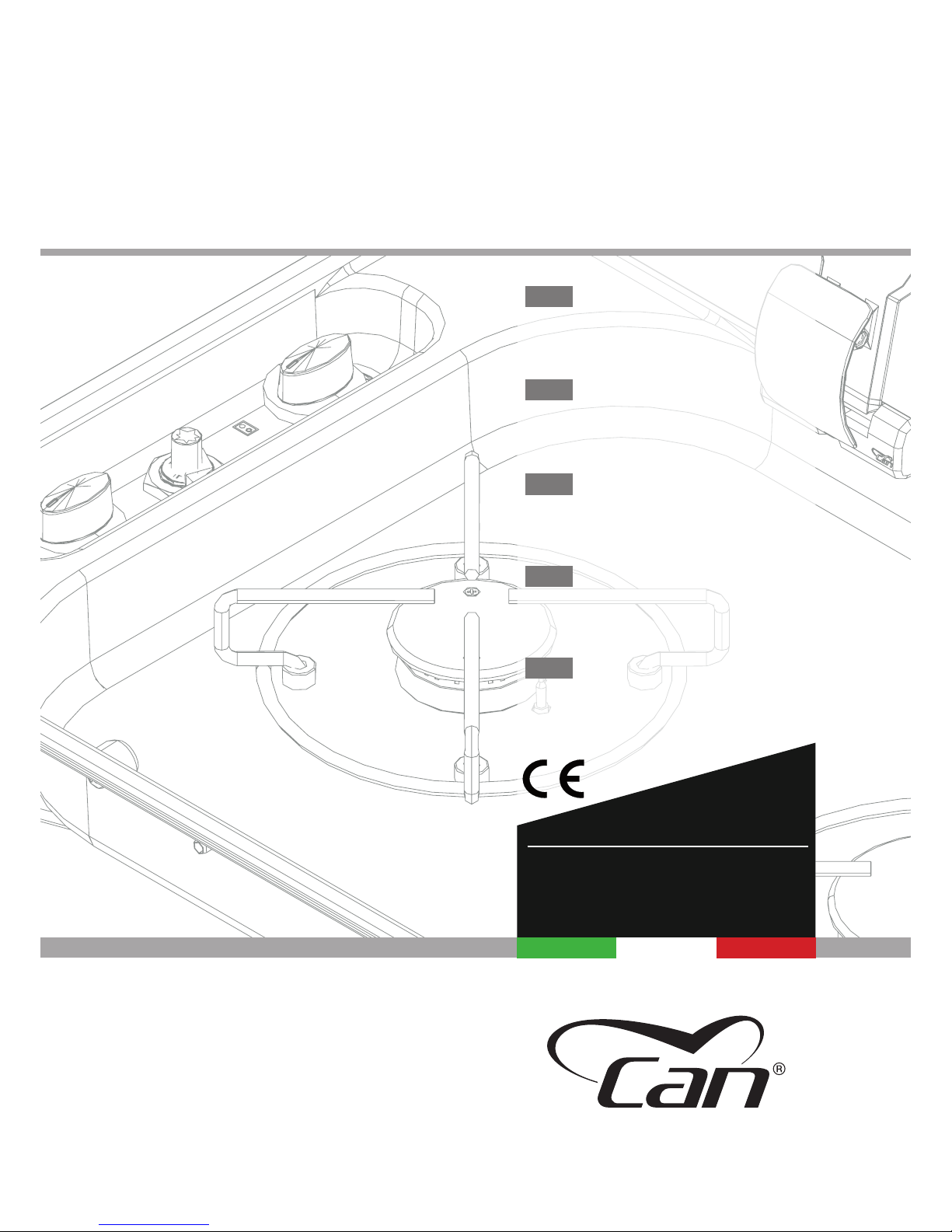

CAN FC Series, FC1336, FC1345, FC1347, FC1348 Installation, Use And Maintenance Instruction Manual

...Page 1

CAN S.r.l.

Via Nazionale 65,

25080 - Puegnago del Garda (BS) ITALY

T. +39 0365 555909

F. +39 0365 651822

info@cansrl.com

www.cansrl.com

DE

HANDBUCH FÜR INSTALLATION,

GEBRAUCH UND WARTUNG

serie FC

IT

MANUALE DI ISTRUZIONI

INSTALLAZIONE-USO-MANUTENZIONE

EN

INSTALLATION, USE AND

MAINTENANCE INSTRUCTION MANUAL

FR

MANUEL D’INSTRUCTIONS D’INSTALLATIOND’UTILISATION-ET D’ENTRETIEN

ES

MANUAL DE INSTRUCCIONES

INSTALACIÓN-USO-MANTENIMIENTO

Page 2

2

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

Thank you for having purchased our cooking device CAN S.r.l.

This is a quality appliance, made in Italy, that reliably and safely accompanies you throughout your vacation

and leisure time, always guaranteeing high level performance.

Installation and use of the device are simple and straightforward.

Please read this manual carefully: this will allow you to install and use your appliance correctly, always

keeping it in perfect working order for years. The instructions in this booklet only apply to the Country

of destination. The gas supply systems must meet current national standards.

The following symbols have been used in the manual to make it easier to read:

SAFETY-RELATED WARNINGS FOR INSTALLERS AND USERS

Failure to comply with these warnings can cause material damage and jeopardise operation of

the appliance.

GENERAL INFORMATION

Additional information for installers and users.

CAN S.r.l., as the manufacturer of the appliance, reserves the right to make changes to its products and to

this manual considered appropriate, without being obliged to give prior notice. The drawings, installation

diagrams and tables in the manual must be considered as guides and exclusively for explanatory purposes.

CAN S.r.l. prohibits fully or partially copying or reproducing the contents of this manual or forwarding it to

third parties without the consent of the Manufacturer.

revision index

Edition 07/2018

Revision 00

Page 3

3

ENGLISH

DECLARATION OF CONFORMITY

CAN S.r.l.

Italian company with headquarters at:

Via Nazionale, 65 – 25080, Puegnago del Garda ( BS) – ITALY

VAT NO. 03607980988 – REA BS548442

DECLARES THAT

the products called

GAS HOB UNITS WITH GLASS RECESSED LID

FC SERIES – TYPE: FC133X – FC134X – FC135X

Meet all the essential requirements of the GAD Directive – 2009/142/EEC of 30/11/2009 and also the

subsequent GAR regulation - 2016/426/EU of 09/03/2016, as well as the following regulations:

• EC regulation 1935/2004

• EU Regulation no.65/2014 – “ENERGY LABEL”

• EU Regulation no.66/2014 – “ECODESIGN”

Our devices are also manufactured in compliance with all relevant harmonised technical standards for the

sector, in particular:

• EN 30-1-1: 2008 + A3 02/2013

• EN 30-2-1: 2015

We hereby declare that all the products of the FC SERIES are built according to the specifications of the

appliances described in:

TYPE TEST CERTIFICATE no. 51CO4387 issued by IMQ S.p.a.

as notified body, with identification number 0051

The undersigned, Lorenzo Bellini, as director of the company CAN S.r.l., assumes full responsibility for the

truthfulness of the declarations herein.

