Page 1

SR50A Sonic Ranging Sensor

Revision: 1/11

Copyright © 2007-2011

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The SR50A SONIC RANGING SENSOR is warranted by Campbell

Scientific, Inc. to be free from defects in materials and workmanship under

normal use and service for twelve (12) months from date of shipment unless

specified otherwise. Batteries have no warranty. Campbell Scientific, Inc.'s

obligation under this warranty is limited to repairing or replacing (at Campbell

Scientific, Inc.'s option) defective products. The customer shall assume all

costs of removing, reinstalling, and shipping defective products to Campbell

Scientific, Inc. Campbell Scientific, Inc. will return such products by surface

carrier prepaid. This warranty shall not apply to any Campbell Scientific, Inc.

products which have been subjected to modification, misuse, neglect, accidents

of nature, or shipping damage. This warranty is in lieu of all other warranties,

expressed or implied, including warranties of merchantability or fitness for a

particular purpose. Campbell Scientific, Inc. is not liable for special, indirect,

incidental, or consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country.

To obtain a Returned Materials Authorization (RMA), contact Campbell

Scientific, Inc., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Declaration of Hazardous Material

and Decontamination” form and comply with the requirements specified in it.

The form is available from our website at

completed form must be either emailed to repair@campbellsci.com

435-750-9579. Campbell Scientific will not process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

www.campbellsci.com/repair

. A

or faxed to

Page 3

SR50A Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. Specifications ..............................................................1

2. Introduction..................................................................2

3. Operation......................................................................2

3.1 Quality Numbers.......................................................................................3

3.2 Temperature Compensation......................................................................3

3.3 SDI-12 Operation .....................................................................................4

3.3.1 SDI-12 Wiring ................................................................................4

3.3.2 SDI-12 Addresses ...........................................................................4

3.3.3 SDI-12 Commands..........................................................................4

3.4 RS-232 Operation .....................................................................................6

3.4.1 RS-232 Wiring................................................................................6

3.5 RS-485 Operation .....................................................................................7

3.5.1 RS-485 Wiring................................................................................7

3.6 RS-232 and RS-485 Settings ....................................................................8

3.6.1 BAUD Rate Setting.......................................................................10

3.6.2 Address .........................................................................................10

3.6.3 Operational Mode Setting .............................................................10

3.6.3.1 Measure in Poll Mode .........................................................10

3.6.3.2 Auto Measure Auto Output Mode.......................................11

3.6.3.3 Auto Measure Polled Output Mode.....................................11

3.6.4 Distance to Target or Depth..........................................................11

3.6.5 Distance to Ground .......................................................................11

3.6.6 Measurement Interval Units..........................................................12

3.6.7 Measurement Interval Value.........................................................12

3.6.8 Output Unit ...................................................................................12

3.6.9 Quality Output ..............................................................................12

3.6.10 Temperature Output....................................................................12

3.6.11 Diagnostics Output......................................................................12

3.7 Serial Commands....................................................................................13

3.7.1 Setup Command............................................................................13

3.7.2 Poll Command ..............................................................................13

3.7.3 Information Command..................................................................13

3.7.4 Temperature Input command........................................................13

3.8 RS-232/RS-485 Data Output Format......................................................14

3.8.1 Measurement Output.....................................................................14

3.8.2 Information Message Output ........................................................15

i

Page 4

SR50A Table of Contents

4. Sensor Mounting and Installation ............................16

5. Maintenance ...............................................................19

6. Disassembly/Assembly Procedures ........................20

7. Jumper Settings.........................................................23

8. SR50A Firmware Updates .........................................24

9. Data Interpretation .....................................................25

4.1 Beam Angle ........................................................................................... 16

4.2 Mounting Height.................................................................................... 17

4.2.1 Reference Point ............................................................................ 17

4.3 Mounting Options .................................................................................. 18

10. Datalogger Program Examples...............................26

10.1 SR50A Examples................................................................................. 26

10.1.1 CR1000 Example (SDI-12 “M1!”) ............................................ 26

10.1.2 CR1000 Example (RS-232 Mode) ............................................. 27

10.1.3 CR10X Example (SDI-12 “M1!”).............................................. 28

10.2 SR50AT Examples............................................................................... 30

10.2.1 CR1000 Example (SDI-12 “M4!”) ............................................ 30

10.2.2 CR1000 Example (RS-232 Mode) ............................................. 32

10.2.3 CR10X Example (SDI-12 “M3!”).............................................. 33

11. Warnings/Cautions ..................................................34

Figures

1. SR50A to MD485 Wiring.......................................................................... 8

2. Beam Angle Clearance............................................................................. 17

3. Distance from Edge of Transducer Housing to Grill ............................... 17

4. SR50A Mounted to a Crossarm via the 19517 Mounting Kit.................. 18

5. The SR50A Mounted to the Crossarm Shown from Another Angle ....... 18

6. SR50A - Mounted using a NU-RAIL Fitting and 19484 Mounting Stem...... 19

7. Disconnect Cable from Sensor................................................................. 20

8. Remove 6 Screws from the Transducer Housing..................................... 21

9. Remove Transducer Housing and Disconnect Wires............................... 21

10. Location of Desiccant in Transducer Housing Assembly...................... 22

11. Remove and Replace Desiccant............................................................. 22

12. Remove the 2 Flat Phillips Screws to Expose the PCB ......................... 23

13. Jumper Settings...................................................................................... 23

ii

Page 5

Warning!

Always disconnect the sensor before opening.

This Device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received,

including interference that may cause undesirable operation.

Page 6

Page 7

SR50A Sonic Ranging Sensor

1. Specifications

Power Requirements: 9 to 18 Vdc

Power Consumption: Quiescent

SDI-12 Mode < 1.0 mA

RS-232/RS485 Mode < 2.25 mA

Peak Measurement Current

250 mA typical

Measurement Time: Less than 1.0 second

Selectable Outputs: SDI-12 (version 1.3)

RS-232 (1200 to 38400 bps)

RS-485 (1200 to 38400 bps)

Measurement Range: 1.6 to 32.8 ft (0.5 to 10 m)

Accuracy: ±0.4 in (±1 cm) or 0.4% of distance to

target, whichever is greater.

Accuracy specification excludes errors in

the temperature compensation.

Note1

NOTES

Resolution: 0.01 in (0.25 mm)

Required Beam Angle Clearance: 30°

Operating Temperature: -45° to +50°C

Maximum Cable Length: SDI-12 196.9 ft (60 m)

RS-232 (9600 bps or less) 98.4 ft (30 m)

RS-485 984.3 ft (300 m)

Cable Type: 4 conductor, 2-twisted pair, 22 AWG,

Santoprene jacket

Dimensions: Length 4 in (10.1 cm)

Diameter 3 in (7.6 cm)

Weight:

Sensor only 0.88 lbs (0.4 kg)

Cable (SR50A) 15 feet 0.55 lbs (0.25 kg)

1: The quiescent current draw is less than 1.25 mA if the baud

rate is 9600 bps or less.

2: Power supply must not drop below 11.0 Volts or heavier

gauge wire is required.

Note2

1

Page 8

SR50A Sonic Ranging Sensor

2. Introduction

The SR50A Sonic Ranging Sensor measures the distance from the sensor to a

target. The most common applications are measuring snow depths and water

levels. The sensor is based on a 50 kHz (Ultrasonic) electrostatic transducer.

The SR50A determines the distance to a target by sending out ultrasonic pulses

and listening for the returning echoes that are reflected from the target. The

time from transmissions to return of an echo is the basis for obtaining the

distance measurement.

