Page 1

ACCESS TUBE INSTALLATI ON GUIDE

Version 1.0

for

EnviroSCAN

EnviroSMART

Diviner 2000

Page 2

Access Tube Installat ion Guide

EnviroSCAN

EnviroSMA RT

Diviner 2000

Al l ri ghts re s erved. No part of this document may be reproduced, transcribed, translated into any language

or transmitted in any form electronic or mechanical for any purpose whatsoever without the prior written

consent of Sentek Pty Ltd. Al l intellectual an d pro per t y r ig hts remain with Sentek Pty Ltd.

All information presented is subject to change wi thout notice.

Names of programs and com puter systems are registered trademarks of their respective companies.

© Copyright 2003 Sentek Pty Ltd

Access Tube Installation Guide Version 1.0

All Rights Reserved.

EnviroSCAN, EnviroSMART and Diviner 2000 are trademarks of Sentek Pty Ltd which may be registered

in ce rt ain jurisdictions. Env iroSCAN, Env iroSMART and Diviner 2000 ar e pr otecte d int er nat i onally by

various patents (and/or patents pending).

Sentek Pty Ltd

77 Ma gil l R o ad

Stepney, South Australia 5069

Phone: +61 8 8366 1900

Fac simile: + 61 8 836 2 8400

Internet: www.sentek.com. au

Email: Sentek@sentek.com.au

Page 3

Access Tube Installat ion Guide Low Res

Contents

Access Tub e Installation Guide i

Contents i

Ab o u t thi s man u al 1

Document Conventions 1

Introduction 2

Site Selection 3

W hat is site selection? 3

Relationship between macro and micro zones i n the field 3

Important factors you should know that affect crop water use 4

A general view of macro scale zone selection 7

Micro scale zone selection 10

Micro zone selecti on guidelines 10

Installing access tubes f or Diviner 2000, EnviroSCAN and EnviroSMART probes 13

Introduction 13

Safety 14

Good versus poor inst allation 14

Standard manual installation method 16

Introduction 16

Items required for standar d manual installations 16

Installati on procedure 18

Troubl eshooting the standard manual installation method 30

S l urry I ns ta l lat i on Meth o d 35

W hat are the different slurry methods? 35

Installati on procedure 38

Removing Access Tubes 45

Items required for access tube removal for EnviroSCAN, EnviroSMART and Diviner 2000 45

Removing EnviroSCAN, EnviroSMART and Diviner 2000 Access Tubes 45

Toolkit Items 48

Sentek access tube items 48

Standard Access Tube Installation Kit Complete (Part No. 07000) 49

Slurry Access Tube Installati on Ki t ( Part No. 07250) 51

Optional T ools for Access Tube Installation 52

Recommended Reading 54

Copyright © 1991 – 2003 Sentek Pty Ltd All rights res erved Page i

Page 4

Access Tube Installat ion Guide Low Res

About this manual

This guide describes the principles of site selecti on and the materials and methods that are used to install

Sentek access tubes .

Document Conventions

Before you start it is important that you understand the conventions used in thi s manual .

Conventions Type of Inform ation

Bold text

This font face This font face is used for the names of tools, methods and miscellaneous i tems, for

Text presented under the heading:

‘Note:’

‘Hint:’

Text presented under the heading:

‘Warning:’

‘Disclaimer:’

‘Caution:’ Information whi ch, if not strictly observed, could result i n dam age to, or destruction

desi gned to be used together. Other brands of probe and access tubes are not

co mpa tible wit h t he Sentek products and shoul d not be used as they m ay damage

Sentek has developed precision i nstallation tools are to be used for the installati on

of Sentek access tubes. The precision of the access tubes and tools is designed

to complement the value of the readings taken by Sentek sensors. The value of

readings is compromised when poor and hasty installation methods are used.

Sentek does not accept any responsibility for damage caused by incorrect site

Bold text is used to highlight names of products and companies, for example Sentek

or an emphasized word, for example, ‘Note:’ or ‘Warning’

example Regu lar T-Ha ndle.

Important information that should be considered before completing an action

Information that makes a process easier or saves ti me

Information whi ch, if not strictly observed, could lead to misleading moisture trends

and wrong irrigation management deci sions.

Cri ti cal information that m ust be considered before completing an action.

Cri ti cal information regarding the liability of Sentek and the responsi bility of the client

to use the equipment responsibly and as described in the manual.

of, equ i pm ent.

Disclaimer:

The access tubes, probes and sensors supplied by Sentek are speci fically

Sentek equipmen t. Damage to Sentek equipme nt th rou gh incorrec t u se will

inva lidate warra nty agreements.

s elec t io n, poor insta l lat io n or inappropria te use of Se nt ek prod uc ts.

Copyright © 1991 – 2003 Sentek Pty Ltd All rights reserved Page 1

Page 5

Introduction

Introduction

The Access Tube Installati on Guide provides important inform ation about how to select m onitoring sites and

install access tubes. Please read this information prior to installing access tubes.

Site selection and access tube installation have a significant impact on the value of the soil moisture data

that can be gathered on your property.

Warni ng: Good Site Sel ec tion is Critical

To obtain representative soil moisture readings, the site where the access tube is

installed must reflect changes in soil moisture and crop water use trends which can

then be used to representatively schedule irrigati ons over a defined area.

This area may be an entire field or a subsection of a field where irrigation water is

appli ed during a watering shift.

The quality of acc ess tube insta llation is cr itic a l. T he acc ess tube must f it ti ghtly

against the soil and cause the least possible di sturbance to the surrounding soil

profile.

To take soil moisture readings, access tubes are installed at m onitoring sites, which should be chosen using

a series of proven evaluation methods described in the section on Site Sel ect ion .

It is important to select monitoring sites so that the information that is gathered from them is representative of

the surrounding crop water use and soil water holding capacity. At each site, one or several PVC access

tubes may be driven into the soil. The access tube prevents the direct contact of the Sentek probe with the

soi l. The bottom stopper and top cap prevent moisture and dirt from enteri ng the tube.

The access tube installati on process is described in the section on Access Tube Installation for Diviner

2000, EnviroSCAN and Enviro SMART .

Warning: If you do not understand any of the inform ation presented here on Site

Selecti on, consult a trai ned Sentek reseller or agronomist. Incorrect site selection

can result in m is lea din g data and/or cr o p damage.

Access tubes are installed using Se ntek precision i nstallation tools designed to install access tubes in a

range of soil types. It is recommended that you always try the Standard manual installation method first. A

slurry method is available for i nstallations in soils with high stone and gravel content.

Note: To identify the tools you require to install the access tube, examine the soil

profile with a shovel or backhoe close to the nominated monitoring si tes. Read the

section on Access T ube Installation for Diviner 2000, EnviroSCAN and

Envi roSM ART to work out which toolkits and additi onal tools will be required for

your install atio ns.

When the monitori ng of a soil profile is no longer required, the access tubes can be removed, cleaned and

stored. T his process is described in the section on Removing Access Tube s.

If you have any questions, Sentek recommends consultation with a trained reseller or agronomist prior to

installation. Trained resellers and agronomists understand the complexity of site selection for irrigation

s c hedu li ng an d the need f or pr o per ins t a l lat io n of the access tubes .

Copyright © 1991 – 2003 Sentek Pty Ltd All rights reserved Page 2

Page 6

Site Selection

Site Selection

The key to effective soil moi sture monitoring is to select monitoring sites which truly represent irrigation

management areas. The same basi c site sel ection principles appl y to the full range of Sentek soil moisture

monitoring devi ces. Many variables influence the spatial distribution of water across an area of land. These

variables and their impact on site selection are di scussed in more detail below.

What is site selection?

A si te is defined here as:

“The location of the access tube within a field or i rrigation shift, where soil water readings are taken at

dif fer e nt dep th l ev e ls wit h in th e so i l profile.”

Note:

If readings are to be used as a basis for scheduling irrigati ons over larger defined

areas, it is imperative that m oni tori ng sites are representati ve of these areas.

Soil moisture data can provide information about the:

• Quality and depth of irrigations

• Level s of soil moisture retention

• Depth of the crop root zone

• Impact of weather and rainfall events on an area

Warning:

Do not sel ect irrigation scheduling si tes at random on your property. Poor site

se lection will re sult in soil moisture data tha t is unrep resenta tive of soil water

changes and crop water use in that field.

Site selection i s carried out in two stages:

• M a cro zone selection

• Micro zone selection

Relationship between macro and micro zones i n the field

Traditional practice within the field and across the whole farm has been for i rrigation to be applied on a

hypothetical “farm average” – i n a similar way to traditional broad acre management practices.

Uniform application of irrigation across areas with highly variable soils and di fferent levels of crop water use

causes signi ficant differences in yield and quality, creating commercial losses and environm ental harm

through increasing problems with rising water tables and increasing salinity.

If di fferent soil types are ignored in terms of thei r different irrigation scheduling requirements, crop setbacks

or failures may occur.

Macro zone selection defines the number of zones on a property where the amount of timing of irrigation

applications can be specifi cally tailored to match soil and crop variability – a macro zone comprises areas

with simila r c rop wat er u se.

Crop water use i s governed by many factors such as soil properties, water quality, weather patterns and type

of irri gati on system. These factors need to be consi dered when defining the macro zones on your property

and are descri bed in the following pages.

© Sentek Pty Ltd Page 3

Page 7

Site Selection

Micro zone selection determines the posi tion of access tubes in rel ation to the crop and irrigation system.

Micro zone selection consi ders the:

• Area of root zone and canopy spread

• Water distribution uniformity (sprinkler pattern)

• Moisture pattern of drip irrigation

• Su rf ace, topographic and soil anomalies

The consi deration of these factors will assist in finding the best representative posi tion or si te for access tube

plac e me nt withi n th e macr o an d micro zones .

Macro and micro zone selection i s described in greater detail in the following pages. If you require further

information, consul t your Sentek reseller and/or a trained agronomist.

Important factors you should know t hat affect crop water use

All the factors li sted below can have an impact on the way the water is stored in the soil and on the way that

plants use that water. They affect transpiration and evaporation rates and have a di rect impact on irrigation

scheduling. In macro zone selection, it is important to consider the way these factors i nfluence water use in

a particular area or zone:

• Climate

• Soils

• Crop

• Cultural management

• Irrigation system

Climate

The most com monly recognized factor infl uencing the amount of crop transpiration is the weather.

Temperature

Crops need to draw up water to compensate for water use through transpiration (water loss through the

leaves) and evaporation (water loss from the surface of soil and leaves). The demand increases with

increasing temperature up to a maximum threshold for each crop (when the stomata close and

photosy nth esis stops).

Humidity

Atmospheric demand for transpiration and evaporation is relative to the humidi ty (amount of water vapour in

the air). The higher the humidity level, the lower the demand.

