Page 1

SDM-INT8

8 Channel Interval Timer

Revision: 12/11

Copyright © 1989-2011

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell's obligation under this warranty is

limited to repairing or replacing (at Campbell's option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a "Statement of Product Cleanliness

and Decontamination" form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9579. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer's expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

SDM-INT8 Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Overview.......................................................................2

2. Specifications ..............................................................3

3. Connections ................................................................. 4

4. Power Supply Considerations....................................5

5. Programming the Datalogger .....................................5

5.1 CRBasic Programming .............................................................................6

5.1.1 Instruction SDMINT8.....................................................................6

5.1.2 SDMSpeed Instruction....................................................................8

5.2 Edlog Programming (Instruction “101”) ..................................................9

6. Programming Details.................................................10

6.1 Parameter 1 - Address.............................................................................10

6.2 Input Configuration ................................................................................11

6.3 Parameters 4 and 5 - Functions...............................................................11

6.4 Output Option .........................................................................................13

6.4.1 Rules for Averaging......................................................................13

6.4.2 Option 0: Execution Interval Averaging......................................16

6.4.3 Option 32768 or 0--: Continuous Averaging ................................16

6.4.4 Option nnnn or XXXX: Specified Averaging Interval ................17

6.4.5 Option –nnnn or XXXX--: Capture All Events Until nnnn

or XXXX Edges On Channel 1.................................................17

6.4.5.1 Option –nnnn.......................................................................17

6.4.5.2 Option XXXX-- ..................................................................17

6.4.6 Option 9999--: Test Memory .......................................................18

6.5 Dest, Input Location, Multiplier, and Offset ..........................................19

6.6 Edlog Output Format ..............................................................................19

7. Program Examples ....................................................20

7.1 CRBasic Program Example ....................................................................20

7.2 Edlog Program Examples .......................................................................21

7.2.1 Cold Crank Engine Test - Capture All Events..............................21

7.2.2 Wind Speed Measurements - Execution Interval Averaging........23

7.2.3 Brake Pressure and Wheel Speed Test - Capture All Events

and P23 Burst Mode..................................................................24

