Page 1

TD OPERATING SYSTEM ADDENDUM FOR CR510, CR10X,

AND CR23X MANUALS

COPYRIGHT

REVISION: 1/03

2002-2003 CAMPBELL SCIENTIFIC, INC.

Page 2

This is a blank page.

Page 3

TABLE DATA ADDENDUM

TD and PakBus Operating System Addendum for

CR510, CR10X, and CR23X Manuals

AD1 Major Differences

Table Data (TD) operating systems have two major differences from the

standard operating systems: First - t he namesake - in the way data are

stored internally and second, in the options available for transferring

that data to external devices. The standard operating systems support

both on site external storage (i.e., storage modules) that may be

manually retrieved and telecommunications. The TD operating systems

have more advanced telecommunication and networking capabilities but

do not support storage modules. There are two versions of the TD

operating system: TD and PakBus. The PakBus operating system

includes the PakBus communications protocol that allows some

additional communications options (Section 12); other features are the

same as the TD operating system.

The datalogger hardware and direct measurement capabilities are the

a

me in either case.

s

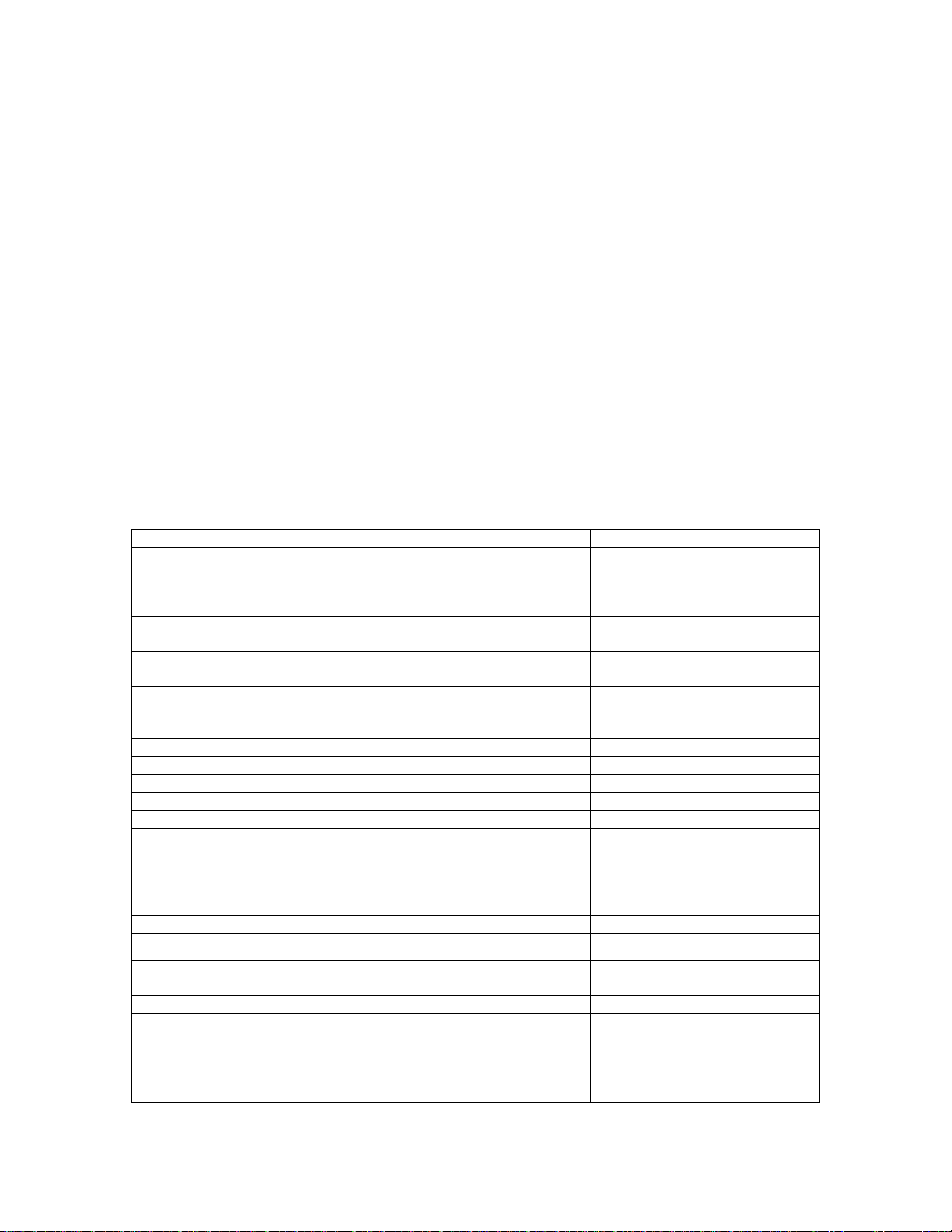

Feature Table Data OS Standard OS

Internal Data Storage Multiple Data Tables, at least

one Table for each output

interval.

Term for a set of values output

together

Term for individual values

within the array or record

Number of elements or fields in

an array or record

Conditional Output Yes Yes

TimeStamps Automatic Optional

At Site / Manual Data Transfer No Yes

Storage Module Support No Yes

Instruction 96 – Serial Output No Yes

Instruction 98 – Send Character No Yes

Telecommunications Commands protocol with error

Error Checking for data Yes Yes

Confirmation for Commands Yes No

Data Advise – data automatically

sent (speeds mu lti-hop RF)

PakBus packet switching. Yes – in PakBus No

Supports Wireless Sensor Yes – in PakBus No

Support for Satellite

Transmitters

Analog Measurements No Difference No Difference

Pulse Measurements

Record (a row of the table) Array

Field (a column of the table) Element

A fixed number, determined by

the program

checking on all commands and

responses. Feedback to confirm

commands have been accepted.

Yes No

No Yes

No Difference No Difference

One or two Final Storage Areas.

Data A

rrays output at different

intervals may share the same area

and are identified by ID.

Generally fixed but conditional

elements possible. Determined

by program

Simple commands with error

ch

ecking on data sent from

datalogger to computer

AD-1

Page 4

TABLE DATA ADDENDUM

AD2 Overview of Data Storage Tables

Within a data table, data is organized in records and fields. Each row in a

table represents a record and each column represents a field. To

understand the concept of tables it may be helpful to consider an example.

A CR10-TD is to be used to monitor 3 thermocouples (TC). Each hour a

temperature for each of the three TC is to be stored. The table has 4 fields

: "DATE_TIME TEMP1 TEMP2 TEMP3". Each hour a new "record"

would be added. The "hourly" table would then be organized as follows:

DATE_TIME TEMP1 TEMP2 TEMP3

01/27/91 10:00:0023.5 24.6 28.2

01/27/91 11:00:0024.2 22.4 23.4

Only the hourly data is stored in the hourly table, Each output interval

s its own table. Data tables can also be "event driven" rather than

ha

interval driven, that is a new record is stored when a specified event

occurs rather than based on time. Each table is completely independent

of any other tables and all records in a given table have the same

number of fields.

The TD operating system supports naming of tables and fields, so any

a

lue can be referenced by the table and field names. For example,

data v

the temperature data for the first thermocouple is referenced as

"HOURLY.TEMP1". Computer software also allows the station to be

named. When multiple dataloggers are in use, this can be used to

reference specific data in the network. If, in the previous example, the

CR10T site was named DALLAS, the first thermocouple's data values

would be referenced by "DALLAS.HOURLY.TEMP1".

AD3 Converting an existing program to Table Based OS

This section is intended for those familiar with programming an Array

based datalogger.

AD3.1 Programming changes

• Remove all Record Real Time instructions (Instruction 77).

• Remove all Serial Data Output and Serial Print instructions

(Instructions 96 and 98).

• Remove all Initiate Telecommunication (callback) instructions

(Instruction 97).

• Check all instructions which set the Output Flag (Flag 0). These

should be replaced with the Data Table Instruction (Instruction 84).

If the Set Active Storage Area instruction (Instruction 80) is used, it

should be removed as Instruction 84 provides this functionality.

• Check all If Time Instructions (Instruction 92) as the units may

change from minutes to seconds. Any instruction 92 that sets the

output flag (Flag 0) is replaced by Instruction 84.

• Check the Move Time To Input Location Instruction (Instruction

18) as some parameters have changed.

AD-2

Page 5

Check the Maximum and Minimum Instructions ( Instructions 73

•

and 74) as there is only one option to store time with the value.

• Edit Input Location labels removing all spaces and special

characters. Only letters, numbers, and the “_” characters are

allowed. Labels should start with a letter.

• Add labels for the Final Storage values. Use the same character as

are allowed for Input Location labels. See Section 2.1

AD3.2 Making the Changes with Edlog

Programs for Array based logger can be converted to Table Based using

EDLOG for most of the editing by doing the following:

1. Make a copy of the original program with the name you want the

new program to have: Load the original into Edlog and “Save As”

the new name .

2. Remove or comment out all Instructions 77, 96, 97, and 98. (first

three points in AD3.1, these instructions are not in the Table OS)

TABLE DATA ADDENDDUM

3. Save the edited program and close it in Edlog.

4. Edit the CSI file with a text editor (e.g., “Notepad” - Edlog will not

allow you to make and save this change) and add –TD to the

datalogger type on the first line, for example, change:

;{CR10X}

to:

;{CR10X-TD}.

Save the CSI file and close the editor.

5. Open the file with Edlog. Edlog should now recognize that the

program is for a table data OS.

6. Add Instructions 84 where necessary and make the other necessary

changes.

AD-3

Page 6

TABLE DATA ADDENDUM

AD4 Summary of Differences from the Datalogger Manual:

Section

Overview

Section 1

Section 2

Section 3

Section 4

Section 5

Section 6

Section 7

Section 8

Section 9

Section 10

Section 11

Differences

Figure OV2.1-2: See Figure 1.5-1 in Addendum.

Table OV3.2-1: See Table OV4.1-1 in TD Addendum.

OV4, OV5, OV6 :See TD Addendum.

Section 1.5 A Mode is replaced by addendum – the TD loggers

allocate memory differently.

Section 1.8 - *D Mode is replaced by TD Addendum – TD loggers do

not support storeing multiple programs or Storage Modules. PakBus

Settings are added to the *D Mode.

Replaced entirely by TD Addendum.

Section 3.7.1 does not apply to the TD operating system which does

not use Output Flag 0.

Table 3.8-1 Valid Flag Commands are 11 – 19 to set high and 21- 29

to set Low. Because the TD operating system does not use Flag 0,

Commands 10 and 20 are not valid with the TD operating system.

Table 3.10-1 TD Addendum. has a corrected version

Does not apply: The TD operating system does not support External

Storage Peripherals.

Does not apply: The communications commands and protocol of the

TD operating system is different than that of the standard operating

systems. Campbell Scientific provides software for communications;

a description of the protocol is beyond the scope of this addendum.

Many of the peripherals discussed in section 6 are not supported by

the TD operating system.

No Change

Replaced entirely by TD Addendum.

Instruction 18 has some differences in the time options, see

addendum.

No Change

Instructions 73 and 74 have only one option for storing the time of

max or min (time is output as a quoted string).

AD-4

Instruction 80 – Set Active Storage Area, is not in the TD o perating

system. Its functions are included in Instruction 84 – Data Table.

Instruction 84 – Data Table, sets the conditions and destination for

output data. This instruction is only in the TD operating system (see

TD Addendum..)