Since the speed of sound in air varies with temperature, an independent

temperature measurement is required to compensate the distance reading for

the SR50A. A simple calculation is applied to initial readings for this purpose.

The SR50A is capable of picking up small targets or targets that are highly

absorptive to sound, such as low density snow. The SR50A makes use of a

unique echo processing algorithm to help ensure measurement reliability. If

desired, the SR50A can also output a data value indicative of measurement

quality.

The SR50A was designed to meet the stringent requirements of snow depth

measurement which makes it well suited for a variety of other applications.

The rugged aluminium housing is built to withstand harsh environments and

offers several mounting options.

3. Operation

The SR50A has several output formats: SDI-12, RS-232 and RS-485. The

SR50A is shipped from the factory configured as an SDI-12 sensor (address 0).

By moving a set of three jumpers inside the SR50A the output type can be

optionally set from SDI-12 to RS-232 or RS-485. Refer to Section 6 for details

on opening the SR50A and Figure 13 for jumper settings.

The SR50A performs multiple echo processing regardless of output formats.

The SR50A bases every measurement on several readings and applies an

algorithm to improve measurement reliability.

The distance to target readings that are obtained from the sensor are referenced

from the metal mesh on the face of the transducer. The SR50A projects an

ultrasonic beam that can pick up objects in its field of view that is 30° or less.

The closest object to the sensor will be detected if it is within this field of view.

Unwanted objects must be outside the field of view. If a target is in motion,

the SR50A may reject a reading if the target distance changes at a rate of 4

centimetres per second or more.

The SR50A will complete a measurement and output the data typically in 1

second. In RS-232 and RS-485 Serial modes the data is completed within one

second for BAUD rates of 9600 and above. The total time for an SDI-12

Measurements can exceed 1 second due to the long communications times

associated with the 1200 BAUD data rate.

2

If the SR50A rejects a reading or does not detect a target, zero will be output

for distance to target or –999 for depth values.

Page 9

3.1 Quality Numbers

Measurement quality numbers are also available with output data; these give an

indication of the measurement certainty. The quality numbers have no units of

measure but can vary from 152 to 600. When the Quality numbers are lower

than 210, the measurements are considered to be of good quality. A value of

zero however, indicates a reading was not obtained. Numbers greater than 300

indicate that there is a degree of uncertainty in the measurement. Causes of

high numbers include:

• sensor is not perpendicular to the target surface

• target is small and reflects little sound

• target surface is rough or uneven

• target surface is a poor reflector of sound (extremely low density snow)

Quality Number Range Quality Range Description

0 Not able to read distance

152-210 Good measurement quality numbers

SR50A Sonic Ranging Sensor

210-300 Reduced echo signal strength

300 to 600 High measurement uncertainty

It is not necessary to make use of the quality numbers but they can provide

additional information such as an indication of surface density in snow

monitoring applications. The quality numbers will increase during snowfall

events consisting of low-density snow.

3.2 Temperature Compensation

The SR50A does not include a temperature sensor to compensate for the speedof-sound variations in air temperature. Temperature corrections for the speed

of sound will need to be applied to the readings. Use a reliable and accurate

probe, such as the 107-L or HMP45C-L to measure air temperature. A

radiation shield is also required when the temperature probe will be exposed to

solar radiation. Temperature compensation must be applied to the sensor

output using the following formula:

FORMULA 1. Temperature Compensation

=DISTANCE

READING

SR50A

KELVINT

°

273.15

CAUTION

The SR50A calculates a distance reading using the speed

of sound at 0°C (331.4 m/s). If the temperature

compensation formula is not applied, the distance values

will not be accurate for temperatures other than 0°C.

3

Page 10

SR50A Sonic Ranging Sensor

3.3 SDI-12 Operation

3.3.1 SDI-12 Wiring

SDI-12 is a Serial Digital Interface standard that is used for communication

between data recorders and sensors. Most Campbell Scientific dataloggers are

SDI-12 compatible.

It is recommended to power down your system before wiring the SR50A.

Never operate the sensor with the shield wire disconnected. The shield wire

plays an important role in noise emissions and susceptibility as well as

transient protection.

Color Function Connection

Black Power Ground Power Ground

Red +12VDC Power Power Source

Green SDI-12 I/O Recorder/Reader SDI-12 Com port or control port

White Not Used Ground

Clear Shield Shield/Earth Ground

3.3.2 SDI-12 Addresses

The SR50A can be set to one of ten addresses (0 to 9) which allows up to ten

sensors to be connected to a single digital I/O channel (control port) of an SDI12 datalogger.

The SR50A is shipped from the factory with the address set to 0. The address

on the SR50A can be changed by sending an SDI-12 change address command.

The change address command can be issued from most SDI-12 recorders. For

some Campbell Scientific dataloggers the SDI-12 transparent mode will need

to be entered to change the address.

When it is necessary to measure more than one SR50A, it is easiest to use a

different control port for each SR50A instead of changing the address. If

additional control ports are not available, then the address will need to be

changed.

To change the address of a sensor that has the default address of 0 to the

address of 1 the following command can be sent:

“0A1!”

Only one sensor of the same address should be connected when using the

change address command.

3.3.3 SDI-12 Commands

4

NOTE

The SDI-12 protocol supports various measurement commands. The SR50A

can use the SDI-12 commands listed in the following table.

The SR50A needs to be powered for 1.5 s before it can receive

an SDI-12 command.

Page 11

SR50A Sonic Ranging Sensor

The different commands are entered as options in the SDI-12 recorder

instruction. The major difference between the various measurement commands

are the data values that are returned. The user has the option to output the

distance to target in either meters or feet, or to include the measurement quality

numbers.

If the SR50A is unable to detect a proper echo for a measurement, the sensor

will return a zero value for the distance to target value.

The SR50AT is a version of the sensor that is available on special order only.

It includes a temperature sensor and can return valid temperature corrected

readings. In order to obtain the Snow Depth values (aM4! or aM8!) the user

must properly set the Distance to Ground value in the SR50AT sensor. This

can be done by sending and extended command in SDI-12 mode or by using

the setup menu in RS-232 or RS-485 modes.

SDI-12

Command

Command Function/Description

Values Returned

aM! Distance-Meters D

aM1! Distance-Meters, Quality Number D, Q

aM2! Distance-Meters, Temperature °C D, T

aM3! Distance-Meters, Quality Number, Temperature °C D, Q, T

Note1

Note1

aM4! Snow Depth Meters, Quality Number, Temperature SD, Q, T

aM5! Distance-Inches D

aM6! Distance-Inches, Quality Number D, Q

aM7! Distance-Inches, Quality Number, Temperature °C D, Q, T

aM8 ! Snow Depth Inches, Quality Number, Temperature SD, Q, T

AM9 ! Temperature °C T

aMC!

aMCn!

Measurement Commands with Checksum

See aM and aM1- aM8

Note1

Note1

Note1

Output is the same as

aM, aM1-aM9

Checksum is added

aC! Concurrent Measurement Command

D

Distance-Meters

aCn! Concurrent Measurements

Same as M1 – M8

Output is the

Same as M1 – M8

aCC!

aCCn!