i

Page 6

SDM-INT8 Table of Contents

Appendices

A. Address Jumper ...................................................... A-1

B. Processing Time Limitations ................................. B-1

C. INT8 Input Schematic..............................................C-1

List of Figures

List of Tables

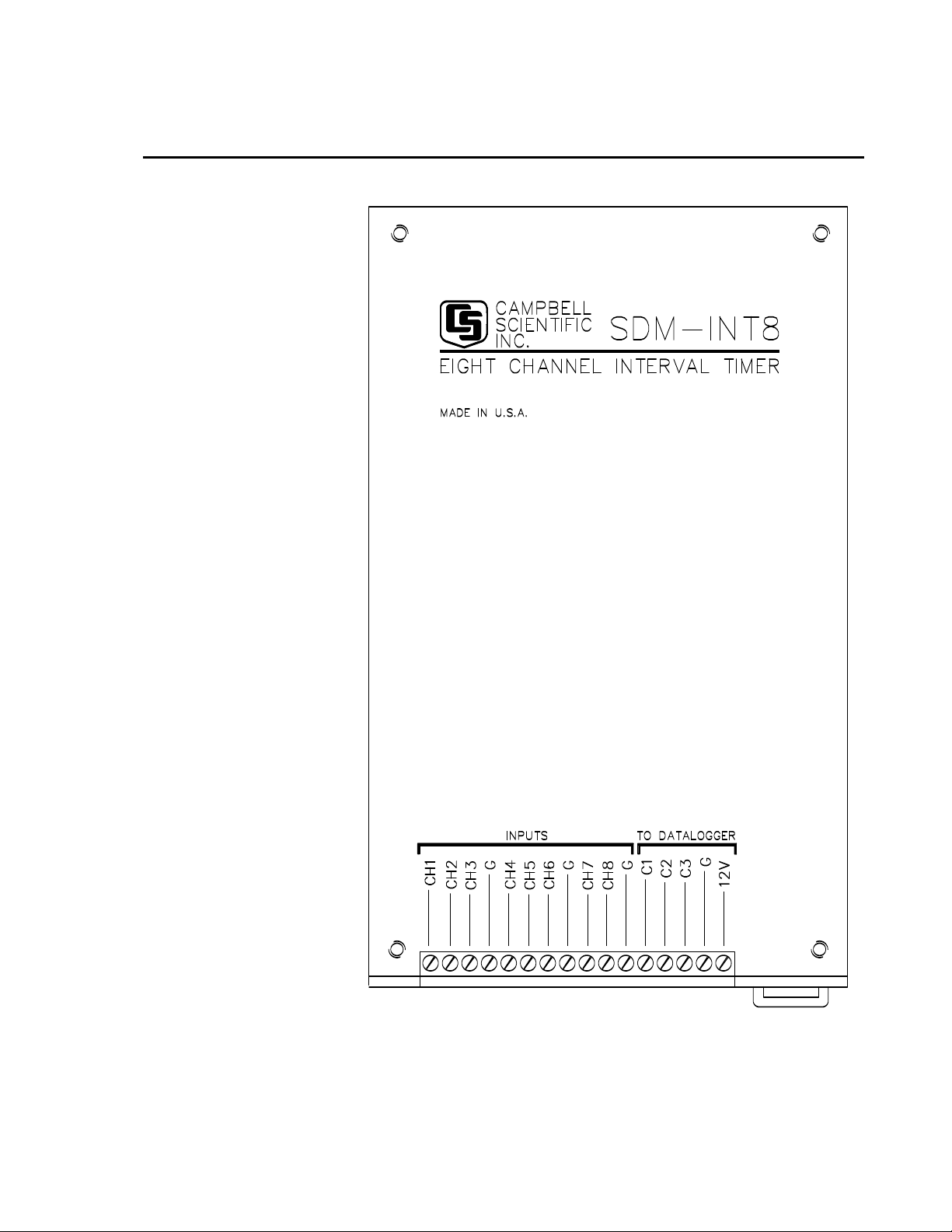

1. SDM-INT8 Front Panel ............................................................................. 1

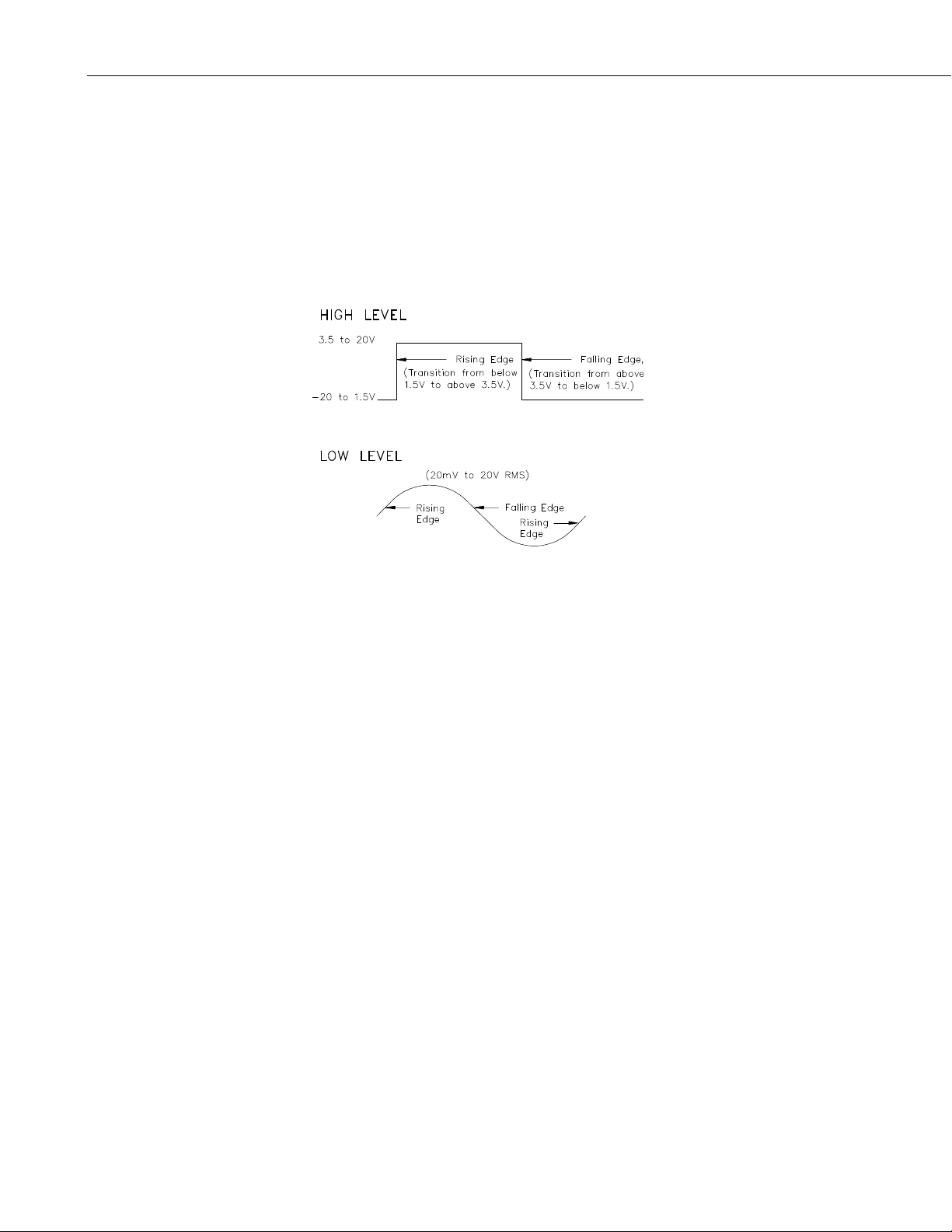

2. Voltage Input Options, Edges and Thresholds........................................... 2

3. Wiring Diagram ......................................................................................... 5

4. Example of Multiple Beginnings and Endings ........................................ 16

A-1. Address Options ................................................................................ A-1

1. Bit Period Values ....................................................................................... 8

2. Instruction 101 ......................................................................................... 10

3. Input Frequency (kHz) at Which Processing Time Equals Measuring/

Storing Time ......................................................................................... 14

4. Sampling Interval (Seconds) to Accumulate 8000 Unprocessed Events

for Functions 1,2,6,7 ............................................................................. 15

5. Definition of Test Memory Option Output .............................................. 19

ii

Page 7

SDM-INT8 8 Channel Interval Timer

FIGURE 1. SDM-INT8 Front Panel

1

Page 8

SDM-INT8 8 Channel Interval Timer

1. Overview

The 8 channel Interval Timer (INT8; see Figure 1) is a measurement module

which outputs processed timing information to a 21X, CR10(X), CR23X,

CR800, CR850, CR1000, CR3000, CR5000, or CR9000(X) datalogger. Each

input channel is programmed to detect transitions from low or high level

voltage inputs (Figure 2). Period, pulse width, frequency, counts, and time

intervals are output to the datalogger for further processing/logging.

FIGURE 2. Voltage Input Options, Edges, and Thresholds

In CRBasic, the SDMINT8 instruction is used to program and control the

SDM-INT8; in Edlog, Instruction 101 is used. These instructions, address,

command, and receive data from the INT8 through three ports on the

datalogger (see Section 3). Multiple INT8s, each with a unique address, may

be controlled by one datalogger.

The INT8 has its own processor which enables it to make measurements and

process data while the datalogger is performing other tasks. Each of the 8

channels may be independently programmed to detect either rising or falling

edges and perform the following functions (Section 5.1.3).

The INT8 can capture timing events with 1 microsecond resolution over a

maximum range of 16.77 seconds. Timing on different channels can be

compared to within ± 1 microsecond. At the same time, the datalogger can be

executing various analog measurements, but the exact time these

measurements are taken is subject to the datalogger's timing resolution.

Section 7.3 discusses the possibilities and limitations of synchronizing INT8

and datalogger measurements.

2

Page 9

2. Specifications

Operating voltage: 9.6 V to 16 V DC

Current drain: 13 to 20 mA active, 400 microamp quiescent

Environmental: -25 to +50 degrees Celsius 0 to 90% RH (non-condensing)

Number of channels: 8

Maximum timing measurement: 16.7 seconds

Resolution: ± 1 microsecond

Dimensions: 8 x 5 x 1 in (13 x 20 x 2 cm)

Weight: 1.4 lbs (635 g)

Input voltage option per channel: high level, low level

SDM-INT8 8 Channel Interval Timer

High Level Voltage Input

- Minimum pulse width: 2 microseconds

- Signals edges:

rising: transition from < 1.5 to > 3.5 volts

falling: transition from >3.5 to<1.5 volts

Maximum input voltage: 20 volts

- Maximum frequency:

5.1 kHz when using Averaging Options

10 kHz when Capturing All Events

The Low Resolution Frequency function allows higher frequencies to be

measured if it is used on all programmed channels with Execution Interval

Averaging. Maximum frequency is dependent on the number of channels

programmed, as shown below:

No. of Channels

1 42.5

2 17.5

3 11.0

4 8.6

5 5.2

6 4.8

7 4.5

8 4.28

Max Freq (kHz)

:

Low Level Voltage Input:

- Minimum AC voltage: 20 millivolts RMS

- Input Hysteresis: 11 millivolts

- Maximum AC voltage: 20 volts RMS

- Minimum frequency: 1 Hz

- Maximum frequency:

3

Page 10

SDM-INT8 8 Channel Interval Timer

Minimum AC Max Freq.

voltage RMS

20 mV 100

50 mV 400

150 mV 1000

2.5 V - 20 V 4000

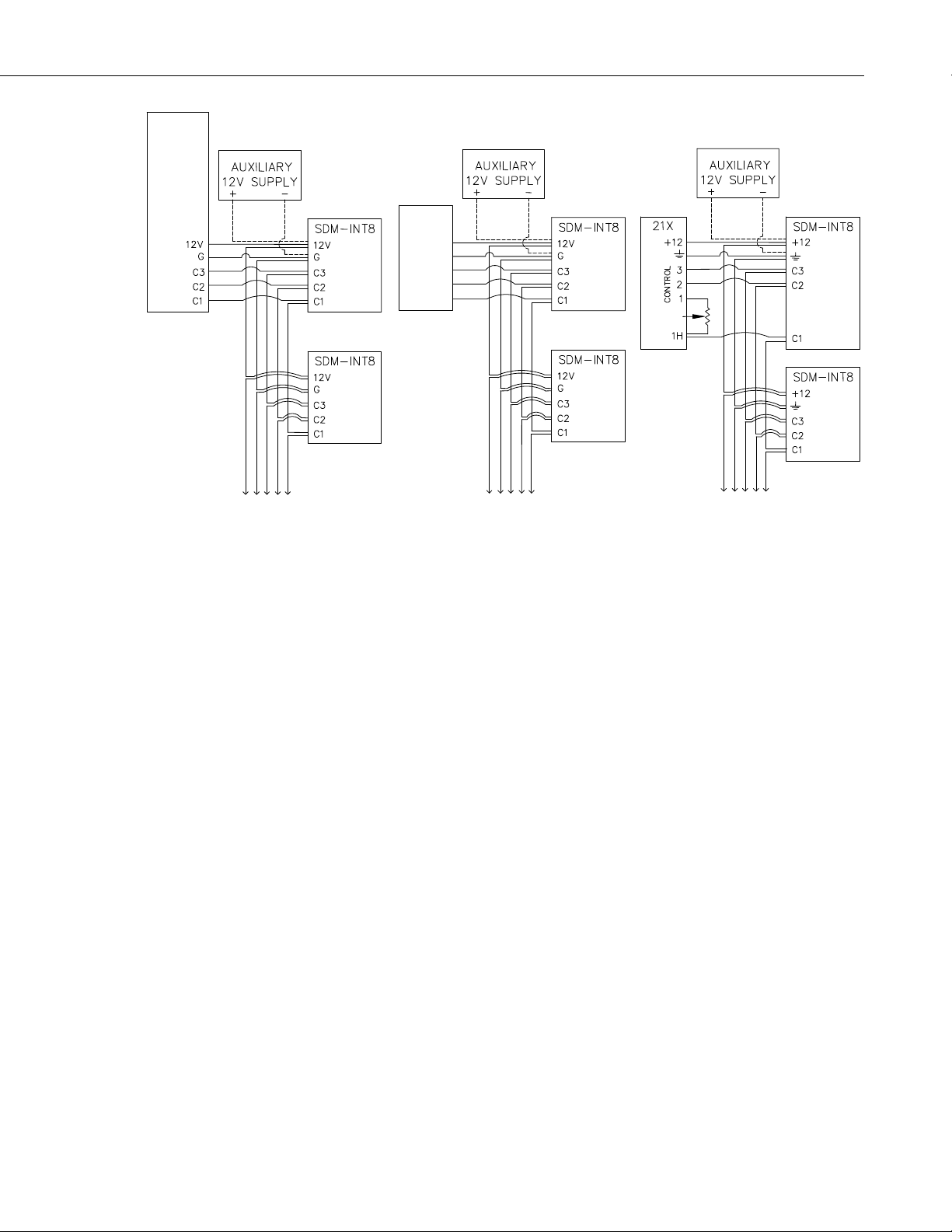

3. Connections

The CABLE5CBL-L cable connects the SDM-INT8 to a datalogger. The

datalogger-to-SDM-INT8 connections are shown in Figure 3. Please note that

the SDM-INT8 connects to the CR9032 CPU module of the CR9000X and the

CR9080 PAM module of the CR9000. INT8s are shipped from the factory

with a 10K Ohm resistor attached to the terminal strip for the convenience of

21X user. This resistor is necessary only when the INT8 is used with a 21X

datalogger.