Page 7

TABLE DATA ADDENDDUM

Section 12

Section 13 No Change

Section 14 No Change

The TD operating system does not use the output Flag 0.

Commands dealing with it are not valid.

Instruction 92 – There is no option for minutes, time is in seconds

only.

Instructions Not In TD OS:

struction 96 – Serial Output

In

Instruction 98 – Send Character

n

struction 111 – Load Program from Flash

I

New Instructions for PakBus:

Instruction 190 – Send or Get Input Locations

Instruction 191 – One way Final Storage Data Transfer

Instruction 192 – PakBus Message

Instruction 193 – Wireless Network Master Control

Instruction 194 – Time Until Transmit

Instruction 195 – Set Clock from Address

Instruction 196 – Wireless Remote

Instruction 197 – Force Route Through Address

AD-5

Page 8

TABLE DATA ADDENDUM

This is a bla nk page.

AD-6

Page 9

MEASUREMENT AND CONTROL MODULE OVERVIEW

While this section of the addendum references the CR10X, everything but the measurement instructions

in the example programs applies to the other dataloggers as well.

Table OV3.2-1 in the CR10X Manual is incorrect for the TD operating system. See Tabl

The following sections OV4, OV5, and OV6 replace those in the CR10X Manual.

OV4. PROGRAMMING THE CR10X

A program is created by entering it directly into

the datalogger or into a computer using the

LOGGERNET program EDLOG. This manual

describes direct interaction with the CR10X.

Work through the direct programming examples

in this overview before using EDLOG and you

will know the basics of CR10X operation as well

as an appreciation for the help provided by the

software. Section OV4.5 describes options for

loading the program into the CR10X.

OV4.1 FUNCTIONAL MODES

CR10X/User interaction is broken into different

tional MODES (e.g., programming the

unc

f

measurements and output, setting time, etc.).

The modes are referred to as Star (*) Modes

since they are accessed by first keying *, then

the mode number or letter. Table OV4.1-1 lists

the CR10X Modes.

OV4.2 KEY DEFINITION

Keys and key sequences have specific functions

ing the CR10KD keyboard or a computer

hen us

w

in the remote keyboard state (Section 5). Table

OV4-2 lists these functions. In some cases, the

exact action of a key depends on the mode the

CR10X is in and is described with the mode in the

manual.

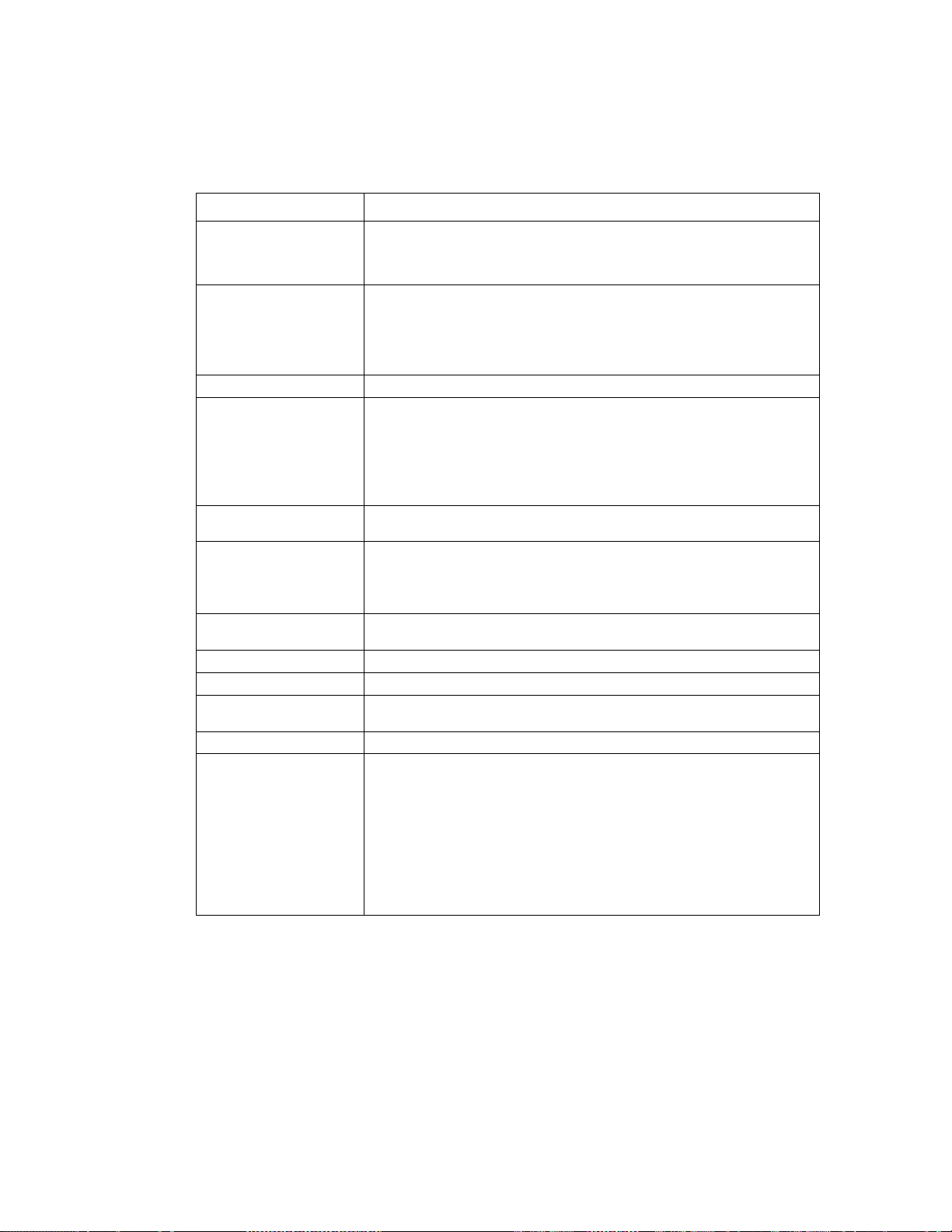

TABLE OV4.1-1. * Mode Summary

Key Mode

*0 LOG data and indicate active Tables

*1 Program Table 1

*2 Program Table 2

*3 Program Table 3, subroutines only

*5 Display/set real time clock

*6 Display/alter Input Storage data,

toggle fl

*7 Display Data Storage Table data

*9 Display Data Storage Table sizes

*A Memory allocation/reset

*B Signature/status

*C Security

TABLE OV4.2-1. Key Description/Editing

Key Action

0-9 Key numeric entries into display

* Enter Mode (followed by Mode

Number

A Enter/Advance

ags and ports

Functions

)

e OV4.1-1 below.

When using a computer/terminal to

municate with the CR10X

om

c

(Telecommunications) there are some keys

available in addition to those found on the

CR10KD. Table OV4.2-2 lists these keys.

B Back up

C Change the sign of a number or index

an input location to loop c

D Enter the decimal point

# Clear the rightmost digit keyed into

the disp

#A Advance to next instruction in

progr

#B Back up to previous instruction in

progr

#D Delete entire instruction

lay

am table (*1, *2, *3)

am table.

ounter

AD-OV-1

Page 10

TD ADDENDUM—OVERVIEW

TABLE OV4.2-2. Additional Keys Allowed in

Telecommunications

Key Action

- Change Sign, Index (same as C)

CR Enter/advance (same as A)

OV4.3 PROGRAMMING SEQUENCE

In routine applications, the CR10X measures

sens

or output signals, processes the

measurements over some time interval and

stores the processed results. A generalized

programming sequence is:

1. Enter the execution interval. In most cases,

ution interval is determined by the

ec

the ex

desired sensor scan rate.

2. Enter the Input/Output instructions required

to meas

3. If processing in addition to that provided by

the Output Pr

is required, enter the appropriate

Processing Instructions.

4. Enter the Data Table Instruction 84 to test

the output c

condition is met. For example, use

This instruction must precede the Output

Proc

a Data Storage Table. Instructions are

described in Sections 9 through 12.

5. Enter the Output Processing Instructions to

t

s

Table. The order in which data are stored

is determined by the order of the Output

Processing Instructions in the table.

6. Repeat steps 4 through 6 for additional

outputs

ure the sensors.

ocessing Instructions (step 5)

ondition and output w

Instruction 84 to output based on time.

Instruction 84 to output every execution

al.

interv

Instruction 84 to output based on a

am Flag.

Progr

essing Instructions which store data in

ore processed data in the Data Storage

ferent intervals or conditions.

on dif

hen the

NOTE: The program must be executed for

output to occur. Therefore, the interval

specified with the Data Table Instruction is

set must be evenly divisible by the execution

interval. For example, with a 2 minute

execution interval and a 5 minute output

interval, the program will only be executed

on the even multiples of the 5 minute

intervals, not on the odd. Data will be output

every 10 minutes instead of every 5 minutes.

Execution intervals are synchronized with

midnight. Output intervals set with Instruction

84 are synchronized with real time starting at

midnight, January 1, 1990.

OV4.4 INSTRUCTION FORMAT

Instructions are identified by an instruction

ber

num

parameters that give the CR10X the information

it needs to execute the instruction.

The CR10X Prompt Sheet has the instruction

num

listed in columns following the description.

Some parameters are footnoted with further

description under the "Instruction Option Codes"

heading.

For example, Instruction 73 stores the

m

Storage location over the output interval. The

instruction has three parameters (1)

REPetitionS, the number of sequential Input

Storage locations on which to find maxima, (2)

TIME, an option of storing the time of

occurrence with the maximum value, and (3)

LOC the first Input Storage location operated on

by the Maximum Instruction. The codes for the

TIME parameter are listed in the "Instruction

Option Codes".

The repetitions parameter specifies how many

tim

For example, four 107 thermistor probes may be

measured with a single Instruction 11, Temp-107,

with four repetitions. Parameter 2 specifies the

input channel of the first thermistor (the probes

must be connected to sequential channels).

Parameter 4 specifies the Input Storage location in

which to store measurements from the first

thermistor. If location 5 were used and the first

probe was on channel 1, the temperature of the

thermistor on channel 1 would be stored in input

. Each instruction has a number of

ber

s in red, with the parameters briefly

ax

imum value that occurred in an Input

an instruction's function is to be repeated.

es

AD-OV-2

Page 11

TD ADDENDUM—OVERVIEW

location 5, the temperature from channel 2 in input

location 6, etc.

Detailed descriptions of the instructions are

given in Sect

into a program table is described in OV5.

OV4.5 ENTERING A PROGRAM

Programs are entered into the CR10X in one of

ays:

o w

tw

1. Keyed in using the CR10X keyboard

2. Stored on disk/seat from computer

A program is created by keying it directly into

the datalogger

on a PC using EDLOG.

EDLOG is used to develop programs for

pbell Sc

Cam

EDLOG is a prompting editor for writing and

documenting programs for Campbell Scientific

CR10X dataloggers. Program files developed

with EDLOG can be downloaded directly to the

CR10X using NetAdmin. NetAdmin supports

communication via direct wire, telephone, or

Radio Frequency (RF).

ions 9-12. Entering an instruction

as

described in Section OV5, or

ientific CR10X dataloggers.

OV5. PROGRAMMING EXAMPLES

We will start with a simple programming

example. There is a brief explanation of each

step to help you follow the logic. When the

example uses an instruction, find it on the

Prompt Sheet and follow through the

description of the parameters. Using the

Prompt Sheet while going through these

examples will help you become familiar with its

format. Sections 9-12 have more detailed

descriptions of the instructions.