Concurrent Measurement Commands with Checksum. See aM and aM1- aM8 Output is the same as

aM, aM1-aM8

Checksum is added

aD0! Send Data Dependent upon

command Sent

aV! Verification command S1,S2,V,WD

S1 = Firmware Signature

S2 = BootRom Signature

V = Supply Voltage

Note1

WD = Watch Dog Errors

aI! Send Identification 013CAMPBELLSR50A

2.0SN

SN = Serial number (5

digits)

5

Page 12

SR50A Sonic Ranging Sensor

SDI-12

Command

?! Address Query a

aAb! Change Address command b is the new address

aXM;D.DDD!

Extended

command

aXI;DDD.DD!

Extended

command

aXT;CC.CC!

Extended

command

aR0! Returns the Distance to Ground Setting in the SR50A. The units returned are

aR1! Returns the Distance to Ground Setting in the SR50A. The units returned are

aR2! Returns the temperature sent to the SR50A for Internal Temperature

Command Function/Description

Set the distance to ground parameter in the SR50A. The distance must be in

meters with no more than 3 decimal places.

Set the distance to ground parameter in the SR50A. The distance must be in

Inches with no more than 2 decimal places.

Provide the SR50A with a temperature value to perform on board temperature

compensation. The temperature must be in degrees Celsius with a maximum

of 7 characters including sign and decimal.

in Meters

in Inches

compensation. This value remains the same unless power is cycled or a new

temperature values is sent.

Values Returned

A

Address is returned

A

Address is returned

A

Address is returned

DG

DG

T

Where a = address of SDI-12 device.

Where n = numbers 1 to 9

NOTE 1: (SR50AT version only)

3.4 RS-232 Operation

The SR50A sensor comes from the factory with the internal jumpers set to

SDI-12 mode. To use the SR50A in the RS-232 mode of operation the jumpers

will need to be set as outlined in Section 7.

3.4.1 RS-232 Wiring

The following table/diagram illustrates the wiring for the SR50A in RS-232

mode.

Color Function Connection

Black Power Ground System Ground and/or RS-232 Receiver

Red +12VDC Power Power Source

Green RS-232 (SR50A Output) Recorder/Reader RS-232 Input

White RS-232 (SR50A Input) Recorder/Reader RS-232 Output

Ground

(Pin 5 of a computer (DTE) DB-9

connector)

(Pin 2 of a computer (DTE) DB-9

connector)

(Pin 3 of a computer (DTE) DB-9

connector)

6

Clear Shield Shield/Earth Ground

Page 13

3.5 RS-485 Operation

The SR50A sensor comes from the factory with the internal jumpers set to

SDI-12 mode. To use the SR50A in the RS-485 mode of operation the jumpers

will need to be set as outlined in Section 7.

The RS-485 on the SR50A supports half-duplex communications. This means

that the SR50A can receive and transmit but both cannot occur simultaneously.

Normally there is a master-slave relationship in most systems to avoid

collisions between transmissions. For this reason the Auto Measure Auto

Output is not recommended for RS-485 communications. It is much better to

have a master initiate the communications by making use of the Measure On

Poll or the Auto Measure Polled Output modes.

Campbell Scientifics’ MD485 interface can be used to connect one or More

SR50A sensors in RS-485 mode to an RS-232 device. This can be useful for

sensors that require lead lengths that exceed the limits of either RS-232 or SDI12 communications.

3.5.1 RS-485 Wiring

The following table/diagram illustrates the wiring for the SR50A in RS-485

mode.

SR50A Sonic Ranging Sensor

Color Function Connection

Black Power Ground System Ground and/or RS-232 Receiver Ground

(Pin 5 of a computer (DTE) DB-9 connector)

Red +12VDC Power Power Source

Green RS-485 A To RS-485 A terminal

White RS-485 B To RS-485 B terminal

Clear Shield Shield/Earth Ground

7

Page 14

SR50A Sonic Ranging Sensor

FIGURE 1. SR50A to MD485 Wiring

3.6 RS-232 and RS-485 Settings

Once the jumpers are set for RS-232 operation a terminal program such as

Hyperterminal can be used to change factory default or existing settings. The

following settings apply to Hyperterminal or any other program that is used for

communications.

BAUD Rate Current SR50A Setting

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

NOTE

The factory default BAUD rate is 9600 BAUD. Once the BAUD

rate is changed the new BAUD rate must be used for further

communications to the SR50A. It is important to keep track of

the BAUD rate setting on the SR50A. If the BAUD rate setting

is unknown, we recommend trying the default value of 9600

BAUD. If that does not work, start at BAUD rate 1200 and go

through all the BAUD rate settings until the correct one is found.

Note

8

When the hyperterminal session is started the command “SETUP” needs to be

entered. Hitting the Enter will transmit the CR LF characters which are

required after the text “SETUP”. The text “SETUP” is not case sensitive so

any combination of upper and lower case letters will work.

Page 15

The Initial menu will look as follows:

SR50A Sonic Ranging Sensor

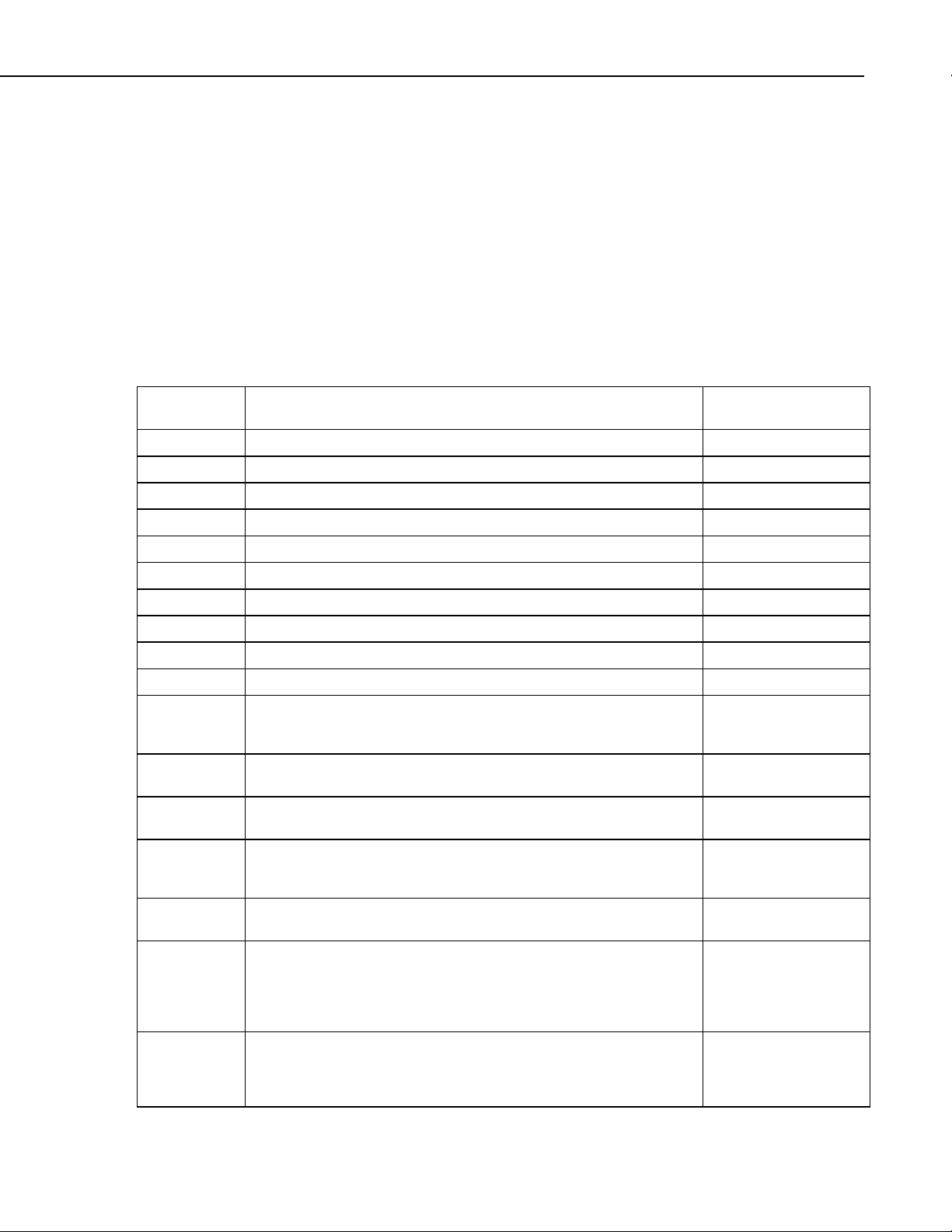

The following is a summary of settings that can be changed on the SR50A RS232 or RS-485 operating modes.