Puegnago del Garda, 26/03/2018

Signature: Lorenzo Bellini

Page 4

4

ENGLISH

TABLE OF CONTENTS

TECHNICAL DATA SHEET: FC1336 6

TECHNICAL DATA SHEET: FC1337 8

TECHNICAL DATA SHEET: FC1343 10

TECHNICAL DATA SHEET: FC1344 12

TECHNICAL DATA SHEET: FC1345 14

TECHNICAL DATA SHEET: FC1347 16

TECHNICAL DATA SHEET: FC1348 18

TECHNICAL DATA SHEET: FC1349 20

TECHNICAL DATA SHEET: FC1350 22

TECHNICAL DATA SHEET: FC1352 24

GENERAL SAFETY WARNINGS 26

INTENDED USE 27

OBLIGATIONS AND PROHIBITIONS 27

OBLIGATIONS 27

PROHIBITIONS 27

IDENTIFICATION OF THE APPLIANCE 28

RECEIVING THE APPLIANCE 29

CONTROL AND HANDLING 29

DISPOSING OF THE PACKAGING 29

GENERAL PRELIMINARY INFORMATION 26

Page 5

5

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

INSTRUCTIONS FOR THE INSTALLER 30

INSTALLATION ROOM 30

FEATURES OF INSTALLATION ROOM 30

FLUE GAS EXHAUST 30

INSTALLATION ON SUPPORT STRUCTURE 31

RECESSED HOLE 31

SAFETY DISTANCES 32

POSITIONING THE APPLIANCE 33

GAS CONNECTION 34

GAS CATEGORIES 34

CONNECTION PIPE REQUIREMENTS 34

GAS CONNECTION PROCEDURE 35

ELECTRICAL CONNECTION (ONLY FOR E VERSION) 35

TROUBLESHOOTING AFTER INSTALLATION 36

INSTRUCTIONS FOR USE 37

SPARE PARTS 54

DESCRIPTION 37

SAFETY WARNINGS DURING USE 48

USE 48

LIGHTING THE BURNERS 49

ADJUSTING THE FLAME 50

COOKING OR WARMING UP FOOD 50

SWITCHING OFF THE BURNER 51

OPERATING FAULTS 51

WHAT TO DO IN CASE OF MALFUNCTIONING 51

MAINTENANCE AND CLEANING 52

LONG IDLE PERIODS 53

WASTE DISPOSAL 53

WARRANTY 53

SPARE PARTS - FC1336 54

SPARE PARTS - FC1337 55

SPARE PARTS - FC1343 56

SPARE PARTS - FC1344 56

SPARE PARTS - FC1345 57

SPARE PARTS - FC1347 58

SPARE PARTS - FC1348 59

SPARE PARTS - FC1349 59

SPARE PARTS - FC1350 60

SPARE PARTS - FC1352 61

Page 6

6

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

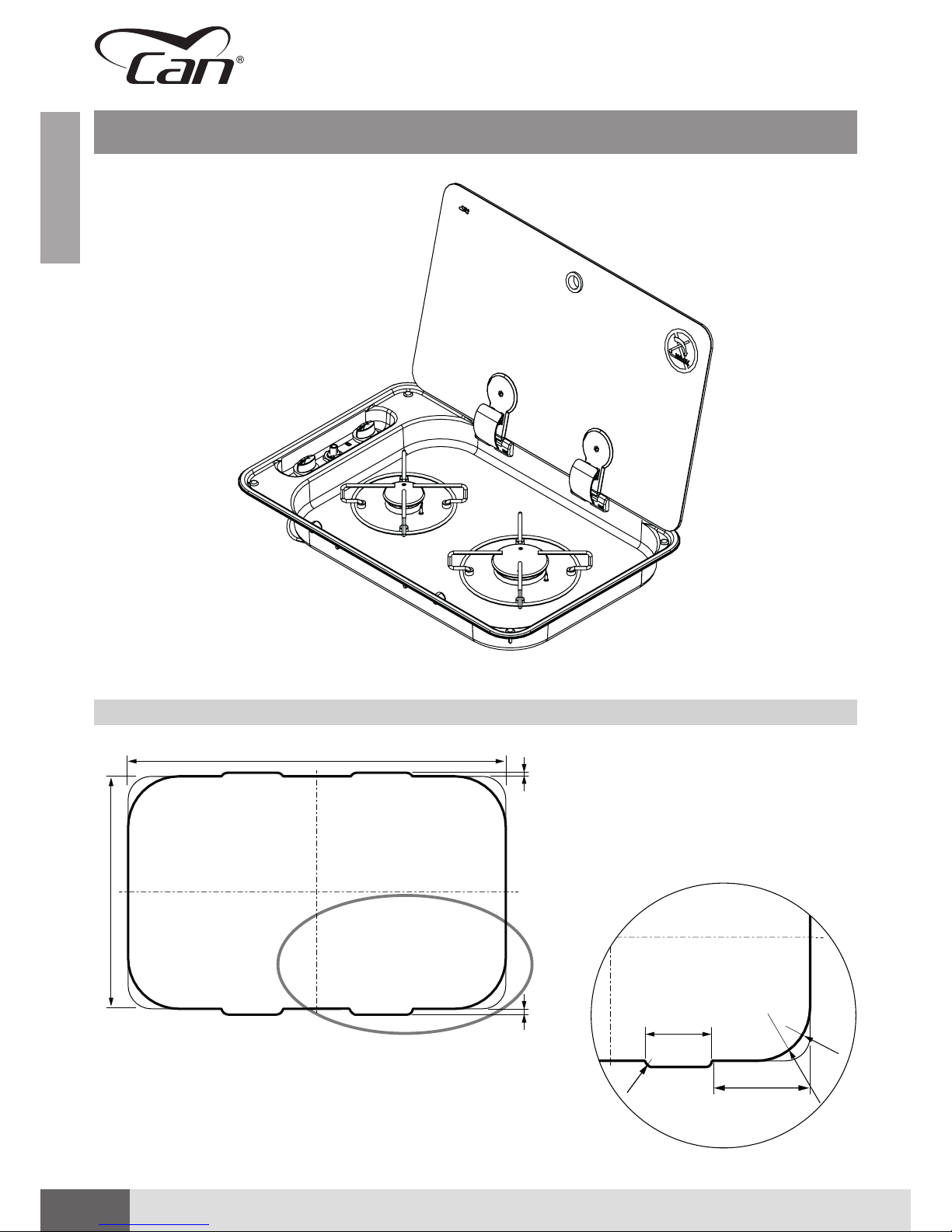

TECHNICAL DATA SHEET: FC1336

RECESSED HOLE FC1336

C

A

B

5 mm

8 mm

Detail C

85 mm

R10

128 mm

R32

R70

Page 7

7

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

Dimensions Width 530 mm

Depth 340 mm

Height 48 mm (hob area)

105 mm (valves area)

Weight 3.6 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX)

Pn 1.00 kW – injector ø 0.50 mm – consumption 72.50 g/h

1 x SEMIRAPID burner (SR):

Pn 1.75 kW – injector ø 0.65 mm – consumption 127.0 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

▪ P (PIEZOELECTRIC) – Mechanically/manually operated piezoelectric igniter inserted

in hob unit

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

TECHNICAL DATA SHEET: FC1336

Page 8

8

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

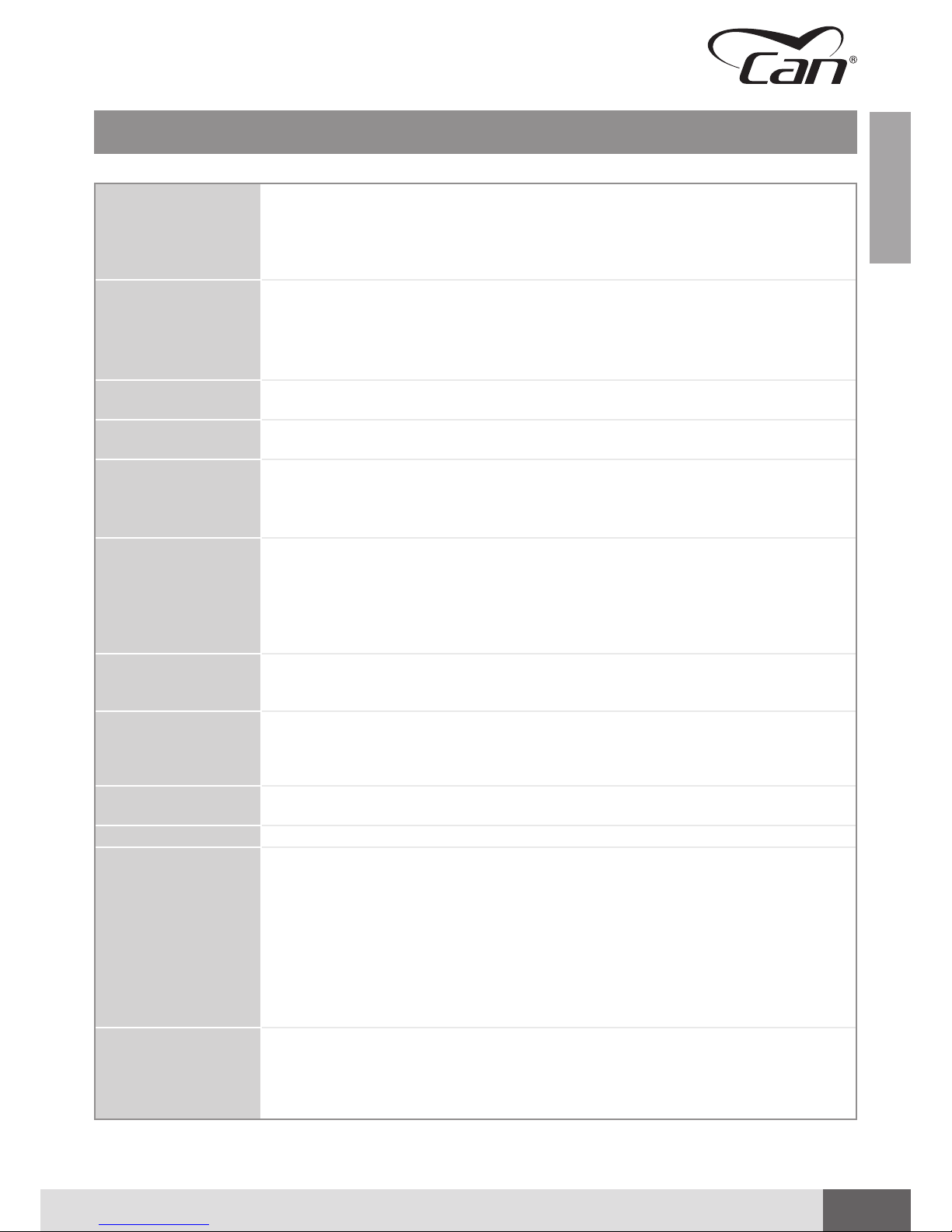

TECHNICAL DATA SHEET: FC1337

RECESSED HOLE FC1337

C

Detail C

A

B

R32

R70

130 mm

30 mm

R8

5

Page 9

9

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1337

Dimensions Width 340 mm

Depth 530 mm

Height 48 mm (hob area)

105 mm (valves area)

Weight 3.8 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX)

Pn 1.00 kW – injector ø 0.50 mm – consumption 72.50 g/h

1 x SEMIRAPID burner (SR):

Pn 1.75 kW – injector ø 0.65 mm – consumption 127.0 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

▪ P (PIEZOELECTRIC) – Mechanically/manually operated piezoelectric igniter inserted

