Page 1

TriSCAN

®

Agronomic User Manual

Version 1.2a

Page 2

TriSCAN Manual Version 1.2a

All rights reserved. No part of this document may be reproduced, transcribed, translated into any language

or transmitted in any form electronic or mechanical for any purpose whatsoever without the prior written

consent of Sentek Pty Ltd. All intellectual and property rights remain with Sentek Pty Ltd.

All information presented is subject to change without notice.

2003 Sentek Pty Ltd

EnviroSCAN, EnviroSMART, EasyAG, TriSCAN and IrriMAX are trademarks or registered trademarks of

Sentek Pty Ltd.

EnviroSCAN, EnviroSMART, EasyAG, TriSCAN and IrriMAX are protected internationally by various

patents (and/or patents pending).

Sentek Pty Ltd

ACN 007 916 672

77 Magill Road

Stepney, South Australia 5069

Phone: +61 8 8366 1900

Facsimile: +61 8 8362 8400

Internet: www.sentek.com.au

Email: sentek@sentek.com.au

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved

Page 3

TriSCAN Manual Version 1.2a

Disclaimer

The access tubes, probes and sensors supplied by Sentek are specifically designed to be used together.

Other brands of probe and access tube are not compatible with the Sentek products and should not be used

as they may damage Sentek equipment. Damage to Sentek equipment through incorrect use will invalidate

warranty agreements.

The TriSCAN sensor produces an output in volumetric ion content (VIC). VIC is a nominal instrument value

that is produced by the sensor data processing model. VIC does not represent the exact soil Electrical

Conductivity value. Changes of units of VIC represent changes in units of soil EC. The exact relationship

between VIC and EC however, varies with soil type. If a relationship between VIC and EC needs to be

established, please refer to section on “Benchmarking Soil Salinity –TriSCAN Calibration” in this manual.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved

Page 4

TriSCAN Manual Version 1.2a

Table of Contents

Disclaimer.................................................................................................................3

Table of Contents......................................................................................................4

List of Figures............................................................................................................i

List of Tables.............................................................................................................ii

Introduction ..............................................................................................................1

TriSCAN: Sentek’s Fertilizer/Salinity and Soil Water Monitoring System..................................................1

Important Definitions and Terms....................................................................................................................1

Salinity – the problem........................................................................................................................................2

Where does the salt come from? ......................................................................................................................3

Global impacts of salinization...........................................................................................................................3

Why measure salinity and soil water content?.................................................................................................3

Fertilizer management .......................................................................................................................................4

What is TriSCAN?....................................................................................................5

TriSCAN Features..............................................................................................................................................5

TriSCAN Applications.......................................................................................................................................6

Benefits of TriSCAN Applications...................................................................................................................6

How does the TriSCAN sensor work?....................................................................7

Sensor output and measurement units.............................................................................................................7

Measurement Range and Soil Suitability..........................................................................................................7

Resolution and Accuracy...................................................................................................................................7

Temperature Effects ..........................................................................................................................................8

Getting TriSCAN ready for logging........................................................................9

Probe Assembly and Sensor Addressing.........................................................................................................9

Probe Configuration and Normalization .......................................................................................................12

Site Selection...........................................................................................................18

What is site selection?......................................................................................................................................18

Relationship between macro and micro zones in the field..........................................................................18

Important factors for macro site selection....................................................................................................19

A general view of macro scale zone selection...............................................................................................23

Micro scale zone selec tion...............................................................................................................................25

Micro zone selection guidelines ......................................................................................................................25

Access Tube and Probe Installation......................................................................28

Standard TriSCAN Access Tube Installation Method.................................................................................28

EasyAG TriSCAN Installation.......................................................................................................................31

Benchmarking Soil Salinity – TriSCAN Calibration............................................33

Sampling Method.............................................................................................................................................33

Laboratory Methods.........................................................................................................................................35

Adjusting the Salinity scale from Volumetric Ion Content (VIC) units to EC or ECe units...................36

Salinity and Soil Water Data Interpretation..........................................................37

Example 1 .........................................................................................................................................................37

Example 2 .........................................................................................................................................................39

Example 3 .........................................................................................................................................................40

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved

Page 5

TriSCAN Manual Version 1.2a

Appendix 1. Units of Salinity Measurement and Conversion Factors................41

Appendix 2: Guidelines for Interpretation of Water Salinity for Irrigation ........42

Appendix 3: Soil Salinity Classes and Cro p Growth.............................................43

Appendix 4: Crop Tolerance and Yield Potential of Selected Crops as

Influenced by Irrigation Water Salinity and Soil Salinity ....................................44

Appendix 5: Relative Salt Tolerance of Agricultural Crops.................................48

Appendix 6: Relative Effect of Fertilizer Materials on the Soil Solution............52

References ...............................................................................................................53

Acknowledgements.................................................................................................54

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved

Page 6

TriSCAN Manual Version 1.2a

List of Figures

Figure 1. Cut-away view of the TriSCAN probe..............................................................................................................................5

Figure 2. Sensor output.........................................................................................................................................................................7

Figure 3. Example of sensor address 5.............................................................................................................................................11

Figure 4. Sensor addressing positions..............................................................................................................................................11

Figure 5. Example Water DU test results .........................................................................................................................................25

Figure 6. Example of EC distribution uniformity in a potato field..............................................................................................26

Figure 7: Example of localized salt accumulation in furrow irrigation (from Ayars & Westcott)........................................27

Figure 8: Field Correlation: Volumetric Ion Content vs. ECe .....................................................................................................36

Figure 9. Sensor response to fertigation...........................................................................................................................................37

Figure 10: Salinity response to incremental applications of fertilizer to a sand colunn..........................................................38

Figure 11. Soil Water and Salinity Graph ........................................................................................................................................39

Figure 12. Tracking movement of salts ............................................................................................................................................40

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page i

Page 7

TriSCAN Manual Version 1.2a

List of Tables

Table 1. Salinity Measurement Units and their Abbreviations......................................................................................................2

Table 2. Expected air and water counts for different sensors.......................................................................................................14

Table 3. Default Calibration Coefficients........................................................................................................................................14

Table 4. Configuration Information for TriSCAN sensors...........................................................................................................16

Table 5. Examples of crop coefficients (FAO)...............................................................................................................................22

Table 6. Useful Conversion Factors..................................................................................................................................................41

Table 7. Guidelines for Interpretations of Water Salinity for Irrigation (from Ayars & Westcott).......................................42

Table 8. Soil Salinity Classes and Crop Growth.............................................................................................................................43

Table 9. Crop Tolerance and Yield Potential of Field Crops as Influenced by Irrigation Water Salinity (ECw) and Soil

Salinity (ECe) – from Ayars and Westcott 1994....................................................................................................................44

Table 10. Crop Tolerance and Yield Potential of Vegetable Crops as Influenced by Irrigation Water Salinity (ECw) and

Soil Salinity (ECe) – from Ayars and Westcott 1994............................................................................................................45

Table 11. Crop Tolerance and Yield Potential of Forage Crops as Influenced by Irrigation Water Salinity (ECw) and

Soil Salinity (ECe) – from Ayars and Westcott 1994............................................................................................................46

Table 12. Crop Tolerance and Yield Potential of Fruit Crops as Influenced by Irrigation Water Salinity (ECw) and Soil

Salinity (ECe) – from Ayars and Westcott 1994....................................................................................................................47

Table 13. Relative Salt Tolerance of Agricultural Crops..............................................................................................................48

Table 14. Relative Effect of Fertilizer Materials on the Soil Solution (from Ayars and Westcot) ........................................52

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page ii

Page 8

TriSCAN Manual Version 1.2a

Introduction

TriSCAN: Sentek’s Fertilizer/Salinity and Soil Water Monitoring

System

Monitoring, understanding and managing irrigated water and nutrients, so that they stay within the active

crop’s root zone, is one of the key challenges in modern agriculture. This is necessary in order to develop

long term, environmentally sustainable irrigation and land management practices.

Today electronic sensor technology can be used in conjunction with analytical software to visualize and

prevent leakage of water and nutrients from production systems into water tables and waterways through

precision irrigation management.

Sentek Pty Ltd has developed a near continuous in -field fertilizer/salinity and soil moisture monitoring

system called TriSCAN in order to help irrigators and land managers to efficiently utilize precious water

resources and fe rtilizer. Implementation of this technology can lead to management of fertilizer, salinity and

water movement to the benefit of the environment. It also has the potential to contribute to substantial

savings in water, fertilizer and power (pumping costs) while at the same time increasing crop yields, quality

and farm profits. Sustainable and profitable agriculture is the goal.

The TriSCAN sensor monitors soil water content and soil salinity on a near continuous basis. Sensors are

placed at multiple depths on probes within the soil profile. Probes are connected to a data logger, where the

data is recorded. Graphed data of soil water content and salinity of each depth level can be viewed

simultaneously.

This manual describes the operation and use of the TriSCAN multi-sensor, profile probe and its data output,

in the context of fertilizer, salinity and irrigation management. It introduces important definitions and terms,

explains the problem and touches on the national and global impacts of salinity. It also stresses the

importance of understanding the link between fertilizer management and salinity. TriSCAN features and

applications are described, along with an explanation on how the sensor works. Known sensor specifications

are provided.

The manual also covers principles of site selection, and details the process of configuring the probe for

connection to a range of different logging systems. Data from these systems can be imported into Sentek’s

customised irrigation and salinity management software, IrriMAX®6 for graphical display.