Setting Description Options Default Value

BAUD Rate 1200

9600 BAUD

4800

9600

19200

38400

Address RS-232/RS-485 Any 2 Alphanumeric

33

Characters

Serial Operational Mode Measure on Poll

Auto Measure Auto Output

Auto Measure Auto Output

Auto Measure Polled Output

Distance to Target or

Depth output

Distance to Target

Depth

Distance to Target

Distance to Ground Decimal Value in Meters 0.0

Measurement Interval Units Seconds

Seconds

Minutes

Hours

Measurement Interval Value Integer 1-255 60

Output Unit Meters

Centimeters

Millimeters

Feet

Inches

Meters

9

Page 16

SR50A Sonic Ranging Sensor

Setting Description Options Default Value

Quality Output On

Temperature Output On

Diagnostics Output On

3.6.1 BAUD Rate Setting

The factory Default BAUD Rate Setting of 9600 BAUD is suitable for most

applications. Lower BAUD rates (1200 or 4800) may improve communication

reliability or allow for longer cable lengths. Higher BAUD rates (19200 or

38400) may be used where faster communications are required.

The quiescent current draw for the SR50A in serial mode is normally 1.25mA

for BAUD rates of 9600 or less. The current draw increases to 1.5 and 2.25

mA for the BAUD rates of 19200 or 38400 respectively.

It is possible to download a firmware update to the SR50A via the RS-232 or

RS-485 communication interface. Higher BAUD rates may be desirable to

speed up this process.

Off

Off

Off

Off

Off

Output valid only for the

SR50AT (available on special

order only)

Off

It may take up to 30 minutes using a speed of 1200 BAUD, 7 minutes using

9600 BAUD, or 3 minutes using 38400 BAUD.

3.6.2 Address

The factory Default Address is 33. Normally for RS-232 applications there is

no need to change the default address. For RS-485 operation multiple sensors

can be polled individually if different addresses are assigned.

3.6.3 Operational Mode Setting

There are 3 different operational mode settings available on the SR50A.

Overall system design and desired performance determine which mode to

select. The SR50A operation for each of the 3 different modes will be

described as well as the advantages and disadvantages of each mode.

3.6.3.1 Measure in Poll Mode

In this mode the SR50A will remain idle until a measurement command is sent

(p33<CR>) where 33 is the default serial address. After the measurement

command is received, the SR50A will immediately begin a measurement and

transmit out the resulting data packet when complete. Typically the SR50A

will transmit the data packet within 1 second of receiving the command packet.

• The SR50A only performs a measurement when requested.

• The data output will lag the measurement command by 1 second.

10

• This configuration is conducive to a multidrop RS-485 system where

individual sensors do not transmit data until they are addressed.

Page 17

3.6.3.2 Auto Measure Auto Output Mode

In this mode the SR50A will automatically exit its low power mode, initiate a

measurement and output the data. The frequency by which the SR50A will

perform this is set by adjusting the Measurement Interval Units and the

Measurement Interval Value parameters.

• No command is required from an external device to obtain a measurement.

• The data recorder or equipment simply needs to read the incoming serial

data from the SR50A.

3.6.3.3 Auto Measure Polled Output Mode

In this mode the SR50A will automatically exit its low power mode, initiating a

measurement. The output data string will not be sent until a poll command is

received. When a poll command is received by the SR50A the output data will

typically commence 100ms after the poll command is sent.

The frequency by which the SR50A will perform the measurement is set by

adjusting the Measurement Interval Units and the Measurement Interval

Value parameters.

SR50A Sonic Ranging Sensor

• The main advantage of this operating mode is that the receiving device

will only have to wait 100ms for the data as opposed to 1 second.

• This configuration is also more conducive to a multidrop RS-485 system

where individual sensors do not transmit until they are addressed.

3.6.4 Distance to Target or Depth

The SR50A can output either distance to target values or calculate snow depth

values. To obtain a valid snow depth value the parameter distance to ground

must be entered.

The SR50AT will compensate the readings for temperature; the SR50AT is

available on special order only.

CAUTION

Do not use this option on the SR50A sensor unless the

SR50A is sent valid temperature readings via the

Temperature Input command (see Section 3.6.10).

3.6.5 Distance to Ground

A valid distance to ground must be entered when the SR50A is configured to

output snow depth values. The value must be in Meters regardless of the

output units that are selected.

If the exact value cannot be obtained it is better to slightly overestimate the

value rather than underestimating it. If a Distance to Ground value is too

small, the SR50A will output an error value as the snow surface should not be

below the ground surface.

11

Page 18

SR50A Sonic Ranging Sensor

3.6.6 Measurement Interval Units

3.6.7 Measurement Interval Value

This setting is only applicable if either the Auto Measure Polled Output or the

Auto Measure Auto Output Modes are used. The options for the Measurement

Interval Units are:

Seconds

Minutes

Hours

Once a unit type is selected the number of units for the interval is set by

changing the Measurement Interval Value parameter. A 60 second interval

can be set by setting the units to seconds and the Measurement Interval Value

to 60. Alternately, the Measurement Interval Unit could be set to Minutes and

the Value could be set to 1. The Value setting can only range from 1 to 255.

This setting is only applicable if either the Auto Measure Polled Output or the

Auto Measure Auto Output Modes are used. The Measurement Interval

Value can range from 1 to 255. The units used for the value is set by the

Measurement Interval Units.

3.6.8 Output Unit

The SR50A always outputs the distance to the target. The units for the

distance value can be set to any of the following values:

Meters

Centimeters

Millimeters

Feet

Inches

3.6.9 Quality Output

The SR50A quality numbers can be optionally included in the data output

string. The Quality Output setting can be set to ON or OFF.

3.6.10 Temperature Output

This setting should only be enabled for the SR50AT version of the sensor; the

SR50AT is available on special order only. The Temperature Output setting

allows the SR50AT temperature reading to be included in the data output

string. It can be set to ON or OFF.

3.6.11 Diagnostics Output

The SR50A diagnostics numbers can be optionally included in the data output

string. The Diagnostics Output setting can be set to ON or OFF.

12

Page 19

3.7 Serial Commands

3.7.1 Setup Command

The setup command places the SR50A in the serial setup mode. This

command should only be sent to customize a sensor’s settings. Upper and

lower case letters are accepted and a carriage return character must also

terminate the string (Enter key for Hyperterminal).

“setup<CR>”

3.7.2 Poll Command

The poll command is used to obtain the sensor’s output values. The poll

command consists of the upper or lower case letter “p” followed by the SR50A

address (default 33). The command must also terminate with a carriage return

character (Enter for hyperterminal).

