Page 1

SDM-SIO1 Serial

Input/Output Module

Revision: 7/13

Copyright © 2008-2013

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell’s obligation under this warranty is

limited to repairing or replacing (at Campbell’s option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction.................................................................1

2. Specifications .............................................................2

2.1 Supported Data Rates and Protocols ....................................................2

2.2 Electrical Parameters............................................................................3

2.2.1 SDM-SIO1 Current Consumption.................................................3

2.2.2 SDM-SIO1 Voltage Specifications...............................................4

2.2.3 EMC Compliance..........................................................................4

2.3 Temperature and Humidity Ranges......................................................5

2.4 Physical Parameters .............................................................................5

2.5 Datalogger Compatibility.....................................................................5

3. Installation...................................................................5

3.1 Connections..........................................................................................6

3.2 Safety Considerations...........................................................................8

3.3 Examples for Connecting the SDM-SIO1 to Other Equipment ...........9

3.3.1 RS-485 One to One Connection Example.....................................9

3.3.2 RS-485 Multi Unit / In Line Example.........................................10

3.3.3 RS-485 Half Duplex Wiring Example ........................................11

3.3.4 RS-485 Internal Circuit Diagram ................................................11

3.3.5 RS-232 Wiring Example with Handshaking ...............................12

3.3.6 RS-232 Basic 3-Wire Example ...................................................12

3.3.7 Connecting a 9-Way Socket to the SDM-SIO1...........................13

3.4 Power Conservation ...........................................................................13

4. Programming the Datalogger ..................................14

4.1 Special Information about the Serial I/O() CRBasic Instructions when

used with the SDM-SIO1 ...............................................................14

4.1.1 SerialOpen()................................................................................14

4.1.2 SerialClose() ...............................................................................17

4.1.3 SerialIn() .....................................................................................17

4.1.4 SerialOut()...................................................................................17

4.1.5 SerialInBlock()............................................................................18

4.1.6 SerialOutBlock() .........................................................................18

4.1.7 SerialInChk()...............................................................................18

4.1.8 SerialInRecord()..........................................................................18

4.1.9 SerialFlush()................................................................................18

4.1.10 Serial Input Errors.......................................................................18

4.2 Configuring Handshaking and Receive Only Modes.........................18

4.2.1 Using RTS/CTS and Automatic Handshaking ............................18

4.2.2 RS-485 Half-Duplex Mode.........................................................19

4.2.3 Using the RS-232 Link in Receive Only Mode ..........................19

i

Page 6

Table of Contents

4.3

Example Datalogger Programs.......................................................... 20

4.3.1 Example Using RS-232 Mode.................................................... 20

4.3.2 Example Using RS-485 Mode.................................................... 21

5. Firmware Upgrades and Flash Signature Errors ...22

5.1 Upgrading the Firmware.................................................................... 22

5.2 Firmware Signature Errors ................................................................ 22

Appendix

Using the Handshaking Lines for General

A.

Input/Output ..........................................................A-1

A.1 The Input Pin (Pin 8) ....................................................................... A-1

A.2 The Output Pin (Pin 9) .................................................................... A-2

Tables

3-1. SDM Address Settings ........................................................................ 6

3-2. SDM-SIO1 Connections (left to right as viewed from the front of

the unit)............................................................................................ 7

3-3. SDM-SIO1 Functional Description of the Connections...................... 7

4-1. Communications Port Parameters RS-232 ........................................ 15

4-2. Communications Port Parameters RS-485 Full Duplex .................... 15

4-3. Communications Port Parameters RS-485 Half Duplex.................... 16

4-4. Communications Port Parameters RS-232 Receive Only Mode ....... 16

ii

Page 7

SDM-SIO1 Serial Input/Output Module

The SDM-SIO1 Module is designed to allow expansion of the number of serial ports

available on a datalogger for communicating with intelligent sensors or driving external

displays.

1. Introduction

The SDM-SIO1 Module connects to Campbell Scientific dataloggers using the

SDM port and communication protocol. It connects to the remote serial device

using industry standard hardware that can be set to RS-232, RS-485 or RS-422

signal levels. When operating in RS-232 mode it also supports hardware

handshaking. RS-422 mode is functionally the same as RS-485 mode except

the connection is limited to a point to point system. Connections and

programming for RS-422 are otherwise identical to RS-485.

The SDM-SIO1 will accept serial data and store it in its buffer which is 2047

bytes in size allowing remote equipment to transmit large amounts of data

without needing to stop other processes in the datalogger. Up to 15 SDM-SIO1

peripherals can be connected to a single logger using the SDM port, allowing

the user to connect 15 different items of equipment to their logger with ease, in

addition to any connections made to the datalogger’s other serial ports.

To start using the SDM-SIO1 it is first necessary to work out how data will be

exchanged with a sensor. In the case of a sensor there are basically two options,

either the datalogger requests data and then picks up the response, or the sensor

transmits data “one-way” using its own time base. The latter mode is more

common but can lead to problems with synchronizing the sensor measurements

with the logger program and can also lead to the occasional missing data value

as there are two independent clocks. Once the method of communication and

the communication standard is defined then refer to Section 3, Installation, to

install the module and connect it to the datalogger and the serial device.

The SDM-SIO1 Module is implemented in such a way that it looks like a builtin serial port to the user when writing programs in CRBasic. This means all the

user needs to do is define the address of the SDM-SIO1, using a rotary switch

on the side of the unit. The serial port can then be used as if it were built into

the datalogger. The only difference in operation between the SDM-SIO1 and a

built-in port is that there will be a small delay when transferring data to and

from the device via the SDM connection (see Section 4.1, Special Information

about the Serial I/O() CRBasic Instructions).

The SDM-SIO1 can also be used in ‘talk-through’ mode to allow a user to talk,

via a terminal module, to a sensor connected to the SDM-SIO1 for test and

diagnostic purposes. Please refer to the logger manual for further details.

Section 4, Programming the Datalogger, gives the differences in the use of this

module compared to the datalogger standard serial ports, plus there are some

simple examples.

1

Page 8

SDM-SIO1 Serial Input/Output Module

2. Specifications

2.1 Supported Data Rates and Protocols

Data rates and protocols are set up using the SerialOpen() instruction in

CRBasic. The SerialOpen() instruction is discussed elsewhere in this

document.

Supported data rates: 300, 1200, 2400, 4800, 9600, 19200,

Supported modes of operation: RS-232 (full duplex and receive only)

38400, 57600, and 115200 bits/s

RS-485 (half and full duplex)

RS-422 (half and full duplex)

NOTE

NOTE

NOTE

Hardware CTS/RTS flow control is supported in RS-232 mode;

the handshaking lines can also be used as general purpose I/O

lines.

Supported data format: 8, and 7 bit data size; none, odd, or even

parity; one or two stops bits.

In 7 bit mode with no parity the user must insure that the

characters received by the SDM-SIO1 have a delay of at least

one bit period or greater between them. This does not affect any

other configuration and does not affect transmissions out of the

SDM-SIO1.

Transmit buffer size: 767 bytes (buffer from the logger to the

sensor)

Receive buffer size: 2047 bytes (buffer from the sensor to the

logger)

Both transmit and receive buffers are fill and discard type (i.e.,

once the buffers become full no new information is accepted and

all further data is discarded until space is made when the logger

requests data from the SDM-SIO1).

2

Miscellaneous information: The SDM-SIO1 does not support auto

baud rate detection nor the use of the serial

port for Modbus, DNP, or general PakBus

communications.

