CAN FC Series, FC1336, FC1345, FC1347, FC1348 Installation, Use And Maintenance Instruction Manual

...

CAN S.r.l.

Via Nazionale 65,

25080 - Puegnago del Garda (BS) ITALY

T. +39 0365 555909

F. +39 0365 651822

info@cansrl.com

www.cansrl.com

DE

HANDBUCH FÜR INSTALLATION,

GEBRAUCH UND WARTUNG

serie FC

IT

MANUALE DI ISTRUZIONI

INSTALLAZIONE-USO-MANUTENZIONE

EN

INSTALLATION, USE AND

MAINTENANCE INSTRUCTION MANUAL

FR

MANUEL D’INSTRUCTIONS D’INSTALLATIOND’UTILISATION-ET D’ENTRETIEN

ES

MANUAL DE INSTRUCCIONES

INSTALACIÓN-USO-MANTENIMIENTO

2

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

Thank you for having purchased our cooking device CAN S.r.l.

This is a quality appliance, made in Italy, that reliably and safely accompanies you throughout your vacation

and leisure time, always guaranteeing high level performance.

Installation and use of the device are simple and straightforward.

Please read this manual carefully: this will allow you to install and use your appliance correctly, always

keeping it in perfect working order for years. The instructions in this booklet only apply to the Country

of destination. The gas supply systems must meet current national standards.

The following symbols have been used in the manual to make it easier to read:

SAFETY-RELATED WARNINGS FOR INSTALLERS AND USERS

Failure to comply with these warnings can cause material damage and jeopardise operation of

the appliance.

GENERAL INFORMATION

Additional information for installers and users.

CAN S.r.l., as the manufacturer of the appliance, reserves the right to make changes to its products and to

this manual considered appropriate, without being obliged to give prior notice. The drawings, installation

diagrams and tables in the manual must be considered as guides and exclusively for explanatory purposes.

CAN S.r.l. prohibits fully or partially copying or reproducing the contents of this manual or forwarding it to

third parties without the consent of the Manufacturer.

revision index

Edition 07/2018

Revision 00

3

ENGLISH

DECLARATION OF CONFORMITY

CAN S.r.l.

Italian company with headquarters at:

Via Nazionale, 65 – 25080, Puegnago del Garda ( BS) – ITALY

VAT NO. 03607980988 – REA BS548442

DECLARES THAT

the products called

GAS HOB UNITS WITH GLASS RECESSED LID

FC SERIES – TYPE: FC133X – FC134X – FC135X

Meet all the essential requirements of the GAD Directive – 2009/142/EEC of 30/11/2009 and also the

subsequent GAR regulation - 2016/426/EU of 09/03/2016, as well as the following regulations:

• EC regulation 1935/2004

• EU Regulation no.65/2014 – “ENERGY LABEL”

• EU Regulation no.66/2014 – “ECODESIGN”

Our devices are also manufactured in compliance with all relevant harmonised technical standards for the

sector, in particular:

• EN 30-1-1: 2008 + A3 02/2013

• EN 30-2-1: 2015

We hereby declare that all the products of the FC SERIES are built according to the specifications of the

appliances described in:

TYPE TEST CERTIFICATE no. 51CO4387 issued by IMQ S.p.a.

as notified body, with identification number 0051

The undersigned, Lorenzo Bellini, as director of the company CAN S.r.l., assumes full responsibility for the

truthfulness of the declarations herein.