in hob unit

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

Page 10

10

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

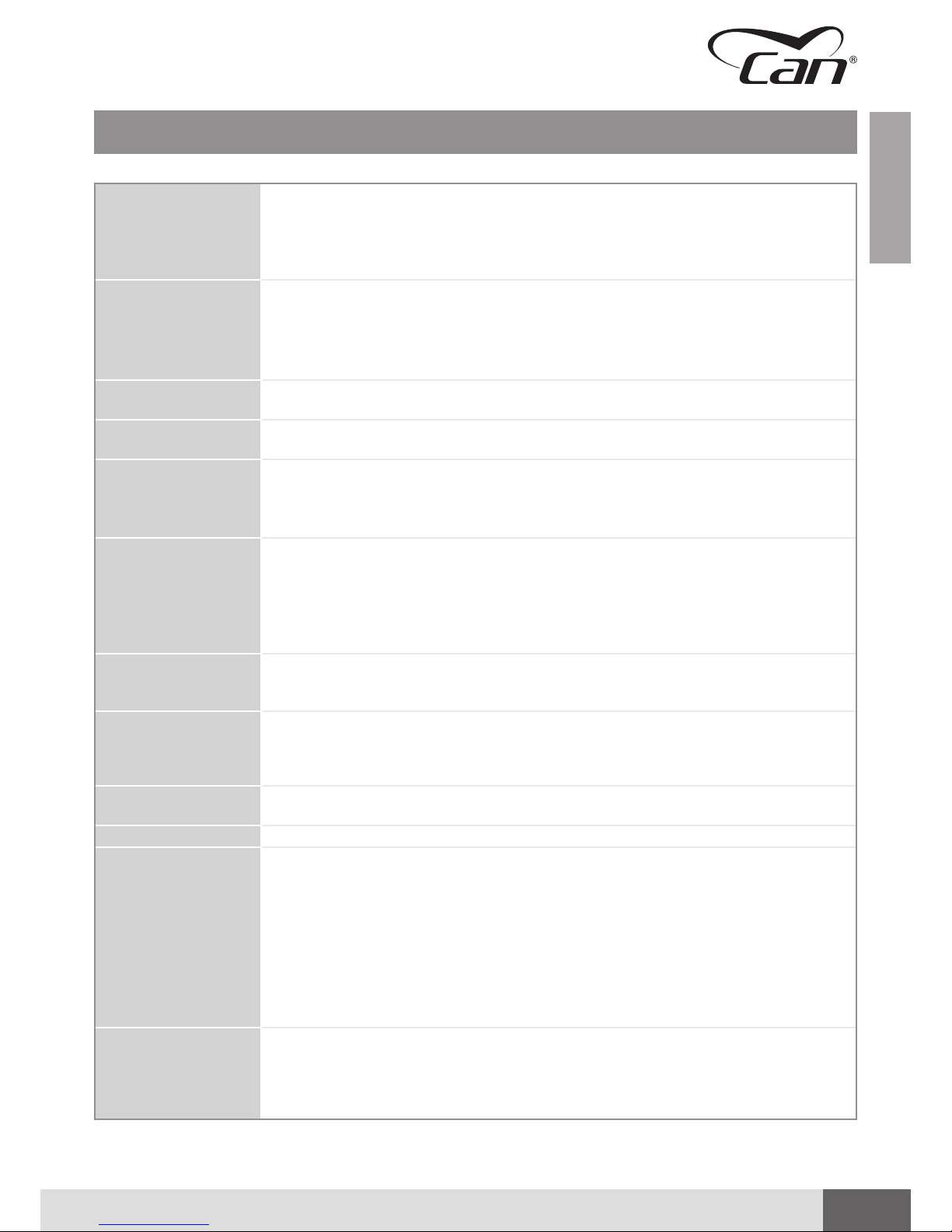

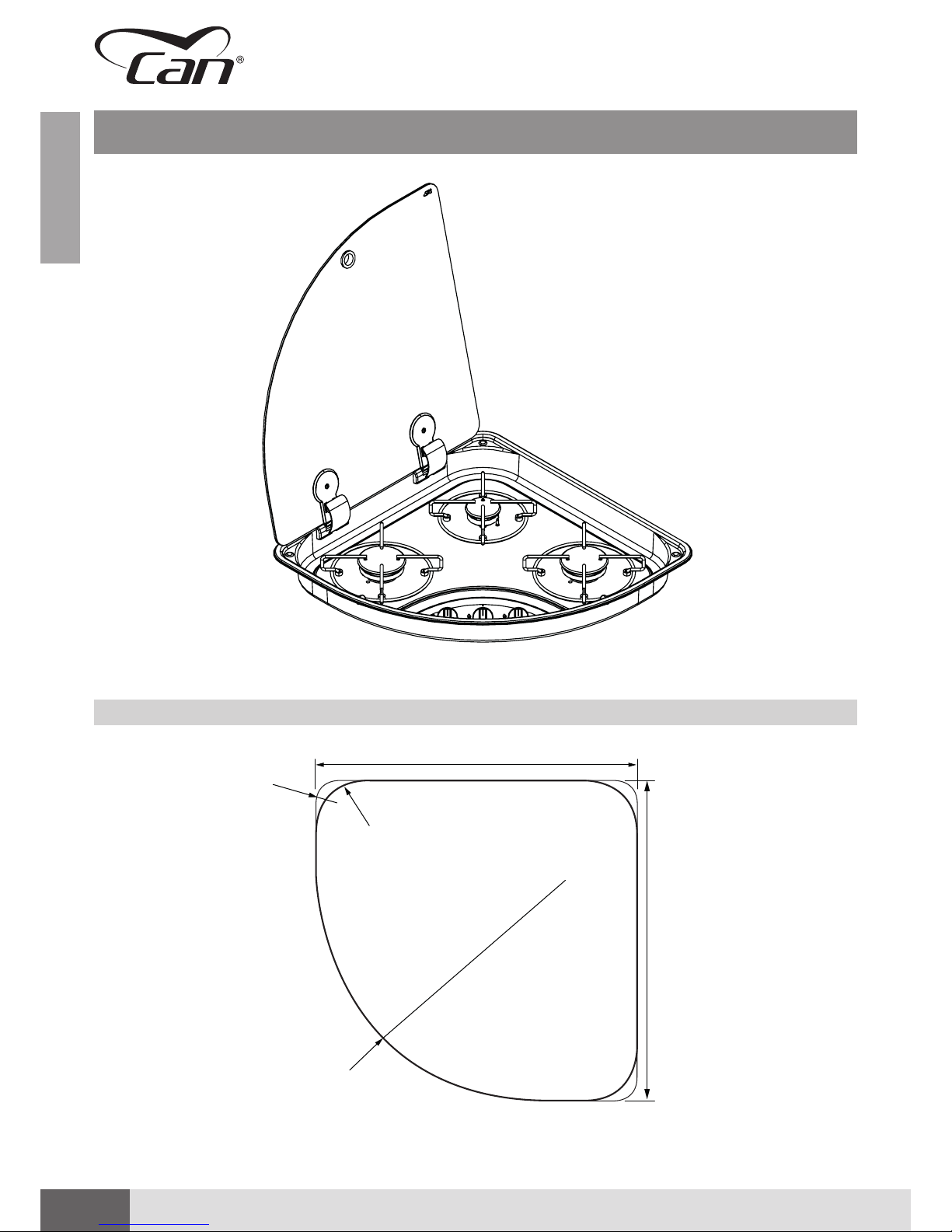

TECHNICAL DATA SHEET: FC1343

A

B

R32

R80

R340

RECESSED HOLE FC1343

Page 11

11

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1343

Dimensions Width 480 mm

Depth 480 mm

Height 105 mm

Weight 5.5 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX)

Pn 1.00 kW – injector ø 0.50 mm – consumption 72.50 g/h

2 x SEMIRAPID burner (SR):

Pn 1.75 kW – injector ø 0.65 mm – consumption 127.0 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

Page 12

12

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

TECHNICAL DATA SHEET: FC1344

RECESSED HOLE FC1344

A

B

R32

R80

R340

Page 13

13

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1344

Dimensions Width 480 mm

Depth 480 mm

Height 105 mm

Weight 5.5 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX)

Pn 1.00 kW – injector ø 0.50 mm – consumption 72.50 g/h

2 x SEMIRAPID burner (SR):

Pn 1.75 kW – injector ø 0.65 mm – consumption 127.0 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

