Page 1

USE AND CARE GUIDE

ISLAND HOOD

Page 2

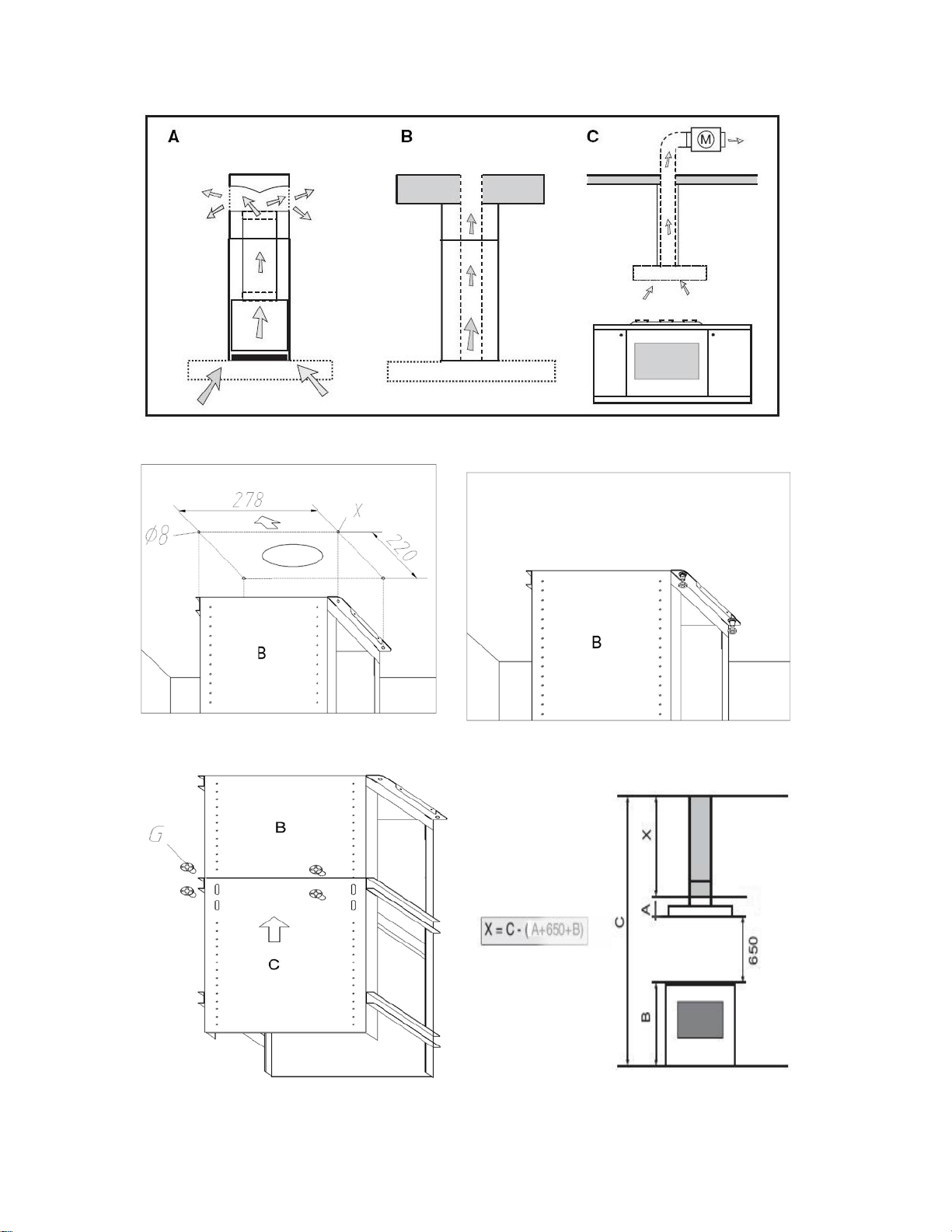

Fig.1

Fig.2 Fig.3

Fig.4 Fig.5

Page 3

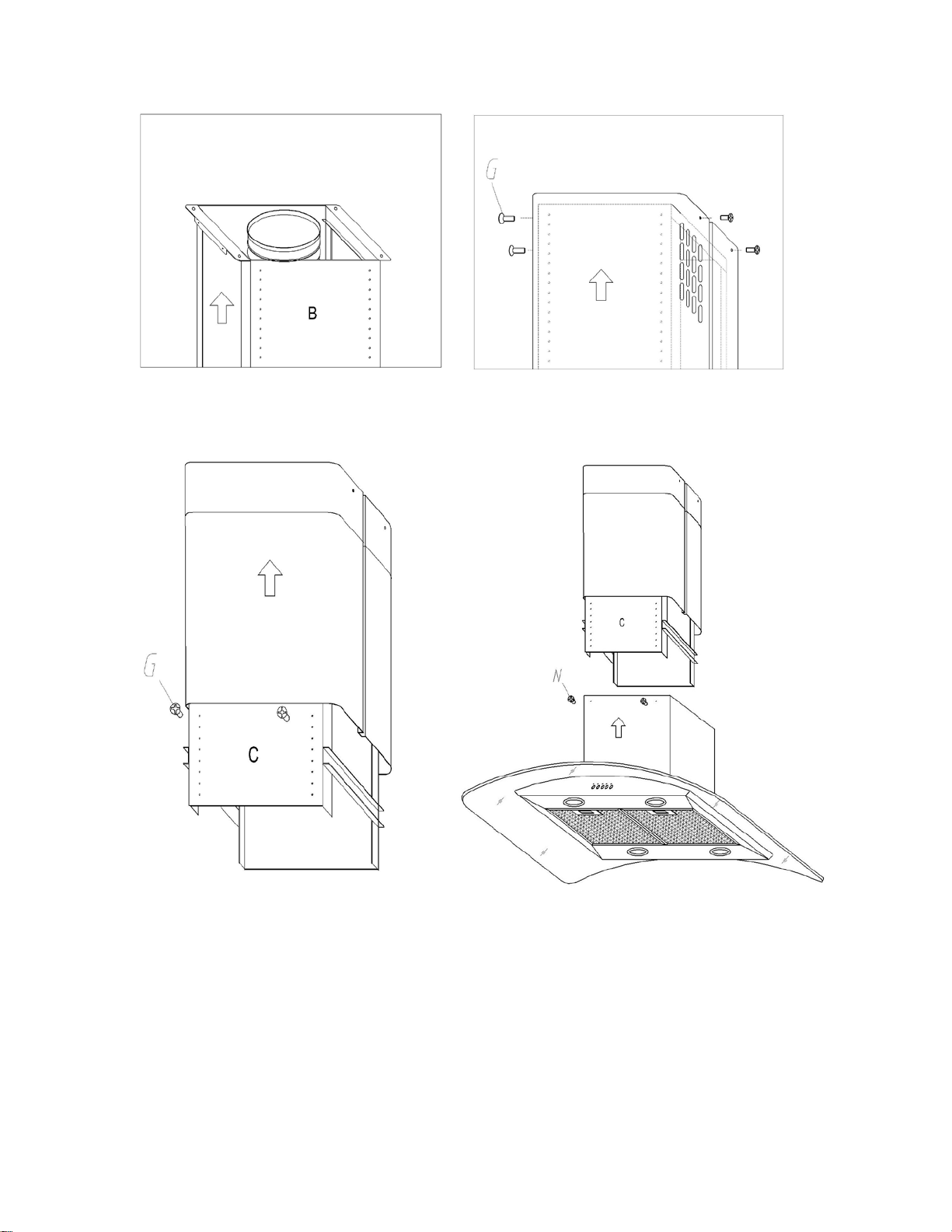

Fig.6 Fig.7