A further section of the manual covers how to benchmark the TriSCAN salinity measurement units

(Volumetric Ion Content, VIC), against the Systéme Internationale (SI) unit for electrical conductivity

(deciSiemens per metre, dS m-1).

The manual closes with a collection of useful appendices and references.

The manual should be used in conjunction with the SDI-12 and RS485 Modbus technical manuals, which

provide information on the interfaces, power consumption and wiring diagrams.

Important Definitions and Terms

The term salinity in this manual refers to the total dissolved concentration of major inorganic solutes or ions

(principally Na+, Ca2+, Mg2+, K+, NH

soils, it refers to the soluble plus readily dissolvable salts in the soil, or in an aqueous extract of a soil

sample.

Ions can be classified in terms of the nature of their charge:

Anion - a single atom or molecule with a net negative charge.

Cation - a single atom or molecule with a net positive charge.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 1

4

+

NO

-

, HCO

3

-

, CO

3

=

3

-, SO

=

and Cl-) in aqueous samples. As applied to

4

Page 9

TriSCAN Manual Version 1.2a

When ionically bonded compounds like NaCl are added to water, they dissociate (break up) into their

constituent positively and negatively charged ions (Na+ and Cl -). This phenomenon causes water, which in

its pure state is a poor conductor of electricity, to become a good electrical conductor. The EC of a solution

is dependent on the type of ions present, their concentration and the temperature of the solution. Therefore,

if the EC of the solution is measured, and if the temperature is known, then the EC can be used to determine

the concentration of ions in the solution.

Salinity is quantified in terms of the total concentration of such soluble salts, or more practically, in terms of

the EC of the solution.

It is not a simple process to measure the concentration of ions in an aqueous soil solution. Soil consists of

an intricate combination of organic and inorganic compounds, each with their own ionic properties. In an

attempt to standardize measureme nts and to establish a reasonable reference for comparison purposes, soil

salinity is commonly expressed in terms of the EC of an extract of a saturated paste (ECe) from a sample of

the soil.

The value of EC for a particular soil sample will vary according to the preparation of the sample. Due to

these differences, it is important to state the technique for sample preparation when defining soil salinity.

The following terms are used is this manual to describe various preparation techniques:

EC

Electrical conductivity of an extract of a 1:5 mixture of soil:water

1:5

ECe Electrical conductivity of a saturation paste extract

ECp Electrical conductivity of an aqueous extract of a soil sample, or pore water salinity

The effect of dissolved or ionized salts on plant growth depends on their concentration in the soil solution at

any particular time. Therefore there is a strong need to be able to measure the concentration of salts

through the soil profile on a continuous basis. Current methods of measuring soil salinity based on

destructive sampling make this extremely difficult. The TriSCAN technology overcomes this problem.

Table 1. Salinity Measurement Units and their Abbreviations

EC Electrical conductivity

EC

1:5

Electrical conductivity of an extract of a 1:5 mixture of

soil:water

EC

Electrical conductivity of water

w

EC

Electrical conductivity of the saturated soil extract

e

-1

dSm

deciSiemens per meter (dS/m)

-1

mmolL

Millimoles per litre (mmol/L or mM)

TDS Total dissolved solids

ppm Parts per million

-1

mgL

Milligrams per litre (mg/L)

-3

gm

Grams per cubic meter (g/m

3

)

Salinity – the problem

Saline soils can be defined as soils containing sufficient soluble salts to adversely affect the growth of

plants. The soluble salts are chiefly sodium chloride and sodium sulfate, but saline soils also contain

appreciable quantities of chlorides and sulfates of calcium and magnesium. For purposes of definition, saline

soils are those which have an electrical conductivity of the saturation soil extract of more than 4 dSm-1 at

25°C.

In field conditions, saline soils can be recognized by the poor growth of crops and often by the presence of

white salt crusts on the surface. When the salt problem is only mild, growing plants often have a blue -green

tinge. Barren areas and stunted plants may appear in cereal or forage crops growing on saline soils. The

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 2

Page 10

TriSCAN Manual Version 1.2a

extent and frequency of bare spots is often an indication of the concentration of salts in the soil. If the salinity

level is not sufficiently high to cause barren spots, the crop appearance may be irregular in vegetative

vigour.

Where does the salt come from?

The presence of excess salts on the soil surface and in the root zone characterizes all saline soils. The main

source of all salts in the soil is the primary rock minerals from which they derive. During the process of

chemical weathering, the salt constituents are gradually released and made soluble. The released salts are

transported away from their source of origin through surface or ground water streams.

The salts in the groundwater stream are gradually concentrated as it moves from a wetter, more humid area

to a drier, less humid one.

Geologic materials are highly variable in their elemental composition and some materials are higher in salts

than others. The kinds of geologic formations through which the drainage water passes thus significantly

influence the composition and total concentration of salts. Salt-affected soils generally occur in regions that

receive salts from other areas. Although the weathering of rocks and minerals is the source of all salts,

rarely are salt-affected soils solely formed from the accumulation of salts in situ.

However, salts released through weathering in the arid regions with limited rainfall are usually deposited at

some depth in the soil profile, the depth depending on such factors as the water retention capacity of the soil

and the annual rainfall. If the salts are deposited beyond the rooting depth of crops, they rarely affect the

crops adversely unles s they are redistributed.

Global impacts of salinization

Accumulation of excess salts in the root zone resulting in a partial or complete loss of soil productivity is a

worldwide phenomenon. Globally, approximately 400,000 square kilometres of land are affected by soil

salinization and waterlogging. It has been calculated that the world is losing at least ten hectares of arable

land every minute, three hectares of which are lost to soil salinization. Nearly 50 percent of the irrigated land

in the arid and semi-arid regions is salinized to some degree, and it is in these regions that irrigation is

essential to increase agricultural production to satisfy world food requirements.

Irrigation is often costly, technically complex and requires skilled management. Failure to apply efficient

principles of water management results in wastage of water through seepage, over watering and inadequate

drainage. This causes waterlogging, high salinity and erosion and reduces soil productivity, leading to a loss

of arable land.

Why measure salinity and soil water content?

A salinity problem exists if salt accumulates in the crop root zone to a concentration that causes a loss of

yield. Yield reductions occur where the salts accumulate in the root zone to such an extent that the crop is

no longer able to extract sufficient water from the soil solution for growth.

The plant extracts water from the soil by three mechanisms: bulk flow, diffusion and osmosis. Bulk flow and

diffusion are driven by transpiration. Water molecules los t to the atmosphere by the leaf and stems are

physically connected by cohesive forces to adjacent water molecules in the plant. This line of force is

connected throughout the plant and ends in the root -to-soil interface. Hence, any loss of water at the leaves

draws water inward from the soil.

Osmosis dictates that water moves across a membrane (root) from a lower solute concentration (more

water) to a higher solute concentration (less water). This force is referred to as osmotic or water potential.

The wat er is said to move down an energy gradient from a higher energy state to a lower one. Salt in the soil

water decreases the water potential and reduces the net influx of water into the plant. Hence, plants grown

in salty water suffer water stress.

Salts are added to the soil with each irrigation. The crop removes much of the applied water from the soil to

meet its evapotranspiration (ET) demand, but leaves most of the salt behind to concentrate in the shrinking

volume of soil water. Salt concentration typically increases with depth due to plants extracting water but

leaving salts behind. Each subsequent irrigation pushes the salts deeper into the root zone where they

continue to accumulate until leached.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 3

Page 11

TriSCAN Manual Version 1.2a

.

The crop does not respond to the extremes of low or high salinity in the rooting depth uniformly, but

integrates water availability, and takes water from wherever it is most readily available. Irrigation timing is

thus important in maintaining soil water availability. This reduc es problems caused when the crop must draw

a significant portion of its water from the less available, highly saline soil water deeper in the root zone. For

good crop production, equal importance must be given to maintaining soil water availability and to leaching

accumulated salts from the rooting depth before the salt concentration exceeds the tolerance of the plant.

When the upper rooting depth is well supplied with water, salinity in the lower root zone becomes less

important. However, if periods between irrigations are extended and the crop must extract a significant

portion of its water from the lower depths, the deeper root zone salinity becomes important. In this case,

absorption and water movement towards the roots may not be fast enough to supply the crop, and severe

water stress results.

Leaching can be used as a management tool in controlling salinity in the crop root zone. However, this is

only effective when the drainage within and below the crop root zone is sufficient.

Salinity problems encountered in irrigated agriculture are very frequently associated with an uncontrolled

water table within one to two metres of the ground surface. In most soils with a shallow water table, saline

water rises into the active root zone by capillary action. Salinization from this source can be rapid in

irrigated areas in hot climates , where portions of the land remain fallow for extended periods. A good

irrigation management plan strives to apply sufficient water to meet the crop water demand plus the leaching

requirement.

Until now there has been no practical way to directly measure the degree of leaching achieved in a soil

profile. The traditional leaching requirement calculation is based on an estimate of the amount of irrigation

required to prevent excessive loss in crop yield caused by salinity build -up within the root zone.

TriSCAN offers the opportunity to directly track leaching of salts through the profile. From real-time

measurements of soil salinity and moisture, one can determine whether salinity is within acceptable limits for

crop production and whether leaching and drainage are adequate.

Fertilizer management

Fertilizers, manure and soil amendments include many soluble salts in high concentrations. Timing and

placement are therefore important, and unless properly ap plied, may contribute to environmental problems.