Page 14

14

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

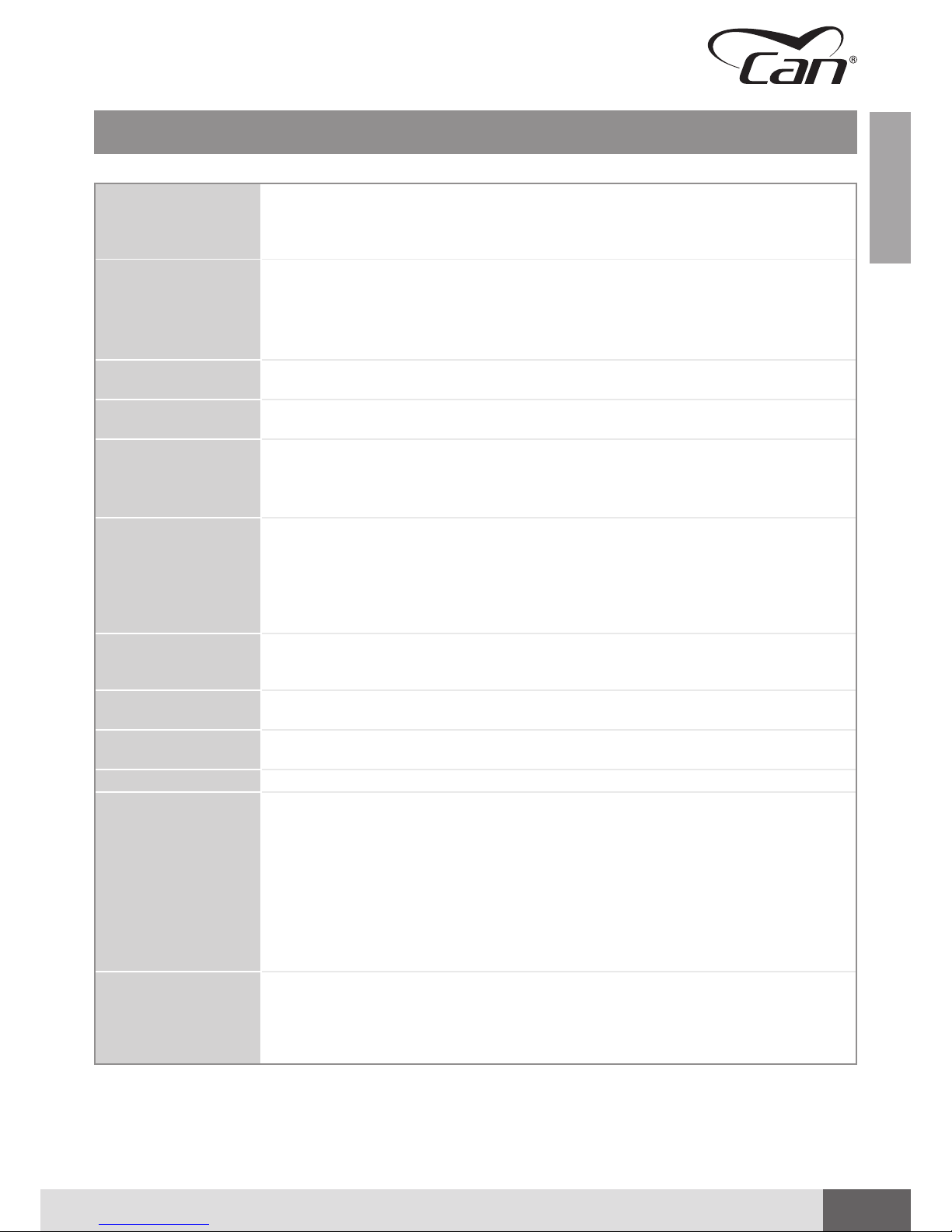

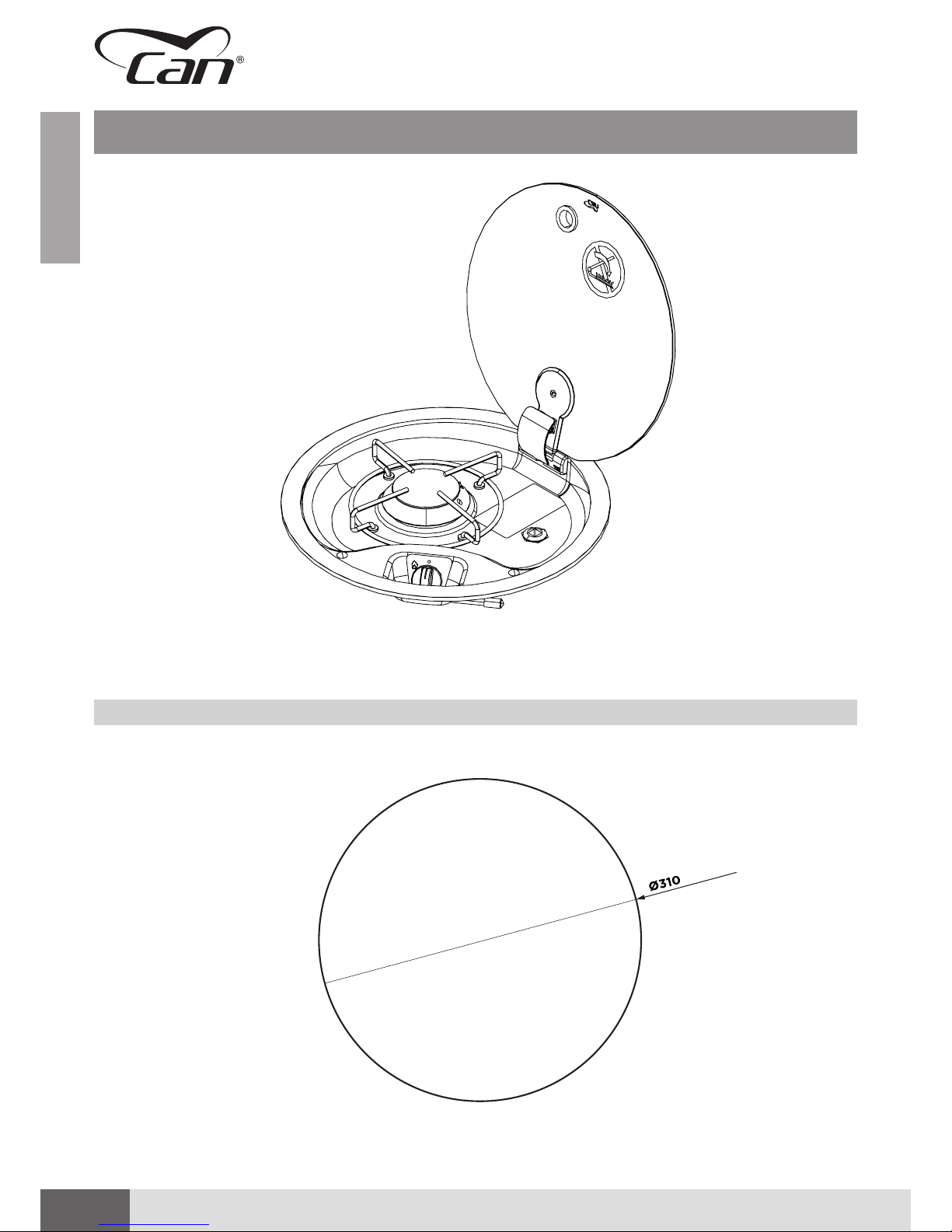

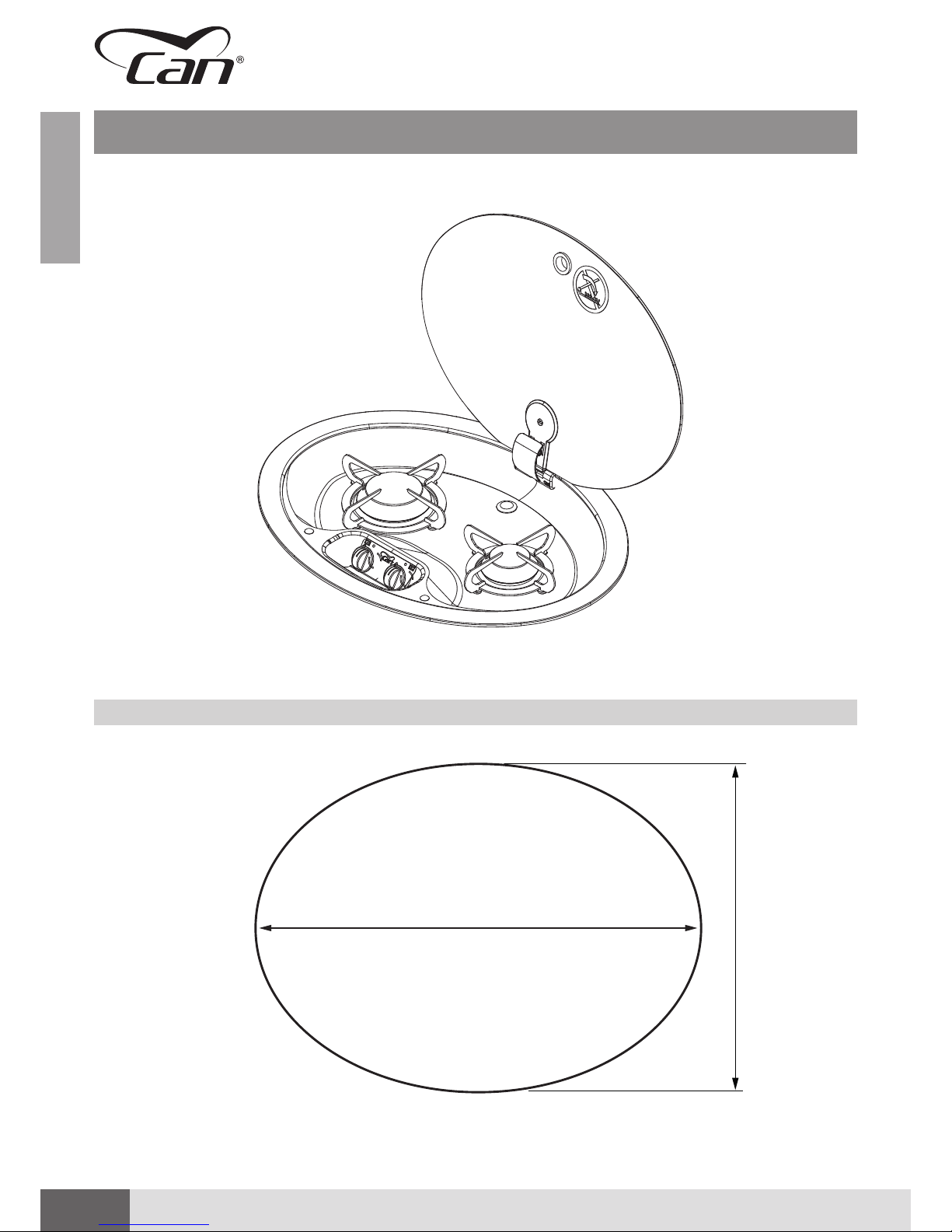

TECHNICAL DATA SHEET: FC1345

RECESSED HOLE FC1345

Please note: secured with adhesive.

Page 15

15

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1345

Dimensions External Diameter (Ø) 340 mm

Height 80 mm

Weight 2.1 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x SEMIRAPID burner (SR):

Pn 2.00 kW – injector ø 0.70 mm – consumption 145.50 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

Gas Connection Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

Page 16

16

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

TECHNICAL DATA SHEET: FC1347

RECESSED HOLE FC1347

A

B

R60

R100

Page 17

17

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1347

Dimensions Width 440 mm

Depth 440 mm

Height 80 mm

Weight 5.3 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX):

Pn 1.10 kW – injector ø 0.52 mm – consumption 80.00 g/h

2 x SEMIRAPID burner (SR):

Pn 2.00 kW – injector ø 0.70 mm – consumption 145.50 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

Page 18

18

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

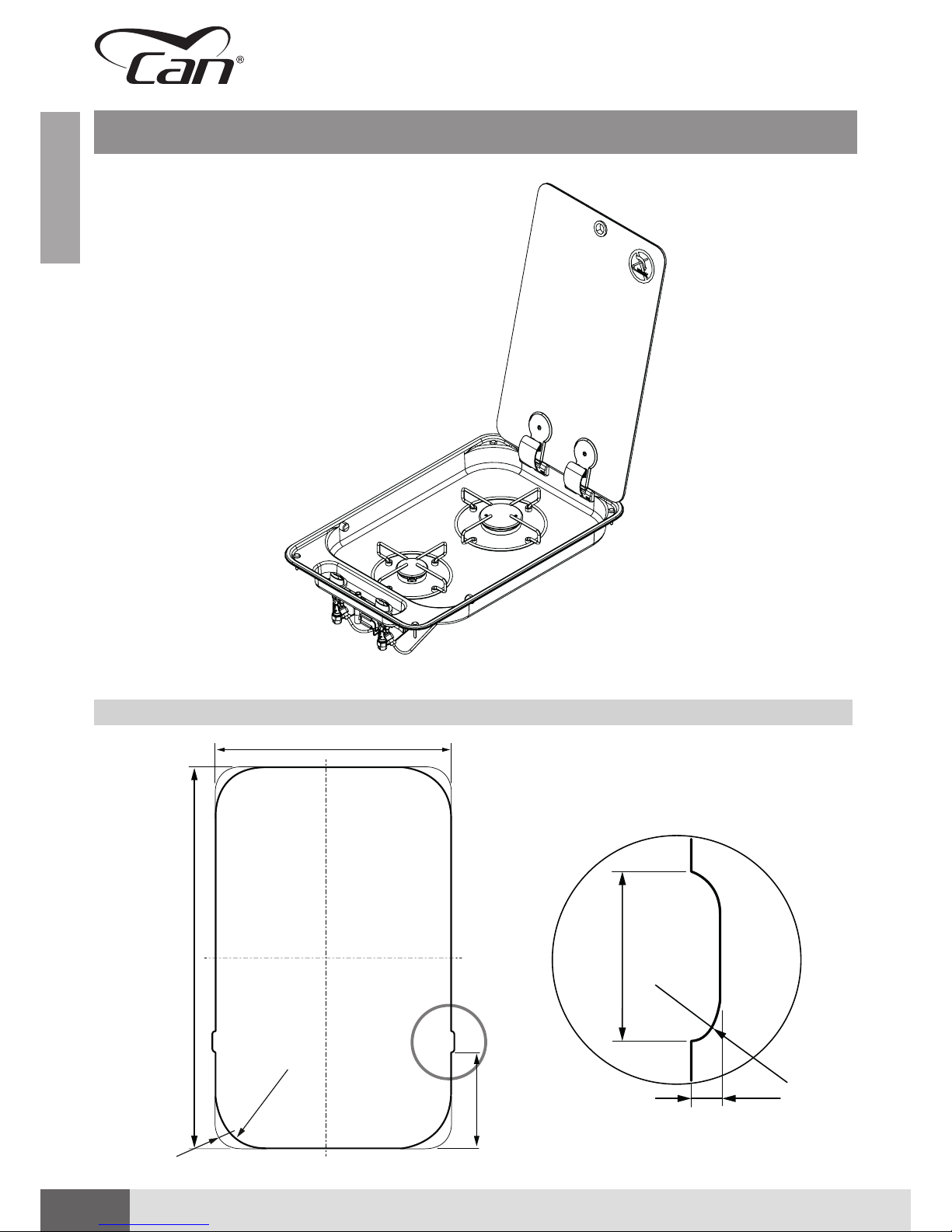

TECHNICAL DATA SHEET: FC1348

RECESSED HOLE FC1348

340

460

Please note: secured with adhesive.