Wind speed

Crop transpiration and evaporation i ncrease with increasing wind speed, creating an increased water

demand. At higher wind speeds, transpirati on eventually decreases due to stomata cl osure, but evaporation

increases.

Solar radiation

On sunny days, crops can synthesize more basic sugars and more complex plant food compounds, through

the combi nation of atmospheric carbon dioxide and soil-derived water, than on cloudy days. Although crops

vary in thei r sensitivity of photosynthetic response, they all require access to greater amounts of soil water.

Rainfall

Rain is generally associated with higher humidity level s and lower solar radiation and temperatures. It

follows that days on which rai nfall occurs are associated with lower water demand and use than dry sunny

days.

© Sentek Pty Ltd Page 4

Page 8

Site Selection

Notwithstanding the care taken to delineate macro zones, som e variability in soil moisture level s is inevitable.

For example: on lar ge pr oper tie s, r ain events may cov er only a porti on of the land area, replen ishi ng some

soi l reservoi rs and leaving others dry.

The aspect or orientation of slopi ng fields can subject the crop to more or less solar radiation, wind exposure

or water run-off – all affecting crop water use.

Soils

An understanding of how soil type influences plant-soil-water-dynamics, and hence irrigation scheduling is

important. Intrinsic soil properties are texture, structure, depth, chemistry, organic matter content, rocks and

stones and clay mineralogy. Influencing factors include compaction, salinity, water-table development,

drainage rate dynamics and topography.

Soil textur e

Water storage in the soil profile and the rate it dries out, depends on the soil texture. At one end of the

spectrum, sandier soils fill up and drain quickl y. Hence these soils, in general, require sm aller and more

frequent irrigations. In contrast, heavier clay soils replenish and drain slowly and to a higher total water

content than lighter (sandier) soils. An infi nite range of textures exist between the two extremes. Textures

often change wi thin a profile, with the layering of different textural bands playing a large part in determining

the water holding capacity of a soil.

Soil structure

Water infiltration rates and ai r and water permeability within the soil profile are closely related to the size and

distribution of soil pores. Porosi ty in turn, is dependent upon the arrangement and aggregati on (binding) of

sand, silt and clay particles (soil structure). Soil structure is as important as soil texture in governing how

much water and air move in the soil and their availability to crops. Roots penetrate more easi ly and rapidly in

soi ls that have stable aggregates than i n similar soil types that have no or highly devel oped structures. The

effectiveness of soil moisture, air and nutrient utilization i s related to the effi ciency of root colonization of the

entire soil profile.

Soil depth

The effective depth of soil affects the extent of root penetration. The deeper the soil, the greater the vol ume

of soil that is availabl e for gaseous exchange and water uptake. Drainage is al so influenced by effective

depth.

Soil compaction

Soil compaction from farm machinery can change pore size and distribution resulting from the natural

arrangement of the sand, silt and clay particl es. This can cause reducti ons in water i nfiltration rates, and air

and water perm eabi lity within the soil profile. The resultant impact upon the effectiveness of root penetration,

air exchange and water uptake affects plant growth effi ciency and hence water demand.

Salinity

Salini ty lowers the osm otic potential, reducing the effici ency with whi ch water and nutrients are taken up by

the p lan t. The domina nc e of the co ntr i buting i ons can r esu lt in a nutr ie nt imba l anc e ca using de f ic i encies of

essential macro and micro nutrients. The reduced plant health and vigor affect crop water use.

Water tables and drai nage rate

Poor drainage can lead to the development of water tables and/or cause a temporaril y saturated soil profile.

The presence of impermeable soil layers can cause the formation of perched water tables, which saturate

parts of the root zone. Efficient gaseous exchange becomes restricted and pl ant health and water use is

reduced.

© Sentek Pty Ltd Page 5

Page 9

Site Selection

Organic Matte r

The presence of organic matter and humus increases the cation exchange capacity (CEC), water holding

capacity and structural stability of soils.

Soil chemistry

Acid, al kaline, sodic (soils characterized by a dominance of sodium ions) or nutrient deficient conditi ons

impact on expected soil chemical properties. For exampl e:

• pH conditions change CEC and the availability of nutrients (by changing their form). Nutrient

deficient plants have a lower water uptake rate

• high levels of sodium can lead to structural collapse, infiltration problems and reduced water

availability

Rocks and stones

Stones and rocks and other coarse fragments within a soil profile occupy part of the soil volume and hence

reduce the soil water storage capacity. Very stony soils have a substantially lower water holding capacity

than soils of the same texture that are free of stones.

Topography

Topography relates to the configuration of the land surface and is described in terms of differences in aspect,

elevation and sl ope. This has an impact on plant-soil-water dynamics via influencing climati c conditions

including:

• rain shadows and sunshine hours

• rainfall and temperature patterns up slopes

• elluviation (washing-out) of cl ays from higher elevations and illuviation (washing-i n and

accumulation) of clays at lower elevations

• r elat iv e ly p oor er dr ai na ge i n low lying are as

Crop

Crop differences have an impact on crop water use and i rrigation scheduling requirements. While all require

management between field capacity and wilting point at most times, the depth of root extraction varies, as do

specialized requirements, e.g. the deliberate stressing of wi ne grapes.

Most pl ant tissues contai n about 90% water and the rate of uptake of water from the soil solution by plant

roots i s largely controlled by the rate of water loss through transpiration. Plant characteristics such as crop

type, si ze, age, vigour, variety, rootstock, developm ent stage, leaf area, nutriti onal status, crop load and

harvest all affect crop water use. Specialized advi ce should be sought in this regard. A rough guide to water

use can be obtained from crop coefficients, which are wi dely available in the literature for different growth

stages of most crops. These express evapotranspiration as a ratio of reference evaporation.

Cultural Managemen t

The i mpacts of cultural management (agronomi c/horticultural practices) also need to be understood for

pr oper irr i gation sche du li ng .

Soil preparation

Culti vation increases evaporation from the topsoil, reducing the amount of soil water availabl e to the plant. It

may also reduce water run-off and improve the infiltration of rain and irrigation water, improving plant water

availability.

© Sentek Pty Ltd Page 6

Page 10

Site Selection

Cover crop and mulch

Cover crops provide more competition for water, but reduce evaporation and facilitate infiltration of rain and

irrigation water, reducing run-off.

Mulch can improve the infiltrati on rate of the soil, reduce water run-off, encourage root growth near the soil

surface and increase the soil water holdi ng capaci ty over time, through the accumulation of soil organic

matter, and reduce soil tem perature.

Oil spraying

Oily substances on leaves reduce water use by temporarily cl osing stomata. An example of this is mite

contr ol in c it r us.

Fertilizer management

In order to ensure that no nutrients are deficient, fertilizer applications are normally based on soil and/or leaf

sam ple analyses. The degree of precision varies from a rough averaging approach to precision farming

where sample points are matched to requirements usi ng satellite tracking technology. Healthy crops require

more water and have different nutrient dynamics to crops that have been stunted or diseased through

inefficient fertilizer management.

Pest/disease management

Good pest/disease management keeps the crop protected and in good health, sustaining its potential growth

and transpiration rates. Infe stations can resul t in lower tha n normal water uptake.

Irrigation S ystem

The effectiveness of an irrigation system to deliver water affects crop water use. Variations in irrigation

system pressure, flow and water di stribution uniformity cause variations in irrigation application. This affects

root zone wetti ng patterns and therefore crop water use.

The preceding crop water use factors should be taken into account when matching your irrigations to areas

of similar crop water use. These areas are then represented by soil water monitoring sites and the data

collected at these sites is used for irrigation scheduling purposes.

Water Quality

The source and constituents of irrigation water impact on osmoti c potential and hence plant water uptake.

Water quality can vary both within and between seasons and between water sources. Hi ghly sodic waters

can al so affect soil structural properties, reducing water infiltrati on rates.

A general view of macro scale zone selection

Macro zone selection is used to identify the total number of required zones and their locations on your

property. A macro zone com prises areas of sim ilar crop water use. The aim of good site selection i s to

sel ect a monitoring si te that reflects changes in soil water content and crop water use trends.

The representative data gained from monitoring si tes is used to schedule i rrigations over a larger defined

area. This area (or macro zone) may be an entire fi eld, or a sub-section of a field, where irrigation i s applied

during a watering shift.

As an i rrigator, you want to replenish the soil water used by plants for growth and transpiration. So, it is

important to understand the many factors that affect crop water use or transpi ration, and how these factors

may vary on your farm .

A primary goal of good irrigation management is to match irrigations to areas with similar crop water use,

withi n the limits of your i rrigation system flexibility. This consi deration will ultimately determine how many

monitoring si tes you will need and where you should l ocate them.