With the Wiring Panel connected to the CR10X,

up the pow

hook

Section OV1.2. Next, connect the CR10X to

either a CR10KD Keyboard/Display or the

computer (Section OV3). The programming

steps in the following examples use the

keystrokes possible on the keyboard/display.

With a terminal, some responses will be slightly

different.

If the CR10KD is connected to the CR10X when

ered up, the display will show:

pow

it is

Display Explanation

HELLO On power-up, the CR10X

after a few seconds delay

:96 The size of the machine's total

OV5.1 SAMPLE PROGRAM 1

In this example the CR10X is programmed to

own internal temperature (using a built

ead its

r

in thermistor) every 5 seconds and to send the

results to Final Storage.

er leads as described in

displays "HELLO" while it checks

the memory (this display occurs

only with the CR10KD).

ory (RAM plus 32 K of

em

m

ROM), in this case 96K

Key Display Explanation

* 00:00 Enter mode.

1 01:00 Enter Program Table 1.

A 01:0.0000 Advance to execution interval (In seconds)

5 01:5 Key in an execution interval of 5 seconds.

A 01:P00 Enter the 5 second execution interval and advance to

i

rst program instruction location.

the f

17 01:P17 Key in Instruction 17 which directs the CR10X to

eas

ure the internal temperature in degrees C. This is

m

an Input/Output Instruction.

A 01:0000 Enter Instruction 17 and advance to the first parameter.

1 01:1 The input location to store the measurement, location 1.

A 02:P00 Enter the location # and advance to the second

am instruction.

ogr

pr

The CR10X is now programmed to read the internal temperature every 5 seconds and place the reading

in Input Storage Loc

ation 1. The program can be compiled and the temperature displayed.

AD-OV-3

Page 12

TD ADDENDUM—OVERVIEW

Key (ID:Data) Explanation

*0 LOG 1 Exit Table 1, enter *0 Mode, compile table and begin

*6 06:0000 Enter *6 Mode (to view Input Storage).

A 01:21.234 Advance to first storage location. Panel temperature is

Wait a few seconds:

*1 01:00 Exit *6 Mode. Enter program table 1.

2A 02:P00 Advance to 2nd instruction location (this is where we

84 02:P84 This is the Data Table Instruction.

A 01:0.0000 Enter 84 and advance to the first parameter (which is

0 01:0 This parameter determines when in the output internal

A 02:0.000 Enter 0 and advance to the second parameter.

0 02:0 This parameter specifies the output interval. 0 stores

A 03:0.0000 Enter 0 and advance to third parameter.

1000 03:1000.00 This parameter specifies how many records to store in

A 03:P00 Enter 1000 and advance to the third program

70 03:P70 The SAMPLE instruction. It directs the CR10X to take

A 01:0000 Enter 70 and advance to the first parameter

1 01:1 There is only one input location to sample; repetitions = 1.

A 02:0000 Enter 1 and advance to second parameter (Input

1 02:1 Input Storage Location 1, where the temperature is

A 04:P00 Enter 1 and advance to fourth program instruction.

* 00:00 Exit Table 1.

0 LOG 1 Enter *0 Mode, compile program, log data.

logging.

the display will show the actual

21.234°C

temperature).

01:21.423 The CR10X has read the sensor and stored the result

again. The inter

is updated every 5 seconds when the table is executed.

At this point the CR10X is measuring the temperature

every 5 seconds and sending the value to Input

Storage. No data are being saved. The next step is to

have the CR10X send each reading to Final Storage.

ft off).

e

l

the tim

data is

data eac

the table bef

example, keep 1000 records.

struction.

n

i

a r

Final Storage (an Output Processing Instruction).

epetitions).

r

(

Stor

t

ored.

s

(

nal temp is now 21.423°C. The value

into the interval).

e

s

tored. 0 stores data on the even interval.

ecution.

h ex

e overwriting the oldest. For this

or

eading f

rom an Input Storage location and send it to

age loc

ation to sample).

AD-OV-4

Page 13

TD ADDENDUM—OVERVIEW

OV5.2 SAMPLE PROGRAM 2

This second example is more representative of a

real-

life data collection situation. Once again the

internal temperature is measured, but it is used

as a reference temperature for the differential

voltage measurement of a type T (copperconstantan) thermocouple; the CR10X should

have arrived with a short type T thermocouple

connected to differential channel 5.

When using a type T thermocouple, the copper

blue)

lead (

differential channel, and the constantan lead

(red) is connected to the low input.

A thermocouple produces a voltage that is

opor

pr

between the measurement and the reference

junctions.

To make a thermocouple (TC) temperature

eas

m

junction (in this example, the approximate panel

temperature) must be measured. The CR10X

takes the reference temperature, converts it to

the equivalent TC voltage relative to 0°C, adds

the measured TC voltage, and converts the

sum to temperature through a polynomial fit to

the TC output curve (Section 13.4).

The internal temperature of the CR10X is not a

uitable r

s

thermocouple measurements. It is used here

for the purpose of training only. To make

thermocouple measurements with the CR10X,

purchase the Campbell Scientific Thermocouple

Reference, Model CR10XCR (Section 13.4) and

make the reference temperature measurement

with Instruction 11.

Instruction 14 directs the CR10X to make a

erential TC temperature measurement. The

f

dif

first parameter in Instruction 14 is the number of

times to repeat the measurement. Enter 1,

because in this example there is only one

thermocouple. If there were more than 1 TC,

they could be wired to sequential channels, and

the number of thermocouples entered for

repetitions. The CR10X would automatically

advance through the channels sequentially and

measure all of the thermocouples.

is connected to the high input of the

tional to the difference in temperature

urement, the temperature of the reference

eference temperature for precision

per degree C difference in temperature between

the two junctions. The ±2.5 mV scale will

provide a range of ±2500/40 = ±62.5°C (i.e.,

this scale will not overrange as long as the

measuring junction is within 62.5°C of the panel

temperature). The resolution of the ±2.5 mV

range is 0.33 µV or 0.008°C.

Parameter 3 is the analog input channel on

hic

h to make the first, and in this case only,

w

measurement. Parameter 4 is the code for the

type of thermocouple used. This information is

located on the Prompt Sheet or in the

description of Instruction 14 in Section 9. The

code for a type T (copper-constantan)

thermocouple is 1.

Parameter 5 is the Input Storage location in

hic

h the reference temperature is stored.

w

Parameter 6 is the Input Storage location in

which to store the measurement (or the first

measurement; e.g., if there are 5 repetitions

and the first measurement is stored in location

3, the final measurement will be stored in

location 7). Parameters 7 and 8 are the

multiplier and offset. A multiplier of 1 and an

offset of 0 outputs the reading in degrees C. A

multiplier of 1.8 and an offset of 32 converts the

reading to degrees F.

In this example, the sensor is measured once a

i

nute, and the average temperature is output

m

every hour. Once a day the maximum and

minimum temperatures and the times they occur

will be output.

The first example described program entry one

ey

stroke at a time. This example does not

k

show the "A" key. Remember, "A" is used to

enter and/or advance (i.e., between each line in

the example below). This format is similar to

the format used in EDLOG.

It's a good idea to have both the manual and the

pt Sheet handy when going through this

om

Pr

example. You can find the program instructions

and parameters on the Prompt Sheet and can

read their complete definitions in the manual.

To obtain daily output, the Data Table

t

ruction is followed by the Output Instructions

ins

to store the daily maximum and minimum

temperatures and the time each occurs.

Parameter 2 is the voltage range to use when

ing the measurement. The output of a type

ak

m

T thermocouple is approximately 40 microvolts

AD-OV-5

Page 14

TD ADDENDUM—OVERVIEW

Instruction # Parameter

(Loc:Entry) (Par#:Entry) Description

*1 Enter Program Table 1

01:60 60 second (1 minute) execution interval

Key "#D"

repeatedly

is displayed

01:P17 Measure internal temperature

02:P14 Measure thermocouple temperature (differential)

until 01:P00 Erase previous Program before continuing.

SAMPLE PROGRAM 2

S

01:1

01:1 1 repetition

02:1 Range code (2.5 mV, slow)

03:5 Input channel of TC

04:1 TC type: copper-constantan

05:1 Reference temp is stored in Location 1

06:2 Store TC temp in Location 2

07:1 Multiplier of 1

08:0 No offset

tore temp in Location 1

03:P84 Data Table Instruction

0 s

01:0

02:3600 3600 second (60 min.) internal

03: 0 Automatically allocate # of records

The CR10X is programmed to measure the thermocouple temperature every sixty seconds.

he CR10X automatic

T

stored. Next the output instruction for the average is added.

Instruction # Parameter

(Loc.:Entry) (Par.#:Entry)

04:P71 Average instruction

05:P84 Data Table Instruction

06: P73 Maximize instruction

07: P74 Minimize instruction

ally allocates the number of records. Time information is automatically

01:1 One repetition

02:2 Location 2 - source of TC temps. to be averaged

01:0 0 seconds into the interval

02:86400 86400 second interval (24 hrs.)

03:0 Automatically allocate # of records

01:1 One repetition

02:1 Output the time of the daily maximum

03:2 Data source is Input Storage Location 2.

01:1 One repetition

02:1 Output the time of the daily minimum

03:2 Data source is Input Storage Location 2.

econds into the interval

Description

AD-OV-6

Page 15

TD ADDENDUM—OVERVIEW

The program to make the measurements and send the desired data to Final Storage has been

ed. T

enter

are correct. (Here the example reverts back to the key by key format.)

Key Display Explanation

*5 00:21:32 Enter *5 Mode. Clock running but not set correctly.

A 05:01.01 Advance to month-day (MMDD).

1004 05:1004 Key in MMDD (Oct 4 in this example).

A 05:1990 Enter and advance to location for year.

1994 05:1994 Key in year.

A 05:00:21 Enter and advance to location for hours and minutes

1324 05:1324 Key in hrs.:min. (1:24 PM in this example).

A 05:27.250 Key in seconds

30 05:30

A 13:24:30 Clock set and running. Changes made when A was

he program is complete. The clock must now be set so that the date and time tags

. time).

(24 hr

sed.

pres

*0 LOG 1 Exit *5, compile Table 1, commence logging data.

OV5.3 EDITING AN EXISTING PROGRAM

When editing an existing program in the

CR10X, enter

instruction; entering a new parameter replaces

the previous value.

To insert an instruction, enter the program table

and advanc

instruction is to be inserted (i.e., P in the data

portion of the display) key in the instruction

number, and then key A. The new instruction

will be inserted at that point in the table,

advance through and enter the parameters.

The instruction that was at that point and all

instructions following it will be pushed down to

follow the inserted instruction.

An instruction is deleted by advancing to the

t

ruction number (P in display) and keying #D

ins

(Table 4.2-1).

