Page 1

SDM-CAN

Datalogger-to-CANbus

Interface

Revision: 8/13

Copyright © 2001-2013

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell’s obligation under this warranty is

limited to repairing or replacing (at Campbell’s option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction.................................................................1

1.1 General Description .............................................................................1

1.2 Specifications .......................................................................................2

1.2.1 General Features and Specifications .............................................2

1.2.2 Electrical Specifications................................................................3

1.2.2.1 Power Consumption...........................................................3

1.2.3 Physical Specifications .................................................................4

2. Installation...................................................................4

2.1 Address Switch Configuration .............................................................4

2.2 Internal Jumper Settings.......................................................................5

2.3 Connection to the Datalogger and Power Supply.................................8

2.3.1 LED Status Indication.................................................................10

2.4 Connection to CAN-Bus. ...................................................................10

3. Programming CR10X, CR7 and CR23X

Dataloggers to use the SDM-CAN.........................12

3.1 General Principles ..............................................................................12

3.2 System Limitations.............................................................................13

3.3 The Datalogger Instruction.................................................................14

3.3.1 Instruction 118: SDM-CAN........................................................15

3.3.2 SDM Address (Parameter 01:)....................................................15

3.3.3 TQUANTA, TSEG1, TSEG2 (Parameters 02:, 03:, 04:)............15

3.3.4 ID (Parameters 05:, 06:, 07:).......................................................17

3.3.5 Data Type (Parameter 08:)..........................................................18

3.3.5.1 Collect and retrieve a data value: .....................................19

3.3.5.2 Build a data frame for transmission: ................................19

3.3.5.3 Transmit individual data values onto the CAN-Bus:........20

3.3.5.4 Transmit a previously built data frame on to the

CAN-Bus (type 25):......................................................20

3.3.5.5 Set-up previously built data frame as a Remote Frame

Response (type 26): ......................................................21

3.3.5.6 Read error counters (type 27):..........................................21

3.3.5.7 Read and reset the error counters (type 28):.....................21

3.3.5.8 Read status (type 29):.......................................................21

3.3.5.9 Read the signature and version number of the

SDM-CAN operating system (type 30): .......................22

3.3.5.10 Send Remote Frame Request (type 31):...........................22

3.3.5.11 Set SDM-CAN internal software switches (type 32): ......22

3.3.5.12 Read SDM-CAN internal switches (type 33):..................24

3.3.6 Start Bit Number (Parameter 09:) ...............................................24

3.3.7 Number of Bits (Parameter 10:)..................................................24

3.3.8 Number of Values (Parameter 11:) .............................................25

3.3.9 Location (Parameter 12:) ............................................................25

i

Page 6

Table of Contents

3.3.10 Multiplier (Parameter 13:).......................................................... 25

3.3.11 Offset (Parameter 14:) ................................................................ 25

3.4 Advanced Programming Techniques................................................. 25

3.4.1 Interrupts Using the I/O Connection .......................................... 25

3.4.2 Group Trigger............................................................................. 27

3.4.3 Frame buffers with filtering and triggering ................................ 27

3.4.3.1 Setup of Mask and Filter / trigger.................................... 28

3.4.3.2 Reading / Polling Buffer.................................................. 28

3.4.3.3 Basic Sequence of Buffer Usage: .................................... 29

3.5 Program Examples............................................................................. 29

3.5.1 Reading CAN Data..................................................................... 29

3.5.2 Simple CAN Data Transmission ................................................ 30

3.5.3 Building and Sending Data Frames............................................ 32

3.5.4 Using the Interrupt Function ...................................................... 32

3.5.5 Using the Group Trigger ............................................................ 34

4. Programming CRBasic Dataloggers to use the

SDM-CAN.................................................................35

4.1 General Principles ............................................................................. 35

4.1.1 High Speed Block Mode ............................................................ 36

4.2 Datalogger Instruction ....................................................................... 36

4.2.1 Reading CAN Data..................................................................... 37

4.2.2 Simple CAN Data Transmission ................................................ 38

4.2.3 Digital I/O Triggered CANbus Measurements........................... 39

4.2.4 SlowSequence Instruction .......................................................... 40

5. Using the RS232 Serial Diagnostics Port ...............40

5.1 Connecting to the RS232 User Port................................................... 40

5.2 Diagnostic Commands....................................................................... 41

5.3 Loading a New Operating System into the SDM-CAN Interface ..... 43

6. Attributions................................................................44

Appendices

Principles of Operation...........................................A-1

A.

A.1 Data Collection................................................................................ A-1

A.2 Frame Transmission ........................................................................ A-2

B. A Summary of Data Types......................................B-1

C. Application of the SDM-CAN on Networks

Complying with the J1939 SAE Standards.........C-1

C.1 J1939 29-Bit Identifier Format ........................................................ C-1

C.2 J1939 11-Bit Identifier Format ........................................................ C-1

C.3 J1939 Data Frame Format ............................................................... C-2

ii

Page 7

C.4 Retrieving J1939 Accelerator Pedal Position Data using a

CR9000/CR5000 (Bus Speed 250k Baud)....................................C-2

C.4.1 Encoding the Identifier Field Values ........................................C-2

C.4.2 Finding the Start Bit..................................................................C-3

C.5 Retrieving J1939 Accelerator Pedal Position Data using a

CR23X/CR10X (Bus Speed 250k Baud) ......................................C-4

C.5.1 Encoding the Identifier Field Values ........................................C-4

C.5.2 Finding the Start Bit..................................................................C-5

D. Examples of CAN Data Frames and Data

Encoding and Decoding ...................................... D-1

Figures

1-1. SDM-CAN CAN-Bus Interface ...........................................................1

2-1. SDM-CAN Internal Jumpers................................................................7

2-2. SDM-CAN Isolation enabled (default) ................................................7

2-3. SDM-CAN Isolation disabled..............................................................8

2-4. Using the Spring Loaded Terminal Blocks (Top Option)....................9

2-5. Using the Spring Loaded Terminal Blocks (Front Option)..................9

Table of Contents

Tables

2-1. Switch Position and Addresses ............................................................5

2-2. LED Status Indication........................................................................10

2-3. CIA CAN Connector Pin Connections...............................................11

3-1. Typical settings of the CAN Speed Parameters .................................17

5-1. RS232 Pin Out ...................................................................................40

C-1. Mapping of the J1939 Fields into a 29-Bit Identifier.......................C-1

C-2. Mapping of the J1939 Fields into a 11-Bit Identifier.......................C-1

C-3. J1939 Data Frame Format................................................................C-2

C-4. Mapping of J1939 Identifier Field values into a 29-Bit Identifier....C-3

C-5. Accelerator Pedal Position Value Byte Number ..............................C-3

C-6. Mapping of J1939 Identifier Field Values into a 29-Bit Identifier...C-4

C-7. Accelerator Pedal Position Value Byte Number ..............................C-5

iii

Page 8

Table of Contents

iv

Page 9

SDM-CAN Datalogger-to-CANbus

Interface

1. Introduction

The SDM-CAN interface is designed to allow a Campbell Scientific datalogger

to sample data directly from a CAN-Bus communications network and thereby

allow such data to be stored along with, and in synchronization with, other data

values measured directly by the datalogger.

To use the SDM-CAN device it is assumed that you have a full working

understanding of the CAN network you wish to monitor. While there are

moves to standardize CAN networks for different types of applications, the

SDM-CAN device is designed to be as generic as possible thus allowing use in

a wide range of applications, including research and development, where you

may be working outside the normal standards.

As a result you will need to know details of the electrical configuration of the

network, the speed and CAN standard in use, plus knowledge of the identifiers

of the data packets that are of interest and the way in which data is encoded

within those packets at the binary level. This information may need to be

obtained from the designers of the network, from proprietary documentation or

from the standards to which a network claims to comply.

Campbell Scientific cannot provide full technical support in the understanding

and decoding of data on all types of CAN networks.

FIGURE 1-1. SDM-CAN CAN-Bus Interface

1.1 General Description

The SDM-CAN forms an intelligent interface between a Campbell Scientific

datalogger and a CAN-Bus communications network. The SDM-CAN is

configured by the datalogger under the control of the user’s datalogger

program.

1

Page 10

SDM-CAN Datalogger-to-CANbus Interface

By this process the SDM-CAN can capture data on the CAN-Bus and filter out

packets of interest to the user. Within each data packet the device is able to

read one or more data values and convert them to numeric values compatible

with the normal data stored by the datalogger.

The SDM-CAN will act as a passive listen-only device with its transmitter

disabled in hardware. Alternatively it can be configured to send/respond to

Remote Frame Requests, allowing it to poll remote devices for data. Data

packets can also be constructed to allow it to send data out onto the CAN-Bus

so it then acts as a sensor itself.

Data is transferred between the SDM-CAN interface and the datalogger using

Campbell Scientific’s high speed SDM communications protocol. This

protocol allows the SDM-CAN to be used in parallel with other SDM devices

(including other SDM-CAN interfaces) which might, for instance, be on other

CAN-Bus networks in the same vehicle.

In addition to connectors to the CAN network and the datalogger, an RS232

port is also provided both for diagnostics and operating system upgrades.

