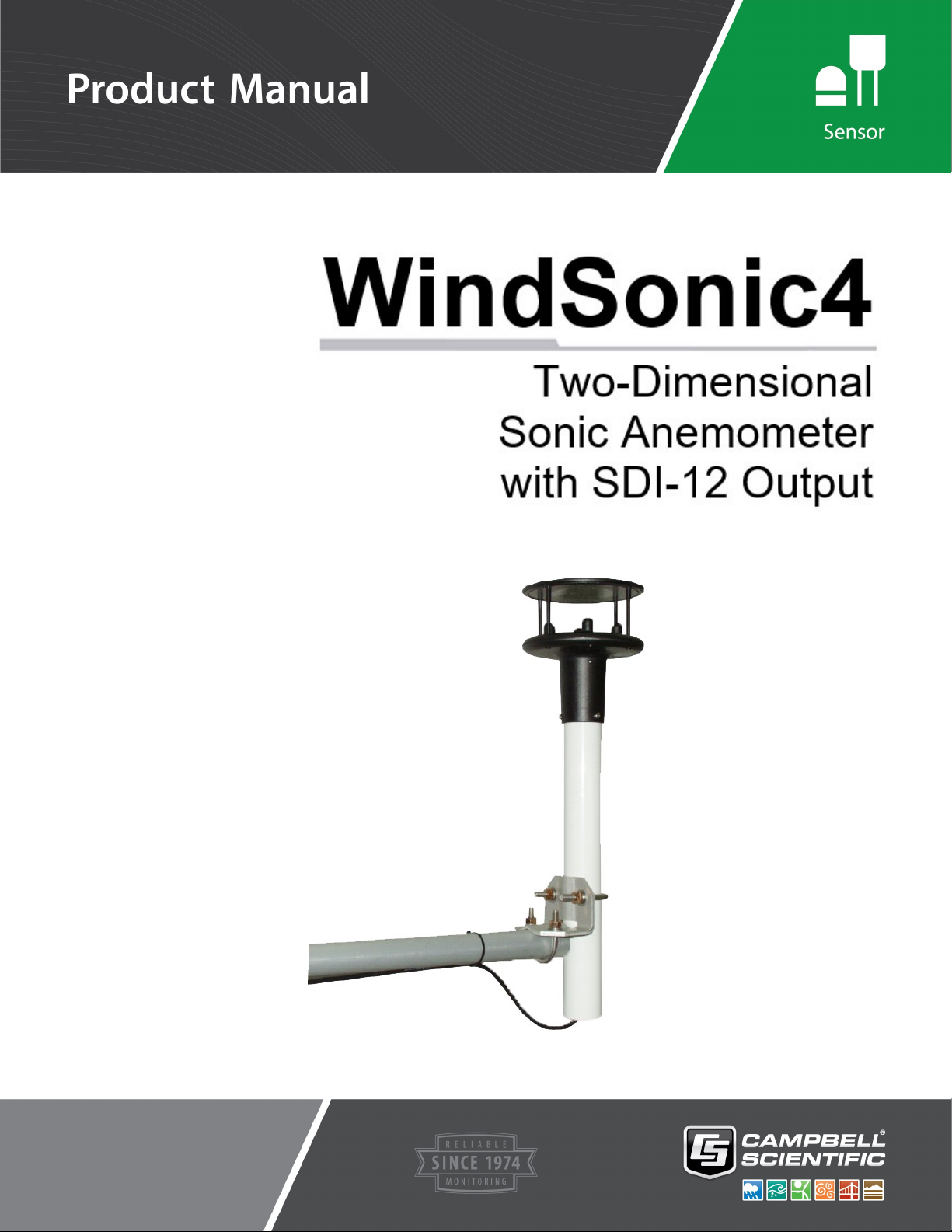

Page 1

Revision: 01/2021

Copyright© 2014 – 2021

Campbell Scientific, Inc.

Page 2

Table of contents

1. Introduction 1

2. Precautions 1

3. Initial inspection 2

4. QuickStart 2

5. Overview 5

6. Specifications 5

6.1 Wind direction 6

6.2 Wind speed 6

7. Installation 6

7.1 WindSonic4 wiring 6

7.2 Data logger programming 7

7.2.1 Programming 8

7.3 Siting 9

7.4 Mount the sensor 9

8. Operation 10

8.1 Sensor configuration 10

8.2 SDI-12 measurement details 11

8.3 Long cables 11

9. Maintenance and troubleshooting 12

9.1 Troubleshooting 12

9.2 Maintenance 12

10. Siting references 13

Appendix A. Importing Short Cut code into CRBasic Editor 14

Appendix B. Determining True North and sensor orientation 15

B.1 Online magnetic declination calculator 17

Appendix C. SDI-12 sensor support 19

C.1 SDI-12 command basics 19

Table of Contents - i

Page 3

C.1.1 Acknowledge active command (a!) 20

C.1.2 Send identification command (al!) 20

C.1.3 Start verification command (aV!) 21

C.1.4 Address query command (?!) 21

C.1.5 Change address command (aAb!) 21

C.1.6 Start measurement commands (aM!) 22

C.1.7 Start concurrent measurement commands (aC!) 22

C.1.8 Start measurement commands with cyclic redundancy check (aMC! and aCC!) 24

C.1.9 Stopping a measurement command 24

C.1.10 Send data command (aD0! … aD9!) 24

C.1.11 Continuous measurement command (aR0! … aR9!) 25

C.2 SDI-12 transparent mode 25

C.2.1 Changing an SDI-12 address 26

Table of Contents - ii

Page 4

1. Introduction

The WindSonic4 is a two-dimensional ultrasonic anemometer for measuring wind speed and

wind direction. It provides an alternative to traditional mechanical cup and vane or propeller and

vane anemometers. Unlike mechanical anemometers, the WindSonic4 has no moving parts that

need to be periodically replaced—minimizing routine maintenance costs.

The WindSonic4 outputs an SDI-12 signal.

NOTE:

This manual provides information only for CRBasic data loggers. For retired Edlog data logger

support, see an older manual at www.campbellsci.com/old-manuals.

2. Precautions

l READ AND UNDERSTAND the Safety section at the back of this manual.

l The WindSonic4 is not recommended for conditions where rime, ice, or horizontal snow

will occur. It is not heated.

l The WindSonic4 is a precision instrument. Please handle it with care.

l If the WindSonic4 is to be installed at heights over 2 m (6 ft), be familiar with tower safety

and follow safe tower climbing procedures.

l DANGER—Use extreme care when working near overhead electrical wires. Check for

overhead wires before mounting the WindSonic4 or before raising a tower.

l The black outer jacket of the cable is Santoprene® rubber. This compound was chosen for

its resistance to temperature extremes, moisture, and UV degradation. However, this jacket

will support combustion in air. It is rated as slow burning when tested according to U.L. 94

H.B. and will pass FMVSS302. Local fire codes may preclude its use inside buildings.

WindSonic4 Two-Dimensional Sonic Anemometer 1

Page 5

3. Initial inspection

l Upon receipt of the WindSonic4, inspect the packaging and contents for damage. File

damage claims with the shipping company. Immediately check package contents against

the shipping documentation. Contact Campbell Scientific about any discrepancies.

l The model number and cable length are printed on a label at the connection end of the

cable. Check this information against the shipping documents to ensure the expected

product and cable length are received.

4. QuickStart

A video that describes data logger programming using Short Cut is available at:

www.campbellsci.com/videos/cr1000x-data logger-getting-started-program-part-3 . Short Cut

is an easy way to program your data logger to measure the sensor and assign data logger wiring

terminals. Short Cut is available as a download on www.campbellsci.com. It is included in

installations of LoggerNet, RTDAQ, and PC400.