Puegnago del Garda, 26/03/2018

Signature: Lorenzo Bellini

4

ENGLISH

TABLE OF CONTENTS

TECHNICAL DATA SHEET: FC1336 6

TECHNICAL DATA SHEET: FC1337 8

TECHNICAL DATA SHEET: FC1343 10

TECHNICAL DATA SHEET: FC1344 12

TECHNICAL DATA SHEET: FC1345 14

TECHNICAL DATA SHEET: FC1347 16

TECHNICAL DATA SHEET: FC1348 18

TECHNICAL DATA SHEET: FC1349 20

TECHNICAL DATA SHEET: FC1350 22

TECHNICAL DATA SHEET: FC1352 24

GENERAL SAFETY WARNINGS 26

INTENDED USE 27

OBLIGATIONS AND PROHIBITIONS 27

OBLIGATIONS 27

PROHIBITIONS 27

IDENTIFICATION OF THE APPLIANCE 28

RECEIVING THE APPLIANCE 29

CONTROL AND HANDLING 29

DISPOSING OF THE PACKAGING 29

GENERAL PRELIMINARY INFORMATION 26

5

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

INSTRUCTIONS FOR THE INSTALLER 30

INSTALLATION ROOM 30

FEATURES OF INSTALLATION ROOM 30

FLUE GAS EXHAUST 30

INSTALLATION ON SUPPORT STRUCTURE 31

RECESSED HOLE 31

SAFETY DISTANCES 32

POSITIONING THE APPLIANCE 33

GAS CONNECTION 34

GAS CATEGORIES 34

CONNECTION PIPE REQUIREMENTS 34

GAS CONNECTION PROCEDURE 35

ELECTRICAL CONNECTION (ONLY FOR E VERSION) 35

TROUBLESHOOTING AFTER INSTALLATION 36

INSTRUCTIONS FOR USE 37

SPARE PARTS 54

DESCRIPTION 37

SAFETY WARNINGS DURING USE 48

USE 48

LIGHTING THE BURNERS 49

ADJUSTING THE FLAME 50

COOKING OR WARMING UP FOOD 50

SWITCHING OFF THE BURNER 51

OPERATING FAULTS 51

WHAT TO DO IN CASE OF MALFUNCTIONING 51

MAINTENANCE AND CLEANING 52

LONG IDLE PERIODS 53

WASTE DISPOSAL 53

WARRANTY 53

SPARE PARTS - FC1336 54

SPARE PARTS - FC1337 55

SPARE PARTS - FC1343 56

SPARE PARTS - FC1344 56

SPARE PARTS - FC1345 57

SPARE PARTS - FC1347 58

SPARE PARTS - FC1348 59

SPARE PARTS - FC1349 59

SPARE PARTS - FC1350 60

SPARE PARTS - FC1352 61

6

ENGLISHENGLISH

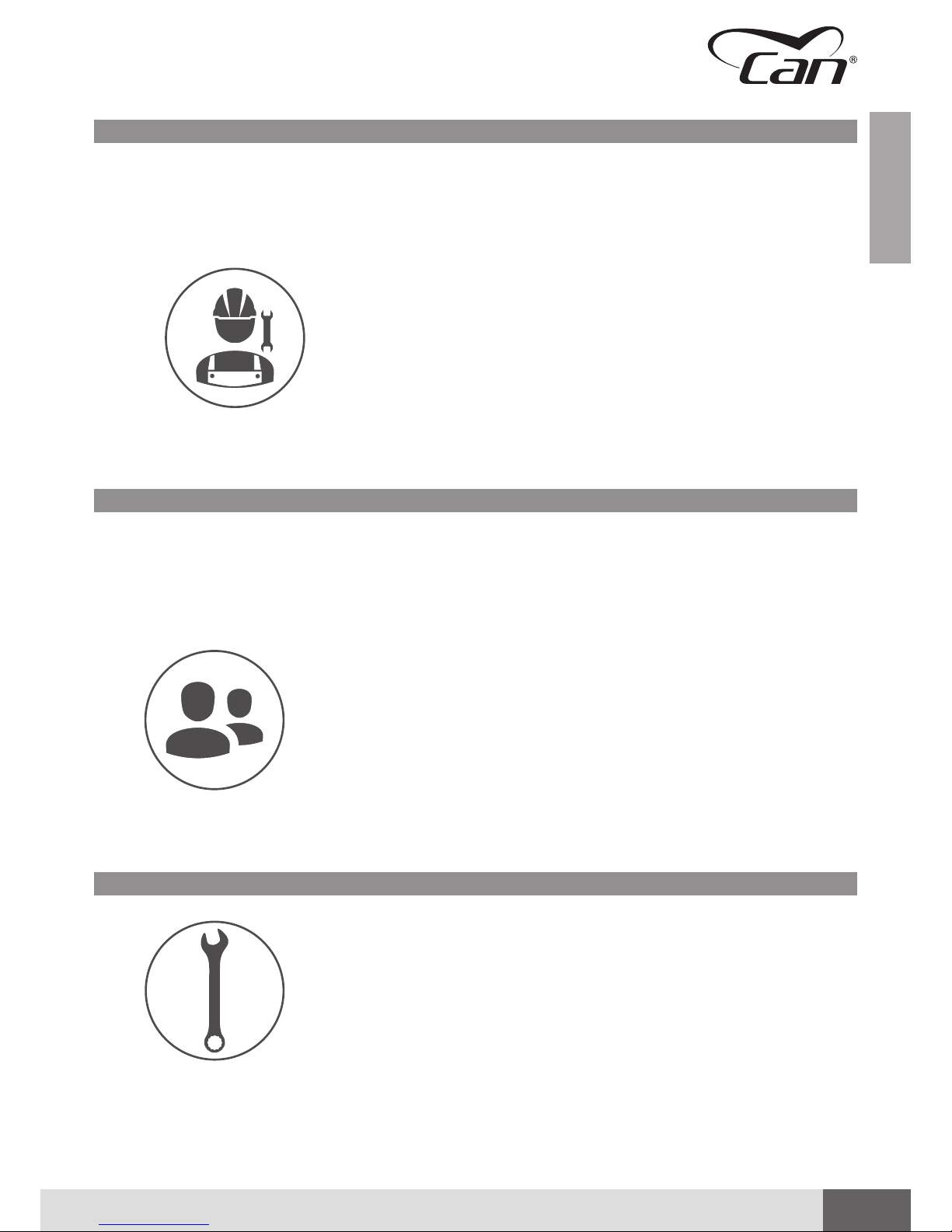

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

TECHNICAL DATA SHEET: FC1336

RECESSED HOLE FC1336

C

A

B

5 mm

8 mm

Detail C

85 mm

R10

128 mm

R32

R70

7

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

Dimensions Width 530 mm

Depth 340 mm

Height 48 mm (hob area)