Page 9

2.2 Electrical Parameters

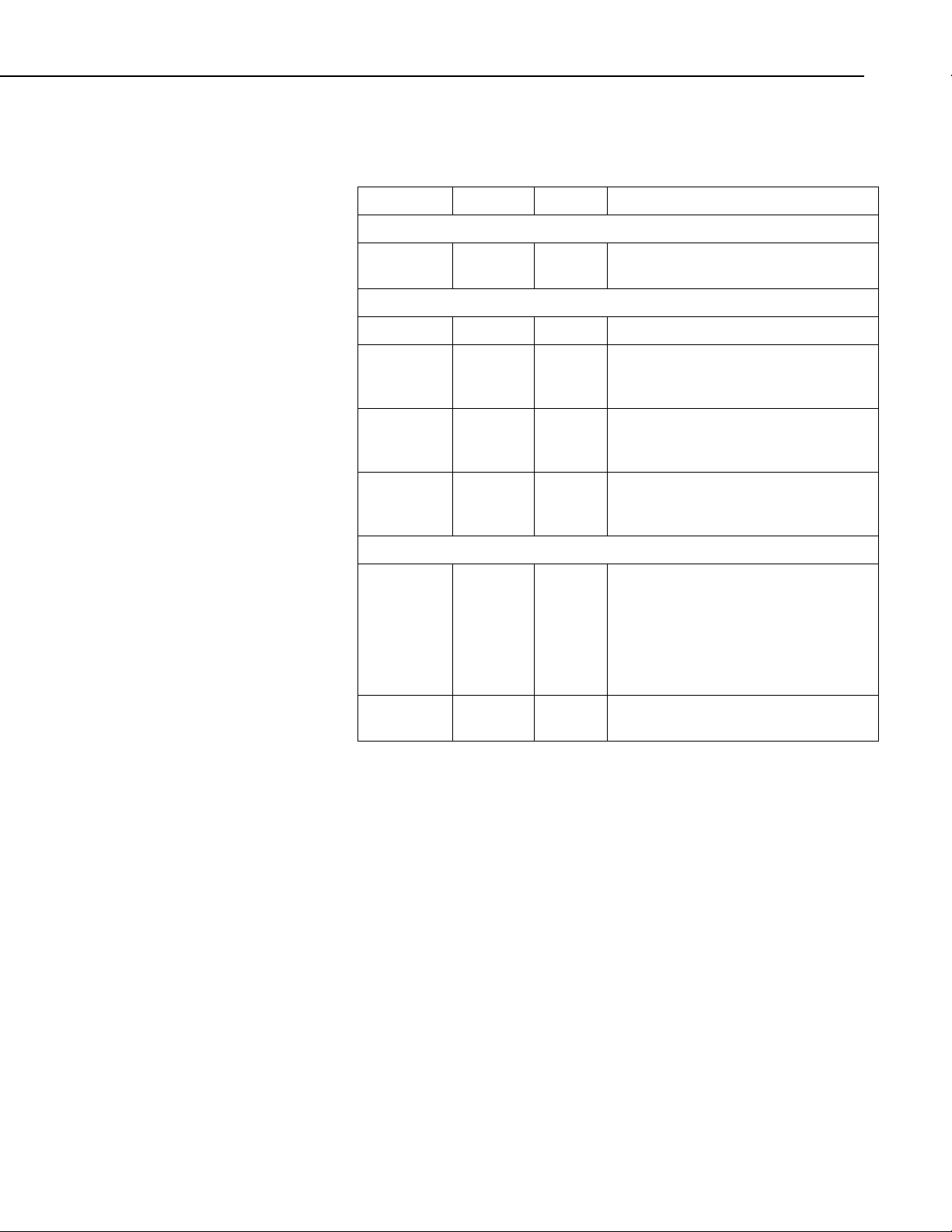

2.2.1 SDM-SIO1 Current Consumption

Nominal Max Notes

General Currents

SDM-SIO1 Serial Input/Output Module

Standby

current

RS-232 and RS-485 Current Consumption

70 µA 100 µA Current after SerialClose has been

called.

(1)

Idle current 5.5 mA 6 mA After SerialOpen has been called

Idle current

4.1 mA 4.5 mA After SerialOpen in receive only mode

(receive

only)

Active

11.5 mA 12 mA Active RS-232 command

current (RS-

232)

Active

current (RS-

12.5 mA 13 mA Active RS-485 command (no

termination resistors)

485)

Line Load Currents

RS-232 line

load

2 mA per

load

3 mA

per load

Average expected increase in drawn

current per RS-232 line connected in

idle or active modes (no extra current in

stand-by mode).

Both TX and RTS are considered to be

RS-232 loads.

RS-485 line

(2)

load

40 mA

(3)

77 mA

(4)

This extra current is only present when

actively transmitting

(1) All currents are measured with no loads connected

(2) The RS-485 transmit pair is disabled when not transmitting in order to save

power higher value resistors can be used to save power dependent upon the

application. For many applications, especially with shorter cable runs, no

load/termination resistors will be needed.

(3) Single 100R load between transmit lines. Two 100R resistors (one on each

end) is the maximum recommended loading. Removing any termination

resistance should dramatically decrease current consumption during transfer of

data

(4) The RS-485 interface is protected against short circuits via a 44R resistance

making this the maximum current possible even during short circuit. This

resistance is part of the ESD protection circuitry and will be present at all

times; it shouldn’t affect normal circuit operations. The ‘RS-485 internal

circuit diagram’ in Section 3.3.4, RS-485 Internal Circuit Diagram, shows the

circuit in detail.

3

Page 10

SDM-SIO1 Serial Input/Output Module

2.2.2 SDM-SIO1 Voltage Specifications

Connection

Power supply, +12 V

connection

(2)

RS-232 input threshold

Low

RS-232 input threshold

High

RS-232 input absolute

maximum

(2)

RS-232 input

resistance

RS-232 output voltage

(3)

swing

RS-232 output

absolute maximum

RS-485 input

(Differential)

RS-485 output

(Differential)

Minimum

Voltage

(1)

Nominal

Voltage

(1)

Maximum

Voltage

(1)

7 V 12 V 20 V

0.8 V – –

– – 2.4 V

– ±15 V ±18 V

3 kΩ 5 kΩ 7 kΩ

±5 V ±5.4 V –

– – ±13.2 V

200 mV

2 V (at 50

(4)

– 6 V

– –

Ohms)

SDM lines (high level)

SDM lines (low level)

(1) Values are volts D.C. (except resistances)

(2) It is NOT recommended that the user runs their SDM-SIO1 at maximum

ratings for extended periods of time

(3) Assuming a worst case 3 KΩ load

(4) It is not recommended that the user allows such low input voltages as there

will be an increased chance that external noise may cause errors in the

incoming data

2.2.3 EMC Compliance

The SDM-SIO1 has been tested and shown to comply with IEC 61326. The

device incorporates transient and surge protection that is designed to meet

IEC61000-4-5, level 4, providing the device is adequately grounded.