The following procedure also shows using Short Cut to program the WindSonic4.

1. Open Short Cut and click Create New Program.

2. Double-click the data logger model.

WindSonic4 Two-Dimensional Sonic Anemometer 2

Page 6

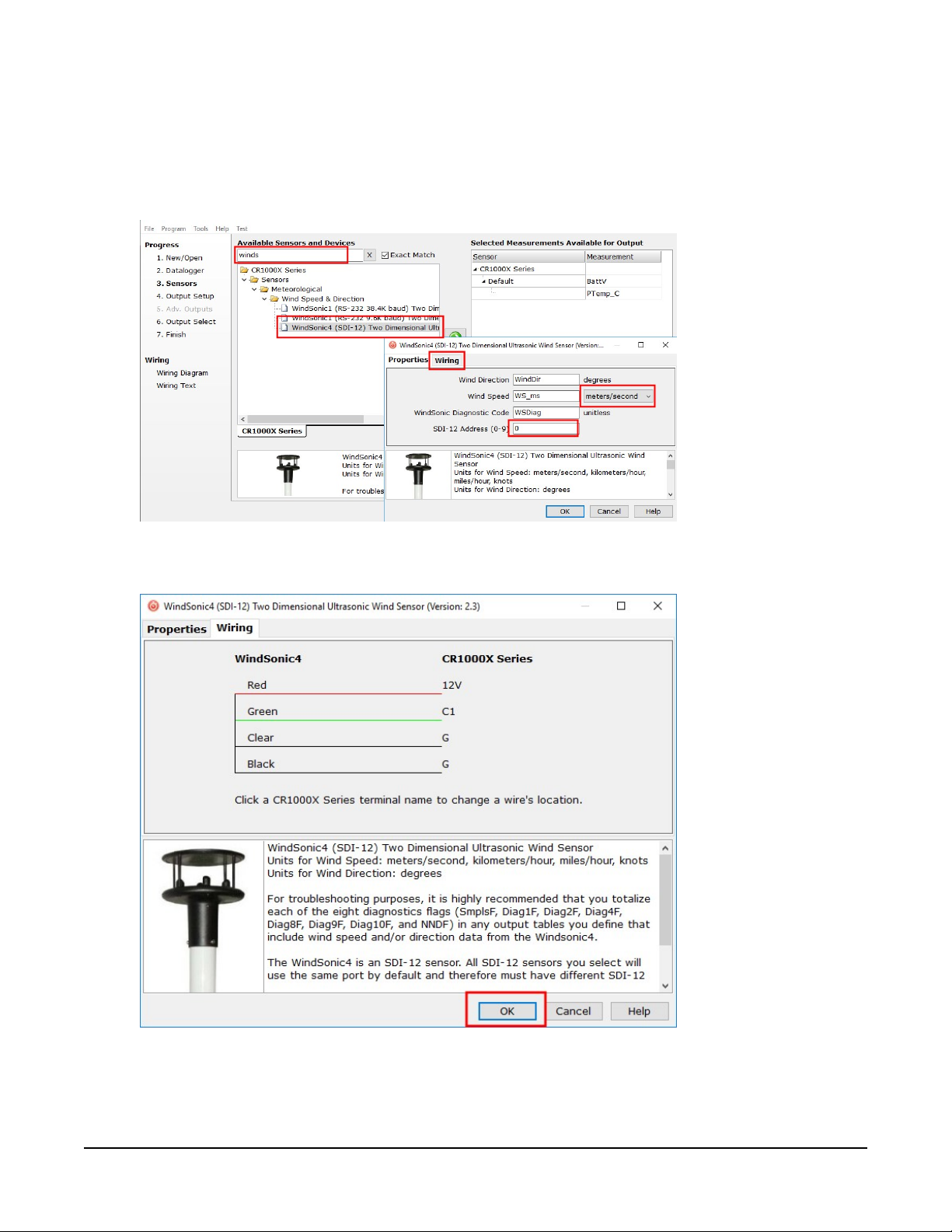

3. In the Available Sensors and Devices box, type WindSonic1 or locate the sensor in the

Sensors > Meteorological > Wind Speed & Direction folder. Double-click the WindSonic4

(SDI-12) Two Dimensional Ultrasonic Wind Sensor. The wind speed defaults to meters per

second. This can be changed by clicking the Wind Speed box and selecting one of the

other options. Type the correct SDI-12 Address; default is 0.

4. Click the Wiring tab to see how the sensor is to be wired to the data logger. Click OK after

wiring the sensor.

5. Repeat steps 3 and 4 for other sensors.

WindSonic4 Two-Dimensional Sonic Anemometer 3

Page 7

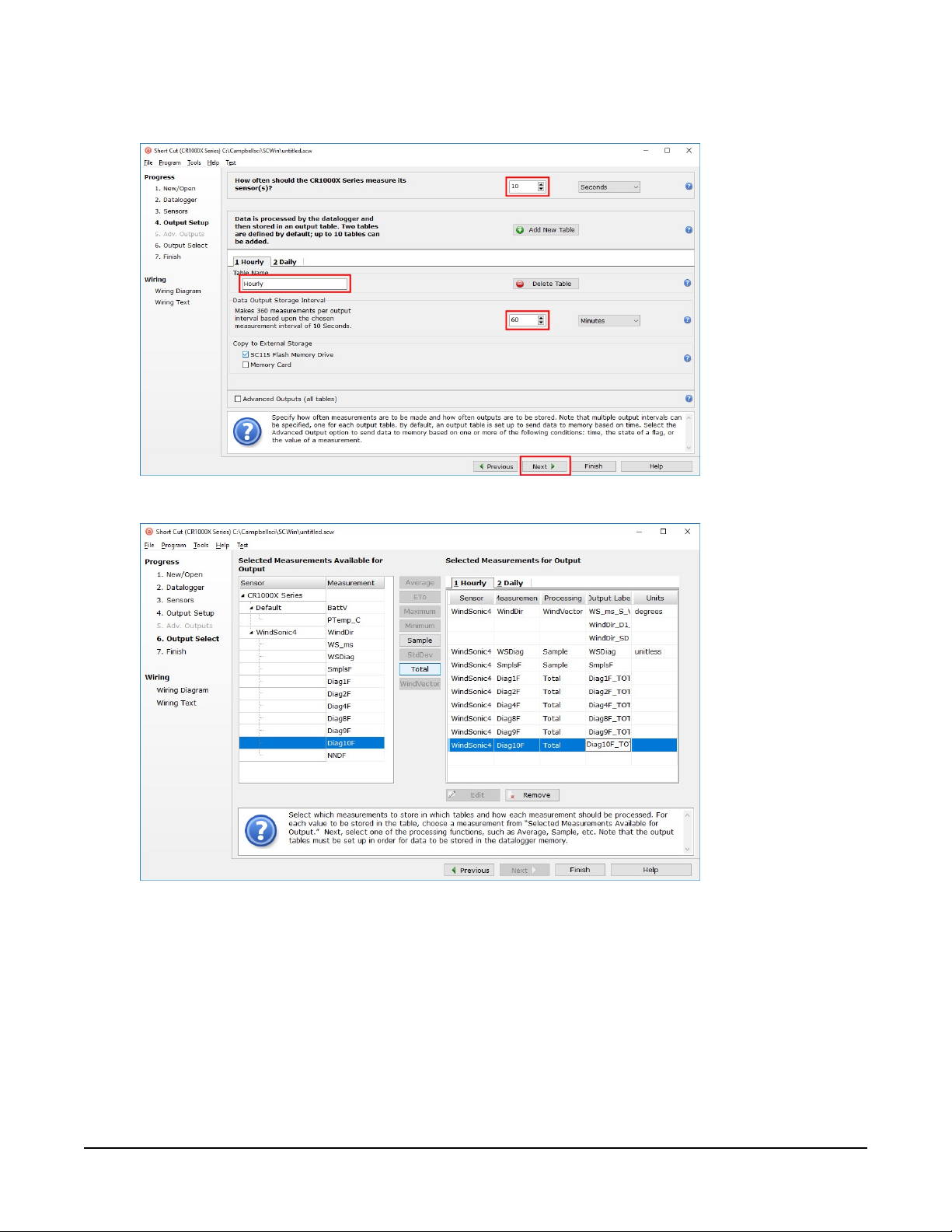

6. In Output Setup, type the scan rate, meaningful table names, and Data Output Storage

Interval. Click Next.