Fig.8 Fig.9

Page 4

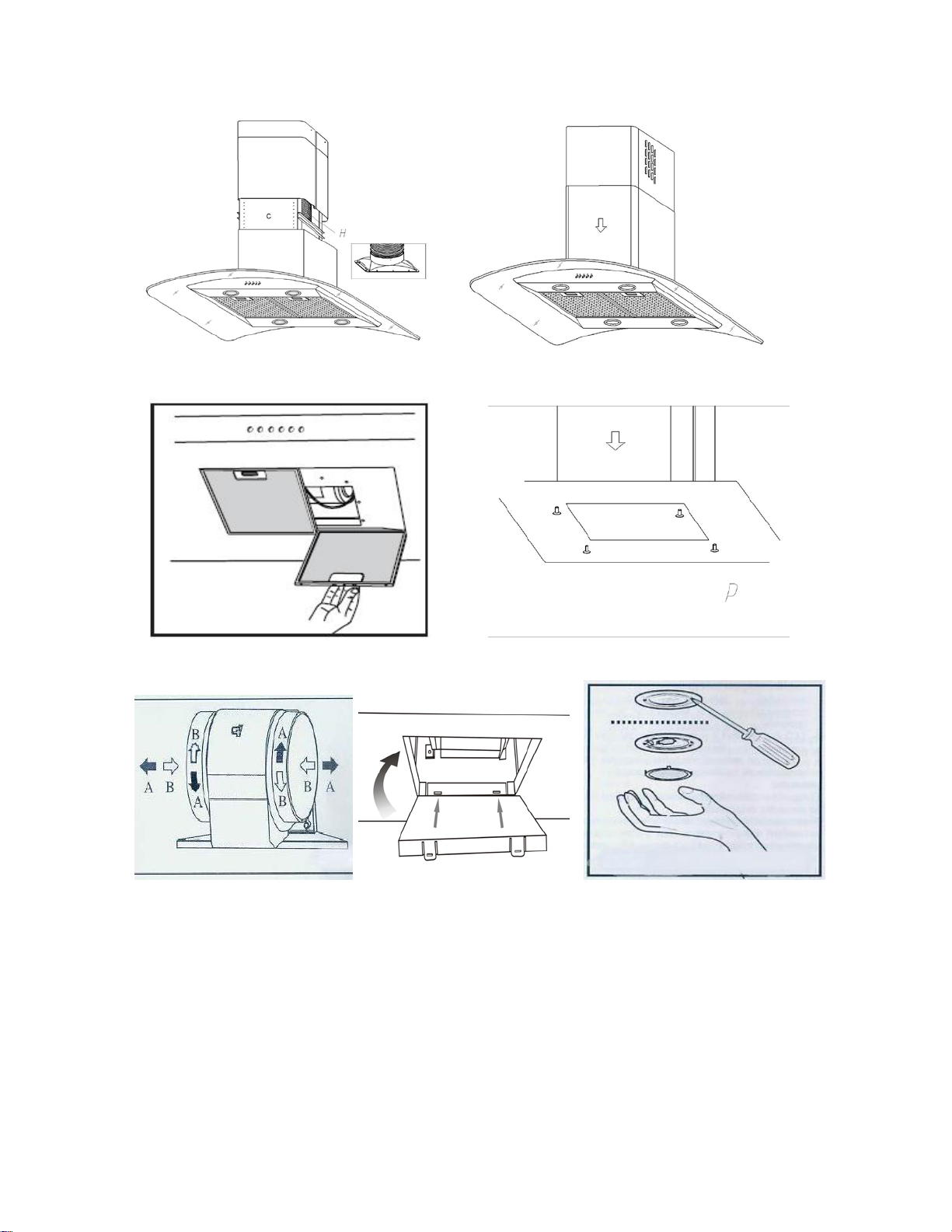

Fig.10 Fig.11

Fig.12 Fig.13

A B

Fig.14 Fig.15

Page 5

Fig.16 Fig.17

Fig.18 Fig.19

Fig.20 Fig.21

Fig.22

Fig.23 Fig.24

Page 6

Fig.25 Fig.26

GENERAL

Carefully read the following important information regarding installation

safety and maintenance. Keep this information booklet accessible for further

consultations.