1.2 Specifications

1.2.1 General Features and Specifications

• Uses Campbell Scientific’s SDM communication protocol to communicate

with the datalogger via a three wire serial multidrop connection. Support

is planned for CR10X, CR23X, CR7, CR5000 and CR9000 dataloggers.

• Up to 16 units can be used per datalogger, with the modules’ SDM address

set by rotary switch.

• CAN 2.0A and 2.0B active and passive modes supported

• Up to 1Mbaud max data rate. Standard baud rates supported are 1M,

800K, 500K, 250K, 125K, 50K, 20K and lower. Other non-standard baud

rates may be possible – please contact Campbell Scientific.

• Receive and transmit up to 128 different data values from up to 128 CAN

ID’s.

• Build and send a CAN data frame.

• Send Remote Frame Requests.

• Send data frame in response to an external Remote Frame Request.

• Supports a number of power down modes to allow power saving in power

critical applications.

2

• All configuration of the interface is specified within the user’s datalogger

program.

• LED status flash at power up

Page 11

• Additional I/O port for signaling to the datalogger that data is available,

e.g. using an interrupt function.

• Has a 9 pin, DCE RS232 port with auto baud rate detection (1200 to

115200) for diagnosis and operating software download.

• Standard operating temperature range (tested), -25ºC to +50ºC. Can be

used over an extended temperature range – contact Campbell Scientific

for details.

• High speed block mode for fast data collection.

• Buffer assisted burst mode for capturing back to back high speed CAN

data.

• Buffer’s support data frame filtering and triggering.

1.2.2 Electrical Specifications

• Power supply range: 7 to 26V DC.

• Optional (switch selectable) galvanic isolation between the datalogger and

the CAN-Bus. The minimum isolation breakdown is 50V – this barrier is

for signal isolation only, i.e. it is not a safety barrier.

SDM-CAN Datalogger-to-CANbus Interface

• Hitachi H8S,16 bit CPU clocked at 10MHz.

• Uses the latest Philips SJA1000 CAN controller clocked at 16MHz.

• CAN-Bus physical interface using Philips PCA82C251 driver for 1Mbaud

capability, for use in 12V or 24V systems.

• CAN-Bus physical connection conforms to CIA draft standard 102 version

2, 9 pin D connector. (The interface will differ from this standard only

with respect to pin 9, which outputs 5V DC instead of 7-13V DC.)

• A 3 way, unpluggable screw terminal block for CAN High, Low and G

also provided.

• Transmit and acknowledge to CAN-Bus can be disabled by a hardware

jumper for safety reasons, e.g. for in-vehicle, listen only monitoring.

• I/O terminal used for interrupts is pulled low by a 100Kohm resistor and is

driven to 5V via a 1Kohm impedance when an interrupt is pending.

1.2.2.1 Power Consumption

• Typical active current in self-powered, isolated mode with the CAN-Bus

in the recessive state: 70mA. (This is when the SDM-CAN is not

transmitting.)

• Typical active current in self-powered, isolated mode with the CAN-Bus

in the dominant state: 120mA (this is when data is being transmitted from

the SDM-CAN device).

3

Page 12

SDM-CAN Datalogger-to-CANbus Interface

• Where the DC-DC converter is not used, and power is provided to the

isolated CAN driver circuits by an external source, the current drain by the

SDM-CAN is approximately 50 mA lower than the figures quoted above.

• Typical active current, non-isolated with the CAN-Bus in the recessive

state: 30mA.

• Typical active current, non-isolated with the CAN-Bus in the dominant

state: 70mA

• Typical Standby Current with or without isolation is less than 1mA (in this

mode the CAN hardware is turned off so the module cannot wake on

receipt of CAN data). Current consumption increases to typically 50 mA

during periods of communication to the datalogger or when the RS232

port is active.

1.2.3 Physical Specifications

• Maximum dimensions: width 175mm, height 100mm, depth 23mm

(without mounting brackets).

• Weight: 300g without mounting brackets.

2. Installation

2.1 Address Switch Configuration

• The device can be vertically mounted with all the connectors on the top

surface.

• The SDM address switch is on the right hand side.

• Fittings are available to allow vertical mounting in the CR9000 or on

enclosure chassis plates.

The SDM-CAN can be mounted in a normal card slot of a CR9000 (using

optional special end brackets), on a chassis plate (using the standard brackets

supplied) or can be left free-standing.

CR9000 and CR7 dataloggers require optional SDM connection kits and all

dataloggers may require an upgrade to a version of operating system which

supports the SDM-CAN interface.

Before installing the SDM-CAN, set the SDM address switch to ensure that the

interface has a unique address on the SDM bus, and that the address is set to

match the commands in the datalogger program relevant to each interface.

4

The SDM address switch can be set to 1 of 16 addresses. The factory-set

address is 00. TABLE 2-1 shows switch position and the corresponding

address. The Base 4 address is also shown, as this is the address entered in the

datalogger program.

Page 13

SDM-CAN Datalogger-to-CANbus Interface

Please see Section 3, Programming CR10X, CR7 and CR23X Dataloggers to

use the SDM-CAN, before using address F (33 base 4) as this address is often

used as a ‘group trigger’ to synchronize measurements by several SDM

devices.

The switch is positioned on the right-hand side of the case, so you may have to

remove the mounting bracket to gain access to this switch.

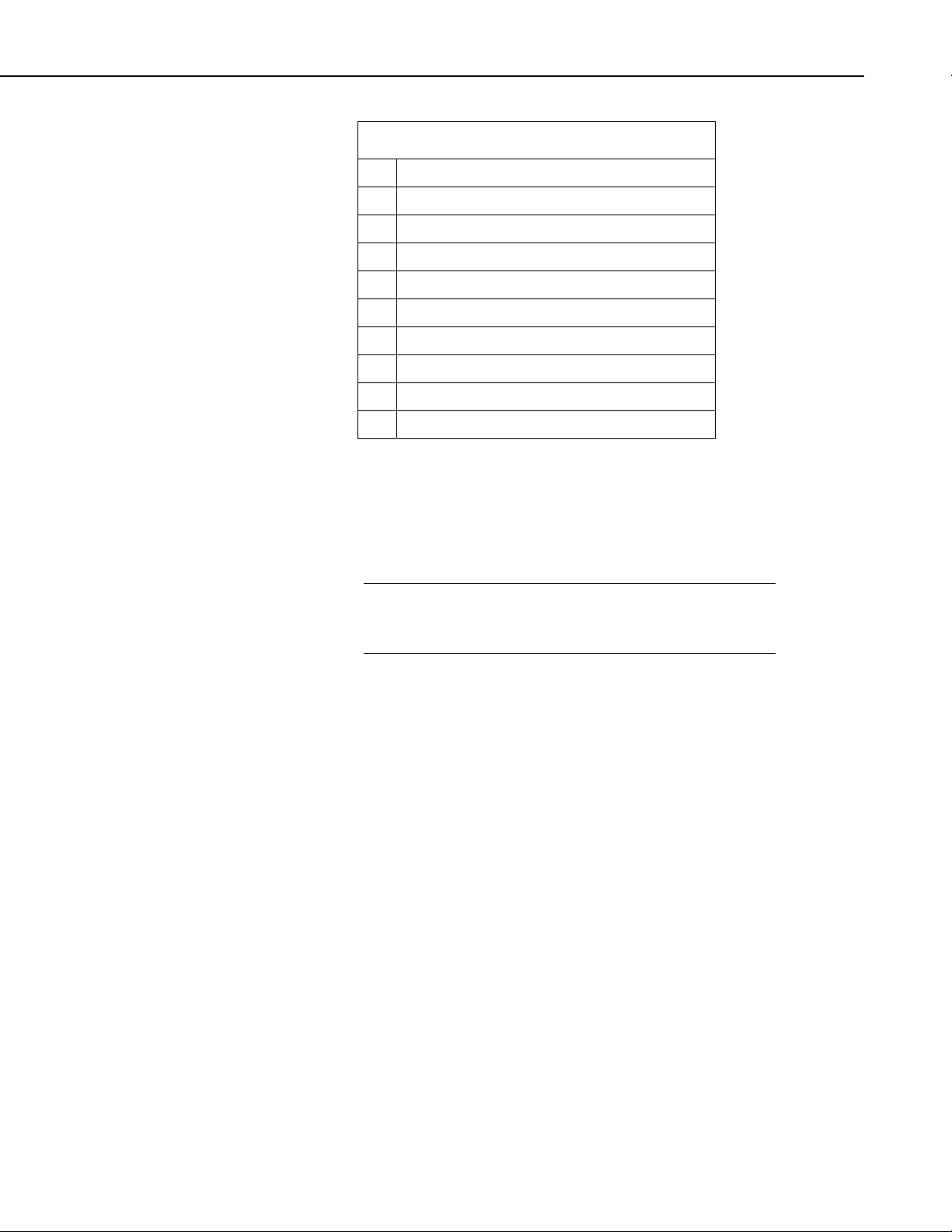

TABLE 2-1. Switch Position and Addresses

Switch Setting Base 4 Address

0 00

1 01

2 02

3 03

4 10

5 11

6 12

7 13

8 20

9 21

A 22

B 23

C 30

D 31

E 32

F 33

2.2 Internal Jumper Settings

The SDM-CAN interface is fitted with a number of jumpers which configure

the connection to the CAN network.