“pAA<CR>” – where AA is a two character address and set from the

factory to 33

“p33<CR>” – Poll command with factory address of 33

SR50A Sonic Ranging Sensor

3.7.3 Information Command

The information command is used to query information from the sensor that is

not associated with the sensor’s output. For detailed information on the output

refer to Section 9.

The information command consists of the upper or lower case letter “i”

followed by the SR50A address (default 33). The command must also

terminate with a carriage return character (Enter for Hyperterminal).

“iAA<CR>” – where AA is a two character address and set from the

factory to 33

“i33<CR>” – information command with factory address of 33

3.7.4 Temperature Input command

The temperature input command is used to send the SR50A version of the

sensor a temperature value that is to be used for temperature compensation.

The value sent must be in degrees Celsius and should not exceed 8 characters.

The command consists of the upper or lower case letter “t” followed by the

SR50A address (default 33) a semicolon and the temperature value. The

command must also terminate with a carriage return character (Enter for

Hyperterminal).

“tAA;-5.5<CR>” – where AA is a two character address and set from the

factory to 33 and –5.5 is the temperature in degrees C

“t33;tt.ttt<CR>” – Temperature command with factory address of 33 and

a temperature value in Celsius.

13

Page 20

SR50A Sonic Ranging Sensor

3.8 RS-232/RS-485 Data Output Format

3.8.1 Measurement Output

The measurement output string for the SR50A is as follows:

<STX>aa;D.DDD;QQQ;TT.TT;VVVVV;CC<CR><LF><ETX>

<STX> is the hex character &h02 (2 in decimal)

aa

These two characters are the serial address of the sensor. The default is 33.

Note this is two ASCII characters of &h33 in Hexidecimal or 51 in decimal.

D.DDD

This is the distance to target reading. The units depend on the Output Units

setting. The number of digits and decimal places also depend on the output

unit that is selected. The decimal digits are as follows:

Meters: D.DDD, 0.000 for no valid reading

DD.DDD possible for values past 9.999 m

Centimeters: DDD.DD

DDDD.DD possible for values past 999.99 cm

000.00 output for no valid reading

Millimeters: DDDD

-999 output for no valid reading

9999 Maximum value

Feet: DD.DDD

00.000 output for no valid reading

Inches: DDD.DD

000.00 output for no valid reading

QQQ

This data value is the optional quality value output. The quality value is

always a 3 digit integer and varies from 152 to 600, where 600 is the poorest

quality.

TT.TT

This is the temperature value in Degrees Celsius read by the SR50AT sensor.

This value is optionally output by setting the Temperature Output option to

ON. Only the SR50AT sensor will output a valid temperature. The SR50A

will output a –999.00 if the Temperature Output option is set to ON. The

temperature is displayed with 2 decimal points of precision.

VVVVV

This is the diagnostic output value. Each digit represents a pass or a fail on a

diagnostic test.

14

XVVVV

If X is a 1, then the ROM Memory has passed the signature test.

Page 21

SR50A Sonic Ranging Sensor

VXVVV

If X is a 1, then no watchdog errors have occurred.

VVXXX

The 3 digits XXX are for factory use and should always read 111.

CC

This is a 2 character checksum of the data packet. The checksum is the two’s

complement of the data packet sum including control characters.

The Least significant byte is used resulting in a 2 character checksum.

<STX> = &h02 (Hexadecimal)

<CR> = &h0D (Hexadecimal)

<LF> = &h0A (Hexadecimal)

<ETX> = &h03 (Hexadecimal)

The following is a sample packet with proper checksum:

<STX>33;1838;194;11011;2C<CR><LF><ETX>

SUM =

02+33+33+3B+31+38+33+38+3B+31+39+34+3B+31+31+30+31+31

+3B+0D+0A+03

=0x3D4

Use Last byte only (D4) and calculate two’s complement = 100 – D4 = 2C

<CR>

Carriage return character. 0x0d in hexadecimal or 13 in decimal

<LF>

Line feed character. 0x0a in hexadecimal or 10 in decimal

<ETX>

End of transmission character. 0x03 in hexadecimal or 3 in decimal

3.8.2 Information Message Output

The measurement output string for the SR50A is as follows:

<STX>aa;SSSSS;H.H;F.F;BBBBB;WWWWW<CR><LF><ETX>

<STX> is the hex character 0x02 (2 in decimal)

aa

These two characters are the serial address of the sensor. The default is 33.

Note this is two ASCII characters of 0x33 in Hexidecimal or 51 in decimal.

SSSSS

This is the serial number of the sensor

H.H

This is the hardware version of the sensor

F.F

This is the firmware version of the sensor

15

Page 22

SR50A Sonic Ranging Sensor

(

)

BBBBB

This is the checksum of the boot code.

WWWWW

This is the checksum of the firmware.

CC

This is a 2 character checksum of the data packet. The checksum is the two’s

complement of the data packet sum including control characters.

The least significant byte is used resulting in a 2 character checksum.

<STX> = &h02 (Hexadecimal)

<CR> = &h0D (Hexadecimal)

<LF> = &h0A (Hexadecimal)

<ETX> = &h03 (Hexadecimal)

The following is a sample packet with proper checksum:

<STX>33;1838;194;11011;2C<CR><LF><ETX>

SUM =

02+33+33+3B+31+38+33+38+3B+31+39+34+3B+31+31+30+31+31

+3B+0D+0A+03

=0x3D4

Use Last byte only (D4) and calculate two’s complement = 100 – D4 = 2C

<CR>

Carriage return character. &h0D in hexadecimal or 13 in decimal

<LF>

Line feed character. &h0A in hexadecimal or 10 in decimal

<ETX>

End of transmission character. &h03 in hexadecimal or 3 in decimal

4. Sensor Mounting and Installation

4.1 Beam Angle

When mounting the SR50A, the sensor's beam angle needs to be considered

(see FIGURE 2. Beam Angle Clearance). It is always best to mount the

SR50A perpendicular to the intended target surface. The SR50A has a beam

angle of approximately 30 degrees. This means that objects outside this 30

degree beam will not be detected nor interfere with the intended target. Any

unwanted target must be outside the 30 degree beam angle.

The following formula is used to determine the required clearance for the beam

angle. By inserting a height value in the Formula, a Clearance Radius in the

same measurement units as the height can be obtained.

Clearance Radius formula:

0.=

268

CONE

FORMULA 2. Beam angle clearance Radius

16

CONE

heightradius

Page 23

4.2 Mounting Height

Any target to the SR50A should be at least 19.7 in (50 cm) or more from the

face of the transducer. An attempt should also be made to not mount the sensor

too far from the target surface. The further the sensor is from the target the

more the absolute error increases. If your application is measuring snow depth

in an area that will likely not exceed 4.1 ft (1.25 m) of snow then a good height

to mount the sensor would be 5.74 to 6.56 ft (1.75 to 2.0 m). Mounting the

sensor 13.1 ft (4 m) above the ground will result in the potential for larger

snow depth errors.

SR50A Sonic Ranging Sensor

FIGURE 2. Beam Angle Clearance

4.2.1 Reference Point

The front grill on the ultrasonic transducer is used for the reference for the

distance values. Because it is difficult to measure from the grill one can use

the outer edge of the plastic transducer housing see FIGURE 3. If this edge is

used, simply add 0.3 in (8 mm) to the measured distance.

