Page 1

Revision:01/2021

Copyright © 2019 – 2021

Campbell Scientific, Inc.

Page 2

Table of contents

1. General information 1

1.1 Packing list 1

1.2 General safety 1

1.3 Sensor unit safety 2

1.4 Laser safety 2

1.5 Electrical safety 4

2. Product overview 5

2.1 Introduction 6

2.1.1 Cloud height detection 6

2.1.2 Sky condition 7

2.1.3 Backscatter profile reporting 7

2.2 Optical measurement 8

2.2.1 Optical arrangement 8

2.3 Internal monitoring 8

2.4 Specifications 9

2.4.1 Measurement specifications 9

2.4.2 Mechanical specifications 9

2.4.3 Electrical specifications 10

2.4.4 Optical specifications 12

2.4.5 Environmental specifications 12

2.4.6 Communications specifications 12

2.4.7 Compliance and testing 13

3. Initial preparation and checks 14

4. Installation 15

4.1 Location and orientation 15

4.2 Grounding 15

4.3 Mounting the SkyVUE 8 16

4.4 Tilt angle 17

4.5 Connectors and wiring 18

4.5.1 Base connectors 18

4.5.2 Wiring using supplied Campbell Scientific cables 19

Table of Contents - i

Page 3

4.5.2.1 Power connections 20

4.5.2.2 Communications connections 21

4.5.3 USB connection 21

4.5.4 I/O connection 22

4.6 Connecting the back-up battery 22

4.7 Bird spike kit 23

4.8 Storage information 24

5. Operation 25

5.1 Terminal mode 25

5.1.1 Entering/exiting the SkyVUE 8 terminal mode 26

5.1.2 Terminal mode commands general 26

5.1.3 Terminal mode command examples 27

5.1.4 Application command message types 41

5.1.5 MCFG command message types 43

5.1.6 Measurement and message intervals 44

5.1.7 Status command 46

5.1.8 Message polling 54

5.1.9 Loading a new operating system (OS) 55

5.1.10 Stratocumulus backscatter calibration 56

5.1.11 CRC-16 codes on terminal commands 58

5.1.12 Service command 58

5.1.13 Locked features 60

5.2 Restoring factory defaults 60

5.3 LED indicator 61

6. Messages 62

6.1 Data messages general 62

6.2 Checksums used in SkyVUE 8 messages 62

6.3 CS messages 63

6.3.1 MESSAGE 001 (no profile, no sky condition) 63

6.3.2 MESSAGE 002 (Profile, no sky condition) 67

6.3.3 MESSAGE 003 (no profile, sky condition) 70

6.3.4 MESSAGE 004 (profile, sky condition) — default message 72

6.4 CL31 messages 76

6.4.1 MESSAGES 101 - 106, (CL31 MESSAGE 1) 76

6.4.2 MESSAGE 005 (no profile, sky condition, mixing layer heights) 77

6.4.3 MESSAGES 107 - 112, CL31 Message 2 81

Table of Contents - ii

Page 4

6.5 CT25K messages 85

6.5.1 MESSAGE 113, CT25K Data Message No. 1 85

6.5.2 MESSAGE 114, CT25K Data Message No. 6 88

7. Maintenance 90

7.1 General 90

7.2 Cleaning 90

7.3 Diagnostic LED indicators within the enclosure 91

7.4 Electrical safety testing 92

Appendix A. Measurement of the attenuated backscatter profile 93

A.1 Initial measurement 93

A.2 Backscatter onset height detection 93

A.3 Produce attenuated backscatter output message 94

Appendix B. Cloud height calculation 95

Appendix C. Sky condition algorithm description 96

Appendix D. Replacing the SkyVUE 8 PSU 98

Appendix E. SkyVUE 8 Laser/APD module replacement 100

List of figures

FIGURE 1-1. Location of laser warning label 4

FIGURE 2-1. Principle of operation 8

FIGURE 2-2. SkyVUE 8 dimensions 10

FIGURE 2-3. PSU types 11

FIGURE 4-1. Mounting base footprint 16

FIGURE 4-2. Setting the tilt angle 17

FIGURE 4-3. Connector layout 18

FIGURE 4-4. Cable connections 21

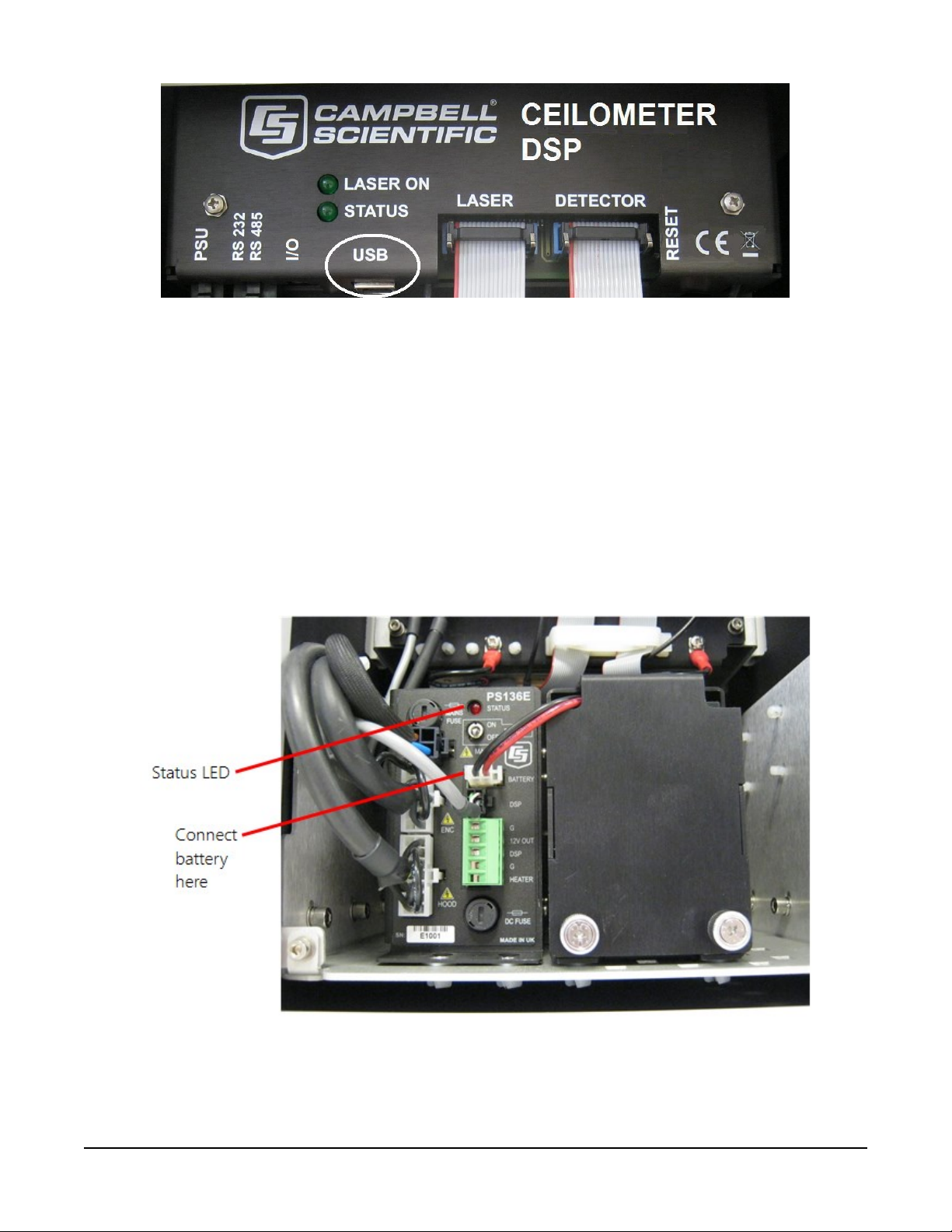

FIGURE 4-5. USB port 22

FIGURE 4-6. Connecting battery 22

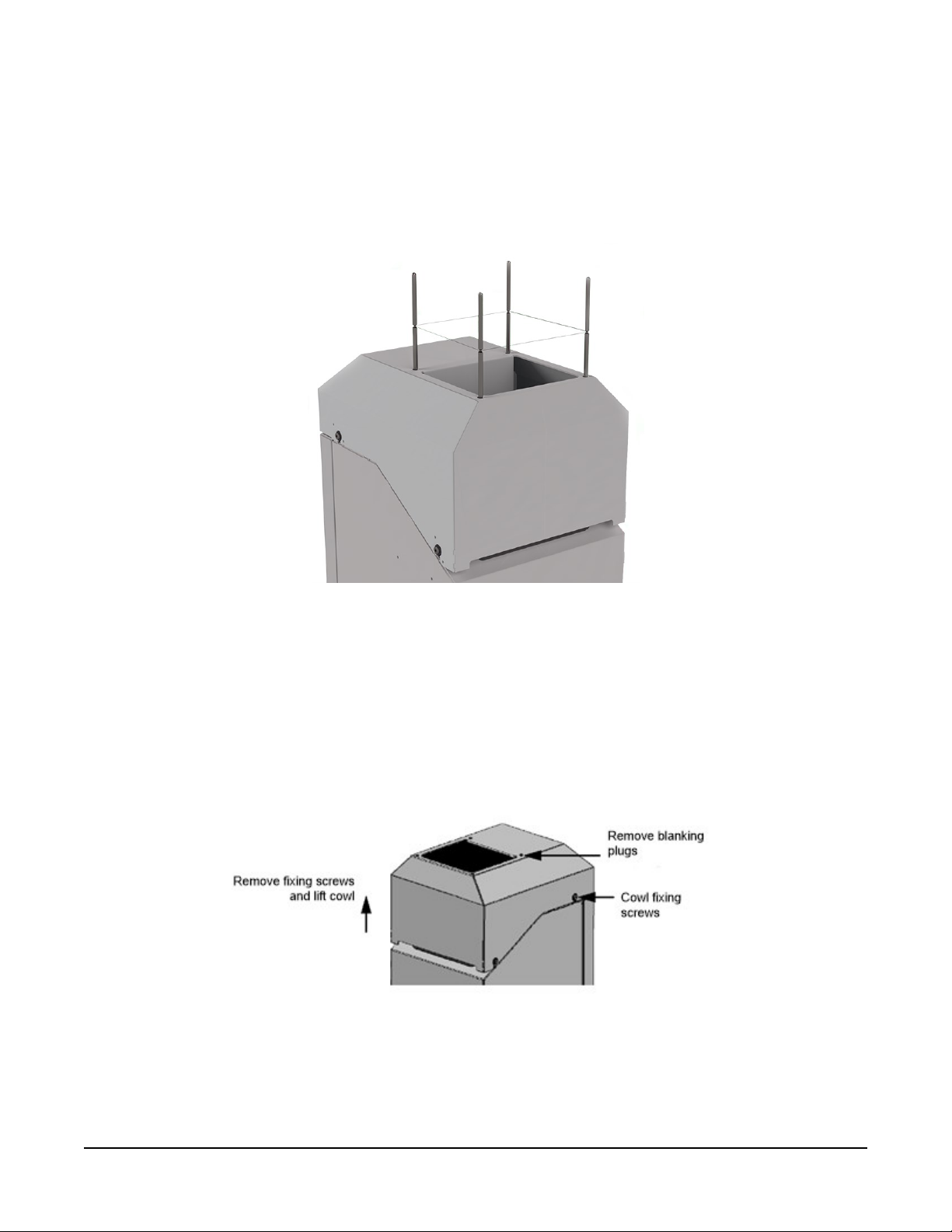

FIGURE 4-7. Ceilometer bird spike kit installed 23

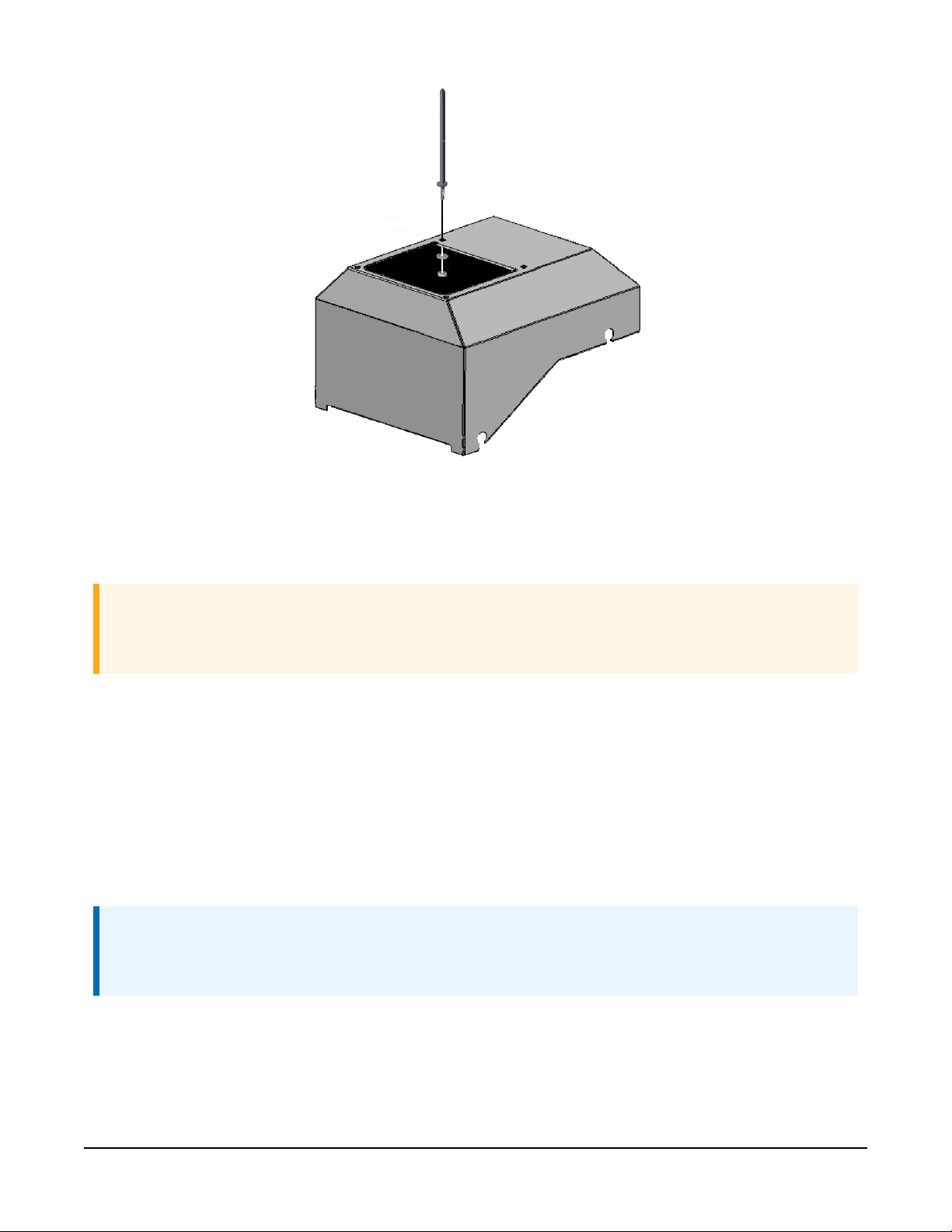

FIGURE 4-8. Preparing the SkyVUE 8 for installing the bird spikes 23

FIGURE 4-9. Attaching bird spikes to the SkyVUE 8 cowl 24

FIGURE 5-1. Restoring factory defaults 61

FIGURE 5-2. LED indicator 61

FIGURE 7-1. Diagnostic LED indicators 92

Table of Contents - iii

Page 5

List of tables

Table 1-1: Packing list 1

Table 4-1: Function of the connector pins for the mains connector 18

Table 4-2: Function of the connector pins for the blower/heater connector 19

Table 4-3: Function of the connector pins for the communications connector 19

Table 5-1: Summary of the terminal mode commands available 28

Table 5-2: Summary of applications and applied settings for SkyVUE 8 42

Table 5-3: Summary of message ID and descriptions 43

Table 6-1: Most significant alarm word for CS messages 64

Table 6-2: Middle alarm word for CS messages 65

Table 6-3: Least significant alarm word for CS messages 66

Table 6-4: Most significant alarm word for CS31 messages 78

Table 6-5: Middle alarm word for CS31 messages 79

Table 6-6: Least significant alarm word for CS31 messages 79

Table 6-7: Most significant alarm word for CT25K messages 86

Table 6-8: Second alarm word for CT25K messages 87

Table of Contents - iv

Page 6

1. General information

1.1 Packing list 1

1.2 General safety 1

1.3 Sensor unit safety 2

1.4 Laser safety 2

1.5 Electrical safety 4

1.1 Packing list

The following table lists the products shipped with the SkyVUE 8.