Proper timing, application and placement of fertilizer products can reduce nutrient and salinity movement

from the soil into waterways. At present, best practice in fertilizer application relies on regular soil and tissue

analysis to ensure that an adequate reserve of nutrients is available in the soil.

TriSCAN offers a practical means of tracking on a real-time basis where the applied fertilizer salts move

within the soil and the rate of plant uptake of these nutrients. While the TriSCAN sensor cannot determine

individual ion constituents, it can be used to optimize the timing of strategic soil sampling and so assist with

nutrient management. This has the dual impact of an economic benefit for the operat or as well as a positive

environmental benefit to our waterways.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 4

Page 12

TriSCAN Manual Version 1.2a

What is TriSCAN?

TriSCAN Features

TriSCAN is the world’s first near-continuous in -field monitoring probe to measure soil water content and soil

salinity throughout a soil profile. Soil water and salinity measurements are taken by the same sensor

successively. The TriSCAN technology is protected by various world patents.

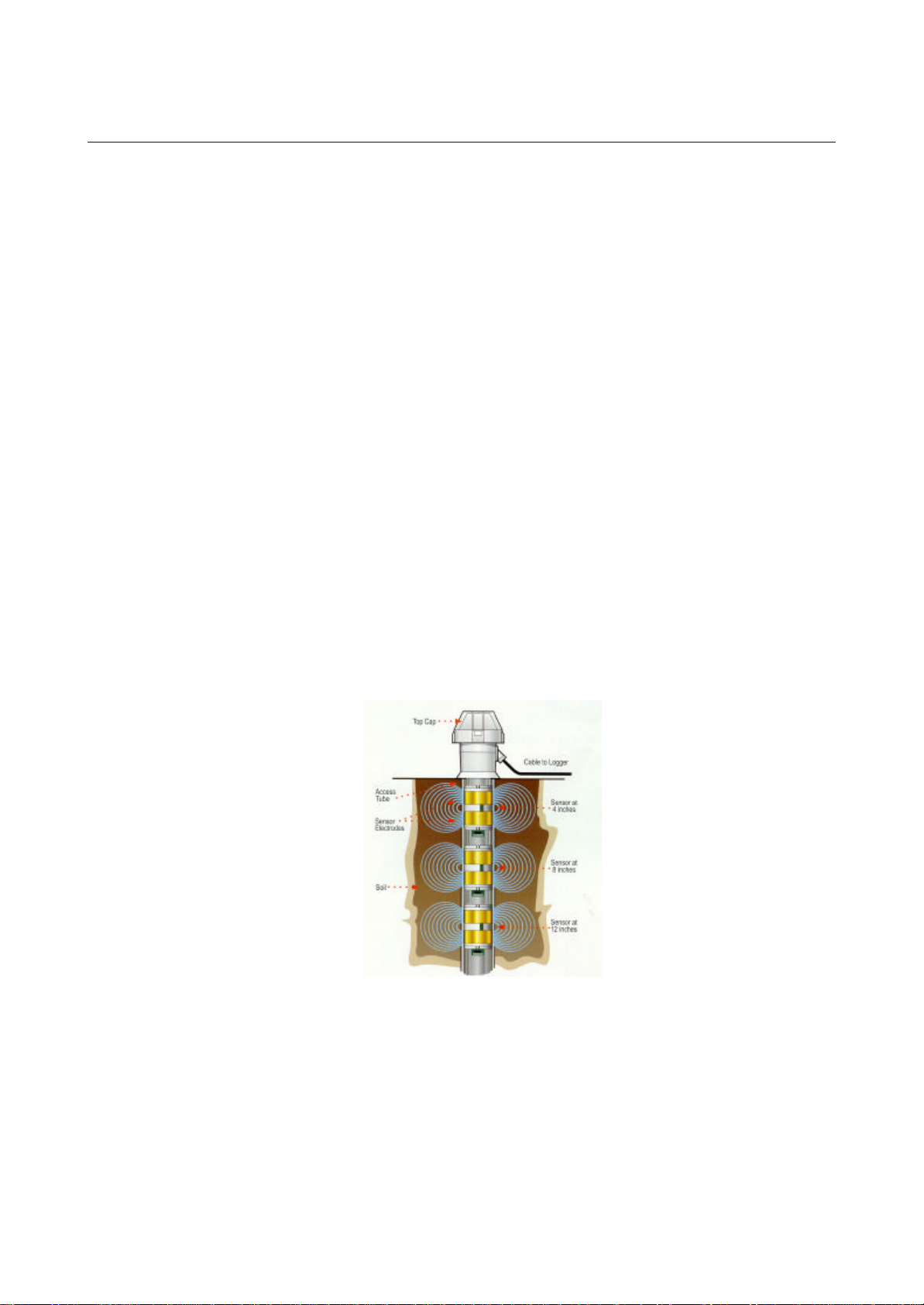

Sensor and Probe

The sensor consists of a tubular housing with two conductive surfaces. The electronic circuit contained

within this housing connects into a ribbon cable running inside the extruded plastic support (probe rod)

which carries the sensors. The probe rod can be fitted with multiple sensors, located at 100 mm intervals

along its length. Each configuration of multiple sensors fitted to a probe rod constitutes a probe. A total of 16

TriSCAN sensors can be mounted to a probe at chosen depth intervals by the user.

Arrays of sensors can be typically installed to depths of 0.5 m, 1.0 m, 1.5 m, 2 m and 3 m. Special probe

lengths can be ordered and installed to greater than 3 m pending favourable installation conditions. The

TriSCAN technology is also offered as an EasyAG probe version, where 4 smaller diameter sensors are

fixed on to a probe rod at depths of 100 mm, 200 mm, 300 mm and 500 mm.

Access Tubes

During installation, the probe is lowered into a specially extruded plastic tube inserted into the soil at the

desired measuring location. Readings of soil water content and soil salinity are taken through the plastic

access tube without any direct contact between the sensor and soil. The top and bottom of the access tube

is sealed to prevent the entry of water and moisture. The top cap of the access tube allows cable entry from

the probe to a suitable data logger through a water-tight grommet.

The TriSCAN EasyAG probes are lowered into the smaller diameter EasyAG access tube body.

Figure 1. Cut-away view of the TriSCAN probe

Probe Interface and Data Acquisition Systems

The TriSCAN can be fitted with two probe interfaces: SDI-12 and RS232/RS485 Modbus. This means that

data loggers supporting the SDI-12 or RS232/RS485 Modbus protocol can be used to connect and log soil

water and salinity data.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 5

Page 13

TriSCAN Manual Version 1.2a

TriSCAN Applications

A Fertilizer Management Tool and Soil Salinity Early Warning System

Sentek has developed TriSCAN to provide a tool for monitoring, understanding and managing irrigation

water and nutrients, so that they are maintained within the active crop root zone, where they are taken up to

the benefit of the plant and irrigator. These are key challenges of irrigation management today to generate

long term, sustainable irrigation practices.

TriSCAN is designed to be a pro -active day to day on-farm management tool for irrigation and fertilizer

application, to visualize and prevent leakage of water and nutrients from agricultural production systems.

TriSCAN is also designed to report rising salinity levels below or in the active plant root zone and so to

provide an early warning system of salinity impact on the plant.

Note: If TriSCA N is to be used as an early warning system to detect damaging salinity concentrations,

salinity benchmarking (a soil salinity check) should be undertaken – refer the section on Salinity

Benchmarking.

Near-continuous data of soil water and soil salinity taken at multiple levels in the soil profile provides a

picture of:

• where the roots are taking up water

• the depth of the active root zone

• the day -to-day concentration changes of salts and applied fertilizers

This is a new, dynamic approach linking soil water and salinity to management of irrigation and fertilizer

applications; an approach that practically and commercially cannot be achieved using soil sampling alone.

The TriSCAN technology is designed to reduce the soil sampling frequency and it is designed as a

complementary technology that will allow soil sampling to be undertaken at strategic points in time.

Determination of EC or ECe in soil samples will verify the magnitude of salinity chang e detected by the

TriSCAN sensors. This process is called “salinity benchmarking”, that sets the upper and lower limits of the

soil salinity range encountered in the field during the crop season.

Benefits of TriSCAN Applications

The use of the TriSCAN technology can potentially lead to several benefits depending on the user,

application and site conditions. These benefits include:

• Optimizing fertilizer uptake by the crop

• Fertilizer savings

• Optimizing crop quality and yield

• Improving economic return

• Minimizing fertilizer leaching into groundwater

• Preventing soil acidification from nitrate leaching

• Providing water savings

• Providing energy (pumping cost) savings

• Improving soil & water conservation

• Reducing leakage from field systems

• Improving irrigation and salinity management

• Reducing costs to the environment and grower

• Conforming to regulatory compliance

• Improving and contributing to the scientific understanding of the water and solute (salt/ fertilizer)

movement in soils

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 6

Page 14

TriSCAN Manual Version 1.2a

How does the TriSCAN sensor work?

Sensor output and measurement units

The TriSCAN sensor provides two outputs.

The first output is a signal of dimensionless frequency (raw count), that is converted via a normalization

equation and then a default or user-defined calibration equation into volumetric soil water content. The

measurement unit is thus volumetric water content (Vol %) or millimetres of water per 100 mm of soil depth.