4.3 V 5 V 5.7 V

0 V – 0.7 V

4

Page 11

SDM-SIO1 Serial Input/Output Module

2.3 Temperature and Humidity Ranges

Temperature

Range

Standard range –25ºC +50ºC

Extended range

(optional)

Humidity Minimum Maximum Notes

Standard range 0% 95% (non-condensing)

2.4 Physical Parameters

Height: 5.4 cm (2.2 in)

Width: 8.0 cm (3.1in) main body; 11.2 cm (4.5 in) with mounting flange

Depth: 2.5 cm (1.0 in)

Weight: 80 g (2.8 oz) approximately

Mounting: Centers are 10.2 cm (4 in)

Minimum Maximum Notes

–40ºC +80ºC (Contact Campbell Scientific

for further extended

temperature requirements)

2.5 Datalogger Compatibility

3. Installation

The SDM-SIO1 is compatible with our CR800, CR850, CR1000, CR3000,

CR5000, and CR9000X dataloggers. The CR5000 and CR9000X’s operating

system must be OS 6 or higher.

The SDM-SIO1 is normally mounted on the backplane of a Campbell

Scientific enclosure using the screws and plastic inserts provided. The SDMSIO1 is designed to be installed in a dry, non-condensing environment. Before

fixing it, select and set the SDM address as this requires access to the side of

the case. The SDM address is set with a screw driver. Below is a list of the

possible SDM addresses and their relationships to the COM port number in the

SerialOpen() instruction.

There can be up to 15 SDM-SIO1s on a single SDM bus. Each SDM-SIO1 will

need to have a unique address before they are powered up. If other equipment

is present on the bus, whether it’s an SDM-SIO1 or not, the user needs to

insure no addresses are the same.

5

Page 12

SDM-SIO1 Serial Input/Output Module

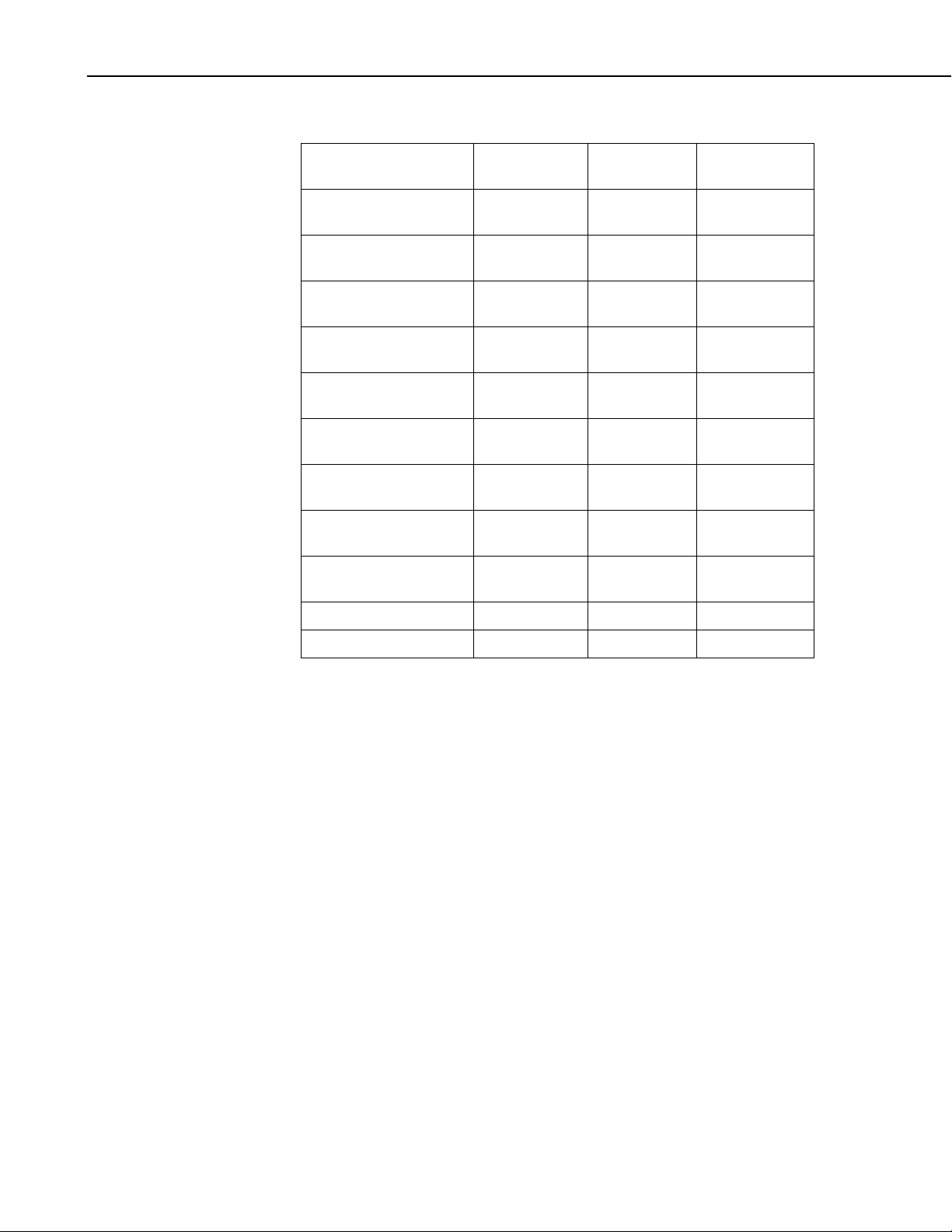

TABLE 3-1. SDM Address Settings

Rotary Switch

Position

SDM Address

SerialOpen Command

Comm. Port Number

0 0 32

1 1 33

2 2 34

3 3 35

4 4 36

5 5 37

6 6 38

7 7 39

8 8 40

9 9 41

A 10 42

B 11 43

C 12 44

D 13 45

E 14 46

(1)

F

15

(1)

47

(1)

(1) Address ‘F’ is not available as it’s the broadcast address. Setting this

address will result in the SDM-SIO1 having an address of ‘0’ not ‘F’.

3.1 Connections

Connection to the SDM-SIO1 is achieved via the 15 terminals arranged along

the top of the unit. The terminals are spring loaded providing an easy and

reliable method of connection. Wires should be stripped .25” (7mm), twisted

and inserted in the round hole while opening the clamp by pushing a

screwdriver in the adjacent rectangular hole, or by pushing a screwdriver into

the hole on the side of the connector. Remove the screwdriver to close the

clamp making sure the clamp grips the wire rather than the plastic insulation.

If there is a need to insert more than one wire in a terminal when using

multistrand wire, twist the conductors together first. If using solid wires, either

solder or crimp wires together before insertion. For RS-485 connections note

that the RS-232 terminals double up as a secondary connection, so it is rare to

have multiple conductors in one terminal as both sets of connections can be

used either for forming an RS-485 daisy-chain or for adding termination

resistors at each end of a network.

When making connections to the datalogger always insure power to the

datalogger is switched off and connect the ground (G) connection first. Below

is a table showing all the connections on the SDM-SIO1. There are a number

of pins that are common within the unit. These are also shown below.

6

Page 13

SDM-SIO1 Serial Input/Output Module

TABLE 3-2. SDM-SIO1 Connections (left to right as viewed from the front of the unit)

SDM Power Connections RS-232 Connections RS-485/RS-422

C1 C2 C3 G +12 V G RX-A CTS-B RTS-Y TX-Z 0 V Z Y B A

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

15 14 13 12 10 9 8 7

Note: Italic numbers indicate which pins are connected internally (for use with RS-485 termination resistors etc.).

For example the signals present on pin 7 will also be present on pin 15.