(Hz)

CAUTION

CAUTION

Except for the 21X, the order in which the datalogger and

SDM-INT8 connections are made is critical. The

datalogger cases and wiring panel bracket are at

datalogger ground. To avoid accidentally shorting 12 V to

the case, connect the 12 V first then the ground. To

prevent voltages in excess of 5 V from entering the

datalogger’s SDM ports (C1 to C3 or SDM-C1 to SDM-C3),

the ports are wired after connecting the ground lead.

For the 21X, a 10K resistor is wired between Control Port 1 and single ended

input 1 (1H). The order in which 21X/INT8 connections are made is not

critical.

The CABLE5CBL-L has a user-specified length. A 1-ft length should be

sufficient when both datalogger and SDM-INT8 are housed in an ENC12/14

enclosure; a 2-ft length may be required if the datalogger and SDM-INT8 are

housed at opposite ends of an ENC16/18. The total cable length for all SDMs

should be as short as possible and preferably does not exceed 20 feet. Longer

lead lengths may be possible for CRBasic dataloggers if the SDMSpeed

instruction is used (see Section 5.1.2). Long lead lengths may prevent

communication.

The signal input lines of the INT8 are protected against the

continuous connection of voltages up to 20 VDC and

against high voltage electrostatic discharge. However,

where there are long cable runs (>3 m) to the sensor and

particularly when the cables run outside, some extra

protection may be required for these inputs to protect the

inputs against high energy surges, as may be induced by

lightning. Please contact Campbell Scientific for further

advice.

4

Page 11

CR800,

CR850,

CR9032

(CR9000X),

CR9080

(CR9000),

CR10(X),

CR23X,

or

CR1000

CR3000,

CR5000

12V

SDM-C3

SDM-C2

SDM-C1

SDM-INT8 8 Channel Interval Timer

G

10K OHM

RESISTOR

FIGURE 3. Wiring Diagram

4. Power Supply Considerations

The datalogger's power supply is typically used to power the INT8, however,

an auxiliary supply may be used as shown in Figure 3. When selecting a

power supply, consideration must be given to the active current drain and the

active time of the INT8. With two exceptions, if the INT8 is programmed it is

drawing 13 to 20 mA. The two exceptions are:

• When the Specified Averaging Interval (Output Option Section 5.4) is

selected, the INT8 enters the quiescent current drain state (400 microamp

current drain) after returning the results to the datalogger.

• If the interval between executions of Instruction 101 exceeds 16.77

seconds, the INT8 enters the quiescent current drain state.

If a 21X datalogger is used to power the INT8, all low level analog

measurements (thermocouples, pyranometers, etc.) must be made

differentially. This is due to slight shifts in the ground potential on the

terminal strip when the 21X is used to power external devices.

5. Programming the Datalogger

The datalogger is programmed using either CRBasic or Edlog. Dataloggers

that use CRBasic include our CR800, CR850, CR1000, CR3000, CR5000, and

CR9000(X). Dataloggers that use Edlog include CR7, CR10(X), CR23X, and

21X. Both CRBasic and Edlog are provided in LoggerNet and PC400.

5

Page 12

SDM-INT8 8 Channel Interval Timer

5.1 CRBasic Programming

5.1.1 Instruction SDMINT8

The SDMINT8 instruction is used to program and control the SDMINT8

interval timer module. Description of the instruction follows.

Syntax

SDMINT8 (Dest, SDMAddress, Config8_5, Config4_1, Funct8_5, Funct4_1,

OutputOpt, CaptureTrig, Mult, Offset)

Dest: Dest is used to specify the array where the results of the instruction are

stored. For all output options except Capture All Events (-nnnn), the Dest

argument should be a one dimensional array with as many elements as there

are programmed INT8 channels. If the Capture All Events output option is

selected, the Dest array must be two dimensional. The magnitude of first

dimension should be set to the number of functions (up to 8), and the

magnitude of the second dimension should be set to at least the maximum

number of events to be captured. The values will be loaded into the array in the

sequence of all of the time ordered events captured from the lowest

programmed channel to the time ordered events of the highest programmed

channel.

NOTE

SDMAddress: This parameter is used to define the address of the INT8 with

which to communicate. Valid SDM addresses are 0 through 14 (factory default

is 0). Address 15 is reserved for the SDMTrigger instruction. If the Reps

parameter is greater than 1, the datalogger will increment the SDM address for

each subsequent device that it communicates with. See Section 6.1 for further

detail.

CRBasic dataloggers use base 10 when addressing SDM devices.

Edlog programmed dataloggers (e.g., CR10X, CR23X) used

base 4 for addressing.

Config8_5: The Config8_5 parameter is a four-digit code used to configure

channels 5 through 8 on the INT8. Each input channel can be configured for

either high or low level voltage inputs and for rising or falling edges. The

digits represent the channels in descending order from left to right (e.g., 8 7 6

5). As an example, the code 0303 would program channels 8 and 6 to capture

the rising edge of a high level voltage, and channels 5 and 7 to capture the

falling edge of a low level voltage. See Section 2 for information about the

specification requirements of high and low level voltage signals.

Description

Code

0 High level, rising edge

1 High level, falling edge

2 Low level, rising edge

3 Low level falling edge

6

Config4_1: The Config4_1 parameter is a four-digit code used to configure

channels 1 through 4 on the INT8. It is identical in function to Config8_5. The

digits represent the channels in descending order from left to right (e.g., 4 3 2

1).

Page 13

SDM-INT8 8 Channel Interval Timer

Function8_5: The Function8_5 parameter is a four digit code used to program

the timing function of channels 5 through 8. Similar to the Config parameters,

digits represent the channels in descending order from left to right (e.g., 8 7 6

5). See Section 6.3 for further details about these functions.

Description

Code

0 No value returned

1 Period (ms) between edges on the programmed channel

2 Frequency (kHz) of edges on the programmed channel

3 Time (ms) between an edge of the previous channel and an edge of

the programmed channel

4 Time (ms) between an edge on Channel 1 and edge on the

programmed channel

5 Number of edges on channel 2 since last edge on channel 1 using

linear interpolation

6 Low resolution frequency (kHz) of edges on programmed channel

7 Total count of edges on programmed channel since last interrogation

8 Number of edges on channel 2 since last edge on channel 1 without

linear interpolation

Function4_1: The Function4_1 parameter is a four digit code used to program

the timing function of channels 1 through 4. It is identical in function to

Function8_5. The digits represent the channels in descending order from left to

right (e.g., 4 3 2 1).

OutputOpt: The OutputOption parameter is a numeric code that is used to

select one of the five different output options. The selected option will be

applied to all of the INT8 channels. A brief explanation is given below for

each code. See Section 6.4 for detailed explanations of each option.

0: Stores an average of the event data since the last time that the INT8 was

interrogated by the datalogger. If no edges were detected, 0 will be returned for

frequency and count functions, and 99999 will be returned for the other

functions. The INT8 ceases to capture events during communications with the

datalogger, thus some edges may be lost.

32768: Performs continuous averaging, which is utilized when input

frequencies have a slower period than the execution interval of the datalogger.

If an edge was not detected for a channel since the last time that the INT8 was

polled, then the datalogger will not update the Dest for that channel. The INT8

will capture events even during communications with the datalogger.

nnnn: Averages the input values over "nnnn" milliseconds. The datalogger

program is delayed by this instruction while the INT8 captures and processes

the edges for the specified time duration and sends the results back to the

datalogger. If no edges were detected, 0 will be returned for frequency and

count functions, and 99999 will be returned for the other functions.