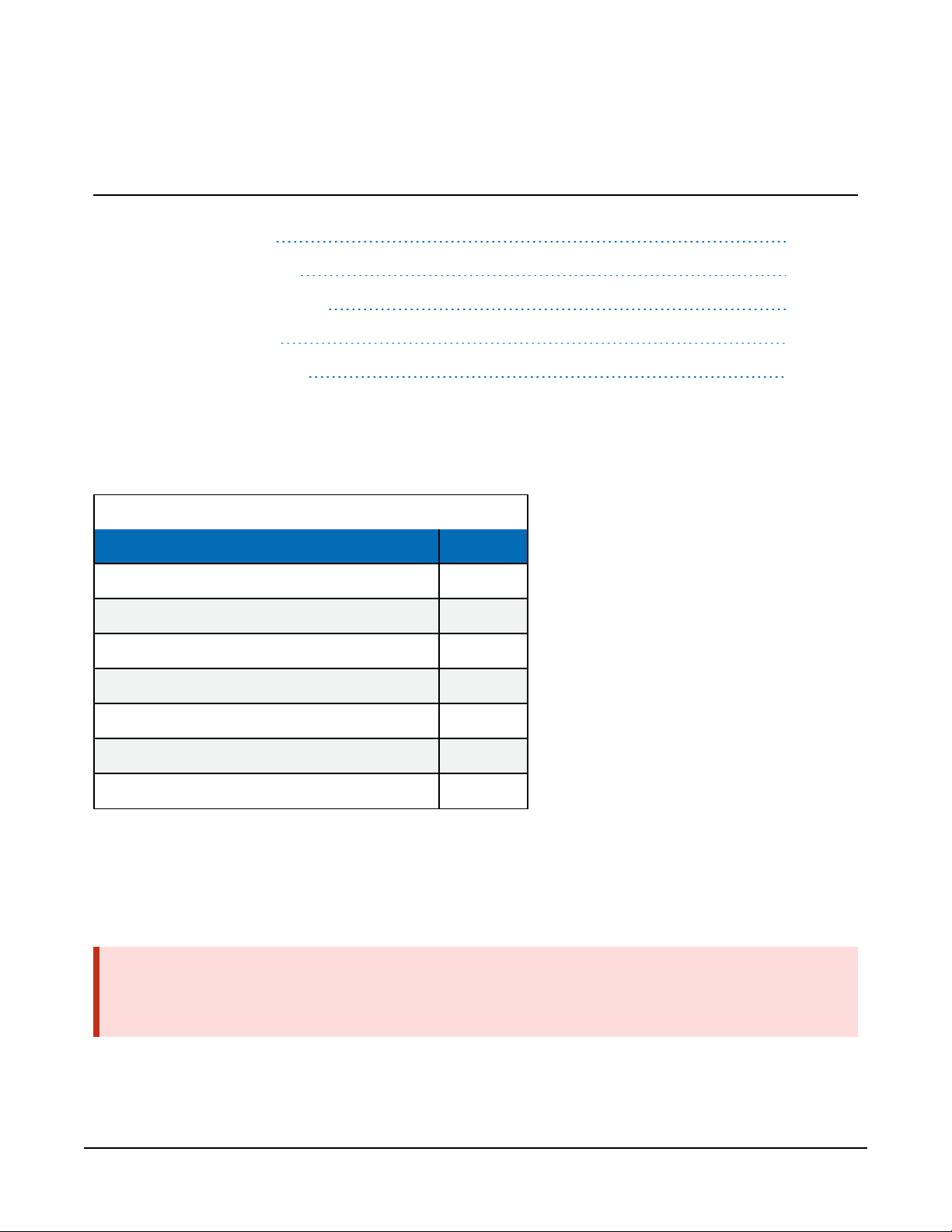

Table 1-1: Packing list

Description Quantity

Ceilometer 1

Power supply cable 1

Data cable 1

Bolt, sleeve anchor 4

Cable, USB type A plug to type B plug, 2 m 1

Triangle key 1

Calibration plate 1

1.2 General safety

This manual provides important safety considerations for the installation, operation and

maintenance of the SkyVUE™8. These safety considerations are classified into three levels:

WARNING:

Warnings alert the installer or user to serious hazards. Ignoring these warnings could result in

injury or death and/or irrevocable damage to the sensor unit.

SkyVUE™8 (CS136) LIDAR Ceilometer 1

Page 7

CAUTION:

Cautions warn of potential hazards. Ignoring these cautions could result in the sensor being

damaged and data being lost.

NOTE:

Notes highlight useful information in the installation, use and maintenance of this product.

These should be followed carefully in order to gain the maximum benefit from the use of this

product.

1.3 Sensor unit safety

The SkyVUE 8 sensor has been checked for safety before leaving the factory and contains no

internally replaceable or modifiable parts.

WARNING:

Do not modify the SkyVUE 8 unit. Such modifications will lead to damage of the unit and

could expose users to dangerous light levels and voltages.

WARNING:

Do not attempt to repair the SkyVUE 8 unit without consulting Campbell Scientific.

CAUTION:

Ensure that the correct voltage supply is provided to the sensor.

1.4 Laser safety

The SkyVUE 8 sensor incorporates an InGaAs laser diode which is rated as a class 3B device. This

is an embedded laser where the output from the sensor unit, through the optics, is minimized to

class 1M. This classification indicates that viewing of the beam with the naked eye is safe but

looking directly into the beam with optical instruments, e.g. binoculars can be dangerous.

From the laser head the output has the following characteristics:

Maximum average power: 15.0 mW (through 50 mm)

Maximum pulse energy: 1500 nJ (through 50 mm)

Pulse duration: 100 ns

Pulse frequency: 10 kHz

Wavelength: 912 nm ± 5 nm

Tested to: EN 60825-1:2014

SkyVUE™8 (CS136) LIDAR Ceilometer 2

Page 8

Half angle divergence: 0.44 mrad

The sensor is marked with the following warning information:

INVISIBLE LASER RADIATION

DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS

CLASS 1M LASER PRODUCT

IEC/EN 60825-1:2014

WARNING:

Removing the laser module with the power applied to the SkyVUE 8 or battery connected

may expose the user to hazardous class 3B laser radiation.

No attempt should be made to operate the laser module outside of the housing.

WARNING:

Annually, check that the laser warning label on the sensor is still visible and can be clearly

read.

When installing the sensor, avoid pointing the laser housing towards areas where binoculars

are in common use.

WARNING:

Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

SkyVUE™8 (CS136) LIDAR Ceilometer 3

Page 9

FIGURE 1-1. Location of laser warning label

Before removing the laser module, the sensor must be disconnected from both the mains supply

and the battery to ensure that the laser is turned off.

1.5 Electrical safety

Because the sensor is powered from potentially hazardous mains voltages, the power-supply

should be wired only by personnel qualified to install electrical equipment. For permanent

outside installations, this usually requires a certified electrician who is also familiar with local

electrical and safety legislation. Some general guidance is given in Connectors and wiring (p. 18),

but the responsibility for the installation lies with the installer.

The unit is tested for electrical safety before dispatch but may need subsequent testing according

to local practice.

NOTE:

The unit should only be serviced by trained personnel.

SkyVUE™8 (CS136) LIDAR Ceilometer 4

Page 10

WARNING:

Removal of electronic module covers or connectors while the unit is powered will expose the

operator to potentially hazardous voltages and risk damage to the sensor.

The SkyVUE 8 has electrical and laser warning labels on the exterior and interior of the unit.

It is fitted with a hex-key access panel. It is recommended that the hood and access panel door

are not opened in conditions of rain, hail or snow.

Isolate the sensor before removing internal components, including the cover to the avalanche

photodiode (APD) module. Only trained personnel should disassemble the instrument.

Mains connectors are shrouded to prevent touching of the contacts. The mains supply should be

isolated when connecting and disconnecting the cables to the sensor.

Where an isolator switch is fitted, this shall be a two-pole isolator, located as near to the sensor

as possible.

The SkyVUE 8 must be properly grounded by a licensed and qualified electrician to protect

against voltage leakage shock risk (Grounding (p. 15)).

Campbell Scientific recommends that RCD protection units be used with all sensors. See Power

connections (p. 20) for further information.