105 mm (valves area)

Weight 3.6 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX)

Pn 1.00 kW – injector ø 0.50 mm – consumption 72.50 g/h

1 x SEMIRAPID burner (SR):

Pn 1.75 kW – injector ø 0.65 mm – consumption 127.0 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

▪ P (PIEZOELECTRIC) – Mechanically/manually operated piezoelectric igniter inserted

in hob unit

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

TECHNICAL DATA SHEET: FC1336

8

ENGLISHENGLISH

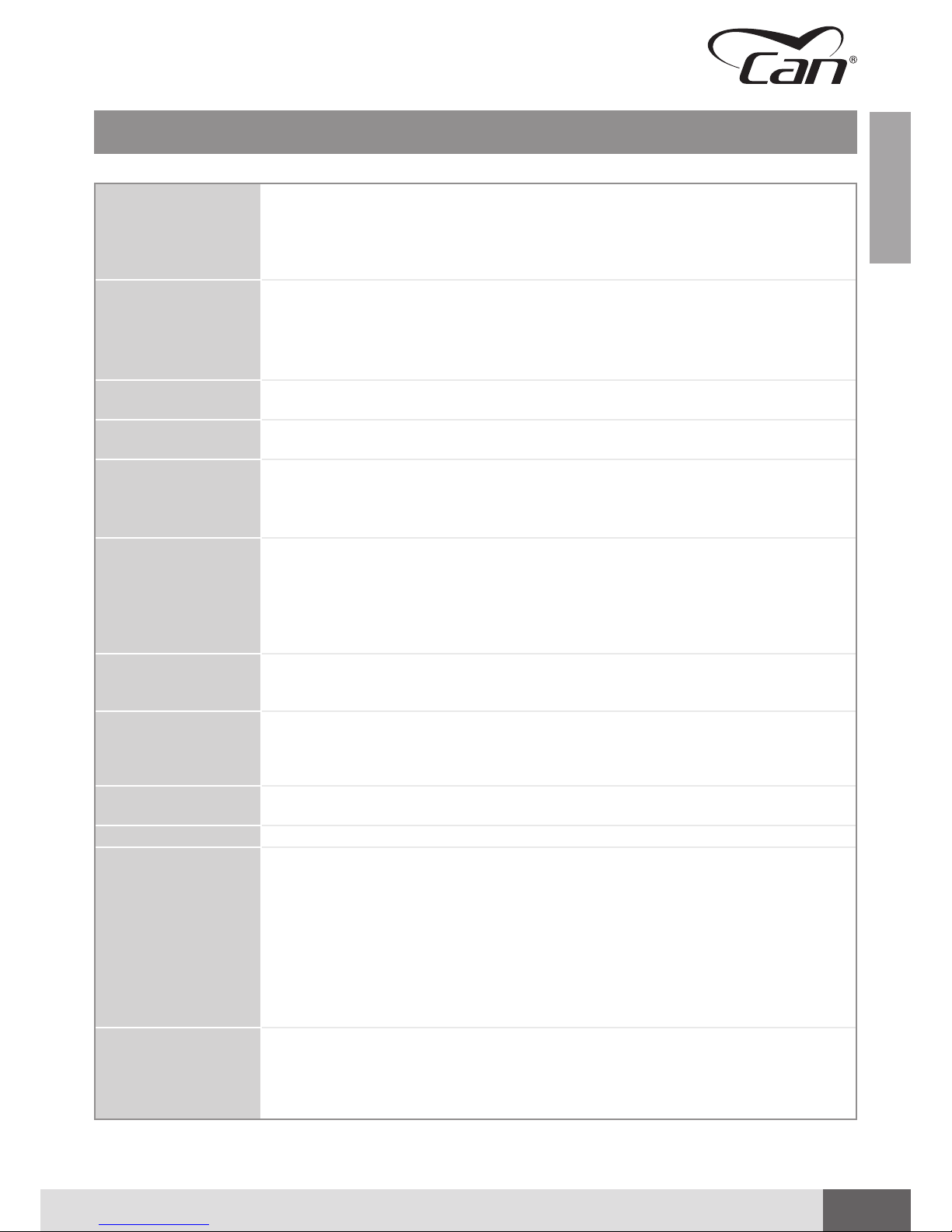

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

TECHNICAL DATA SHEET: FC1337

RECESSED HOLE FC1337

C

Detail C

A

B

R32

R70

130 mm

30 mm

R8

5

9

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1337

Dimensions Width 340 mm

Depth 530 mm

Height 48 mm (hob area)

105 mm (valves area)

Weight 3.8 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX)

Pn 1.00 kW – injector ø 0.50 mm – consumption 72.50 g/h

1 x SEMIRAPID burner (SR):

Pn 1.75 kW – injector ø 0.65 mm – consumption 127.0 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