-nnnn: Instructs the INT8 to capture all events until "nnnn" edges have

occurred on channel 1, until the datalogger addresses the INT8 with the

CaptureTrig argument true, or until 8000 events have been captured. When the

CaptureTrig argument is true, the INT8 will return up to the last nnnn events

for each of the programmed INT8 channels, reset its memory, and begin

capturing the next nnnn events. The INT8 waits for the first edge on channel 1

7

Page 14

SDM-INT8 8 Channel Interval Timer

as a trigger to start making measurements. The Dest parameter must be

dimensioned large enough to receive the captured events.

-9999: Initiates a self memory test of the INT8. A numeric code is returned to

indicate the results of the test.

Code

0 Bad ROM

-0 Bad ROM and bad RAM

positive integer: Good ROM (value returned is the ROM signature) and good

RAM

negative integer: Good ROM (value returned is the ROM signature) and bad

RAM

CaptureTrig: This argument is used when the Capture All Events output

option is used. When CaptureTrig is true, the INT8 will return the last nnnn

events.

Mult: The multiplier with which to scale the raw data.

Description

Offset: The offset that is to be applied to the raw data.

NOTE

This instruction must NOT be placed inside a conditional

statement when running in pipeline mode.

5.1.2 SDMSpeed Instruction

The SDMSpeed instruction is used to change the bit period that the datalogger

uses to clock the SDM data. Slowing down the clock rate may be necessary

when long cable lengths are used to connect the datalogger and SDM devices.

The syntax of this instruction is as follows:

SDMSpeed (BitPeriod

The BitPeriod argument can be an integer or a variable. If the SDMSpeed

instruction is not in the program, a default bit period is used. If 0 is used for

the argument, the minimum allowable bit period is used. Table 1 shows the

default, minimum allowable, and maximum bit period for each of our CRBasic

dataloggers.

Datalogger

)

TABLE 1. Bit Period Values

Default

Bit Period

Minimum Allowable

Bit Period

Maximum

Bit Period

8

CR800, CR850

CR1000

CR3000

CR5000

26.04 μsec 8.68 μsec

26.04 μsec 8.68 μsec

26.04 μsec 8.68 μsec

30 μsec 8 μsec

2.2 msec

2.2 msec

2.2 msec

3 msec

Page 15

SDM-INT8 8 Channel Interval Timer

The equation used to calculate the bit rate depends on the datalogger used.

The datalogger will round down to the next faster bit rate.

Equation for CR800, CR850, and CR1000:

bit_rate=INT((k*72)/625)*Resolution

Where:

k= the value entered in BitPeriod

Resolution=8.68 microseconds

Equation for CR3000:

bit_rate=INT((k*144)/625)*Resolution

Where:

k= the value entered in BitPeriod

Resolution= 4.34 μsec.

Equation for CR5000:

bit_rate=INT(k*20)*Resolution

Where:

k= the value entered in BitPeriod

Resolution=50 nsec.

5.2 Edlog Programming (Instruction “101”)

In Edlog, Instruction 101 (see Table 2) is used to address, command, and

retrieve data from the INT8. On the first execution of Instruction 101, the

INT8 is programmed. Subsequent executions of Instruction 101 may

command the INT8 to send its processed data to the datalogger or to

reinitialize its measurement process. If multiple INT8s are connected to a

datalogger, each INT8 must have a corresponding Instruction 101 and a unique

address.

The datalogger tracks the first time a 101 Instruction is executed to know if the

associated INT8 is programmed or not. If two or more 101 Instructions are

used to address the same INT8, the first execution of each Instruction will

program the INT8 returning no data. If the INT8 must be called more than

once per datalogger execution interval, place Instruction 101 in a subroutine

and call the subroutine when Instruction 101 must be executed. The INT8 is

programmed on the first call, with data being returned on subsequent calls.

9

Page 16

SDM-INT8 8 Channel Interval Timer

Parameter Data Description

Type

01: 2 Address (Section 6.1)

02: 4 *Input config; channels 8,7,6,5

03: 4 *Input config; channels 4,3,2,1

04: 4 **Function; channels 8,7,6,5

05: 4 **Function; channels 4,3,2,1

06: 4 ***Output option

07: 4 Loc

08: FP Mult

09: FP Offset

Execution time: 2.3 ms + 1.65 ms/value + averaging interval

(See Appendix B to estimate processing time on higher

Intermediate Storage: 1 location

* Input configurations (Section 6.2):

0 = high level, rising edge

1 = high level, falling edge

2 = low level, rising edge

3 = low level, falling edge

**Functions (Sec. 6.3):

0 = no value returned

1 = period in ms

2 = frequency in kHz

3 = time since previous channel is ms

4 = time since channel 1 in ms

5 = counts on channel 2 since channel 1

6 = low resolution frequency in kHz

7 = counts

8 = integral counts on channel 2 since channel 1

*** Output (Sec. 6.4):

0 Execution interval averaging

0- - Continuous averaging

XXXX Specified averaging interval in ms, XXXX>0

XXXX- - Capture all events until XXXX edges of channel 1

9999- - Test memory

TABLE 2. Instruction 101

frequency signals)

(0<XXXX<8000)

6. Programming Details

6.1 SDM Address

The INT8 is enabled by an address sent from the datalogger. A terminal block

located inside the INT8 has two jumpers which define the INT8 address. The

address defined by the jumpers must match the address entered into SDMINT8

or Instruction 101. The jumpers are set at the factory for address 00. If the

jumpers have not been changed, the SDM address entry is 00. Each INT8

10

Page 17

connected to the datalogger must have a unique address. See Appendix A for

details on changing the address.

6.2 Input Configuration

Each of the 8 input channels can be configured for either high level or low

level voltage input, and for rising or a falling edge detect (see Figure 2). One

digit (0,1,2, or 3) is specified to configure each channel, as shown below.

0 = high level, rising edge

1 = high level, falling edge

2 = low level, rising

3 = low level, falling

Example:

Channel 1 thru 5: high level, rising edge

Channel 6: high level, falling edge

Channel 7 and 8: low level, rising

02:2210 (channels 8,7,6,5)

03:0000 (channels 4,3,2,1)

SDM-INT8 8 Channel Interval Timer

6.3 Functions

Each of the 8 channels can be programmed independently for various timing

functions. Channel functions are programmed with one digit (0,1,2,3,4,5,6,7,

or 8) for each channel. Functions 0 through 8 are described below.

0 - no value

1 - Period (ms)--

The time between signal edges on this channel in milliseconds.

2 - Frequency (kHz)--

The frequency of signal edges on this channel in kHz. Frequency is

calculated from a measurement of period.

3 - Time since previous channel (ms)--

The time between the signal edge on the next lower numbered channel

and the signal edge on this channel is in milliseconds. This function can

be used to measure pulse width by connecting the signal to two adjacent

channels programmed with opposite edge detect directions.

4 - Time since channel 1 (ms)--

The time between the signal edge on channel 1 and signal edge on this

channel is in milliseconds.

5 - Count on channel 2 since channel 1--

The number of signal edges on channel 2 between channel 1's signal edge

and this channel's signal edge. Linear interpolation is used to derive a

fraction of a count at both the beginning and end of counting

11

Page 18

SDM-INT8 8 Channel Interval Timer

6 - Low resolution frequency (kHz)--

Higher frequencies may be measured if fewer channels are used (see

For this function, any data value less than 1 is returned as 0. This must be

The frequency is returned to the datalogger in a low resolution format (16

Fewer bits are transferred to the datalogger in the 16 bit format, speeding

7 - Counts--

For this function to return low resolution data, it must be the only function

used in the instruction. If this is not the only function used in the

instruction, it returns high resolution data, the same as Function 2.

Section 2, Specifications).

considered when calculating the multiplier and offset (Parameters 8 and

9).

bit floating point). This format allows for a range of positive real

numbers between 1 and 65480 with 4 digit resolution on values whose

mantissa is less than 8192. Three (3) digit resolution is given on values

with mantissas greater than or equal to 8192.

up the instruction execution time by 0.3 ms per value.

"Counts" will always return an integer value when Instruction 101 is

executed. The value will be the number of edges that have occurred since

the last execution of Instruction 101. If no edges have occurred, a zero is

returned. This function does not work with the Capture All Events

Output Option.