7. Select the measurement and its associated output option.

8. Click Finish and save the program. Send the program to the data logger if the data logger

is connected to the computer.

9. If the sensor is connected to the data logger, check the output of the sensor in data display

in LoggerNet, RTDAQ, PC400, or PC200W to make sure it is making reasonable

measurements.

WindSonic4 Two-Dimensional Sonic Anemometer 4

Page 8

5. Overview

The WindSonic4 is manufactured by Gill Instruments, Ltd. It is an ultrasonic anemometer for

measuring wind direction and wind speed. Two pairs of orthogonally oriented transducers sense

horizontal wind. The transducers bounce the ultrasonic signal from a hood, minimizing the

effects of transducer shadowing and flow distortion.

The WindSonic4 outputs data using the SDI-12 interface, which is compatible with all

contemporary data loggers as well as the CR200(X)-series and CR5000. SDI-12 is a three-wire

digital interface standard used by processor-based sensors and digital recording devices.

The WindSonic4 includes a user-specified cable to interface to a Campbell Scientific data logger.

A serial cable (WINDSONICRCBL-L) is available for interfacing a WindSonic4 to a computer

running the manufacturer’s computer support software. The cable and software are used during

troubleshooting. A copy of this computer support software is available at

www.gill.co.uk/main/software.html. WindView is used for WindSonic4 anemometers with serial

numbers of 0810001 or greater, and WindCom is used for WindSonic4 anemometers with serial

numbers that are less than 0810001.

Features:

l Low maintenance—no moving parts significantly reduces maintenance cost and time

l Minimum detectable wind speed of 0.01meters per second

l Compatible with Campbell Scientific CRBasic data loggers: CR6, CR3000, CR1000X, CR800

series, CR300 series, CR1000, CR200(X) series, and CR5000

6. Specifications

Output signal:

Output variables:

Measurement frequency:

Current drain:

Operating temperature:

SDI-12 version 1.3; address factory set to 0

wind direction, wind speed, and diagnostic or ux, uy, and

diagnostic

40Hz block averaged to a programmable output frequency,

factory set to 1Hz

<12 mA @ 12 V

–35 to 70 °C

WindSonic4 Two-Dimensional Sonic Anemometer 5

Page 9

Storage temperature:

–40 to 80 °C

Dimensions:

Weight:

Operating humidity:

142 x 160 mm (5.6 x 6.3 in)

500 g (1.1 lb)

<5% to 100% RH

6.1 Wind direction

Operating range:

Accuracy:

Output resolution:

0 to 359° (no dead band)

±3°

1°

6.2 Wind speed

Operating range:

Accuracy:

Output resolution:

0 to 60 m/s

±2% @ 12 m/s

0.01 m/s

7. Installation

If you are programming your data logger with Short Cut, skip WindSonic4 wiring (p. 6) and Data

logger programming (p. 7). Short Cut does this work for you. See QuickStart (p. 2) for a Short Cut

tutorial.

7.1 WindSonic4 wiring

The WindSonic4 interfaces to a Campbell Scientific data logger using SDI-12 (Table 7-1 (p. 7)).

WindSonic4 Two-Dimensional Sonic Anemometer 6

Page 10

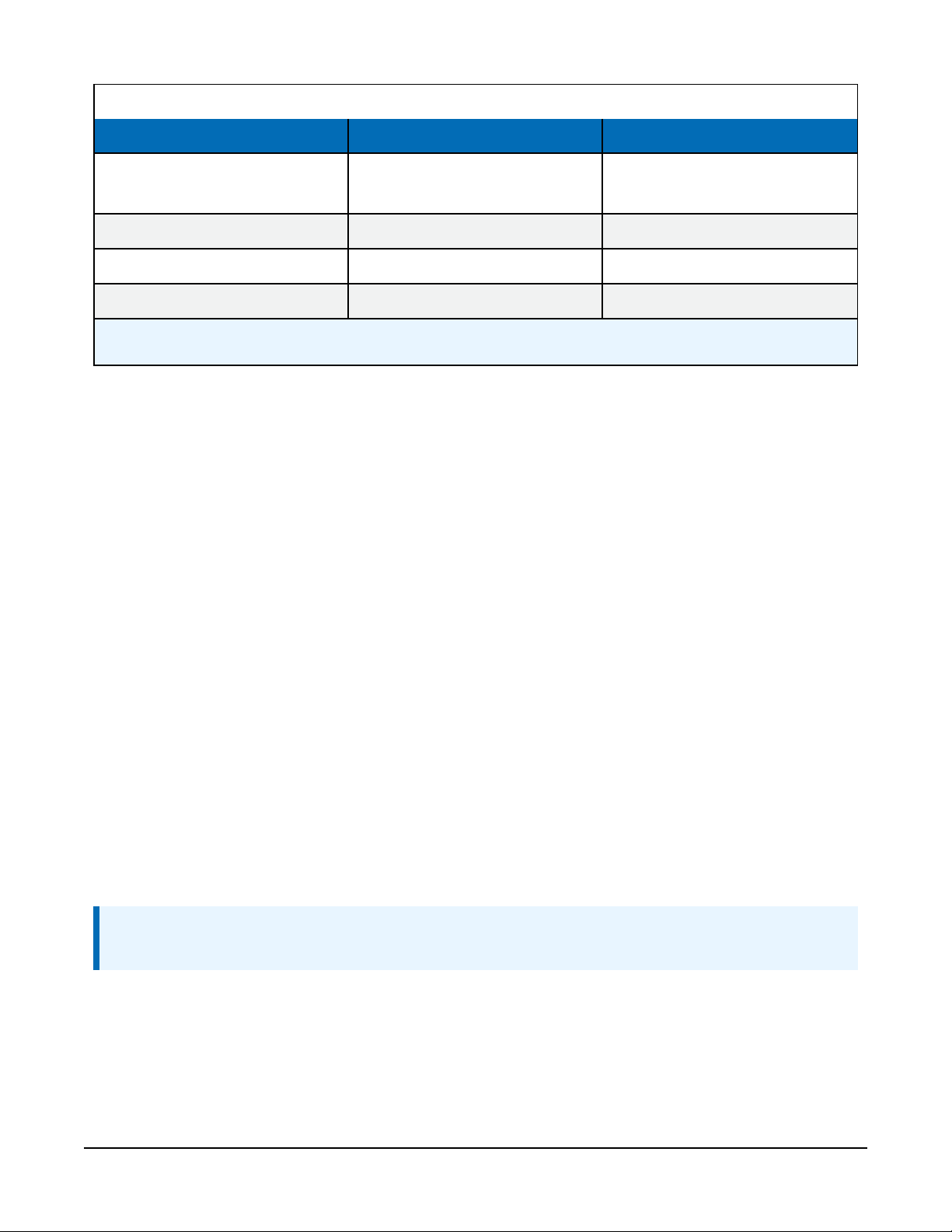

Table 7-1: WindSonic4 to data logger connections

Description Color Data logger

SDI-12 Data Green

SDI-12 Power Red 12V

SDI-12 Reference Black G

Shield Clear ⏚ (analog ground)

1

U and C terminals are automatically configured by the measurement instruction for Campbell Scientific CR6 data

logger.