Mains powered heaters are enclosed to prevent contact.

CAUTION:

When powered, the heaters may operate automatically and without warning. They may

remain hot when not powered. Follow the isolation precautions, to avoid shock and burn

hazards.

The sealed battery has cables and protected connectors to prevent shorts. Avoid shorting the

battery to protect it from damage and to avoid burns to personnel through contact with hot

surfaces.

2. Product overview

2.1 Introduction 6

2.2 Optical measurement 8

2.3 Internal monitoring 8

2.4 Specifications 9

SkyVUE™8 (CS136) LIDAR Ceilometer 5

Page 11

2.1 Introduction

The SkyVUE 8 is a light detection and ranging (LIDAR) ceilometer that emits short pulses of near

infrared light into the atmosphere from a semiconductor laser. The pulses of infrared light are

scattered back by aerosols including cloud droplets. The time between transmission of the pulse

and the return signal gives the range, and therefore height, of the scattering aerosols. The

variation in the strength of the back-scattered light signal with height gives a profile of scatter

coefficients and allows identification of cloud bases. If significant scattering is detected without a

defined cloud base, then a vertical visibility can be calculated.

The control system of the SkyVUE 8 is divided into three modules, DSP, TOP and PSU as follows:

DSP (Digital Signal Processor) is the main data processing and communications unit of the

SkyVUE 8. It hosts two separate time keeping circuits that are cross checked. An alarm is triggered

if the circuits disagree.

TOP (top of the unit) provides safety shutdown features such as over and under laser output

level. It also contains the calibration circuitry and dirty windows system.

PSU (Power Supply Unit) controls the power supply including battery charging and deep

discharge protection.

The SkyVUE 8 has a rugged environmental enclosure that protects the instrument from the

harshest conditions and will measure the atmosphere with high stability and repeatability.

2.1.1 Cloud height detection

A scatter profile is measured as described in Measurement of the attenuated backscatter profile

(p. 93).

Cloud height detection is carried out as described in Cloud height calculation (p. 95). Up to four

cloud heights can be detected.

If clouds are not detected, the SkyVUE 8 will give one of these reports:

l No significant backscatter.

l Full obscuration determined but no cloud base detected. This is reported if the criteria for

detecting cloud base is not met but the integrated scattering coefficient reaches the limit

of vertical visibility below a set height limit. The default value is 2000m (6560ft) but can be

changed by the user. The height at which this occurs is given as vertical visibility.

l Some obscuration detected but determined to be transparent is reported if scattering is

detected but no cloud is detected and the calculated vertical visibility exceeds a set height

limit.

SkyVUE™8 (CS136) LIDAR Ceilometer 6

Page 12

If no cloud is detected but significant scattering is detected below 50m (160ft), then vertical

visibility is set to 0.

2.1.2 Sky condition

Sky condition is an assessment of cloud cover measured in units of eighths known as oktas. The

number of oktas is the density of cloud in eighths of that layer. The SkyVUE 8 can report up to

five layers of cloud when reporting sky condition. The algorithm used in the SkyVUE 8 follows

guidance in the ICAO 9837, Manual on Automatic Meteorological Observing Systems at

Aerodromes.

Sky condition is not an instantaneous measurement. It is based on cloud data for the previous 30

minutes, with cloud detection in the previous 10 minutes given an extra weighting. Therefore, sky

condition is not available until sufficient data has been collected. See Sky condition algorithm

description (p. 96) for more detail.

2.1.3 Backscatter profile reporting

Several possible data messages give the two-way attenuated backscatter profile. This consists of

2048 groups of five-character values (10,240 characters in total). Each character is 8 bits long and

therefore each 5 figure group is 40 bits. They are given as signed two complement integers and

numbers greater than 239–1 represent negative integers.

NOTE:

After 1600, the remaining groups are all of 00000.

Therefore, each group actually represents negative, a value between –239to +(239–1), rather than

0 to (240–1), which would be the case for unsigned, positive, 40-bit integers.

Apply the following two-stage process to correct the decimal value:

1. Convert the hexidecimal characters to a decimal number.

2. If the number resulting from this conversion is greater than 1048575, subtract

1,099,511,627,776, which is 240.

To use this backscatter coefficient in units of sr-1m-1, the sensor multiplies the calculated decimal

number by a factor of 10-8. The values are scaled by the Attenuated_SCALE parameter, see

Table 5-1 (p. 28).

NOTE:

The profile is not corrected for tilt angle even if cloud heights are corrected.

SkyVUE™8 (CS136) LIDAR Ceilometer 7

Page 13

2.2 Optical measurement

FIGURE 2-1. Principle of operation

2.2.1 Optical arrangement

The SkyVUE 8 uses a single biaxial lens design that increases optical signal-to-noise ratio, while

maintaining Class 1M eye safety by integrating larger optics into a compact package (see FIGURE

2-1 (p. 8)). Half of the lens is used by the transmitter, and the other half is used by the receiver.

This design provides an alternative to traditional two lens or common-optics designs. The optical

isolation of traditional biaxial systems is maintained to increase detector sensitivity, while the low

overlap onset height of common-optics systems is incorporated to allow measurements at close

ranges.

2.3 Internal monitoring

The SkyVUE 8 monitors window contamination, key voltages and currents, internal temperature

and relative humidity, and other parameters relevant to its performance. Data messages (see

Operation (p. 25)) include this information allowing remote diagnosis of the SkyVUE 8 condition.

In addition, a special status message can be polled.

SkyVUE™8 (CS136) LIDAR Ceilometer 8

Page 14

2.4 Specifications

2.4.1 Measurement specifications 9

2.4.2 Mechanical specifications 9

2.4.3 Electrical specifications 10

2.4.4 Optical specifications 12

2.4.5 Environmental specifications 12

2.4.6 Communications specifications 12

2.4.7 Compliance and testing 13

2.4.1 Measurement specifications

Maximum reporting range: 8 km (26,250 ft)

Minimum reporting resolution:

Hard target range accuracy:

Reporting cycle:

Cloud layers reported:

5 m (15 ft)

± 0.25% ± 4.6 m (15 ft)

2 to 600 s

Up to four layers reported

reported in Sky Condition.

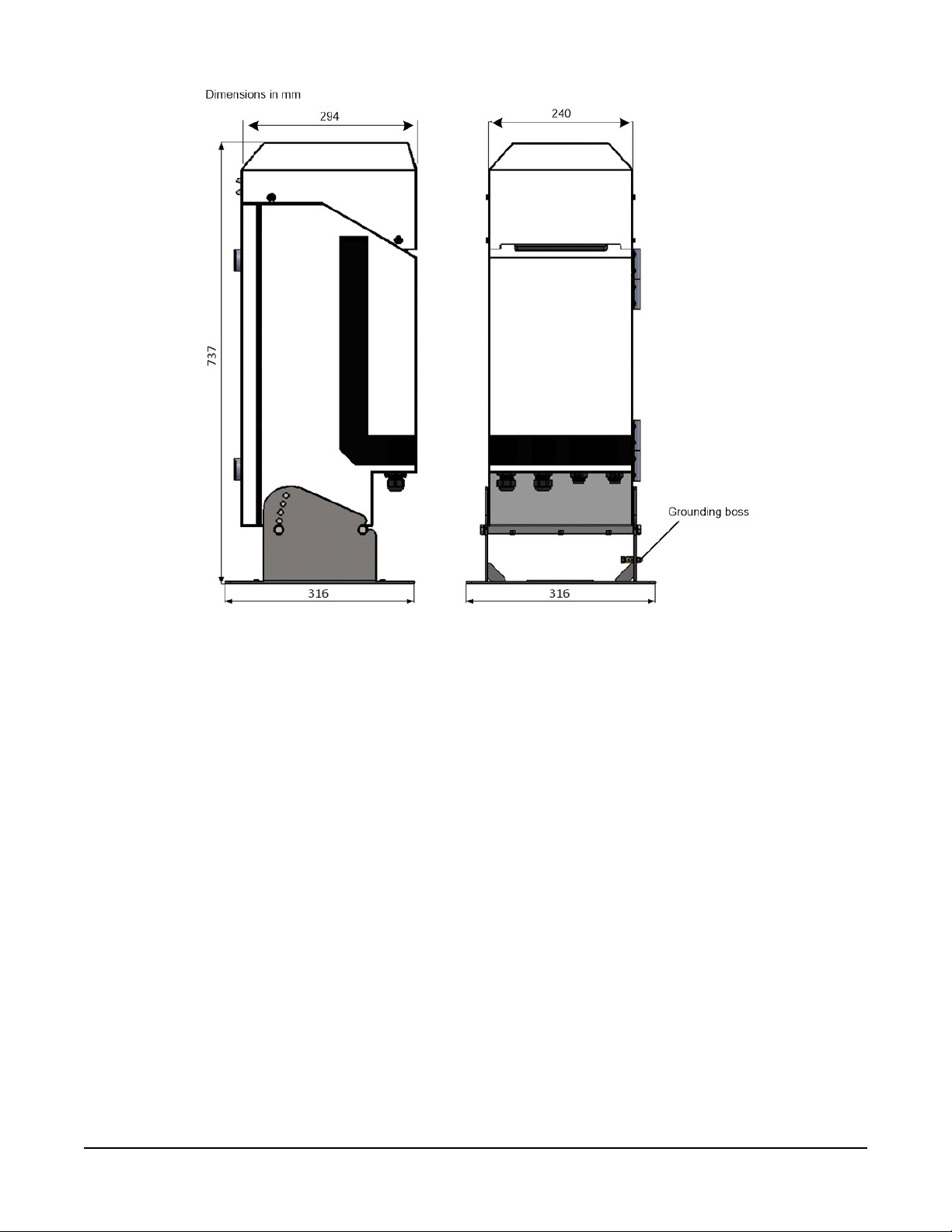

2.4.2 Mechanical specifications

Height: 737 mm (29 in)

Width: 294 mm (11.6 in)

Depth: 240 mm (9.5 in)

Total weight: 18 kg (40 lb)

Shipping weight: 24.6 kg (54 lb)

Base plate:

316 x 316 mm (12.4 in x 12.4 in)

, excluding cables

, instantaneously. Up to five layers

SkyVUE™8 (CS136) LIDAR Ceilometer 9

Page 15

FIGURE 2-2. SkyVUE 8 dimensions

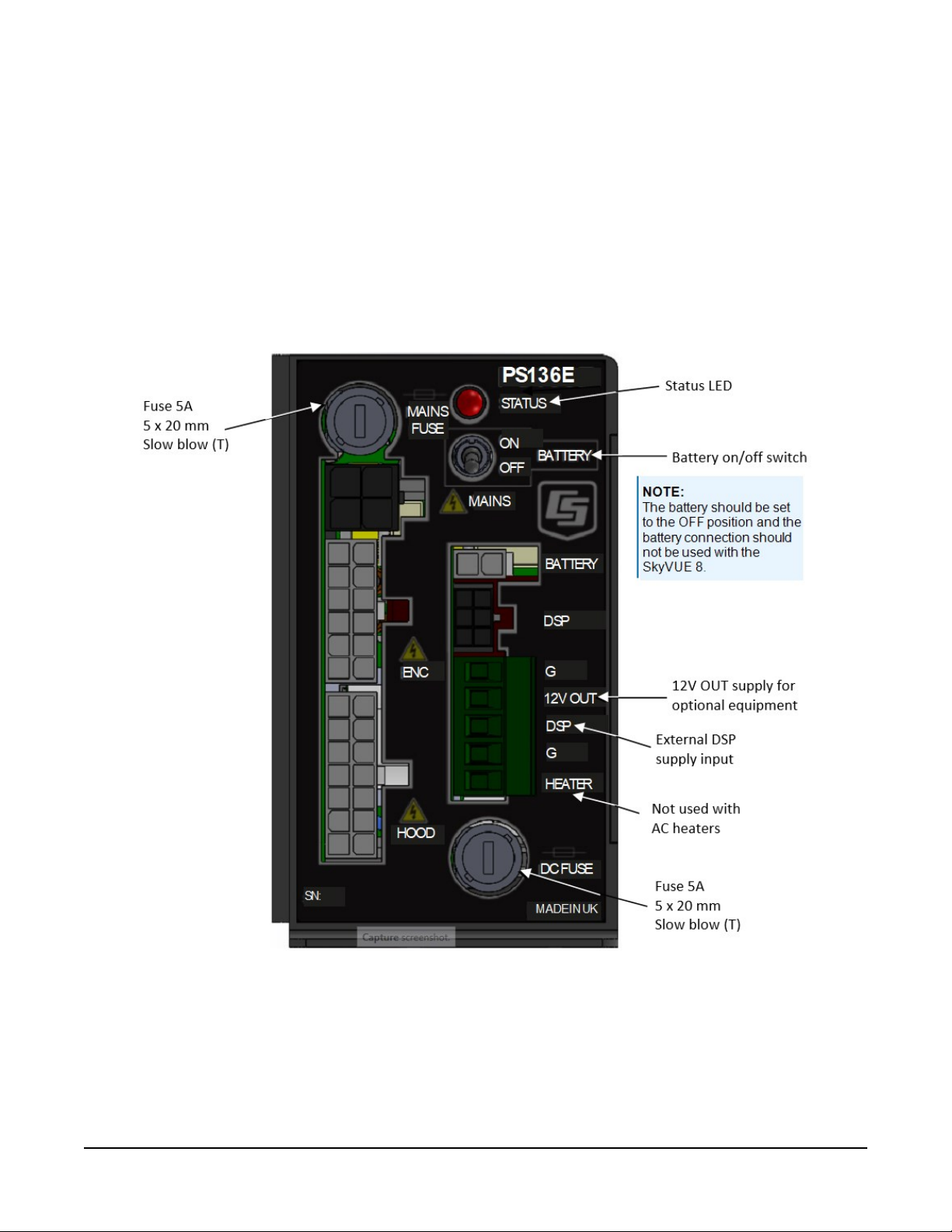

2.4.3 Electrical specifications

Power required: Nominal 115 VAC (106 to 137 VAC) or nominal 230 VAC (216

to 253 VAC) (automatic selection), 47 to 63 Hz, 380

maximum

W total

DSP:

12V OUT: 12 VDC /

Heater: Input not used with AC heaters.