▪ P (PIEZOELECTRIC) – Mechanically/manually operated piezoelectric igniter inserted

in hob unit

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

10

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

TECHNICAL DATA SHEET: FC1343

A

B

R32

R80

R340

RECESSED HOLE FC1343

11

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1343

Dimensions Width 480 mm

Depth 480 mm

Height 105 mm

Weight 5.5 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX)

Pn 1.00 kW – injector ø 0.50 mm – consumption 72.50 g/h

2 x SEMIRAPID burner (SR):

Pn 1.75 kW – injector ø 0.65 mm – consumption 127.0 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

12

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

TECHNICAL DATA SHEET: FC1344

RECESSED HOLE FC1344

A

B

R32

R80

R340

13

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1344

Dimensions Width 480 mm

Depth 480 mm

Height 105 mm

Weight 5.5 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX)

Pn 1.00 kW – injector ø 0.50 mm – consumption 72.50 g/h

2 x SEMIRAPID burner (SR):

Pn 1.75 kW – injector ø 0.65 mm – consumption 127.0 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

14

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

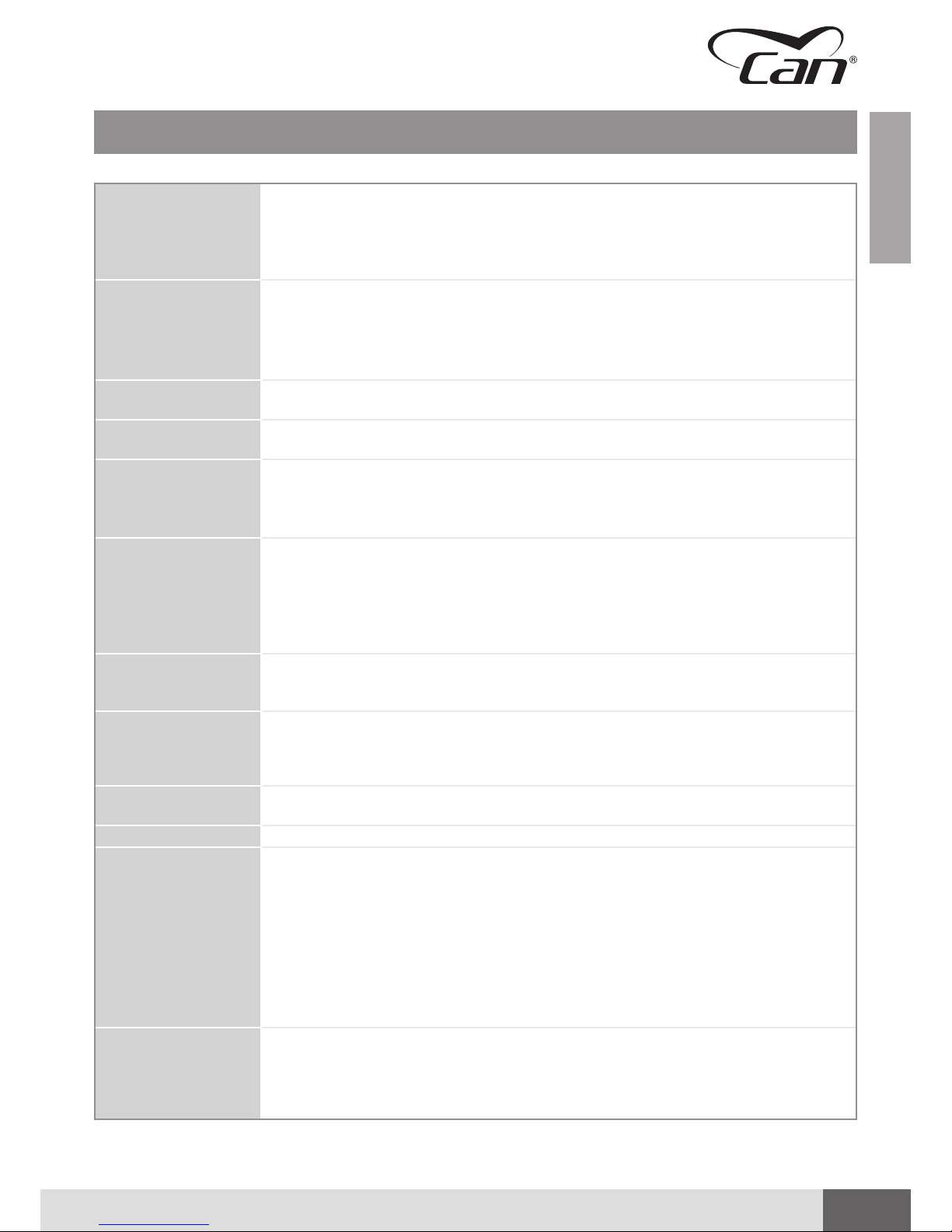

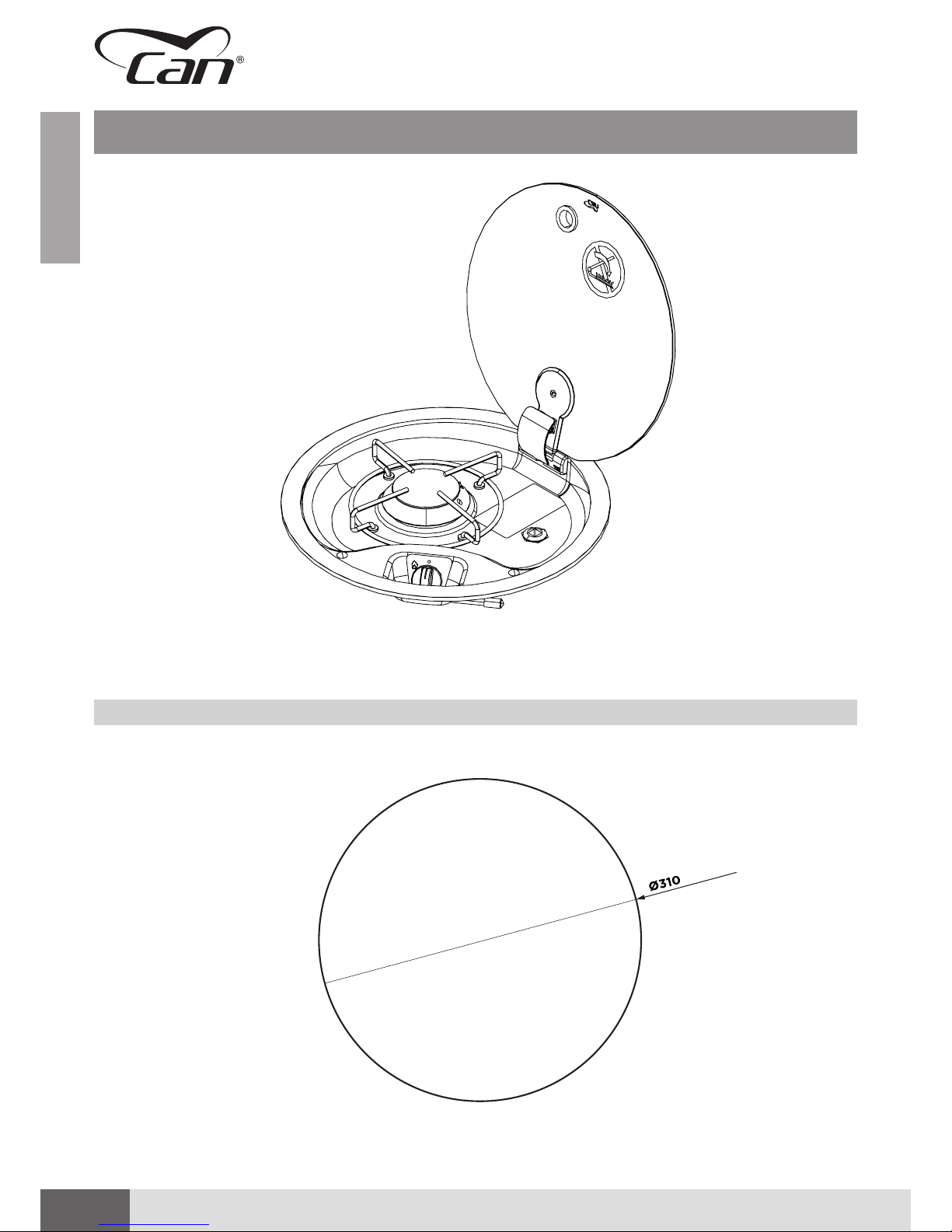

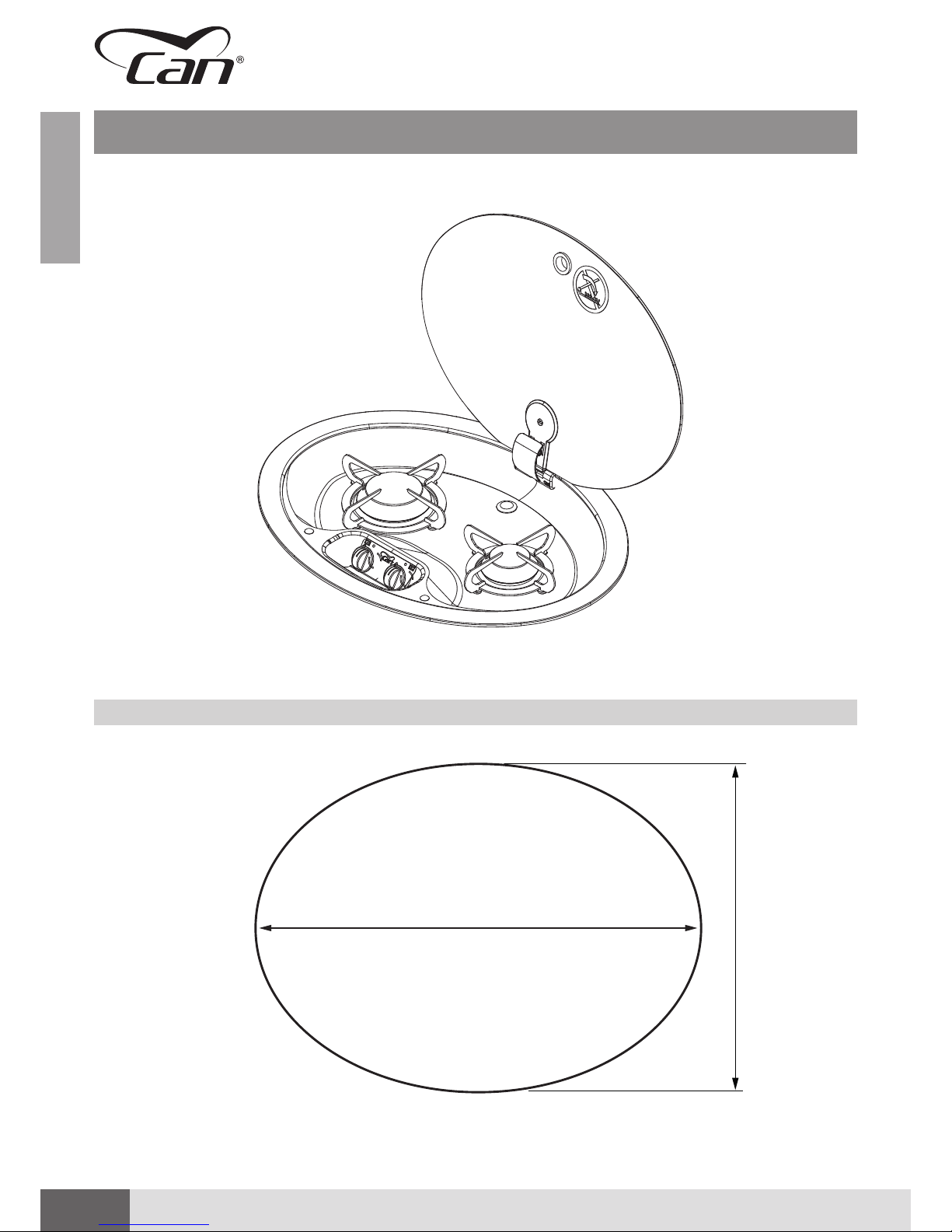

TECHNICAL DATA SHEET: FC1345

RECESSED HOLE FC1345

Please note: secured with adhesive.

15

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1345

Dimensions External Diameter (Ø) 340 mm

Height 80 mm

Weight 2.1 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x SEMIRAPID burner (SR):

Pn 2.00 kW – injector ø 0.70 mm – consumption 145.50 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