The second output is also a dimensionless frequency (raw count) that, in conjunction with the first output

signal, is proportional to changes in soil water content and salinity. A proprietary data model processes the

changes of both output signals simultaneously to reflect the changes in soil salinity. The output of the data

model is a nominal Volumetric Ion Content (VIC). Measurement units of VIC can be quantitatively related

(benchmarked ) to the soil EC through site-specific soil sampling and analysis.

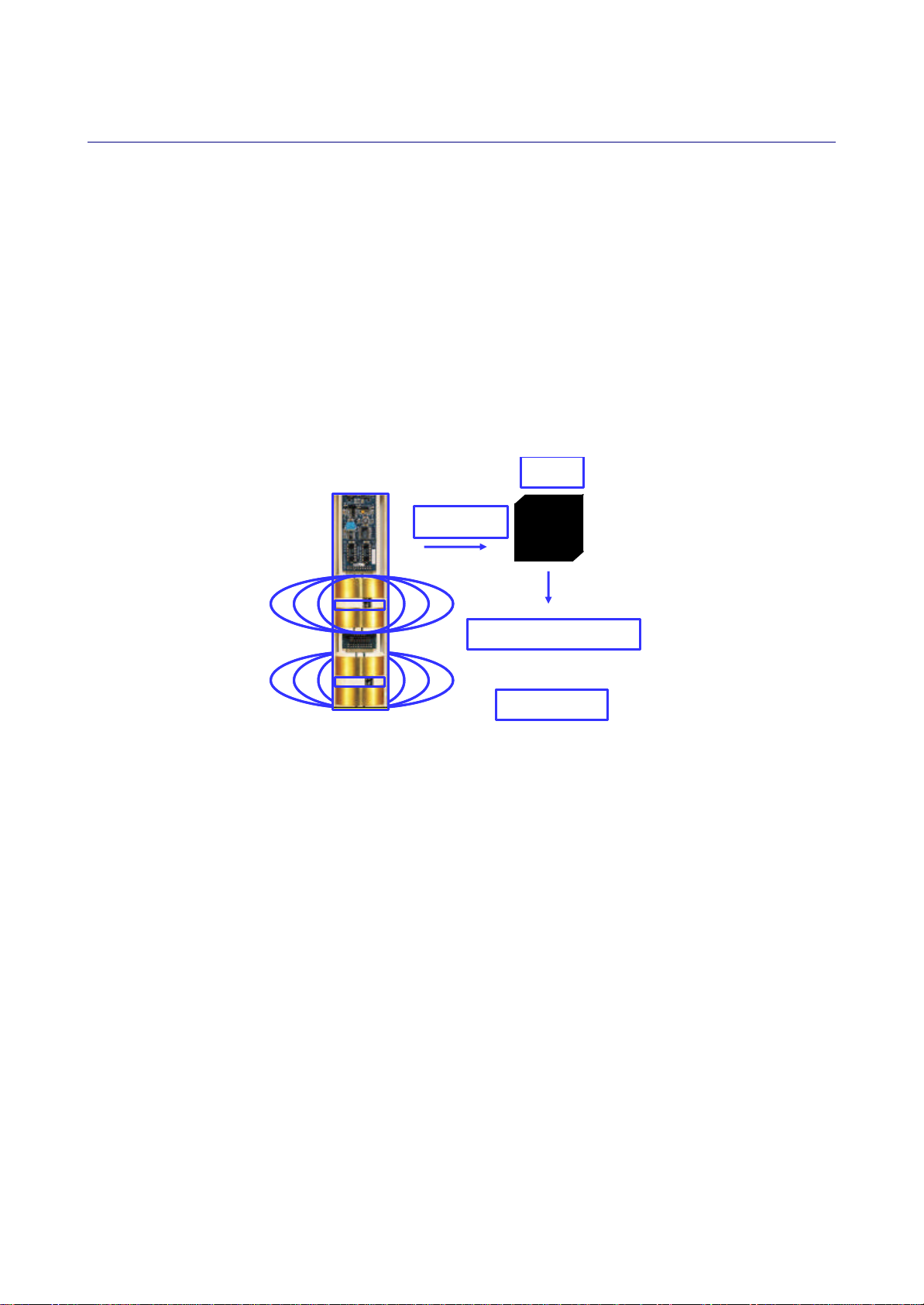

Figure 2. Sensor output

Both outputs can be presented as dynamic trend changes over a chosen time scale.

Raw Data

Soil Water Content

Soil Water Content

Model

+

+

Soil Salinity

Soil Salinity

Measurement Range and Soil Suitability

The effective measurement range of TriSCAN is between 0 and 17 dSm-1 in sand, loamy sand and sandy

loam textures (Australian Soil and Land Survey Field Handbook). Use of TriSCAN at salinity levels and soil

textures outside this range is currently unsupported by Sentek.

Resolution and Accuracy

The resolution and accuracy of the sensor can be considered in terms of the two different outputs.

Volumetric Water Content:

The sensor has a resolution of 0.1 mm of soil moisture. Consecutive readings in equilibrated soil have a

coefficient of variation of 0.1% .

The accuracy of the system is dependent upon the similarity of the soil site to that of the original default soil

type used by Sentek. Calibration coefficients based on this default soil type are used in normal operation. If

site-specific (quantitative) values are required, then a calibration procedure is required to be performed

(refer to “Calibration of Sentek Probes” Manual). A high level of accuracy can be attained with careful

calibration.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 7

Page 15

TriSCAN Manual Version 1.2a

Salinity:

There are two levels at which resolution and accuracy may be considered with regard to the TriSCAN®

sensor:

• Resolution and accuracy of the electronic sensor

• Resolution and accurac y of the benchmarking (correlation of VIC to EC) procedure

The resolution of the electronic sensor, i.e. the smallest measurable increment , has been determined to be

as low as 1 microSiemen/cm (0.001 mS/cm) in dry soil conditions, and as high as 14 micoSiemen/cm (0.014

mS/cm) in saturated soil conditions.

The accuracy of the benchmarking of the VIC values to soil EC is dependent upon the degree of alignment

possible as limited experimentally. This is affected by many things, including the ability of the operator to

measure the physical EC, soil sampling technique and sample timing. In Sentek’s own field testing, strong

relationships (r2=0.9) have been achieved (refer Figure 8, Benchmarking section).

At Sentek’s laboratories, the accuracy of the sensor to predict the EC has been determined at ±8.06%

(range: 6.0 – 10.1%). This figure was determined through analysis of the inherent variability of discrete

salinity measurements as taken over a range of water contents from 4% (dry sand) to 20% (saturated) and a

salinity range from 0 to 4.9 mS/cm.

Temperature Effects

The precise temperature effects on TriSCAN data output are currently unknown. It is however, known that

there is a minor positive relationship between VIC and soil temperature. The TriSCAN model currently does

not include temperature correction.

In the field the graph pattern produced is easily discernable as a small temperature effect distinct from

salinity changes.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 8

Page 16

TriSCAN Manual Version 1.2a

Getting TriSCAN ready for logging

Probe Assembly and Sensor Addressing

Assembling the Probe

The TriSCAN probe consists of the following components:

• Handle set with screws

• Interface board

• TriSCAN sensors

• Probe Rod

Assemble the probe following these steps:

1. Insert the probe handle into the top of the probe rod, with the lugs on the handle facing the

connector side of the probe rod.

2. Attach the interface board to the probe rod. Fit the interface board between the lugs on the handle

and the probe rod guides, with the green phoenix connector facing the top of the probe. Plug the

interface into the first available connection on the probe rod.

3. Gently move the interface board along the probe rod so that the holes at the top of the board align

with the holes in the probe rod handle behind. Insert the two small scre ws into these holes, being

careful not to over-tighten.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 9

Page 17

TriSCAN Manual Version 1.2a

4. Insert the large screws into the holes in the side of the handle and tighten to hold them in place. Be

careful not to over tighten the screws, as this may damage the interface board.

5. Locate the desired sensor positions on the probe rod, keeping in mind that each probe connection is

spaced 100 mm apart.

6. Position the sensor at the bottom of the probe rod with the ribbon cable facing towards the bottom of

the probe and the connec tor facing the side of the probe rod that holds the connector plugs.

7. Depress the lever on the bottom side of the sensor, and slide the sensor along the probe rod into

position.

8. Align the lug on the back of the sensor with the notch in the probe rod, and click into position by

pushing the lever outwards with a finger or screwdriver inserted behind the lever.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 10

Page 18

TriSCAN Manual Version 1.2a

9. Firmly plug the sensor into the connector on the probe rod, ensuring that all the pins are correctly

aligned.

10. Repeat for the other sensors.

Addressing the Sensors

After positioning and securing each sensor in its proper location, every sensor on a probe needs to be

assigned a unique address. The sensor address is set by changing the position of the address link on the

ribbon cable board of the sensor. This address is a means of differentiating between each sensor on the

probe, and can be assigned a numerical value between 1 and 16. The sensor address is not necessarily

related to the sensor position on the probe rod.