To use more than one sensor per data logger, either connect the different sensors to different

terminals on the data logger or change the SDI-12 addresses of the sensors and wire them to the

same terminal. Each SDI-12 sensor connected to the same terminal must have a unique SDI-12

address. The factory-set address for the WindSonic4 is 0. Possible addresses are a number from 0

to 9. Using unique SDI-12 addresses reduces the use of terminals on the data logger and allows

sensors to be connected in a daisy-chain fashion that can minimize cable runs in some

applications. At a 1Hz measurement rate, a maximum of four WindSonic4s can be measured by a

data logger.

For the CR6 and CR1000X, triggering conflicts may occur when a companion terminal is used for

a triggering instruction such as TimerInput(), PulseCount(), or WaitDigTrig(). For

example, if the WindSonic4 is connected to C3 on a CR1000X, C4 cannot be used in the

TimerInput(), PulseCount(), or WaitDigTrig() instructions.

U configured for SDI-12

C, SDI-12,

1

7.2 Data logger programming

Short Cut is the best source for up-to-date programming code for Campbell Scientific data

loggers. If your data acquisition requirements are simple, you can probably create and maintain a

data logger program exclusively with Short Cut. If your data acquisition needs are more complex,

the files that Short Cut creates are a great source for programming code to start a new program

or add to an existing custom program.

NOTE:

Short Cut cannot edit programs after they are imported and edited in CRBasic Editor.

A Short Cut tutorial is available in QuickStart (p. 2). If you wish to import Short Cut code into

CRBasic Editor to create or add to a customized program, follow the procedure in Importing

Short Cut code into CRBasic Editor (p. 14). Programming basics for CRBasic data loggers are

WindSonic4 Two-Dimensional Sonic Anemometer 7

Page 11

provided in the following section. Downloadable example programs are available at

www.campbellsci.com/downloads/windsonic4-program-examples.

7.2.1 Programming

The WindSonic4 updates the SDI-12 output at a frequency of 1 Hz. The SDI12Recorder()

CRBasic instruction programs the data loggers to measure the WindSonic4. This instruction sends

a request to the sensor to make a measurement and then retrieves the measurement from the

sensor. For the most data loggers, the SDI12Recorder() instruction has the following syntax:

SDI12Recorder(Destination, SDIPort, SDIAddress, “SDICommand”, Multiplier,

Offset, FillNAN, WaitonTimeout)

For the SDIAddress, alphabetical characters need to be enclosed in quotes (for example, “A”).

Also enclose the SDICommand in quotes as shown. The most appropriate SDI-12 command to

retrieve data from the WindSonic4 is the Ro!, where o is the data format option (Table 7-2 (p.

8)). When using the "Ro!" command, the Destination parameter needs to be a variable

array with three elements.

FillNAN and WaitonTimeout are optional parameters (refer to CRBasic Help for more

information).

When using a CR200(X)-series data logger, the SDI12Recorder() instruction has the

following syntax:

SDI12Recorder(Destination,"OutString",Multiplier,Offset)

OutString consists of the SDI-12 address and command. Enclose the OutString in quotes

as shown.

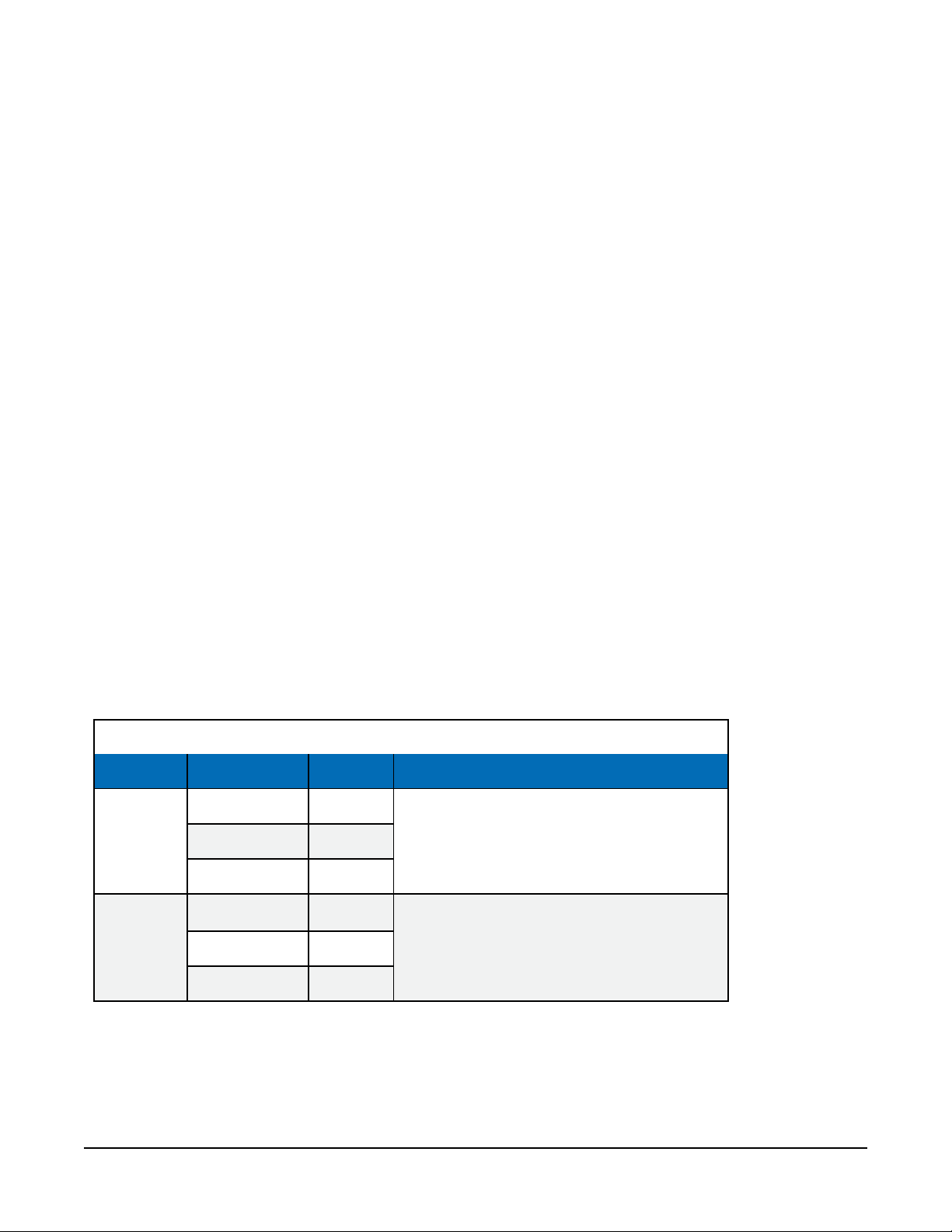

Table 7-2: WindSonic4 data format option

Option (o) Output Units Comment

wind direction degrees

0

status unitless

uxwind

1

uywind m/s

status unitless

m/s

Compass polar coordinate systemwind speed m/s

Orthogonal right hand coordinate system

WindSonic4 Two-Dimensional Sonic Anemometer 8

Page 12

NOTE:

To support the Ro! command, a CR200(X)-series or CR5000 data logger need a current

operating system. The most current data logger operating systems are available on the

Campbell Scientific website at: www.campbellsci.com/downloads.

See SDI-12 measurement details (p. 11) for more information about this instruction.