To change the value entered for a parameter,

advanc

value then press A. Note that the new value is

not entered until A is keyed.

ing a new instruction inserts the

e to the pos

e to the par

ition where the

ameter and key in the correct

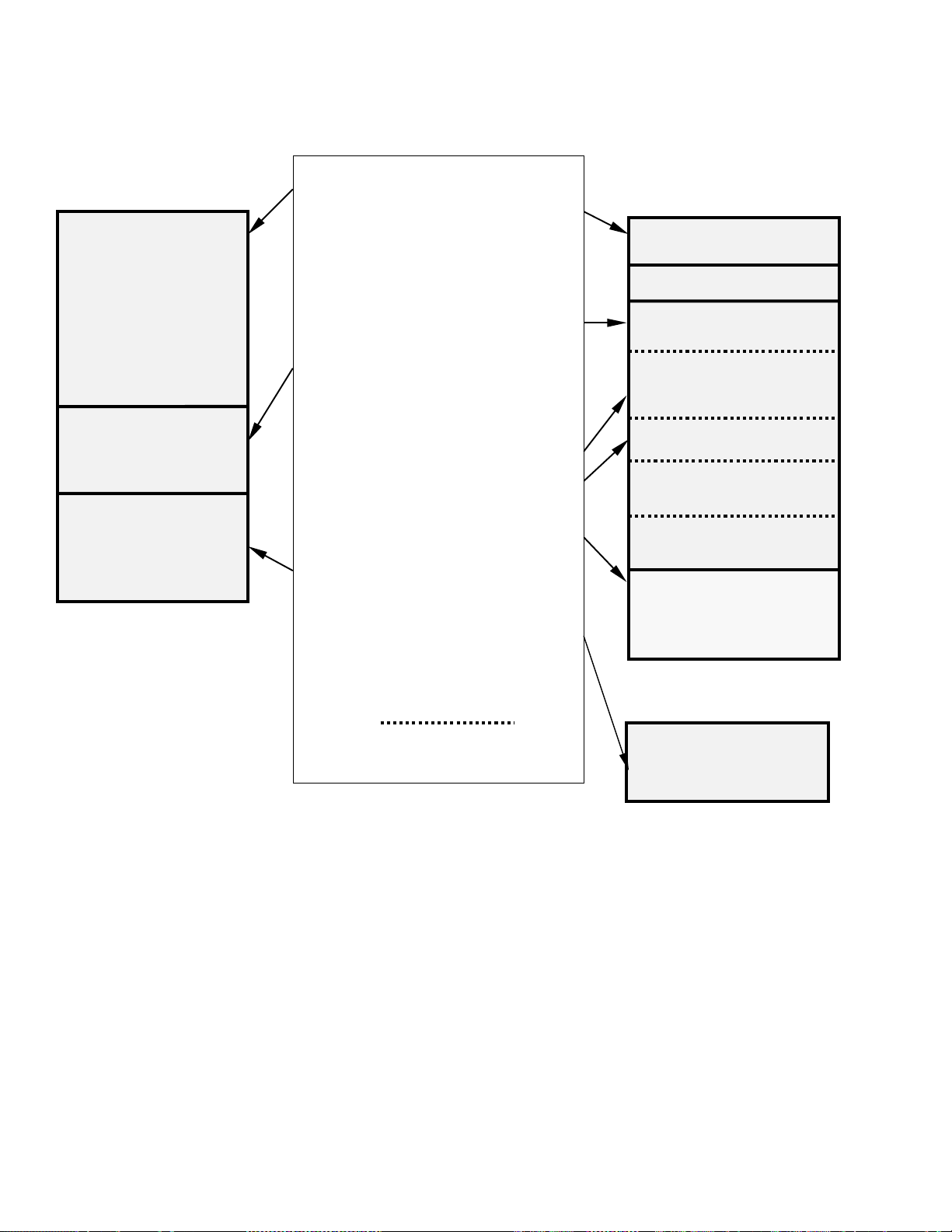

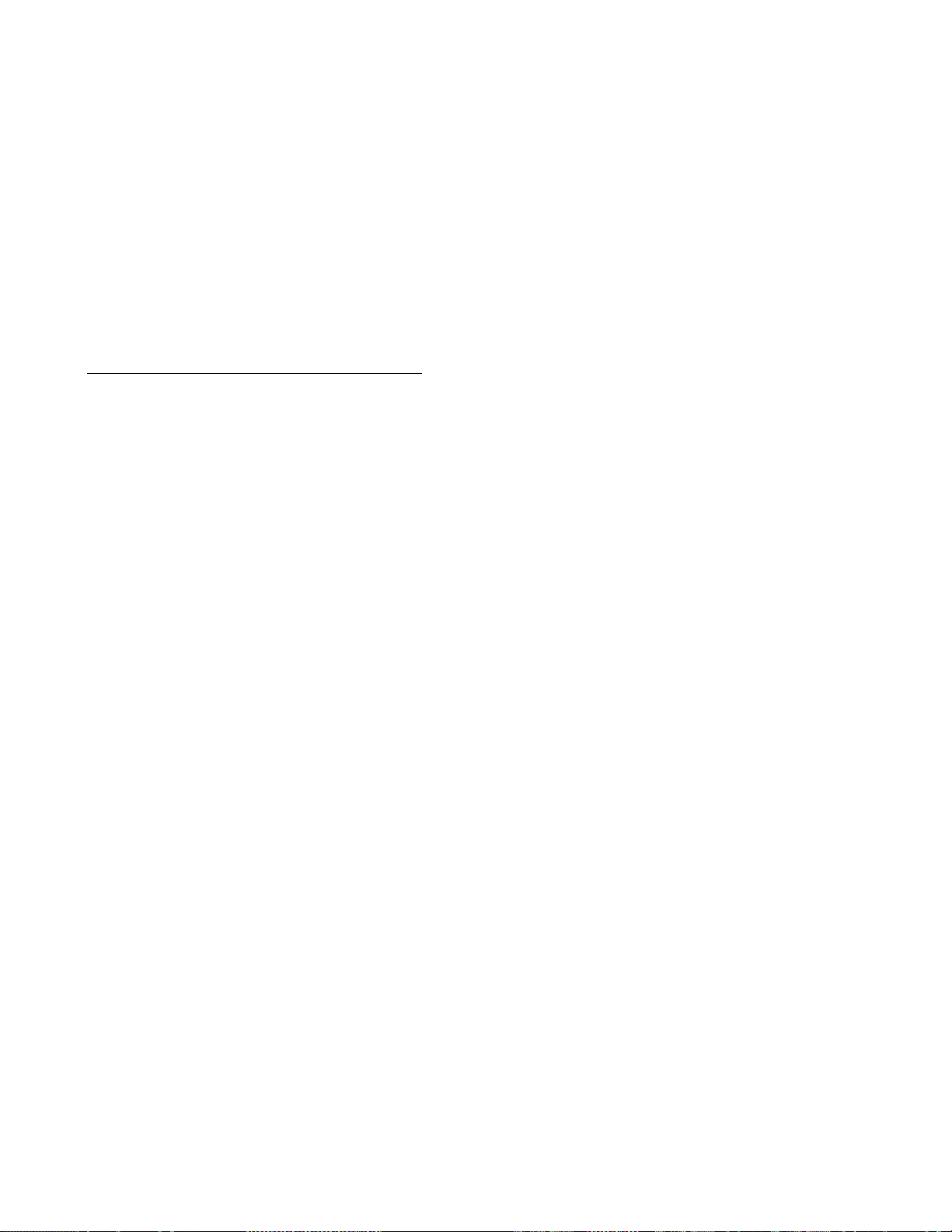

OV6. DATA RETRIEVAL OPTIONS

Data is retrieved over some form of

telecommunications link, whether it be RF

(radio), telephone, short haul modem, coaxial

cable (mulitdrop) , or direct link. The table data

operating system does not support on-line

output to peripheral storage devices (see Figure

OV 6.1-1).

The retrieval of data does NOT erase those

om the Data Storage Tables in Final

r

data f

Storage. The data remains in the table ring

memory until:

The are written over by new records of data.

S

ection 2.1)

(

Input Storage memory is reallocated

ection 1.5)

(S

The datalogger program is changed and

mpiled.

co

Power to the datalogger is turned off.

AD-OV-7

Page 16

TD ADDENDUM—OVERVIEW

DATALOGGER

MD9

MULTIDROP

INTERFACE

COAXIAL

CABLE

MD9

MULTIDROP

INTERFACE

SC12 CABLE SC12 CABLE

SC532

RS-232

INTERFACE

RF95 RF

MODEM

RF100/RF200

TRANSCIEVER

W/ ANTENNA

& CABLE

RF100/RF200

TRANSCIEVER

W/ ANTENNA &

CABLE

RF232 RF

BASE

STATION

ASYNCHRONOUS SERIAL

COMMUNICATIONS PORT

SC32A

RS-232

INTERFACE

COMPUTER

SC932

INTERFACE

SRM-6A RAD

SHORTHAUL

MODEM

2 TWISTE D

PAIR WIRES

UP TO 5 MI.

SRM-6A RAD

SHORTHAUL

MODEM

RS-232

CABLE

COM210

PHONE

MODEM

PHONE

LINE

HAYES

COMPATIBLE

PHONE

MODEM

COM100

CELLULAR

PHONE

NOTES: 1. ADDITIONAL METHODS OF DATA RETRIEVAL ARE:

A. SATELLITE TRANSMISSION

B. DIRECT DUMP TO PRINTER

C. VOICE PHONE MODEM TO VOICE PHONE OR PC WITH HAYES COMPATIBLE

E MODEM

N

PHO

2. THE DSP4 HEADS UP DISPLAY ALLOWS TH

E USER TO VIEW DATA IN INPUT

STORAGE. ALSO BUFFERS FINAL STORAGE DATA AND WRITES IT TO

CASSETTE TAPE, PRINTER OR STORAGE MODULE.

3. ALL CAMPBELL SCIENTIFIC RS-232 INTERFACES HAVE A FEMALE 25 PIN RS-232

CONNECTOR.

IGURE OV6.1-1. Data Retrieva

F

l Hardware Options

AD-OV-8

Page 17

SECTION 1. FUNCTIONAL MODES

Sections 1.5 and 1.8 are replaced by the following sections.

1.5 MEMORY ALLOCATION - ∗A

1.5.1 INTERNAL MEMORY

When powered up with the keyboard display

attached, the CR10KD dis

performing a self check. The total system

memory is then displayed in K bytes. The size

of memory can be displayed in the ∗B mode.

Input Storage is

Input/Output and Processing Instructions. The

values stored in input locations may be

displayed using the ∗6 Mode (Section 1.3).

Final Storage holds

permanent record. Output Instructions store

data in Final Storage Data Tables. The data in

Final Storage can be monitored using the ∗7

Mode (Section 2.3).

us

plays HELLO while

ed to store the results of

tored data for a

s

cratch pad for

Intermediate Storage is

Output Processing Instructions. It is used to

store the results of intermediate calculations

necessary for averages, standard deviations,

histograms, etc. Intermediate Storage is not

accessible by the user.

Each Input or Intermediate Storage location

equir

es 4 bytes of memory. Each Final

r

Storage location requires 2 bytes of memory.

Low resolution data points require 1 Final

Storage location and high resolution data points

require 2. Section 2 describes Final Storage

and data retrieval in detail.