If counts are being totalized by the datalogger, use the Continuous

Averaging Output with "Counts" to avoid missing any counts (Section

5.4).

8 - Integral counts on chnl 2 since chnl 1--

Same as function 5 with no linear interpolation.

Example: The INT8 is used in an automotive test to measure crank

angle, engine RPM when spark #1 fires, and fuel injector duty cycle.

Parameters 2 and 3 are programmed as follows:

Parameter 2:0001 (channels 8,7,6,5)

Parameter 3:0000 (channels 4,3,2,1)

Channel 1: crank shaft reference pulse, rising edge (0)

Channel 2 pulse from the flywheel teeth, rising edge (0)

Channel 3: pulse from spark #1, rising edge (0)

Channel 4: fuel injector pulse, rising edge (0)

Channel 5: fuel injector pulse, falling edge (1)

Parameters 4 and 5 are programmed for the following functions:

Parameter 4:0003 (channels 8,7,6,5)

Parameter 5:2502 (channels 4,3,2,1)

12

Page 19

Channel 1: frequency (2)

Channel 3: counts on channel 2 since channel 1 (5)

Channel 4: frequency (2)

Channel 5: time since previous Channel (3)

Channel 2,6,7,8: none (0)

Channel 1: RPM may be calculated from crankshaft frequency.

Channel 3: Flywheel teeth count between the crankshaft reference

Channel 4: The frequency of fuel injection may be multiplied by

Channel 5: Time of the positive pulse width of the fuel injector is given

6.4 Output Option

An important conceptual difference between Output Options and Functions is

that one Output Option is selected per Instruction (SDMINT8 or Instruction

101) and applied to data from all channels. Functions are applied to individual

channels.

SDM-INT8 8 Channel Interval Timer

pulse, and the spark gives reference to the crank angle.

channel 5's positive pulse width to yield fuel injector duty

cycle. The multiplication is not performed in the INT8.

in milliseconds.

6.4.1 Rules for Averaging

This Section applies to only those Output Options which perform averaging

(i.e., 0, 32768, nnnn in SDMINT8 or 0, 0--, XXXX in Instruction 101).

Averaging is performed on events which are defined by at least two edges. For

example, to average a period two rising edges are required to define a period.

To average the time since the previous channel, an edge on the previous

channel followed by an edge of the channel programmed for time since

previous channel is required.

No averaging is done on channels programmed for Function 7, "Counts".

Channels programmed for counts do not require two edges for an event.

Single edges of the specified direction are counted.

The maximum interval that the INT8 can time is 16.77 seconds. Edges which

are separated by a time longer than this will result in a false measurement.

In all Output Options that average, the INT8 is storing measurements and

processing. The measuring/storing task takes priority over the processing task.

If the input signal exceeds a certain frequency, processing will lag behind

measuring/storing. Table 3 provides the maximum average frequency at which

the processing task keeps up with the measuring/storing task.

13

Page 20

SDM-INT8 8 Channel Interval Timer

TABLE 3. Input Frequency (kHz) at Which Processing

N 1,2,6,7 3 4 5 8

1 * 3.4 3.7 0.14 - 0.05F2 3.4 - 0.81F2

2 3.5 1.6 1.7 0.07 - 0.02F2 1.6 - 0.38F2

3 2.1 0.99 1.1 0.05 - 0.02F2 0.99 - 0.24F2

4 1.4 0.70 0.76 0.04 - 0.01F2 0.70 - 0.17F2

5 .99 0.53 0.57 0.03 - 0.01F2 0.53 - 0.13F2

6 .75 0.42 0.45 0.02 - 0.01F2 0.42 - 0.10F2

7 .59 0.34 0.37

8 .47 0.28 0.30

N = Number of channels measuring given Function

* = Greater than the maximum input frequency of 5.1 kHz

F2 = Average input frequency on channel 2

See Appendix B to formulate the equations used to generate

Table 3. Frequencies show in Table 3 are for "worst case"

conditions. Faster input frequencies are possible depending on

the phase relationship of the channel to channel signal.

With Options 0, 32768, and 0--, the average returned to the datalogger is the

most recently processed average when the INT8 is addressed. If processing

lags measuring/storing, the number of samples used in the average is reduced

as is the effective averaging interval. For functions that average, this is not a

problem, assuming the input frequency does not change significantly over the

sampling interval. It is a problem if counts are being totalized (Function 7,

Output Option 32768 or 0--). In this case the count will intermittently be low

(Section 6.4.3).

Time Equals Measuring/Storing Time

14

The Specified Averaging Interval Option (nnnn or XXXX) uses all events

captured over the specified interval to calculate an average. If the processing

tasks gets behind the measuring/storing task, the additional time required to

process all the edges is taken at the expense of the execution time (refer to

Table 3.)

Due to finite memory in the INT8, when processing lags behind by 800 edges,

the measuring/storing task is suspended for that interval. For Option nnnn or

XXXX to average over the entire specified interval, the interval must be short

enough to prevent the processing tasks from getting behind by more than 8000

edges. Table 4 gives the sampling interval at which 8000 unprocessed events

will accumulate for a given input frequency.

Page 21

SDM-INT8 8 Channel Interval Timer

TABLE 4. Sampling Interval (Seconds) to Accumulate

8000 Unprocessed Events for Functions 1,2,6,7

Input Number of Channels

Freq. kHz 3 4 5 6 7 8

1.1 5.26

1.3 7.97 2.84 1.48

1.5 4.21 1.81 1.00

1.7 2.67 1.26 .73

1.9 5.62 1.87. .93 .55

2.1 3.68 1.38 .72 .43

2.3 2.64 1.07 .57 .35

2.5 2.00 .86 .47 .29

2.7 6.55 1.57 .7 .39 .24

2.9 4.64 1.27 .58 .33 .20

3.1 3.50 1.05 .49 .28 .18

3.3 2.76 .88 .42 .24 .15

3.5 2.24 .75 .37 .21 .13

3.7 1.86 .65 .32 .19 .12

3.9 1.57 .57 .28 .17 .11

4.1 1.35 .50 .25 .15 .10

4.3 8.91 1.17 .45 .23 .13 .09

4.5 6.73 1.03 .40 .20 .12 .08

4.7 5.33 .91 .36 .19 .11 .07

4.9 4.36 .81 .33 .17 .1 .06

5.1 3.65 .73 .30 .15 .09 .06

Sampling intervals shown in Table 4 are for "worst case"

conditions. Longer sampling intervals are possible

depending on channel phase relationships. See Appendix B

to calculate maximum intervals for other Functions.

When the low resolution frequency function is used, summing is not required;

an average over the full interval is always available.

In all options that do averaging, the functions that involve time or count

differences between different channels (time since channel 1, counts on 2 since

1, and time since previous channel) behave as follows: if there are multiple

beginning edges and/or ending edges, i.e., more than 1 beginning edge per

ending edge or visa versa, then only the last of the beginning edges and the

first of the ending edges are used in the average. For example, assume all

detection is on rising edges, and the function is counts on channel 2 since 1 for

channel 3. A diagram of this example is presented in Figure 4. Multiple

beginning edges are shown on channel 1, and multiple ending edges on

channel 3. In this example, only 2 edges are used in the average.

15

Page 22

SDM-INT8 8 Channel Interval Timer

FIGURE 4. Example of Multiple Beginnings and Endings

6.4.2 Option 0: Execution Interval Averaging

When Option 0 is selected, the result from each channel is a value averaged

over the interval since the INT8 was previously addressed. Normally this

would be the execution interval. The value returned to the datalogger is the

average at hand when the INT8 is addressed. If processing lags the

measuring/storing task, the unprocessed events are not used in the averaging

and are deleted from memory.

With Option 0, the datalogger should be programmed to execute Instruction

101 at least every 16.77 seconds while making measurements. If this period is

exceeded, the INT8 enters a low power stand by mode and events are missed.

If no event occurs during the interval, 0 is returned for frequency and count

functions, and 99999 (infinity) is returned for the other functions.

With Option 0, the INT8 ceases to capture events while it is communicating

with the datalogger and reinitializes its measurement operation afterwards.

Thus, edges that occur during this communication period (generally 2.3 ms +

1.7 ms/value) are ignored by the INT8.