Page 19

19

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1348

Dimensions Width 510 mm (maximum overall dimension)

Depth 390 mm (maximum overall dimension)

Height 80 mm

Weight 3.8 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX):

Pn 1.10 kW – injector ø 0.52 mm – consumption 80.00 g/h

1 x SEMIRAPID burner (SR):

Pn 2.00 kW – injector ø 0.70 mm – consumption 145.50 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

▪ P (PIEZOELECTRIC) – Mechanically/manually operated piezoelectric igniter inserted

in hob unit

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

Page 20

20

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

TECHNICAL DATA SHEET: FC1349

FC1349

RECESSED HOLE FC1349

A

B

5 mm

8 mm

C

85 mm

R10

135 mm

R32

R70

Detail C

Page 21

21

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1349

Dimensions Width 716 mm

Depth 340 mm

Height 48 mm (hob area depth)

102 mm (gas circuit depth)

Weight 5.6 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX):

Pn 1.10 kW – injector ø 0.50 mm – consumption 72.50 g/h

2 x SEMIRAPID burner (SR):

Pn 1.75 kW – injector ø 0.65 mm – consumption 127.00 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

Page 22

22

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

TECHNICAL DATA SHEET: FC1350

RECESSED HOLE FC1350

A

B

5 mm

8 mm

C

85 mm

R10

135 mm

R32

R70

Detail C

Page 23

23

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1350

Dimensions Width 716 mm

Depth 340 mm

Height 48 mm (hob area depth)

102 mm (gas circuit depth)

Weight 5.6 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX):

Pn 1.10 kW – injector ø 0.50 mm – consumption 72.50 g/h

2 x SEMIRAPID burner (SR):

Pn 1.75 kW – injector ø 0.65 mm – consumption 127.00 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

Page 24

24

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

A

B

304 mm

Ø 10

350 mm 350 mm

TECHNICAL DATA SHEET: FC1352

RECESSED HOLE FC1352

D

Detail D

C

85 mm

5

R10

8

R10

40

8

R10

40

Detail C

Page 25

25

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TECHNICAL DATA SHEET: FC1352

Dimensions Width 748 mm

Depth 310 mm

Height 54 mm (hob area depth)

110 mm (gas circuit depth)

Weight 5.8 kg

Hob Unit

(straight valves with

bypass Ø 0.36 mm)

Nominal values:

1 x AUXILIARY burner (AUX):

Pn 1.10 kW – injector ø 0.52 mm – consumption 80.00 g/h

2 x SEMIRAPID burner (SR):

Pn 2.00 kW – injector ø 0.70 mm – consumption 145.50 g/h

Device Class

(EN 30-1-1 4.3)

CLASS 3 – Recessed hob unit

Device Category

(EN 30-1-1 5.1.1.2)

CATEGORY I

Admitted Gases

family

(EN 437)

(EN 30-1-1 4.2.2.4)

GAS OF THE THIRD FAMILY

▪ I3 B/P

▪ I3+

Gas Supply CATEGORY I3 B/P

▪ Butane (G30) 30 mbar

▪ Propane (G31) 30 mbar

CATEGORY I3+

▪ Butane (G30) 28-30 mbar

▪ Propane (G31) 37 mbar

Electric Connection

(only for “E” version with

electronic lighting)

ELECTRIC CONNECTION IN EXTRA-LOW VOLTAGE - 12V / DC

Lighting ▪ S (MANUAL) – using external igniter

▪ E (ELECTRONIC) - 12 V/DC GENERATOR - SPARK - 10Kv @ 30 pF

Gas Connection

Galvanised steel train: Ø 8 mm - 1 mm thick

smooth end piece (30 mm) suitable for press fitting connecting with rigid / flexible hose

Gas Capillaries Copper capillary pipes: Ø 4 mm – 0.5 mm thick

Materials ▪ Stainless steel AISI 304

▪ Glass

▪ Chromium-plated iron

▪ Zama

▪ Brass

▪ Copper

▪ Galvanised steel

▪ Aluminium alloy

▪ Enamelled steel

▪ Epdm

Declaration of

Conformity

(GAR 2016/426/EC)

▪ no asbestos

▪ suitable materials according to chapters 2 and 3 (Annex I)

▪ there are no welds with melting point lower than 450°C

▪ flammable materials were not used

▪ the materials are suitable according to the requirements of chapter 3.7

Page 26

26

ENGLISH

GENERAL PRELIMINARY INFORMATION

Read these instructions carefully before installing and/or using the appliance.

This installation, use and maintenance instruction manual is an integral part of the appliance. Keep this

documentation in a place which all users may have access for future reference. If the appliance is transferred

or sold, make sure that this booklet is also delivered to the new user in order to inform them of the installation

procedure, use and safety requirements.

GENERAL SAFETY WARNINGS

ATTENTION!

CAN S.r.l. will not be held liable for any use other than indicated. Do not use this appliance as

a room heater.

ATTENTION!

Do not modify the appliance, unless the change is authorised and carried out by the

Manufacturer or by his authorised technicians.

ATTENTION!

CAN S.r.l. will not be held liable for personal harm or property damage caused by failure to

comply with the above-mentioned provisions or resulting from tampering with even a single

part of the appliance and using non-original spare parts.

ATTENTION!

Wear the proper personal protective equipment during installation. Also follow the applicable

safety standards.

ATTENTION!

Gas and electric appliances must only be installed by qualified and certified professionals.

ATTENTION!

Make sure that the type of gas and pressure match the specifications of the appliance. The

specifications are shown on the data plate.

ATTENTION!

Pay the utmost attention to standards regarding ventilation of the installation rooms, currently

in force in the country of use.

ATTENTION!

If it is not possible to assemble the device according to the instructions herein, contact

CAN S.r.l.

ATTENTION!

Only replace failed or faulty components with original spare parts CAN S.r.l.

ATTENTION!

Do not close the glass lid when the burners are lit or still hot.

Page 27

27

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

ATTENTION!

Do not allow the cooking vessels to come into contact with the glass lids, the hinges or other

plastic components while the device is in use.

INTENDED USE

The appliance is intended to cook and warm up food. Any other use must be considered improper.

CAN S.r.l. will not be held liable for any use other than indicated.

▪ Do not use the appliance outdoors.

▪ Do not use this appliance as a room heater.

ATTENTION!

Using a gas fired appliance produces heat and humidity in the room it is installed in. Always

guarantee proper ventilation of the rooms keeping air vents/intakes or windows open. If this

is not enough, install a mechanical ventilation/extraction device for the combustion products

(e.g. extractor hood).

ATTENTION!

The appliance is equipped with a glass lid. Glass lids can shatter if overheated or struck by

blunt objects. Always open the lid before lighting any burner, making sure to switch the

burners off and let them cool for a few minutes before reclosing the glass lid at the end of

each operating cycle.

OBLIGATIONS AND PROHIBITIONS

OBLIGATIONS

▪ The appliance’s installation site must have a regulation ventilation system, according to standards in

the sector, be in good maintenance condition and proper working order, as well as appropriately sized

for the purpose.

▪ Follow the instructions in chapter "Instructions for the installer" when installing the appliance.

Installation must only be carried out by qualified technical personnel.

▪ The appliance must only be used with the types of gas indicated in paragraph "Gas categories".

▪ When operating the appliance, only use suitable pots and pans (refer to the specific paragraph)

on the appropriate pan supports supplied with the hob units. Make sure that these devices remain

perfectly horizontal and parallel to the hob, so that they do not tip over and risk causing burns and

scalding for the users. Burn hazard.

▪ Always monitor the hob unit while in use and especially when cooking very greasy dishes or fried

food.

PROHIBITIONS

▪ Do not install the appliance if damaged upon delivery.

▪ Never leave the appliance unattended while in use.

▪ Do not allow the appliance to be used by children younger than 14 years old or persons with reduced

physical, mental or sensory capabilities or without adequate knowledge.

▪ The cooking areas and nearby surfaces become very hot. Do not touch high temperature surfaces.

Burn hazard.

▪ Do not close the lid of the appliance while in use.

▪ Do not use vessels which are damaged, of an inappropriate size and/or which extend beyond the

edges of the hob unit or are positioned improperly.

Page 28

28

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

▪ Do not heat empty pans or without a sufficient amount of cooking fluid.

▪ Do not expose the appliance to air draughts. The burners could go out.

▪ Do not force the knobs if blocked. Contact the Technical Assistance Service.

▪ Do not use the hob unit as a support surface.

▪ Do not modify or tamper with the appliance in any way.

▪ Do not place heat sensitive or flammable objects (e.g. mitts, curtains, alcoholic beverages, etc.) near

the appliance.

IDENTIFICATION OF THE APPLIANCE

There is an identification label at the bottom of the appliance bearing:

▪ serial number information,

▪ typological/functional features,

▪ certification data and CE marking.

The CE marking certifies that the product meets the requirements of EU regulation 2016/426

on appliances burning gaseous fuels.

ATTENTION!

The identification plate must not be removed.

1

9

3 11

10

8 7

4 25 6

pos.

element

1

Manufacturer Logo

2

Manufacturer Address

3

Name of appliance family

4

Series and type

5

Model

6

EC certification serial number

7

Operating pressures - Type-approval parameters - Countries

8

Total power and consumption

9

Barcode - Production serial number

10

Production data

11

CE marking applied by manufacturer

Page 29

29

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

RECEIVING THE APPLIANCE

The appliance is delivered to the customer in a cardboard box (A), protected by shaped polystyrene shells

(B) to avoid damage during transport and storage.

In addition to the appliance, the box also contains:

▪ the installation, use and maintenance manual (C),

▪ a fixing kit (D) including screws and accessories for installation of the appliance on the support structure.

A

B

D

C

CAN S.r.l.

Via Nazionale 65,

25080 - Puegnago del Garda (BS) ITALY

T. +39 0365 555909

F. +39 0365 651822

info@cansrl.com

www.cansrl.com

DE

HANDBUCH FÜR INSTALLATION,

GEBRAUCH UND WARTUNG

serie FC

IT

MANUALE DI ISTRUZIONI

INSTALLAZIONE-USO-MANUTENZIONE

EN

INSTALLATION, USE AND

MAINTENANCE INSTRUCTION MANUAL

FR

MANUEL D’INSTRUCTIONS D’INSTALLATIOND’UTILISATION-ET D’ENTRETIEN

ES

MANUAL DE INSTRUCCIONES

INSTALACIÓN-USO-MANTENIMIENTO

CONTROL AND HANDLING

Upon receiving the appliance, proceed to unpack it.