Hood heater: 220

Internal heater: 110

Fuses:

DSP fuse:

10 to 40 VDC input;1A at 12 VDC;

1.7 A for optional or external equipment (if the

SkyVUE 8

14VDC for this to be available

W, maximum

HBC 5A (T)

is using a DC supply,

W, maximum

(not available in DC operation)

(not available in DC operation)

SkyVUE™8 (CS136) LIDAR Ceilometer 10

0.5

A at 24 VDC

this must be greater than

.)

Page 16

PSU fuse:

HBC5A(T)

All fuses are 5 x 20 mm slow blow (T) and are the same for

both 115VAC and 230VAC.

Battery:

The heaters are resistive, which is advantageous when connected to generators or when current

consumption is important.

Internal 12V, 7Ah sealed lead-acid battery. The power supply

is equipped with a system to prevent deep discharge of the

battery.

FIGURE 2-3. PSU types

SkyVUE™8 (CS136) LIDAR Ceilometer 11

Page 17

2.4.4 Optical specifications

Pulse duration:

Pulse frequency:

Wavelength:

Half-angle laser divergence: 0.44

Field of view: 2.0

Laser lifetime:

Eye safety class:

100 ns

10 kHz

912 ± 5 nm

mrad

mrad

10 years typical

1M

2.4.5 Environmental specifications

Standard operating

temperature range:

Battery temperature range:

Relative humidity range:

IP rating:

–40 to 60 °C

–20 to 50 °C (alternative battery types available)

0 to 100%

IP 66

(excluding battery)

Maximum wind speed:

55 m/s

2.4.6 Communications specifications

Supported serial settings:

Supported data rates: 300 baud 19200 baud

Supported standards:

8 bits, no parity, 1 stop bit (default)

7 bits, even parity, 1 stop bit

7 bits, odd parity, 1 stop bit

600 baud 38400 baud

1200 baud 57600 baud

2400 baud 76800 baud

4800 baud 115200 baud (default)

9600 baud

RS-232 (default)

RS-485 full duplex

RS-485 half duplex

SkyVUE™8 (CS136) LIDAR Ceilometer 12

Page 18

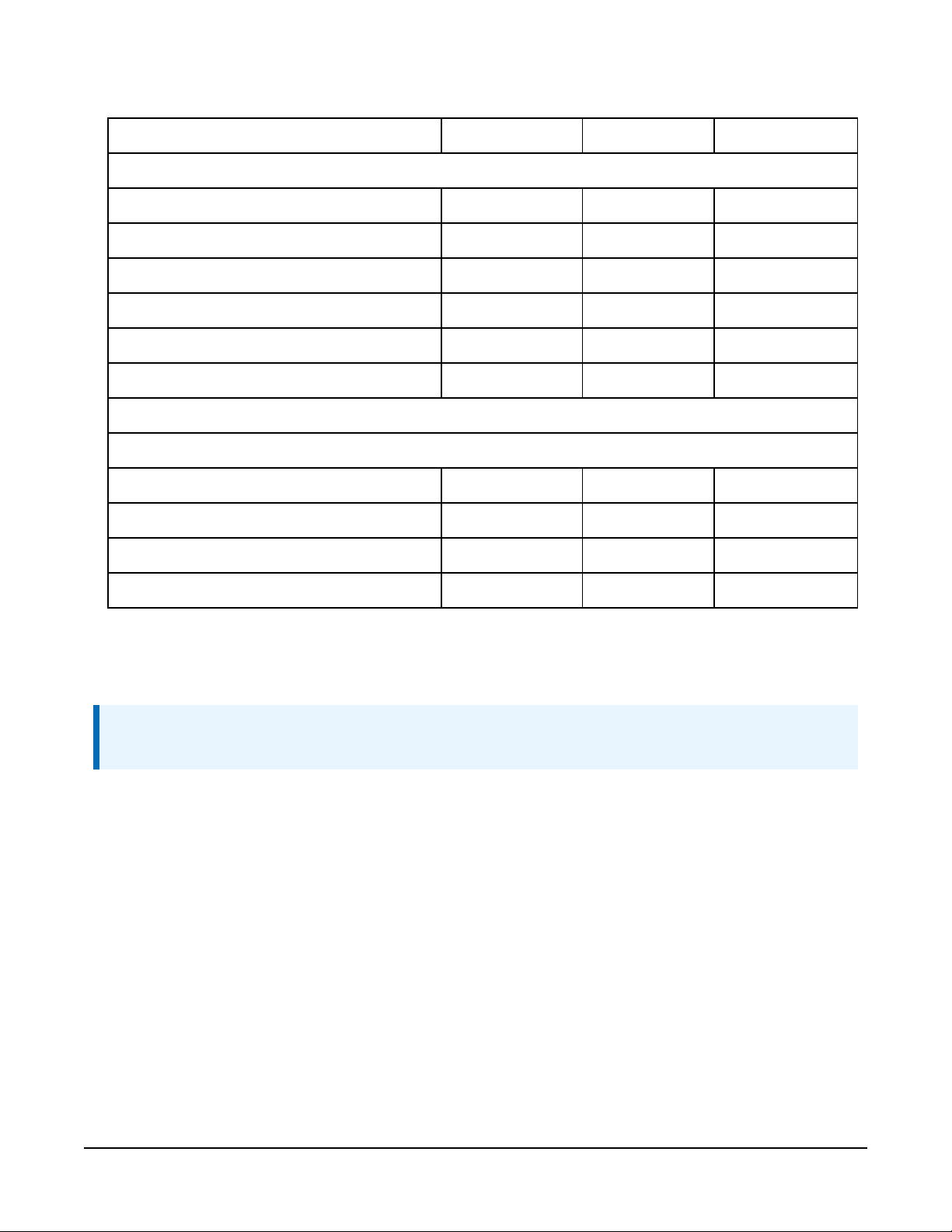

Signal voltage levels:

Minimum value Nominal value Maximum value

RS-232 communications

RS-232 input threshold low 0.8 V 1.5 V –

RS-232 input threshold high – 2.0 V 2.4 V

RS-232 input absolute maximum –15 V – +15 V

RS-232 input resistance 12 KΩ – –

RS-232 output voltage low – – 0.4 V

RS-232 output voltage high (into 3 KΩ) 4.4 V – –

RS-485/422 communications

RS-485/422 input threshold voltage –0.2 V – +0.2 V

RS-485/422 output (unloaded) – – 5V

RS-485/422 output (load 50 Ω) 2 V – –

Maximum voltage at any terminal –7 V – +7 V

USB Service Port USB1.1 and 2.0 compatible, fixed 115200 baud.

2.4.7 Compliance and testing

NOTE:

Further details regarding compliance and testing are available upon request.

EMC compliance:

Electrical safety compliance:

Laser safety compliance:

Eye safety standard:

Vibration:

Frequency range:

EN 61326-1:2013

EN 61010-1:2010

EN 60825-1:2014

Class 1M

BS EN 60068-2-6:2008 Test Fc: Vibration (Sinusoidal)

5 to 150 Hz (exceeds Lloyd's Register test levels)

SkyVUE™8 (CS136) LIDAR Ceilometer 13

Page 19

3. Initial preparation and checks

The following steps will provide basic familiarization with the SkyVUE 8 and perform basic

functionality checks. To do these, open the door and connect the battery (see Connecting the

back-up battery (p. 22)).

WARNING:

The laser begins operating as soon as the battery is connected. Do not point the laser in any

direction where it could be viewed with magnifying optics.

The green LED visible from above should flash once every 10 seconds (see FIGURE 5-2 (p. 61)).

Connect the SkyVUE 8 USB port (see FIGURE 4-5 (p. 22)) to a computer and use a terminal

emulation program to set to 115200 baud, 8N1 bits/parity settings.

The computer should identify the USB connection and allocate a port number. Enter the port

setting in the terminal emulator program. Older computer operating systems may need

upgrading or additional software.

The SkyVUE 8 will output message type 004 (default) every 30 seconds (see CS messages (p. 63)).

Use the open 0 command to open the terminal mode. You should now see the prompt CS136>.

Type Status to see the sensor status information described in Status command (p. 46). If using

date/time information, checked it since the date/time can drift up to ±14 seconds per day.

If the unit has been in storage or transit for more than a few months, the clock battery may be

discharged. However, it will charge from the back-up battery or mains power.

Use the Close command to exit the terminal mode. It will close automatically after 10 minutes of

inactivity.

If you are not installing the unit and connecting mains power, you should disconnect the battery

to avoid it being discharged.

SkyVUE™8 (CS136) LIDAR Ceilometer 14

Page 20

4. Installation

4.1 Location and orientation 15

4.2 Grounding 15

4.3 Mounting the SkyVUE 8 16

4.4 Tilt angle 17

4.5 Connectors and wiring 18

4.6 Connecting the back-up battery 22

4.7 Bird spike kit 23

4.8 Storage information 24

4.1 Location and orientation

The SkyVUE 8 measures environmental variables and is designed to be located in harsh weather

conditions. However, there are a few considerations to take into account if accurate and

representative data from a site are to be obtained.

To reduce the service frequency with the unit, place the SkyVUE 8 away from sources of

contamination. More regular maintenance will be required when the instrument is placed in

areas where contamination is unavoidable or where measurements may be safety related.

Take care that the orientation allows tilting in whatever direction is desired.

WARNING:

If installing at an airport, check and follow local guidance for allowed locations for a nonfrangible object 1 m (3.2 ft) tall. Please contact Campbell Scientific if frangible fittings are

required.

4.2 Grounding

The SkyVUE 8 must be properly grounded by taking a ground wire with a minimum cross

sectional area of 16mm2(0.62in) and maximum length of 10m (32.8ft) from the brass

grounding boss to an adequate grounding point. FIGURE 2-2 (p. 10)) shows the location of the

grounding boss.

SkyVUE™8 (CS136) LIDAR Ceilometer 15

Page 21

4.3 Mounting the SkyVUE 8

Mount the SkyVUE 8 by bolting to a firm, level foundation. When bolting down, ensure the

SkyVUE 8 can tilt in all desired directions. FIGURE 4-1 (p. 16) shows the mounting footprint. If a

suitable surface does not already exist, construct a concrete foundation, at least 600mm (23.6in)

square and 600mm (23.6in) deep, by using the following procedure:

1. Drill four 12mm (0.47in) diameter holes using the mount base as a template (see FIGURE

4-1 (p. 16)) to a depth of 77mm (3.03in).

2. Clean the holes of all debris.

3. Place washers and nuts on the ends of the wedge anchors supplied (to protect the threads

during installation).

4. Hammer the wedge anchors into the holes until the start of the threads are below the

surface.