Gas Connection Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

16

ENGLISHENGLISH

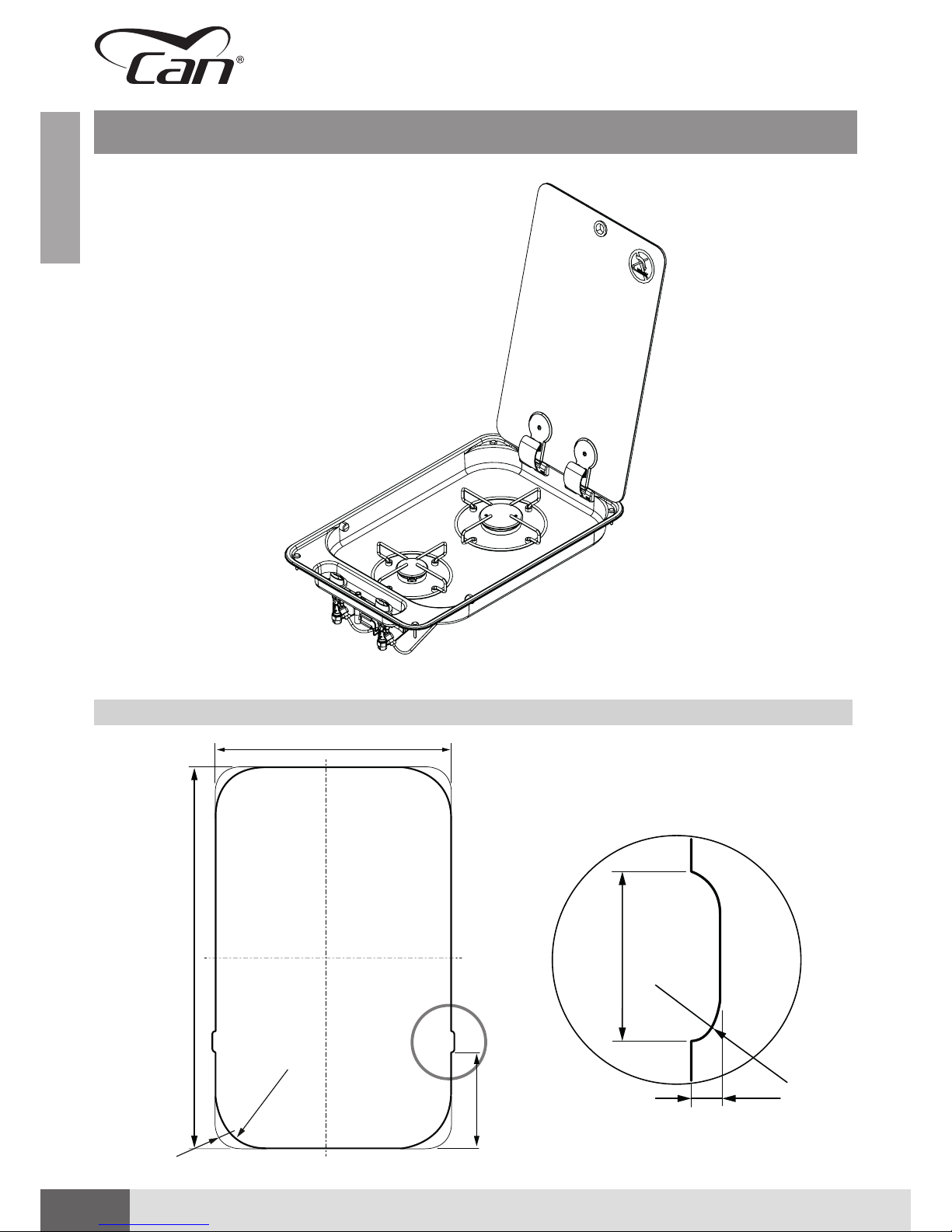

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

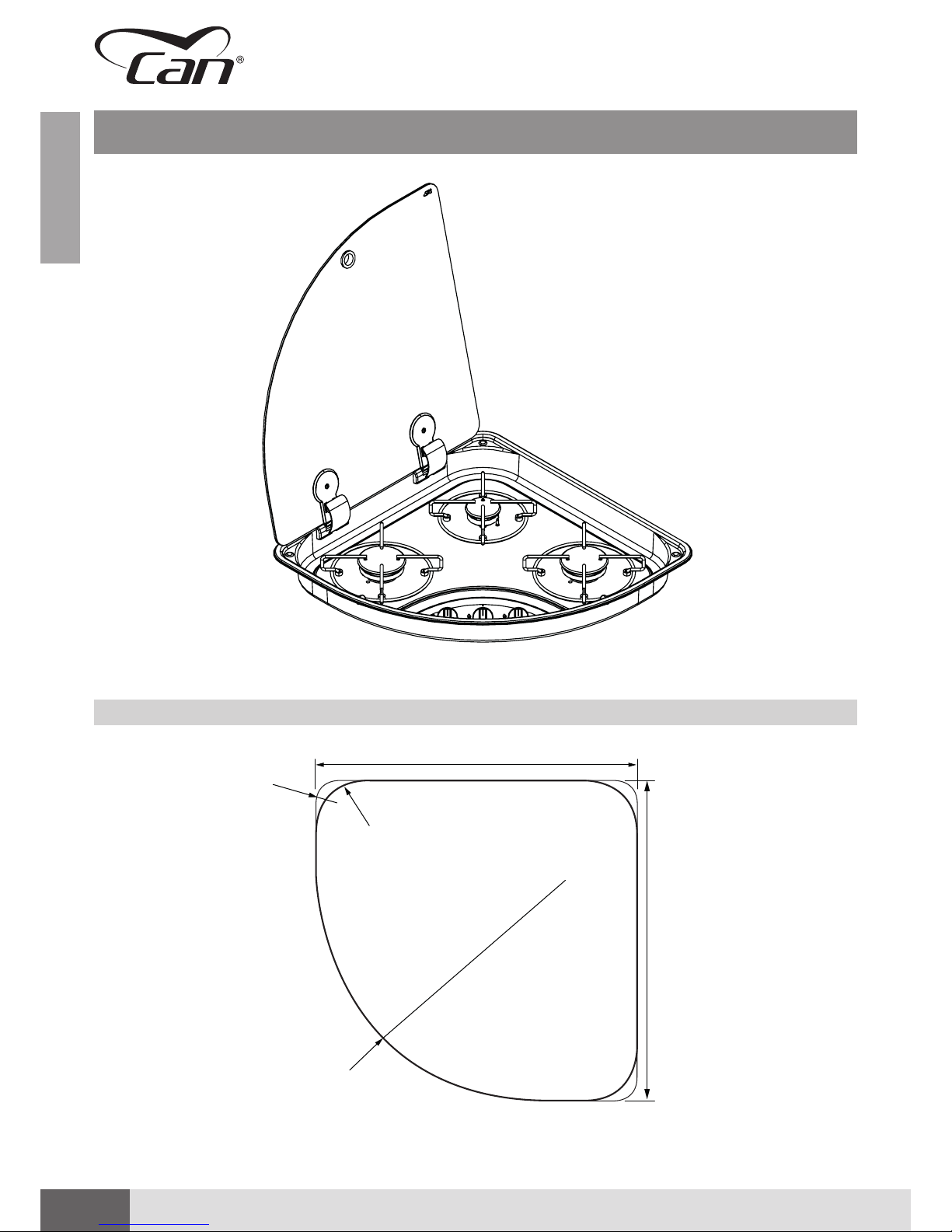

TECHNICAL DATA SHEET: FC1347

RECESSED HOLE FC1347

A

B

R60

R100

17

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1347

Dimensions Width 440 mm

Depth 440 mm

Height 80 mm

Weight 5.3 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX):