After having removed all the packaging material and protective film, check for any faults.

Should any faults be discovered, do not install the appliance and contact your dealer within 8 days from

the date of purchase, reporting the data on the identification label of the appliance and the problems

encountered.

ATTENTION!

Do not leave unattended or release the packaging or parts of it into the environment because

they are potentially hazardous (risk of suffocation for children and animals).

Lift the appliance by hand to move it to the installation site.

ATTENTION!

During handling, take care not to damage the appliance, persons, animals or objects in the

immediate vicinity.

DISPOSING OF THE PACKAGING

The materials used for packaging are recyclable and must be collected according to local standards on

separate waste collection.

ATTENTION!

Separate the different materials making up the packaging and dispose of them in compliance

with standards in force in the Country of installation.

Page 30

30

ENGLISH

INSTRUCTIONS FOR THE INSTALLER

ATTENTION!

Installation and all the interventions on the appliance described in this instruction manual

must be carried out by qualified technical personnel and in compliance with standards in

force.

ATTENTION!

The gas connection systems and the installation rooms must be suitable and meet the safety

standards in force in the Country of use.

ATTENTION!

During installation, maintenance or repair operations, always close the main gas valves, so

that the gas supply line to the hob unit is "GAS FREE" and there is no risk of fire/explosion or

poisoning/suffocation.

ATTENTION!

Make sure the power line is also disconnected to avoid the risk of the installer being

electrocuted.

▪ Do not install or use the appliance if damaged.

▪ Respect the minimum distance from the walls and other equipment (see paragraph “Safety distances”).

▪ The appliance is not connected to a combustion product extractor device. The user must make sure

that the appliance is installed in an environment with a high ventilation rate.

INSTALLATION ROOM

FEATURES OF INSTALLATION ROOM

The appliance was not designed to work outdoors. It is not allowed to install the appliance

outdoors and directly exposed to the elements.

The appliance must be installed indoors, in a room suitable for the purpose. The room was meet the safety

standards in force in the Country of use.

ATTENTION!

The installation rooms must have a continuous air exchange or at least such to guarantee normal

and correct gas combustion (according to standard UNI 7131 or other technical standards of

reference in the sectors of use, for example EN721 - EN1645-1 - EN1646-1 - EN1949 - EN ISO 10293).

FLUE GAS EXHAUST

The appliance is not equipped with an extraction/exhaust system of flue gas and combustion products.

Always check that there are proper ventilation vents in the room.

If a hood is installed above the hob unit, refer to the installation instructions of the hood which

shows the correct distance to be respected.

Page 31

31

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

INSTALLATION ON SUPPORT STRUCTURE

The appliance must be mounted on a support structure, made of material resistant to heat and with all of

the sturdiness requirements indicated by the technical sector standards (for example EN14749). The work

table must be perfectly horizontal and perpendicular to all surrounding vertical panelling. The area near

the appliance could get very hot. Pay the utmost attention and do not place sockets, other household

appliances, power cables, piping and any other heat-sensitive or flammable material in this area.

ATTENTION!

The appliance must be installed in a room without air draughts which can have a negative

effect on combustion. The chosen installation position must also prevent the accumulation of

unburnt gases.

Comply with the sizes indicated in this manual. Any deviation could cause the temperature to rise excessively.

The surrounding surfaces must be able to withstand temperature rises admitted by standard EN30-1-1 and in

compliance with the design of this unit. All combustible material, such as curtains and shelves, must be kept

far away from the appliance. Check the admissible temperature of the materials used for the surrounding

surfaces to guarantee their compliance with the requirements of EN30-1-1.

RECESSED HOLE

The support structure must be provided with a suitable recessed hole. For information regarding the

dimensions of the hole of your model, refer to the table below and follow the drawings in the technical data

sheets of each model in the first section of this manual.

recessed hole sizes

model a

[mm]

b

[mm] Ø [mm]

FC1336 530 340 -

FC1337 340 530 -

FC1343 480 480 -

FC1344 480 480 -

FC1345 - - 340

FC1347 440 440 -

FC1348 510 390 -

FC1349 716 340 -

FC1350 716 340 -

FC1352 748 310 -

Refer to the drawings in the TECHNICAL DATA SHEETS for the recessing details of each model.

Page 32

32

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

SAFETY DISTANCES

The appliance must be kept a certain distance away from side and upper walls. Consult the following table:

dimensions and minimum safety distances for installation

model a

[mm]

b

[mm]

c

[mm]

d

[mm]

e

[mm]

FC1336

50 55 640 650 110

FC1337

50 105 550 650 110

FC1343

50 100 680 650 110

FC1344

50 100 680 650 110

FC1345

50 100 540 650 110

FC1347

50 100 640 650 110

FC1348

50 100 710 650 110

FC1349

50 55 826 650 110

FC1350

50 55 826 650 110

FC1352

50 55 858 650 110

max

150 mm

D

D

E

C

B

A

1

D

C

B

E

A

1

D

C

E

B

A

1

If the appliance is recessed above an oven or another

powered home appliance, a separation panel must

also be installed as indicated in point 1.

Remember to prepare adequate holes in the furniture

to pass through the gas, water and electrical power

pipes of the appliance, if any.

Page 33

33

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

POSITIONING THE APPLIANCE

Proceed as follows to position the appliance on the support structure:

step action

1 Position the gasket (sold separately) on the edges of the metal moulding or sealant paste (if present).

2 Position the appliance on the recessed hole and push it onto the support structure.

3 Secure the appliance by the fixing screws provided in the specific kit and screw them into the holes made at

the four corners of the metal moulding.

Note: make sure that the appliance is positioned properly in the slot before performing the final fixing.

The following are excluded from the aforementioned fixing system:

▪ models FC1345 and FC1348 which, since they do not have fixing holes, require an adhesive

to be placed on the external perimeter of the metal moulding for them to be glued directly

to the work table;

▪ model FC1352, which is fixed from the bottom in line with the bushings on the lower surface

of the perimeter edge of the hob unit.

ATTENTION!

There must be an opening below the hob of at least 50 x 50 mm for the passage of the gas

and electrical connections.

EQUIPMENT REQUIRED

4 x 4 x

2

1

3

Page 34

34

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

GAS CONNECTION

ATTENTION!

Before setting up the connection, make sure that the gas system and the installation rooms are

suitable for the purpose and comply with the standards in force in the Country of installation.

Refer to the specific technical standards regarding conformity of gas systems (LPG) for the

household (UNI CIG 7131 and 7129), nautical ( UNI EN ISO 10239) and recreational vehicles

(UNI EN 1949) sectors.

Before connecting the gas, check that:

▪ the supply line is free from obstructions and has a sufficient flow rate to guarantee correct operation

of the appliance;

▪ there is a suitable pressure regulator/reducer compliant with the gas categories used on the appliance

immediately downstream of the gas cylinder or container feeding the system;

▪ a gas shut-off valve or a valve disconnecting the system is installed on the supply line, downstream

of the regulator and immediately upstream of the appliance being connected, in a place which can

easily be accessed and inspected (Please note: this valve must always be shut during installation and

maintenance on the appliance).

ATTENTION!

Make sure that the type of gas feeding the appliance is among those allowed and listed in the

instruction booklet (see paragraph “Gas categories”).

CAN S.r.l. declines any liability for incorrect connections, not carried out in a workmanlike manner or

performed by non-professionally qualified individuals.

GAS CATEGORIES

The appliance was designed for correct operation only with the types of gas categories and operating

pressures listed below:

gas category and country of

destination

name of gas operating pressure

I3B/P (30)

AT-BE-DE-DK-FI-GB-NL-NO-PT-SE-SI

Butane (G30)

Propane (G31)

30 mbar

30 mbar

I3+ (28-30/37)

BE-CH-ES-FR-GB-IE-IT-PT-SI

Butane (G30)

Propane (G31)

28 - 30 mbar

37 mbar

CONNECTION PIPE REQUIREMENTS

ATTENTION!

The appliance must be connected to the gas pipeline by means of a suitable connection pipe

making use of certified sealed fittings of the most suitable type for the application.

It is possible to use flexible connection hoses. They must:

▪ always be able to be inspected,

▪ be protected against contact with hot parts (e.g. burner cups),

▪ be protected from the movable parts of the recessing (drawers, doors, etc.),

▪ have a length which complies with the technical standards for each sector of reference.

Avoid any type of mechanical stress on the flexible hoses during installation and use (protection against

traction, twisting, crushing, etc.).

ATTENTION!

Perform maintenance and periodically replace the flexible hose within the expiration date

written on the sheath. Do not use expired or damaged flexible hoses by any means.

Page 35

35

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

GAS CONNECTION PROCEDURE

The appliance is supplied with a gas train with a

smooth end section and free for at least 30 mm, fit

to house suitable press fittings. Proceed as follows

to set up the gas connection:

Please note: the fittings are not supplied with the product.

They are solely supplied and connected by the installer.

EQUIPMENT REQUIRED

step action

1 Connect the Ø 8 mm pipe to the clamp fitting of

the gas distribution network.

ATTENTION!

During the installation and connection

operations, the gas supply pipe of the

appliance must not be subject to twisting,

traction or any other mechanical stress

which could jeopardise tightness and

strength.

After having connected the appliance to the gas mains, check the tightness of the fittings with soap and

wa t er.

ATTENTION!

It is absolutely prohibited to use naked flames to check tightness and to put the device into

service! If the test is satisfactory, light all the burners to make sure that the flame is regular

and stable.

ELECTRICAL CONNECTION (only for E version)

E versions are equipped with a low voltage spark generator (12 V DC) to light the burners, generally installed

on the metal bracket at the bottom of the hob unit. To connect the generator to the local power mains,

proceed as follows:

step action

-

+

12 V DC

1

1 Power cable positive pole

2 Power cable negative pole

3 Connection cable generator

button

4 Glow plugs fast-on housing

5 Glow plugs fast-on

connectors

6 12V DC (+ -) power supply

fast-on connectors

2

3

4

44

55 5 6

1 Connect the free end of the black conductor (-)

to the negative pole of the terminals of the mains

or of a battery.

2 Connect the free end of the black conductor (+)

to the positive pole of the terminals of the mains

or of a battery.

ATTENTION!

Any type of connection of the appliance

to a power mains other than 12V and in

direct current (DC) is strictly prohibited.

Any other connection can pose a severe

danger for the user of the appliance and

cause irreversible damage to the device

itself.

Page 36

36

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

TROUBLESHOOTING AFTER INSTALLATION

If the appliance does not work properly after installation, perform the controls in the table.

problem possible solutions

The gas flow

seems irregular

Check that the gas cock is completely open.