6.4.3 Option 32768 or 0--: Continuous Averaging

The Continuous Averaging Option is similar to Option 0 with the following

differences:

1. The INT8 keeps capturing input edges during communication with the

datalogger. If the time required for processing is less than or equal to the

time required for measuring/storing (see Table 3), events will not be

missed.

2. The datalogger will not update the input location of a channel that has not

had an event since the last time the INT8 was addressed.

With the Continuous Averaging option, the datalogger should be programmed

to execute SDMINT8 instruction or Instruction 101 at least every 16.77

seconds while making measurements. If this period is exceeded, the INT8

enters a low power stand by mode and events are missed.

16

The Continuous Averaging option is designed for input frequencies or

intermittent signals that are at a slower rate than the execution interval of the

datalogger. It is also used for totalizing counts.

Page 23

SDM-INT8 8 Channel Interval Timer

Assume the input frequency is 0.5 Hz, and the execution interval of Instruction

101 is 10 Hz. The datalogger input location is updated at about 0.5 Hz if a

change occurred, not every time the INT8 is addressed.

An example of an intermittent signal is a Cub Scout Pinewood Derby where

the measured event is the elapsed time of a race, but several minutes separate

each heat. Three cars per heat are gravity powered down a straight track. The

start of the race triggers an edge on INT8 channel 1. The three cars each

trigger an edge on separate channels as they cross the finish line. Function 4 is

used to measure "time since channel 1" to provide the elapsed time for each

car. The datalogger can be addressing the INT8 as often as desired with this

option, but variables or input locations will only be updated at the finish of a

new heat.

The Continuous Averaging Option is used for totalizing counts (Function 7)

because the INT8 continues to measure and store events even when

communicating with the datalogger. However, counts will be missed if the

measuring/storing task exceeds the processing task (see Table 3).

6.4.4 Option nnnn or XXXX: Specified Averaging Interval

Option nnnn or XXXX is used to average over an exact interval when the

instruction is executed. The averaging interval is specified in units of

milliseconds. The datalogger program is delayed for the specified interval

while the INT8 captures, edges, plus the extra time required for processing if

the processing task lags behind the measuring/storing task. After returning the

results to the datalogger, the INT8 enters the low power standby mode (400

microamp current drain), increasing battery life.

Like Option 0, this option will return 0 for frequency and count functions and

99999 for all functions if no result is available during the specified interval, i.e.

the signal was too slow.

6.4.5 Option –nnnn or XXXX--: Capture All Events Until nnnn or XXXX Edges On Channel 1

6.4.5.1 Option –nnnn

Option –nnnn instructs the INT8 to capture all events until “nnnn” edges have

occurred on channel 1, until the datalogger addresses the INT8 with the

Capture Trigger argument true, or until 8000 events have been captured.

When the CaptureTrig argument is true, the INT8 will return up to the last

nnnn events for each of the programmed channels, reset its memory, and begin

capturing the next nnnn events. The INT8 waits for the first edge on channel 1

as a trigger to start making measurements. The Dest parameter must be

dimensioned large enough to receive the captured events.

6.4.5.2 Option XXXX--

Option XXXX-- outputs all available timing information with no averaging.

"All events" means that every occurrence of each programmed functions is

recorded, i.e., each period, each pulse width, etc. as opposed to one averaged

value.

17

Page 24

SDM-INT8 8 Channel Interval Timer

Since the number of values returned may be variable, making it difficult to

assign a fixed number of input locations, the Capture All Events Option

outputs data directly to the datalogger's Final Storage when Instruction 101 is

executed.

If the Output Flag is not set when the instruction is executed, the datalogger

commands the INT8 to start measuring, and no results are returned. If the

Output Flag is set, the datalogger retrieves the events that have been stored

since the last time the instruction was executed and stores them directly in

Final Storage. Data from the lowest numbered programmed channel are output

first. Each subsequent channel's output has a new array ID which is

incremented by 1. When all data are transferred, the INT8 starts its measuring

process again.

The INT8 waits for the first edge on channel 1 as a "trigger" to start making

measurements. It will then capture edges until XXXX edges on channel 1, or

until the datalogger again addresses it, or until 8000 edges have been captured,

whichever happens first. Output will not be returned until Instruction 101 is

executed with the Output Flag set, even if the edge limits are reached.

With this option, Instruction 101 does not have to be executed every 16.77

seconds. The INT8 will continue to measure without entering the low power

mode until 8000 edges are captured. Events being measured by the INT8 must

not exceed 16.77 seconds, or false measurements will be returned. The

maximum input is 10 kHz for all channels.

On a 10 second one-shot test, for example, Instruction 101 could be executed

with the Output Flag cleared and then executed 10 seconds later with the

Output Flag set. Or, Instruction 101 could be placed in a subroutine and called

from different points in the programs.

For a 10 second test repeated every 10 seconds, the Output Flag could be set

every time the instruction is executed.

Analog measurements can be made by the datalogger while the INT8 is

capturing events. To some degree, and with caution, datalogger measurements

can be synchronized with INT8 measurements. For example, the datalogger

can execute the Burst Mode after executing Instruction 101 and trigger on the

same signal that triggers channel 1 of the INT8. The caution is that the trigger

on channel 1 cannot occur before the datalogger has a chance to enter the Burst

Mode. To synchronize datalogger and INT8, the Burst Mode should be ready

and waiting for the "trigger".

6.4.6 Option 9999--: Test Memory

Option 9999-- causes the INT8 to do a self memory test instead of measure

and process timing functions. The signature of the INT8 PROM is returned to

the datalogger's Input Location of the initial execution of the instruction. If the

value is negative it indicates bad RAM; 0 indicates a bad PROM, as shown in

Table 5.

18

Page 25

SDM-INT8 8 Channel Interval Timer

TABLE 5. Definition of Test Memory

Option Output

Output Definition

positive integer = ROM signature, good RAM

negative integer = ROM signature, bad RAM

0 = bad ROM

-0 = bad ROM, bad RAM

A result of executing Option 9999-- is that the program residing in the INT8 is

deleted, and the INT8 goes into the low current drain standby mode. To initiate

INT8 measurements, SDMINT8 or Instruction 101 must be executed without

9999--.

6.5 Dest, Input Location, Multiplier, and Offset

For the SDMINT8 instruction, Dest is used to specify the array where the

results of the instruction are stored. For all output options except Capture All

Events (-nnnn), Dest argument should be a one dimensional array with as

many elements as there are programmed INT8 channels. If the Capture All

Events output option is selected, the Dest array must be two dimensional. The

magnitude of the first dimension should be set to the number of functions (up

to 8), and the magnitude of the second dimension should be set to at least the

maximum number of events to be captured. The values will be loaded into the

array in the sequence of all of the time ordered events captured from the lowest

programmed channel to the time ordered events of the highest programmed

channel.

For Instruction 101 the input location is designated in parameter 7. Except for

the Capture All Events Options, data from the INT8 are returned to the starting

input location in ascending programmed channel order. Output from Capture

All Events is returned directly to Final Storage in the datalogger.

Except for the "Test memory" option, the multiplier and offset are applied to

all results by the INT8 before they are returned to the datalogger.

For Low Resolution Frequency (Function 6), any value less then 1 is returned

as 0. This must be considered when calculating the multiplier and offset.

6.6 Edlog Output Format

The Output Option specifies the format of the output received by the

datalogger. The format of the three options that do averaging (Options 0, 0--,

and XXXX) are identical. A single value for each programmed channel is

stored in consecutive input locations starting at the location specified in

parameter 7, Instruction 101. If only three INT8 channels are programmed,

then only three Input Locations will be utilized. Output Processing

Instructions, such as Instruction 70 (Sample) must be used to store the results

in Final Storage.

19

Page 26

SDM-INT8 8 Channel Interval Timer

When using the Capture All Events Option (no averaging), the data are

directed to Final Storage of the datalogger rather than Input locations. The

first execution of Instruction 101 will program the INT8. Subsequent

executions of Instruction 101 with the Output Flag set will output all events to

Final Storage. If the Output Flag is not set, the INT8 will be reinitialized with

out returning any data. The output returned for each programmed channel will

be all events that have occurred since the last execution of Instruction 101.

Each channel will have a unique Array ID. If other Output Processing

Instructions precede Instruction 101, the first channel's data will be grouped

with the previous Final Storage data (i.e. same Array ID.). This first Array ID

will be incremented by one for each additional programmed channel.

Output for the Test Memory Option is a single value returned to the specified

input location.