TABLE 3-3. SDM-SIO1 Functional Description of the Connections

Case Text Description

1 C1 SDM data enable line – connect to datalogger SDM C1

2 C2 SDM clock line – connect to datalogger SDM C2

3 C3 SDM data line – connect to datalogger SDM C3

4 G Connect to the datalogger power ground (G)

(1)

CAUTION

5 +12 V Main power supply – connect to logger 12 V

6 G RS-232 0 V reference/second G connection

(2)

7 RX-A RS-232 receive line

8 CTS-B RS-232 CTS hardware handshaking line / output

9 RTS-Y RS-232 RTS hardware handshaking / input

10 TX-Z RS-232 transmit line

11 0 V RS-485 0V reference line

(3)

12 Z ‘–’ RS-485 output line, line Z

13 Y ‘+’ RS-485 output line, line Y

14 B ‘–’ RS-485 input line, line B

15 A ‘+’ RS-485 input line, line A

(1) At least one of the two G terminals (‘G’) must be connected to the logger’s

ground terminal or earth boss.

The ground connection to the datalogger should be made

with large gauge wire, e.g. 16/0.2 to provide a low

impedance path to ground to allow full protection from

static and electrical transients.

(2) The ‘G’ (pin 6) can be used for the RS-232 zero volt reference or any other

ground connection needed, e.g. shields.

(3) There is a 100R resistor in series with the datalogger’s ground connection.

This connection should be used when connecting RS-485 equipment by long

wire lengths. It insures both systems have a common ground reference point.

See Section 3.2, Safety Considerations, before connecting.

7

Page 14

SDM-SIO1 Serial Input/Output Module

As shown above in TABLE 3-3 connections 1 to 5 need to be made to the

datalogger. SDM connections are made to appropriate logger control ports or to

the dedicated SDM port when fitted, e.g. the CR3000. The connection of the

wires to the remote serial device will vary with type of device and method of

communication. It is necessary to work out the best mode of operation of the

serial device, taking into consideration issues such as power consumption,

cable lengths (RS-485 being better than RS-232), synchronization of data

collection etc.

In Section 3.3, Examples for Connecting the SDM-SIO1 to Other Equipment,

there are some examples of different connection schemes for the serial devices.

Further discussion of different modes of operation is given in Section 4,

Programming the Datalogger.

NOTE

Do not connect both RS-232 and RS-485 interfaces to the SDMSIO1 at the same time as this may cause a bus contention and

even possibly cause damage.

3.2 Safety Considerations

The SDM-SIO1 is considered to be a component of a measurement system that

is installed in an enclosure and wired up in accordance with this manual. Due

to space considerations full details of the maximum ratings of the connections

are not given on the device. Instead the user should study this manual and in

particular Section 2.2.1, SDM-SIO1 Current Consumption, to determine the

maximum voltages that are applicable to any terminal before starting an

installation.

The RS-485 0V ground reference connection may be needed to insure all units

are referenced to a common ground voltage. This is more often needed with

long cable runs. It is advisable to check the difference in ground potential with

some caution before connecting any wires, to insure the potential differences

are reasonably close and excessive current will not flow between the two

ground wires. There is a current limiting resistor fitted in the 0V line in the

SDM-SIO1, but this will not be adequate in the event of a serious ground fault,

e.g. the ground references being 120 V apart, due to faulty AC wiring. If a

large potential difference is found please seek the advice of a qualified

electrician before continuing with the installation.

8

Page 15

SDM-SIO1 Serial Input/Output Module

3.3 Examples for Connecting the SDM-SIO1 to Other Equipment

3.3.1 RS-485 One to One Connection Example

1 C1

2 C2

3 C3 To logger

4 G

5 +12V

6 G 100 R or higher

7 RX-A R

8 CTS-B

9 RTS-Y R

10 TX-Z

11 0V RS-485 0V

12 Z RS-485_B

13 Y RS-485_A

14 B RS-485_Z

15 A RS-485_Y

Notes:

• Z, Y, B and A are connected to their corresponding differential wire pairs

when in RS-485/RS-422 mode. Where A and Y are the ‘+’ lines and ‘B and Z

are the ‘-‘ lines.

• Connections 7-10 are connected internally to connections 12-15. This allows

for terminations resistors to be added when in RS-485 mode (if needed) or,

more than one connection to the I/O lines or TX and RX lines in RS-232 mode.

• If the use of termination resistors is required in RS-485 mode then they

should be connected between pins TX-Z and RTS-Y for the ZY line and CTSB and RX-A for the A B line (see diagrams elsewhere in document).

• In half duplex RS-485/RS-422 mode the Z Y and A B pairs are connected

internally by the hardware without the need for any user interaction. The user

should connect their wires to ZX and YS, as ‘A’ and ‘B’ are disabled.

RS-485

equipment with

termination

resistors

9

Page 16

SDM-SIO1 Serial Input/Output Module

3.3.2 RS-485 Multi Unit / In Line Example

1 C1

2 C2 RS-485 0V for ground referencing

3 C3 To logger

4 G

5 +12V

6 G RS-485_0V

7 RX-A RS-485_Y

8 CTS-B RS-485_Z

9 RTS-Y RS-485_A

10 TX-Z RS-485_B

11 0V RS-485 0V

12 Z RS-485_B

13 Y RS-485_A

14 B RS-485_Z

15 A RS-485_Y

NOTE

As with all RS-485 configurations the use of termination

resistors is optional. They tend not to be required with shorter

cable runs and with modern slew-rate limited driver technology

(as used in the SDM-SIO1).

First RS-485

equipment

Second RS-485

equipment

10

Page 17

3.3.3 RS-485 Half Duplex Wiring Example

1 C1

2 C2

3 C3 To logger

4 G

5 +12V

SDM-SIO1 Serial Input/Output Module

6 G

7 RX-A

100 R or higher

(Termination resistor may not be

needed for many applications)

8 CTS-B

9 RTS-Y R

10 TX-Z

11 0V RS-485 0V

12 Z RS-485_B

13 Y RS-485_A

14 B RS-485_Z

15 A RS-485_Y

3.3.4 RS-485 Internal Circuit Diagram

TX

Internal External

22R

22R

100R or higher*

R

RS-485

equipment

Z

Y

B

100R or higher*

A

0V

RX

0V

22R

22R

100R

R

* Note the external termination resistors are optional. Some applications can use much higher value resistors

and some may not need resistors at all depending on the distance and wire quality involved.

If the termination resistor is primarily needed for impedance matching then a value matching the line

resistance will have to be used, i.e. 100R.

11

Page 18

SDM-SIO1 Serial Input/Output Module

3.3.5 RS-232 Wiring Example with Handshaking

1 C1

2 C2

3 C3 To logger

4 G

5 +12V

6 G 0V

7 RX-A RS-232_RX

8 CTS-B RS-232 RTS

9 RTS-Y RS-232 CTS

10 TX-Z RS-232 TX

11 0V

12 Z

13 Y

14 B

15 A

DTE DCE

* Note CTS and RTS are optional if hardware

handshaking is not required. Not connecting the

handshaking lines will decrease the overall current

consumption of the SDM-SIO1 and the RS-232

device.