Check that the fuel supply circuit has a suitable flow rate.

Check that the burner spreaders and relative caps are positioned correctly and free

from obstructions.

Check that the nozzles are suitable for the type of gas used.

Check compatibility and correct calibration of the pressure regulator, if applicable.

Check the gas supply pipe (pipe obstructed, bent/crushed, excessively long,

unsuitable, etc.).

If the appliance still does not work properly after all the checks have been made, contact the

authorised local dealer.

Page 37

37

ENGLISH

INSTRUCTIONS FOR USE

DESCRIPTION

See the exploded drawings on the following pages for the position of the components listed in

the table.

pos.

component

1

Wire pan support

2

Ring for glass lid

3

Glass lid

4

Hinge for glass lid

5

Plastic cap

6

Silent block for resting lid

7

Fixing screws cap

8

Hob unit fixing screw

9

CE label

10

Metal moulding

11

SR burner cup with injector nozzle

12

Gas capillary pipe for SR burner

13

Gas cock with safety valve

14

AUX burner cup with injector nozzle

15

Gas capillary pipe for AUX burner

16

Main gas train

17

SR burner spreader

18

SR burner cap

19

AUX burner spreader

20

AUX burner cap

21

Burner caps and spreaders fixing screws

22

Rubber feet/bushings for pan support

23

Knob for gas cock

24

Gas cock fixing nut

25

Control panel sticker

26

Piezoelectric igniter

27

Ignition glow plug

28

Thermocouple

29

Burner stud bolt

30

Thermocouple fixing nut

31

Glow plug fixing clip

32

Hinge and silentblock fixing screw

33

Glass support rubber buffer

34

Bushing for pan retaining system

35

Single-pole lighting button

Page 38

38

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

TYPE FC1336

detail C

29

2

4

9

detail C

16

17

18

21

22

25

3

6

5

10

26

13

12

7

8

Fixing kit

detail B

detail A

detail A

27

31

detail B

30

28

32

32

24

23

20

19

14

1

11

15

Page 39

39

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TYPE FC1337

detail B

30

detail C

29

7

8

Fixing kit

detail A

27

31

28

1

23

32

4

9

11

detail A

detail B

detail C

16 14 15

13

12

26

6

32

25

24

23

17

18

21

22

20

19

Page 40

40

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

TYPE FC1343

15

10

11

16

22

24

detail B

28

25

detail C

29

7

8

Fixing kit

30

2

3

4

32

17

18

19

20

21

1

23

6

32

9

14

1312

detail A

27

31

detail A

detail C

detail B

Page 41

41

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TYPE FC1344

15

10

11

16

22

detail B

28

25

detail C

29

7

8

Fixing kit

30

2 3

432

17

18

19

20

21

1

23

6

32

9

14

1312

detail A

27

31

24

detail A

detail B

detail C

Page 42

42

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

TYPE FC1345

detail B

28

30

detail A

27

31

33

32

34

11

1613

12

25

23

24

17

18

22

1

2

10

9

detail A

detail B

3

4

32

Page 43

43

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TYPE FC1347

detail B

28

7

8

Fixing kit

30

detail A

27

31

2

1

22

17

18

19

20

4 32

109

23

25

11

12

13

detail A

detail B

16

15

14

3

24

Page 44

44

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

TYPE FC1348

detail B

28

30

detail A

27

31

15

33

34

11

1613

12

25

23

24

22

1

2

10

9

detail A

3

4

32

18

17

20

19

detail B

14

Page 45

45

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TYPE FC1349

detail B

28

detail C

29

7

8

Fixing kit

30

detail A

27

31

2

17

18

19

20

4 32

10

9

23

25

11

13

detail A

detail B

16

1

3

22

21

6 5

32

detail C

Page 46

46

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

1

2

3

10

11

12

detail C

16

15

17

18

19

20

22

6

32 5

14

detail B

TYPE FC1350

4

32

23

24

25

13

9

detail A

21

detail B

28

detail C

29

7

8

Fixing kit

30

detail A

27

31

Page 47

47

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

TYPE FC1352

detail B

28

30

detail A

27

31

1

22

19

20

17

18

6

32

4

32

23

24

25

10

11

16

15

detail B

13

9

14

detail A

12

35

3

Page 48

48

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

SAFETY WARNINGS DURING USE

ATTENTION!

During operation and for a few minutes after use, some parts of the appliance reach very high

temperatures. Do not touch these parts without adequate personal protections. Burn hazard!

▪ Always use the supplied pan supports. Do not place pots and pans directly on the burner spreader

or caps.

▪ Do not cook food in direct contact with the flame.

▪ Do not cover the appliance or parts of it with aluminium foil or similar.

▪ Do not heat tin boxes or hermetically closed containers on the appliance as the overpressure generated

by the heat could make them explode and cause serious personal harm.

▪ Make sure that the cooking vessels sit properly on the pan support without rocking. The diameter of

the vessels must be adequate for the chosen burner and must not protrude from the pan support. The

Manufacturer will not be held liable and will not acknowledge the Warranty rights if this requirement

is neglected.

▪ Always monitor the appliance throughout operation.

▪ Switch the burner off after each use.

▪ Do not set or keep flammable liquids or materials or objects which can easily catch fire on the appliance

or in its immediate vicinity.

▪ Do not place hot pans on the controls.

▪ Do not light the burner without pans and/or with empty pans.

ATTENTION!

If cooking grease or hot oil catches fire, do not put out the flames with water, but suffocate

them with a moist rag or similar and immediately notify the fire brigade.

USE

Before using the appliance for the first time, clean it and all of its components as instructed

in the paragraph “Cleaning”.

The first few times the appliance is used, it could release smoke and unpleasant smells.

There is no reason for concern as this is due to the combustion of the grease used to process it in the

factory. We recommend airing out the rooms.

The burners are equipped with safety thermocouple.

The thermocouple is a heat sensitive device: as long as it is heated by the fire of the lit burner, it

allows gas to exit the nozzle; if the fire goes out accidentally (for example when liquid spills from

the pan), in a few seconds the thermocouple cools off and this blocks the release of gas from the

nozzle preventing the room from being saturated with unburnt gas.

use of burners

OFF

MAX

MIN

Page 49

49

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

LIGHTING THE BURNERS

ATTENTION!

Before use, make sure that the burner spreaders, caps and pan holders are positioned properly.

burner spreader positioning

The matching burner is indicated on each knob.

The burner can be lit:

▪ manually using the external igniter (on S versions),

▪ electronically with 12 V/DC generator (on E versions),

▪ piezoelectrically with mechanically/manually operated piezoelectric igniter (on P versions).

Proceed as follows to light the burner:

step action

1

2

1 press the knob corresponding to the burner you

want to light and turn it anticlockwise (to the

maximum symbol).

2 Simultaneously, activate the electric (or

piezoelectric) lighting device with several fast

repeated pulses.

3 When lit, keep the knob pressed all the way for

another 5 seconds (at maximum) and then release

it, adjusting the desired intensity of the flame.

Please note: this delay in releasing the knob heats

up the safety thermocouple.

If the burner does not remain lit when you release the knob, it means that the thermocouple did not heat

up sufficiently. To solve this problem, repeat the operations described in the table, holding the knob down

longer after the burner is lit.

ATTENTION!

The burner must be lit without any pan or any other object on the hob unit above the burners.

Page 50

50

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

ADJUSTING THE FLAME

Check that the flame is regular and stable.

To adjust the flame, turn the knob to the desired

position (MIN or MAX).

The knob can also be set in the middle, between the

maximum and minimum position. Do not place the

knob between the maximum and “off” position.

ATTENTION!

If the flame is irregular, check that the

burner spreader and caps are positioned

properly.

ATTENTION!

The flame must not extend beyond the

bottom of the pan. Use only vessels with

a flat bottom.

flame adjustment range

90°

160°

MAX

MIN

adjusting the flame

COOKING OR WARMING UP FOOD

ATTENTION!

Do not forget the burners on without vessels or with empty vessels on them.

Place the pan in the middle of the lit burner, so that it is stable on the pan support.

Use only pans, trays and accessories expressly designed for this purpose, made in material resistant to high

temperatures and suitable for contact with food.

maximum and minimum admissible diameters for pots and pans

AUX

SR

Ø MIN Ø MAX

SR 160 220 mm

AUX 80 160 mm

key:

= Ø max pots and pans

For the best efficiency of the burners, with maximum performance and minimum gas consumption,

it is recommended to use vessels of a diameter suited to the type of burner chosen.

For rational use of energy, it is recommended to cook with pans covered with the supplied lid

and to lower the flame to make and keep the water boiling, without unnecessarily overheating

the cooking liquids.

Page 51

51

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

SWITCHING OFF THE BURNER

When finished cooking, switch off the appliance by placing the knob at “off”.

Remove the pan from the appliance using appropriate personal safety protections.

OPERATING FAULTS

The following situations are considered operating faults and require the intervention of the Assistance

Service if:

▪ The burner flame is yellow.

▪ Soot is formed on the cooking utensils.

▪ The burners do not light correctly.

▪ The burners do not remain lit.

▪ The burners go out when the kitchen doors are opened or closed.

▪ It’s difficult to turn the gas valves.

If the appliance does not work properly, contact the authorised local Assistance Service.

WHAT TO DO IN CASE OF MALFUNCTIONING

Before contacting the nearest Assistance Centre, carry out the following operations:

▪ check that the hob unit is correctly connected to the system;

▪ check that the hob unit is correctly powered;

▪ find the appliance data on the CE plate bearing the product’s serial number;

▪ find the date and a suitable proof (invoice or till receipt) of purchase of the appliance.

ATTENTION!

While waiting to solve the problem, the appliance should not be used and should be

disconnected from all the systems it is connected to.

Do not try to repair or modify the appliance.

CAN S.r.l. will provide maximum collaboration and assistance should any technical or other type

of problem arise on any of its products.

For any information or assistance request, contact the nearest dealer or contact CAN S.r.l.

Page 52

52

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

MAINTENANCE AND CLEANING

No specific maintenance procedures are required for the appliance aside from correct and regular

cleaning.

ATTENTION!

Before cleaning the appliance, make sure that the burner is off.

Always wait for the appliance to completely cool down.

▪ Clean the appliance on a regular basis to prevent the materials making up the surface from deteriorating.

▪ Disconnect the power (if on) and close the gas supply cocks before any cleaning operation or when

expected to remain idle for a long time. Make sure that all the knobs are always in the “off” position

when you are finished using the appliance.

▪ Do not use steam appliances or direct water jets to clean the hob unit.

ATTENTION!

Do not use hydrochloric acid (muriatic acid and/or detergents containing chlorides) on the

stainless steel surfaces.