© Sentek Pty Ltd Page 7

Page 11

Site Selection

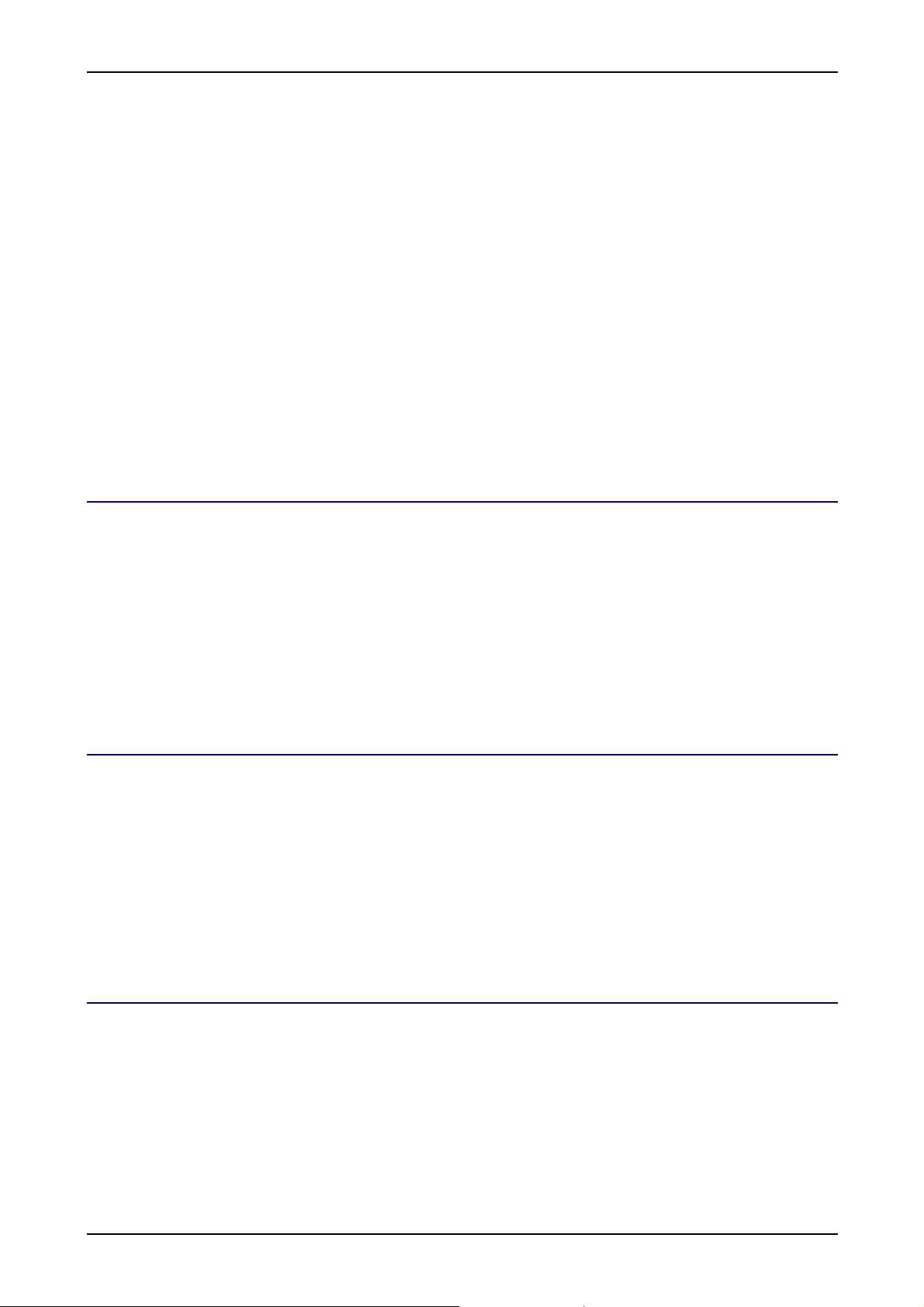

The diagrams on the following pages show an exampl e of how ‘factors that affect crop water use’ can be

used to determine macro zones. Consult your local soil specialist for further information on the soils at your

si te. Firstl y the soil properties and types are considered, to differentiate between areas of varying soil-water

properties:

Then the soil limitations and suitability for the proposed use are identified i n order to determine the need for

s oil impr ovem ents and am elior at io n:

© Sentek Pty Ltd Page 8

Page 12

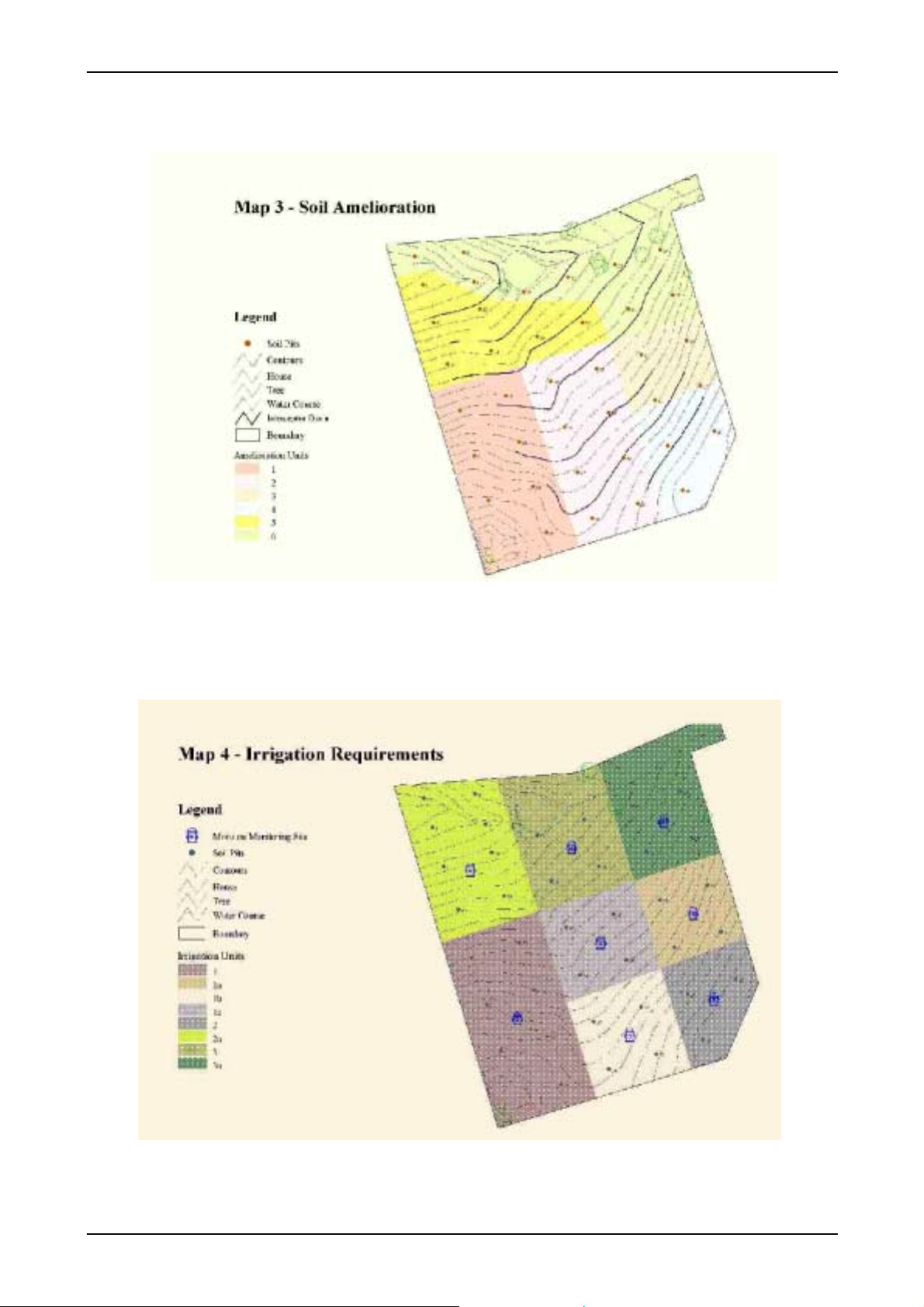

From this the requirements for soil improvements and amelioration are outlined:

Site Selection

Once the soil has been ameliorated and improved, then the altered soil properties are considered in

conj unction with the topography, irri gati on system and crop types to delineate irrigation management units.

© Sentek Pty Ltd Page 9

Page 13

Site Selection

Overlaying all this information makes it possible to identify, wi thin a property, areas (zones) that have

si gnificantly different requirements.

In the example used, the property has been divided into eight macro zones. Each m acro zone requires a

monitoring si te. Potential sites are shown by the dots, but final posi tioni ng can be determined by the

information in the micro scale zone sel ection.

Micro scale zone selection

With macro zone selection you have identi fied the i rrigation management units on your property. Micro scale

zone selection is used to target the actual site of the access tube in relation to crop, micro-scale soil

var iability and ir r iga tion deliver y point.

Note: Micro zone selection is equally as important as macro zone selection and

has a direct effect on the representati ve value of the data.

In soil-based monitoring the measurements are taken from a small part of the root zone. Sentek sensors

record the dynamics of m oisture i n the part of the soil profile where the access tube has been installed. If

you miss the root system or install the access tube i n dry or wet irrigation spots, the data wi ll not make sense

and cannot be used for irrigation scheduling, as it will not be representati ve of an entire i rrigation

management unit.

So il moisture m onitorin g ins t r um ents are of t en bl a med if there is no inc rease in moistur e c ontent aft er a n

irrigation, but testing will al most always show that the si ting of the equipment i s wrong. For example i t is

common to fi nd that the access tube is placed in a dry spot, cause by a sprinkler system havi ng a poor

distribution uniform ity. Also, on slopi ng ground, the lateral movem ent of water needs to be taken into

consideration when si ting the access tube.

Where there are variations in the micro relief or soil properties and depth over very small distances that

affect the root di stribution and growth of the plant (e.g. in gilgai soils), it may be necessary to i nstall more

than one soil moisture probe in the same area to represent these variations.

Micro zone selection gui delines

Followi ng i s a set of guidel ines for selecti ng access tube i nstallation sites within irrigati on m anagement units.

Thre e ma jor fac t or s need to be taken in to ac co unt; irr ig ation, pl ant health and s oi l type.

Irrigation sy ste m

It is important to check that your irrigation system is performing as per the design specifi cations prior to

installation. Variations in sprinkler pressure and flow, pump performance, distribution uniformity and wind

can result i n uneven patterns of watering and irrigation depths. This can lead to salinity problems,

development of water tables, water logging, root death and an overall decline in crop health, yield and

quali ty.

Before you commence irrigation scheduling make sure your irrigation system performance is at an

acceptable level. Read the recommended l iterature (Merriam & Keller, 1978) to perform detailed checks on

irrigation systems or contact your irrigation consultant or Department of Agriculture for further advice. It is

important to check your i rrigation system at least once a year.

Conducting a distribution uniformity (DU) test

Prior to installing the site, it is also necessary to check the distribution uniformity of the system. The

uniformity of water distribution from sprinkl ers can be checked with a simple can test. The method involves

arrangi ng cans in a grid pattern withi n the wetted area and measuring the volume of water i n each can.

© Sentek Pty Ltd Page 10

Page 14

Site Selection

In the example illustrated below, cans in the blue shaded area received above average water; those in the

red shading below average; while those in the green shaded area received an average amount.

Due to the specific nature of each site in terms of irrigation system, it is inappropriate to give prescriptive

adv ic e on tu be pl ac e me nt. For soil mo is tur e mo ni tor i ng, tu be placement s hou ld how ever, be re pr esenta t iv e

and consistent of the area being watered. General guidelines for commonl y used systems and principles of

sample site sel ection fol l ow.

For sprinkler systems, it is preferable to use two access tubes per site, placing one into an area receiving

average precipitation and the other one into a wet or dry spot, depending on a soil salinity or water table

problem.

In centre pivots, if the distribution uniformity tests show si gnificant variation between booms, two or more

access tubes should be installed, with at l east one tube in each different area. For high pressure rain guns,

measure the water application pattern under di fferent wind conditions to ensure that you don’t pick on area of

extremely l ow or high water application.