Prior to setting these jumpers you need to give some consideration on how best

to connect the SDM-CAN interface to the network:

1) Decide whether the CAN network is already terminated, or if the SDM-

CAN needs to provide termination. In most instances the network will

already be terminated and so the default setting is no termination.

2) Decide whether to operate the SDM-CAN in a mode where it is isolated

from the CAN network. This is the ‘safest’ mode of operation as it

minimizes the risk of corrupting the CAN data by the formation of

grounds loops which could inject noise onto the CAN-Bus. The default

setting is to run in isolated mode.

5

Page 14

SDM-CAN Datalogger-to-CANbus Interface

3) If running in isolated mode decide whether the SDM-CAN will supply

power via a built-in DC-DC converter for the isolated CAN interface

components, or whether power will be sourced from an external supply.

Using a converter adds 40-50mA to the power consumption of the SDMCAN when it is active. However, if a converter is not used, power must be

provided from elsewhere (see below). The default setting is for the

converter to be OFF, although for many applications you may need to turn

it on once you have considered the implications for your power supply.

4) Decide whether the transmit functions of the SDM-CAN interface need to

be enabled in hardware. The disabled mode of operation is the safest,

especially in vehicle applications, as it avoids the risk of the SDM-CAN

sending bad data onto the CAN network. However, in some modes of

operation, transmission is obligatory e.g. to let the SDM-CAN request

data, acknowledge data or to transmit data onto the bus. If transmission is

to be enabled, the relevant jumpers need to be changed. Additionally

transmission must be enabled by sending the SDM-CAN an instruction

which both enables and specifies the method of transmission. See Section

3.3, The Datalogger Instruction, data type 32, below.

Access to the jumpers requires the removal of the lid of the SDM-CAN. Please

follow anti-static precautions during the removal of the lid and also when

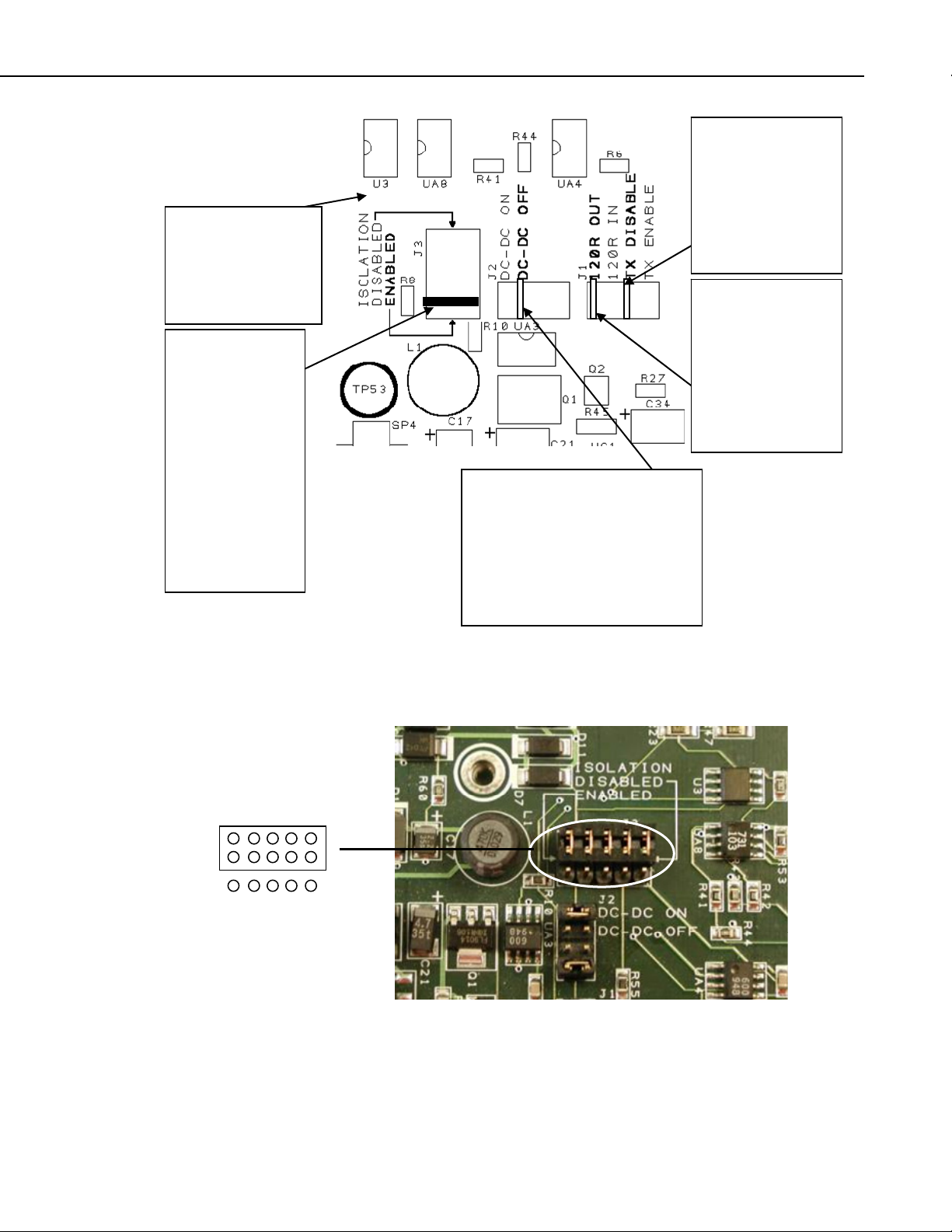

changing the jumpers. Refer to FIGURE 2-1 for details of the jumper positions.

Labels are also provided in white writing on the circuit board.

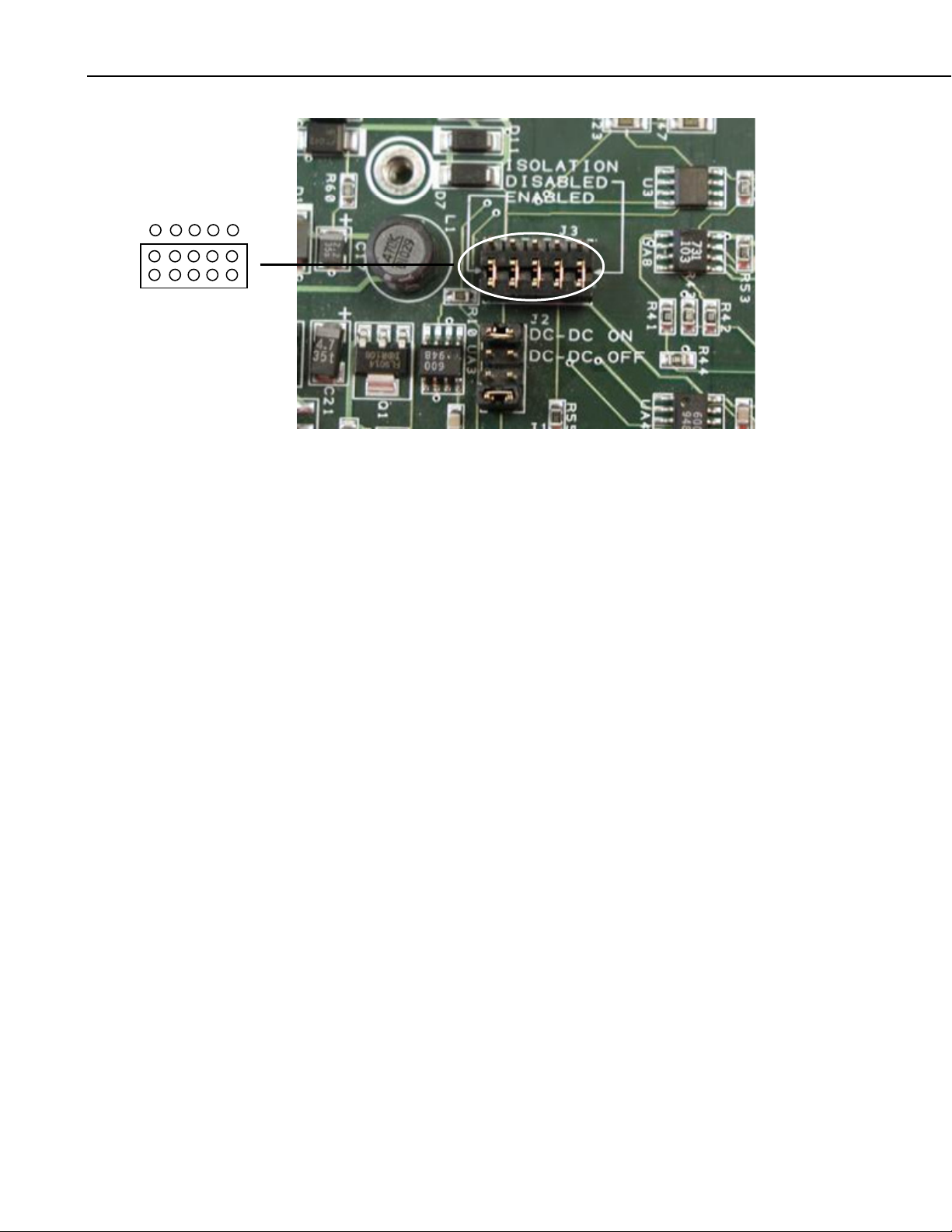

If white jumper block not fitted then refer to FIGURE 2-2 for isolation enabled

and FIGURE 2-3 for isolation disabled.