ATTENTION!

Not use abrasive powder detergents which could ruin the appearance of the surface finish.

If some particularly acidic substances (e.g. vinegar, lemon juice, etc.) remain on the appliance

for a long time, they could corrode the surfaces creating unsightly rings which however do not

jeopardise appliance operation.

type of cleaning description

STAINLESS STEEL SURFACES

Use a soft cloth slightly soaked in specific neutral detergent or warm

vinegar. Rinse with warm water and dry.

Please note: follow the manufacturer’s instructions to see how to use the

cleaning products.

BURNER SPREADER/CAPS

Remove the components from their housing and wash them with warm

water and dishwashing soap. Stubborn filth on the enamelled components

can be removed using a slightly abrasive sponge and a degreaser, taking

care not to damage the surfaces.

Rinse with warm water and dry. Afterwards, put the components back in

place with the utmost attention.

KNOBS

Use a soft cloth slightly soaked in neutral detergent.

Make sure that the detergent does not leak under the knobs.

Do not remove the knobs from the pin they are mounted on.

Please note: follow the manufacturer’s instructions to see how to use the

cleaning products.

ATTENTION!

During and after cleaning, check that no nozzle hole is obstructed by impurities or whether

any detergent residues remain at the bottom of the burner cups. If so, remove the impurities

and residues by vacuuming them, without using liquid detergent or similar.

Only for products with steel or chrome-plated iron pan holders: progressive burnishing of the

pan holders is caused by normal use of the appliance and does not jeopardise its performance.

Page 53

53

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

After cleaning, make sure that the pan holders have been put back in place correctly, paying attention not

to invert them or couple them to different burners. The pan holders must always be stable and sit without

rocking on the hob unit or be set firmly inside the specific fixing seats.

LONG IDLE PERIODS

If you do not expect to use the appliance for a long period of time (beyond 2-3 weeks) proceed as follows:

▪ clean the appliance thoroughly;

▪ disconnect or safely interrupt the electrical and gas supply.

WASTE DISPOSAL

The symbol of a crossed out bin indicates that the product must be sent to suitable separate

waste collection facilities. Do not dispose of the appliance bearing this symbol together with

normal household waste.

ATTENTION!

Unlawful or incorrect disposal of the product entails application of the sanctions set forth by

current legal standards.

Abide by the standards in force in your country. Make the appliance intended for disposal unusable by

removing the power cables.

WARRANTY

The warranty terms and conditions set forth by law apply. If the product should be found to be faulty,

contact the nearest Authorised Assistance Centre or your Dealer.

To have the appliance repaired, you must send the following documentation:

▪ copy of the invoice with the date of purchase of the product;

▪ description of the fault.

Page 54

54

ENGLISH

SPARE PARTS

ATTENTION!

Use only original spare parts. The use of components other than those supplied by the

Manufacturer terminates the Warranty and could cause personal harm or damage the appliance.

ATTENTION!

Parts must be replaced safely by authorised and qualified personnel.

To make it easier to recognise the spare parts, read the tables below together with the exploded

drawings shown in paragraph "Description".

SPARE PARTS - FC1336

The column "Pos." refers to the exploded drawing "TYPE FC1336" on page 38.

P VERSION - PIEZOELECTRIC LIGHTING

code

component

pos.

component

2000008 4

Hinge for glass lids

3000506 3

Glass lid FC1336

3000083 22

Tall rubber bushing for pan holders

3000073 1

Wire pan holder for AUX burner

3000074 1

Wire pan holder for SR burner

3000454 6

Silentblock Ø 15

4000026 29

2nd series lid stud bolt

4000170 2

Glass lid cable gland

4000224 7

Intense black screw cap

4000260 23

Black/chrome knob Ø 34

4000031 30

Universal nut for thermocouple

4000069 28

Thermocouple for fast-on magnet cock

4000025 19

Burner spreader for 2nd series AUX burner

4000021 20

Ø 55 perforated and enamelled cover 2nd series AUX burner

4000024 17

Burner spreader for 2nd series SR burner

4000019 18

Ø 75 perforated and enamelled cover 2nd series SR burner

4000153 5

Cap for blind holes Ø 5.5 PE black

4000318 21

Countersunk flat head screw + M2.5 x 18 DIN EN ISO 7046 GV

4000223 8

Chipboard screw to secure the hob unit

7000138 -

Glass lid flame label

4000253 26

Short piezo igniter 18 x 1.5 mm

4000321 27

Burner lighting glow plug L 410

4000232 27

Burner lighting glow plug L 350

4000137 31

Clip for glow plug

4000229 32

5 x 6 CH screw to secure the hinge and silentblock

Page 55

55

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

E VERSION - ELECTRONIC LIGHTING

code

component

pos.

component

4000319 -

Single-pole button 3A red key

2000147 -

12V generator kit + assembly bracket

4000168 -

Universal lighting cable (-)

4000169 -

IGN lighting cable L320

4000297 -

IGN lighting cable 2 (+)

4000232 27

Burner lighting glow plug L350

4000321 27

Burner lighting glow plug L410

4000137 31

Clip for glow plug

SPARE PARTS - FC1337

The column "Pos." refers to the exploded drawing "TYPE FC1337" on page 39.

P VERSION - PIEZOELECTRIC LIGHTING

code

component

pos.

component

2000008 4

Hinge for glass lids

3000495 3

Glass lid FC1337

3000083 22

Tall rubber bushing for pan holders

3000073 1

Wire pan holder for AUX burner

3000074 1

Wire pan holder for SR burner

3000454 6

Silentblock Ø 15

4000026 29

2nd series lid stud bolt

4000170 2

Glass lid cable gland

4000224 7

Intense black screw cap

4000260 23

Black/chrome knob Ø 34

4000031 30

Universal nut for thermocouple

4000069 28

Thermocouple for fast-on magnet cock

4000025 19

Burner spreader for 2nd series AUX burner

4000021 20

Ø 55 perforated and enamelled cover 2nd series AUX burner

4000024 17

Burner spreader for 2nd series SR burner

4000019 18

Ø 75 perforated and enamelled cover 2nd series SR burner

4000318 21

Countersunk flat head screw + M2.5 x 18 DIN EN ISO 7046 GV

4000223 8

Chipboard screw to secure the hob unit

7000138 -

Glass lid flame label

4000253 26

Short piezo igniter 18 x 1.5 mm

4000321 27

Burner lighting glow plug L 410

4000232 27

Burner lighting glow plug L 350

4000137 31

Clip for glow plug

4000229 32

5 x 6 CH screw to secure the hinge and silentblock

E VERSION - ELECTRONIC LIGHTING

code

component

pos.

component

4000319 -

Single-pole button 3A red key

2000147 -

12V generator kit + assembly bracket

4000168 -

Universal lighting cable (-)

4000169 -

IGN lighting cable L320

4000297 -

IGN lighting cable 2 (+)

4000232 27

Burner lighting glow plug L350

Page 56

56

ENGLISHENGLISH

GAS HOB UNITS WITH GLASS RECESSED LID ▪ FC series

4000321 27

Burner lighting glow plug L 410

4000137 31

Clip for glow plug

SPARE PARTS - FC1343

The column "Pos." refers to the exploded drawing "TYPE FC1343" on page 40.

VERSION S - MANUAL LIGHTING

code

component

pos.

component

2000008 4

Hinge for glass lids

3000430 3

Glass lid FC1343

3000083 22

Tall rubber bushing for pan holders

3000073 1

Wire pan holder for AUX burner

3000074 1

Wire pan holder for SR burner

3000453 6

Silentblock Ø 11

4000026 29

2nd series lid stud bolt

4000170 2

Glass lid cable gland

4000224 7

Intense black screw cap

4000008 23

Standard black knob

4000031 30

Universal nut for thermocouple

4000069 28

Thermocouple for fast-on magnet cock

4000025 19

Burner spreader for 2nd series AUX burner

4000021 20

Ø 55 perforated and enamelled cover 2nd series AUX burner

4000024 17

Burner spreader for 2nd series SR burner

4000019 18

Ø 75 perforated and enamelled cover 2nd series SR burner

4000318 21

Countersunk flat head screw + M2.5 x 18 DIN EN ISO 7046 GV

4000223 8

Chipboard screw to secure the hob unit

7000138 -

Glass lid flame label

4000229 32

5 x 6 CH screw to secure the hinge and silentblock

E VERSION - ELECTRONIC LIGHTING

code

component

pos.

component

4000015 -

Single-pole button 3A red key

2000147 -

12V generator kit + assembly bracket

4000168 -

Universal lighting cable (-)

4000169 -

IGN lighting cable L320

4000297 -

IGN lighting cable 2 (+)

4000232 27

Burner lighting glow plug L350

4000137 31

Clip for glow plug

SPARE PARTS - FC1344

The column "Pos." refers to the exploded drawing "TYPE FC1344" on page 41.

VERSION S - MANUAL LIGHTING

code

component

pos.

component

2000008 4

Hinge for glass lids

3000507 3

Glass lid FC1344

Page 57

57

ENGLISHENGLISH

Installation, use and maintenance instruction manual ▪ Ed. 07/2018 Rev. 00

3000083 22

Tall rubber bushing for pan holders

3000073 1

Wire pan holder for AUX burner

3000074 1

Wire pan holder for SR burner

3000453 6

Silentblock Ø 11

4000026 29

2nd series lid stud bolt

4000170 2

Glass lid cable gland

4000224 7

Intense black screw cap

4000008 23

Standard black knob

4000031 30

Universal nut for thermocouple

4000069 28

Thermocouple for fast-on magnet cock

4000025 19

Burner spreader for 2nd series AUX burner

4000021 20

Ø 55 perforated and enamelled cover 2nd series AUX burner

4000024 17

Burner spreader for 2nd series SR burner

4000019 18

Ø 75 perforated and enamelled cover 2nd series SR burner

4000318 21

Countersunk flat head screw + M2.5 x 18 DIN EN ISO 7046 GV

4000223 8

Chipboard screw to secure the hob unit

7000138 -

Glass lid flame label

4000229 32

5 x 6 CH screw to secure the hinge and silentblock

E VERSION - ELECTRONIC LIGHTING

code

component

pos.

component

4000015 -

Single-pole button 3A red key

2000147 -

12V generator kit + assembly bracket

4000168 -

Universal lighting cable (-)

4000169 -

IGN lighting cable L320

4000297 -

IGN lighting cable 2 (+)

4000232 27

Burner lighting glow plug L350

4000137 31

Clip for glow plug

SPARE PARTS - FC1345

The column "Pos." refers to the exploded drawing "TYPE FC1345" on page 42.

VERSION S - MANUAL LIGHTING

code

component