The appliance has been designed for use in the ducting version (air exhaust

to the outside – Fig.1B), filtering version (air circulation on the inside –

Fig.1A) or with external motor (Fig.1C).

SAFETY PRECAUTION

1. Take care when the cooker hood is operating simultaneously with an

open fireplac e or burner that depend on the air in the environ men t a nd are

supplied by other than electrical energy, as the cooker hood removes the

air from the environment which a burner or fireplac e need for combustion.

The negative pressure in the environment must not exceed 4Pa (4x10-5

bar). Provide adequate ventilation in the environment for a safe operation

of the cooker hood.Follow the local laws applicable for external air

evacuation.

Before connecting the model to the electricity network:

- control the data plate (positioned inside the app liance) to ascertain that the

Page 7

voltage and power correspond to the network and the socket is suitable. If in

doubt ask a q ua lif ie d ele c tr ici an.

2. WARNING !

In certain c ircumstances electri cal appliances may be a danger hazar d.

A) Do not check the status of the filt ers while the cooker hood is operating

B) Do not touch bulbs or adjacent areas, during or straight after prolonged

use of the lighting in s tal la ti o n.

C) Flambè cooking is prohibited un derneath t he cooker hood

D) Avoid fre e flame, as it is damaging for the filters and a fire hazard

E) Constantly check food frying to avoid that the overheated oil may

become a fire hazard

F) Disconne ct the electrical plug prior to any maintenance.

G) This appliance is not intended for use by young children or infirm

persons without supervision

H) Young children should be supervised to ensure they do not play with the

appliance

I) There shall be adequate ventilation of the room when the range hood is

used at the sa me time as a ppliances burning gas or other fuels

J) There is a risk of fire if cleaning is not carried out in accordance with the

instructions

INSTALLATION INSTRUCTIONS

Assembly and electrical connections must be carried out by specialised

personnel.

• Electric Connection

Page 8

The appliance has been manufactured as a class I, therefore earth cable is

IEC227

North America

L=live

Brown

Black

N=neutral

Blue

White

E=earth

Green/Yellow

Green

necessary.

The connec tion to the mains is carried out as follows:

If not provided, connect a plug for the electrical load indicated on the

description label. Where a plug is provided,

the cooker hood must be installed in order that the plug is easily accessi ble.

An omnipolar switch with a minimum opening of 3mm

between contacts, in line with the electrical load and local standards, must be

placed between the appliance and the network in the case of direct

connection to the electri cal network.

• The minimum distance betwe en the support surfaces of the cooking pots on

the cooker top and the lowest part of the cooker hood must be at least 65 cm.

If a connect ion tube composed of two parts is used, the

upper part must be placed outside the lower part. Do not connect the cooker

hood exhaust to the same conductor used to circulate hot air or for

evacuating fumes from other appliances generated by other than an electrical

source. Before proceeding with the assembly operations, remove the

anti-grease filter(s) (Fig.12) so that the unit is easier to handle. In the case of

assembly of the appliance in the suction version prepare the hole for

evacuatio n of the air.

• Hood assembly

Remove the structure from the packaging and separate the upper part from

Page 9

the lower part.

- Please attention that the arrow is positioned on the same side as the

appliance controls. Make 4, Ø8 holes in the ceiling and drive in 3 screws

without completely tightening them(Fig2). Pay attention not to insert the

screw into the hole marked with an X on the hole template (the screws and

expansion p lugs must be suitable for the type of wall).

- Take the upper part of the structure B and insert the 3 slots onto the 3

screws that are not completely tightened. (Fig3)

Rotate slightly to fit.