6

Page 15

SDM-CAN PCB

Once the case lid

has been removed.

OBSERVE ANTISTATIC

PRECAUTIONS.

This jumper block

is used to select

isolated or nonisolated CAN-Bus

interface. The

jumper block can

be removed and

rotated so that the

red bar is nearest

to the mode arrow

head. The default

is for isolation

enabled.

SDM-CAN Datalogger-to-CANbus Interface

The DC-DC converter is off by

default. This will reduce power

consumption from the +12V

supply but means that the isolated

circuits must be powered

externally. To enable the DC-DC

converter move the jumper to the

DC-DC ON position.

Transmission of

CAN data is

hardware

disabled

by default. To

enable transmission,

move the jumper to

the TX enable

position.

The CAN-Bus

termination

impedance is

disabled by default.

If you need the bus

to be terminated,

then move the

jumper to the 120R

IN position.

FIGURE 2-1. SDM-CAN Internal Jumpers

FIGURE 2-2. SDM-CAN Isolation enabled (default)

7

Page 16

SDM-CAN Datalogger-to-CANbus Interface

FIGURE 2-3. SDM-CAN Isolation disabled

2.3 Connection to the Datalogger and Power Supply

To allow communication between the SDM-CAN and a datalogger, firstly

connect it to the datalogger’s SDM port, and then connect to a 12V power

supply. Both the datalogger and the SDM-CAN 12V power supply must share

a common ground.

The SDM port is provided in different ways on different dataloggers:

CR10X and CR23X – use the C1, C2 and C3 control ports.

CR7 – a special SDM terminal block is provided as part of the SDM upgrade

kit. This terminal block is fitted on a small module adjacent to the 9 way

‘Serial I/O’ connector on the front of the 700 control module. The connections

are labeled C1, C2 and C3.

CR5000 – use the port connections labeled SDM-C1, SDM-C2 and SDM-C3.

CR9000 – connections are made via the 9 way, ‘CSI Serial I/O’ connector on

the 9080 PAM card. Pins 6, 7 and 8 are used as C3, C2 and C1 respectively.

Pin 2 is ground. Campbell Scientific offers connection modules for this port

which allow access to the SDM function as well as retaining normal function

of the serial port, please contact your local sales office for further details.

The SDM-CAN requires a nominal 12V power supply connection (7-26V)

rated at 150mA. Normally the datalogger supply can be used for this feed. A

connection to ground is also required. If the 12V supply is separate from the

datalogger, both the ground of the supply and datalogger must be connected

together.

8

The SDM and power connections are made to a black terminal block on the

left-hand side of the SDM-CAN interface. This terminal block has special

spring loaded terminals which are simple to use and highly resistant to

loosening in high vibration environments. To open the terminal simply insert

Page 17

SDM-CAN Datalogger-to-CANbus Interface

the tip of a small flat blade screw driver (3mm width) into the rectangular hole

above the circular terminal hole. Push in the blade of the screwdriver until the

spring is released and the terminal opens. Insert the pre-stripped wire and then

remove the screwdriver. See FIGURE 2-4. If space is limited, as when the unit

is mounted in an enclosure etc., the screwdriver can be inserted into the front of

the terminal block to push open the spring, as shown in FIGURE 2-5.

FIGURE 2-4. Using the Spring Loaded Terminal Blocks (Top Option)

FIGURE 2-5. Using the Spring Loaded Terminal Blocks (Front Option)

Where you need to install more than one wire in a single terminal connector,

use only stranded wires and twist the wires together before inserting them in

the terminal. This type of terminal is not suitable for use with multiple solid

core wires unless the wires are joined externally, e.g. using a ferrule.

Route the wires from the SDM-CAN interface to the datalogger connections

using the shortest route. Avoid running them near cables which could cause

noise pickup. In noisy environments use low capacitance signal cable with an

overall foil screen, connecting the screen to the datalogger power ground.

Where multiple SDM devices are in use connect them in parallel to datalogger

SDM ports, making sure each device has a unique SDM address. Ensure that

the maximum cable length between the datalogger and the SDM-CAN does not

exceed 3 meters.

9

Page 18

SDM-CAN Datalogger-to-CANbus Interface

An additional I/O terminal is provided on the SDM-CAN for use with

dataloggers which support interrupt driven logging events. This might typically

be used to enable the rapid capture of time critical CAN data, where the I/O

port can be used to indicate to the datalogger that data has been captured and is

available for immediate collection (see below). In most applications this

function will not be used and the terminal need not be connected. Where it is

required, it should be connected to a digital input on the datalogger.

2.3.1 LED Status Indication

When power is applied to the SDM-CAN the red ‘STATUS’ LED will flash to

indicate the current status of the unit as a result of the power-up checks.

If the LED flashes once, the module has passed all power-up tests and should

operate correctly. The other flash sequences are shown below. Problems with

the operating system can normally be fixed by reloading the operating system.

Please contact Campbell Scientific if you are unable to resolve the problem.

TABLE 2-2. LED Status Indication

Number of flashes Indication

1 SDM-CAN is ok.

2 OS signature bad.

10 OS downloaded has failed.

2.4 Connection to CAN-Bus.

The physical connection to the CAN-Bus is achieved by one of two methods

which is by either the 3 way un-pluggable screw terminals or the 9 pin ‘D’ plug

which conforms to CIA draft standard 102 version 2.

The basic connections of the CAN-Bus to the three-way terminal are CAN

High, CAN Low and 0V ground reference. The 3 way screw terminal is

marked as ‘G H L’ on the SDM-CAN case, where G=Ground, H=CAN High,

L=CAN Low.

The CIA, 9 pin, ‘D’ connector pin configuration is shown in TABLE 2-3.

10

Page 19

SDM-CAN Datalogger-to-CANbus Interface

TABLE 2-3. CIA CAN Connector Pin Connections

Pin Function

1 Reserved, NOT INTERNALLY CONNECTED.

2 CAN Low.

3 CAN Ground.

4 Reserved, NOT INTERNALLY CONNECTED.

5 CAN Shield.

6 CAN Ground.

7 CAN High.

8 Reserved, NOT INTERNALLY CONNECTED.

9 CAN +5volts. Input or output (see text).

If the SDM-CAN hardware is configured (in either isolated or non-isolated

mode) with the DC-DC converter ON, then Pin 9 of the 9 pin ‘D’ connector

will provide +5V +/-10% at up to 40mA to any external device. If isolation is

enabled and the DC-DC converter is set to OFF then this pin acts as an input

for an external power supply capable of providing +5volts +/-10% at up to

100mA to provide power to the isolated circuitry of the SDM-CAN.

NOTE

The 3-way terminal block and CIA connector are connected in

parallel internally and are not two separate connections to

different CAN interfaces.

Please refer to the documentation for your CAN network to check the preferred

method of connection. For many applications various standards will apply

giving recommended practices for connection. Apart from the choice of

connector some standards recommend different ways of ‘tapping’ into CAN

networks and also recommend maximum lengths for ‘T’s or ‘stubs’ off the

network. For instance, at the highest baud rate of 1Mbit/s, ISO11898

recommends a maximum bus length of 40 m and a maximum stub length of 0.3

m. These lengths increase significantly at lower bit rates.

As discussed above you also need to consider:

• If the SDM-CAN should terminate the network

• If it should be configured in isolated mode

• If transmission should be enabled

• The source of power for the isolation hardware.

11

Page 20

SDM-CAN Datalogger-to-CANbus Interface

3. Programming CR10X, CR7 and CR23X Dataloggers to use the SDM-CAN

This section describes the programming methods used for the above

dataloggers to configure and use the SDM-CAN Interface. This section also

covers general principles and techniques which are relevant to the other

dataloggers.

3.1 General Principles

The SDM-CAN interface is controlled by instructions that the user enters in the

datalogger program. For the dataloggers covered by this section the Program

Instruction is number P118. Full details of the instruction are given below. This

sub-section has been written to introduce the parameters of Instruction P118

and how they allow you to control the different operations of the SDM-CAN.

The initial function is to configure the SDM-CAN interface when the

datalogger program is compiled. At this stage, the datalogger analyses the P118

parameters used by the program and sends the relevant commands to the SDMCAN to configure it to perform appropriate tasks.

The most common configuration task, at compile time, is to set up the SDMCAN to instruct it to filter out only the data frames of interest from all data

‘passing on the bus’.

The other configuration task done at this point is to specify the speed at which

the CAN-Bus is to operate. It is important to ensure the parameters which

define the speed are set correctly and all instructions have the same values

entered for these parameters otherwise either no data will be received, or you

risk corrupting data on the bus, if the SDM-CAN is enabled for transmission.

The next common function is to read data back from the SDM-CAN, to

decode it, and to store it in input locations once the program is running. A

single entry of P118 in the program can both configure the SDM-CAN during

program compilation and also cause data to be read back from the SDM-CAN

when that instruction is executed during normal program execution.

Similarly there is also a function which is used to send simple data from the

datalogger input locations onto the CAN-Bus via the SDM-CAN. Again a

single call of P118 can both configure and then transmit the data when the

program is running.