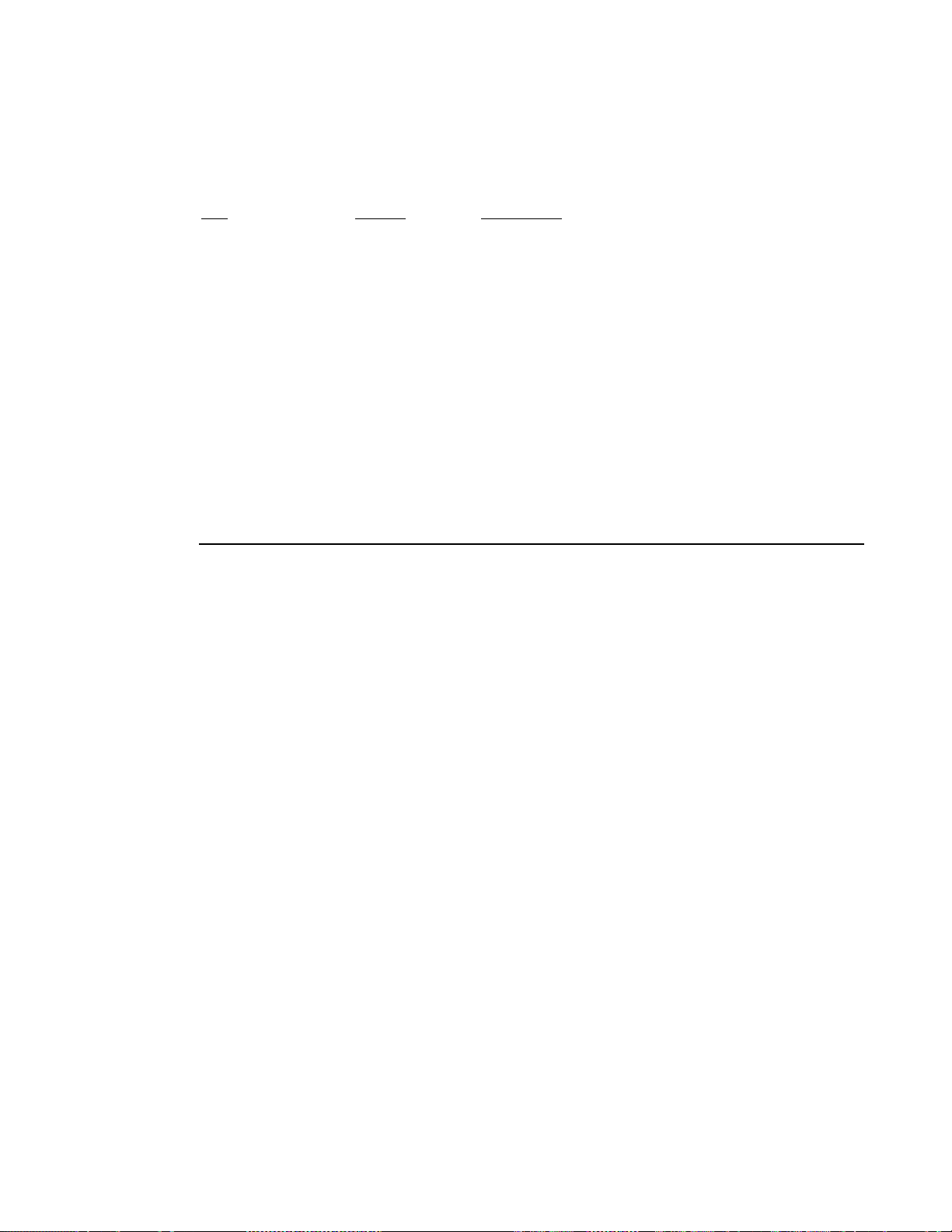

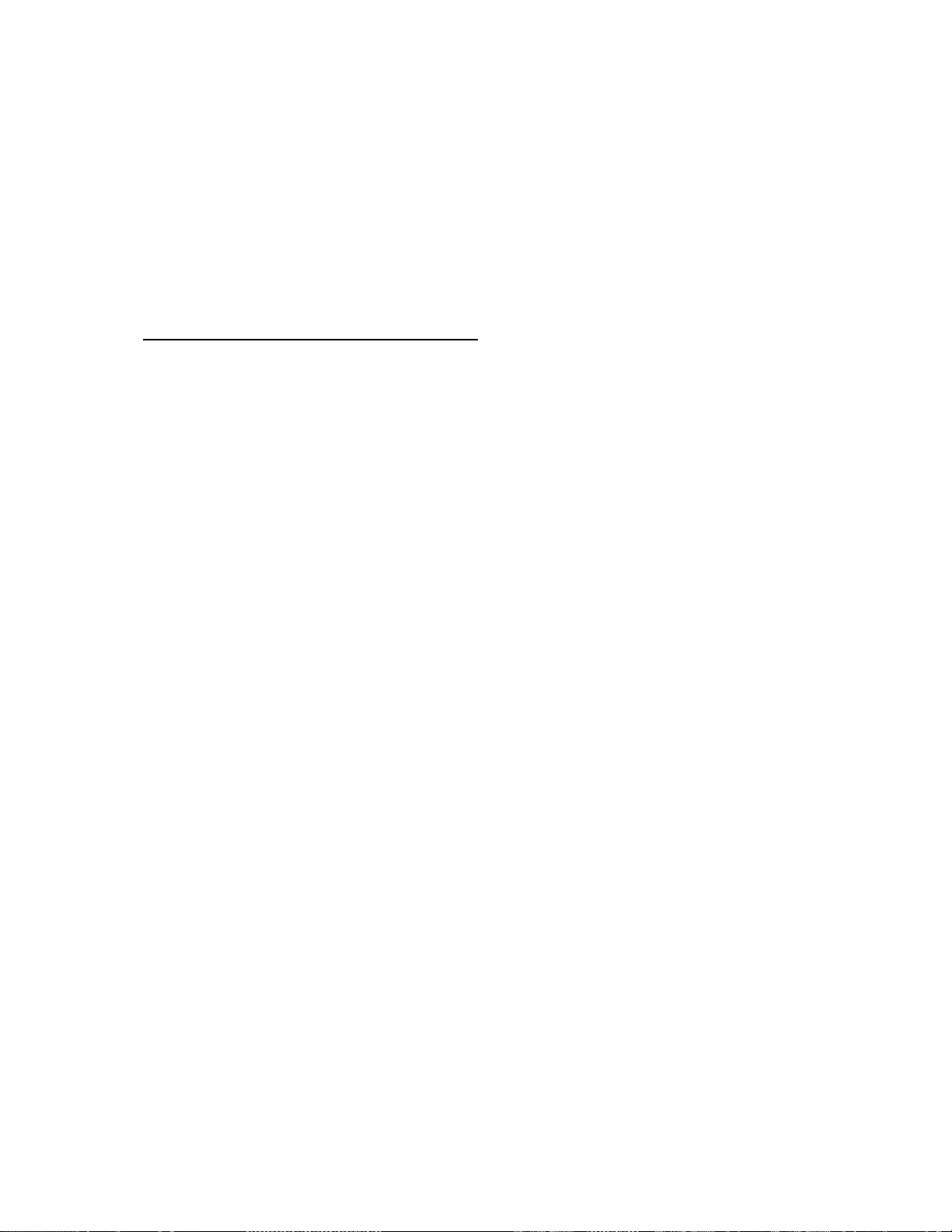

Figure 1.5-1 lists the basic memory functions

and the am

ount of

a s

memory allotted to them.

AD-1-1

Page 18

TD ADDENDUM SECTION 1. FUNCTIONAL MODES

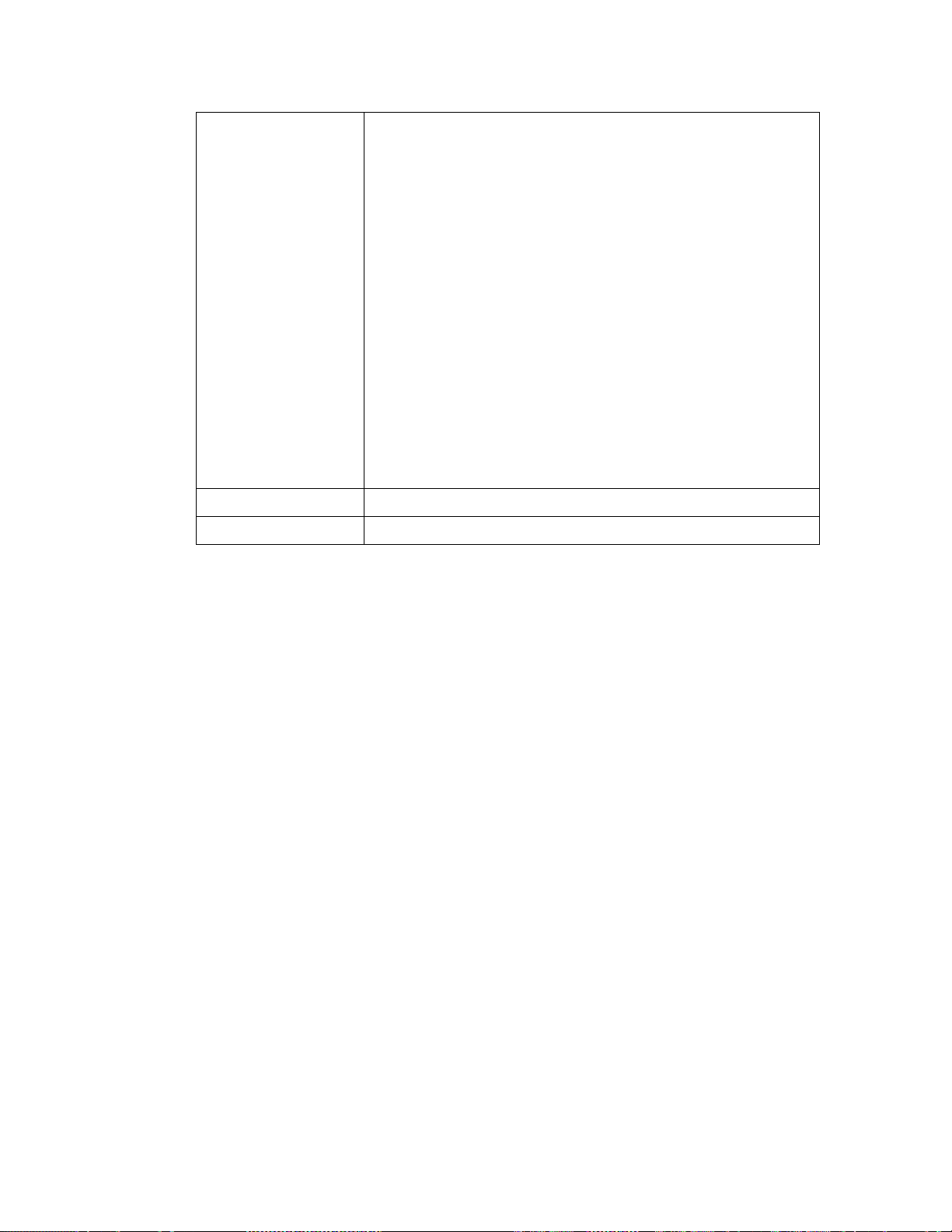

Flash Memory

(EEPROM)

Operating System

(96 Kbytes-CR10X)

(128 Kbytes-CR23X)

Active Program

(16 Kbytes)

Input and Final

Storage Lables

(16 Kbytes)

How it works:

The Operating System is loaded into

Flash Memory at the factory. System

Memory is used while the CR10X is

running for calculations, buffering data

and general operating tasks.

Any time a user loads a program into

the datalogger, the program is

compiled in SRAM and stored in the

Active Program areas. If the

datalogger is powered off and then on,

the Active Program is loaded from

Flash and run.

The Active Program is run in SRAM to

maximize speed. The program

accesses Input Storage and

Intermediate Storage and stores data

into Final Storage for later retrieval by

the user.

Table Data Operating Systems Save

Input Storage and Final Storage

Lables.

Flash Memory, increases Final Storage

by 524,288 data values per Mbyte.