3.3.6 RS-232 Basic 3-Wire Example

1 C1

2 C2

3 C3 To logger

RS-232 DCE

equipment

12

4 G

5 +12V

6 G 0V

7 RX-A RS-232_RX

8 CTS-B

9 RTS-Y

10 TX-Z RS-232 TX

11 0V

12 Z

13 Y

14 B

15 A

DTE DCE

RS-232 DCE

equipment

Page 19

SDM-SIO1 Serial Input/Output Module

3.3.7 Connecting a 9-Way Socket to the SDM-SIO1

1 C1

2 C2

3 C3 To logger

4 G DTE Configuration

5 +12V RS-232 9-Way Dtype Connector

6 G 0V Pin 5

7 RX-A RS-232_TX Pin 3

8 CTS-B RS-232 CTS Pin 8

9 RTS-Y RS-232 RTS Pin 7

10 TX-Z RS-232 RX Pin 2

11 0V

12 Z

13 Y

14 B

15 A

Note 2

1) Note this diagram is for adding a 9 way D-type plug to the SDM - SIO1. A

standard one to one serial lead can then be used to connect to another piece of

equipment (e.g. a PC or sensor)

2) Since there is no standard that indicates whether certain devices should be

DTE or DCE it may be necessary to reverse the CTS – B and RTS-Y pins

when wiring hardware handshaking. You may cross the wires either by

crossing them manually (as shown by dotted lines) or, by purchasing a special

cable for this purpose.

Notes:

• The CTS-B (CTS) and RTS-Y (RTS) lines can also be used to trigger external

circuitry if desired when not being used in handshaking mode. Note that when

using CTS-B and RTS-Y lines as input and output that the voltage levels are

+/-12V NOT 0 and 5V.

• CTS-B and RTS-Y can’t be used as separate input and outputs when in RS485 mode.

3.4 Power Conservation

The SDM-SIO1 features an industry standard RS-232/RS-485 driver chipset

(Maxim 3160) which insures maximum likelihood of compatibility with all

other devices. When the driver is powered on it uses more power than one of

the datalogger’s control port based “com ports” – typically 6 mA minimum,

partly because it generates the correct signal levels which in itself requires

power and partly because, in the case of RS-232 signals, the resting state of

~–6V driving a nominal RS-232 ~3k load implicitly wastes ~2 mA of current

per line.

To avoid excess current use, the chip can be turned off when not in use, e.g.

between polled measurements, simply by closing the serial port, using

Serialclose (see below). When running in RS-232 mode with a sensor that only

13

Page 20

SDM-SIO1 Serial Input/Output Module

sends data one-way to the datalogger, run the SDM-SIO1 in “receive only

mode” as this does not turn on the output drivers.

If using RS-232 mode avoid connecting handshaking lines that are not

required. This eliminates 2 mA drain per line for unused lines.

4. Programming the Datalogger

The normal serial port instructions such as SerialOpen() and SerialIn() are

used with the SDM-SIO1. A program written for a standard serial port will

usually work with the SDM-SIO1, as long as the timing of the measurements is

not very critical.

4.1 Special Information about the Serial I/O() CRBasic Instructions when used with the SDM-SIO1

The following section gives more information about the CRBasic programming

language and how the serial instructions are to be used with the SDM-SIO1.

This section assumes the user has knowledge of the CRBasic programming

language. If not then please contact Campbell Scientific for further assistance.

Only the parameters that need special explanation or where their functionality

has changed are listed below. Other parameters don’t need changing.. Please

refer to the datalogger manual and/or the CRBasic help system for more

guidance.

4.1.1 SerialOpen()

All internal buffers in the SDM-SIO1 will be flushed when this command is

called resulting in the loss of any data that might have been in them at that

point in time.

COMPort parameter

The COMPort numbers are defined in the Address configuration section (see

TABLE 3-1). Comport numbers in the range of 32 to 47 are reserved for use

with the SDM-SIO1.

BaudRate parameter

Baud rate is used to set the SDM-SIO1s baud rate for the RS-232 interface.

The SDM-SIO1 does not support automatic baud rate recognition.

Setting the rate to a negative number sets the automatic flow control system

(RTS/CTS). This system is discussed in greater detail elsewhere in the

document.

SerialOpenFormat parameter

This parameter defines data format, normal RS-232, listen only RS-232, full or

half-duplex, and RS-485 modes as defined in the tables below.

14

Page 21

SDM-SIO1 Serial Input/Output Module

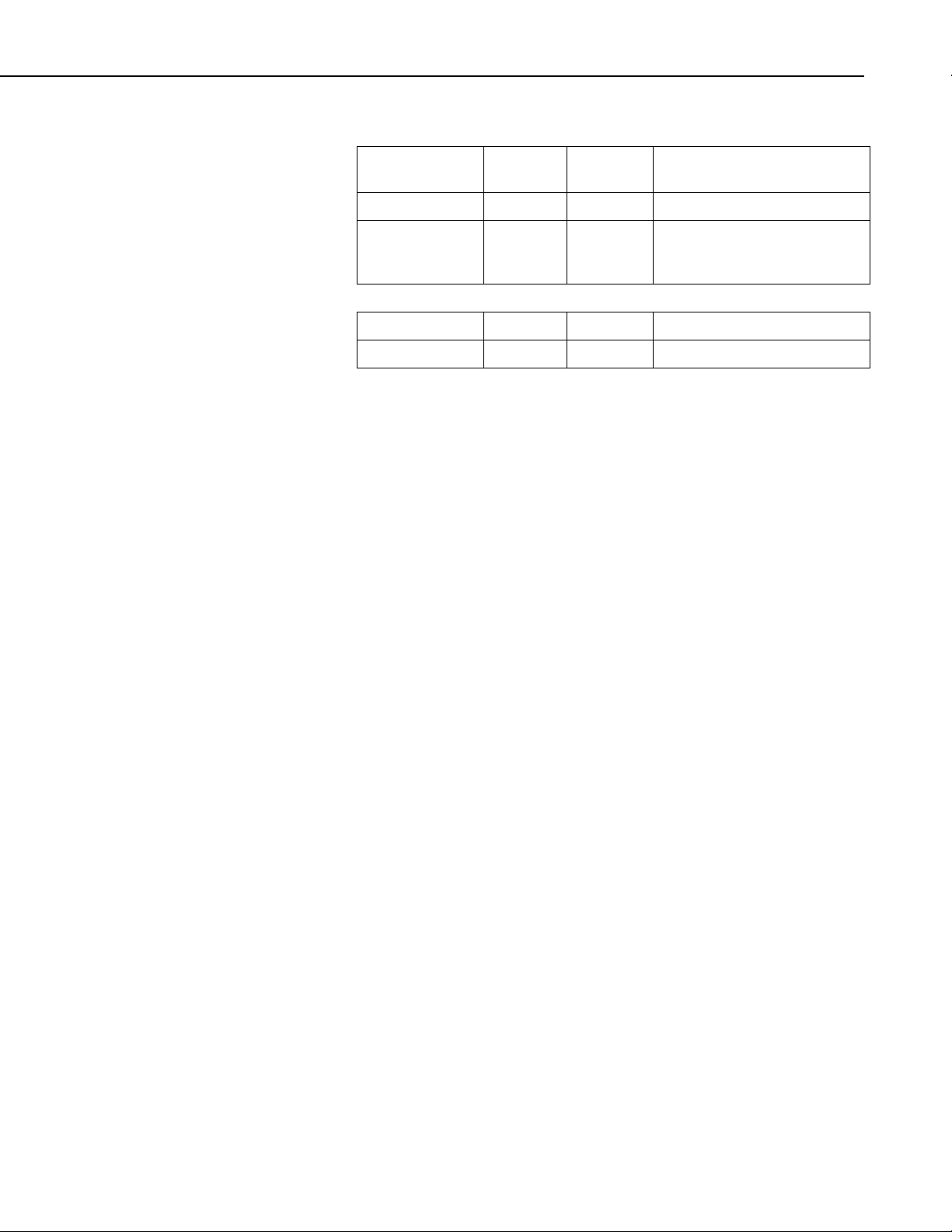

TABLE 4-1. Communications Port Parameters RS-232

Code Parity No. Stop Bits No. Data Bits

0 None 1 8

1 Odd 1 8

2 Even 1 8

3 (default) None 1 8

4 Not used

5 Odd 2 8

6 Even 2 8

7 None 2 8

8 Not used

9 Odd 1 7

10 Even 1 7

(1)