A more complicated version of this function is also possible where multiple

P118 instructions are used to build a transmit data frame within the SDMCAN, made up of a series of fixed or variable data values from input locations.

A subsequent P118 is used to instruct the SDM-CAN to transmit the frame

either immediately or in a response to a remote frame request from another

device.

12

Finally there are some special functions normally achieved by a single a call of

P118. One such function is used to change internal ‘switches’ within the SDMCAN which control its mode of operation, e.g. power mode, response to failed

transmissions etc. Similar functions also allow you to read back the settings of

these ‘switches’ into input locations and also to read and/or reset the number of

Page 21

CAN errors detected and to also determine the general status of the SDM-CAN

interface.

3.2 System Limitations

The SDM-CAN interface, in combination with a datalogger, has some

limitations of which you need to be aware:

1) Memory Allocation and P118

Firstly, as discussed above, when the datalogger compiles a program with

P118 in it, it sends commands to the SDM-CAN instructing it what to do

at run time. When it does this the SDM-CAN allocates some of its

memory (a ‘bin’) for each call of P118 in the program. Appendix A,

Principles of Operation, discusses the operation of these bins and other

buffers in the SDM-CAN in more detail. However, most users only need

to know that there is a limit of 128 bins in the SDM-CAN thus

constraining the number of instances of P118 for any one SDM-CAN to

128.

It is, of course, possible to have several SDM-CAN devices connected to

the datalogger(s), each with separate SDM addresses, and each with up to

128 calls of P118.

SDM-CAN Datalogger-to-CANbus Interface

2) Data Capture Limitations

Another limitation is the capability of the overall speed at which the

datalogger can pick up and transfer data values back to its memory. These

limitations do not arise within the SDM-CAN interface itself, as it uses a

high speed CAN interface along with a fast microprocessor. Data can

therefore be captured off the CAN-Bus at close to the maximum bus

loading at the maximum baud rate. However, the limitations arise from the

datalogger itself, both in terms of its capability to call P118 often enough

(especially when making other measurements) and also in its capability to

transfer the data from the SDM-CAN back into its memory over the SDM

communications port.

The exact throughput possible is determined by a very complicated

combination of variables, including the speed of the datalogger in

question, the program it is running, how many SDM devices are in use

and, to a lesser degree, other tasks it is running, e.g. communications

activity.

In practice, for fast data, it will not be practical to capture every single data

packet. However, the SDM-CAN will be used to sample the last reading it

received on the CAN-Bus before the datalogger requests data.

If a new data value has not been captured from the CAN-Bus since the last

value was transferred to the datalogger, the SDM-CAN can either be set to

always return the previous value captured (default) or it can be configured

(see the internal software switch settings below) to return the standard out

of range value to the datalogger, i.e. –99999 if the value has already been

read. This value will also be returned in the event of other errors including

communication errors between the datalogger and SDM-CAN.

13

Page 22

SDM-CAN Datalogger-to-CANbus Interface

Data stored in packets on the CAN-Bus can be encoded in a number of

different ways. The SDM-CAN itself can cater for many different types of

data, but there are some limitations imposed by the way in which the data

is stored in the datalogger. The prime limitation is that data read into the

datalogger is first converted into a 4 byte floating point format which can

only resolve, at most, 23 bits, or roughly 7 digits, of the decimal equivalent

of any number stored. Furthermore, when data is stored to final storage,

the resolution is truncated again to either 4 or 5 digits (with the exception

of the CR5000/9000 dataloggers which also support storage in IEEE4

format).

To avoid over-running the datalogger’s internal floating point resolution,

the maximum length of integer that the SDM-CAN can send or receive is

therefore limited to 16 bits. This limited resolution can cause problems

when reading CAN data where data is encoded as 32 or 64 bit integers.

The simplest solution, in those cases, is to read the value as a series of 16

bit integers written to separate input locations in the datalogger. These can

then either be combined once the data has been recovered to a computer

or, if some of the resolution is not needed, the data values can be

combined in the datalogger using its normal maths functions. You must

bear in mind, however, the limitations of the 4-byte floating point

calculations and the output resolution of the datalogger.

The CAN standard also allows some types of data to be spread across

several data packets, where those data packets all have the same identifier.

Such data normally would consist of fixed identifiers stored as ASCII data,

which do not normally have to be logged. Reliably capturing such data

with the SDM-CAN is not possible, with the current software, unless the

sequential packets are transmitted relatively slowly. Please contact

Campbell Scientific for further information if you have a requirement to

do this.

14

3) When transmitting CAN frames from the SDM-CAN there are situations

where some frames are not transmitted. This is because the SDM-CAN has

a two layer buffer for transmitted frames. This allows a frame to be

transmitted whilst a new frame is being built. However if your program

tries to send frames too quickly, before earlier frames are sent, the frames

will be overwritten and lost.

This scenario generally does not happen with CR10X / CR23X loggers as

they are not fast enough. But with the CR5000 / CR9000 loggers it is

possible to overrun the double buffer especially in pipe line mode if you

are transmitting more than 2 frames per scan. It is recommended to use

sequential mode in this case as it allows a delay between CAN-BUS

instructions.

3.3 The Datalogger Instruction

The instruction used by all of the dataloggers covered in this chapter is

Instruction 118. The structure of the instruction and parameter types is shown

below. This structure is given in the same format that normal instructions are

shown in the datalogger manuals. Please refer to the datalogger manual for a

Page 23

SDM-CAN Datalogger-to-CANbus Interface

description of the data types, entry of the instruction and how to index (‘--’)

parameters.

NOTE

In some previous versions of datalogger operating systems,

Instruction 118 was used for the now obsolete OBDII interface.

Older datalogger manuals and Edlog help systems may still refer

to this instruction. Please make sure you are using a version of

the operating system that supports P118 and refer to a more

recent datalogger manual or Edlog help system.

It will be apparent for some functions of P118 that some parameters are not

relevant or have no function. In these cases simply leave the parameter(s) at

their default value(s) which is normally zero.

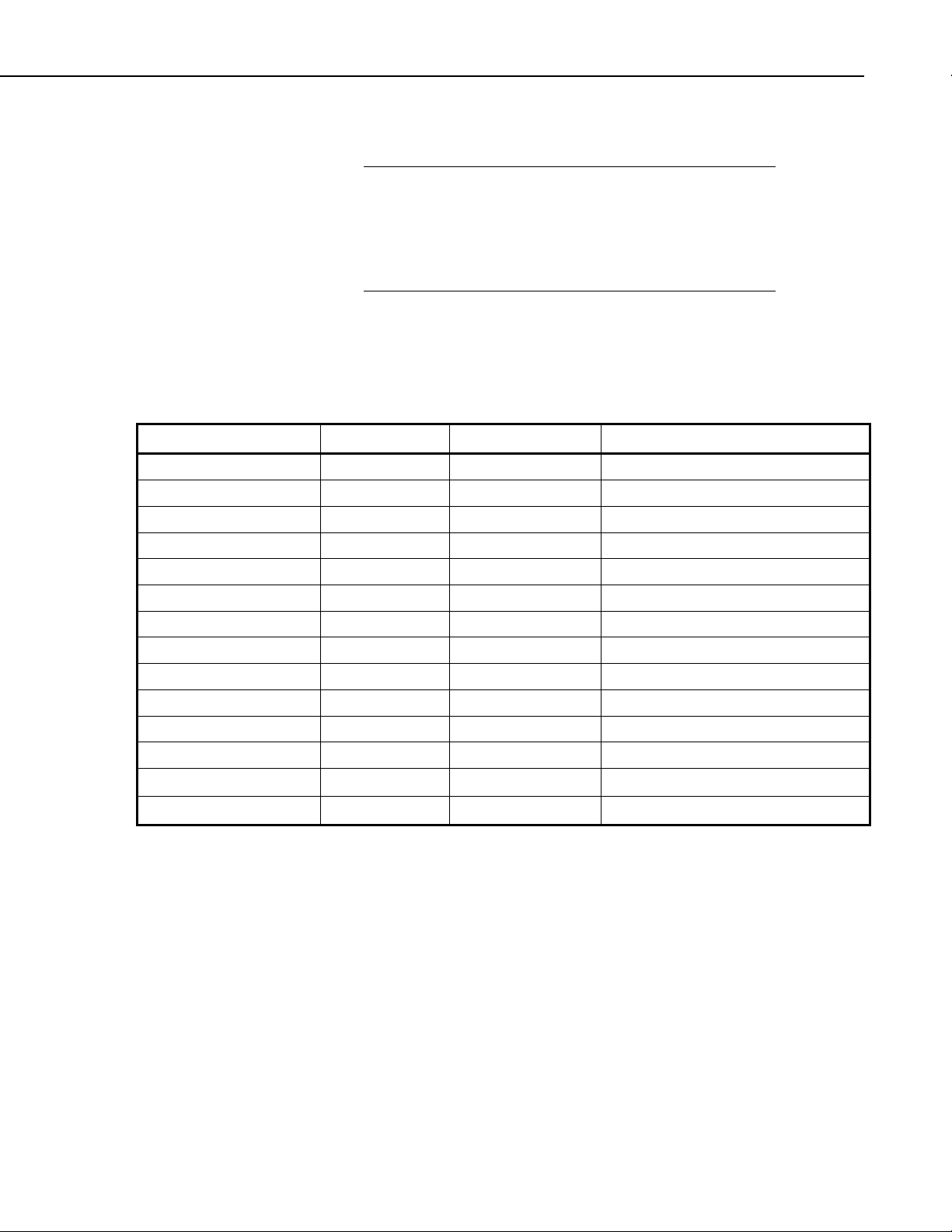

3.3.1 Instruction 118: SDM-CAN

PARAM. NUMBER DATA TYPE DESCRIPTION RANGE

01: 2 SDM address 00..33

02: 2 TQUANTA 0-63

03: 2 TSEG1 0-15

04: 2 TSEG2 0-7

05: 4 ID bits 0-10 0-2047 ‘--’ Set 11bit ID.