Drive in the fourth screw X and tighten the remaining 3 to a llow definitive

blocking of the upp er part of str uc tur e B.

- Take the lower part of the telescopic structure C and insert it into the

upper struct ure B.

- Adjust the height (Fig.5) by referring to the amounts indicated in and

block it using the 8 unit screws G that a re supplied (Fig.4)

- Suction version: fix the flexible pipe to the prepared air evacuation hole

(Fig.6).

- Take the upper chimney piec e and fix it with 4 unit screw s G. (Fig.7)

- Take the lower chimney and fix it with 2 unit screws G, drive in hood to

avoid it down .(Fig.8)

- Insert the suction unit inside the structure and set in 4 mounting hole,

drive in 4 unit screw N (Fig. 9) .

- Fix the air evacuation pipe H (not supplied) onto the connection flange

(Fig.10)

- Unscrew the 2 screws G.and rest the lower chimney piece above the

cooker hood ( Fig.11).

Page 10

- If the cooker hood is supplied with a lower chimney piece that must be

fixed to the hood body with screws, remove the anti-grease filters from

the hood by acting on the relevant handles (Fig.12). T hen screw the lower

chimney piece pipe to the inside of the hood, using screws P(Fig.13).

Re-locate the filters in t heir seat.

USE AND MAINTENANCE

• It is recommended to operate the appliance prior to cooking.

It is recommended to leave the appliance in operation for 15 minutes after

cooking is terminated in order to completely eliminate cooking vapours and

odours.

The proper function of the cooker hood is conditioned by the regularity of

the mainten an ce oper ati o ns, in pa r tic u lar, the active carbon filter.

• The anti -grease filters capture the grease particles suspended in the air, and

are therefore subject to clogging according to the frequency of the use of the

appliance.

In order to prevent fire hazard, it is recommendable to clean the filter at a

maximum of 2 months by carrying out the following instructions:

- Remove the filters from the cooker hood and wash them in a solution of

water and neutra l li quid de te r gen t, leav i ng to soak.

- Rinse thoroughly with warm water and leave to dry.

- The filters may also be washed in the dishwas her.

The aluminum panels may alter in color after several washes. This is not

cause for cu stomer complaint nor r e pla cement of panels.

• The active carbon filters purify the air that is replaced in the environment.