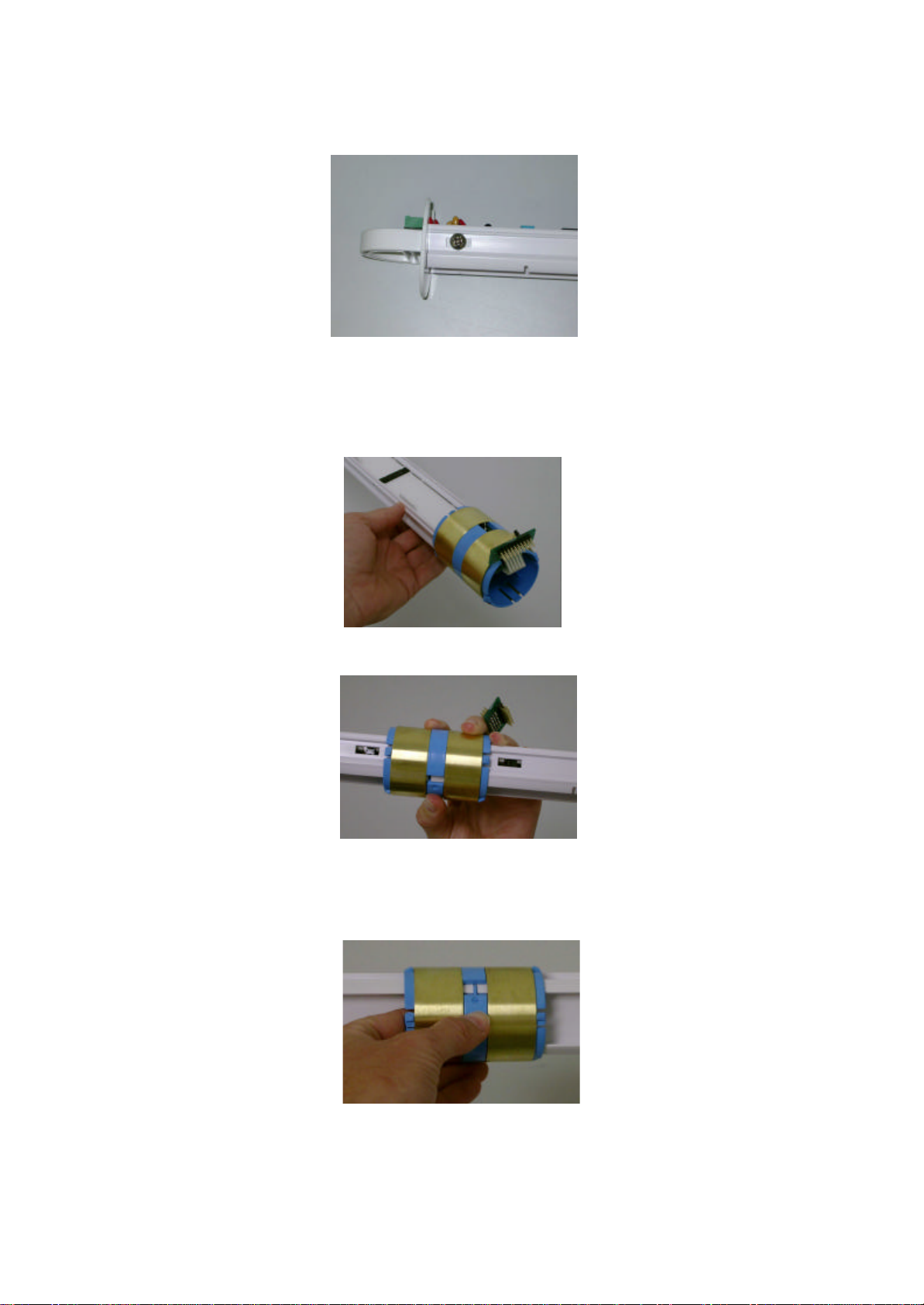

Figure 3 below shows the address link in position 5 on the sensor.

Figure 3. Example of sensor address 5

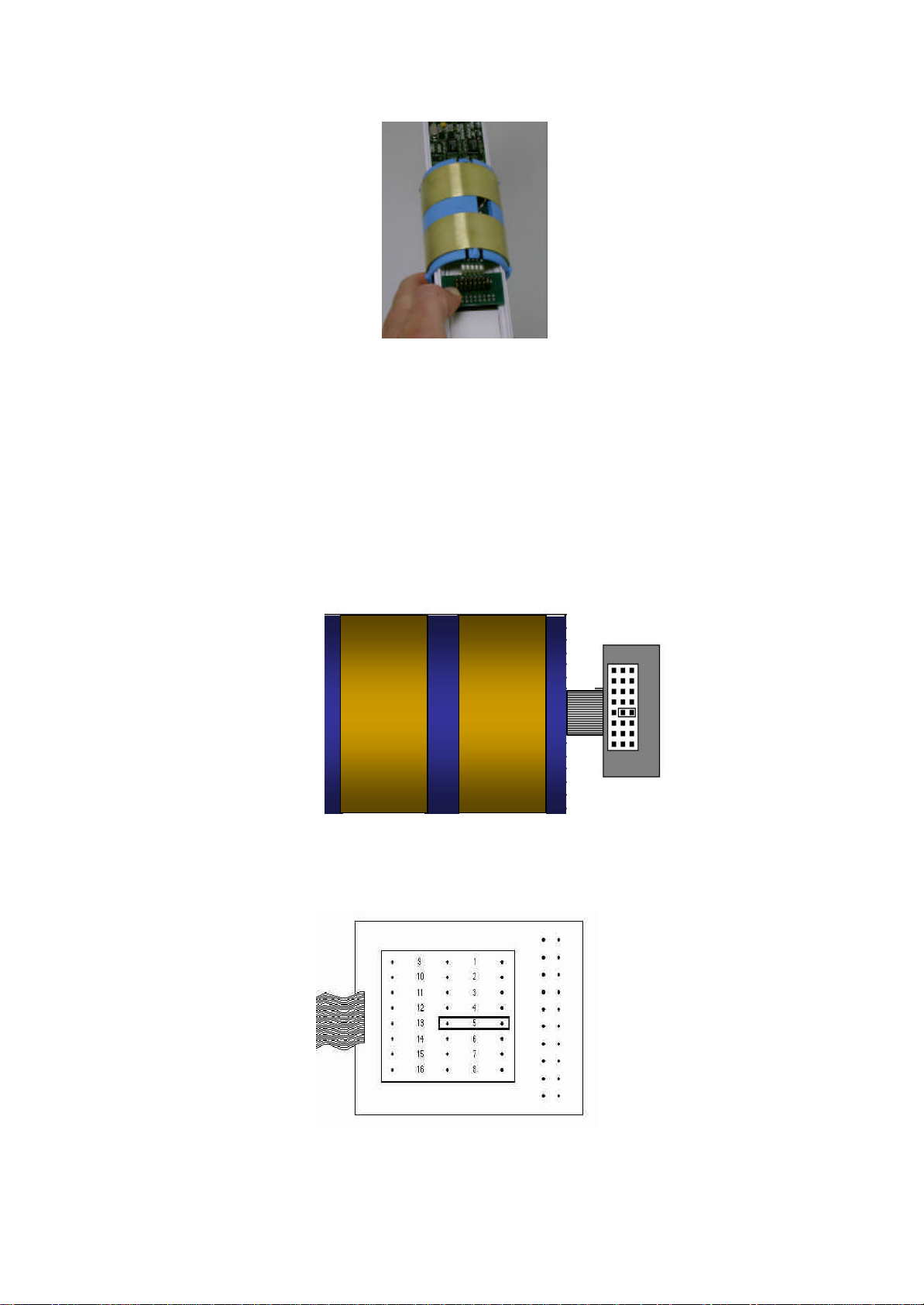

Figure 4 below outlines the sensor address link positions for all the different possible addresses.

Figure 4. Sensor addressing positions

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 11

Page 19

TriSCAN Manual Version 1.2a

For each probe, assign the top sensor with the lowest address (e.g. address 1) and then address each

sensor below it with a sequentially higher address, such as 2, 3, 4 and so on.

Probe Configuration and Normalization

The probe is now ready to normalize. The following paragraphs outline the procedure for normalizing the

probe using the IP Configuration Utility Software Version 1.4.1 or later. For more details on the IP

Configuration Utility Software, refer to the IP Configuration Utility User Guide.

Step 1 – Powering the probe

Connect a 12 volt power supply to the probe. Refer to the relevant SDI-12 or RS232/ RS485-Modbus

Manual for the correct wiring procedure. Power can either be supplied from the logger power source or

directly to the probe.

Warning:

Incorrect wiring may lead to damage to the probe, or blow the fuse on the probe interface. Any damage

due to incorrect wiring will void the warranty. Therefore it is recommended that the wiring procedure be

checked prior to connecting the power to avoid such damage.

