

6401 Work area low

limit

0h Number of sub

indices

1h Work area low

limit channel 1

30

integer

32, ro

integer

32, rw

- The objects shows the lower value of the

work area� Bit 2 of the existing work area

status in object 6400h will change when

the work area is fallen below�

This object is directly linked with object

2104h (limit switch min�)�

1h

0h

Page 31

CANopen encoder

Index S-Idx Name Type,

6402 Work area high

limit

0h Number of sub

indices

1h Work area high

limit channel 1

6500 0 Operating

status

6501 0 Single-turn

resolution

6502 0 Number of

distinguishable

revolutions

6504 0 Supported

alarms

6507 0 Profile and

software

version

MSB LSB

Software version Profile version

Upper software

version

access

integer

32, ro

integer

32, rw

u16, ro - Operating status of the encoder�

u32, ro see type label The object indicates the physical

u16, ro see type label The object indicates the physical number

u16, ro - Not supported�

u32, ro - The object contains the implemented

Lower software

default value Description

- The object indicates the upper value of

the working area� Bit 1 of the working

status existing in object 6400h will

change when the working area is

exceeded�

This object is directly linked with object

2105h (limit switch max�)�

1h

UK

0h

The operating status object is linked with

the value of the object 6000�

resolution per revolution of the encoder�

of revolutions of the encoder�

profile versions and the manufacturerspecific software version of the encoder�

Upper profile version Lower profile version

version

6509 0 Offset value integer

32, ro

0 Offset value of the encoder� This value is

determined by the preset value and shifts

the physical position by this offset value�

31

Page 32

CANopen encoder

Index S-Idx Name Type,

650A Module

0 Largest

1 Manufacturer-

2 Manufacturer-

3 Manufacturer-

650B 0 Serial number u32, ro - Serial number of the shaft encoder� If the

identification

sub index

specific offset

specific min�

position value

specific max�

position value

access

integer

32, ro

integer

32, ro

integer

32, ro

integer

32, ro

default value Description

The object indicates the manufacturerspecific offset, the manufacturer-specific

minimum and maximum of the position

value�

3

-

-

-

serial number is not supported by the

encoder, the value is always 0xffffffff�

32

Page 33

CANopen encoder

9 Terms and abbreviations

0b ��� Binary value (for bit coding), e�g� 0b0001 0000

0d ��� Decimal value, e�g� 0d100

0x ��� Hexadecimal value, e�g� 0x64 (= 100 decimal)

Baud rate Transmission speed (1 baud = 1 bit/s)

CAL CAN Application Layer

CAN-based network protocol on application level

CAN Controller Area Network (bus system for the use in mobile vehicles)

CAN_H CAN high; CAN connection/cable with high voltage level

CAN_L CAN low; CAN connection/cable with low voltage level

CANopen CAN-based network protocol on the application level with an open

conguration interface (object directory).

CiA "CAN in Automation e�V�"

(user and manufacturer organisation in Germany/Erlangen)

denition and control body for CAN and CAN-based network protocols

CiA DS Draft Standard (published CiA specication which usually has not been

modied or supplemented for one year)

CiA DSP Draft Standard Proposal (published CiA specication draft)

CiA WD Work Draft (work draft accepted for discussion within CiA)

CiA DS 301 Specication concerning the CANopen communication prole;

describes the basic communication mechanisms between the network

participants such as the transfer of process data in real time,

the data exchange between devices or the conguration phase.

Completed by the following CiA specications according to the application:

CiA DS 401 Device prole for digital and analogue I/O modules

CiA DS 402 Device prole for drives

CiA DS 403 Device prole for HMI

CiA DS 404 Device prole for measurement and control technology

CiA DS 405 Specication for interfaces to programmable systems (IEC 61131-3)

CiA DS 406 Device prole for encoders

CiA DS 407 Application prole for local public transport

COB CANopen communication object (PDO, SDO, EMCY, ���)

COB ID CANopen identier of a communication object

Communication The synchronisation time to be monitored; max� time between 2

cycles sync objects

EMCY object Emergency object (alarm message; device signals an error)

Error reg Error register (entry with an error code)

Guarding error Node or network participant could or can no longer be found

Guard MASTER: one or several SLAVES no longer reply

Guard SLAVE: no polling of the device (SLAVE)�

Guard Time Within this time the network participant expects a "node guarding" of the

network master

Heartbeat Congurable cyclic monitoring among network participants.

In contrast to "node guarding" no superior NMT master is required�

ID Identier; identies a CAN message. The numerical value of the ID

(also identier) also contains a priority for the access to the bus system.

ID 0 = top priority�

Idx Index; together with the S index it forms the address of an entry in the object

directory

Life Time Factor Number of attempts in case of a missing guarding response

Monitoring Is used to describe the error class (guarding monitoring, sync etc�)�

NMT Network Management

NMT master/slaves The NMT master controls the operating statuses of the NMT slaves

Node Guarding Adjustable cyclic monitoring of slave network participants by a

UK

33

Page 34

CANopen encoder

higher-level master node as well as monitoring of this polling

process by the slave participants�

Node ID Nodal point identier (identication of a participant in the CANopen

network)

Object (also OBJ) Term for data/messages which can be exchanged in the CANopen

network

Object directory Contains all CANopen communication parameters of a device

as well as device-specic parameters and data.

Access to the individual entries is possible via the index and S-index�

Operational Operating status of a CANopen participant�

In this mode SDOs, NMT commands and PDOs can be transferred�

PDO Process Data Object;

in the CANopen network to transfer process data in real time such

as motor speed�

PDOs have a higher priority than SDOs; in contrast to the SDOs

they are transferred without conrmation.

PDOs consist of a CAN message with identier and up to 8 bytes of

user data�

PDO mapping Describes the application data transferred with a PDO�

Pre-Op Preoperational; operating status of a CANopen participant�

After application of the supply voltage each participant automatically

goes into this state�

In the CANopen network only SDOs and NMT commands can be

transferred in this mode but no process data�

Prepared (Also stopped) operating status of a CANopen participant�

In this mode only NMT commands are transferred�

Rec PDO (Receive) Process Data Object

(also Rx PDO)

ro read only (unidirectional)

rw read-write (bidirectional)

Rx queue Input buer

s16 Data type signed 16 bits (incl� sign, 16-bit format)

SDO Service Data Object

With this object direct access to the object directory of a network

participant is possible (read/write)�

An SDO can consist of several CAN messages� The transfer of the

individual messages is conrmed by the addressed participant.

With the SDOs, devices can be congured and parameters can be

set�

Server SDO Process and parameter set to make the object directory of a network

participant available to other participants (clients)�

S-Idx (also SIdx) Sub index within the object directory of a CANopen-capable device

Start Guarding Start node monitoring

str Data type string (variable for strings such as text "load")

Sync error Missing sync object OBJ in the adjustable synchronisation time

Sync OBJ Synchronisation object for simultaneous update in the complete

network or for accepting process data of the respective

parameterised PDOs�

Sync windows Time during which the synchronous PDOs have to be transferred�

Time stamp Time stamp to align existing clocks in network participants

Trans Type Type of process data transmission; synchronous, asynchronous

Trans PDO Transmit Process Data Object

(also Tx PDO)

Trans SDO (Transmit) Service Data Object

(also Tx SDO)

34

Page 35

CANopen encoder

Tx queue (Transmit) Transmission buer

u8 (16, 32) Data type unsigned 8 (16, 32) bits (without sign, 8 (16, 32) bit-format

wo write only

UK

35

Loading...

Loading...