The filters are not washable nor reuseable and must be replaced at maximum

Page 11

every four months. The saturation of the active carbon filter depends on the

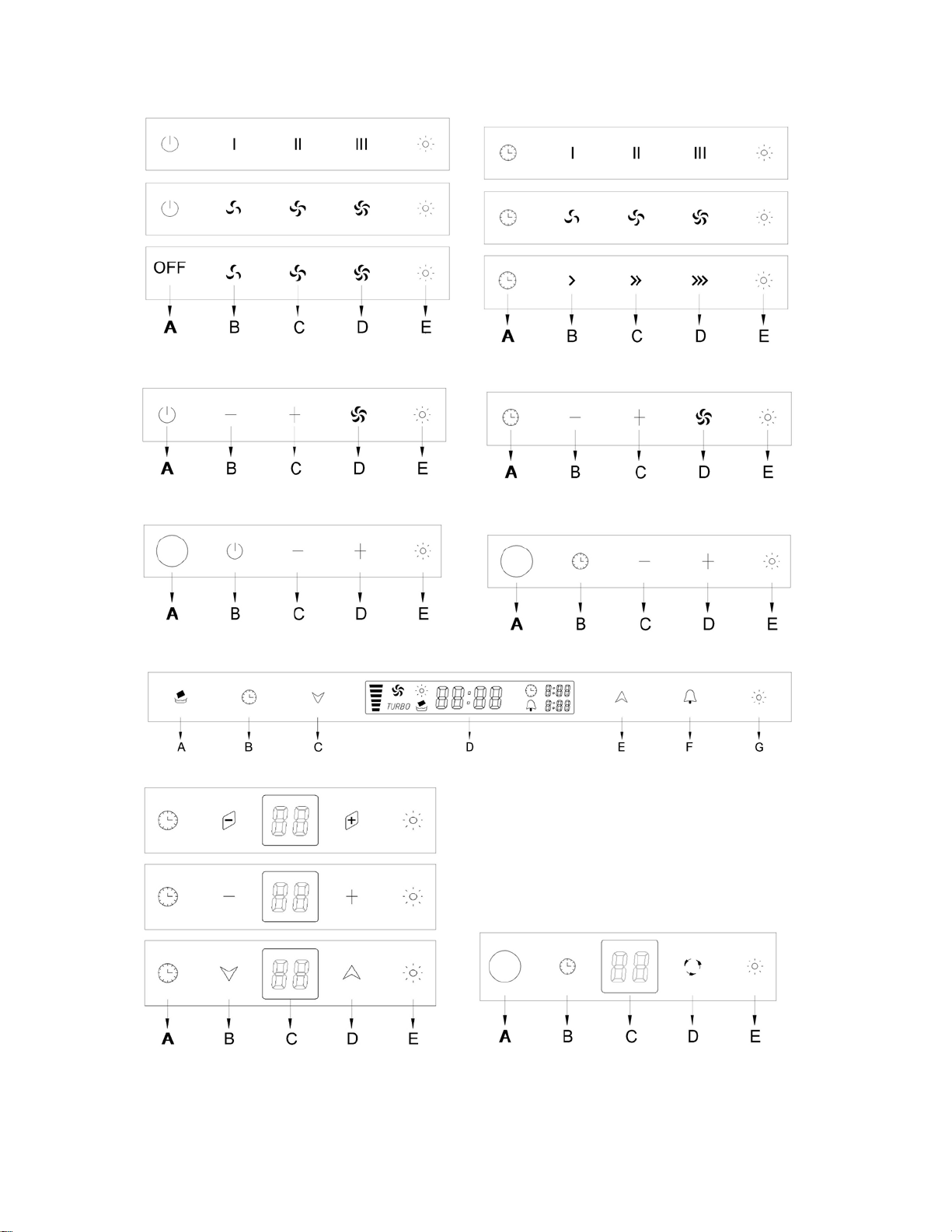

•COMMANDS: (Fig.17)

E =LIGHT

frequency of use of the appliance, by the type of cooking and the reg ularity

of cleaning the antigrease filters. (Fig.14) To remove the charcoal filters

place on hand on one filter at a time and turn it toward the front part. The

charcoal filter can now be removed. Always ensure to replace both filters at

the same time .

• Clean the fan and other surfaces of the cooker hood regularly using a cloth

moistened with denatured alcohol or non abrasive liquid detergent.

• The illumination installation is designed for use during cooking and not for

prolonged general illumination of the environment. Prolonged use of the

illumination installation notably reduces the duration of the bulb. Use a

one-edged screwdriver or any other appropriate tool to lift and remove the

overhead light fixture. Replace the damaged lamp. Use only halogen lamps

as the original specification, avoiding contact with hands. Return the light

fixture to its position (snap fastening). (Fig. 15)

• COMMANDS: (Fig.16)

A = OFF

B = SPEED I / OFF

C = SPEED II / OFF

D = SPEED III / OFF

E = LIGHT

• If your appliance does not have the INTENSIVE speed function, press key

A for two seconds and it will be activated for 15 minutes after which it will

return to the previously set speed. When the function is active the LED

flashes.

By pressing any key for the exclusion of the hoo d light the hood wi ll return

immediately to its normal functioning.

The “automatic stop timer” delays stopping of the hood, which will

continue functioning for 15 minutes at the operating speed set at the

time this function is activated.