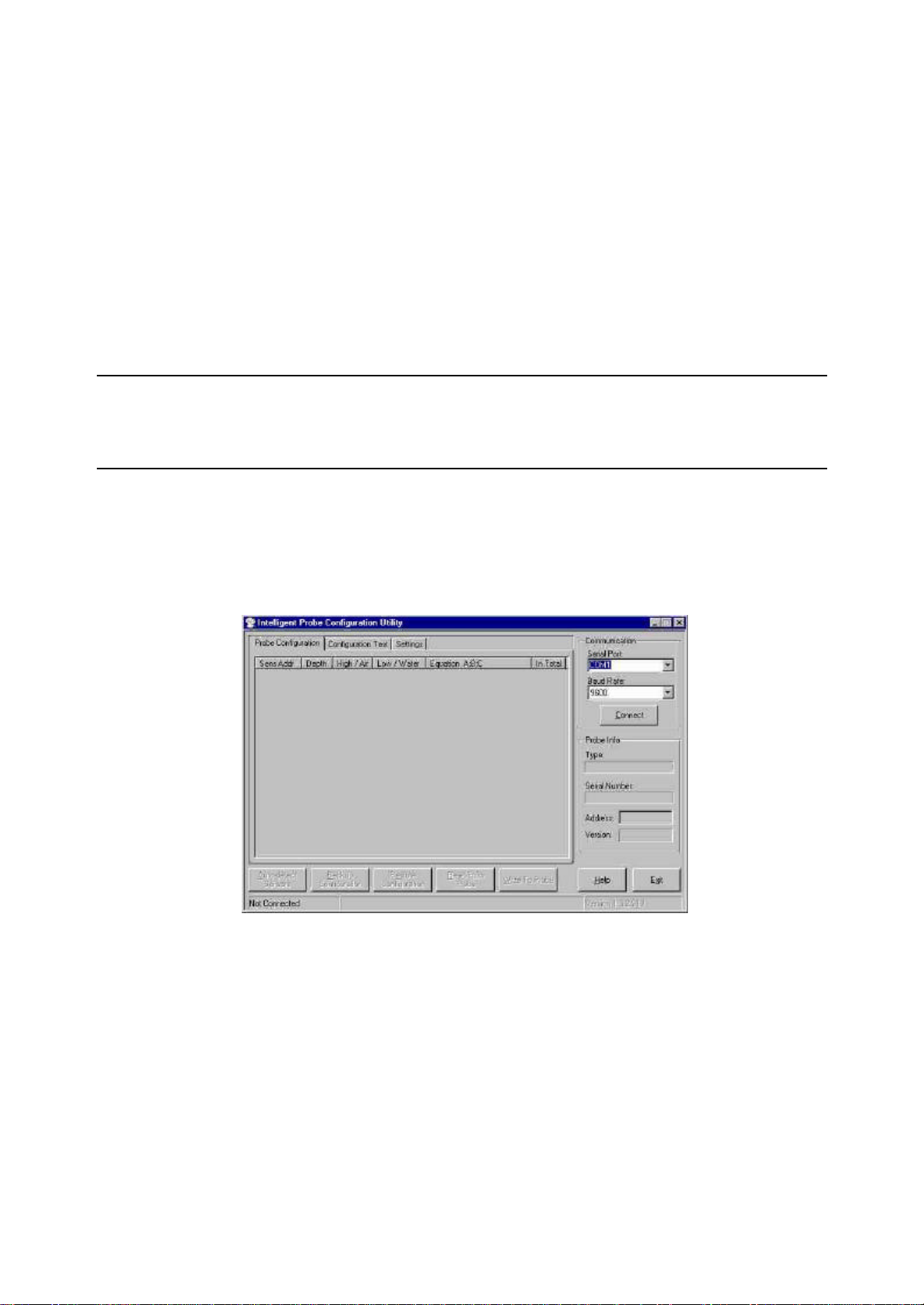

Step 2 – Connecting to IP Configuration Software Utility

1. Connect the IP Configuration Utility Cable to the probe interface and to the serial port on the

computer.

2. Open the IP Configuration Utility Software.

3. Select which serial port the probe is connected to from the Serial Port drop down list. Also select the

baud rate to use from the Baud Rate drop down list. If you are unsure of the baud rate you can

select “Auto” for the baud rate which will use auto detection of the baud rate when connecting.

4. Click the Connect button to connect to the probe. If connection is successful then the status bar will

now display “Connected” and the Connect button will have changed to Disconnect. If “Auto” was

specified as the baud rate then the correct baud rate will now be displayed in the Baud Rate drop

down list. On successful connection, the probe’s information (name, serial number, address and

firmware version number) will be displayed, and the probe will be queried for its configuration

settings.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 12

Page 20

TriSCAN Manual Version 1.2a

Step 3 – Getting the configuration from the probe

To detect the probe configuration, click on the Auto-detect Sensors button. This will automatically detect all

the sensors on the probe. After the sensors are detected the configuration information will be displayed in

the list.

Step 4 – Changing the sensor depths

1. Click on the sensor depth when it is selected and it will go into edit mode as show n above.

2. Type the new depth or use the up/down arrows to increase or decrease the depth value 10 units at

a time. The minimum allowable depth is 5.

3. To accept the new depth, click outside the cell or press Enter. The new depth will not be set in the

probe’s configuration until you use the Write to Probe button. If you want to discard the changes,

press Escape and the depth will change back to the old value.

Note:

The depth number is not associated with any units and is just a stored value for informative purposes.

Therefore the value may mean "inch", "cm", etc.

Step 5 – Normaliz ing the sensor air and water counts

The effective range of each sensor needs to be set between a high and low value. To achieve this each

sensor is normalized under identical conditions.

To normalize the air counts:

1. With the probe inside an access tube and held in the air, click on the buttons in the “High / Air”

column one at a time to start direct sensor reading. Ensure that the probe is held well away from

any objects when obtaining the air counts.

2. Wait for a few seconds at each sensor while the reading stabilizes before clicking on the next one.

To normalize the water counts:

1. Insert the probe into the tube in the normalization container filled with reverse osmosis (RO) water

(EC less than 300µScm-1), so that the sensor that you wish to take the water counts from is in the

centre of the tube.

Note:

The water in the normalisation container must be RO water for TriSCAN sensors, as other water supplies

may contain ions that affect the reading of the sensor.

2. Click the button in the “Low / Water” column that refers to that sensor to start direct sensor reading

mode. Wait until the reading stabilizes and the value displayed is updated. To accept the new water

count value click the button again to stop direct sensor reading.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 13

Page 21

TriSCAN Manual Version 1.2a

3. Repeat this process for each sensor on the probe.

The expected air and water counts are dependent on the sensor type and sampling mode. Normalization

values outside the expected range may indicate errors in the normalization steps or problems with the

hardware.

Table 2. Expected air and water counts for different sensors

Sensor Type Sampling Mode Air Range Water Range

EnviroSCAN sensor (white) Moisture 36000±3000 23000±3000

TriSCAN sensor (blue) Moisture 33000±2000 22800±2000

Salinity 20500±2000 13500±2000

EasyAG sensor (white) Moisture 44000±2000 31000±2000

Moisture (sensor at bottom) 50000±2000 32000±2000

EasyAG with TriSCAN sensor (blue) Moisture 33000±2000 25000±2000

Salinity 20500±2000 15000±2000

Step 6 – Changing the Calibration Coefficients

To change the calibration coefficients of the sensors:

1. Click on the sensor coefficients cell when it is selected and it will go into edit mode as shown above.

2. Type the new coefficients separated by semicolons. To accept the new coefficients click outside the

cell or press Enter. If you want to discard the changes while in edit mode then press Escape. The

new coefficients will not be set in the probe’s configuration until you use the Write to Probe button.

The default calibration equation coefficients provided for different sensor types are listed in Table 3.

Table 3. Default Calibration Coefficients

Sensor Type A B C

Moisture sensors 0.1957 0.404 0.02852

TriSCAN sensors

1.0 1.0 0

Step 7 – Addressing the Probe

Where there are multiple probes connected to a logger in a multi-drop situation, it is necessary to assign

each probe a unique address to avoid a clash in communication.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 14

Page 22

TriSCAN Manual Version 1.2a

To change the probe address, type the new address in the Address tab on the Probe Configuration page.

The address of the probe should be in the range 1-65534 for most types of probes. Probes supporting

specific protocols such as SDI-12 and Modbus accept only addresses in their specific formats (i.e. ASCII '0''9', 'a' -'z', 'A'-'Z' for SDI-12 probes, 1 to 247 for Modbus probes).

Step 8 - Writing the Configuration to the Probe

Writing the configuration to the probe will send the currently displayed sensor configuration (and output port

configuration, if applicable) to the probe. The probe’s address will also be set to the one displayed in the

Probe Info section. Existing configuration information in the probe will be overwritten. If you do not write the

configuration to the probe, the changes to the probe configuration will not be saved onto the probe itself.

To write the configuration to the probe:

1. Click the ‘Write to Probe’ button. You will be prompted to make sure you want to write both the

sensor configuration and the probe output port configuration (if applicable for the connected probe)

to the probe.

2. Click ‘Yes’ and the configuration information for that page will be written. Settings will be verified

when you click the ‘Write to Probe’ button.

Step 9 – Backing up the Configuration File

The Probe Configuration information should be saved as a configuration file. This is useful if the probe

interface ever needs to be changed, as the original probe configuration (i.e. depth settings, air and water

counts, probe address and calibration coefficients) can then be written to the new interface.

To backup the configuration to a file:

1. Click the Backup Configuration button.

2. Specify the file you would like to save it in and click OK. The sensor configuration (and probe output

port configuration, Modbus or Analog if applicable) information displayed should now be stored in

the specified file.

Important Information for Configuring TriSCAN probes

The probe configuration page is for displaying and editing the probe configuration.

The colour red represents an item that has been modified, and an asterisk appears on the title tab to

indicate some change has occurred on that page, which has not been written to the probe (this will remain

until ‘Write to probe’ is performed).

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 15

Page 23

TriSCAN Manual Version 1.2a

Some important information on the configuration of the TriSCAN sensors is summarized in Table 4.

Table 4. Configuration Information for TriSCAN sensors

Sensor

Address

Displays the sensor address for each sensor.