5. Tighten the nuts until about 25mm (0.98in) of thread protrudes above the surface.

6. Remove the washers and nuts from the protruding length screw, then lower the SkyVUE 8

into place.

7. Secure the SkyVUE 8 with the washers and nuts.

8. If the surface is not level and flat, add washers under the base on one or more of the

foundation screws.

FIGURE 4-1. Mounting base footprint

SkyVUE™8 (CS136) LIDAR Ceilometer 16

Page 22

4.4 Tilt angle

The SkyVUE 8 can be tilted 6°, 12°, 18° or 24° from vertical. In tropical regions, tilting the sensor

north in the northern hemisphere and south in the southern hemisphere can prevent the sun

from shining directly into the sensor. The tilt angle also can reduce problems caused by direct

specular reflections from ice crystals, and prevent rain or snow from falling onto the window. To

adjust the tilt angle, remove the bolts shown in FIGURE 4-2 (p. 17), move the SkyVUE 8 to the

required tilt angle, and replace the bolts.

The SkyVUE 8 has tilt sensors in both axes to compensate the cloud height when the base is not

level. Set or disable cloud height compensation by using the UNITS command (Terminal mode

command examples (p. 27)). This feature is useful for mobile or marine applications. Profile data

is NOT compensated but tilt angles are included in data messages.

NOTE:

Increasing the tilt angle beyond 24° can cause significant errors in vertical visibility

measurements if scatter coefficients vary significantly with height.

FIGURE 4-2. Setting the tilt angle

SkyVUE™8 (CS136) LIDAR Ceilometer 17

Page 23

4.5 Connectors and wiring

4.5.1 Base connectors 18

4.5.2 Wiring using supplied Campbell Scientific cables 19

4.5.3 USB connection 21

4.5.4 I/O connection 22

4.5.1 Base connectors

The SkyVUE 8 has two connectors on its base. One connector (6 pins) is for communications;

another connector (4 pins) provides power to the unit.

NOTE:

Tilting the unit provides better access to these connectors.

FIGURE 4-3. Connector layout

The function of the connector pins is shown in Table 4-1 (p. 18), Table 4-2 (p. 19), and Table 4-3

(p. 19).

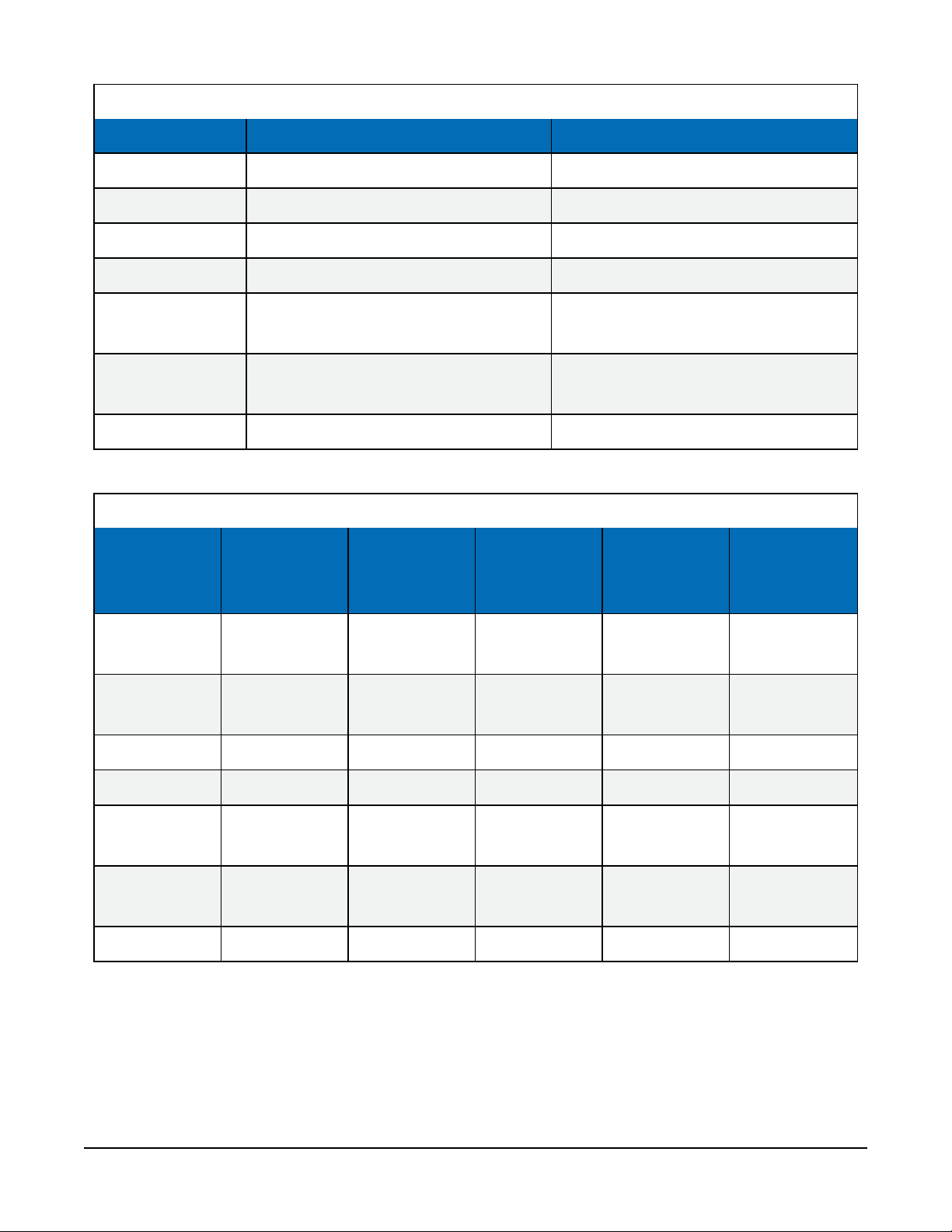

Table 4-1: Function of the connector pins for the mains connector

Pin Function Color of supplied cable cores

1 Live Brown

2 Not connected NA

3 Neutral Blue

4 Earth Green/yellow

SkyVUE™8 (CS136) LIDAR Ceilometer 18

Page 24

Table 4-2: Function of the connector pins for the blower/heater connector

Pin Function Color of supplied cable cores

1 Neutral Black (1)

2 Fan + 12 VDC Black (2)

3 Thermistor Black (3)

4 Thermistor (0 V) Black (4)

5

6

E Earth Green/yellow

Table 4-3: Function of the connector pins for the communications connector

Pin on

connector on

SkyVUE 8

1 Red 8

2 Yellow 7

3 Green 5 Gnd

Color of

supplied cable

cores

Switched 230/115 VAC

high voltage heater

Switched 230/115 VAC

low voltage heater

9-pin D

connector

Black (5)

Black (6)

RS-485 half

RS-232

duplex

CTS (DCE)

B/D+

output

RTS (DCE)

input

RS-485 full

duplex/

RS-422

Y/TXD

non-inverting

B/RXD

non-inverting

4 Black Gnd Gnd

5 White 2

6 Blue 3

E Screen

RXD (DCE)

A/D–

output

TXD (DCE)

input

Z/TXD

inverting

A/RXD

inverting

4.5.2 Wiring using supplied Campbell Scientific cables

Two cables are supplied, each 10m (32.8ft) long. One is for the mains power supply and the

other is for communications.

SkyVUE™8 (CS136) LIDAR Ceilometer 19

Page 25

WARNING:

Incorrectly wiring the power cable can cause irrevocable damage to the unit and can cause

serious injury or death.

WARNING:

The power cable must not be carrying mains voltage when it is being connected or

disconnected.

4.5.2.1 Power connections

The following is a guide for wiring and installing a permanent power supply.

As the sensor is used outside, a qualified electrician should install the power cables. Please check

local safety regulations.

Ensure that the termination type, cable type, and cable run of the mains power source complies

with local regulations and fits the installationrequirements.

The power source needs to provide the correct voltage, frequency, and current in excess of the

power requirement of the system.

Voltage requirements: 106 to 137 VAC or 216 to 253 VAC (auto select)

Power requirements: 380 W

Input frequency: 47 to 63 Hz

The power source needs fuses with ratings of 5A or larger and a slow-blow design. Cable

extensions or replacement cables should be capable of carrying current in excess of that fuse

rating.

Include a two-pole isolator as close to the sensor as is possible.

The power cable needs three conductors (live, neutral, and a protective earth), normally with IEC

wiring colors to match those used.

The equipment requires the connection of earth ground using the earth wire of the power

connector/cable or via the earth stud on the sensor base. Ensure the earth connection at the

power source is suitable for this purpose.

This equipment also requires correct connection of the live and neutral conductors — make sure

these are identified and wired correctly at the power source.

Normally, fit the power source with its own or system wide earth leakage breaker (also known as

an RCD).

For short term testing of the sensor, fit the power cable with a suitable plug can be fitted to the

end of the power cable and the sensor plugged into a standard mains supply capable of

SkyVUE™8 (CS136) LIDAR Ceilometer 20

Page 26

providing 5A at the rated voltage. If this is done, the earth wire of the sensor must be connected

to a suitable protective earth point.

For DC operation, the SkyVUE 8 requires a 10 to 40VDC supply capable of 1A at 12VDC or 0.5A

at 24VDC.

4.5.2.2 Communications connections

The communications cable terminates at one end with a removable 9-pin, D-connector (DB9).

The D-connector connects directly to a computer or data logger such as the Campbell Scientific

CR1000X using a suitable interconnecting cable such as the SC110. FIGURE 4-4 (p. 21). The

connector can easily be removed for direct connection to screw terminals.

See www.campbellsci.com/downloads/skyvue-example-programs for CRBasic programs that

connect the SkyVUE 8 to a Campbell Scientific data logger.

CAUTION:

The supplied cable is not recommended for lengths greater than 10m (32.8ft). Longer

RS-485 cables should incorporate twisted pairs. Contact Campbell Scientific if needing longer

cable lengths.

FIGURE 4-4. Cable connections

4.5.3 USB connection

The USB port provided inside the enclosure is for on-site maintenance. It supports

communication of commands to the SkyVUE 8 and responses in the same form as the main serial

port, except the baud rate is fixed at 115200 (see FIGURE 4-5 (p. 22)).

SkyVUE™8 (CS136) LIDAR Ceilometer 21

Page 27

FIGURE 4-5. USB port

4.5.4 I/O connection

The I/O port is only used for factory setting of the instrument.

4.6 Connecting the back-up battery

The SkyVUE 8 is shipped with the back-up battery disconnected and includes desiccant used for

transport. Before using the unit, open the door, connect the internal battery (FIGURE 4-6 (p. 22),

remove the desiccant, and close the door.

FIGURE 4-6. Connecting battery

SkyVUE™8 (CS136) LIDAR Ceilometer 22

Page 28

4.7 Bird spike kit

The optional bird spike kit deters birds from sitting on the SkyVUE 8. It includes four stainlesssteel spikes with rounded ends and a small reel of stainless-steel wire. The following figure shows

installed bird spikes.

FIGURE 4-7. Ceilometer bird spike kit installed

To install the bird spikes, remove the cowl and blanking plugs from the cowl (FIGURE 4-8 (p. 23).

If the SkyVUE 8 is an older unit without pre-existing holes, then drill four holes each 4.5mm

(0.17in) diameter, evenly spaced around the aperture and 10mm (0.39in) in from the edge. For

each hole, place a nut and washer then thread the spike into the hole. Tighten the nuts and

washers (see FIGURE 4-9 (p. 24)). Replace the cowl on the SkyVUE 8.

FIGURE 4-8. Preparing the SkyVUE 8 for installing the bird spikes

SkyVUE™8 (CS136) LIDAR Ceilometer 23

Page 29

FIGURE 4-9. Attaching bird spikes to the SkyVUE 8 cowl

Wrap the stainless steel wire around each spike using the grooves in the spike then wrap it back

on itself.

CAUTION:

Do not tighten the wire too much as it may pull the spikes inwards and obscure the field of

view of the SkyVUE 8 optics.

Only use one strand of wire to reduce the possibility of water drops being collected.

Check the wire during maintenance and replace if necessary.

4.8 Storage information

Store the SkyVUE 8 in a dry place at –40 to 70 °C, preferably with the enclosures securely

fastened. Protect the optics from possible accidental damage. Disconnect the back-up battery

when storing the SkyVUE 8.

NOTE:

If the battery remains connected during storage, the unit will be powered until the battery

voltage falls below a shut-down threshold.