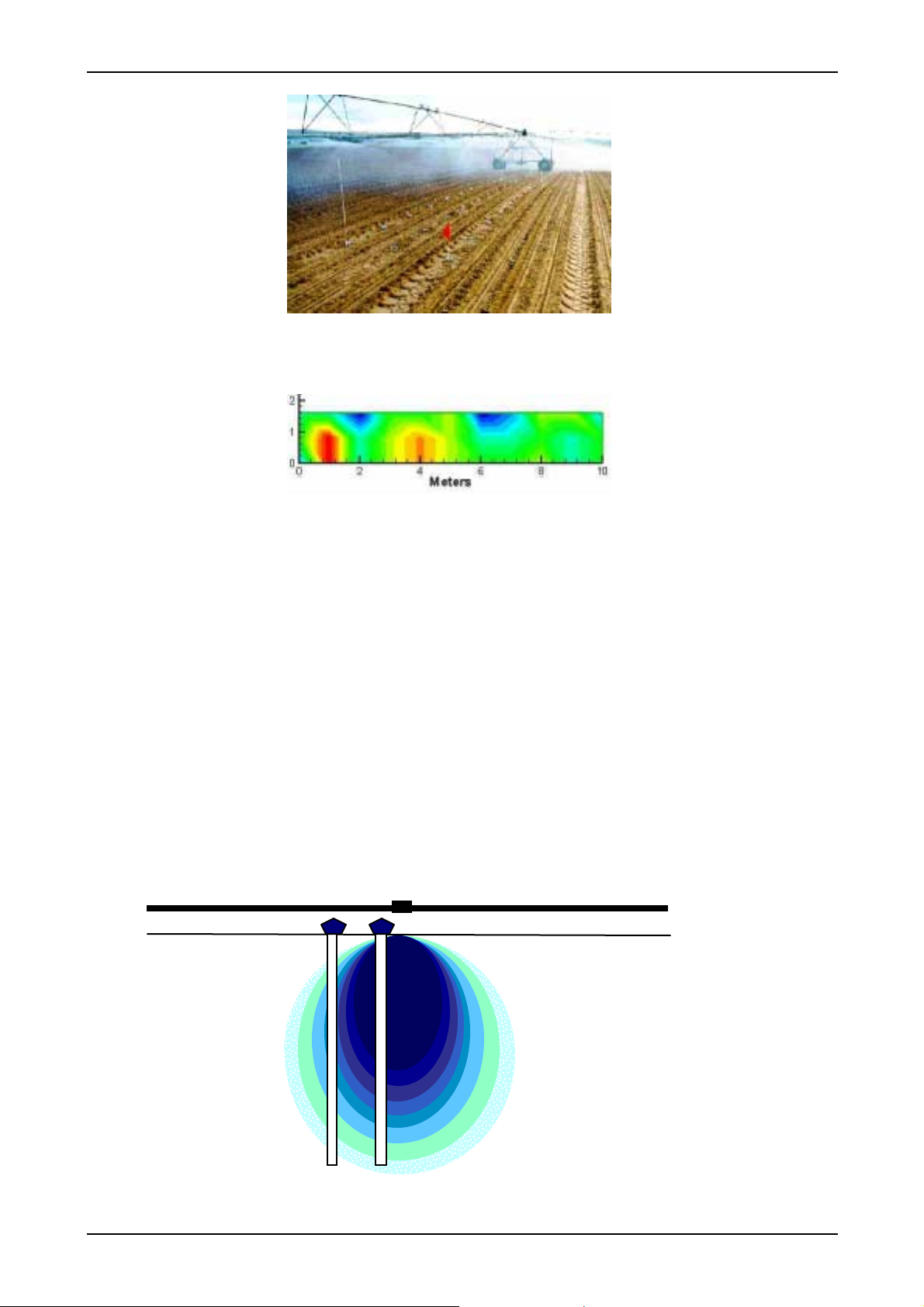

Installation of probes in drip irrigated crops needs consideration of the extent of the ‘wetting onion.’ Use at

least two probes to moni tor soil moisture of drip irrigated crops to measure both the vertical and the lateral

spread of water. The schematic below shows an example of the variation i n the wetting pattern below a

dripper. The darker blue colour signi fies wetter soil conditions, while the lighter blue colour signifi es drier soil

condi tions. The pl ant roots will utilize the water from di fferent locations under the dripper at different

intervals; therefore it is very important to measure these differences using more than one probe.

© Sentek Pty Ltd Page 11

Page 15

Site Selection

In addition, in drip irrigation, the slope needs to be taken into consideration, to account for movement of

wate r do wn slop e.

In furrow irrigated fields, access tubes should be installed 50 to 100 metres away from the head ditch.

Access tubes should not be installed solely at the opposite side to the head ditch, as tail water from the

irrigation may back up the furrows and give unrepresentative readings. Placement of tubes here may be

considered when measurement of deep percolation below an irrigation field is required. Consideration

should also be given to placing another tube in the middle of the field to measure the depth of irrigation

there.

Plant h ealth

Select a site next to an average-sized, heal thy plant representing the Irrigation management unit. Avoid:

• Stunted or sick plants

• Unusual ly l ar ge p lan ts or trees

• Spots where plants are missing

General guidelines for key crops include:

• In fi eld crop and vegetable production, choose a uniform crop stand, and ensure that the

probes are inserted within the actively growing root zone.

• In orchards, use two access tubes to monitor the site. Place one access tube under the

canopy of the trees and another outsi de the canopy – there will be some interception of rainfall

by the canopy so less rain water will penetrate the ground directly under the canopy. Select a

si te that represents dynamic data trends (more root activity) and again consi der irrigation

dist r ibu tion unif ormity.

Soil p roperties

Soil properties influence probe placement in drip irrigati on, as the wetti ng pattern is highl y dependent upon

the soil. In uni form sands, most of the water applied under the dri pper will tend to move vertically through

the profile, with minimal lateral spread. Conversely, i n uniform clay soils, the water will tend to spread

laterally as well as vertically. In soils of contrasting textures, there will be varyi ng wetting patterns that need

to be taken into consideration.

In many soils there are substantial variati ons in the thickness of horizons and in the potenti al rooting depth.

This can lead to si gnificant variations in soil water storage capaci ty and plant growth over relatively short

distances. Under these conditions, it is recomm ended to install to two access tubes to ensure that this

variability is taken into accou n t.

Other micro zone selection considerations

There are several other factors when considering micro zone selecti on that also need to be taken into

consideration. These are:

• Do not install access tubes in outsi de rows. These locations are usually exposed to wind and

dust, particularly in the vicinity of roads or adjoining broad-acre properties.

• Avoi d the ‘drip ring’ in, for example, citrus orchards, where sprinkler irrigation water is

channeled by the canopy to the outside bottom edge of the foliage creating wetter soil

condi tions at the edge of the canopy.

• Avoi d wheel tracks (and wheel track rows) as the soil is more compacted in these areas and

stores less readily available water than the rest of the field (non wheel track rows).

© Sentek Pty Ltd Page 12

Page 16

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

Installing access tu b es for Divin er 2000, EnviroS C AN and

EnviroSMART probes

Introduction

It is ne cessary to install Sentek access tubes before Sentek sensors can be used to measure vol umetric soil

water content. Access tubes are installed at sel ected sites usi ng Sentek instal lation tools. The tools are

specific to the installation method so it i s important to understand the installati on method before purchasing

your installation tools. A slurry installation method may be used for soil with a high gravel and stone content.

Note:

Inspect the soil types on your property prior to undertaking an installation to

ensure that you have the correct tools. The standard installation kit is designed for

installation i n most soi l types, but in some situations such as very heavy clay or

roc ky soils, additional tools may be require d.

Once you have i dentified your soil properties, read the rel evant section of this

manual to determine what tools you require.

If yo u ar e unsure about any aspect of t he i nstalla t ion m et h od, c on tac t y our Sen tek

reseller and discuss the sites you have selected and your installation needs.

The aim of the installation process is to cause minimum disturbance to the surroundi ng crops and soil profile.

Disturbances to the soil may introduce pockets of air and loosely packed soil material. The disturbances

affect the contact of the outer surface of the access tube wi th the surrounding soil profile and may lead to

preferential flow of irrigation water or rain to a greater depth compared with the rest of the field. If readings

are taken under disturbed soil conditions they m ay by i ncorrect or misleadi ng.

Warning:

Access tubes must be installed so that they fit tightly in the soil along their entire

length. Permanent errors can be introduced into the readings through poor or

hasty installations. Any air gaps between the length of the access tube and the soil

will cause data deviations.

For exa mp le , the penet r at i on de pt h of an ir r i ga ti on appear s to be m uc h de eper if

there is an air gap next to the access tube. This misrepresents the depth of the

irrigation in the field at that site.

The addition time taken i n careful installati on ensures access to accurate and

me an in gfu l dat a.

© Sentek Pty Ltd Page 13

Page 17

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

Disclaimer:

The access tubes, probes and sensors supplied by Sentek are speci fically

desi gned to be used together. Other brands of probe and access tube are not

compati ble with the Sentek products and should not be used as they may damage

Sentek equipm en t thro ug h inco rrect use a nd will invalida te warranty agreement s.

Sentek has developed precision i nstallation tools to be used for the installation of

Sentek access tubes. The precisi on of the access tubes and tools is designed to

complement the high value of readings taken by the Sentek sensors. T his value of

both relative and absolute readings is compromised when poor and hasty

installation methods are used.

Safety

Sentek encourages the use of safe practices that minimize the risk to users, their machinery and their

property. The following safety information i s provided to help you prevent acci dents on your property.

Carrying equip ment into th e field

An access tube installation requires access tube kits, toolkits, miscell aneous tools and duck boards. Often

yo u can not drive a vehi cl e al ongsi de the installation si te so it is i mpo rtant to conside r ho w y ou will ge t the

required equipment to the site.

The toolkits come i n cases that protect them from the elements and from general damage. T hese ki ts have

handles to help you carry them into the field. It is important to carry the longer kits in a way that does not

place undue stress on your body nor damage crops.

When carrying equipment into the field remember to:

• Bend your knees and keep your back straight when lifting

• Make several small trips rather th an trying to carry too much at one time

Wor k ing with in sta lla tio n e quipm e nt

It is important that you wear gloves and safety goggles to protect your hands from burns and to prevent your

eyes from penetration injuries caused by splinters of metal or soil.

When using motors to drive augers, ensure you wear ear protectors to minimize the affects of the motor on

your hearing.

Protect ing and caring for equipment

There are numerous items in the various toolkits. It is important to keep all of the items clean and to put

the m away in the ir pr otectiv e cas es when not in use.

Good versus poor installation

The aim of any installati on i s to cause as little disruption to the normal soil structure as possi ble, and provide

an envi ronment where the soil moi sture may be detected repeatedly and accurately over an extended period

of time.

If the surrounding soil is disturbed during the installation process, then air gaps m ay form down the side of

the tube, which can lead to preferential flow of water between the soil and the access tube. Water will travel

dee per t han in the s ur r ound in g s oi l, lea di ng t o a mis l ea di ng r e pr esent at ion of wat er mov emen t in the soil.