A= TIMER – 15 MINUTES

B= SPEED I

C= SPEED II

D= SPEED III

Page 12

FUNCTION KEYS: (Fig.18)

A == OFF

B == SPEED 1/“-”Control

C == SPEED 2/“+”Control

D == SPEED 4

E == LIGHT

By pressing key B、C or D individually, the speed for each key will be the

same as above table. At the same time indicated light will flash on the each

function key button. To stop the speed function pres s key A.

If Speed 3 is r equired,press key C adjust“+”. At Speed 3 program both key

B and key C in dication light will flash on each function key button.

To on the light press key E. To off the light press key E again.

FUNCTION KEYS: (Fig.19)

A == Automatic Stop T im er —15 minutes

B == Speed 1/“-”Control

C == Speed 2/“+”Control

D == Speed 4

E == Light

By pressing key B、C or D individually, the speed for each key will be the

same as above table. At the same time indicated light will flash on the each

function key butt ons. To stop the speed function press key A.

If Speed 3 is r equired,press key C adjust“+”. At Speed 3 program both key

B and key C in dication light will flash on each function key button.

To on the light press key E. To off the light press key E again.

When the appliance and light are ON together or separately, press key A the

Automatic Stop Timer will start the 15 minutes count down. Indication light

on the key A button will flash for the duration. To stop the Automatic Stop

Timer Function before 15 minutes time frame, pr ess key A again.

FUNCTION KEYS: (Fig.20, Fig.25)

A == Infrared Remote Control

B == Off

C == Speed 1/“-”Control

D == Speed 2/“+”Control

E == Light

By pressing key C or D individually, the speed for each key will be the same

as above table. At the same time indication light will flash on the each

Page 13

function key button. To stop the speed function pr ess key B.

If Speed 3 is r equired,press key D and adjust“+”. At Speed 3 program both

key C and key D indication light will flash on each function ke y button.

To on the light press key E. To off the light press key E again.

FUNCTION KEYS: (Fig.21, Fig.26)

A == Infrared Remote Control

B == Automatic Stop Timer —15minutes

C == Speed 1/“-”Control

D == Speed 2/“+”Control

E == Ligh

By pressing key C or D individually, the speed for each key will be the same

as above table. At the same time indicated light will flash on the each

function key buttons. To stop the speed function press key B. If using

Remote Control just press the“OFF”button

If Speed 3 is r equired,press key D and adjust“+”. At Speed 3 program both

key C and key D indication light will flash on each function key button. If

Speed 4 function is available, when Speed 4 function is ON key C and D

indication light will flash. If using Remote Control pre ss the “

”key.

To on the light press key E. To off the light press key E again.

When the appliance and light are ON together or separately, press key A the

Automatic Stop Timer will start the 15 minutes count down. Indication light

on the key A button will flash for the duration. To stop the Automatic Stop

Timer Function before 15 minutes time frame, press key A again.

•COMANDS PATTERN :( Fig.22)

A= Filterin g system / Set clock

B= Delay Timer

C= Speed 1/ “-” adjust / off

D= Digital display

E= Speed 1/ “+” adjust / off

F= Alarm

G= Light

When the Key A is flashing, at the same time “

”is flashing on the

digital display, it reminds the user to clean the filters. After it’s cleaned and

then assemble back, push the key A till the light is off to set the function

again.

When pushing key A for 3 seconds, the clock “

”on the digital

Page 14

display flashing, push key A to switch to set hours and minutes, and then

push C or E to s et the correct time. The Clock’s system is 24 hours.

When the motor is on, push the key B, the light is on, at the same time it

shows “

” is flashing as well on the digita l display,and to push

key B to switch hours and minutes, and it’s to set the time to

automatically shut off the motor by pushing key C or E. Push key B for 3

seconds to s top the delay timer.