(Memory Areas separated by dashed

lines:

can be re-sized.)

SRAM

Total 128 Kbytes

32K SRAM

Main Memory

System Memory

Active Program

(automatically allocated)

Input Storage

default: 28 locations

(Size Set with *A)

Intermediate Storage

(automatically allocated)

PakBus Routing Table

(Size Set with *D 15)

PakBus Settings

(Size Set with *A)

96K SRAM

Final Storage Data

Tables

Flash EEPROM

Optional in CR10X

Final Storage

(Additional 524,288

locations per Mbyte)

FIGURE 1.5-1. Datalogger Memory

1.5.2 ∗A MO

The ∗A Mode is us

Storage, Intermediate Storage, Final Storage,

Program Memory; PakBus and user Settings

memory 2) check the number of bytes remaining in

Flash Program memory; Main Memory, and Label

Memory 3) change the memory allotted to Input

Locations and Settings; and 5) to completely reset

the datalogger.

When ∗A is

is the number of memory locations allocated to

AD-1-2

DE

ed to 1) check the size of Input

ed, the first number displayed

enter

Input Storage. The "A" key is used to advance

through the next 6 windows. Table 1.5-2

describes what the values in the ∗A Mode

represent.

The sizes of Input Storage and Settings Memory

m

ay

be altered by keying in the desired value and

entering it by keying "A".

Page 19

Keyboard Display

Entry ID: Data

A

∗

A

A

A

A

A

A

A

01: XXXX Input Storage Locations (minimum of 28, maximum of 6655,

02: XXXX Intermediate Storage Locations (maximum limited by available

03: XXXXX Final Storage Locations (minimum of 0, maximum limited by

04: XXXXX Bytes allocated for user program. The CR10X-TD will assign the

05: Bytes free in Flash Memory for active program. The user

06: PakBus and user Settings memory

07: Main Memory Free

06: Label Bytes Free

TD ADDENDUM SECTION 1. FUNCTIONAL MODES

TABLE 1.5-2. Description of ∗A Mode Data

Description of Data

but the usable maximum is less than this because intermediate

and program storage require some of this memory). This value

can be changed by keying in the desired number.

memory and constraints on Input and Final Storage). The

CR10X-TD will assign the exact number needed for the active

program. The CR10X-TD erases all data whenever the program

is changed and compiled.

available memory). Changing this number automatically

reallocates Final Storage Area 1.

exact number needed. The CR10X-TD erases all data whenever

the program is changed and compiled. Key in 98765 to

completely reset datalogger.

cannot change this window. It is a function of window 5 and the

program.

The maximum size of of Final Storage is

determined by the memory installed (Table 1.5-

1). The size of Final Storage and the rate at

which data are stored determines how long it

will take for Final Storage to fill, at which point

new data will write over old.

Twenty-eight is the minimum number of Input

allowed. Intermediate Storage and

ations

loc

Final Storage are erased when the number of

Input locations is changed. This feature may be

used to clear memory without altering

programming. The number of locations does

not actually need to be changed; the same

value can be keyed in and entered.

Intermediate Storage and Program Memory are

atic

autom

ally allocated. All data are erased any

time the program is changed and compiled. If

there is not enough memory available in the

32K Main Memory for the Intermediate Storage

required by the current program, the "E:04"

ERROR CODE will be displayed in the ∗0, ∗6,

and ∗B Modes.

After repartitioning memory, the program must be

ompiled. Compiling erases Intermediate

ec

r

Storage. Compiling with ∗0 erases Input Storage;

compiling with ∗6 leaves Input Storage unaltered

(If its size was unchanged).

ENTERING 98765 in the program memory

i

ndow 6 COMPLETELY RESETS THE CR10X.

w

All memory is erased including the program and

memory is checked. Memory allocation returns

to the default. The reset operation requires

approximately 1 minute for a CR10X, 5 minutes

for a CR10X-1M, and 10 minutes for a CR10X2M. Please be patient while the reset takes

place; if the CR10X is turned off in the middle of

a reset, it will perform the reset the next time it is

powered up.

1.6 MEMORY TESTING AND SYSTEM

STATUS - ∗B

No changes from standard operating system,

see datalogger manual.

1.7 ∗C MODE -- SECURITY

No changes from standard operating system,

see datalogger manual.

1.8 ∗D MODE – TRANSFER

PROGRAMS, GENERAL SETTINGS

The ∗D Mode is used to transfer datalogger

programs between a datalogger and a

computer, to erase a program, to set the degree

AD-1-3

Page 20

TD ADDENDUM SECTION 1. FUNCTIONAL MODES

to which memory is cleared on powerup, to set

the PakBus ID, and to set communication to full

or half duplex.

CSI datalogger support software makes use of the

∗D Mode to upload and download pr

computer. Appendix C gives some additional

information on Commands 1 and 2 that are used

for these operations.

When "∗D

"13:00". A c

by keying the command number and "A".

Command Description

If the CR10X program has not been compiled

when the command to save a program is entered,

it will be compiled before the program is saved.

When a program is loaded, it is immediately

compiled and run. When a command is complete,

"13:0000" is displayed; ∗D must be entered again

before another command can be given.

TABLE 1.8-2. Progr am Load Error Codes

E 94 Program Storage Area full

E 95 Program does not exist in flash

E 96 Storage Module not connected or

E 97 Data not encountered within 30 sec.

E 98 Uncorrectable errors detected

E 99 Wrong type of file or Editor Error

1.8.1 ERASING CURRENT PROGRAM

The 7 command may be used to delete the

cur

rent program as show in Table 1.8-3.

" is keyed in, the CR10X will display

ommand (Table 1.8-1) is entered

TABLE 1.8-1. ∗D Mode

1 Send (Print) ASCII Program

2 Load ASCII Program, ∗0 Compile

2-- Load ASCII Program, ∗6 Compile

3 # Rings Before Answering Phone

7 Erase Current Program

10 Set Powerup Options

12 Set Initial Baud

15 PakBus Address/Routing Table

16 Memory for General Purpose File

17 PakBus Routing Table

18 PakBus Beacon Interval

19 PakBus Neighbor List

r

ong address

w

ograms from a

Commands

TABLE 1.8-3 Deleting Current Datalogger

Program

Key entry Display

∗D 13:00

7A

You may now enter:

0A Erase active program (i.e., load a

1.8.2 PROGRAM TRANSFER WITH STORAGE MODULE

Not supported in Table Data Operating

stems.

Sy

1.8.3 FULL/HALF DUPLE X

Not supported in Table Data Operating

y

stems.

S

1.8.4 SET DATALOGGER ID

Command 8 not supported in Table Data

per

ating Systems.

O

1.8.5 SETTING POWERUP OPTIONS

Setting options for the Program on Powerup

s

the user to specify what information to

allow

retain from when the datalogger was last on.

This allows Flag/Port status, the User Timer,

and the Input/Intermediate Storage to be

cleared or not cleared.

Table 1.8-8. Setting Powerup Options

Key entry Display

∗D 13:00

10A

Where X is the powerup option currently

ted. You may now change the option:

selec

0A Clears input locations, ports, flags, user

timer

1A Clears intermediate storage only (leaves

Input Stor

as is).

2A Doesn’t clear anything.

07:00

blank pr

and Final Storage are reset).

10:0X

, and intermediate storage locations.

age, F

ogram; memory allocation

lags/Ports, and User Timer

AD-1-4

Page 21

TD ADDENDUM SECTION 1. FUNCTIONAL MODES

1.8.6 SET INITIAL BAUD

Table 1.8-10 shows the option codes available

for

setting the initial baud rate. Setting the initial

baud rate forces the CR10X to try the selected

baud rate first when connecting with a device.

TABLE 1.8-9. Set Initial Baud Rate / Set

RS232 Power

Key

Entry Display Comments

*D 13:00 Enter Command

12A 12:00 Connect Baud Rate

Enter Baud Rate Code X

(Table 1.8-11).

TABLE 1.8-10. Baud Rate Codes

X = 0 300 Baud

X = 1 1200 Baud

X = 2 9600 Baud

X = 3 76.8 K Baud

TABLE 1.8-11. PakBus Address and

Routing Table

Key

Entry Display Comments

*D 13:00 Enter Command

15A 15:xxxx PakBus Address , Enter zero if

the datalogger is

as a PakBus device (1..4094 is

legal, the default is 1)

A 01:xxxx If the datal

a router, enter the maximum

number of nodes (PakBus

Addresses) to a llocate space

for in the pakbus network. 0 =

leafnode, <>0 = router

A 02:xxxx Enter the maximum number of

neighbor

network to allocate space for.

This parameter is used only if

datalogger is used as a router

(01: is non-zero).

s

not to be used

ogger i

in the pakbus

s to be used a

1.8.7 SET PROGRAM COMPILE OPTION

Command 13 is not supported in Table Data

operating s

1.8.8 SET PAKBUS ADDRESS

*D 15 allows the user to set the PakBus

Addr

maximum size for its routing table.

ystems.

es

s of the datalogger and to set the

A 03:xxxx Enter maximum number of

outer

s in the pakbus network

r

to allocate space for. This

parameter is used only if

datalogger is used as a router

(01: is non-zero).

A 04:xxxx Enter the PakBus address for a

ault r

def

default router). The default

router is used for a message if

the destination PakBus

address is not in the routing

table. A router discovering new

routes will not explore beyond

its own default router.

The memory for a routing table comes out of

the pool for program, input locations, and

intermediate storage.

The total number of bytes used for the routing

table =

Nodes x 12

+ Neighbors x 8

+ Routers x 6

+ (Routers x (Nodes – Routers) + (Routers

(

Routers – 1))/2) x 4

x

outer (1..4094, 0 for no

AD-1-5

Page 22

TD ADDENDUM SECTION 1. FUNCTIONAL MODES

The *D15 entries are sent when the program is

retrieved. They can also be set like other *D

settings via the DLD file.

1.8.9 ALLOCATE MEMORY FOR GENERAL

PURPOSE F

*D16:xx ;allocate xx 64K byte chunks of

1.8.10 VIEW ROUTING TABLE

*D17 allows viewing the current routing table

rmation. This is view only.

o

inf

TABLE 1.8-12. Values in Routing Table

Key

Entry Display

*D 13:00 Enter Command

17A Enter the view routing table

(Repeats for next destination node.)

ILES

ory for general purpose files.

mem

The area comes out of final storage

space. Files are stored in a circular

buffer (ring memory) in this space.

Comments

com

mand

01:xxxx ;pakbus address of desti

node

02:xxxx ;via neighbor w

address

03:xxxx ;a worst case response tim

metric (seconds)

ith xxxx pakbus

nation

e

1.8.11 SET PAKBUS ROUTER BEACON INTERVAL

TABLE 1.8-13. Set Beacon interval

Key

Entry Display

*D 13:00 Enter Command

18A Enter the beacon interval

A

A 02:xxxx Enter the Interval (seconds) for

A 03:xxxx Enter the Interval (seconds) for

A

1.8.12 PAKBUS NEIGHBOR FILTER

In some networks, sending beacons can be

disr

disables the beacon. A PakBus datalogger with

nonzero *D19 settings will not send beacons

and will only respond to beacons from nodes

with addresses in the neighbor list.

Instead of sending beacons, the datalogger will

end “

s

determine if it can communicate with them.

Neighbors (or potential neighbors) should be

nodes that communicate directly with the

datalogger without going through a router.