Note 1: Moisture sensor addresses start at 1. The sensor address is controlled by the

address jumper plug on the physical probe sensor assembly (refer to section of Probe

Assembly and Sensor Addressing). Non-existent sensors will not be assigned a sensor

address e.g. On an EasyAG -50 probe sensor addresses are detected as 1, 2, 3, 5 (no

sensor 4).

Note 2: Salinity sensor addresses start at 65 in firmware that supports salinity. If salinity

sensor addresses start at 129 then the firmware loaded in the probe does not support

salinity and sensors readings will be indeterminate.

Note 3: Temperature sensor addresses start at 129 in firmware that supports salinity

sensors (earlier firmware versions have a temperature sensor at address 66). At present

only one temperature sensor exists and it only samples the temperature on the interface

device circuit board. This sensor is only accessible using this IPConfig program and

cannot be accessed through the output port.

Note 4: Salinity sensors (if present) always correspond to a moisture sensor address i.e.

salinity sensor 65 is associated with moisture sensor 1, 80 with 16 etc.

Note 5: The sensors are sorted by type (moisture, salinity, temperature) then depth, then

sensor address. This sort order cannot be changed.

Depth Depth of each sensor.

When a new sensor is detected a depth of value '0' (zero) is assigned to it. This indicates

that the sensor has not been configured yet. Clicking a depth when the row is selected

allows changing the depth. Pressing Enter or clicking outside the cell confirms the

changes. Pressing Escape discards any changes. The depth figure should reflect the

actual (physical) depth of each sensor.

Note: The depth number is not associated with any units and is just a stored value for

informative purposes. Therefore the value may mean "inch", "cm", etc.

The following notes only apply to firmware that supports salinity sensors .

You cannot directly set the depth of salinity sensors. The depth is taken from the

corresponding moisture sensor depth.

Warning:

The depth of a salinity sensor remains zero until the following steps are performed.

1. The corresponding moisture sensor depth is set.

2. The salinity sensor is normalized (air and water counts set).

3. Write to Probe has been performed.

4. The salinity depths (using IPConfig version 1. 4.1) are not updated after the above

steps, until “Read from Probe ” (or Disconnect/Connect) has been done.

High / Air Displays the high counts of the sensor. This field contains buttons for taking new air

counts from moisture and salinity sensors. Clicking on these buttons will start or stop

direct sensor reading for that sensor.

Low / Water Displays the low counts of the sensors. This field contains buttons for taking new water

counts from moisture and salinity sensors. Clicking on these buttons will start or stop

direct sensor reading for that sensor.

Equation

A;B;C

Displays the calibration equation coefficients for the sensors. The A, B and C

components of the equation must be separated by semicolons. Clicking on the calibration

equation when the row is selected will enable editing of these coefficients. Pressing Enter

or clicking outside the cell confirms the changes. Pressing Escape discards any changes.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 16

Page 24

TriSCAN Manual Version 1.2a

In Total Sentek Smart Probes support a feature, by which the probe can provide a sum of values

of the selected sensors. This is useful when an overall amount of water in the soil profile

is to be found. A tick specifies that the sensor is used in the “In Total Moisture

Calculations”. Double click in this column to change which sensors are used. A red cross

or a blank cell specifies that the sensor is not used in the “In Total Moisture Calculations”.

Note: Early probe versions do not allow de-selection of all sensors from the ‘In Total’

reading.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 17

Page 25

TriSCAN Manual Version 1.2a

Site Selection

The key to effective soil water and soil volumetric ion content (VIC) monitoring is to select sites which truly

represent irrigation management areas. The same basic site selection principles apply to the full range of

Sentek soil moisture and salinity monitoring devices.

In addition, when monitoring soil solution VIC, consideration of VIC variability in relation to the irrigation

emitter needs to be taken into account.

Many variables influence the spatial distribution of soil water and VIC across an area of land. These

variables and their impact on site selection are discussed in more detail below.

What is site selection?

A site is defined here as:

“The location of the access tube within a field or irrigation shift, where soil water and soil volumetric ion

content (VIC) readings are taken at different depth levels within the soil profile.”

Note:

If readings are to be used as a basis for scheduling irrigation; managin g fertilizer applications or

monitoring salinity, it is imperative that monitoring sites are representative of these areas.

Soil moisture data can provide information about the:

• Quality and depth of irrigations

• Levels of soil moisture retention

• Depth of the crop root zone

• Impact of weather and rainfall events on an area

Soil VIC data can provide information about the:

• Movement of ions within the profile

• Uptake of ions by the plant or loss to the atmosphere

• Leaching of salts below the root zone

• Excessive build-up of salts within the root zone to detrimental levels

Warning:

Do not position TriSCAN sensors at random on your property. Poor site selection will result in

unrepresentative soil moisture and salinity data.

Site selection is carried out in two stages:

• Macro zone selection

• Micro zone selection

Relationship between macro and micro zones in the field

Traditional practice within the field and across the whole farm is for irrigation and fertilizer to be applied on a

hypothetical “farm average” – similar to traditional broad acre management practices.

Uniform application of irrigation and fertilizer across areas with highly variable soils, nutrient levels and

different levels of crop water use causes significant differences in yield and quality. This creates commercial

losses and environmental harm through increasing problems with rising water tables and increasing salinity.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 18

Page 26

TriSCAN Manual Version 1.2a

If different soil types are ignored in terms of their different irrigation scheduling requirements and nutrient

management, crop setbacks or failures may occur. This effect is displayed in the aerial photograph of a

citrus orchard (Photo 1).

Photo 1. Variable growth due to uniform management across variable soil types

Macro zone selection defines the number of zones on a property where the amount and timing of irrigation

and fertilizer applications can be specifically tailored to match soil and crop variability. A macro zone thus

comprises areas with similar crop water and nutrient requirements and salinity characteristics.

Crop water use is governed by many factors such as soil properties; water quality; weather patterns and

type of irrigation system. These factors need to be considered when defining the macro zones on your

property.

Micro zone selection determines the position of access tubes in relation to the crop and irrigation system.

Micro zone selection considers the:

• areas of root zone and canopy spread

• water distribution uniformity (sprinkler pattern)

• moisture patterns of drip irrigation

• surface, topographic and soil anomalies

The consideration of these factors will help you find the best representative position or site for access tube

placement within the macro and micro zones.

Macro and micro zone selection is described in greater detail in the following pages. If you require further

information, consult your Sentek reseller and/or undertake further reading.

Important factors for macro site selection

Many factors can have an impact on the way the water is stored in the soil and on the way crops use that

water. They affect transpiration and evaporation rates and have a direct impact on irrigation scheduling. In

macro zone selection, it is important to consider the way the following factors influence water use in a

particular area or zone:

• Climate

• Soils

• Crop

• Cultural management

• Irrigation system

• Water quality

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 19

Page 27

TriSCAN Manual Version 1.2a

Climate

The most commonly recognized factor in influencing the amount of crop transpiration is the weather.

Temperature

Crops need to draw up water to compensate for water use through transpiration (water loss through the

leaves) and evaporation (water loss from the surface of soil and leaves). The demand increases with

increasing temperature up to a maximum threshold for each crop (when the stomata close and

photosynthesis stops).

Humidity

Atmospheric demand for transpiration and evaporation is relative to the humidity (amount of water vapor in

the air). The higher the humidity level, the lower the demand.

Wind speed

Crop transpiration and evaporation increase with increasing wind speed, creating an increased water

demand. At higher wind speeds, transpiration eventually decreases due to stomata closure, but evaporation

increases.

Solar radiation

On sunny days, crops can synthesize more basic sugars and complex plant food compounds, through

combining atmospheric carbon dioxide and soil-derived water, than on cloudy days. Although crops vary in

their sensitivity of photosynthetic response, they all require access to greater amounts of soil water.

Rainfall

Rainfall is generally associated with higher humidity levels and lower solar radiation and temperatures. It

follows logically, than days on which rainfall occurs, are associated with lower water demand and use than

dry, sunnier days.

Notwithstanding the care taken to delineate macro zones, some variability in soil moisture levels is

inevitable. For example: on large properties rain events may cover only a portion of the agricultural area,

replenishing some soil reservoirs and leaving others dry.

The aspect or orientation of sloping fields can subject the crop to more or less solar radiation, wind exposure

or water run -off – all affecting crop water use.

Soils

An understanding of how soil type influences plant -soil-water dynamics, and hence irrigation scheduling is

important. Intrinsic soil properties are texture, structure, depth, soil chemistry, organic matter content, rocks

and stones and clay type. Influencing factors include compaction, salinity, water -table development,

drainage rate dynamics and topography.

Soil texture

Water storage in the soil profile depends on the soil texture. At the one end of the spectrum, sandier soils

with a low porosity (total volume of pore space) and weak adhesion forces (strength with which water and

nutrients are held), fill up and drain quickly. The nutrient holding capacity is also low and hence these soils,

in general, require smaller and more frequent irrigations and fertilizer/fertigation applications. In contrast, the

heavier clay soils have a high porosity and strong adhesion properties. Consequently, they replenish and

drain slowly and to a higher total water content than lighter (sandier) soils. Nutrient holding capacity is also

high. An infinite range of textures exist between the two extremes. Textures often change within a profile,

with the layering of different textural bands playing a large part in determining the water holding capacity of a

soil.