Pn 1.10 kW – injector ø 0.52 mm – consumption 80.00 g/h

2 x SEMIRAPID burner (SR):

Pn 2.00 kW – injector ø 0.70 mm – consumption 145.50 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

18

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

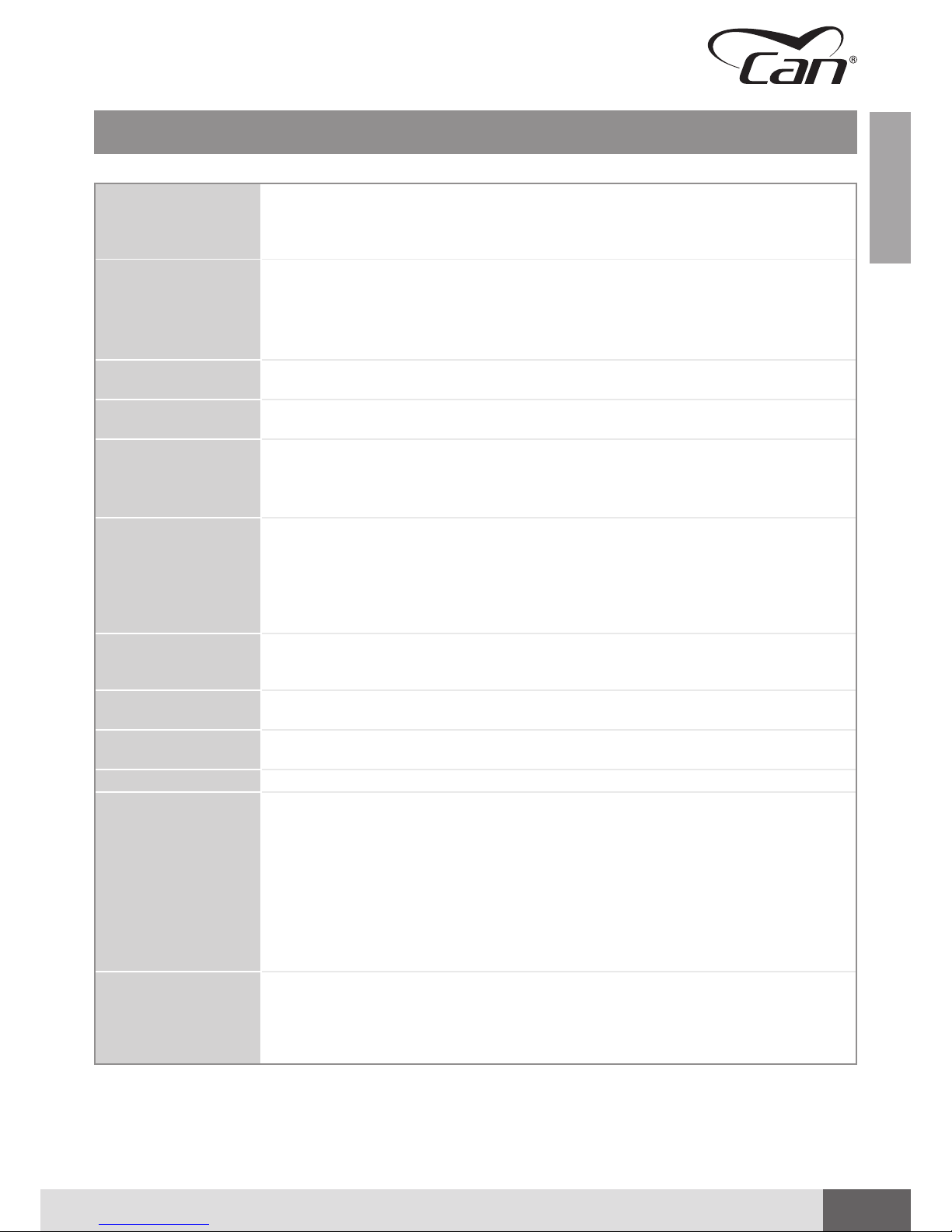

TECHNICAL DATA SHEET: FC1348

RECESSED HOLE FC1348

340

460

Please note: secured with adhesive.

19

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1348

Dimensions Width 510 mm (maximum overall dimension)

Depth 390 mm (maximum overall dimension)

Height 80 mm

Weight 3.8 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX):

Pn 1.10 kW – injector ø 0.52 mm – consumption 80.00 g/h

1 x SEMIRAPID burner (SR):

Pn 2.00 kW – injector ø 0.70 mm – consumption 145.50 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

▪ P (PIEZOELECTRIC) – Mechanically/manually operated piezoelectric igniter inserted

in hob unit

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

Loading...

Loading...