11

None 1 7

12 Not used

13 Odd 2 7

14 Even 2 7

15 None 2 7

(1) This mode is only supported if there is at least a one bit delay between

characters received by the SDM-SIO1

TABLE 4-2. Communications Port Parameters RS-485 Full Duplex

Code Parity No. Stop Bits No. Data Bits

16 None 1 8

17 Odd 1 8

18 Even 1 8

19 None 1 8

20 Not used

21 Odd 2 8

22 Even 2 8

23 None 2 8

24 Not used

25 Odd 1 7

26 Even 1 7

(1)

27

None 1 7

28 Not used

29 Odd 2 7

30 Even 2 7

31 None 2 7

(1) This mode is only supported if there is at least a one bit delay between

characters received by the SDM-SIO1

15

Page 22

SDM-SIO1 Serial Input/Output Module

TABLE 4-3. Communications Port Parameters RS-485 Half Duplex

Code Parity No. Stop Bits No. Data Bits

48 None 1 8

49 Odd 1 8

50 Even 1 8

51 None 1 8

52 Not used

53 Odd 2 8

54 Even 2 8

55 None 2 8

56 Not used

57 Odd 1 7

58 Even 1 7

(1)

59

None 1 7

60 Not used

61 Odd 2 7

62 Even 2 7

63 None 2 7

(1) This mode is only supported if there is at least a one bit delay between

characters received by the SDM-SIO1

TABLE 4-4. Communications Port Parameters

RS-232 Receive Only Mode

Code Parity No. Stop Bits No. Data Bits

64 None 1 8

65 Odd 1 8

66 Even 1 8

67 None 1 8

68 Not used

69 Odd 2 8

70 Even 2 8

71 None 2 8

72 Not used

73 Odd 1 7

74 Even 1 7

(1)

75

None 1 7

76 Not used

77 Odd 2 7

78 Even 2 7

79 None 2 7

16

(1) This mode is only supported if there is at least a one bit delay between

characters received by the SDM-SIO1

Page 23

4.1.2 SerialClose()

4.1.3 SerialIn()

SDM-SIO1 Serial Input/Output Module

This will place the SDM-SIO1 unit into shutdown mode where only SDM

communications will operate. This means any data coming into the SDM-SIO1

on the RS-232/RS-485 interface will be lost. This is the lowest power mode

and for optimum power efficiency the SDM-SIO1 should be placed in this

mode whenever possible.

The primary difference when using this command compared to when it is used

with a serial port built into the datalogger is timing. If the data has already been

sent by the remote sensor/system, the instruction will run in a few tens of

microseconds as the data is read from internal memory. However, when using

the SDM-SIO1 extra time is required to transfer data from the module and into

the datalogger memory. The extra time (in microseconds) taken to transfer

data from the SDM-SIO1 to the logger can be calculated using the formula

below.

Time = (C + 1) * (8 * SDMRate)

Where,

NOTE

4.1.4 SerialOut()

C = Number of characters to transfer from the SDM-SIO1

SDMRate = Rate set using the SDMSpeed() instruction in CRBasic giving the

time in microseconds for one bit period.

It’s worth noting that the bit rate defined by SDMSpeed() is not exact and will

vary slightly depending on the logger used. If you require more accurate

information about SDM data rates consult the logger documentation.

Example

The instruction SerialIn(Dest,32,1,0,10) using a 30 μs bit rate would transfer

its 10 bytes of data from the SDM-SIO1 to the logger in approximately 2.7 ms.

Time = (10 + 1) * (8 * 30)

30 μs per bit is the default data rate for most Campbell loggers. It

is possible to reduce this time and the transfer time by using the

SDMSpeed() instruction. This can be done if using short cable

runs between the logger and all SDM devices.

Transmission from the SDM-SIO1 will commence once the first byte of user

information is received from the logger. There will be a total delay of 16 bit

periods (at the SDMSpeed()) before transmission commences. Normally this

delay can be ignored as it is short (0.48 ms), but some applications may need to

account for it.

17

Page 24

SDM-SIO1 Serial Input/Output Module

4.1.5 SerialInBlock()

The SerialBlock() instruction can be used as described in the datalogger

manual. However, if using the option to capture only the most recent data,

make sure the instruction is called often enough to avoid filling up the SDMSIO1's buffer. The SDM-SIO1's buffer operates in a fill and stop mode, and

therefore will not include the most recent data if it gets full.

4.1.6 SerialOutBlock()

No special information. This can also be used to set the general purpose output

line (see Appendix A, Using the Handshaking Lines for General Input/Output).

4.1.7 SerialInChk()

This returns the number of characters that have been received by the SDMSIO1 and that are currently held in its buffer (0-2047). In addition it also

allows the program to determine the state of the input handshaking line by

setting bit 16 of the returned number if the port is high. If that port (pin 8) is

not connected then the instruction can be used in the same way as with a

standard port. If the port can be high or you wish to determine the state of the

handshaking line, please refer to Appendix A.1, The Input Pin (Pin 8), for

further details and program examples.

4.1.8 SerialInRecord()

No special information.

4.1.9 SerialFlush()

This command will purge all information in the logger and SDM-SIO1

transmit and receive buffers.

4.1.10 Serial Input Errors

For any of the serial input instructions above, the character ‘?’ will be returned

in place of the expected data whenever a parity, framing or overrun error is

detected. These errors are only flagged for RS-232/RS-485/RS-422 data

coming into the SDM-SIO1. A large number of such characters could indicate

an incorrectly setup protocol configuration using the SerialOpen() instruction,

or one of the wires is loose or incorrectly terminated.

4.2 Configuring Handshaking and Receive Only Modes

4.2.1 Using RTS/CTS and Automatic Handshaking

Handshaking is a method used by RS-232 to insure communications equipment

is free to receive or transmit data. This interface is often called RTS/CTS

(Hardware handshaking) or DTR/DTE.

18

Automatic handshaking for the SDM-SIO1 is activated through use of the

SerialOpen() instructions BaudRate setting. When the BaudRate value is set to

a negative number the SDM-SIO1 will enable automatic handshaking. It is

Page 25

SDM-SIO1 Serial Input/Output Module

worth noting that normally setting the BaudRate to a negative number will

enable automatic baud rate detection, this is not the case for the SDM-SIO1.

When enabled, the two I/O ports (pins 8 and 9) will operate as RTS and CTS

lines. It is important that the remote equipment supports handshaking as no

data will be sent if handshaking is enabled but isn’t supported by the

equipment connected to the SDM-SIO1.

Once handshaking is enabled pins 8 and 9 are no longer available for general

use and are dedicated to the auto-handshaking system.

Enabling handshaking will increase active current consumption due to the extra

RS-232 load. It will not affect sleep current however as the RS-232 chip is

disabled (sleep is set by calling the ‘SerialClose’ function).

For connection diagrams and further information on using handshaking consult

Section 3.3, Examples for Connecting the SDM-SIO1 to Other Equipment.