7.3 Siting

Locate the WindSonic4 away from obstructions such as trees and buildings. The distance

between wind sensors and the nearest obstruction should be ten times the height of the

obstruction. If it is necessary to mount the WindSonic4 on the roof of a building, the height of

the sensor, above the roofline, should be at least 1.5 times the height of the building. See Siting

references (p. 13) for a list of references that discuss siting wind direction and speed sensors.

7.4 Mount the sensor

Mount the WindSonic4 using the WindSonic Mounting Pipe Kit, which consists of an aluminum

mounting tube, three pan truss screws, CM220 Right Angle Mounting bracket, two U-bolts, and

four nuts.

1. Thread the connector end of the cable through the mounting tube; start at the end without

the three threaded holes.

2. Attach the female mating connector on the cable to the male mating connector located on

the bottom of the WindSonic4.

3. Secure the WindSonic4 to the mounting tube using the three pan-head screws.

4. Attach the mounting tube to a crossarm using the the CM220 Right Angle Mounting

bracket, U-bolts, and nuts (see FIGURE 7-1 (p. 10)).

5. Mount the crossarm to the tripod or tower.

6. Orient the WindSonic4 so that the colored North marker arrows point to True North (see

FIGURE 7-1 (p. 10)). See Determining True North and sensor orientation (p. 15) for more

information.

WindSonic4 Two-Dimensional Sonic Anemometer 9

Page 13

FIGURE 7-1. WindSonic4 mounted on a crossarm

7. Route the sensor cable along the underside of the crossarm to the tripod or tower, and to

the instrument enclosure.

8. Secure the cable to the crossarm and tripod or tower using cable ties.

8. Operation

This section discusses the following:

8.1 Sensor configuration 10

8.2 SDI-12 measurement details 11

8.3 Long cables 11

8.1 Sensor configuration

To mimic a mechanical anemometer, the WindSonic4 output frequency must match the data

logger scan frequency. The factory setting for the WindSonic4 is 1 Hz, which is 1 output per

second. The data output frequency of the WindSonic4 cannot be changed.

WindSonic4 Two-Dimensional Sonic Anemometer 10

Page 14

8.2 SDI-12 measurement details

The WindSonic4 typically uses an R0! or R1! command. When the data logger issues an R0! or

R1! command, the WindSonic4 immediately begins transmitting the most current wind

measurements to the data logger. After receiving the R0! or R1! command, it takes the

WindSonic4 approximately 190 milliseconds ±10 milliseconds to transmit the data.

The WindSonic4 can also use an M0! or M1! command. When using an M0! or M1! command,

the data logger waits for the time specified by the sensor, sends the D! command, pauses its

operation, and waits until either it receives the data from the sensor or the sensor timeout

expires. If the data logger receives no response, it will send the command a total of three times,

with three retries for each attempt, or until a response is received. The M0! or M1! command will

take slightly longer to retrieve the data because of the additional handshaking required. For all

practical purposes, a data logger can measure up to four WindSonic4s at 1 Hz.

The WindSonic4 also supports the R0C!, R1C!, M0C!, and MC! commands, which are the same

as the R! and M! commands, but a cyclic redundancy check (CRC) is performed that validates

the data. Use of the checksum option is only necessary for long cable runs.

NOTE:

This section briefly describes using the SDI-12 commands. For additional SDI-12 information,

refer to SDI-12 sensor support (p. 19). A complete list of SDI-12 commands supported by the

WindSonic4 is available in the Gill WindSonic manual at

www.gill.co.uk/products/anemometer/windsonic.htm.

8.3 Long cables

Although the SDI-12 standard specifies the maximum total cable length to be 61 m (200 ft), the

WindSonic4 can have cable lengths up to 90 m (300 ft). Digital data transfer eliminates offset

errors due to cable lengths. However, digital communications can break down when cables are

too long, resulting in either no response from the sensor or corrupted readings.

WindSonic4 Two-Dimensional Sonic Anemometer 11

Page 15

9. Maintenance and troubleshooting

NOTE:

All factory repairs and recalibrations require a returned material authorization (RMA) and

completion of the “Statement of Product Cleanliness and Decontamination” form. Refer to

the Assistance page at the end of this manual for more information.

9.1 Troubleshooting

The WindSonic4 outputs a status code (Table 9-1 (p. 12)) along with each wind direction and

speed measurement. The data logger program can filter out data when the status code is not 00.

If the WindSonic4 is not powered, not connected, is using the wrong COM port/SDI-12 address,

or has missed a sample, the wind direction and speed measurement will be NaN. The program

can filter out these values and report the number of good samples that were used in computing

the online statistics. If the total number of good samples is less than 98% of the expected

samples, send the WindSonic4 to the factory for repair (see Assistance).

Table 9-1: Status codes

Code Status Comment

00 Okay All okay

01 Axis 1 failed Insufficient samples, possible path obstruction

02 Axis 2 failed Insufficient samples, possible path obstruction

04 Both axes failed Insufficient samples, possible path obstruction

08 NVM error Nonvolatile Memory checksum failed

09 ROM error Read Only Memory checksum failed

10 Maximum gain Questionable wind measurements

9.2 Maintenance

There are no user-serviceable parts on the WindSonic4. Keep the transducer paths clear of any

obstructions.

WindSonic4 Two-Dimensional Sonic Anemometer 12

Page 16

CAUTION:

When clearing the transducer paths, do not remove or damage the rubber caps on the

transducers.

Use a cloth and mild detergent to gently clean the transducers.

CAUTION:

Do not use solvents and avoid scratching or damaging the rubber caps.

If the WindSonic4 is damaged, fails to output data, or sends a nonzero status number (Table 9-1

(p. 12)), return it to Campbell Scientific for repair (see Assistance).

10. Siting references

The following references give detailed information on siting wind direction and wind speed

sensors.

EPA, 1987: On-Site Meteorological Program Guidance for Regulatory Modeling Applications,

EPA-450/4-87-013, Office of Air Quality Planning and Standards, Research Triangle Park, NC,

27711.

EPA, 1989: Quality Assurance Handbook for Air Pollution Measurements System, Office of

Research and Development, Research Triangle Park, NC, 27711.

The State Climatologist, 1985: Publication of the American Association of State Climatologists:

Height and Exposure Standards, for Sensors on Automated Weather Stations, vol. 9, No. 4.

WMO, 1983: Guide to Meteorological Instruments and Methods of Observation, World

Meteorological Organization, No. 8, 5th edition, Geneva, Switzerland.

WindSonic4 Two-Dimensional Sonic Anemometer 13

Page 17

Appendix A. Importing Short

Cut code into CRBasic Editor

Short Cut creates a .DEF file that contains wiring information and a program file that can be

imported into the CRBasic Editor. By default, these files reside in the C:\campbellsci\SCWin

folder.

Import Short Cut program file and wiring information into CRBasic Editor:

1. Create the Short Cut program. After saving the Short Cut program, click the Advanced tab

then the CRBasic Editor button. A program file with a generic name will open in CRBasic.

Provide a meaningful name and save the CRBasic program. This program can now be

edited for additional refinement.

NOTE:

Once the file is edited with CRBasic Editor, Short Cut can no longer be used to edit the

program it created.

2. To add the Short Cut wiring information into the new CRBasic program, open the .DEF file

located in the C:\campbellsci\SCWin folder, and copy the wiring information, which is at

the beginning of the .DEF file.

3. Go into the CRBasic program and paste the wiring information into it.

4. In the CRBasic program, highlight the wiring information, right-click, and select Comment

Block. This adds an apostrophe (') to the beginning of each of the highlighted lines, which

instructs the data logger compiler to ignore those lines when compiling. The Comment

Block feature is demonstrated at about 5:10 in the CRBasic | Features video .