SkyVUE™8 (CS136) LIDAR Ceilometer 24

Page 30

NOTE:

Storing the SkyVUE 8 below 0.0 °C will increase the start-up time by up to ten minutes. At –20

°C, the SkyVUE 8 will not achieve full accuracy for an hour.

NOTE:

Remove the battery if the SkyVUE 8 is to be stored outside the –20 to 50 °C temperature

range.

5. Operation

5.1 Terminal mode 25

5.2 Restoring factory defaults 60

5.3 LED indicator 61

5.1 Terminal mode

5.1.1 Entering/exiting the SkyVUE 8 terminal mode 26

5.1.2 Terminal mode commands general 26

5.1.3 Terminal mode command examples 27

5.1.4 Application command message types 41

5.1.5 MCFG command message types 43

5.1.6 Measurement and message intervals 44

5.1.7 Status command 46

5.1.8 Message polling 54

5.1.9 Loading a new operating system (OS) 55

5.1.10 Stratocumulus backscatter calibration 56

5.1.11 CRC-16 codes on terminal commands 58

5.1.12 Service command 58

5.1.13 Locked features 60

SkyVUE™8 (CS136) LIDAR Ceilometer 25

Page 31

5.1.1 Entering/exiting the SkyVUE 8 terminal mode

Use the OPEN Sensor_ID Password command to enter the menu system. The menu will

time out and close automatically if not used for ten minutes.

Sensor_ID is the SkyVUE 8 identification, a single character 0-9, a-f, A-F case sensitive. Default

is 0. Enter the password if using one. The following text should be displayed:

CS136>. The SkyVUE 8 is now ready for terminal mode commands.

The SkyVUE 8 commands are not case sensitive, but the parameters and password are case

sensitive.

Example of the open command followed by the 0 parameter:

OPEN 0

Example of the open command with the password Secret:

OPEN 0 Secret

5.1.2 Terminal mode commands general

Table 5-1 (p. 28) provides a summary of the terminal mode commands.

To send commands that setup and control the SkyVUE 8, use the terminal interface, data logger,

or terminal emulators built into many Campbell Scientific software products.

NOTE:

To load an operating system (OS), you need a terminal emulator with XMODEM protocol

such as Tera Term.

Use the following settings:

Setting RS-232/422/485 interface (default) USB service port

RS-232

Baud rate 115200 115200

Data bits 8 8

Parity none none

Stop bits 1 1

Flow control none none

The baud rate of the SkyVUE 8 must match the port setting baud rate in the terminal emulator.

The SkyVUE 8 should now be ready to accept commands.

SkyVUE™8 (CS136) LIDAR Ceilometer 26

Page 32

NOTE:

Commands will always output all parameters on a new line after a CR LF (carriage return and

line feed) and then the SkyVUE 8 prompt CS136>. If you only want to see parameter values

without changing them, then enter the command without parameters. If a particular

parameter did not need changing, then the parameter can be replaced with a comma (,).

Back space will abort the command.

5.1.3 Terminal mode command examples

How to enter a command

Example 1

The following text shows an example of setting up the SkyVUE 8 serial port. This example sets the

serial port to RS-232 hand shaking at 115200 bps, 8 data bits, no parity and if it was in RS-485

mode, then a 100ms turn around delay.

serial 0 10 0 100

You could also type the following to obtain the same results as the RS-485 turn around delay is

not needed:

serial 0 10 0

To change only the data baud rate, you can replace mode parameter, with a comma (,) as shown

below.

serial , 10

Alternatively if you just wished to change the parity to 8-bits no parity, then type the following:

serial , , 0

You do not need to replace the remaining parameters with a comma (,); you only need to replace

the ones up to the parameter you wish to edit.

NOTE:

Leave a space character between the command and the parameters as shown in the

examples.

Example 2

Entering the MCFG command, as shown below, will set the sensor to send messages at 10 second

intervals and to send one message only with the message number 112.

MCFG 10 112 0 0 0 0 (return)

The four zeros indicate that no other message outputs have been set. The MCFG command is

described in Table 5-1 (p. 28).

SkyVUE™8 (CS136) LIDAR Ceilometer 27

Page 33

Table 5-1: Summary of the terminal mode commands available

Command

ALARMS Angle

APPLICATION

parameter block

Application_n Application_n selects pre-configured user

Parameter/

Description

Angle is the threshold tilt angle of the sensor beyond

which an alarm will be flagged. The settable range is

0 to 90.0 degrees tilt and the default is 45.0 degrees.

settings optimized for a specific application. For the

following values of n:

0 = Help

10 = Aviation

20 = Research

40 = Meteorology

225 = User defaults

The default application for the SkyVUE 8 is 10,

Aviation. Settings adjusted by the APPLICATION

command include settings in BS, MCFG, and UNITS.

BS

(see

Measurement

and message

intervals (p. 44)

for more

information on

compatibility of

different

parameters)

Attenuated_

SCALE,

BS_Av_Time,

Noise_Gate,

Measurement_

Period,

Rolling_

Average,

Message_

Interval

BS_Temporal_

Filter_Mode

Rules for BS command are:

BS_Av_Time <= Measurement_Period-1s.

Message_Interval must be a multiple of

Measurement_Period.

Attenuated_SCALE is the scalar for the

attenuated backscatter percent. 0.001 to 100%

(default 100%)

BS_Av_Time is the backscatter average time in

seconds. 1 to 30 (default 7).

Note: Must not be greater than Measurement_

Period – 1.0

Noise_Gate controls the noise threshold applied

to back-scatter.

Noise_Gate = -1000, all backscatter range is

corrected.

SkyVUE™8 (CS136) LIDAR Ceilometer 28

Page 34

Table 5-1: Summary of the terminal mode commands available

Command

Parameter/

Description

parameter block

Noise_Gate = 0.0 to 1000.0, standard deviation

(default 2) for noise threshold. Only backscatter

above this is range corrected.

Measurement_Period = 0 or 2 to 600 seconds

(default 10). If set to 0 and the SkyVUE 8 is polled, it

will output the last measurement made. If between 2

and 600 seconds, the SkyVUE 8 continually outputs

messages. For sky condition output, Campbell

Scientific recommends setting the measurement_

Period ≤ 30 seconds. If a measurement_

Period is greater than 30 seconds, the sky condition

algorithm will be less able to resolve coverage for

higher layers.

Note: Must be a sub multiple of Message_

Interval

Rolling_Average = 1 to 29 (default 3). This is the

number of measurement_periods to use in a

rolling average of the backscatter.

Message_Interval is the message interval in

seconds. Range is 2 to 600 seconds (default 10 s); 0

gives polled messages.

Note: Must be a multiple of Measurement_

Period

BS_Temporal_ Filter_Mode allows the

selection of backscatter filtering modes.

0 = Averaging

1 = Median signal processing

Default setting is 1, the median mode for aviation.

CLOSE No parameters Closes the terminal interface to allow normal

message output and saves new settings to flash nonvolatile storage.

SkyVUE™8 (CS136) LIDAR Ceilometer 29

Page 35

Table 5-1: Summary of the terminal mode commands available

Command

CLOUDMODE CloudMode_A

DEFAULTS

GETUSER

Parameter/

parameter block

No parameters Loads factory defaults

Description

CloudMode_A turns on a filter that reports the

highest cloud during precipitation to avoid

precipitation from being reported as low cloud.

0 = Filter Off

1 = Filter On (default). Reports the highest cloud

during precipitation

Reads all user settings as a string of text. Parameters

are read in the following order:

user = text user

volVer = user volume version

OS_VER = DSP OS version

PsuOsVer = PSU OS version

TopOsVer = TOP OS version

Id = SkyVUE 8 ID

Pw = SkyVUE 8 password

terminalCrc = terminal crc mode

terminalTimeout = terminal timeout

unitsTiltMode = units and tilt mode

hoodHBMode = hood heater / fan heater mode

hoodHBTestInt = hood heater / blower test

interval in hours

battBoost_mV = boost voltage used for battery

charging mV

battCharge_mA = battery charge current mA

psuPresent = PSU present switch

hoodHBNormSpeed = fan voltage for normal

speed mV

SkyVUE™8 (CS136) LIDAR Ceilometer 30

Page 36

Table 5-1: Summary of the terminal mode commands available

Command

Parameter/

Description

parameter block

hoodHBHighSpeed = fan voltage for high speed

mV

hoodHBLowSpeed = fan voltage for low speed mV

intHMode = internal heater mode

message[0] = fields for message 0

message[1] = fields for message 1

message[2] = fields for message 2

message[3] = fields for message 3

message[4] = fields for message 4

messagePeriod = output message period in

seconds

heightOffset= height offset meters

bsAvTime= backscatter average time in seconds

laserMode = laser operation mode

laserPower = laser power

laserHeater = laser heater mode

attenuatedSCALE = attenuated backscatter

scaling factor

logInterval = debug logging interval

measurementPeriod = measurement interval in

seconds

serMode = serial port mode

baudSel = serial port baud rate mode

dataParityStop = serial port parity mode

rx2txTimeout = serial port RX to TX turnaround

time

snrMarginBoundary = onset of backscatter

detection threshold

SkyVUE™8 (CS136) LIDAR Ceilometer 31

Page 37

Table 5-1: Summary of the terminal mode commands available

Command

Parameter/

Description

parameter block

snrMarginDetector = cloud detection threshold

alphaGuessEnd = cloud alpha guess at boundary

alphaMin = cloud detection alpha minimum

Vcld_D = cloud detection

delta_Vcld_D = cloud detection

vis_Av_T = cloud detection

alphaGuess = visibility initial alpha guess

ratioLevel = visibility ratio

alphaMin = visibility alpha minimum

cap = visibility cap in meters

tiltLimit = tilt limit in degrees used by alarms

noiseGate = attenuated backscatter noise gate

mode

vvLimit_percent = sky condition report vertical

visibility %

alphaGuessStart= cloud detection alpha guess

at lowest height bin

reserved

reserved

reserved

reserved

reserved

reserved

cloudMode = cloud detector mode parameter

(03072019a)

CRC = 4-digit character. CRC calculated from the u

up to but not including the CRC using the standard

CRC-16.

SkyVUE™8 (CS136) LIDAR Ceilometer 32

Page 38

Table 5-1: Summary of the terminal mode commands available

Command

Parameter/

Description

parameter block

Note: Many parameters are not adjusted. This

command allows a reliable technique for copying

full settings from one SkyVUE 8 to another with the

SETUSER command.

A typical response to the GETUSER command is:

>>>>> COPY FROM START OF NEXT LINE >>>>>

user 7 007638-6da 106 510 0 , 0 10 2 0 1 14520 400 1

1000 1000 2000 0 1 0 0 0 0 10 0.000E+00 2.000E+00 1

1.000E+00 0 1.000E+00 0 10 1 0 10 0 100 4.000E+00

6.000E+00 2.000E-03 2.500E-04 1.000E+03 2.200E+01

4.800E+03 1.000E-01 9.000E-01 2.500E-04 2.000E+03

4.500E+01 2.000E+00 50 2.00E-03 3.000E+01

1.500E+02 1.800E+00 5.000E+00 1.000E+01 150 98b2

<<<<< TO START OF THIS LINE <<<<<

HEATERS Hood

Internal

Laser

Test_interval

HELP

No parameters Calls up a list of user commands with brief

Sets or reads heater settings as follows:

Hood = 0, Hood blower and heater OFF

Hood = 1, Hood blower ON and heater OFF

Hood = 2, Hood blower ON and heater ON

Hood = 3, Hood blower and heater AUTO (default)

– (see note (1) below).

Internal = 0, Internal heater OFF

Internal = 1, Internal heater ON

Internal = 2, Internal heater AUTO (default)

Laser = 0, laser heater off

Laser = 1, laser heater on (default)

Test_interval = 1 to 168 hours (default 24

hours). Heater/Blower test interval

descriptions

SkyVUE™8 (CS136) LIDAR Ceilometer 33

Page 39

Table 5-1: Summary of the terminal mode commands available

Command

HOFFSET Height_offset

ID Sensor_ID

LASER Laser

LASEROFF

Parameter/

parameter block

Laser_Power

No parameters Instructs the SkyVUE 8 to turn the laser off until either

Description

Height_offset is the offset to be added or

subtracted in the range of ±1000 m (±3281 ft).

Positive values are added to measured height and

negative values are subtracted from measured height.

The default is 0.

Reads or sets the sensor ID, a single character, 0-9, a z or A - Z, case sensitive. Default ID = 0.

Note: Lower case letters are not allowed if using a

CT25K message.