NOTE

• Auto flow control should only be selected in RS-232 mode

• When Autoflow control is enabled the user can’t set or clear

the spare I/O ports (pins 8 and 9)

4.2.2 RS-485 Half-Duplex Mode

In RS-485, half duplex mode the SDM-SIO1 will wait for approximately 2.5

ms after a character is received before it tries to transmit data in the transmit

buffer. This is to insure that a contention does not occur on the data line which

will cause data corruption.

NOTE

When in either RS-485 half duplex or full duplex modes the user

can’t set or clear the spare I/O ports (Pins 8 and 9).

4.2.3 Using the RS-232 Link in Receive Only Mode

To place the SDM-SIO1 into RS-232 receive only mode, use the SerialOpen()

instruction with the SerialOpenFormat value set within the range of 64 to 79.

Consult Section 4.1.1, SerialOpen(), for more detailed information about these

settings. In receive only mode the SDM-SIO1 will consume less current than

normal but still can receive new information on its RS-232 port.

The example below will set the SDM-SIO1 with the address 0 into receive only

mode. All normal baud rates and buffer sizes are supported.

Example

SerialOpen(32,115200,64,100,10000) ‘Set receive only mode

19

Page 26

SDM-SIO1 Serial Input/Output Module

4.3 Example Datalogger Programs

Some simple examples of how to write programs in CRBasic to send and

receive data using the SDM-SIO1 follow. These programs are not extensive

and are fundamentally no different to those written for use when reading data

from a standard serial port.

The exact program to be used will vary with the serial device being used.

Unfortunately the number of possible variations of reading different sensors is

almost infinite. If you are struggling to write code please contact Campbell

Scientific who may already have experience with the sensor and may be able to

offer advice on how to deal with it.

4.3.1 Example Using RS-232 Mode

'----------------------------------------------------------------------' Example use of the SDM-SIO1.

' This example shows how to open the a serial port using an SDM-SIO1.

' A prompt is sent from the logger to the sensor and it then waits for a response

' before reading the data.

' The logger then retrieves the data and places it into a string

'-----------------------------------------------------------------------

Public ReturnedData as string * 100 'string where the data from the logger is stored

BeginProg

Const SensorPort = 32 'Declare the serial port the sensor is set to

'The sensors address switch should be set to position 0

SDMSpeed (30) 'Optionally set the SDMSpeed - not normally needed

Scan(1000,mSec,0,0)

'Open serial port to RS-232 mode, 115200bps, 8-bit data, 1 stop bit and no parity

SerialOpen (SensorPort,115200,3,100,10000) 'open the serial port to the sensor

'Request data' will need to be replaced with the correct command for your sensor

'In this example we wait for the response Start, for up to 1 second before continuing

SerialOut (SensorPort,"Request data","Start",1,100) 'Send data to the sensor

SerialIn (ReturnedData,SensorPort,100,0,100) 'Get data from the sensor

SerialClose (SensorPort) 'Close the serial port to the sensor

'(this places the SDM-SIO1 into its lowest power mode)

'Now there would be code to read the data out of the ReturnedData string and either store

'it as strings or convert the string into number(s).

Next Scan

EndProg

20

Page 27

SDM-SIO1 Serial Input/Output Module

4.3.2 Example Using RS-485 Mode

'----------------------------------------------------------------------' Example use of the SDM-SIO1.

' This example shows how to open the a RS-485 serial port using an SDM-SIO1.

' Data is sent from the logger to the sensor.

' The program then sits in a loop until the SDM-SIO1 reports it had data

' available

' The logger then retrieves the data and places it into a string

' The returned string is then converted to a float and an offset is applied

'-----------------------------------------------------------------------

Public ChkValReturned 'value returned by the SerialInChk function

Public AvailableData 'amount of data in the SDM-SIO1s buffer at present

Public ReturnedData as string * 100 'string where the data from the logger is stored

Public ConvertedValue as float 'floating point value returned by sensor

Sequentialmode

BeginProg

Const SensorPort = 32 'Declare the serial port the sensor is set to

'The sensors address switch should be set to position 0

SDMSpeed (30) 'Optionally set the SDMSpeed not normally needed

Scan(1000,mSec,0,0)

'Open serial port to RS-485 mode, 115200bps, 8-bit data, 1 stop bit and no parity

'note that the 'SerialOpenFormat' parameter is 19 for RS-485 mode

SerialOpen (SensorPort,115200,19,100,10000) 'open the serial port to the sensor

'Request data' will need to be replaced with the correct command for your sensor

SerialOut (SensorPort,"Request data","",0,10) 'Send data to the sensor

'wait for the sensor to respond using a loop this time – this may be useful if there

'is not a predictable response from the sensor.

Do

ChkValReturned = SerialInChk (SensorPort) 'Get available data

AvailableData = ChkValReturned AND 4095 'mask off the input pin flag (bit 16)

Loop until AvailableData <> 0 'wait until data is available

SerialIn (ReturnedData,SensorPort,100,0,100) 'Get data from the sensor

'Convert string to float

ConvertedValue = ReturnedData

'add an offset to the returned floating point value

ConvertedValue = ConvertedValue + 100

SerialClose (SensorPort) 'Close the serial port to the sensor

'(this places the SDM-SIO1 into its lowest power mode)

'Now there would be code to read the data out of the ReturnedData string and either store

'it as strings or convert the string into number(s).

Next Scan

EndProg

21

Page 28

SDM-SIO1 Serial Input/Output Module

5. Firmware Upgrades and Flash Signature Errors

5.1 Upgrading the Firmware

Firmware upgrades can be done by connecting it to a PC and using the

Campbell Scientific Device Configuration program to load the operating

system. (This program can be downloaded free of charge from

www.campbellsci.com/downloads).

The SDM-SIO1 needs a reliable source of 12 V power connected in the

standard way and a cable made similar to that shown in Section 3.3.7,

Connecting a 9-Way Socket to the SDM-SIO1, to connect to an RS-232 port on

the PC, except there is no requirement to connect any handshaking lines.

Start the Device configuration program and select the SDM-SIO1 device (the

SDM-SIO1 device may not be available in older versions of the software. New

versions can be downloaded from the Campbell website). Follow the

instructions for that device to load a new operating system. At the end of the

process a success message will be shown if successful. During the loading of

the operating system do not disturb or disconnect power to the SDM-SIO1

otherwise it may need to be returned to the factory for repair.

5.2 Firmware Signature Errors

The operating system is stored in “flash” memory. When a new version is

loaded a checksum signature is automatically created the first time its run and

stored in memory too. This signature value can be read back using the logger

and compared to the signature supplied with the version that was just loaded

(contact Campbell Scientific if you require doing this).

If the SDM-SIO1 is not operational or is exhibiting random faults then the

flash memory may be corrupted. This is very unlikely due to the robust nature

of the flash device used. The unit automatically checks the flash memory

against its signature upon power up. If an error is found it will send out the

string ‘sigerror:XXXX:YYYY’ when an error is detected, where ‘XXXX’ is

the signature as it’s being read and ‘YYYY’ is the stored signature.

The error string is sent out via the RS-232 port automatically and, will also be

returned to the datalogger the next time any attempt is made to read

information from the sensor. The message will be output at the default baud

rate of 9600bps, 8-bits, 1 stop and no parity.

If this error is seen contact Campbell Scientific to obtain a copy of the latest

operating system and load it into the SDM-SIO1 using the above procedure. If

this does not correct the fault then the unit may be faulty and needs to be

returned to the factory for repair.