01:xxxx Enter the Interval (seconds) for

04:xxxx Enter the Interval (seconds) for

uptive. Entering values in the *D19 mode

hello” messages to neighbors in the list to

Comments

settings

SDC7

SDC8

Pin Enabled, 9600 baud

CS I/O

RS232, 9600 baud (

only

)

CR23X

AD-1-6

Note that this list is not automatically cleared by

om

piling a new program. (It may be changed

c

if the new program contains *D19 entries.) It

can be edited by changing entries. Once 0 is

entered for a neighbor address, all entries

beyond the 0 entry are cleared.

Page 23

TD ADDENDUM SECTION 1. FUNCTIONAL MODES

TABLE 1.8-14. Set PakBus Neighbors

Key

Entry Display

*D 13:00 Enter Command

19A 19:00 Port (17- SDC7, 18 – SDC8, 02

A 19:0000 Interval in seconds of the

A 01:xxxx PakBus Address of

A 01:xx Swath of neighbors with

A 02:xxxx PakBus Address of

A 02:xx Swath of neighbors with

Comments

– CSI/O, 02—CR23X

port, 9600 baud

pec

ted rate of

ex

communication. A neighbor is

aged after 2.5 times this

interval and the Hello attempt

will be reinitiated.

sequential addr

with above address.

sequential addr

with above address.

RS232

ghbor

nei

esses starting

nei

ghbors

esses starting

1.9 *9 DATA TABLES SIZES.

The *9 Mode is used to view the sizes of the

Data Storage Tables (section 2.1) created by

the datalogger program (*1, *2, or *3). The *9

Mode will also display how long until any

automatically allocated Data Storage Tables fill.

All Data Storage Tables are in a ring

configuration such that the oldest records are

overwritten by new records once the table is full.

The sizes are given as the number of records.

A record can be thought of as a row of data

where each field (i.e., column) is a data value

associated with an Output Processing

Instruction. The order and number of fields in a

Data Table are determined by the Output

Processing Instructions following the Data Table

Instruction. The tables are numbered in the

order the Data Table Instruction appear in the

Program Tables, *1 first, *2 second, and *3 last.

... etc.

A nn:0000 Terminates the list.

TABLE 1.9-1. Description of * 9 Data

Keyboard Display

Entry ID: Data

*9 09:xx Number of tables/ Enter table number to jump to that table or 0

0A 00:x.xxxx Days before any automatically allocated table fills.

A 0

A 02:xxxxx Number of records in table 02

A nn:xxxxx. Number of records in table nn

1:xxxxx. Number of records in table 01

Description

to see next parameter.

AD-1-7

Page 24

TD ADDENDUM SECTION 1. FUNCTIONAL MODES

This is a blank page.

AD-1-8

Page 25

THIS SECTION ENTIRELY REPLACES THE DATALOGGER MANUAL SECTION 2.

SECTION 2. INTERNAL DATA STORAGE

2.1 FINAL STORAGE AND DATA TABLES

Final Storage is that portion of memory where

final processed data are stored. It is from Final

Storage that data is transferred to your

computer. With the TD datalogger, Final

Storage is organized into Data Storage Tables.

These data tables should not be confused with

the program tables *1, *2, and *3 that contain

the datalogger program.

Within each data table, data is organized in

ec

ords and fields. Each row in a table

r

represents a record and each column

represents a field. To understand the concept

of tables it may be helpful to consider an

example. A CR10X is to be used to monitor 3

thermocouples (TC). Each hour a temperature

for each of the three TC is to be stored. The

table has 4 fields: "DATE_TIME TEMP1 TEMP2

TEMP3." Each hour a new "record" would be

added. The "hourly" table would then be

organized as follows:

DATE_TIME TEMP1 TEMP2 TEMP3

01/27/91 10:00:00 23.5 24.6 28.2

01/27/91 11:00:00 24.2 22.4 23.4

Only the hourly data is stored in the hourly table,

h output inter

Eac

tables can also be "event driven" rather than

interval driven, that is a new record is stored

when a specified event occurs rather than

based on time. Each table is completely

independent of any other tables and all records

in a given table have the same number of fields.

Each table is allocated (manually by the user or

atic

autom

records. Different tables have different

numbers of records. Each data table is in a ring

memory configuration such that when the

allocated number of records has been stored,

each subsequent new record will overwrite the

oldest stored record. The *9 Mode may be

used to view the size of the Data Storage

Tables. (Section 1.9)

The TD datalogger supports naming of tables and

elds, so any data value can be referenced by the

i

f

table and field names. For example, the

ally by the datalogger) a number of

val has its own table. Data

temperature data for the first thermocouple is

referenced as "HOURLY.TEMP1." As Data Tables

are allocated in the datalogger program, some

Final Storage Memory is reallocated for the

storage of these labels and other data table

overhead.

NOTE: All Data Storage Tables are

reallocated and erased whenever the

datalogger program is recompiled (*0, *6,

*B), when Input Storage Memory is

reallocated (*A), or when a new datalogger

program is transferred from the computer to

the datalogger. ALWAYS RETRIEVE

UNCOLLECTED DATA BEFORE MAKING

ANY CHANGES.

A time stamp and record number are

automatically included with the each record in

each table. These are used as part of the data

collection protocol.

2.1.1 TIME AND TIMESTAMPS

Each record in a table has a time stamp

s

ociated with it. With Instruction 84 set for

as

interval output (a interval in seconds is specified

as the second parameter), time is not actually

stored with each record. Using the timestamp

of the last record stored and the table interval,

the datalogger can calculate the timestamp for

any previous record. When retrieved, each

record in the data file will have a timestamp.

This saves 6 bytes per record by not storing

time with each record. A consequence of not

storing time is that if output does not occur at a

scheduled time, the datalogger must keep track

of the discontinuity in the timestamps so it can

correctly calculate timestamps for records older

than the missing record. The datalogger will

keep track of the 10 most recent discontinuities

in each table. If more than ten discontinuities

occur, records with timestamps older than the

oldest discontinuity cannot be reliably

timestamped when collected. For this reason

interval tables should not be used if outputs will

be routinely missed. Outputs can be missed

(discontinuities can occur) when:

• The datalogger clock is changed such that

is passes an output interval.

AD-2-1

Page 26

TD ADDENDUM—SECTION 2. INTERNAL DATA STORAGE

The output interval is not an even multiple

•

of the scan rate (table execution interval).

• Table execution is such that Instruction 84

is not executed each scan.

• Table overruns occur.

• Watchdog errors (E08) occur.

2.1.2 RECORD NUMBERS

In addition to a timestamp, each record has

ord number. The record numbers are

rec

unique within a data table. Record numbers are

4 byte unsigned numbers ranging from 0 to

4,294,967,296. When the datalogger program

is compiled the next record number for each

table is set to zero.

2.1.3 TABLES AND FIELDS.

There are four "built in" tables. These tables

e pr

esent when the datalogger is powered on.

ar

These tables are named INLOCS, TIMESET,

ERRORLOG, and STATUS. The fields within

these tables are also already defined with the

exception of the INLOCS. The field names for

each of the fields is given below. TmStamp is

the label for the timestamp and RecNbr is the

label for the record number.

TimeSet

TmStamp, RecNbr, OldTime

ErrorLog

TmStamp, RecNbr, Code

Status

TmStamp, RecNbr, Battery, WatchDog,

v

erRuns, InLocs, PrgmFree, Storage, Tables,

O

DaysFull, Holes, PrgmSig, PromSig, PromID,

ObjSrlNo

Where the labels are defined as follows:

ates

Battery − Indic

voltage.

the datalogger battery

Storage − Number

available for Data Storage Tables. Section

1.5.2

Tables − Num

DaysFull − Size (

Tables using automatic record allocation. See

Instruction 84.

Holes − Num

all Data Storage Tables. Section 2.1.1

PrgmSig − Signature of

program. Same as *B mode first window.

Section 1.6.

PromSig − Signatur

as *B mode second window. Section 1.6.

Prom ID − Item num

mode seventh window. Section 1.6.

ObjSrlNo − Obj

PROM. Same as *B mode eighth window.

Section 1.6.

Like the InLocs table, a new Status record is

ys available when the datalogger is checked

alwa

for data. For this reason the Status table is usually

collected for display rather than archive.

InLocs

TmStamp, RecNbr, Flags, Ports, Loc1, Loc2,

4, Loc5, Loc6, Loc7, Loc8, Loc9

3, Loc

Loc

Like the Status table, a new InLocs record is

ys available when the datalogger is checked

alwa

for data. For this reason these tables are usually

collected for display rather than archive.

By default only nine Input Location are labeled.

he def

T

with user created labels. These labels are

created with EDLOG technique for Input

Location labels. Press CTRL-L when editing a

LOC field.

ault InLocs field labels can be replaced

of Final Storage Locations

ber

of user created Data Tables.

in days) of the Data Storage

ber

of missed records or holes in

program memory

e of

datalogger PROM. Same

ber of PROM. Same as *B

ect code serial number of

WatchDog − The num

(E08). (Maximum 99). Section 3.10

OverRuns − Progr

occurred (Maximum 99). Section 1.1.1.

InLocs − Number

been allocated. Section 1.5.2

PrgmFree − Amount (

remaining. Section 1.5.2

AD-2-2

ber of Watchdog Errors

am table overruns that have

of Input Location that have

bytes) of program memory

When additional data tables are created with

t

ruction 84, these tables and the fields they

Ins

contain can also be named by the user. The

datalogger will supply a default name for tables

and fields if they are not named. The default

names are T01, T02, for the tables and F01,

F02, etc. for the fields, numbered in the order

they appear. Edlog allows the programmer to

name the tables and fields.

Page 27

TD ADDENDUM—SECTION 2. INTERNAL DATA STORAGE

The Timestamp and record number labels are

added automatically.

2.2 DATA OUTPUT FORMAT AND

RANGE LIMITS

Data is stored internally in Campbell Scientific's

Binary Final Storage Format (Appendix C.2).

Data may be sent to Final Storage in either

LOW RESOLUTION or HIGH RESOLUTION

format.

2.2.1 RESOLUTION AND RANGE LIMITS

Low resolution data is a 2 byte format with 4

gnificant digits and a maximum magnitude of

i

s

+7999. High resolution data is a 4 byte format

(see Section 2.2.2).

TABLE 2.2-1. Resolution Range Limits of

CR10 Data

Minimum Maximum

Resolution Zero

Low 0.000 + 0.001 +7999.

High 0.0000 1x10

The resolution of the low resolution format is

reduced to 3 significant digits when the first (left

most) digit is 8 or greater. Thus, it may be

necessary to use high resolution output or an

offset to maintain the desired resolution of a

measurement. For example, if water level is to

be measured and output to the nearest 0.01 ft.,

the level must be less than 80 ft. for low

resolution output to display the 0.01 ft.

increment. If the water level was expected to

range from 50 to 90 feet the data could either

be output in high resolution or could be offset by

20 ft. (transforming the range to 30 to 60 ft.).

2.2.2 HIGH RESOLUTION FINAL STORAGE

T

A, INPUT, AND INTERMEDIATE

DA

STORAGE DATA FORMAT

While low resolution output data have the limits

described above, computations are done in

floating point arithmetic. In high resolution Final

Storage Input and Intermediate Storage, the

numbers are stored and processed in a binary

format with a 23 bit binary mantissa and a 6 bit

binary exponent. The largest and smallest

numbers that can be stored and processed are

18

9 x 10

and 1 x 10

the number determines the resolution of the

Magnitude Magnitude

-19

19

-

, respectively. The size of

+9x10

+18

arithmetic. A rough approximation of the

resolution is that it is better than 1 in the

seventh digit. For example, the resolution of

97,386,924 is better than 10. The resolution of

0.0086731924 is better than 0.000000001.