7. Program Examples

These examples are given to demonstrate concepts. The starting conditions for

each example are followed by a datalogger program. These examples are not

to be used verbatim.

7.1 CRBasic Program Example

Measure 2 Wind Sentry Anemometer (03101) on CR1000 pulse channel P1

and P2 and measure 5 Wind Sentry Anemometer (03101) connected to the

SDM INT8 channel 1 through channel 5. See Section 5.1.1 for a description of

the CR1000 “SDMINT8” instruction parameters.

Wiring

CR1000 SDMINT8

12 V 12 V

Gnd Gnd

C1 C1

C2 C2

C3 C3

Sensor Wiring

SDM-INT8

CH1 Black - WS #1

CH2 Black - WS #2

CH3 Black - WS #3

CH4 Black - WS #4

CH5 Black - WS #5

All white and clear wires are

connected to ground.

Note: Set/check the SDM

Address on this module.

20

Page 27

SDM-INT8 8 Channel Interval Timer

‘Declare Public Variables

Public Int8(5)

Public PulseCh(2)

Dim I

‘Define Data Tables

DataTable (Dat5min,1,-1)

DataInterval (0,5,Min,10)

average (5,Int8(),FP2,False)

EndTable

‘Main Program

BeginProg

Scan (5,Sec,0,0)

‘measure 03101 on P1 & P2 WS_ms:

PulseCount (PulseCh(1),1,1,1,1.75,.2)

PulseCount (PulseCh(2),1,2,1,1.75,.2)

‘measure 03101 on SDMINT8 channel 1 through channel 5

SDMINT8 (Int8(),3,0002,2222,0002,2222,0,1,1.75,.2)

‘For I = 1 to 5

‘If Int8(I)<0.21 Then Int8(I)=0

‘next I

‘Call Data Tables and Store Data

CallTable Dat5min

NextScan

EndProg

7.2 Edlog Program Examples

7.2.1 Cold Crank Engine Test - Capture All Events

The INT8 is used to obtain timing information during 20 crank cycles or 10

seconds of a 4 cylinder engine cold start test. A crank shaft reference pulse is

wired into channel 1. Pulses from the flywheel enter channel 2 so that the

counts on 2 since 1 function can be used to measure crank angle. The 4 spark

plug firings are picked off a distributor wire and fed into channel 3. Channels

4 and 5 hook onto a fuel injector pulse for measurement of fuel injection pulse

width.

The inputs into channels 1 - 5 are as follows:

Channel 1 - crank shaft reference pulse, rising edge

Channel 2 - pulse per flywheel tooth, rising edge

Channel 3 - pulses from the four spark plugs, rising edge

Signals common to single distributor pick-up wire

Channel 4 - fuel injector "on" pulse, rising edge

Channel 5 - fuel injector "on" pulse, falling edge

The channel functions are programmed as follows:

Channel 1 - Frequency, to get RPM

Channel 3 - Counts on 2 since 1, to get crank angle of the spark plug firings

Channel 5 - Time since previous channel to get pulse widths of the fuel

injector.

21

Page 28

SDM-INT8 8 Channel Interval Timer

Parameter 6 (Capture All Events) is programmed for 20--to capture edge times

on channels 1-5 until 20 edges are received on channel 1.

Flag 2 is used in the example to indicate the start of the cranking. In actual test

program, this flag could be set in response to an ignition switch measurement

indicating the start of the test.

When the ignition is turned on (Flag 2 set), Instruction 101 is called, and the

INT8 is programmed. A "loop with delay" is entered to delay for 10 seconds.

The Output Flag is set high before executing Instruction 101 again to retrieve

the test data.

Three arrays with the following Output array IDs are transferred to the

datalogger's Final Storage.:

105 - Stored are hour:minute, seconds, channel 1 frequencies (kHz).

106 - Stored are crank angle results (teeth on flywheel).

107 - Stored are fuel injector pulse widths (ms).

Array 105 - Each time the crankshaft reference is reached, a pulse is generated

on channel 1. INT8 measurements are started by the initial (trigger) pulse on

channel 1. The pulse frequency (kHz) will be stored on each subsequent pulse

on channel 1 (one pulse per revolution). The pulse frequency can be converted

to RPM by multiplying by 60,000. This conversion must be done in the

computer, after the test.

Array 106 - Channel 2 receives one pulse each time a flywheel tooth passes a

fixed reference point. When a crank shaft reference pulse occurs (channel 1),

the crankshaft is in a known position. Each time a spark plug fires, a pulse

occurs on channel 3. The output for channel 3 is the number of pulses that

have occurred on channel 2 since a pulse from the crank shaft reference

(channel 1). A value (number of pulses) will be output for each cylinder in

their respective firing order. Every fourth data value in Array 106 will

correspond to the same cylinder. The crank angle at each firing can be

calculated by multiplying the number of teeth since the crankshaft reference

pulse by 360/N, where N is the total number of teeth on the flywheel and

subtracting this quantity from 360.

Array 107 - Channel 4 senses a rising edge when the fuel injector is activated.

Channel 5 senses a falling edge when the fuel injector is deactivated. The

INT8 calculates the time (ms) between these two edges, thereby calculating the

pulse width, or the length of time the fuel injector is on for each pulse.

*Table 1 Programs

01: .5 Sec. Execution interval

1: If Flag (P91) If ignition is

1: 22 2 is reset (Ignition not on) on, execute

02: 0 Go to end of Program Table following

2: Do (P86) address/prgm INT8

1: 1 Call Subroutine 1

22

Page 29

SDM-INT8 8 Channel Interval Timer

3: Beginning of Loop (P87) loop to make a 10 sec.

1: 1 Delay delay

2: 20 Loop Count

4: End (P95) end of loop

5: Do (P86) set the output

1: 10 Set high Flag 0 (output) flag

6: Real Time (P77) time tag the output

1: 11 Hour-Minute, Seconds

7: Do (P86) retrieve INT8 data

1: 1 Call Subroutine 1

8: Do (P86) initialize flag 2

1: 22 Set low Flag 2

9: End Table 1 (P)

*Table 3 Subroutines

1: Beginning of Subroutine (P85)

1: 1 Subroutine Number

2: SMD-INT8 (Extended) (P101)

1: 0 Address Option

2: 0001 Chan8765=HLrise/HLrise/HLrise/HLfall/

3: 0000 Chan4321=HLrise/HLrise/HLrise/HLrise/

4: 0003 Chan8765=none/none/none/TsinceP/

5: 0502 Chan4321=none/C2sincel/none/kHz/

6: 20-- Edges of Chan 1 in events mode

7: 1 Loc: <--- Ignored in "Events" Option

8: 1 Mult

9: 0 Offset

3: End (P95)

7.2.2 Wind Speed Measurements - Execution Interval Averaging

The INT8 is used to make 1 second averages of frequencies from 6 RM Young

Wind Monitors. Frequencies are converted to wind speed in m/s, and place in

Input Locations 1 - 6. Wind directions are then measured, scaled, and placed

in Input Locations 7-12. Programming does not output the data to the

dataloggers' Final Storage.

Note that wind speeds of less than 0.2 m/s, corresponding to 2 Hz, will read 0

if a cycle of the Wind Monitor does not get completed within the 1 second

execution interval.

23

Page 30

SDM-INT8 8 Channel Interval Timer

*Table 1 Programs

01: 1 Sec. Execution interval

1: SDM-INT8 (P101) measure wind speed

1: 00 Address Option

2: 0022 Chan8765=HLrise/HLrise/LLrise/LLrise/

3: 2222 Chan4321=LLrise/LLrise/LLrise/LLrise

4: 0022 Chan8765=none/none/kHz/kHz/

5: 2222 Chan4321=kHz/kHz/kHz/kHz/

6: 0 Execution interval averaging (1 second)

7: 1 Loc [:m/s ]

8: 98.0 Mult m/s (convert from kHz to m/s)

9: 0 Offset

2: Excite,Delay,Volt(SE) (P4) measure wind direction

1: 6 Reps

2: 15 2500 mV fast Range

3: 1 IN Chan

4: 1 Excite all reps w/EXchan 1

5: 0 Delay (units .01sec)

6: 2500 mV Excitation

7: 7 Loc [:degrees ]

8: .1420 Mult degrees

9: 0 Offset

7.2.3 Brake Pressure and Wheel Speed Test - Capture All Events and P23 Burst Mode

A CR10X controls an INT8 to capture about 2 seconds worth of wheel speeds

while measuring corresponding brake pressures in Burst Mode. The CR10X's

Burst Mode (P23) triggers the INT8 with Control Port 1 (C1) when the first

analog channel measures pressure over the trigger level.