WindSonic4 Two-Dimensional Sonic Anemometer 14

Page 18

Appendix B. Determining True North and sensor orientation

The orientation of the WindSonic4 north arrow markers is found by reading a magnetic compass

and applying the site-specific correction for magnetic declination; where the magnetic

declination is the number of degrees between true north and magnetic north. Obtain the

magnetic declination for a specific site from a USGS map, local airport, or through a NOAA web

calculator (Online magnetic declination calculator (p. 17)). A general map showing magnetic

declination for the Conterminous United States is shown in FIGURE B-1 (p. 15).

FIGURE B-1. Magnetic declination for the conterminous United States (2015)

Declination angles east of True North are considered negative, and are subtracted from 360

degrees to get True North as shown FIGURE B-2 (p. 16) (0° and 360° are the same point on a

compass). Declination angles west of True North are considered positive, and are added to 0

degrees to get True North as shown in FIGURE B-3 (p. 16).

WindSonic4 Two-Dimensional Sonic Anemometer 15

Page 19

For example, the declination for Longmont, CO (10 June 2006) is 9.67°, thus True North is 360° –

9.67°, or 350.33° as read on a compass. Likewise, the declination for McHenry, IL (10 June 2006) is

–2.68°, and True North is 0° – (–2.68°), or 2.68° as read on a compass.

FIGURE B-2. A declination angle east of True North (positive) is subtracted from

360 (0) degrees to find True North

FIGURE B-3. A declination angle west of True North (negative) is subtracted from

0 (360) degrees to find True North

WindSonic4 Two-Dimensional Sonic Anemometer 16

Page 20

B.1 Online magnetic declination calculator

The magnetic declination web calculator published by NOAA’s Geophysical Data Center is

available at www.ngdc.noaa.gov/geomag-web. This web page calculates declination based on

the latitude and longitude. You can look up your site’s latitude and longitude by entering the

Zip Code or the Country and City, and then clicking the Get & Add Lat/Lon button (FIGURE B-4

(p. 17)). Click the Calculate button to get the magnetic declination.

FIGURE B-4. NOAA web calculator

FIGURE B-5 (p. 18) shows that the calculated declination for Logan, UT is 11.78 degrees (11 August

2015). The declination for Utah is positive (east of north), so True North for this site is 360 – 11.78,

or 348.22 degrees. The annual change is 6 minutes west per year.

WindSonic4 Two-Dimensional Sonic Anemometer 17

Page 21

FIGURE B-5. NOAA calculated declination using HTML result format

WindSonic4 Two-Dimensional Sonic Anemometer 18

Page 22

Appendix C. SDI-12 sensor support

SDI-12, Serial Data Interface at 1200 baud, is a protocol developed to simplify sensor and data

logger compatibility. Only three wires are necessary — serial data, ground, and 12 V. With unique

addresses, multiple SDI-12 sensors can connect to a single SDI-12 terminal on a Campbell

Scientific data logger.

This appendix discusses the structure of SDI-12 commands and the process of querying SDI-12

sensors. For more detailed information, refer to version 1.4 of the SDI-12 protocol, available at

www.sdi-12.org.

For additional information, refer to the SDI-12 Sensors | Transparent Mode and SDI-12 Sensors |

Watch or Sniffer Mode videos.

C.1 SDI-12 command basics

SDI-12 commands have three components:

l Sensor address (a) – a single character and the first character of the command. Use the

default address of zero (0) unless multiple sensors are connected to the same port.

l Command body – an upper case letter (the “command”), optionally followed by one or

more alphanumeric qualifiers.

l Command termination (!) – an exclamation mark.

An active sensor responds to each command. Responses have several standard forms and always

terminate with <CR><LF> (carriage return and line feed). Standard SDI-12 commands are listed

in Table C-1 (p. 19).

Table C-1: Campbell Scientific sensor SDI-12 command and response set

Name Command

Acknowledge Active

Send Identification

Start Verification

Address Query

a!

aI!

aV!

?!

Response

a<CR><LF>

allccccccccmmmmmmvvvxxx...xx

<CR><LF>

atttn <CR><LF>

a<CR><LF>

1

WindSonic4 Two-Dimensional Sonic Anemometer 19

Page 23

Table C-1: Campbell Scientific sensor SDI-12 command and response set

Name Command

Change Address

Start Measurement

Start Measurement

and Request CRC

Start Concurrent Measurement

StartConcurrentMeasurement

and Request CRC

Send Data

Continuous Measurement

Continuous Measurement

and Request CRC

aAb!

aM!

aM1!...aM9!

aMC!

aMC1!...aMC9!

aC!

aC1!...aC9!

aCC!

aCC1!...aCC9!

aD0!...aD9!

aR0!...aR9!

aRC0!...aRC9!

Response

b<CR><LF>

atttn<CR><LF>

atttn <CR><LF>

atttnn<CR><LF>

atttnn<CR><LF>

a<values><CR><LF> or

a<values><CRC><CR><LF>

a<values><CR><LF>

a<values><CRC><CR><LF>

1

Extended Commands

1

Information on each of these commands is given in the following sections.

aXNNN!

a<values><CR><LF>

C.1.1 Acknowledge active command (a!)

The Acknowledge Active command (a!) is used to test a sensor on the SDI-12 bus. An active

sensor responds with its address.

C.1.2 Send identification command (al!)

Sensor identifiers are requested by issuing command aI!. The reply is defined by the sensor

manufacturer but usually includes the sensor address, SDI-12 version, manufacturer’s name, and

sensor model information. Serial number or other sensor specific information may also be

included.

aI!

a Sensor SDI-12 address

ll SDI-12 version number (indicates compatibility)

allccccccccmmmmmmvvvxxx...xx<CR><LF>

cccccccc 8-character vendor identification

WindSonic4 Two-Dimensional Sonic Anemometer 20

Page 24

mmmmmm 6 characters specifying the sensor model

vvv 3 characters specifying the sensor version (operating system)

xxx…xx

<CR><LF>

Source: SDI-12: A Serial-Digital Interface Standard for Microprocessor-Based Sensors (see References).

Up to 13 optional characters used for a serial number or other specific

sensor information that is not relevant for operation of the data logger

Terminates the response

C.1.3 Start verification command (aV!)

The response to a Start Verification command can include hardware diagnostics, but like the aI!

command, the response is not standardized.

Command: aV!

Response: atttn<CR><LF>

a = sensor address

ttt = time, in seconds, until verification information is available

n = the number of values to be returned when one or more subsequent D! commands are issued

C.1.4 Address query command (?!)

Command ?! requests the address of the connected sensor. The sensor replies to the query with

the address, a. This command should only be used with one sensor on the SDI-12 bus at a time.

C.1.5 Change address command (aAb!)

Multiple SDI-12 sensors can connect to a single SDI-12 terminal on a data logger. Each device on

a single terminal must have a unique address.

A sensor address is changed with command aAb!, where a is the current address and b is the

new address. For example, to change an address from 0 to 2, the command is 0A2!. The sensor

responds with the new address b, which in this case is 2.

NOTE:

Only one sensor should be connected to a particular terminal at a time when changing

addresses.

WindSonic4 Two-Dimensional Sonic Anemometer 21

Page 25

C.1.6 Start measurement commands (aM!)

A measurement is initiated with the M! command. The response to each command has the form

atttn<CR><LF>, where

a = sensor address

ttt = time, in seconds, until measurement data is available. When the data is ready, the sensor

notifies the data logger, and the data logger begins issuing D commands.

n = the number of values returned when one or more subsequent D commands are issued. For

the aM! command, n is an integer from 0 to 9.