Push key C or E, the first speed is on, and it shows “

display,and push key C once again to turn off;To run the 2

” o n the digital

nd

, 3rd and

“Turbo” speed, then push Key E. If it’s “Turbo”speed on, then push E

rd

once again to turn off; and to push key C down to 3

, 2nd and 1st

speed.

Push the key F, the light is flashing, and it shows“

” flashing on

the digital disp lay ,to push key F to switch hours and minutes,and to set

the alarm time by pushing the key C or E. To stop the alarm, push the

key F. And to cancel the alarm set, then push the key F for 3 sec onds.

Push the key G, the light is on, and it shows“

” on the digital display,

and push the G again to turn off the light.

•COMMANDS: (Fig.23)

A= Timer (a utomatic shut off)

B= Speed 1 / adjust / switch off

C= digital display screen (showi ng timer and speed)

D= Speed 3 / adjust / swi tch off

E= Light

When pushing A, digita l display sc reen shows "15 minutes" for timer, and

the minutes can be adj usted by pushing "+" or "-" on B and D. And the first

speed is on, pushin g A once to switch off, the digital disp lay shows "00".

When pushing B, it show s " F1" on the digital display screen, and the first

speed is on. Pushing B on ce to switch off, and the d igital display shows

"00".

When pushing D, it shows "F 3" on the d ig i tal di spl a y scree n, a nd the thir d

speed is on. Pushing D twice to swit ch off, and it shows "00" o n the scre en.

The second speed F2 and Turbo speed F4 can be adjusted by pushi ng B or

D.

When pushing E, the butt ons li g ht is on an d the light is on, only push E once

again to switch off th e lig ht.

Page 15

If the motor, light are working together , or only motor is working, pushing A,

Problem

Possible re ason

Solution

Hood doesn’ t work

No electric supply

Check the plug is connected

Check the main switch i s turned on

Poor airflow

Aluminum grease

filters clogged

Clean the filters and replace when

dry

Charcoal filters

clogged

Replace the charcoal filters

Motor running but no

air flow

Butterfly valve jammed

Contact techn ic ia n

Motor cuts after a

High temperature

safety devi ce activated

The kitchen is not sufficiently

ventilated

The hood is installed

The hood must be least 65cm from

automatic switch off timer is on, an d it will dela y 15 minutes to turn off the

motor and light. To push B or D to adju st the time, and to push A again to

stop the timer.

FUNCTION KEYS: (Fig.24, Fig.26)

A == Infrared Remote Control

B == Timer (Automatic Sh ut Off)

C == Digital Display(Timer/Speed)

D == Speed F1 /Cycle Control Adjustment/Off

E == Light

When key B is pressed, digital display screen will display 15 minutes. For

cycle control adjustment and Speed F1 press key D. To stop the operation

press key B again the digital display screen will show 00. If using remote

control pre ss “OFF” button.

When key D is being pressed, the digital display screen will show F1 and

speed 1 will ON. To stop F1 function press key D until the digital display

screen shown 00.

The F2, F3 Or F4 (Turbo) function can be adj ust e d thr u key D.

For ON/OFF l ight press key E.

When the appliance and light are ON together or separately, press key B the

Automatic Stop Timer will start the 15 minutes count down. Key D can also

be used to extend the time of Automatic Stop Timer. To stop the Automatic

Stop Timer Function before 15 minutes time frame, pr ess key B again.

Troubleshooting

few minutes

Page 16

too near the cooking

stove

stove

Strong cooking smell

Charcoal filters not

installed

In re-circulating mode, charcoal

filters must be installe d

Oil dripping onto

stove

Oil cup missing or not

Remove aluminum filter and

Aluminum grease filter

saturated

Wash the aluminum grease filters

Whirring sou nd

Something in contact

with fan blade

Contact with te c hnician

installed

replace oil cup

THE MANUFACTURORY DECLINES ALL RESPONSIBILITY FOR

EVENTUAL DAMAGES CAUSED BY BREACHING THE ABOVE

WARNINGS.

Loading...

Loading...