© Sentek Pty Ltd Page 14

Page 18

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

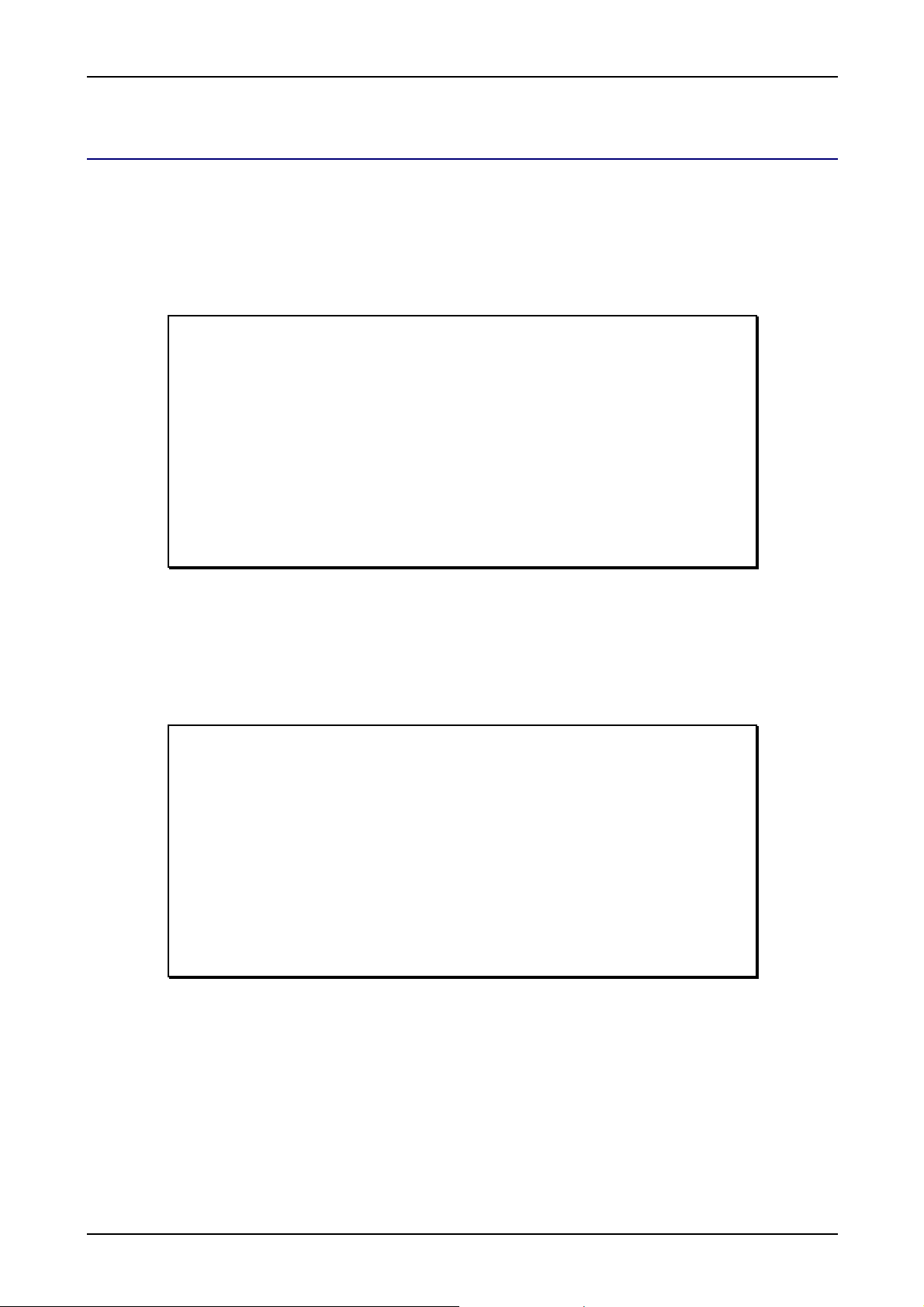

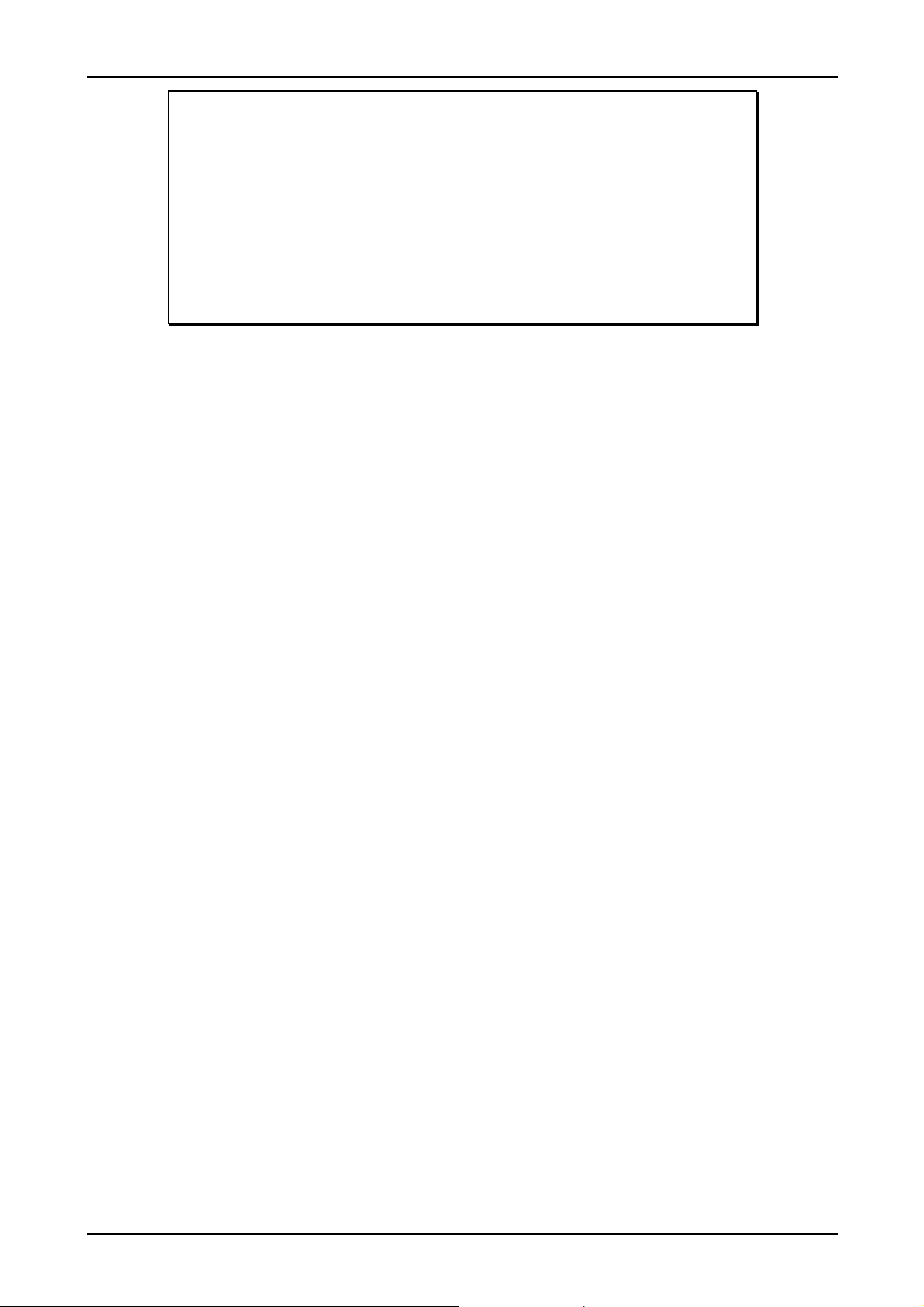

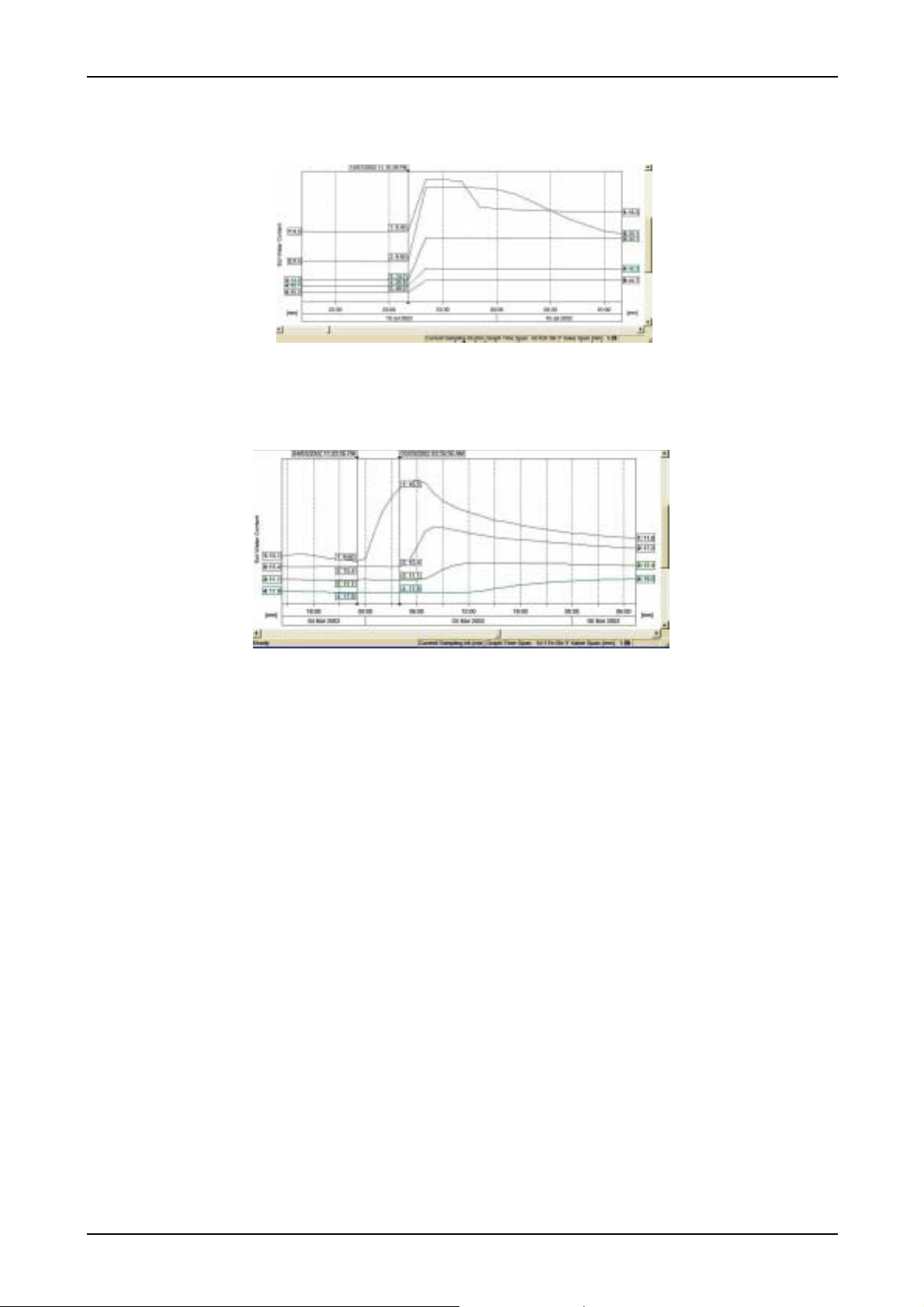

The figure below shows preferential flow of water down the side of the access tube, where the wetting front

moves to the bottom sensor almost instantaneously.