Flag 1 is manually set by the operator to control when the program is entered.

After each test, the program sets Flag 1 low to return control to the operator.

The first time through the table, the INT8 is programmed and starts measuring,

looking for the edge on channel 1 that the Burst Mode Instruction (P23) will

trigger using C1.

The real time of the brake event (immediately after it occurred) is stored in

array ID 9 with P77, followed by the analog burst data in arrays 1,2,3,4 and the

timing data from the INT8 (picked up each time on the subsequent time

through the table) in arrays 5,6,7,8.

The Burst Mode measures for 2 seconds (200 scans at 10 ms/scan). The INT8

measures for about the same 2 seconds, as defined by the trigger edge on

channel 1 caused by the start of Burst Mode and the ending edge caused by

pulsing Port 1 after the Burst Mode. Data from the INT8 is stored in Final

Storage the next time the table is executed, and the INT8 is reinitialized for the

next brake event.

24

Page 31

SDM-INT8 8 Channel Interval Timer

*Table 1 Programs

01: .125 Sec. Execution interval

1: If Flag/Port (P91)

1: 21 Do if flag 1 is low

2: 0 Go to end of Program Table

2: Do (P86)

1: 10 Set high Flag 0 (output)

3: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 5 Array ID or location

4: SDM-INT8 (P101)

1: 00 Address Option

2: 0000 Chan4321=HLrise/ HLfall/HLrise/HLrise/

4: 0002 Chan8765=none/none/none/kHz/

5: 2220 Chan4321=kHz/kHz/kHz/none/

6: 1-- Edges of Chan 1 in events mode

7: 1 Loc : (ignored in events mode)

8: 1 Mult

9: 0 Offset

5: Burst Measurement (P23)

1: 4 Reps

2: 12 7.5 mV fast Range

3: 1 IN Chan

4: 2100 TrigINchanSetC1/AboveLim/INpStr/Diff

5: 10 Time per (ms.)

6: .2 Scans ( in thousands )

7: 0 Samples before Trigger

8: 10 mV Limit

9: 0 mV Excitation

10: 1 Loc :

11: 1 Mult

12: 0 Offset

6: Do (P86)

1: 71 Pulse Port 1

7: Do (P86)

1: 10 Set high Flag 0 ( output )

8: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 9 Array ID or location

9: Real Time (P77)

1: 11 Hour-Minute,Seconds

10: Do (P86)

1: 10 Set high Flag 0 ( output )

25

Page 32

SDM-INT8 8 Channel Interval Timer

11: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 1 Array ID or location

12: Sample (P70)

1: 200 Reps

2: 1 Loc

13: Do (P86)

1: 10 Set high Flag 0 (output)

14: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 2 Array ID or location

15: Sample (P70)

1: 200 Reps

2: 201 Loc

16: Do (P86)

1: 10 Set high Flag 0 (output)

17: Set Active Storage Area (P80)

1: 1 Final Storage Area 1

2: 3 Array ID location

18: Sample (P70)

1: 200 Reps

2: 401 Loc

19: Do P86

1: 10 Set high Flag 0 (output)

20: Set Active Storage Area (P80)

1: 1 Final Storage Area

2: 4 Array ID or location

21: Sample (P70)

1: 200 Reps

2: 601 Loc

22: Do (P86)

1: 21 Set low Flag 1

23: End of Table 1 (P)

*Mode 10 Memory Allocation

01: 805 Input Locations

02: 64 Intermediate Locations

03: 0.0000 Final Storage Area 2

26

Page 33

Appendix A. Address Jumper

The address is factory set at address 00. Figure A1 (also shown inside the

INT8 cover) shows the 16 possible positions and their corresponding address.

Use the addresses shown in Figure A1 in Instruction 101.

The address block requires soldering to change the address. If two or more

INT8s are to be used on the same datalogger, one can remain at address 00,

while the others must be changed. Disconnect power before opening the case

and soldering.

Every SDM device connected to the datalogger must have a unique address.

Figure A-1. Address Selection

A-1

Page 34

Page 35

Appendix B. Processing Time Limitations

With the exception of the Capture All Events Option or when all channels are

programmed for low resolution frequency (Function 6), the INT8 is

performing two tasks simultaneously: (1) measuring and storing, and (2) doing

the processing necessary for the final calculations of averages. The time

required for processing varies depending on the total number of channels that

are used, the total number of edges that occur during the averaging interval,

and the function that each channel is programmed for.

With relatively high frequencies and particularly with the more involved

processing of the Counts on 2 Since 1 Function, the processing task can lag

behind the measuring and storing of the raw edge times. When averaging over

the execution interval or when doing continuous averaging (Output Options 0

and 0--) this can shorten the actual averaging window. When averaging over a

specified interval (Output Option XXXX) it can lengthen the execution time of

the INT8 instruction. The following formulas are used to calculate the Total

processing time (Tt).

Tt = To + ΣTi

To = Sampling Interval Overhead, ms

= 0.511*S +Et*(.034+.010*N)

Ti = processing Time for Function i, ms

T

T

T

T

T

T

T

T

where:

N = Number of channels measured.

Ei = Total number of edges occurring during the interval on those

Et = Total number of edges during the interval on all channels.

Ec2 = Edges occurring during the interval on channel 2.

S = The sampling interval in ms over which the INT8 samples the

If the Tt for Output Options 0 and 0-- is greater than the sampling interval, the

communication time with the INT8 will be extended from the minimum time

(2.3 ms +1.65 ms/value) only by the processing time needed to obtain an

answer for each channel, i.e., till at least one measurement is obtained. These

Options should have data ready immediately except in the case of a very slow

signal mixed in with relatively fast signals.

= 0.015*E1

1

= 0.015*E2

2

= 0.10*E3

3

= 0.086*E4

4

= 3.320*E5 +.116*Ec2

5

= 0.015*E6

6

= 0.015*E7

7

= 0.1*E8 + .116*Ec2

8

channels programmed with Function i (i = 1...8).

channels.

B-1

Page 36

Appendix B. Processing Time Limitations

If the Tt for Output Option XXXX is greater than the specified interval, the

extra time will be added to the execution time of Instruction 101.

Example 1

:

Given

Output Option = XXXX

Specified interval = S = 500 ms

Function = frequency (Function 2)

Number of channels measured = N = 6

Average input frequency = F = 1kHz

: Total Processing Time, Tt

Find

Solution

:

Tt = To+ΣTi = To+T2

= 0.511*S+Et*(.034+.010*N) +0.015*E2

= 583 ms

S = 500 ms

N = 6

Et = N * S * F = 3000

E2 = Et = 3000

In this case 83 ms is added to the execution time of Instruction 101.

Example 2

: N = number of channels measured

Given

F = Frequency of input signal, kHz

Function = frequency (Function 2)

Output Option = 0 or 0--

: Maximum average frequency, F, at which the processing time is ≤ the

Find

measuring/storing time.

Solution

:

Tt must be ≤ to S;

To+T2≤S

B-2

0.511*S +Et*(.034+.010*N) + 0.015*E2 ≤ S

Note: Et = E2 = N*F*S

0.511*S+N*F*S*(.034+.010*N)+

0.015*N*F*S≤S

F<.489/(N*(.049+.01*N))

Results for the above example using all Functions is presented in TABLE 2,

Section 5.4.1

Page 37

Appendix B. Processing Time Limitations

Example 3

: N = number of channels measured

Given

F = Frequency of input signal, kHz

Function = frequency (Function 2)

Output Option = XXXX with specified sampling interval, S

: Sampling interval, S, such that the number of unprocessed events is ≤

Find

8000

Solution

: The interval required to process 8000 events after the sampling

interval is Tt-S, therefore;

(Tt-S)*F*N≤8000

S≥Tt-(8000/(F*N))

S≥(0.511*S+Et*(.034+.010*N)+0.015*E2)

-(8000/(F*N))

Note: E2 = Et = N*F*S

S≤8000/[F*N((0.511+N*F*(0.49 +.01*N))-1)]

Results for the above example are presented in Table 3, Section 5.4.1

B-3

Page 38

Appendix B. Processing Time Limitations

B-4

Page 39

Appendix C. INT8 Input Schematic

C-1

Page 40

Page 41

Page 42

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br • suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...