FIGURE 3. Distance from Edge of Transducer Housing to Grill

17

Page 24

SR50A Sonic Ranging Sensor

4.3 Mounting Options

There are two standard mounting options available for the SR50A sensor.

The first is the SR50A Mounting Kit, part number 19517. This bracket is used

to mount the SR50A to a CM206 crossarm or a pipe with a 1 in. to 1.75 in. OD.

Figures 4 and 5 show a couple of angles of the SR50A mounted to a crossarm.

A u-bolt attaches the bracket to the crossarm and two screws attach the SR50A

to the bracket.

Another mounting option shown in FIGURE 6 utilizes a mounting stem (part

number 19484) and a NU-RAIL. The mounting stem is sized to fit a 1” NURAIL (#1049). This mounting method was used for the SR50 (predecessor to

the SR50A ) and the stem can be used to fit the SR50A into existing SR50

mounts.

FIGURE 4. SR50A Mounted to a Crossarm via the 19517 Mounting Kit

FIGURE 5. The SR50A Mounted to the Crossarm

Shown from Another Angle

18

Page 25

SR50A Sonic Ranging Sensor

FIGURE 6. SR50A - Mounted using a NU-RAIL Fitting and

19484 Mounting Stem

SR50A with 6-plate gill radiation shield – the picture below shows the

SR50A stem attachment

5. Maintenance

The SR50A’s electrostatic transducer requires equal pressure on both sides.

Vent holes in the transducer housing are used to equalize pressure. Desiccant

is placed inside the transducer housing to prevent the possibility of condensing

humidity. The desiccant must be inspected and, if required, replaced on a

regular basis. The desiccant supplied with the SR50A uses an indicating silica

gel and will remain blue if it is still capable of absorbing moisture. Once the

desiccant becomes saturated the color will change from blue to pink. If the

SR50A is used in humid environments, the desiccant should be replaced more

frequently. To inspect or replace the desiccant, follow the procedures outlined

in Section 6 under disassembly.

The five small desiccant packets used in the transducer housing are part

number 4091.

19

Page 26

SR50A Sonic Ranging Sensor

It is recommended that the transducer housing assembly (part number 19486 –

Transducer Maintenance Kit) be replaced every 3 years.

If the SR50A is used in an environment with high humidity, it is recommended

that the transducer housing assembly be replaced every year.

6. Disassembly/Assembly Procedures

It is important to follow these instructions to disassemble the SR50A.

Disassembly is required to change the transducer and the Option jumpers, and

to inspect or replace the desiccant.

Before proceeding with any maintenance on a data acquisition system, always

retrieve the data first. It is also recommended that the datalogger program be

saved.

If the sensor is in operation, always disconnect the SR50A from the datalogger

or the connector before disassembling. Refer to Section 3.4.1 or Section 3.5.1,

Wiring for further information on your specific wiring connection and

disconnection.

20

FIGURE 7. Disconnect Cable from Sensor

Page 27

SR50A Sonic Ranging Sensor

FIGURE 8. Remove 6 Screws from the Transducer Housing

FIGURE 9. Remove Transducer Housing and Disconnect Wires

21

Page 28

SR50A Sonic Ranging Sensor

FIGURE 10. Location of Desiccant in Transducer Housing Assembly

22

FIGURE 11. Remove and Replace Desiccant

Page 29

SR50A Sonic Ranging Sensor

FIGURE 12. Remove the 2 Flat Philips Screws to Expose the PCB

Carefully reassemble in reverse order.

7. Jumper Settings

The following diagram illustrates how the Jumpers are located on the SR50A

sensor.

FIGURE 13. Jumper Settings

23

Page 30

SR50A Sonic Ranging Sensor

The SR50A can be configured with either SDI-12, RS-232 or RS-485

communications. Shunt jumpers can be located on any of the 3 sets of

communication selection headers. All 3 jumpers should be placed only on one

group at a time. Never install more than 3 jumpers and never mix the jumpers

amongst the SDI-12, RS-232 or RS-485 locations.

The other jumper located on the SR50A places the sensor in either the normal

operation mode or in the Program update mode. The program mode is only

used for updating the internal firmware of the sensor. For operation the jumper

must be left in the RUN position.

Refer to Section 8 for SR50A Firmware Updates.

8. SR50A Firmware Updates

The firmware on the SR50A can be updated by using a terminal program such

as Hyperterminal. If your SR50A is configured for RS-232 communications,

the SR50A can be programmed from the I/O cable. The SR50A also contains

an internal female DB-9 connector.

Firmware updates should only be performed at an appropriate workstation with

static control procedures in place. Failure to follow the procedures may cause

damage to the sensor.

• Ensure that the SR50A is completely disconnected.

• Open the SR50A as follows:

o Remove the 6 slot head screws that are located on the bottom side of

the transducer housing.

o The transducer housing will separate from the main housing.

o Ensure that the screws and o-rings are kept and set aside.

o Disconnect the transducer housing assembly from the main body

assembly by pressing the tab on the connector and separating the

connector.

o Remove the 2 phillips screws from the bottom disk assembly.

o The bottom disk assembly should now separate from the main

housing.

o The circuit board will still remain connected to the housing via the

signal wires.

o Place the bottom disk/ circuit assembly on the work bench with the

circuit board and DB-9 connector facing up. Ensure that no part of

the PCB is in contact with the lid or other conductive objects.

24

• Move the jumper on the Run/Program Header from the Run position to the

Program position.

• Connect to the DB9 connector on the SR50A.

Page 31

SR50A Sonic Ranging Sensor

• Power can now be applied to the SR50A by connecting the connector and

applying power to the sensor. The Green LED should remain on when

powered up properly.

• Setup Hyperterminal or the communications program that you are using as

follows:

o BAUD rate: 38400

o Data Bits: 8

o Parity: None

o Stop Bits: 1

o Flow control: XON/XOFF

o 25ms line delay (under ASCII setup)

• From the Hyperterminal menu select Transfer -> Send Text File.

• Select the new download text file and the transfer should begin.

• Initially the LED should remain constantly on. When data transfer begins

the LED will flash rapidly with each line that is reprogrammed.

• Upon completion the LED will remain steadily on again. If there are any

errors the LED will flash to indicate that an error occurred.

• If the LED does flash attempt the reprogram process again.

• After the reprogramming is successful, disconnect the sensor from the

power supply.

• Move the jumper back from the Program position to the Run position.

• Re-assemble the sensor.

• Verify operation of the sensor by obtaining a measurement.

9. Data Interpretation

Although not common the SR50A can occasionally output invalid reading

indicators if it was unable to obtain a measurement. For distance to target

values a 0.0 reading is usually output. For snow depth outputs a -999 is output

as an error indicator value. An invalid temperature reading is also indicated by

a -999 reading. For snow depth applications these can be easily filtered out

when analysing the data.

Consideration should be taken in a control type application to deal with invalid

readings. For example if the sensor is used to initiate a water level alarm then

multiple readings should be used to ensure that a single invalid reading does

not trigger the alarm condition.

25

Page 32

SR50A Sonic Ranging Sensor

10. Datalogger Program Examples

In the following datalogger program examples only the CR1000 and the

CR10X dataloggers are used. The programming of CR800, CR850 and the

CR3000 dataloggers are effectively the same as the CR1000. Also for a

CR23X datalogger refer to the CR10X programming examples.

10.1 SR50A Examples

10.1.1 CR1000 Example (SDI-12 “M1!”)

'CR1000 Series Datalogger

'In this example, the SR50A is mounted 2.5 meters above the ground.