A precise calculation of the resolution of a

number may be determined by representing the

number as a mantissa between .5 and 1

multiplied by 2 raised to some integer power.

The resolution is the product of that power of 2

24

-

and 2

.9336 * 2

. For example, representing 478 as

9

, the resolution is 29 * 2

24

= 2

15

-

-

0.0000305. A description of Campbell

Scientific's floating point format may be found in

Appendix C.

2.3 DISPLAYING STORED DATA ON KEYBOARD/DISPLAY *7 MODE.

The keyboard display (or the computer in

Keyboard/Display mode) can be used to

examine Data Storage Tables in Final Storage

table data.

Key *7. The display will show: 07:nn where nn

the num

is

Enter a table number (followed by the “A” key)

to view that table. Tables are numbered in the

order of the appearance of the Data Storage

Table Instruction (84) in the datalogger

program. Tables in the *1 program area are

numbered first, followed by *2 and those in the

*3 subroutines numbered last.

The display will then show the first field of the

new

not change, the select table has not had any

data stored in it yet.

When a table is visualized the newest data

ec

ord is at the bottom and the oldest is at the

r

top. When the table is full and a new record is

stored, the records shift up pushing the oldest

record off the top and storing the new record at

the bottom.

The display (or value displayed on the

om

c

can be moved up and down or right and left

through the data. The display shows the field

number to the left of the colon and the data

value to the right. The keys used to move the

display/cursor are summarized in the following

table:

ber of Data Storage Tables defined.

es

t record in the table. If the display does

puter) can be thought of as a cursor, which

=

AD-2-3

Page 28

TD ADDENDUM—SECTION 2. INTERNAL DATA STORAGE

TABLE 2.3-1. *7 Mode Command Summary

KEY ACTION

A "Advances" along a record, when the

end of the record is reached the

'cursor' advances to the first field in

the next record.

B "Backs" up along a record, wraps to

element in the previous

the las

record

C "Climbs" up the table, toward the

oldes

D "Drops" down the table, toward the

newes

# Enter Time Mode to display timestamp.

Enter new tim

Each record of data in a table has a time

associated with it. Event data stores the time

as part of the data, interval tables calculate the

time based on the interval and a reference time.

The time associated with each record consist of

a year, month/day, hour/minute, and seconds

value. Julian dates are not used. When

viewing data in the *7 mode, event data records

have time as part of the record. The field

number on the keyboard/display does not

change while viewing the four time values since

time is considered a single field. Interval data

does not contain time and it is not displayed as

part of the record. To see the time values for a

given record, press the # key while viewing any

of the fields within the record.

t

t data, s

t data, stops on newest record.

tops on oldest record.

e values to jump to record.

records long is maintained inside Intermediate

Storage to keep track of "holes" in the recorded

data, due to watch dog errors or clock changes,

so that the time of each record can be implicitly

maintained.

This "hole" table rings around, and any recorded

data that c

"hole" table cannot be displayed.

To view the “hole” table for a given table, Key

*7. The dis

the number of Data Storage Tables defined.

Enter the number of table where you want to

view the “holes." Then press the C key

followed by the A key. The Hole table fields are

as follows:

01:time of hole;

02:number of holes.

annot be tim

play will show: 07:nn, where nn is

e stamped using this

The A and B key are used move through the

our

time values for the record. The C and D

f

keys can be used to move to newer or older

records and view the same time value of the

new record. Pressing the # key again while

viewing time or using the A or B keys to

advance or back beyond the time values will

return the display to the same field as was

displayed when the time mode was entered.

The time field is displayed as: day.month, year,

:m

in, seconds

hr

While viewing time, entering new time values

will allow

time values closest to those entered. The jump

takes place when the time mode is left.

Interval tables do not store time as part of the

ec

r

AD-2-4

the display to jump to the record with

ord, but calculate the time. A table 10

Page 29

SECTION 3. INSTRUCTION SET BASICS

Section 3.7.1 does not apply to the TD operating system which does not use Output Flag 0.

Table 3.8-1 Valid Flag Commands are 11 – 19 to set high and 21- 29 to set low. Because the TD

operating system does not use Fl

ag 0, Commands 10 and 20 are not valid with the TD operating system.

The following table replaces Table 3.10-1 for the TD operati

TABLE 3.10-1. Error Codes

Code Type Description

03 Editor Program table full

04 Compile Intermediate Storage full

05 Compile Storage Area #2 not

alloca

ted

08 Run Time CR10X reset by

hdog timer

watc

09 Run Time Insufficient Input Storage

10 Run Time Low Battery Voltage

11 Editor Attempt to allocate more

Input or Inter

Storage than is available

20 Compile SUBROUTINE encountered

or

e END of previous

bef

subroutine

21 Compile END without IF, LOOP or

SUBRO

22 Compile Missing END

23 Compile Nonexistent

SUBROU

24 Compile ELSE in SUBROUTINE

thout IF

wi

25 Compile ELSE without IF

26 Compile EXIT LOOP without

LOOP

27

28 Compile At compile time, no

Compile IF CASE without BEGIN

CASE

output s

or unable to automatically

allocate at least one

record per P84

mediate

U

TINE

TINE

pec

ified after P84

29 Compile Output table requests

30 Compile IF and/or LOOP nested

31 Run Time SUBROUTINES nested

32 Compile Instruction 3 and interrupt

33 Compile Cannot use Control Port

40 Editor Instruction does not exist

41 Editor Incorrect execution

43 Compile Time in Instruction 84 or

44 Compile Loop (P87) cannot

60 Compile Insufficient Input Storage

61 Compile Burst Measurement Scan

62 Compile N<2 in FFT

68 Compile Instruction 118 without

80 Compile Illegal Interval in P193

81 Compile Illegal Node ID in P193

82 Compile Illegal Reps in P193

92 Compile Instruction 92, intervals in

ng system.

r

e memory than

mo

available

too deep

too deep

ubr

outine use same port

s

ounter or interrupt

6 as c

subroutine with

Instruction 15 or SDM or

SDI-12 input/output

v

al

inter

92 is not a m

execution interval (note:

time is in seconds)

ontain Data T

c

Rate too shor

enough Inst

onds: Time into Interval

sec

> 59 or Interval > 60

ultiple of

able (P84)

t

ructions 68 or 63

AD-3-1

Page 30

TD ADDENDUM—SECTION 3. INSTRUCTION SET BASICS

94 Program Program Storage Area

Transfer full

95 Program Program does not exist in

ansfer Flash memory

Tr

96 Program Addressed

ansfer device not connected

Tr

97 Program Data not received within

ansfer 30 seconds

Tr

98 Program Uncorrectable errors

ansfer detected

Tr

99 Program Wrong file type or editor

ansfer error

Tr

AD-3-2

Page 31

THIS SECTION ENTIRELY REPLACES THE CR10X MANUAL SECTION 8.

SECTION 8. PROCESSING AND PROGRAM CONTROL EXAMPLES

This section contains examples for the CR10X. The appropriate voltage range codes would have to be

selected for the CR23X (see CR23X Manual Section 8 for the measurement instructions). The CR510TD may not support all the examples.

The following examples are intended to illustrate the use of Processing and Program Control

t

ructions, flags, and the capability to direct the results of Output Processing Instructions to Input

Ins

Storage.

The specific examples may not be as important as some of the techniques employed, for example:

Directing Output Processing to Input Storage is used in the Running Average and Rainfall Intensity

amples

ex

Flag tests are used in the Running Average, Interrupt Subroutine, and Converting Wind Direction

.1, 8.5, and 8.7).

(8

Control ports and the Loop are illustrated in the AM32 example (8.3).

As in Section 7 these examples are not complete programs to be taken verbatim. They need to be

altered to fit s

(8.1 and 8.2).

pecific needs.

8.1 COMPUTATION OF RUNNING AVERAGE

It is sometimes necessary to compute a running

average (i.e., the average covers a fixed

number of samples and is continuously updated

as new samples are taken). Because the

output interval is shorter than the averaging

period, Instruction 71 cannot be used; the

algorithm for computing this average must be

programmed by the user. The following

example demonstrates a program for

computing a running average.

In this example, each time a new measurement

ade (in this case a thermocouple

m

is

temperature) an average is computed for the 10

most recent samples. This is done by saving all

10 temperatures in contiguous input locations

and using the Spatial Average Instruction (51)

to compute the average. The temperatures are

stored in locations 11 through 20. Each time

the table is executed, the new measurement is

stored in location 20 and the average is stored

in location 2. The Block Move Instruction (54) is

then used to move the temperatures from

locations 12 through 20 down by 1 location; the

oldest measurement (in location 11) is lost

when the temperature from location 12 is

written over it.

Input Location Labels:

1:Panl Temp 15:Temp_i5

2:smpl10av 16:Temp_i4

11:Temp_i9 17:Temp_i3

12:Temp_i8 18:Temp_i2

13:Temp_i7 19:Temp_i1

14:Temp_i6 20:Temp_i

Where i is current reading, i1 is previous

eading, etc

r

* 1 Table 1 Programs

01: 10 Sec. Execution Interval

01: P17 Module Temperature

01: 1 Loc [:Panl_Temp]

02: P14 Thermocouple Temp (DIFF)

01: 1 Rep

02: 1 2.5 mV slow Range

03: 1 IN Chan

04: 1 Type T (Copper-Constantan)

05: 1 Ref Temp Loc Panl_Temp

06: 20 Loc [:Tempi ]

07: 1 Mult

08: 0 Offset

03: P51 Spatial Average

01: 10 Swath

02: 11 First Loc Temp_i9

03: 2 Avg Loc [:smpl10avg]

04: P54 Block Move

01: 9 No. of Values

02: 12 First Source Loc Temp_i8

03: 1 Source Step

04: 11 First Destination Loc

05: 1 Destination Step

.

p_i9 ]

em

[:T

AD-8-1

Page 32

TD ADDENDUM—SECTION 8. PROCESSING AND PROGRAM CONTROL EXAMPLES

05: P84 Data Table

01: 0 Seconds into interval

02: 0 Every time

03: 0 Records (0=auto; -=redirect)

06: P70 Sample

01: 1 Reps

02: 2 Loc smpl10avg

07: P End Table 1

In the above example, all samples for the

age ar

aver

necessary when an average must be output

with each new sample. In most cases,

averages are desired less frequently than

sampling. For example, it may be necessary to

sample some parameter every 5 seconds and

output every hour an average of the previous

three hours' readings. If all samples were

saved, this would require 2160 input locations.

The same value can be obtained by computing

an hourly average and averaging the hourly

averages for the past three hours. To do this

requires that hourly averages be stored in input

locations.

Instruction 84 is used to send the 1 hour

aver

3 hour average to Final Storage.

Input Location Labels:

* 1 Table 1 Programs

01: 5 Sec. Execution Interval

01: P2 Volt (DIFF)

01: 1 Rep

02: 25 2500 mV 60 Hz rejection Range

03: 3 IN Chan

04: 5 Loc [:XX_mg_M3 ]

05: 10 Mult

06: 0 Offset

02: P84 Data Table

01: 0 Seconds into interval

02: 3600 Seconds interval

03: -3 Records (0=auto; -=redirect)

03: P71 Average