Laser = 0, laser off after power up (user must

switch laser on)

Laser = 1, laser on after power up (default)

Laser_Power = 20% to 100%, default 100%

a power cycle or the sensor is instructed to turn the

laser back on.

LASERON

LOADOS Module

MCFG Message_

No parameters Instructs the SkyVUE 8 to try and turn the laser on

Interval

Message_ID_A

Message_ID_B

Message_ID_C

Message_ID_D

Message_ID_E

Loads new operating system.

This command must be sent using XMODEM

protocol. Refer to Loading a new operating system

(OS) (p. 55) for more information.

Set or read message configuration

Message_Interval is the message interval in

seconds. Range is 2 to 600 s (default 10); 0 gives

polled messages.

Note: This command may affect measurement

parameters within the BS command. See

Measurement and message intervals (p. 44).

Message_ID is the message type to output

between 0 and 999 (default 001). If Message_ID =

SkyVUE™8 (CS136) LIDAR Ceilometer 34

Page 40

Table 5-1: Summary of the terminal mode commands available

Command

Parameter/

parameter block

OPEN ID

Password

PASSWORD Password

Description

0, no message type is output. Up to five messages can

be set (refer to MCFG command message types (p.

43)).

Opens the SkyVUE 8 terminal mode

ID = Sensor ID as per the terminal ID command.

AnySkyVUE 8 with firmware OS2 or newer will

respond to global ID = 99, regardless of its own ID

number.

Password = The sensors user password as per the

terminal PASSWORD command. The default is no

password.

Sets or clears a password from 1 to 10 characters in

length. Valid characters, 0-9, a - z or A – Z, and letters

are case sensitive. Typing the PASSWORD command

without any parameters clears the password. The

default is no password.

POLL Sensor_ID

Message_ID

POWEROFF

REBOOT

No parameters Prepares the PSU to power down the SkyVUE 8 even

No parameters Forces a system reboot. This will restore previously

Requests Message_ID from Sensor_ID.

Refer to Message polling (p. 54) for more information

on this command

Note: If Message_ID is omitted, the SkyVUE 8

outputs the message configured by MCFG.

if the battery is connected. As soon as the mains

supply is disconnected, the SkyVUE 8 will power off

and NOT run on battery back-up. The SkyVUE 8 can

be re-activated with battery back-up enabled by

reconnecting the mains supply. You will be asked to

confirm.

saved user settings. Any unsaved changes will be lost.

(Settings are saved in the terminal mode when the

SkyVUE™8 (CS136) LIDAR Ceilometer 35

Page 41

Table 5-1: Summary of the terminal mode commands available

Command

SCCAL

SERIAL Mode

parameter block

No parameters but

user interaction

required

Baud

Bits_Parity

Delay

Parameter/

Description

CLOSE command is typed, which exits the terminal

mode).

Stratocumulus backscatter calibration.

This requires a human observer to confirm a stable

Stratocumulus cloud layer between 250 m to 2500 m

without holes, precipitation or reduced visibility and

has been stable for at least 10 minutes prior to

running this command. See Stratocumulus

backscatter calibration (p. 56) for more information.

Set or read the serial port.

Mode = 0, RS-232, full duplex (default)

Mode = 1, RS-232, half duplex

Mode = 2, RS-485, full duplex

Mode = 3, RS-485, half duplex

Mode = 4, reserved

Mode = 5, RS-422, full duplex

Baud = 0, 300 baud

Baud = 1, 600 baud

Baud = 2, 1200 baud

Baud = 3, 2400 baud

Baud = 4, 4800 baud

Baud = 5, 9600 baud

Baud = 6, 19200 baud

Baud = 7, 38400 baud

Baud = 8, 57600 baud

Baud = 9, 76800 baud

Baud = 10, 115200 baud (default)

Bits_Parity = 0, 8 bits, no parity, 1 stop bit

SkyVUE™8 (CS136) LIDAR Ceilometer 36

Page 42

Table 5-1: Summary of the terminal mode commands available

Command

SERVICE

SETUSER

Parameter/

parameter block

(default)

Bits_Parity = 1, 7 bits, even parity, 1 stop bit

Bits_Parity = 2, 7 bits, odd parity, 1 stop bit

Delay = delay time, in milliseconds, before

transmitting (RS-485 half-duplex mode only). Range:

0 to 100 ms (default 100 ms).

No parameters but

user intervention

required

String Load all user settings as a string of text.

Performs a service procedure

(not changed) = parameter will not be updated and

the previously set value will persist.

String = user (not changed)

Description

volVer = user volume version (not changed)

OS_VER = DSP OS version (not changed)

PsuOsVer = PSU OS version (not changed)

TopOsVer = TOP OS version (not changed)

Id = SkyVUE 8 ID (not changed)

Pw = SkyVUE 8 password (not changed)

terminalCrc = terminal crc mode

terminalTimeout = terminal timeout

unitsTiltMode = units and tilt mode

hoodHBMode = hood heater / fan heater mode

hoodHBTestInt = hood heater / blower test

interval in hours

battBoost_mV = boost voltage used for battery

charging mV

battCharge_mA = battery charge current mA

SkyVUE™8 (CS136) LIDAR Ceilometer 37

Page 43

Table 5-1: Summary of the terminal mode commands available

Command

Parameter/

Description

parameter block

psuPresent = PSU present switch

hoodHBNormSpeed = Fan voltage for normal

speed, mV

hoodHBHighSpeed = Fan voltage for high speed,

mV

hoodHBLowSpeed = Fan voltage for low speed,

mV

intHMode = internal heater mode

message[0] = fields for message 0

message[1] = fields for message 1

message[2] = fields for message 2

message[3] = fields for message 3

message[4] = fields for message 4

messagePeriod = output message period in

seconds

heightOffset = height offset meters

bsAvTime = backscatter average time in seconds

laserMode = laser operation mode

laserPower = laser power

laserHeater = laser heater mode

attenuatedSCALE = attenuated backscatter

scaling factor

logInterval = debug logging interval

measurementPeriod = measurement interval in

seconds

serMode = serial port mode

baudSel = serial port baud rate mode

dataParityStop = serial port parity mode

SkyVUE™8 (CS136) LIDAR Ceilometer 38

Page 44

Table 5-1: Summary of the terminal mode commands available

Command

Parameter/

Description

parameter block

rx2txTimeout = serial port RX to TX turnaround

time

snrMarginBoundary = onset of back-scatter

detection threshold

snrMarginDetector = cloud detection threshold

alphaGuessEnd = cloud alpha guess at boundary

alphaMin = cloud detection alpha minimum

Vcld_D = cloud detection

delta_Vcld_D = cloud detection

vis_Av_T = cloud detection

alphaGuess = visibility initial alpha guess

ratioLevel = visibility ratio

alphaMin = visibility alpha minimum

cap = visibility cap in meters

tiltLimit = tilt limit in degrees used by alarms

noiseGate = attenuated backscatter noise gate

mode

vvLimit_percent = sky condition report vertical

visibility %

alphaGuessStart = cloud detection alpha guess

at lowest height bin

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

cloudMode = cloud detector mode parameter

SkyVUE™8 (CS136) LIDAR Ceilometer 39

Page 45

Table 5-1: Summary of the terminal mode commands available

Command

STATUS

Parameter/

Description

parameter block

(03072019a)

CRC = 4-digit character. CRC calculated from the u

up to but not including the CRC using the standard

CRC-16.

Note: String is added as text and should be cut and

pasted from a stored file.

No parameters Outputs SkyVUE 8, serial number, ID, DSP OS version,

Time and Date, DSP version, TOP OS version, PSU OS

version, watch dog counts, serial parameters, blower

heater mode, internal heater mode, message

parameters, tilt angle, units, temperature/humidity,

temperatures, supply voltages, height offset, visibility

cap, laser run days, window parameters, backscatter

parameters, features, alarms, warnings, and status.

TERMINAL Terminal

Timeout

TIME

UNITS

Date_Time Date is in the format yyyy/mm/dd

Units Sets measurement units and tilt correction

Note: Refer to Status command (p. 46) for more

information on this command

Sets the user terminal time out.

Timeout is the delay in minutes from 1 to 15 where

the terminal will automatically close if no characters

are sent to the SkyVUE 8. The default is 10 minutes.

Time is in the format hh:mm:ss

yyyy=year, mm=month, dd=day

hh=hours, mm=minutes, ss=seconds

For example: time 2013/05/25 10:00:00, sets the date

and time to May 25, 2013 at 10:00:00)

Note: The set time could drift by up to ±14 seconds

a day.

Units = 0, meters corrected by tilt

SkyVUE™8 (CS136) LIDAR Ceilometer 40

Page 46

Table 5-1: Summary of the terminal mode commands available

Command

UNLOCK

VIS

NOTE:

If AUTO is set, then the heater / blower will heat to 80 °C if (sky condition > 1 okta coverage)

or (cloud height <3km (9842ft) AND sky condition > 1 okta coverage) OR window Tx <80%

OR precipitation detected. When the event has passed, the blower/heater will remain active

at 80°C for a further 15 minutes before going into a fan-off state and the heater temperature

drops to an average of approximately 40°C, ready to be activated again.

Parameter/

Description

parameter block

Units = 1, meters not corrected by tilt

Units = 2, feet corrected by tilt (default)

Units = 3, feet not corrected by tilt

Key Key = a 12 digit key purchased from Campbell

Scientific. The key unlocks features such as Mixing

Layer Height assessment.

The key is specific to the individual SkyVUE 8 and

only has to be entered once.

Cap Cap is the vertical visibility maximum range 100 to

10000 in meters or 328 to 32808 in feet (default 2000

m or 6561 ft).

5.1.4 Application command message types

The Application_n parameter for the APPLICATION command defines settings to optimize

the ceilometer for a range of applications, Aviation, Research and Meteorology. The default

application setting for the SkyVUE 8 is Aviation, but this can be changed, or returned to, using

the Application_n command.

Users can adjust any element of these settings once an application has been applied through the

following individual commands:ALARMS, BS, CLOUDMODE, MCFG and UNITS.

SkyVUE™8 (CS136) LIDAR Ceilometer 41

Page 47

Table 5-2: Summary of applications and applied settings for SkyVUE 8

Application modes for SkyVUE 8

using OS2 and newer

Aviation

Settings

(default)

ALARMS (tilt degs) 30 45 45 45

APPLICATION: Application n (sets

user application settings)

BS: Attenuated scale (%) 100 100 100 100

BS: Backscatter averaging time (s) 2 7 7 7

BS: Noise Gate 2 (ON) -1000 (OFF) -1000 (OFF) -1000 (OFF)

BS: Measurement

Period (s)

BS: Rolling Averages (sets the

number of readings for averaging.

Alternative description:

Backscatter temperal filter rolling

samples

Application10Application20Application

10 10 10 10

3 6 3

Research Meteorology

40

Defaults using

OS1

General

application

N/A

3

BS: Message Interval (s) 30 30 30 30

BS: BS_Temporal_ Filter_Mode

(Sets Averaging or Median Mode.)

CLOUDMODE: CloudMode_A

(Reports highest cloud only

during precipitation)

MCFG: Message ID

UNITS

1 (Median) 0 (Average) 0 (Average)

ON OFF ON N/A

4

(CB,SC,BS)

2 (Feet, tilt

corrected)

6

4

(CB,SC,

(CB,SC,BS)

MLH,BS)

0 (Meters,

0 (Meters, tilt

tilt

corrected)

corrected)

N/A

(Average)

4

CB,SC,BS)

0 (Meters, tilt

corrected)

SkyVUE™8 (CS136) LIDAR Ceilometer 42

Page 48

5.1.5 MCFG command message types

The Message_ID_x parameter for the MCFG commands defines the output types. Refer to

Messages (p. 62) for further information on message output types.

Table 5-3: Summary of message ID and descriptions

Message_

ID_x type

000 No message

001 Campbell Scientific Message 1, no sky condition, no profile data

Campbell Scientific Message 2, no sky condition, profile data, 1600 range bins, 5 m

002

003 Campbell Scientific Message 3, sky condition, no profile data

004

(default)

101 CL31 Message 1, 770 range bins, 10 m resolution

102 CL31 Message 1, 385 range bins, 20 m resolution

103 CL31 Message 1, 1500 range bins, 5 m resolution

104 CL31 Message 1, 770 range bins, 5 m resolution

resolution. 2048 bins in total are output. However, after bin 1600, the bins only

contain zeros.