'The CR1000 sends an 'SDI12 command to the SR50A,

'which outputs a raw distance value and a signal quality.

'Declare Public Variables:

Public SR50(2)

Alias SR50(1)=Raw_Dist

Alias SR50(2)=SignalQuality

Public Temp_Corr_Distance

Public Air_Temp

Public Snow_Depth

'Declare the initial distance of the SR50A from the ground in meters:

Const Initial_Distance = 2.5

'Define Data Tables:

DataTable (Table1,True,-1)

DataInterval (0,60,Min,10)

Sample (1,Snow_Depth,FP2)

EndTable

'Main Program:

BeginProg

Scan (60,Sec,0,0)

'Measure the SR50A:

'Use SDI12 command "M1!" to receive Distance

'and Signal quality from the SR50AT

SDI12Recorder (SR50(),1,0,"M1!",1,0)

'Measure the 107 temperature sensor:

Therm107 (Air_Temp,1,1,Vx1,0,250,1.0,0)

'Use Air_Temp to calculate corrected distance:

Temp_Corr_Distance=Raw_Dist*(SQR((Air_Temp+273.15)/273.15))

'Subtract the corrected distance from the initial distance of the SR50A to the ground:

Snow_Depth=Initial_Distance-Temp_Corr_Distance

'Call Data Table and Store Data:

CallTable (Table1)

NextScan

EndProg

26

Page 33

SR50A Sonic Ranging Sensor

10.1.2 CR1000 Example (RS-232 Mode)

'CR1000 Series Datalogger

'In this example, the SR50A is mounted 2.5 meters above the ground.

'The SR50A is used in RS-232 mode (internal jumpers are set).

'The CR1000 sends a serial string to the SR50A, which is in "Measure on Poll Mode",

'and then receives a serial string in return which is parsed into different values.

'Wiring: Black: Power Ground

' clear: Power Ground

' Red: +12V,

' White: C1

' Green: C2

'Declare Variables

'Declare SR50AData as a dimensioned string of maximum 50 chrs

Dim SR50AData as STRING * 50

Public ParseVals(5) as FLOAT

Alias ParseVals(1)=SerialAddress

Alias ParseVals(2)=Raw_Distance

Alias ParseVals(3)=SignalQuality

Alias ParseVals(4)=Diagnostics

Alias ParseVals(5)=Chcksum

Public Temp_Corr_Distance

Public Air_Temp

Public Snow_Depth

'Declare the initial distance of the SR50A from the ground in meters:

Const Initial_Distance=2.5

'Define Data Tables

DataTable (Table1,True,-1)

DataInterval (0,60,Min,10)

Sample (1,Snow_Depth,FP2)

EndTable

'Main Program

BeginProg

'Open RS232 port for communications 9600 BAUD is the default:

SerialOpen (Com1,9600,0,0,2000)

Scan (60,Sec,0,0)

'Measure the SR50A:

'Transmit serial command "p33<CR>"

SerialOut (Com1,"p33"+chr(13),"",0,0)

'Flush the serial buffer

SerialFlush (Com1)

'Recieve serial string from SR50A

SerialIn (SR50AData,Com1,200,13,50)

SplitStr (ParseVals,SR50AData,"",5,0)

27

Page 34

SR50A Sonic Ranging Sensor

'Measure the 107 temperature sensor:

Therm107 (Air_Temp,1,1,Vx1,0,250,1.0,0)

'Use Air_Temp to calculate corrected distance:

Temp_Corr_Distance=Raw_Distance*(SQR((Air_Temp+273.15)/273.15))

'Subtract the corrected distance from the initial distance of the SR50A to the ground:

Snow_Depth=Initial_Distance - Temp_Corr_Distance

'Call Data Table and Store Data:

CallTable (Table1)

NextScan

EndProg

10.1.3 CR10X Example (SDI-12 “M1!”)

;{CR10X}

;

;In this example, the SR50A is mounted 2.5 meters above the ground.

;The CR10X sends an SDI-12 command to the SR50A, which outputs a

;non-temperature compensated distance value (Raw_Dist) and signal quality value.

;Two input locations are used to store incoming data.

*Table 1 Program

01: 60 Execution Interval (seconds)

;Measure the 107 temperature probe:

1: Temp (107) (P11)

1: 1 Reps

2: 1 SE Channel ;SE channel 1 used for this example

3: 1 Excite all reps w/E1 ;Excite channel 1 used for this example

4: 1 Loc [ T_Kelvin ]

5: 1.0 Multiplier

6: 273.15 Offset ;This converts the value to degrees Kelvin

;Use SDI-12 command "M1!" to receive Distance and Signal Quality from the SR50A

2: SDI-12 Recorder (P105)

1: 0 SDI-12 Address

2: 1 Start Measurement (aM1!)

3: 1 Port ;Use Ports 5-8 for CR23X

4: 3 Loc [ Raw_Dist ]

5: 1.0 Multiplier

6: 0.0 Offset

;Apply air temperature compensation to distance:

3: Z=F x 10^n (P30)

1: 273.15 F

2: 0 n, Exponent of 10

3: 5 Z Loc [ Ref_Temp ]

4: Z=X/Y (P38)

1: 9 X Loc [ T_Kelvin ]

2: 5 Y Loc [ Ref_Temp ]

3: 6 Z Loc [ Mult1 ]

28

Page 35

SR50A Sonic Ranging Sensor

5: Z=SQRT(X) (P39)

1: 6 X Loc [ Mult1 ]

2: 6 Z Loc [ Mult1 ]

;Distance to the Snow Surface is obtained by multiplying the temperature correction

;to the Raw Distance value

6: Z=X*Y (P36)

1: 3 X Loc [ Raw_Dist ]

2: 6 Y Loc [ Mult1 ]

3: 7 Z Loc [ DistToSnw ]

;Set the initial distance from the SR50A to the ground in meters:

7: Z=F x 10^n (P30)

1: 2.5 F

2: 00 n, Exponent of 10

3: 2 Z Loc [ DisToGnd ]

8: Z=X-Y (P35)

1: 2 X Loc [ DisToGnd ]

2: 7 Y Loc [ DistToSnw ]

3: 8 Z Loc [ SnowDepth ]

;Hourly Data Output

9: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 1 Set Output Flag High (Flag 0)

10: Set Active Storage Area (P80)^28428

1: 1 Final Storage Area 1

2: 60 Array ID

11: Real Time (P77)^30811

1: 1220 Year,Day,Hour/Minute (midnight = 2400)

12: Sample (P70)^20443

1: 1 Reps

2: 8 Loc [ SnowDepth ]

;The SR50A signal quality value can optionally be stored as well

13: Sample (P70)^22572

1: 1 Reps

2: 4 Loc [ Sig_Qual ]

*Table 2 Program

02: 0.0000 Execution Interval (seconds)

*Table 3 Subroutines

End Program

29

Page 36

SR50A Sonic Ranging Sensor

10.2 SR50AT Examples

10.2.1 CR1000 Example (SDI-12 “M4!”)

'CR1000 Series Datalogger

'The following sample program obtains the Snow depth output

'directly from an SR50AT sensor.

'This program is written for the SR50AT version only. For an SR50A

'sensor a valid depth can not be output unless a temperature value

'is passed from the datalogger to the SR50A via the extended SDI-12 command

'Declare Public Variables

Public PTemp, batt_volt

Public SR50ADistanceToGround

'Once the SR50AT is installed the Distance from the SR50AT to the

'Ground must be placed into this parameter. Once successfully transferred

'to the SR50AT the SR50AT will store the parameter in EE memory and retain

'the value even when power is removed.