06: 4 ID bits 11-23 0-8191

07: 2 ID bits 24-28 0-31

08: 2 Data type 0-33

09: 2 Start bit number 0-64, ‘--’ Left-hand referenced LSB.

10: 2 Number of bits 0-64, ‘--' Enable Interrupt mode.

11: 4 Number of values 0-99

12: 4 Input Location

13: FP Multiplier

14 FP Offset

3.3.2 SDM Address (Parameter 01:)

This parameter should match the SDM address set by the address switch on the

side of the module to which this instruction applies. Please see Section 2.1,

Address Switch Configuration, above, for more details. Also see the section

below, regarding the special function of address 33.

3.3.3 TQUANTA, TSEG1, TSEG2 (Parameters 02:, 03:, 04:)

These parameters are used to set the bit rate and other timing parameters for the

CAN-Bus network. On some networks the relationship between some of these

parameters is predefined and just one parameter, the baud rate, is quoted. For

maximum flexibility, though, the user is given access to all of the relevant

parameters. TABLE 3-1 gives some typical values of the parameters for a

15

Page 24

SDM-CAN Datalogger-to-CANbus Interface

b

range of baud rates. However, be sure to check that these are correct for your

specific network before using them.

The parameters are entered as integer numbers which define various times that

control when the binary data is sampled by the CAN hardware. The following

discussion and nomenclature is common to the set-up of most CAN controller

chips. If you are not familiar with CAN at this level please seek the advice of

someone who is familiar with your network to determine these parameters.

The overall speed of the network is specified by the baud rate, in bits per

seconds, which define the time per bit (

t

= 1 / baudrate

bit

Within the time period for each bit the CAN standards define three different

time segments which ultimately control when the CAN hardware samples the

signal.

This is often shown in a diagram, thus:

t

) by the simple relationship:

bit

1 time-quanta

Bit time (t

S-SG PROP_SEG PHASE_SEG1 PHASE_SEG2

t

t

(tq)

TSEG1

)

it

Sample point

t

The bit time is divided into time-quanta (

time- quantum in the bit time. The

t

), of which there are between 8-23

q

(in seconds) used by the SDM-CAN is

q

set by the scaling factor TQUANTA (parameter 02). This is the parameter that

largely determines the baud rate. To work out a suitable value of TQUANTA,

t

knowing the required

TQUANTA = t

q

, the following equation is used:

q

* 8*106

The first time segment is known as the synchronization segment (S-SG) and

by convention is one time-quanta long.

This is followed by two segments known as the propagation segment and phase

segment one. These are determined by the characteristics of the network and

other devices on the network. The total of these two time segments determines

the time

TSEG2

when the SDM-CAN samples the data bit and is known as t

segment is known as phase segment two or t

TSEG2

TSEG1

. The final

16

Page 25

SDM-CAN Datalogger-to-CANbus Interface

The relationship between these times is summarized by:

t

bit=tq+tTSEG1+tTSEG2

t

(in seconds) is set using the scaling factor TSEG1 (parameter 03), the

TSEG1

value of which is calculated using the following equation:

TSEG1 = t

t

is set using scaling factor TSEG2 (parameter 04) the value of which is

TSEG2

TSEG1

/ tq

calculated using:

TSEG2 = t

TSEG2

/ tq

When determining the settings of these parameters it is important to ensure that

the size and total number of t

exactly matches the baud rate at which the

q

network is to run, as the tolerance allowable is normally quoted as +/-1.5%.

The relative settings of TSEG1 and TSEG2 are not so critical as they control

when the hardware samples the data value and there is normally quite a wide

tolerance over which this will work.

If no data other than the baud rate of a network is available a simple ‘rule of

thumb’ is to set the parameters such that there are at least eight time-quanta in

the span of the bit width and that the sample point is 80% through the bit

width.

TABLE 3-1. Typical settings of the CAN Speed Parameters

Baud rate TQUANTA TSEG1 TSEG2

1M 1 5 2

800 K 1 7 2

500 K 2 5 2

250 K 4 5 2

125 K 8 5 2

50 K 16 7 2

20 K 40 7 2

NOTE

The same three values for these parameters should be used in

every call of the P118 instruction in the datalogger program.

3.3.4 ID (Parameters 05:, 06:, 07:)

A CAN data frame includes an identifier (ID) which is used by devices on the

network to identify each type of packet on the network. Some standards reserve

certain IDs or ranges of IDs for specific functions. The J1939 SAE standard for

instance reserves certain parts of the ID to identify the type of data, its priority

and its origin (see Appendix C, Application of the SDM-CAN on Networks

Complying with the J1939 SAE Standards, for a discussion of this standard and

use with the SDM-CAN). The SDM-CAN is, however, transparent to any

17

Page 26

SDM-CAN Datalogger-to-CANbus Interface

special meaning of the ID; each packet is only referenced by the full ID. The

CAN 2.0A standard uses an ID with 11 bits, while CAN 2.0B uses 29 bits.

When entering IDs into Instruction P118, three parameters are used. This is

because the ID size, in number of bits, is too large to be encoded into a single

parameter.

The first ID parameter (parameter 05) sets bits 0..10, entered as a number

between 0 and 2047. This parameter also determines whether an 11-bit or a 29bit Identifier is set. If you index this parameter then an 11bit Identifier is set;

the following two parameters are then irrelevant and are normally left at zero.

The second ID parameter (parameter 06) encodes bits 11..23 entered as 0 to

8191. The third ID parameter (parameter 07) is for bits 24 to 28 entered as 0 to

31.

NOTE

CAN networks either work with 11 or 29 bit IDs. As a general

rule you cannot have packets with different length IDs on the

same network. Therefore make sure parameter 05 specifies the

same length ID for all calls of P118.

3.3.5 Data Type (Parameter 08:)

This parameter determines the type of data involved and/or the type of function

this call of P118 will perform. The data type parameter is entered as a two-digit

parameter in the range of 0-33. A summary table of the data types described

below is given in Appendix B, A Summary of Data Types, of this manual for

quick reference.

As a general rule, this function is applied only to data packets with the ID

specified in parameters 05..07. The action applies to a certain number of bits

within the data frame that is specified in parameter 10, starting at the bit

specified in parameter 09. In some cases the number-of-bits parameter is

overridden implicitly by the data type specified, e.g. IEEE4 data is always 32

bits in length. For integer values, the longest integer you read or send from one

datalogger input location is 16 bits as a result of limitations in the datalogger.

See Section 3.2, System Limitations, above for an explanation and workarounds.

For data types that read or set status, switches or error codes, only the input

location parameter, multiplier and offset are used. Other parameters can be set

to zero.

18

As defined by the CAN standard, data is always encoded or decoded on the

assumption that the least significant bit is transmitted last or is on the ‘righthand side’ of a data frame. The data frame can be from 0 to 64 bits in length,

but is normally a multiple of 8-bit bytes. This means there are typically 0-8

bytes in the data frame.

Please refer to Appendix D, Examples of CAN Data Frames and Data

Encoding and Decoding, for examples of typical data frames and how to

decode data within them. Appendix D, Examples of CAN Data Frames and

Data Encoding and Decoding, also contains diagrams to show the method of

pointing to the start bit within the data frame.

Page 27

For convenience the start bit can be referenced from either end of the frame

(see parameter 09 below), but this does not change the direction in which data

is encoded or decoded. Within a byte the MSBit is always first (on the left).

Where the number-of-values parameter (parameter 11) is greater than one, the

same function is applied to successive sections of the data frame, moving

towards the ‘left’ of the frame. Data values are read to, or written from,

successive input locations in the datalogger.

The data types can be grouped into different type of functions, as follows:

3.3.5.1 Collect and retrieve a data value:

This function programs the SDM-CAN to capture a particular data packet and

pass specific data from the data frame within that packet back to the

datalogger.

Parameter Value Data Type

1 Unsigned integer, most significant byte 1st.

2 Unsigned integer, least significant byte 1st.

3 Signed integer, most significant byte 1st.

4 Signed integer, least significant byte 1st.

5 4 byte IEEE floating point number, most significant byte 1st.

6 4 byte IEEE floating point number, least significant byte 1st.

SDM-CAN Datalogger-to-CANbus Interface

3.3.5.2 Build a data frame for transmission:

The data will be sent to the SDM-CAN where it is written into a working 8byte buffer in memory. The data is written starting at the bit position

determined by parameter 09 and the number of bits stored by parameter 10.

When the data type parameter is set in the range of 7..12, the data is written to

the buffer directly, i.e. it overwrites any previous data in that memory (see also

types 13..18).