22

Page 29

Appendix A. Using the Handshaking Lines for General Input/Output

This Appendix describes how to use the CTS and RTS lines for input and output ports.

The I/O pins (pins 8 and 9) can be read or set by the user as required allowing

unique protocols to be created, or they can simply be used as flags or enable

lines.

If the user enables automatic handshaking as discussed earlier then pins 8 and 9

can’t be accessed.

A.1 The Input Pin (Pin 8)

The state of the input line (pin 8) can be read by the SerialInChk() instruction

in CRBasic.

The SerialInChk() instruction has been modified compared to the standard.

SerialInChk() will return a 16-bit value representing the number of bytes

available within the SDM-SIO1s receive buffer, this value can be anywhere

from 0 to 2047.

th bit (the furthest left or most significant) is reserved when using an

The 16

SIO1 for indicating the status of the spare input line (pin 8). If this bit is set

then the line is high and if it is not set then the line is low.

If the SerialInChk(comport) is used and the input line is high and no data is

available in the loggers buffer then 32768 would be returned (i.e., 0x8000 in

hex). This means that any number returned that’s greater than 32767 indicates

that the input line is set high.

If the CRBasic command SerialInChk(comport) is used and the input line is

low and no data is available in the loggers buffer then 0 would be returned (i.e.,

0x0000 in hex).

To get the amount of data in the SDM-SIO1s receive buffer without the 16th

bit affecting the result, mask the returned value as shown below.

CRBasic example of SerialInChk() masking and input line status checking

public ChkValReturned

public InputStatus

public AvailableData

…

scan(250,mSec,0,0)

…

ChkValReturned = SerialInChk (32) ‘Get the raw data

‘This statement will remove the input line status from the retuned

‘value leaving only the amount of data available in the SDM-SIO1s buffer

AvailableData = ChkValReturned AND 4095 ‘Mask off lowest 12 bits (Ox0FFF in hex)

A-1

Page 30

Appendix A. Using the Handshaking Lines for General Input/Output

‘IF value returned is over 4095 then input line is high

‘ELSE input line must be low

If ChkValReturned > 4095 Then

InputStatus = 1 ‘Flag that input line is high

else

InputStatus = 0 ‘Flag input line is low

EndIf

…

next scan

…

The input line can accept 0 and 5V logic inputs OR -12 and +12V RS-232 level

inputs. Below is a break down of the different input voltages allowed and the

state of the input line flag.

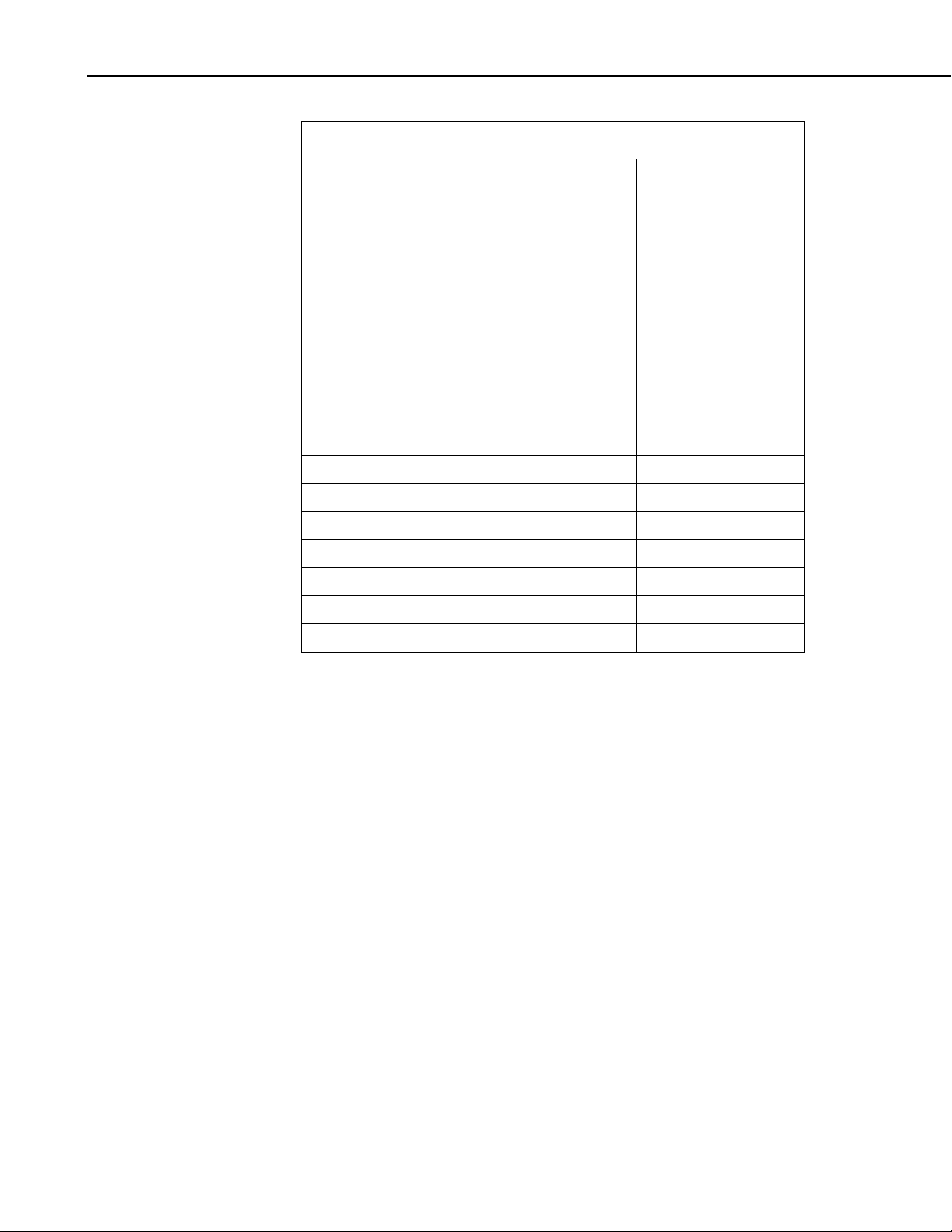

Voltage on the input line State of bit 16

+12V 1

-12V 0

5V 1

0V 0

A.2 The Output Pin (Pin 9)

To set the spare output pin (pin 9) you must use the ‘SerialOutBlock’

command.

The spare I/O lines are RS-232 lines NOT logic lines. This means that the

output line voltage is -12V and +12V (approximately) not 0 and 5V.

The following examples show you how to set the output pin using the

SerialOutBlock() instruction.

CRBasic example for setting the output pin

SerialOutBlock(32, 1, 0) ‘This will set the spare output pin high

SerialOutBlock(32, 0, 0) ‘This will set the spare output pin low

The two example lines of code above will set the output pin on the SDM-SIO1

high then low respectively on the SDM-SIO1 device set to address 0 on its

rotary switch.

A-2

Any value greater than 1 will set the output pin high, but usually the number 1

is used, as this will improve the readability of he code.

Page 31

Appendix A. Using the Handshaking Lines for General Input/Output

Value of ‘SerialOutBlock’

‘SerialExpression’ variable Voltage on the output line

1 +12V(1)

0 –12V(1)

(1) Approximate voltage; do not drive relays or high current loads directly

from this pin

A-3

Page 32

Appendix A. Using the Handshaking Lines for General Input/Output

A-4

Page 33

Page 34

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Loading...

Loading...