The movement of wetting front should match the hydraulic properties of the soil, such as shown in the

exa mp le be l ow .

© Sentek Pty Ltd Page 15

Page 19

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

S tandard manual inst al l ation method

Introduction

The Standard manual installation method is recommended for most soil types. In this method the access

tube hole is hand augered into the soil, through and slightly ahead of the access tube. This i s done using the

47.0 mm Regular Auger. The augered hole is slightly smaller than the access tube. The access tube is

fitted with a cutting edge that cuts the l ast of the soil away, providing a ti ght fit down the length of the access

tube.

This method prevents the formation of air pockets along the length of the access tube and causes minimum

disturbance to the surrounding soil profile. Thi s installation method is proven to be the most reliable and

provides the best soil moisture data.

Items required for standard manual installations

Sentek has developed a set of installation tools specifically for the installati on of their access tubes. An

inst allation requires:

• Sentek access tube item s

• Sentek toolk its

• Miscellaneous items

Each toolkit comes in a protective carry case. Items that look similar are marked with their measurements for

easy identification. Protective tubes are included to encase augers and other sharp tools. This protects

them in transit and prevents damage to the tool bag.

All tools requi red for the Standard manual installation method are contained in the Standard Access Tube

Installation Kit Complete. The tools are supplied in two carry bags.

Read through the installation method to identify the tools, cutting edges and bottom stoppers you will need

and ensure you have those tools before proceeding to the installation site.

Sentek access tube it ems

Item Part Number

Div iner 2000

Access Tube Ki ts at ordered

lengths (includes Access

Tubes, Cutting Edges, Top

Cap Assemblies and

Expandable Bungs)

EnviroSCAN & Envi roSMART

Access tubes at ordered

lengths

Cutting edges

Top cap assembly complete

Expandable bungs

11720, 11700, 11710

20510, 21010, 21510, 22010

80035, 80040

22400

22455

© Sentek Pty Ltd Page 16

Page 20

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

Toolkit items

Item Part Number

Sta ndard Acce ss Tube Ins tallation Toolkit Complete

Part A – Auger Kit, includes:

1 x Regular Auger 47.0 mm

1 x Regular (clay) Auger 53.0 mm

2 x Auger Extension Rods (0.5 m)

1 x Auger Extension Rod (1.0 m)

1 x Regular T -handle

2 x Tommy bars

1 x Access tube rag cleaning tool

1 x Access tube brush cleaning tool

1 x Access tube bailer

1 x Expandable bung tightening tool

1 x Extraction tool

1 x Toolbag No. 1

Part B – Tripod Kit, i ncludes:

1 x Access tube installati on tripod

3 x Tripod anchor pins

1 x Base plate

1 x Auger centralisation pol y guide

07050

07000

70135

70140

70125

70130

70150

70190

70110

70112

70195

70160

70305

70100

07150

70230

70215

70220

70225

© Sentek Pty Ltd Page 17

Page 21

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

1 x Ny lon dolly

1 x Heavy duty dolly

1 x Toolbag No. 3

M is c ellan e ous ite ms (ins taller t o sup ply)

• A le ngth of rope – to tie branches or vines tem porarily out of the way so that they do not get

damaged or i nterfere with the augering process

• A se t of duck boards – to prevent soi l compaction around the access tube during the

installation process

• 1 x sledge ham m er – to drive the access tubes i nto the soil. A 3-4 kg (8-10 lb) hammer is

recommended.

• 1 x meas uring tape – to measure the required depth

• 1 x marki ng pen

• 1 x 10 litre (2 gallon) bucket – to collect the augered soil and remove it from the site

• 1 x flashlight (torch) – to inspect the inside wal ls of the access tubes after the cleaning

process

• 1 x notepad and pencil – to record the depth and texture variation throughout the soil profile

and any other site information

• Methylated spirits – to moi sten the cloth used with the access tube rag cleaning tool to

remove possibl e water and mud from the walls of the access tube, if required.

• Cotton cleaning cl oths – to clean the inside of the access tubes and other tools after

installation.

• Silicon glue – to seal the base of the top cap to the top of the access tube.

70205

70210

70300

Installation procedure

Step 1 – Preparing the sit e

In all installati ons, disturbance to the surrounding crops and soil profiles must be minimized because soil

compaction alters the capacity of the soil to absorb water.

1. Use duckboards at the site

2. Use ropes to tie crops out of the way if necessary

Step 2 – Assembling the tripod

The tri pod keeps the auger in a stationary central position and prevents di sturbance to the surrounding soil

through ‘wear out’ or hole enl argement. It also stabilises the access tube during the installati on process by

stopping the access tube from flexing at the point where the access tube enters the soil each time i t absorbs

a hammer blow. This prevents air gaps from forming along the side of the access tube.

Warning:

This tripod must be used to ensure a sound installation using the standard

‘through the access tube drilling method.’ Any air gaps between the access tube

and the soil will give false readings.

© Sentek Pty Ltd Page 18

Page 22

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

To assemble the tripo d at the site:

1. Attach the base plate to the base of the tripod.

2. Centre the access tube installation tripod over the site where the access tube is to be

installed.

3. Loosen the wing nuts and spread the legs of the tripod until the base plate touches the

gr oun d and the low er le gs are pro tr udin g approx i mat e ly 5 cm (2 inches ) out of t he up per le g

sections. Note: The legs of the tripod can be adjusted for a straight access tube i nstallation

on sl opi ng ground or on top of m ounds.

4. Secure the tripod i n position by driving the tripod pins through the holes in the foot of each

leg into the soil using a sledge hammer. Note: Ensure the pin head touches the foot plate to

ensure the feet of the tripod legs don’t move during installation.

5. Check that all the wing nuts are loose. Insert the sledge hammer handl e into the tri pod

cylinder and straighten the tri pod by moving the tripod cylinder into a vertical position.

© Sentek Pty Ltd Page 19

Page 23

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

Watch the bubble in the spirit level on the side of the tripod. Move the handle around until

the bubble is located in the centre of the level window.

6. When the tripod cylinder is in a vertical position, firmly tighten the wing nuts of the legs.

S tep 3 – In s talling th e a c c e s s tube

Access tubes are supplied with 50 cm (20 inches) of extra length to accommodate at least one bottom

stopper. In sites severely affected by a water table, two bottom stoppers may be used.

To install the access tube

1. Put on gl oves to protect your hands and increase your ability to gri p the equipment.

2. Put on safety goggles to protect your eyes from metal splinters, which may dislodge from the

inst allation dolly on hamme r impac t.

3. Select the yellow metal cutting ed g e. Tu rn the cutting edge on its sid e and, with a twi sti ng

motion, shave a layer of PVC from the lip of the access tube. Carefully bounce the access

tube and the partially fitted cutting edge on the si de of the sl edgehammer head until the

cutting edge fits squarely onto the end of the access tube.

© Sentek Pty Ltd Page 20

Page 24

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

4. Select the 47.0 mm regular auger head. Note: This auger is designed for all soils and

should be used where possibl e, even in heavy textured soils, as it provides the best

possibl e access tube installation method. The other augers are used to take over when you

run into probl ems. See the Troubleshooting Section for further information.

5. Select the required extension rods and screw the au ger hea d an d T-handle to the extension

rods.

Note: To add extra extension tubes to an existing auger assembl y,

place the auger on the ground. Insert the Tommy bar into the hole of

the ext e nsion tu be be l ow th e T-Handle. Loosen the extension rod from

the T-handle using one quick jerk of the T ommy bar. When loose,

remove the Tommy bar and unscrew these two parts until separated.

Screw the additional extension(s) onto the exi sting auger extension and

refit the T-Handle.

6. The total length of the auger should be a minimum of 20 cm longer than the access tube.

Push the auger through the access tube until the auger head protrudes by 20 cm. Use the

marking pen to mark the auger extension rod at the point where i t disappears into the top of

the access tube. This mark is later used to show the depth to which to auger.

© Sentek Pty Ltd Page 21

Page 25

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

7. Disengage the metal “tooth” on the tripod by turning the lever located on the tripod cylinder.

The metal “tooth” is designed to prevent the access tube from spinni ng during augering, and

should not be engaged while hammering in the access tube.

8. Insert the access tube with fitted cutting edge into the tripod guide tube, with c utting edge

facing downwards.

9. Select the H eavy du ty dolly and insert it i nto the top of the access tu be.

10. Use the sledge hammer to tap the dolly until the access tube is embedded approximately 510 cm (2-4 inches) i n to the soil.

11. Place the auger inside the a ccess tube and turn the auger handle clockwise to remove the

soi l from inside the access tube. Continue to auger ahead of the access tube by

approximately 20 cm (8 inches). Use the pen mark on the rod to indicate when the desired

© Sentek Pty Ltd Page 22

Page 26

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

depth has been reached. Note: If the access tube spins while augering, engage the meta l

“tooth” on the tripod by turning the lever located on the tripod cylinder.

12. Use the auger cleaning tool to remove the soil from the auger head. Do not empty the

augered soil near the access tube as it may change the infiltration rate of irrigation and

rainfall . Dispose o f the so il away from the monitorin g site.

13. Sel ect the Heav y dut y dolly and re-insert it in the top of the access tube.

14. Turn the lever to make sure that the meta l tooth on the tri pod cylinder is “disengaged”. T ake

the sledge hammer and hit the dolly to drive the access tube further into the pre-drilled hole.

15. When you reach the bottom of the pre-drilled hole, hammering becomes noticeably more

difficult. Re m ove the do lly .

© Sentek Pty Ltd Page 23

Page 27

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

16. Auger ahead of the access tube by approximately 10 – 20 cm (4 – 8 inches). Alternate

between augering and ham mering until the dolly resting on top of the access tube nearly

touches the top of the tripod.