When the aM! is issued, the data logger pauses its operation and waits until either it receives the

data from the sensor or the time, ttt, expires. Depending on the scan interval of the data logger

program and the response time of the sensor, this may cause skipped scans to occur. In this case

make sure your scan interval is longer than the longest measurement time (ttt).

Table C-2: Example aM! sequence

0M!

00352<CR><LF>

0<CR><LF>

0D0!

0+.859+3.54<CR><LF>

The data logger makes a request to sensor 0 to start a measurement.

Sensor 0 immediately indicates that it will return two values within

the next 35 seconds.

Within 35 seconds, sensor 0 indicates that it has completed the

measurement by sending a service request to the data logger.

The data logger immediately issues the first D command to collect

data from the sensor.

The sensor immediately responds with the sensor address and the two

values.

C.1.7 Start concurrent measurement commands (aC!)

A concurrent measurement (aC!) command follows the same pattern as the aM! command with

the exception that it does not require the data logger to pause its operation, and other SDI-12

sensors may take measurements at the same time. The sensor will not issue a service request to

notify the data logger that the measurement is complete. The data logger will issue the aD0!

command during the next scan after the measurement time reported by the sensor has expired.

To use this command, the scan interval should be 10 seconds or less. The response to each

command has the form atttn<CR><LF>, where

a = the sensor address

ttt = time, in seconds, until the measurement data is available

WindSonic4 Two-Dimensional Sonic Anemometer 22

Page 26

nn = the number of values to be returned when one or more subsequent D commands are

issued.

See the following example. A data logger has three sensors wired into terminal C1. The sensors

are addresses X, Y, and Z. The data logger will issue the following commands and receive the

following responses:

Table C-3: Example aC! sequence

XC!

X03005<CR><LF>

YC!

Y04006<CR><LF>

ZC!

Z02010<CR><LF>

ZD0!

The data logger makes a request to sensor X to start

a concurrent measurement.

Sensor X immediately indicates that it will have 5

(05) values ready for collection within the next 30

(030) seconds.

The data logger makes a request to sensor Y to start

a concurrent measurement.

Sensor Y immediately indicates that it will have 6

(06) values ready for collection within the next 40

(040) seconds.

The data logger makes a request to sensor Z to start

a concurrent measurement.

Sensor Z immediately indicates that it will have 10

values ready for collection within the next 20 (020)

seconds.

After 20 seconds have passed, the data logger starts

the process of collecting the data by issuing the first

D command to sensor Z.

Z+1+2+3+4+5+6+7+8+9+10<CR><LF>

XD0!

X+1+2+3+4+5<CR><LF>

Sensor Z immediately responds with the sensor

address and the 10 values.

10 seconds later, after a total of 30 seconds have

passed, the data logger starts the process of

collecting data from sensor X by issuing the first D

command.

The sensor immediately responds with the sensor

address and the 5 values.

WindSonic4 Two-Dimensional Sonic Anemometer 23

Page 27

Table C-3: Example aC! sequence

YD0!

Ten seconds later, after a total of 40 seconds have

passed, the data logger starts the process of

collecting data from sensor Y by issuing the first D

command.

Y+1+2+3+4+5+6<CR><LF>

The sensor immediately responds with the sensor

address and the 6 values.

C.1.8 Start measurement commands with cyclic redundancy check (aMC! and aCC!)

Error checking is done by using measurement commands with cyclic redundancy checks (aMC!

or aCC!). This is most commonly implemented when long cable lengths or electronic noise may

impact measurement transmission to the data logger. When these commands are used, the data

returned in response to D or R commands must have a cyclic redundancy check (CRC) code

appended to it. The CRC code is a 16-bit value encoded within 3 characters appended before the

<CR><LF>. This code is not returned in the data table but checked by the data logger as it

comes. The code returned is based on the SDI-12 protocol. See the SDI-12 communication

specification for version 1.3 available at www.sdi-12.org to learn more about how the CRC code is

developed.

C.1.9 Stopping a measurement command

A measurement command (M!) is stopped if it detects a break signal before the measurement is

complete. A break signal is sent by the data logger before most commands.

A concurrent measurement command (C!) is aborted when another valid command is sent to the

sensor before the measurement time has elapsed.

C.1.10 Send data command (aD0! … aD9!)

The Send Data command requests data from the sensor. It is issued automatically with every type

of measurement command (aM!, aMC!, aC!, aCC!). When the measurement command is aM!

or aMC!, the data logger issues the aD0! command once a service request has been received

from the sensor or the reported time has expired. When the data logger is issuing concurrent

commands (aC! or aCC!), the Send Data command is issued after the required time has elapsed

(no service request will be sent by the sensor). In transparent mode (see SDI-12 transparent mode

(p. 25) ), the user asserts this command to obtain data.

Depending on the type of data returned and the number of values a sensor returns, the data

logger may need to issue aD0! up to aD9! to retrieve all data. A sensor may return up to 35

WindSonic4 Two-Dimensional Sonic Anemometer 24

Page 28

characters of data in response to a D command that follows an M! or MC! command. A sensor

may return up to 75 characters of data in response to a D command that follows a C! or CC!

command. Data values are separated by plus or minus signs.

Command: aD0! (aD1! … aD9!)

Response: a<values><CR><LF> or a<values><CRC><CR><LF>

where:

a = the sensor address

<values> = values returned with a polarity sign (+ or –)

<CR><LF> = terminates the response

<CRC> = 16-bit CRC code appended if data was requested with aMC! or aCC!.

C.1.11 Continuous measurement command (aR0! … aR9!)

Sensors that are able to continuously monitor the phenomena to be measured can be read

directly with the R commands (R0! … R9!). The response to the R commands mirrors the Send

Data command (aD0!). A maximum of 75 characters can be returned in the <values> part of the

response to the R command.

C.2 SDI-12 transparent mode

System operators can manually interrogate and enter settings in probes using transparent mode.

Transparent mode is useful in troubleshooting SDI-12 systems because it allows direct

communication with probes. Data logger security may need to be unlocked before activating the

transparent mode.

Transparent mode is entered while the computer is communicating with the data logger through

a terminal emulator program. It is accessed through Campbell Scientific data logger support

software or other terminal emulator programs. Data logger keyboards and displays cannot be

used.

The terminal emulator is accessed by navigating to the Datalogger list in PC200W, the Tools list

in PC400, or the Datalogger list in the Connect screen of LoggerNet.

Watch the video: SDI-12 Sensors | Transparent Mode.

Data loggers from other manufacturers will also have a transparent mode. Refer to those manuals

on how to use their transparent mode.

WindSonic4 Two-Dimensional Sonic Anemometer 25

Page 29

The following examples show how to enter transparent mode and change the SDI-12 address of

an SDI-12 sensor. The steps shown in Changing an SDI-12 address (p. 26) are used with most

Campbell Scientific data loggers.

C.2.1 Changing an SDI-12 address

This example was done with a CR1000X, but the steps are only slightly different for CR6, CR3000,

CR800-series, CR300-series, CR1000 data loggers.

1. Connect an SDI-12 sensor to the CR1000X.

2. In LoggerNet Connect, under Datalogger, click Terminal Emulator. The terminal emulator

window opens.

3. Under Select Device, located in the lower left side of the window, select the CR1000X

4. Click Open Terminal.

5. Select All Caps Mode.

6. Press Enter until the data logger responds with the CR1000X> prompt.

7. Type SDI12 and press Enter.

8. At the Select SDI12 Port prompt, type the number corresponding to the control port where

the sensor is connected and press Enter. The response Entering SDI12 Terminal indicates

that the sensor is ready to accept SDI-12 commands.