Public NewDistanceToGround

Public SR50AReturnValues(3) as FLOAT

Public XtendedDistValStr as STRING * 16

Public ExtendedCMDResult as FLOAT

Alias SR50AReturnValues(1) = SR50A_SnowDepth_Meters

Alias SR50AReturnValues(2) = SR50A_QualityVal

Alias SR50AReturnValues(3) = SR50A_AirTempC

'Declare Other Variables

'Example:

'Dim Counter

Dim SDI12commandstring as STRING * 16

'Declare Constants

'Example:

'CONST PI = 3.141592654

'Define Data Tables

DataTable (Test,1,-1)

DataInterval (0,60,Sec,10)

Minimum (1,batt_volt,FP2,0,False)

Sample (1,PTemp,FP2)

Sample (1,SR50A_SnowDepth_Meters,IEEE4)

Sample (1,SR50A_QualityVal,FP2)

Sample (1,SR50A_AirTempC,IEEE4)

EndTable

30

Page 37

SR50A Sonic Ranging Sensor

'Main Program

BeginProg

Scan (60,Sec,0,0)

PanelTemp (PTemp,250)

Battery (Batt_volt)

'Once installed enter the actual distance from the SR50AT to the Ground with

'no snow present. If in doubt it is better to use a slightly larger value

'than a smaller value. Errors in the value will show up as an offset error

'in the snow depth values

'If a new value for the variable NewDistanceToGround is entered (non zero)

'The following code will send that value to the SR50AT.

If NewDistanceToGround > 0.0 then

'Convert the floating point value to a text string for the SDI-12 command

XtendedDistValStr = FormatFloat (NewDistanceToGround,"%4.3f")

'To send the Distance to ground (in meters) value to the SR50A the

'SDI-12 extended command is as follows:

'aXDM.MMM!- where M.MMM is the value such as 2.345 Meters

SDI12commandstring = "XM;" + XtendedDistValStr + "!"

'Send out the SDI-12 command to the sensor

SDI12Recorder (ExtendedCMDResult,1,0,SDI12commandstring,1.0,0)

'Read back the Distance to Ground value in the SR50A to confirm

SDI12Recorder (SR50ADistanceToGround,1,0,"R0!",1.0,0)

'If the Sensor is present confirm the value was sent correctly

'Never use more than 3 deciaml places of precision for the new value

If ExtendedCMDResult = 1.0 then

'Reset the value so that no more attempts will be made to update the

'Distance to Ground value.

NewDistanceToGround = 0.0

'Read back the Distance to Ground value from the SR50A to confirm.

'This is not necessary but recommended.

SDI12Recorder (SR50ADistanceToGround,1,0,"R0!",1.0,0)

EndIf

EndIf

'Read the Snow depth from the SR50A "M4!" command returns depth with

'quality and temperature

SDI12Recorder (SR50AReturnValues,1,0,"M4!",1.0,0)

'Call Output Tables

'Example:

CallTable Test

NextScan

EndProg

31

Page 38

SR50A Sonic Ranging Sensor

10.2.2 CR1000 Example (RS-232 Mode)

'CR1000 Series Datalogger

'In this example, the SR50AT is mounted 2.5 meters above the ground.

'The SR50AT is used in RS-232 mode (internal jumpers are set).

'The CR1000 sends a serial string to the SR50AT, which is in "Measure on Poll Mode",

'and then receives a serial string in return which is parsed into different values.

'Wiring: Black: Power Ground

' clear: Power Ground

' Red: +12V,

' White: C1

' Green: C2

'Declare Variables

'Declare SR50AData as a dimensioned string of maximum 50 chrs

Dim SR50AData as STRING * 50

Public ParseVals(6) as FLOAT

Alias ParseVals(1)=SerialAddress

Alias ParseVals(2)=Dist_To_Snow

Alias ParseVals(3)=SignalQuality

Alias ParseVals(4)=SR50AT_Temp

Alias ParseVals(5)=Diagnostics

Alias ParseVals(6)=Chcksum

Public Snow_Depth

'Declare the initial distance of the SR50AT from the ground in meters:

Const Initial_Distance=2.5

'Define Data Tables

DataTable (Table1,True,-1)

DataInterval (0,60,Min,10)

Sample (1,Snow_Depth,FP2)

EndTable

'Main Program

BeginProg

'Open RS232 port for communications 9600 BAUD is the default:

SerialOpen (Com1,9600,0,0,2000)

Scan (10,Sec,0,0)

'Measure the SR50A:

'Transmit serial command "p33<CR>"

SerialOut (Com1,"p33"+chr(13),"",0,0)

'Flush the serial buffer

SerialFlush (Com1)

'Recieve serial string from SR50A

SerialIn (SR50AData,Com1,200,13,50)

SplitStr (ParseVals,SR50AData,"",6,0)

32

Page 39

SR50A Sonic Ranging Sensor

'Subtract the corrected distance from the initial distance of the SR50A to the ground:

Snow_Depth=Initial_Distance - Dist_To_Snow

'Call Data Table and Store Data:

CallTable (Table1)

NextScan

EndProg

10.2.3 CR10X Example (SDI-12 “M3!”)

;{CR10X}

;

;In this example, the SR50AT is mounted 2.5 meters above the ground.

;

;The CR10X sends an SDI-12 command to the SR50AT, which outputs the

;temperature compensated distance value (Meters),

;the signal quality value and the temperature.

;

;Three input locations are used to store incoming data.

*Table 1 Program

01: 60 Execution Interval (seconds)

;Use SDI-12 command "M3!" to receive Distance, Signal Quality and Temperature

1: SDI-12 Recorder (P105)

1: 0 SDI-12 Address

2: 3 Start Measurement (aM3!)

3: 1 Port ;Use Ports 5-8 for CR23X

4: 3 Loc [ SR50ATDIS ]

5: 1.0 Multiplier

6: 0.0 Offset

;Set the initial distance from the SR50A to the ground in meters:

2: Z=F x 10^n (P30)

1: 2.5 F

2: 00 n, Exponent of 10

3: 2 Z Loc [ DisToGnd ]

;Subtract the Distance to the snow surface from the Distance to Ground

;to obtain snow depth

3: Z=X-Y (P35)

1: 2 X Loc [ DisToGnd ]

2: 3 Y Loc [ SR50ATDIS ]

3: 6 Z Loc [ SnowDepth ]

;Hourly Data Output

4: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

5: Set Active Storage Area (P80)^27063

1: 1 Final Storage Area 1

2: 60 Array ID

33

Page 40

SR50A Sonic Ranging Sensor

6: Real Time (P77)^30811

1: 1220 Year,Day,Hour/Minute (midnight = 2400)

7: Sample (P70)^20443

1: 1 Reps

2: 6 Loc [ SnowDepth ]

;Store the Signal quality value

8: Sample (P70)^23223

1: 1 Reps

2: 4 Loc [ Sig_Qual ]

;Store the Temperature reading from the SR50AT

9: Sample (P70)^1224

1: 1 Reps

2: 5 Loc [ SR50AT_T ]

*Table 2 Program

02: 0.0000 Execution Interval (seconds)

*Table 3 Subroutines

End Program

11. Warnings/Cautions

Never open the SR50A while the sensor is connected to power or any other

device. Always disconnect the SR50A via the connector or disconnect the

cable wires from their termination points.

34

Page 41

Page 42

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br • suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...