17. Insert the yello w Nylon dolly (which has the same diameter as the access tube) into the

access tube and continue hammering and augeri ng until the mark on the dolly is l evel with

the top of the trip od.

Note: Installing the access tube to this depth will enable the ba se of the

top cap to sit flush with the ground. T his will position the middle of the

first sensor at 10 cm below the ground surface. Som etimes i t may be

desi rable to posi tion the first sensor 5 cm below the ground surface. If

this is the case, only hammer in the yellow ny l on do l ly until the mark on

the dolly is 5 cm above the top of the tripod.

18. Auger out the remaining soil from insi de the access tube.

19. Remove the tripod pins by insert ing t h e Tommy bars into the holes of the tripod pins and

pu lli ng them upwards with a twis t ing motio n.

© Sentek Pty Ltd Page 24

Page 28

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

20. When all pins are removed, carefully lift the tri pod straight upward and off the access tube.

21. Try twisting and moving the tube backwards and forwards while examining the surface soil

surrounding the access tube. The tube should not m ove and there should be no visible air

gaps.

22. If there is an air gap, retri eve the access tube and start the installation process again at a

site that is at least on e metre away from the failed installa tion.

Note: Clean the tools and return them to the case after use to ensure they are not

lost or damaged.

© Sentek Pty Ltd Page 25

Page 29

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

St ep 4 – Cleaning t he access tube

The access tube must be cleaned before the top cap is installed and readings are taken. The bottom

stopper i s installed after cleaning in all soils, except for very wet and saturated soils. In these soi l s it is

in stalled first to prevent the rise of wate r into the tube during cleaning.

To clean th e tube

1. Installing an access tube in most soil types leaves a thin layer of soil coating on the inside

wall.

2. Detach the au ger head and attach the Access Tube Nylon Brush Cleaning Tool to the auger

extension. Plunge it up and down the access tube using a rotating acti on. T he brush tool

wil l d is lod ge any s oil coatings.

3. Select the Access Tube Rag Cleaning Tool. Fold the cleaning tool to i ts full length and

s ec ur e it by s l id in g t he locking br ac ket int o p l ac e.

4. Insert a clean cotton cloth into the eyelet and saturate it with methylated spirits.

5. Insert the cotton cloth and move the tool up and down the access tube to clean any

remaining soil particles from the wall of the access tube. The methylated spirits will also

acc e ler at e the dr y i ng pr ocess on th e ins id e of t he tub e if the rem ov e d soil is w et.

© Sentek Pty Ltd Page 26

Page 30

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

6. Change cotton cloths as required and continue with the cleani ng action until inspection with

a flashlight (torch) shows that the access tube is clean and dry.

7. Note: In sandy soils, it m ay not be necessary to use the nyl on br ush to ol as the access tube

can be easily c le aned w ith the rag tool. An alternative is to use a f oam cle aning tool, which

is avai lable as an Optional Extra (refer to section on Toolkit Items).

S tep 5 – In s talling the bott om sto ppe r bung

The bottom stopper bung is installed after the access tube has been cleaned in all soil conditions, except for

in very wet and saturated soils. In these conditions, the bottom stopper bung is installed prior to cleaning.

To ins tall t he bo t t om st o ppe r bung

1. Ensure the access tube is clean before proceeding.

2. P artially insert t he expandable bu ng i nto the access tube and hold it at the upper end so that

about 75% of the top rubber ri ng i s withi n the access tube.

3. Tighten the wing nut to the point where there is enough fri ction on the wall of the access

tube to prevent the bung from turning in the tube while the wing nut is tightened. Note: Do

not tighten the bung t oo much as air will be un able to move past the bun g and will ma ke it

hard or impossibl e to push to the bottom of the access tube.

4. Attach the Expandabl e Bung Tightening Tool to the auger extensi on rod and use the tommy

bars to tighte n it f irmly to the extensi on rods.

Caution:

Failure to tighten this tool securely may resul t in the tool loosening,

coming off the extension rod and landing i n the bottom of the access

tube.

© Sentek Pty Ltd Page 27

Page 31

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

5. Place the Expandable Bung T ightening Tool over the wi ng nut and slowly push the bung

down the access tube. Allow ai r to escape until the bung rests on top of the internal cutting

edg e o n t he inside of the tube.

6. Sl owly tur n the T-Handle until you feel you firm resi stance to further turning. Note: The

bottom stopper bung is designed to run out of thread while tightening. This prevents over-

tightening whi ch could cause damage to the walls of the access tube.

7. When the bung is sitting tight, twist the tool clockwise quickly while pulling upwards. This

will release the spring on the tool from the wi ng nut and enable you to pull the tool out of the

access tube.

Warning:

A watertight installation of the bottom stopper bung is essential to

prevent m oisture and free water entering the access tube. Water inside

the access tube will distort soil moisture readings and damage electronic

circuitry.

In soils with water tables, it may be necessary to use two bottom

stoppers to ensure a totally water tight installation.

S tep 6 – In s talling th e top c a p

The top cap assem bly i s installed after the access tube has been cleaned and the bottom stopper fitted.

To install the top cap

1. Make sure the 4 cm (1.6 inches) of access tube protruding from the soil is clean inside and

out.

© Sentek Pty Ltd Page 28

Page 32

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

2. Take a si licon gun with a new nozzle and apply three rings of silicon around the outside of

the access tube, approximatel y 1 cm (0.4 inch) below the top rim of the tube.

3. Unscrew the cap from the top cap assem bly base.

4. For EnviroSCAN an d Envi roSMART applications, feed the cable through the Fai rRite bead

and then through the ca b le gland.

5. Take the top cap base and slowly push it onto the top of the access tube wi th a slight

forward and backward rotating motion until the bottom foot of the top cap touches the

undisturbed soil surface. T his wil l di stribute the si licone evenly.

Note: Ensure that no soil, grass or other material is present between the

top cap and access tube, as this can provi de pathways for water

movement through the silicon and into the top cap.

6. For EnviroSCAN an d Envi roSMART installati ons, ensure that the cabl e glan d is pointi ng in

the direction that the cable i s to be laid.

7. Wipe off any excess silicon from inside the access tube.

© Sentek Pty Ltd Page 29

Page 33

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

8. For EnviroSCAN an d Envi roSMART probes, strip back the outer sheath of the cable until the

end of the outer sheath sits just inside the cable gland. Fill around the wires inside the end

of the cable sheath with silicone to prevent moisture from travelling along the cable into the

top cap. Insert the electronics and connect the cable to the probe interface. For further

details on wiring of probes refer to the EnviroSCAN and EnviroSMART hardware manuals.

Posi tion a dry silic a gel bag on top of the electronics.

9. Screw the top cap back onto the top cap housi ng. For EnviroSCAN and EnviroSMART

probes, tighten the FairRite Bead on the cabl e next to the top cap.

Troubleshooting the standard manual installation method

The f oll ow i ng a lter n ative acc ess tube insta l lat i on t ec h n iqu es may be used wh en t he Standar d ma nual

installation method proves unsuccessful.

Read the description of the problem and its solution. Select the solution that best fits your situation before

trying the method. Alternative tools are available to assi st in difficult installations and can be purchased

separatel y as optional items (refer to section on Toolkit Items).

M ois t and s tick y he a vy clay s oils

Under moist and sticky, heavy clay conditions, the standard method of augering through the access tube and

hammering in the access tube may be too strenuous using the 47.0 mm regul ar auger. If thi s is the case,

us e the fo l lowin g install ation meth od.

To install access tubes in moist and sticky heavy clay soils

1. Ensure the tripod i s set up correctly and centred over the instal lation si te.

2. Select the 53 mm Clay auger and the required extension rods.

3. Fit the Auger Stabilisation Poly Guide over the extension rods and attach the T-Handle.

4. Put on gl oves and safety goggles to protect your hands and eyes from damage.

© Sentek Pty Ltd Page 30

Page 34

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

5. Insert the assembled auger into the tripod ensuring the centralization poly guide is fitt ed to

the top of the tripod cylinder.

6. Turn the auger 4-5 turns and lift i t gently approximately five centimetres, then turn the auger

another 3-4 turns. The lifting action moves the soil upward, partially filling the space around

the auger head and providing a greater uptake for additional soil. Note: Do not try to auger

too muc h s oi l at on e tim e, as the au ger may ov er - fi l l with s oi l, mak in g it d iffic u lt to r e m ov e

from the hole.

7. Clean the auger head and repeat the process to the required depth of installation.

8. When augering is complete, check the final depth with a measuring tape to ensure that you

have enough depth for your tube length. To posi tion the middle of the fi rst sensor at 10 cm

below the ground surface, ensure that 4 cm of access tube is protruding above the ground.

9. Ensure the yellow metal cut ting edge is fitted sq uarely onto the access tube.

10. Place the access tube fitted with cutting edge i n the tripod guide and insert the heavy du t y

dolly into the top of the access tube.

11. To prevent the access tube from flexing, attach extension rods to the Heavy Dut y Dolly,

ensuring they are firmly tightened.

12. Drive the access tube into the ground usi ng the sledge hammer. If the driving of the access

tube becomes too strenuous, use the 47 mm regular auger to clean out the soil shavings

repeatedly from the inside of the access tube. Continue hammering until you have reached

the fi na l de pth.

Dry an d heavy clay so il

For dry and heavy clay soils the Dry Clay 56.0 mm auger (available from Sentek as an accessory item) is

used as it cuts only 0.5 mm sm aller than the outside diameter of the access tube. T his reduces the friction

when drivi ng i nto the access tube. The red cutting edge with a longer neck is used for better stabilization.

To install access tubes into dry and heavy clay soils

1. Ensure the tripod i s set up correctly and centred over the access tube installation site.

2. Select the Dry Clay 56.0 mm auger and the required extension rods. Attach the auger head

to the extensi on rods.

© Sentek Pty Ltd Page 31

Page 35

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

3. Fit the A uger Cen traliz ati on Pol y Guide over the ex tens io n a nd attach the T-Handle.

4. Put gloves and safety goggles on to protect your hands and eyes from damage.

5. Insert the assembled auger into the tripod ensuring the centralizati on poly guide i s fitted to

the top of the tripod cylinder.

6. Turn the auger 4-5 turns and lift i t gently approximately five centimetres, then turn the auger

another 3-4 turns. The lifting action moves the soil upward, partially filling the space around

the au ger hea d and pr ovid in g a gr e ater uptak e for additiona l soil . Note: Do not try to auger

too muc h s oi l at on e tim e, as the au ger may ov er - fi l l with s oi l, mak in g it d iffic u lt to r e m ov e

from the hole.