Once the buffer is complete, after using other P118s with this range of data

types to construct the desired data frame, it is sent out onto the CAN-Bus by a

further call of P118 with parameter 08 set to 25 or 26 (see below).

Parameter Value Data Type

7 Unsigned integer, most significant byte 1st.

8 Unsigned integer, least significant byte 1st.

9 Signed integer, most significant byte 1st.

10 Signed integer, least significant byte 1st.

11 4 byte IEEE floating point number, most significant byte 1st.

12 4 byte IEEE floating point number, least significant byte 1st.

Setting parameter 08 in the range of 13..18 has the same function as in

the7..12 range, except that the data values written are logically ‘OR’ed with

19

Page 28

SDM-CAN Datalogger-to-CANbus Interface

values previously written into the memory buffer. This allows complex bit

patterns to be defined, sometimes changing only as little as one bit at a time.

Parameter Value Data type

13 Unsigned integer, most significant byte 1st.

14 Unsigned integer, least significant byte 1st.

15 Signed integer, most significant byte 1st.

16 Signed integer, least significant byte 1st.

17 4 byte IEEE floating point number, most significant byte 1st.

18 4 byte IEEE floating point number, least significant byte 1st.

3.3.5.3 Transmit individual data values onto the CAN-Bus:

This range of parameter values instructs the datalogger to send a data value to

the SDM-CAN in the format specified; it is loaded into the specified point in a

data frame and then immediately transmitted onto the CAN-Bus. Bits within

the data frame that are not set are left at zero. The data frame length is set to the

minimum size (in whole bytes) required to hold the type of data value

specified.

Parameter Value Data Type

19 Unsigned integer, most significant byte 1st.

20 Unsigned integer, least significant byte 1st.

21 Signed integer, most significant byte 1st.

22 Signed integer, least significant byte 1st.

23 4 byte IEEE floating point number, most significant byte 1st.

24 4 byte IEEE floating point number, least significant byte 1st.

3.3.5.4 Transmit a previously built data frame on to the CAN-Bus (type 25):

When parameter 08 is set to 25, P118 will cause the datalogger to tell the

SDM-CAN to transmit a previously ‘built’ data frame which is stored in the

memory buffer for this packet ID (see data types 7..18 above).

The length of the data frame transmitted is determined by parameter 10. If

number of bits is less than a complete number of full bytes (1-8) then the

number of bytes sent will be rounded up and all unused bits will be set to zero.

The data start bit position will normally be set to one so the data frame starts at

the beginning of the memory buffer. However, you can enter a value greater

than one to allow part of the buffer to be transmitted, which can simplify some

binary masking operations.

20

The memory buffer is left unchanged after transmission.

Page 29

SDM-CAN Datalogger-to-CANbus Interface

3.3.5.5 Set-up previously built data frame as a Remote Frame Response (type 26):

When parameter 08 is set to 26, P118 will configure the SDM-CAN to use a

previously ‘built’ data frame as remote frame response for packets of the

specified ID. The length and start positions are specified as for data type 25.

3.3.5.6 Read error counters (type 27):

This will return 4 values, in successive input locations starting at the location

set by parameter 12, which show certain errors the SDM-CAN has recorded.

The errors are written in the following order: transmit, receive, overrun and

watchdog counts. Each is a count from 0 to 255.

The transmit, receive and overrun counters are measures of the errors on the

CAN-Bus network as defined by the CAN standards. If the transmit counter

reaches 255 then the CAN device goes into a ‘bus-off’ state, where it

effectively disconnects itself from the network.

If the SDM-CAN switches to the ‘bus-off’ state, any further reads of the error

counters will show the transmit counter fixed at 127. The counters then need to

be reset to enable further use of the SDM-CAN (see data type 28, below). If

this situation occurs on a regular basis, firstly check the datalogger program

(P118 parameters). If these are correct, check the structure and design of the

network.

The watchdog counter only increments (and is automatically reset) when the

SDM-CAN ‘crashes’ either due to an internal software error or a hardware

fault. Please contact Campbell Scientific for further advice.

3.3.5.7 Read and reset the error counters (type 28):

This functions in exactly the same way as type 27 except that after reading the

error counters they are reset to zero. This will also re-enable the SDM-CAN

interface to the CAN-Bus if it has automatically entered the ‘bus-off’ state.

When the counters are reset, the CAN controller chip enters a special state and

waits until it sees a period equal to 11 successive bits of inactivity on the CANBus before it returns to the normal ‘on-line’ state. Therefore this function

should not be called too frequently otherwise data may be lost.

3.3.5.8 Read status (type 29):

This data type instructs the datalogger to request the current status of the SDMCAN and writes the results into a single, specified, input location. The status is

encoded within that location in the format ‘abcd’ where each letter is a digit in

the range 0 to 9 indicating a different type of status information.

Status ‘a’: 0 This digit is currently unused.

Status ‘b’: 0 This digit is currently unused.

Status ‘c’: 0 This digit is currently unused.

Status ‘d’: 0 Bus-On; the SDM-CAN is involved in bus activities. All of

the error counters are less than 96.

21

Page 30

SDM-CAN Datalogger-to-CANbus Interface

1 Bus-On; the SDM-CAN is involved in bus activities. One

2 Bus-Off; the SDM-CAN is not involved in bus activities.

3 Bus-Off; the SDM-CAN is not involved in bus activities.

See data type 28 above for details of the error counters and how to reset them.

3.3.5.9 Read the signature and version number of the SDM-CAN operating system (type

30):

This will return the OS signature and the OS Version number in separate

locations. If the SDM-CAN detects that the OS signature is bad then zero will

be returned.

3.3.5.10 Send Remote Frame Request (type 31):

A special type of CAN frame, called ‘remote frame request’ is transmitted with

the CAN ID specified.

of the error counters is equal to or greater than 96.

All of the error counters are less than 96.

One of the error counters is equal to or greater than 96.

3.3.5.11 Set SDM-CAN internal software switches (type 32):

This data type instructs the datalogger to change some internal software switch

settings that control the way it works. The new switch settings are read from a

specified input location. The settings are encoded within that location in the

format of a four digit number. For explanation purposes the four digits are

represented as ‘abcd’ where each letter is a digit in the range 0 to 9 which

indicates a different type of switch setting.

Once set the switches remain set until changed by another call of P118 or on

loading a different program. Therefore it is only necessary to call a P118 to set

these switches once, after program compilation, or when a switch needs to be

changed using a call of P118 within an IF..THEN program construct (see the

program examples below).

Switch ‘a’: 0 This digit is currently unused; enter zero

Switch ‘b’: 0 SDM-CAN returns the last value captured from the

network, even if read before (Default)

1 SDM-CAN returns –99999 if a data value is requested by

the datalogger and a new value has not been captured

from the network, since the last request.

2-9 Currently unused

Switch ‘c’: 0 Disable I/O Interrupts (Default) – see Section 3.4.1,

Interrupts Using the I/O Connection

22

1 Enable I/O Interrupts, pulsed mode

2 Enable I/O Interrupts, fast mode

Page 31

SDM-CAN Datalogger-to-CANbus Interface

3-7 Currently unused

8 Set low power standby mode. The SDM-CAN cannot

wake from this state as a result of CAN-Bus activity.

Setting this switch to any other value will bring the SDMCAN out of standby.

9 Leave this switch setting unchanged

Switch ‘d’: 0 Listen only mode, no CAN transmission or

acknowledgement to a correctly received CAN frame is

possible. The SDM-CAN runs in ‘Error Passive’ mode

(Default).

1 One shot transmission, no re-transmission will occur in

the event of loss of arbitration or error. Frames received

correctly from an external node are acknowledged

2 Self-reception. A frame transmitted from the SDM-CAN

that was acknowledged by an external node will also be

received by the SDM-CAN but no re-transmission will

occur in the event of loss of arbitration or error. Frames

received correctly from an external node are

acknowledged

3 Normal, re-transmission will occur in the event of loss of

arbitration or error. Frames received correctly from an

external node are acknowledged. This is the usual setting

to use if the SDM-CAN is to be used to transmit data.

4 One shot transmission and self test mode. The SDM-CAN

will perform a successful transmission even if there is no

acknowledgement from an external CAN node. Frames

received correctly from an external node are

acknowledged

5 Self-reception and self test mode. The SDM-CAN will

perform a successful transmission even if there is no

acknowledgement from an external CAN node. Frames

received correctly from an external node are

acknowledged. The SDM-CAN will receive its own

transmission

6 Normal and self test mode. The SDM-CAN will perform a

successful transmission even if there is no

acknowledgement from an external CAN node. Frames

received correctly from an external node are

acknowledged.

7 Similar to switch setting 'd-3' , but this setting is

'remembered' at power-up. During power-up, the SDMCAN will acknowledge all valid messages.

NOTE: This setting relies on the datalogger having set up

the SDM-CAN before use.

8 Not defined

9 Leave this switch setting unchanged

23

Page 32

SDM-CAN Datalogger-to-CANbus Interface

NOTE

3.3.5.12 Read SDM-CAN internal switches (type 33):

Please refer to the CAN standards and your own network

documentation for a more detailed explanation of the switch ‘d’

modes. It is important to choose the correct setting when the

SDM-CAN is required to transmit data. Also remember to check

the jumper settings inside the SDM-CAN if enabling

transmission, as the default setting is for transmission to be

disabled in hardware.