Soil structure

Water infiltration rates, and air and water permeability within the soil profile are closely related to the size

and distribution of soil pores (porosity). Porosity, in turn, is dependent upon the arrangement and

aggregation (binding) of sand, silt and clay particles (soil structure). Soil structure is as important as soil

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 20

Page 28

TriSCAN Manual Version 1.2a

texture in governing how much water and air move in soil and therefore their availability to crops. Roots

penetrate more easily and rapidly in soils that have stable aggregates, than in similar soil types that have no

or highly developed structures. The effectiveness of soil moisture, air and nutrient utilization, is related to the

efficiency of root colonization of the entire soil profile.

Soil depth

The effective depth of soil affects the extent of root penetration. The deeper the soil, the greater the volume

of soil that is available for gas eous exchange and water and nutrient uptake. Drainage is also affected by

effective depth.

Soil compaction

Soil compaction from farm machinery can change pore size and distribution resulting from the natural

arrangement of the sand, silt and clay particles. This can cause reductions in water infiltration rates, and air

and water permeability within the soil profile. The resultant impact upon the effectiveness of root penetration,

air exchange and nutrient and water uptake, affects plant growth efficiency and hence water and nutrient

uptake.

Salinity

Salinity lowers osmotic potential, reducing the efficiency with which nutrients and water are taken up by the

plant. The dominance of the contributing ions can result in a nutrient imbalance causing deficiencies of

essential macro and micro nutrients. The reduced plant health and vigour affect crop water use.

Water tables & drainage rate

Poor drainage can lead to the development of water tables and/or cause a temporarily saturated soil profile.

The presence of impermeable soil layers can cause the formation of perched water tables, which saturate

parts of the root zone. Efficient gaseous exchange becomes impossible, and plant health and water use is

reduced.

Organic Matter

The presence of organic matter and humus increases the cation exchange capacity (CEC), water -holding

capacity and structural stability of soils. This influence is predominantly in the top soil, although lamellae

(thin organic matter layers further down the profile) can be important properties.

Type of clay

Clays are highly variable in their water -holding capacity, CEC (ability to hold and release nutrients) and

stability (shrink -swell potential). At the one end of the spectrum, the so-called smectite-type clays have high

CEC’s, water-holding capacities and low stability. Highly weathered (kaolinite or oxide) clays, at the other

extreme, are stable with relatively lower CEC’s and water -holding capacities. Most soils have a mixture of

clay types depending on parent material and climate. At present TriSCAN is only recommended for

predominantly sandy soils.

Soil chemistry

Acid, alkaline, sodic (soils characterized by a dominance of sodium ions) or nutrient deficient conditions

impact on expected soil chemical properties. For example:

• pH conditions change CEC; the availability of nutrients (by changing their form) and the solubility of

ions.

• High levels of sodium can lead to structural collapse.

Rocks and stones

Stones and rocks within a soil profile occupy part of the soil volume and hence reduce the soil water storage

capacity. Very stony soils have a substantially lower water holding capacity than soils of the same texture

that are free of stones.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 21

Page 29

TriSCAN Manual Version 1.2a

Topography

Topography relates to the configuration of the land surface and is described in terms of differences in

aspect, elevation and slope. This impacts on plant-soil-water dynamics via influencing climatic conditions

including:

• Rain shadows and sunshine hours

• Rainfall and temperature patterns up slopes

• Elluviation (washing-out) of clays from higher elevations and illuviation (washing-in and

accumulation) of clays at lower elevations

• Relatively poorer drainage at lower elevations

Crop

Crop differences have an impact on crop water use and irrigation scheduling requirements. While all require

management between full point and refill point at most times, the depth of root extraction varies, as do

specialized requirements e.g. the deliberate stressing of horticultural crops during flowering.

Most plant tissues contain about 90% water and the rate of uptake of water from the soil solution by plant

roots is largely controlled by the rate of water loss through transpiration. Plant characteristics such as crop

type, size, age, vigour, variety, rootstock, development stage, leaf area, nutritional status, disease status,

crop load and harvest all affect crop water use. Specialized advice should be sought in this regard. A rough

guide to water use can be obtained from crop coefficients, which are widely available in the literature for

different stages of growth for most crops (Table 5). These express evapotranspiration as a ratio of reference

evaporation (in this case Penman-Monteith).

Table 5. Examples of crop coefficients (FAO)

Crop Kc (initial) Kc (mid) Kc (end)

Green beans 0.5 1.052 0.9

Artichokes 0.5 1 0.95

Cereals 0.3 1.15 0.4

Sugar cane 0.4 1.25 0.75

Alfalfa 0.4 0.95 0.9

Cultural Management

The impacts of cultural management (agronomic/horticultural practices) also need to be understood for

proper irrigation scheduling.

Soil preparation

Cultivation increases evaporation from the topsoil, reducing soil water available to the plant. It may also

reduce water run -off and improve the infiltration of rain and irrigation water, improving plant water

availability. The dynamics of nutrient availability are also affected. An example is the dependence of

mineralization rates, of particularly nitrogen, upon aeration.

Cover crop and mulch

Cover crops provide more competition for water, but reduce evaporation and facilitate infiltration of rain and

irrigation water, reducing run-off.

Mulch can improve the infiltration rate of the soil, reduce water run-off, encourage root growth near the soil

surface and increase the soil water holding capacity over time, through the accumulation of soil organic

matter, and reduc tion of soil temperature.

Oil spraying

Oily substances on leaves reduce water use by temporarily closing stomata. An example of this is mite

control in citrus.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 22

Page 30

TriSCAN Manual Version 1.2a

Fertilizer management

In order to ensure that no nutrients are deficient, fertilizer applications are normally based on soil and/or leaf

sample analyses. The degree of precision varies from a rough averaging approach, to precision farming

where sample points are matched to requirements using satellite tracking technology. He althy crops require

more water and have different nutrient dynamics to crops that have been stunted or diseased through

inefficient fertilizer management.

Pest/disease management

Good pest/disease management keeps the crop protected and in good health, sustaining its potential growth

and transpiration rates. Infestations can result in lower than normal water and nutrient uptake.

Irrigation System

Variations in irrigation system pressure, flow and water distribution uniformity cause variations in irrigation

application. This affects root zone wetting patterns and therefore crop water use.

The preceding crop water use factors should be taken into account when matching your irrigations to areas

of similar crop water use. These areas are then represented by soil water monitoring sites and the data

collected at these sites is used for irrigation scheduling purposes.

Water Quality

The source and constituents of irrigation water, impact on osmotic potential (and hence plant water uptake).

Measured volumetric ion content (VIC), will increase with increasing irrigation water electrical conductivity

(EC). Water quality can vary both within and between seasons and between water sources.

A general view of macro scale zone selection

Macro zone selection is used to ide ntify the total number of required zones and their locations on your farm.

A macro zone comprises areas of similar crop water use and fertilizer requirements.The aim of good site

selection is to select a monitoring site that reflects representative changes in soil water content, fertilizer

mineralization and crop water / fertilizer use trends.

The representative data gained from monitoring sites is used to schedule irrigations over a larger defined

area. This area (or macro zone) may be an entire field, or a sub -section of a field, where irrigation is applied

during a watering shift or fertilizer application.

As an irrigator, you want to replenish the soil water used by plants for growth and transpiration, whilst

maintaining nutrients at a level sufficient to ensure growth, but not too high so as to cause leaching losses. It

is important to understand the many factors affecting crop water use or transpiration and how these factors

may vary on your property.

A primary goal of good irrigation management is to match irrigations to areas with similar crop water use,

within the limits of your irrigation system flexibility. This consideration will ultimately determine how many

monitoring sites you will need and where you should locate them. The diagrams on the following pages

show how ‘factors that affect crop water use’ can be used to determine macro zones.

Firstly the topography must be considered,

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 23

Page 31

TriSCAN Manual Version 1.2a

Then the soils,

Then the type of irrigation and system layout,

And finally, the crop types.

Overlaying all this information makes it possible to identify, within a property, areas (zones) that have

significantly different requirements.

In the example used, the property has been divided into four macro zones. Each macro zone requires a

monitoring site. Potential sites are shown by the dots, but final positioning can be determined by the

information in the micro scale zone section.

Copyright © 1991 – 200 4 Sentek Pty Ltd All rights reserved Page 24

Page 32

TriSCAN Manual Version 1.2a

Micro scale zone selection

During macro zone selection you identified the irrigation management units on your property. Micro scale

zone selection target s the actual site of the access tube in relation to crop and irrigation delivery point.

Note:

Micro zone selection is equally as important as macro zone selection and has a direct effect on the

representative value of the data.

In soil-based monitoring, the measurements are taken from a small part of the root zone. Sentek sensors

record the dynamics of moisture in the part of the soil profile where the access tube has been installed. If

you miss the root system or install the access tube in abnormally dry or wet irrigation spots, the data will not

be representative of the irrigation management unit.

Micro zone selection guidelines

The following is a set of guidelines for selecting access tube installation sites within irrigation management

units. Two major factors need to be taken into account; irrigation and plant health.

Irrigation system

It is important to check that your irrigation system is performing as per design specifications prior to

installation and at least annually thereafter. Variations in sprinkler pressure and flow, pump performance,

distribution uniformity and wind can result in uneven patterns of watering. This can lead to; the development

of water tables, dry spots and salinity problems.

Conducting a Distribution Uniformity (DU) test

Prior to installation, it is also necessary to check the distribution uniformity (DU) of the system. This can be

done with a simple can test. The method involves arranging cans in a grid pattern, in a representative area

within the macro zone. In the example illustrated in Figure 5, cans in the blue shaded area received above