Campbell Scientific Message 4, sky condition and profile data, 1600 range bins, 5 m

resolution. 2048 bins in total are output. However, after bin 1600, the bins only

contain zeros.

Description

105 CL31 Message 1, No profile data

106

107 CL31 Message 2, 770 range bins, 10 m resolution

108 CL31 Message 2, 385 range bins, 20 m resolution

109 CL31 Message 2, 1500 range bins, 5 m resolution

110 CL31 Message 2, 770 range bins, 5 m resolution

111 CL31 Message 2, No profile data

112

113 CT25K Message 1

114 CT25K Message 6

CL31 Message 1, Full SkyVUE 8 output, 1600 range bins, 5 m resolution. 2048 bins in

total are output. However, after bin 1600, the bins only contain zeros.

CL31 Message 2, Full SkyVUE 8 output, 1600 range bins, 5 m resolution. 2048 bins

in total are output. However, after bin 1600, the bins only contain zeros.

SkyVUE™8 (CS136) LIDAR Ceilometer 43

Page 49

5.1.6 Measurement and message intervals

The message interval is the time, in seconds, between the automatic message transmissions. It

can be set between 2 to 600s (0 gives polled messages). The default is 10, meaning a message

will be sent automatically every 10 seconds. The message interval must be a multiple of the

measurement period.

The backscatter average time, BS_Av_Time, is the period over which the laser is firing and

taking measurements.

The measurement period is the time interval between the start of backscatter average time (BS_

Av_Time), during which the laser fires, and the start of the next measurement period. The

measurement period must be long enough to include the backscatter average time and some

processing time. The minimum measurement period is 2 seconds, which assumes the backscatter

average time is 1 second. The measurement period can be set between 2 to 600 s (default is 10s).

If it is set to 0, then measurements must be polled.

The rolling average (1 to 29, default 3) is the number of periods used to calculate each scatter

value that is either used in a profile message or in a calculation of cloud height.

The message interval chosen may affect measurement parameters allowed within the BS

command, which can be used to set non-standard measurement parameters) as follows:

If message interval = measurement period = 2 (the lowest values allowed), then the backscatter

average time (BS_Av_Time) must equal 1 and the rolling average must equal 1.

If the message interval is between 3 and 9s, then the measurement period must be the same as

the message interval.

In the following examples, yellow means laser firing.

To comply with the requirements for Sky Condition the total measurement period for rolling

averages should not exceed 30 seconds.

In this case, the SkyVUE 8 sends a message every 2 seconds based on one measurement averaged

over 1 second. Therefore, each message is based on a single 1 second period of backscatter

average data.

Laser firing (yellow)

(BS_AV_Time) = 1 s 1s

Measurement Period = 2 s 2 s

Message Interval = 2 s 2 s

In this case, with the rolling average set to 1, the SkyVUE 8 sends a message every 30 seconds. It

takes three, 2 second, measurements at 10 second intervals. Only the last measurement is used in

SkyVUE™8 (CS136) LIDAR Ceilometer 44

Page 50

the output message but all three are used for calculating sky condition. Therefore, each message

is based on a single 2 second period of backscatter average data.

Laser firing (yellow)

(BS_AV_Time) = 2 s 2s

Measurement Period = 10 s 10 s 10 s 10 s

Message Interval = 30 s 30 s

In this case, with the rolling average set to 3 (default), the SkyVUE 8 sends a message every 30

seconds that contains the average of the latest three measurements. Therefore, each message is

based on three, 10 second measurement periods, with each containing 2 seconds of backscatter

average data.

Laser firing (yellow)

(BS_AV_Time) = 2 s 2s

Measurement Period = 10 s 10 s 10 s 10 s

Message Interval = 30 s 30 s

In this case, with the rolling average set to 3 (default), the SkyVUE 8 sends a message every 10

seconds that contains the average of the latest three measurements. Therefore, each message is

based on three, 10 second measurement periods, with each containing 2 seconds of backscatter

average data.

Laser firing (yellow)

(BS_AV_Time) = 2 s 2s

Measurement Period = 10 s 10 s 10 s 10 s

Message Interval = 10 s 10 s 10 s 10 s

In this case, the SkyVUE 8 sends a message every 14 seconds based on one measurement taking 4

seconds over a 14 second interval. Therefore, each message is based on a single 4 second period

of average data.

Laser firing (yellow)

(BS_AV_Time) = 4 s

Measurement Period = 14 s 14 s 14 s 14 s 14 s

Message Interval = 14 s 14 s 14 s 14 s 14 s

This message cannot be set up using the MCFG command alone.

SkyVUE™8 (CS136) LIDAR Ceilometer 45

Page 51

The BS command has to be used as follows:

BS_Av_Time (averaging period) has to be set to 4, not the default value.

5.1.7 Status command

The STATUS command returns the following information:

Line Example line output

1 Identification CS136 SN1000 ID 0

Description of the line sections

Section Description

CS136 Product name

SN1000 Sensor serial number

ID 0 Sensor identification number

Line Example line output

2 Date Time 2012/01/10 11:39:46

Description of the line sections

Section Description

2012/01/10 Date in the format yyyy/mm/dd

11:39:46 Time in the format hh:mm:ss

Line Example line output

3 DSP_OS A

Description of the line sections

Section Description

A DSP OS revision number

SkyVUE™8 (CS136) LIDAR Ceilometer 46

Page 52

Line Example line output

4 TOP_OS_HW 8 2

Description of the line sections

Section Description

A TOP board OS revision number and hardware revision

Line Example line output

5 PSU_OS 1 PS136

Description of the line sections

Section Description

A PSU board OS revision number

Line Example line output

6 Watchdog A

Description of the line sections

Section Description

A Watchdog counter for unscheduled system resets

Line Example line output

7 Serial A B C D

Description of the line sections

Section Description

A Serial mode (Note: Refer to the SERIAL command)

B Serial baud rate (Note: Refer to the SERIAL command)

C Parity and stop bits (Note: Refer to the SERIAL command)

D

Receive to transmit delay time in RS-485 mode (Note: Refer to the

SERIAL command)

SkyVUE™8 (CS136) LIDAR Ceilometer 47

Page 53

Line Example line output

8 Heaters A B C D

Description of the line sections

Section Description

A Hood blower mode

B Internal heater mode

C Laser heater mode

D Heater/blower test interval in hours

Line Example line output

9 MCFGX A B C D E

Description of the line sections

Section Description

X Message interval (Note: Refer to the MCFG command)

A Message ID A (Note: Refer to the MCFG command)

B Message ID B (Note: Refer to the MCFG command)

C Message ID C (Note: Refer to the MCFG command)

D Message ID D (Note: Refer to the MCFG command)

E Message ID E (Note: Refer to the MCFG command)

Line Example line output

10 AngleA B C

Description of the line sections

Section Description

A X axis tilt

B Y axis tilt

C Beam angle from vertical

SkyVUE™8 (CS136) LIDAR Ceilometer 48

Page 54

Line Example line output

11 Units A

Description of the line sections

Section Description

A

Line Example line output

12 TRHA B C

Description of the line sections

Section Description

A Sensor internal temperature reading in degrees Celsius

B Sensor internal humidity reading as a percentage

C Sensors internal dew point value in degrees Celsius

Line Example line output

13 TA B C D E F G

Measurement units and tilt correction. (Note: Refer to the UNITS

command)

Description of the line sections

Section Description

A External fan blower assembly temperature in degrees Celsius

B PSU internal temperature in degrees Celsius

C TOP board laser monitor temperature in degrees Celsius

D TOP board calibration LED temperature in degrees Celsius

E Laser module temperature in degrees Celsius

F Photo diode module temperature in degrees Celsius

G Internal heater temperature in degrees Celsius

SkyVUE™8 (CS136) LIDAR Ceilometer 49

Page 55

Line Example line output

14 SupplyVoltage A B C D E

Description of the line sections

Section Description

A DSP board supply voltage

B PS136E internal supply voltage

C Cyclic power cycle counter. Resets after 31 cycles

D Hood heater voltage

E Internal heater voltage

Line Example line output

15 HOffset A

Description of the line sections

Section Description

A

Line Example line output

16 Visibility Cap A

Description of the line sections

Section Description

A Vertical visibility maximum range

Height offset reported in feet or meters dependent upon the UNITS

command

SkyVUE™8 (CS136) LIDAR Ceilometer 50

Page 56

Line Example line output

17 LaserRunDaysA

Description of the line sections

Section Description

A Number of days that the laser module has been active for

Line Example line output

18 WindowTX A

Description of the line sections

Section Description

A Window transmittance %

Line Example line output

19 BS A B C D E F (Note: refer to the BS command)

Description of the line sections

Section Description

A Attenuated scale

B Averaging time

C Noise Gate

D Measurement period

E Rolling average

F Message interval

SkyVUE™8 (CS136) LIDAR Ceilometer 51

Page 57

Line Example line output

21 Features A

Description of the line sections

Section Description

A List of features enabled

Line Example line output

22 Flags 0000 0000 0000

Description of the most significant alarm word (left side, bits going left to right). Each alarm

word is a hexadecimal sum of all the error bits.

Bit Description

8000 XXXX XXXX Units. feet = 0, meters = 8

4000 XXXX XXXX Reserved for future use

2000 XXXX XXXX Reserved for future use

1000 XXXX XXXX Reserved for future use

0800 XXXX XXXX DSP clock out of specification

0400 XXXX XXXX Laser shut down due to operating temperature out of range

0200 XXXX XXXX The lead acid battery voltage is reading low

0100 XXXX XXXX Mains supply has failed (requires a PSU to be present)

0080 XXXX XXXX The external heater blower assembly temperature is out of bounds

0040 XXXX XXXX External heater blower failure

0020 XXXX XXXX The PSUs internal temperature is high

0010 XXXX XXXX PSU OS has failed its signature check

0008 XXXX XXXX No communications between DSP and PSU

0004 XXXX XXXX

0002 XXXX XXXX Tilt beyond limit set by user, default 45 degrees

Photo diode and Laser windows are dirty. This can only be set if the

laser is on

0001 XXXX XXXX No communications between DSP and inclinometer board

SkyVUE™8 (CS136) LIDAR Ceilometer 52

Page 58

Description of the middle alarm word (middle word, bits going left to right)

Bit Description

XXXX 8000 XXXX The sensors internal humidity is high

XXXX 4000 XXXX

XXXX 2000 XXXX DSP input supply voltage is low

XXXX 1000 XXXX Self-test active

XXXX 0800 XXXX Watch dog counter updated

XXXX 0400 XXXX User setting stored in flash failed their signature checks

XXXX 0200 XXXX DSP factory calibration stored in flash has failed its signature check

XXXX 0100 XXXX DSP board OS signature test failed

XXXX 0080 XXXX DSP board RAM test failed

XXXX 0040 XXXX DSP boards on board PSUs are out of bounds

XXXX 0020 XXXX TOP board non-volatile storage is corrupt

XXXX 0010 XXXX TOP board OS signature test has failed

XXXX 0008 XXXX TOP boards ADC and DAC are not within specifications

XXXX 0004 XXXX TOP boards on board PSUs are out of bounds

Communications to the DSP boards temperature and humidity chip

have failed

XXXX 0002 XXXX Communications have failed between TOP board and the DSP

XXXX 0001 XXXX Photo diode background radiance is out of range

SkyVUE™8 (CS136) LIDAR Ceilometer 53

Page 59

Description of the least significant alarm word (right side, bits going left to right)

Bit Description

XXXX XXXX 8000 Photo diode temperature is out of range

XXXX XXXX 4000 Photo diode is saturated

XXXX XXXX 2000 Photo diode calibrator temperature is out of range

XXXX XXXX 1000 Photo diode calibrator has failed

XXXX XXXX 0800 The sensor could not reach the desired gain levels

XXXX XXXX 0400 Laser run time has been exceeded

XXXX XXXX 0200 Laser temperature out of range

XXXX XXXX 0100 Laser thermistor failure

XXXX XXXX 0080 Laser is obscured. This can only be set if the laser is on

XXXX XXXX 0040 Laser did not achieve significant output power

XXXX XXXX 0020 Laser max power exceeded

XXXX XXXX 0010 Laser max drive current exceeded

XXXX XXXX 0008 Laser power monitor temperature out of range

XXXX XXXX 0004 Laser power monitor test fail

XXXX XXXX 0002 Laser shutdown by top board

XXXX XXXX 0001 Laser is off

5.1.8 Message polling

The POLL Sensor_ID Message_ID command requests the Message_ID from the