This data type returns the internal switch settings, into a specified input

location. The switch values shown are encoded in the same way as they are set

(see type 34 above), with the exception that a switch setting of 9 is reserved to

show an undefined error (please contact Campbell Scientific if such an error

occurs).

3.3.6 Start Bit Number (Parameter 09:)

The start bit number is used to point to the least significant bit (LSB) of the

data value within the CAN data frame to which this instruction relates. Within

CAN data frames there is no general standard as to the order or format of the

binary data. ISO11898 does specify that data should be sent with the most

significant bit (MSB) first, least significant bit (LSB) last. Most diagrams show

the MSB on the left and the LSB on the right. However, some users may find

the start point for the data is referenced in the opposite fashion, i.e. as a count

from the left side of the frame, and so the SDM-CAN supports both methods of

referencing the start point.

By default the SDM-CAN follows the ISO standard and the LSB is referenced

to the right-most bit of the frame. The bit number can range from 1 to 64 as

there are up to 64 bits in a CAN frame. If the parameter is indexed, (marked ‘-’) then the reference is changed to point to the LSB relative to the left-hand

most bit of the frame. Please note, though, that choosing this option does not

have any automatic affect on the type (direction) of encoding or decoding used

– it only changes the method of pointing to the LSB.

NOTE

When entering the start bit, you should always point to the

position of the least significant bit of the data to be

decoded/encoded. Please refer to Appendix D, Examples of CAN

Data Frames and Data Encoding and Decoding, for diagrams

and examples of typical data types.

3.3.7 Number of Bits (Parameter 10:)

This relates to the number of bits to use in this transaction. This number can

range from 1 to 64 as there are up to 64 bits in a CAN frame. If this parameter

is indexed (‘--’) then, when a new value is received, the SDM-CAN, relevant to

this particular call of Instruction P118, will pulse the I/O port to indicate to the

datalogger that the data has been captured and can be read (see below).

24

Page 33

NOTE

For some data types this parameter will be overridden by a fixed

number of bits required by the data type; even so the interrupt

setting can still be set. For integer values, the longest integer you

can read or send from one datalogger input location is 16 bits as

a result of limitations within the datalogger (see Section 3.2,

System Limitations, above for an explanation and work-arounds.

3.3.8 Number of Values (Parameter 11:)

This is the number of values that will be transferred to or from the datalogger

in one operation. For each value transferred, the number of bits (parameter 10)

will be added to the start bit number (parameter 9) when the start point is

referenced to the right-hand side of the data frame. If referenced to the lefthand side, then the number of bits is subtracted from the current bit position.

The consequence of this is that successive values are always from right to left

in the frame.

3.3.9 Location (Parameter 12:)

This is the start input location where data will be read from or stored to. For

any remaining values/repetition, each value will be read from, or stored into,

the next incremental location.

SDM-CAN Datalogger-to-CANbus Interface

3.3.10 Multiplier (Parameter 13:)

The data written to, or read from, an input location is multiplied by this

parameter.

3.3.11 Offset (Parameter 14:)

The data written to, or read from, an input location has this offset parameter

added to it.

3.4 Advanced Programming Techniques

3.4.1 Interrupts Using the I/O Connection

The I/O port can be used to signal to a datalogger that specific data has been

captured, by the SDM-CAN, from the CAN network and is available for

collection by the datalogger.

The main application for this is where CAN data needs to be captured at a

much faster rate than the normal scan interval of the datalogger and the

requirement is to capture as many CAN packets as possible. In this case the

interrupt facility can be used to give capture of the CAN data as a higher

priority over the normal scheduled measurement tasks, allowing the data to be

captured at the highest rate possible.

The interrupt facility can also help solve the conceptual problem of capturing

data into the datalogger from another system (one of the other devices on the

CAN-Bus) which is running on a different asynchronous clock from the

datalogger itself. This problem needs some consideration in all applications

25

Page 34

SDM-CAN Datalogger-to-CANbus Interface

except those where the datalogger can be made the master (i.e. where it

requests data from the remote devices when its needs the data).

In other applications one has to cater for the possibility that data might not be

available from the CAN network when the datalogger clock causes the

datalogger to run its program. This can happen even when the CAN data is

being transmitted at the same rate as the datalogger is running, simply because

the two system clocks drift relative to each other. The interrupt facility allows

you to ensure that data can be captured at the highest possible rate, but you still

have to use special programming and/or data analysis techniques to

synchronize the data with other measurements. The main problem is that the

interrupt function might run more time stamps to the faster measurements in

order to allow normal data analysis.

To enable the interrupt facility on the SDM-CAN you need to index (--) the

program on the number-of-bits parameter (10) of the particular P118

instruction that you want to cause the interrupt when data is received. The

following rules apply:

• The interrupt function only applies to data types which read data from

the CAN-Bus.

• You can mark more than one P118 instruction to generate an interrupt,

but you will then need to read data from all the possible data types

which are indexed, as one or more may contain a new value and all

new data must be read before the interrupt is cleared.

• With the CR10X and CR23X dataloggers you should ensure that all of

the P118 instructions which are marked to cause an interrupt are in the

same interrupt subroutine, normally number 98. Other dataloggers do

not currently support the interrupt subroutine mechanism, but can be

used in a similar mode by polling the digital input connected to the

SDM-CAN I/O port, and only actually reading the data when the port

is high.

As well as indexing parameter 10 of the instructions, you also have to enable

the interrupt function by changing an internal software ‘switch’ in the SDMCAN. This is done by calling P118 with data type 32, and setting digit ‘c’ to 1

or 2. (See above).

A switch value of 1 causes the interrupt function to operate in the following

way:

a) With no Interrupt pending the I/O port is pulled low with 100Kohms.

b) With an interrupt pending,

first check that no other device is holding the port high and then pulse

high for 50 milliseconds. If the I/O terminal is held at +5V by another

peripheral it will wait until the I/O terminal goes low and has been low for

50 milliseconds before trying to drive it high to +5V again. The I/O line

has a drive impedance of 1Kohms.

i.e. data has been captured, the SDM-CAN will

26

This method of driving the I/O line allows multiple SDM-CANs and other CSL

products that support the I/O line to be wired in parallel. One consequence of

the above technique, though, is that there will be a gap of up to 50 milliseconds

Page 35

SDM-CAN Datalogger-to-CANbus Interface

following the end of one interrupt before the SDM-CAN will raise the port for

another interrupt. This could be a limitation in high speed data capture

applications, hence the need for switch 2.

When switch 2 is set, the SDM-CAN responds immediately to data receipt and

raises the port as soon as data has been received, filtered and processed. The

SDM-CAN will only lower the line again permanently when the datalogger

reads the data out of the SDM-CAN that caused the interrupt. To prevent

problems with some events which might cause the datalogger to miss

interrupts, the SDM-CAN will pulse the I/O port low for 1 ms after 50 ms, take

the line high and then repeat this cycle until all the relevant data has been read.

Using this switch setting will provide the quickest way of capturing data but

may not work with other devices sharing the datalogger interrupt port.

NOTE

To ensure proper configuration of the SDM-CAN by the

datalogger for interrupt driven applications, it will pulse its I/O

port on and off at 50ms intervals for 6 seconds after power-up or

program recompilation.

3.4.2 Group Trigger

The group trigger function provides a mechanism to synchronize the data

capture by one or more SDM-CAN (and some other SDM devices too).

This mode is enabled when an SDM-Group Trigger (P110) instruction is

encountered. When this instruction runs, it broadcasts a special SDM message

which causes all the SDM-CAN devices to copy the last data values captured

from the CAN-bus into the working data buffers, and no further updates are

allowed until P110 runs again (normally at the next execution of the program

table). P118 instructions will read the locked values which are all sampled at

once.

This SDM-Group trigger command is normally positioned at the beginning of

the program table to lock all data samples exactly to the start of the scan

interval. It should be remembered, however, that in the case of the SDM-CAN

it will simply lock these values to the last values captured which could already

have been transmitted some time earlier.

The SDM-Group trigger instruction actually broadcasts its message to SDM

address 33

Group trigger command is to be used. This effectively reduces the number of

SDM peripherals that support global trigger to 15 units.

(base 4), which prevents this address being available if the SDM-

4

3.4.3 Frame buffers with filtering and triggering

Operating systems V3 include the ability for the user data logger program to

attach a buffer of 256 frames to any receiving CAN ID up to a limit of 25

different ID’s.

NOTE

If the user program tries to allocate more than 25 buffers then the

additional buffer allocations will be ignored.

27

Page 36

SDM-CAN Datalogger-to-CANbus Interface

Each buffer can be configured as a standard ring buffer with no trigger or filter

associated with it. The buffer can also be set to start to capture data when a

predefined trigger pattern is encountered within the CAN data, or it can filter

and buffer only the CAN frames that have some part of the data that fits a

pattern.

To configure a filter or trigger two masks are used. The first is user defined as

a 64 bit include AND mask applied to the CAN data of the CAN ID of interest.

A second 64 bit user defined pattern is compared with the CAN data and when

it matches the results of the previous `AND’ operation the buffer will either