WindSonic4 Two-Dimensional Sonic Anemometer 26

Page 30

9. To query the sensor for its current SDI-12 address, type ?! and press Enter. The sensor

responds with its SDI-12 address. If no characters are typed within 60 seconds, the mode is

exited. In that case, simply type SDI12 again, press Enter, and type the correct control port

number when prompted.

10. To change the SDI-12 address, type aAb!, where a is the current address from the previous

step and b is the new address. Press Enter. The sensor changes its address and responds

with the new address. In the following example, the sensor address is changed from 0 to B.

11. To exit SDI-12 transparent mode, click Close Terminal.

NOTE:

The transparent mode for the CR6, CR3000, CR800-series, CR300-series, and CR1000 data

loggers is similar to that shown for the CR1000X.

WindSonic4 Two-Dimensional Sonic Anemometer 27

Page 31

Limited warranty

Products manufactured by Campbell Scientific are warranted by Campbell Scientific to be free

from defects in materials and workmanship under normal use and service for twelve months from

the date of shipment unless otherwise specified on the corresponding product webpage. See

Product Details on the Ordering Information pages at www.campbellsci.com. Other

manufacturer's products, that are resold by Campbell Scientific, are warranted only to the limits

extended by the original manufacturer.

Refer to www.campbellsci.com/terms#warranty for more information.

CAMPBELL SCIENTIFIC EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Campbell Scientific hereby

disclaims, to the fullest extent allowed by applicable law, any and all warranties and conditions

with respect to the Products, whether express, implied or statutory, other than those expressly

provided herein.

Page 32

Assistance

Products may not be returned without prior authorization.

Products shipped to Campbell Scientific require a Returned Materials Authorization (RMA) or

Repair Reference number and must be clean and uncontaminated by harmful substances, such as

hazardous materials, chemicals, insects, and pests. Please complete the required forms prior to

shipping equipment.

Campbell Scientific regional offices handle repairs for customers within their territories. Please

see the back page for the Global Sales and Support Network or visit

www.campbellsci.com/contact to determine which Campbell Scientific office serves your country.

To obtain a Returned Materials Authorization or Repair Reference number, contact your

CAMPBELL SCIENTIFIC regional office. Please write the issued number clearly on the outside of

the shipping container and ship as directed.

For all returns, the customer must provide a “Statement of Product Cleanliness and

Decontamination” or “Declaration of Hazardous Material and Decontamination” form and

comply with the requirements specified in it. The form is available from your CAMPBELL

SCIENTIFIC regional office. Campbell Scientific is unable to process any returns until we receive

this statement. If the statement is not received within three days of product receipt or is

incomplete, the product will be returned to the customer at the customer’s expense. Campbell

Scientific reserves the right to refuse service on products that were exposed to contaminants that

may cause health or safety concerns for our employees.

Page 33

Safety

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND TRIPODS, TOWERS,

AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES, ANTENNAS, ETC. FAILURE TO PROPERLY

AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS, TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED

WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE. TAKE ALL

REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS. CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR

PROCEDURES AND REQUIRED PROTECTIVE EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design limits. Be

familiar and comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.com. You are responsible for

conformance with governing codes and regulations, including safety regulations, and the integrity and location of structures or land to which

towers, tripods, and any attachments are attached. Installation sites should be evaluated and approved by a qualified engineer. If questions or

concerns arise regarding installation, use, or maintenance of tripods, towers, attachments, or electrical connections, consult with a licensed and

qualified engineer or electrician.

General

l Protect from over-voltage.

l Protect electrical equipment from water.

l Protect from electrostatic discharge (ESD).

l Protect from lightning.

l Prior to performing site or installation work, obtain required approvals and permits. Comply with all governing structure-height

regulations.

l Use only qualified personnel for installation, use, and maintenance of tripods and towers, and any attachments to tripods and towers.

The use of licensed and qualified contractors is highly recommended.

l Read all applicable instructions carefully and understand procedures thoroughly before beginning work.

l Wear a hardhat and eye protection, and take other appropriate safety precautions while working on or around tripods and towers.

l Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take reasonable precautions to secure tripod and

tower sites from trespassers.

l Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

l You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are installing, constructing, using, or

maintaining, or a tool, stake, or anchor, come in contact with overhead or underground utility lines.

l Maintain a distance of at least one-and-one-half times structure height, 6 meters (20 feet), or the distance required by applicable law,

whichever is greater, between overhead utility lines and the structure (tripod, tower, attachments, or tools).

l Prior to performing site or installation work, inform all utility companies and have all underground utilities marked.

l Comply with all electrical codes. Electrical equipment and related grounding devices should be installed by a licensed and qualified

electrician.

l Only use power sources approved for use in the country of installation to power Campbell Scientific devices.

Elevated Work and Weather

l Exercise extreme caution when performing elevated work.

l Use appropriate equipment and safety practices.

l During installation and maintenance, keep tower and tripod sites clear of un-trained or non-essential personnel. Take precautions to

prevent elevated tools and objects from dropping.

l Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

l Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks, frayed cables, loose cable clamps, cable

tightness, etc. and take necessary corrective actions.

l Periodically (at least yearly) check electrical ground connections.

Internal Battery

l Be aware of fire, explosion, and severe-burn hazards.

l Misuse or improper installation of the internal lithium battery can cause severe injury.

l Do not recharge, disassemble, heat above 100 °C (212 °F), solder directly to the cell, incinerate, or expose contents to water. Dispose of

spent batteries properly.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS, THE CUSTOMER

ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR MAINTENANCE OF TRIPODS, TOWERS, OR

ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES, ANTENNAS, ETC.

Page 34

Campbell Scientific regional offices

Australia

Location:

Phone:

Email:

Website:

Brazil

Location:

Phone:

Email:

Website:

Canada

Location:

Phone:

Email:

Website:

China

Location:

Phone:

Email:

Website:

Garbutt, QLD Australia

61.7.4401.7700

info@campbellsci.com.au

www.campbellsci.com.au

São Paulo, SP Brazil

11.3732.3399

vendas@campbellsci.com.br

www.campbellsci.com.br

Edmonton, AB Canada

780.454.2505

dataloggers@campbellsci.ca

www.campbellsci.ca

Beijing, P. R. China

86.10.6561.0080

info@campbellsci.com.cn

www.campbellsci.com.cn

France

Location:

Phone:

Email:

Website:

Germany

Location:

Phone:

Email:

Website:

India

Location:

Phone:

Email:

Website:

South Africa

Location:

Phone:

Email:

Website:

Vincennes, France

0033.0.1.56.45.15.20

info@campbellsci.fr

www.campbellsci.fr

Bremen, Germany

49.0.421.460974.0

info@campbellsci.de

www.campbellsci.de

New Delhi, DL India

91.11.46500481.482

info@campbellsci.in

www.campbellsci.in

Stellenbosch, South Africa

27.21.8809960

sales@campbellsci.co.za

www.campbellsci.co.za

Thailand

Location:

Phone:

Email:

Website:

UK

Location:

Phone:

Email:

Website:

USA

Location:

Phone:

Email:

Website:

Bangkok, Thailand

66.2.719.3399

info@campbellsci.asia

www.campbellsci.asia

Shepshed, Loughborough,

UK

44.0.1509.601141

sales@campbellsci.co.uk

www.campbellsci.co.uk

Logan, UT USA

435.227.9120

info@campbellsci.com

www.campbellsci.com

Costa Rica

Location:

Phone:

Email:

Website:

San Pedro, Costa Rica

506.2280.1564

info@campbellsci.cc

www.campbellsci.cc

Spain

Location:

Phone:

Email:

Website:

Barcelona, Spain

34.93.2323938

info@campbellsci.es

www.campbellsci.es

Loading...

Loading...