7. Clean the auger head then repeat the process to the required depth of i nstallation.

Hint:

If the augering becomes too difficult, attach the Heavy Duty T -Handle

and reinforced extension rods, and gentl y tap the top of the T-Handle

with the sledge hammer between auger turns to assi st the auger in

“biti ng” into the so il .

8. When augering is complete, check the final depth with a measuring tape to ensure you have

enough depth for your tube length. To position the middle of the first sensor at 10 cm below

the ground surface, ensure that 4 cm of access tube is protruding above the ground.

9. Fit the red metal cuttin g edge squarel y onto the access tube.

10. Place the access tube fitted with cutting edge i n the tripod guide and insert the He avy Duty

Dolly into the top of the access tube.

11. To prevent the access tube from flexing, attach extension rods to the Heavy Dut y Dolly,

ensuring they are firmly tightened.

12. Ensure you have safety goggles on and drive the access tube into the ground using the

sl edge hammer. If the dri ving of the access tube becomes too strenuous, use the 47 mm

r egu lar auger to clean out the soil shavings repeatedly from the inside of the access tube.

Continue hammer i ng unt i l you hav e r eache d t he fi nal de pt h.

© Sentek Pty Ltd Page 32

Page 36

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

Gravelly s oils

If you encounter a layer of small stones or gravel and the 47.0 mm regular auger i s unable to proceed, attach

the 47.0 mm Open Centre Tungsten Tip Auger. This auger is capable of breaking up and retri eving gravel of

up to thumbnail size under most conditions.

If you encounter larger stones, attach the 47.0 mm rockbreaker to the reinforced auger extension rod and fit

the Hea v y Dut y T-Handle. This will allow occasional large stones to be broken.

Under ver y dr y or w et co nd it io ns, you may ne ed to attach the Ac ces s Tube Spiral Cleaning To ol to remove

very dry and loose sand or gravel in liquid mud. When you have passed this obstacle you can continue

aug er i ng using th e Standard Manual Installation Method.

Ext remely dry an d loose san d

If you are installing access tubes into very dry and loose sand there could be problems with the augered

material falli ng out of the auger when you pull it out of the access tube. If this occurs use the Access Tu be

Spiral Cleaning Tool as the aug er i ng devic e. The on e- tur n me t a l s pir a l t oo l do es an exce llent job retr i eving

the ma teria l in th es e cond it i ons.

Water tables

On sites with a perched or shallow water table, water will enter the bottom of the access tube hole. Use the

acce ss tube bai le r to remove water and liquid mud between each augering. Lower the bailer i nto the bottom

of the access tube, wai t a few seconds for it to fill, then pull the bailer up and empty it into a bucket. You will

only be able to dig a certain distance into completely saturated soil, until conditions become too sloppy to

co nti nu e work. The bot tom sto pper will ne ed to be ready for immedia te insta llation after retri eving th e la st

auger load.

© Sentek Pty Ltd Page 33

Page 37

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

S tony Soils

The standard manual installati on method is not suitable for stony soi ls. If you know your soils are very

gravely and stony, the Slurry Installation Method must be used (see followi ng pages).

© Sentek Pty Ltd Page 34

Page 38

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

Slurry Installation Method

What are the dif ferent slurry methods?

The slurry installation methods are techniques used in soils with a hi gh stone and gravel content. Stony soils

are hard to auger and do not break up evenly. Large air pockets form easily when installing access tubes in

these soils, causing unrel iable readings.

Note:

The slurry methods are suggested for:

• Where the site soil has been tested and found to be high in stone and gravel content

• In access tube installations deeper than 2.5 – 3 m.

Warning:

Slurry installations are not recommended in sandy soils.

A sl ightly oversized hole is drilled and party filled with slurry. The slurry is a special mud mixture of kaolinite

and cem ent that is poured into the augered hole and fills the spaces where air would normally gather. The

access tube is pushed through the slurry and air bubbl es move up through the slurry and are released. As

the slurry dries, i ts moisture content balances with the moisture content of the surrounding soils.

Note: The equilibrium with the surrounding soil may not be 100%, however the

sphere of infl uence of the sensor penetrates the 5-10 mm slurry and measures the

soi l water content of the surrounding soil.

Although you are not m easuring the pure undisturbed soil with this installation method, Sentek experience

has shown that you can achi eve good sci entific study outcomes and commercial benefits usi ng this method.

Warning:

If you require absol ute data, Se ntek sensors need to be calibrated with the dried

sl urry in place, as described in the Sentek Calibration Manual.

Two drillin g me thods a re u sed for slurry installations:

• Manual slurry installation method – where a slightly oversi zed hole i s drilled into very stony and

gravelly soils using a hand auger

• Machine slurry installation method – where a slightly oversized hole is dri lled into very stony

and gravelly soils using a motorized auger.

The access tube installati on i s the same for both methods, which are described in detail bel ow.

Sentek has developed a set of installation tools specifically for manual slurry installations (Slu rry Acce ss

Tube Installation Kit).

An installation requires:

• Sentek access tube it ems

• Slurr y Access T ube Insta l lati o n Toolki t

Read through the installation method to identify the tools you will need and u ndersta nd thei r use. Ensure

that you have the tools you require before proceeding to the installation site.

© Sentek Pty Ltd Page 35

Page 39

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

Note: Slurry installations take some preparation time, and also sufficient time

needs to be allowed for the sl urry to dry and equilibrate with the surrounding soil

before the data can be used. Slurry installations should only be attempted in soils

where the standard installation method is not possibl e.

Items req u ired f or slurry in stallatio n s

Sentek access tu b e items

Item Part Number

Div iner 2000

Access Tube Ki ts, Slurry

(includes Access Tubes, Top Cap

Assemblies and Slurry Bottom

Stoppers)

EnviroSCAN & Envi roSMART

Access tubes at ordered lengths

Top cap assemblies – complete

Slurry bottom stoppers

11725, 11705, 11715

20510

22405

22206

Toolkit ite ms

Item Part Number

Slurry Access Tube Inst al la tion Kit ,

includes:

1 x Auger extensi on 0.5 m

1 x Auger extensi on 1.0 m

1 x Slurry auger 61.0 mm

1 x Heavy duty T -handle

2 x Tommy bars

5 kg bag of kaolin clay

1 x toolbag

07250

70125

70130

70148

70030

70190

80090

70400

© Sentek Pty Ltd Page 36

Page 40

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

Additional items for difficult stony soils

Item Part Number

Ope n Cen tr e Tu ngsten Ti p Auger 61.0 mm

Rock Breaker 54.0 mm

Auger extension rods re-enforced 1.0 m

70045

70025

70015

Mi sc ell an eous I tems (Installer to supply)

Length of rope – to tie branches or vi nes temporarily out of the way so that they do not get damaged or

interfere with the augering process.

Duck boards – to prevent soil campaction around the access tube during the installation process.

Measuring tape – to measure to the required depth

M ark ing pen

2 x 10 litre (2 gallon) buck ets – to coll e ct the augered soil and remove it from the si te , and to mix the sl u rry

in.

Notepa d and pencil - to record the depth and texture variation throughout the soil profile and any other site

information.

Paint stirrer with electric drill attachment – for mi xing the slurry.

Co r dl ess el ect r ic dril l – to attach to th e paint stirrer for m ixing the slu rry.

Spatula or br oad k ni fe – to chip aw ay excess sl urry

Sl u rry C omponents

Grey cement

Kaolinite (potters clay as fine powder)

Wa ter

© Sentek Pty Ltd Page 37

Page 41

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

Installation procedure

Step 1 – Glue in botto m stopp er

The slurry bottom stopper should be glued into the access tube prior to installation. Allow sufficient time for

the PVC g l ue to dr y .

To p r epare the access tube

1. Use PVC cleaning fluid to clean the bottom rim of the sl urry bottom stopper and the insi de of

the acc ess tube.

2. Use PVC glue and apply evenly to both surfaces.

3. Insert the slurry bottom stopper into the access tube and hold in place until the glue sets.

© Sentek Pty Ltd Page 38

Page 42

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

Ste p 2 – Auger the hole

To man ual ly au g er the acces s tube hol e

1. Select the required extension rods and screw the regular 61.0 mm (slurry) auger head and

T-handle to the extension rods.

Note: To add extra extension tubes to an existing auger assembl y,

place the auger on the ground. Place one foot on either side of the T-

Handle and insert the To mmy b ar into the hole of the extension tube

below the T-handle. Loosen the extension rod from the T-Handle us ing

one quick jerk of the Tommy bar. When loose, remove the Tommy bar

and unscrew these two parts until separated. Screw the additional

extensions onto the existi ng auger extensi on and then refit the T-

Handle.

2. Put on gl oves to increase your grip on the equipment and to protect your hands from heated

met a l w he n ins t a l ling on ho t d ay s .

3. Auger the hole to the required depth.

4. Insert the access tube with slurry bottom stopper fitted into the hole to check the depth level,

and then remove the access tube. The top of the access tube shoul d protrude out of the hole

by 4 cm (1.6 inches) for the top cap to sit flush with the ground. This will place the centre of

the first sensor 10 cm below the ground surface.

© Sentek Pty Ltd Page 39

Page 43

I nstalling EnviroSCAN, Enviro SMART & Diviner 2000 access t ub es

Hint:

If you encounter diffi culties augering through rocky or stony soils with

the regular 61.0 mm (slurry auger), use the Open Centre Tungsten Tip

Auger 61.0 mm or Rock Breaker 54 mm Auger. The Open Centre

Tungsten Tip Auger is capable of breaking up and retri eving gravel of

up to thumbnai l si ze. The 54 mm rock breaker will al low occasional

larger stones to be broken. The 54 mm rock breaker must be used wi th

the re-inforced T-Handle and auger extension rods.

If you still cannot auger a hole to the required depth, reposition the

auger in an alternative site, or use a motorized or mechanical auger to

drill the hole.

To drill the access tube hole using a motorized or mechanical auger

1. Select flight auger rods a nd attach a 61.0 mm tungsten tipped drill bit.

2. Attached the flight auger to a motor or drill rig assembl y.

3. Use gloves, ear protectors and safety goggles to auger the hole to the required depth.

Notes on using a handheld motor auger :

Getting the correct hole si ze in various soi ls using a flighted auger requires an understandi ng of what is

happening whi le digging. In moist clay soils (or any soil whi ch tends to adhere to the auger flight) the

procedure used will e ith er produc e too tigh t a ho le or a c orrec tly sized h ole.

No hole should be dug by going straight down, without lifti ng at intervals to clear the soil from the hole, or an

undersized hole may resul t. The tendency for the soil to re-adhere to the wall of the hole as i t moves up the

flight wi ll cause the hole to be undersized from the cutter size, m aking digging forces greater and the effort