Page 1

Revision: 02/2021

Copyright © 2020 – 2021

Campbell Scientific, Inc.

Page 2

Table of contents

1. Introduction 1

2. Precautions 1

3. Initial inspection 1

4. QuickStart 2

5. Overview 4

6. Specifications 5

7. Installation 6

7.1 Wiring 6

7.2 Data logger programming 7

7.2.1 SDI-12 programming 7

7.3 Siting 8

7.4 Mounting 8

8. Operation 13

8.1 SDI-12 measurements 13

8.2 SDI-12 extended commands 15

8.3 SDI-12 version 1.4 identify measurement commands and responses 17

8.4 Rainfall intensity correction 19

8.5 Device Configuration Utility 19

9. Maintenance and troubleshooting 24

9.1 Maintenance 25

9.1.1 Internal lithium battery 25

9.1.2 Updating operating system 26

9.2 Troubleshooting 27

Appendix A. Importing Short Cut code into CRBasic Editor 29

Appendix B. XTEST! operation 30

Appendix C. SDI-12 sensor support 32

C.1 SDI-12 command basics 32

Table of Contents - i

Page 3

C.1.1 Acknowledge active command (a!) 33

C.1.2 Send identification command (al!) 33

C.1.3 Start verification command (aV!) 34

C.1.4 Address query command (?!) 34

C.1.5 Change address command (aAb!) 34

C.1.6 Start measurement commands (aM!) 35

C.1.7 Start concurrent measurement commands (aC!) 35

C.1.8 Start measurement commands with cyclic redundancy check (aMC! and aCC!) 37

C.1.9 Stopping a measurement command 37

C.1.10 Send data command (aD0! … aD9!) 37

C.1.11 Continuous measurement command (aR0! … aR9!) 38

C.1.12 Extended commands 38

C.2 SDI-12 transparent mode 38

C.2.1 Changing an SDI-12 address 39

C.3 References 41

Table of Contents - ii

Page 4

1. Introduction

The RainVUE-series rain sensors are an ideal solution for many hydrological or meteorological

applications such as weather stations and flood warning systems. The models differ in their body

material; the RainVUE™10 has a molded UV-stabilized plastic body and the RainVUE™20 has a

rugged aluminum body. A microprocessor corrects for rainfall intensity and outputs an SDI-12

signal to communicate with any SDI-12 recorder including Campbell Scientific data loggers.

NOTE:

The RainVUE-series rain sensors are compatible with all data loggers that support SDI-12

communications. This manual focuses on Campbell Scientific CRBasic data loggers.

2. Precautions

l READ AND UNDERSTAND the Safety section at the back of this manual.

l RainVUE-series is a precision instrument that must be handled with care.

l Remove the piece of foam from under the tipping mechanism. This foam may be saved and

used whenever the sensor is transported.

l Pull and remove the insulator tab used to prevent draining of the backup coin cell battery

during shipping and storage. The tab extends from the bottom of the RainVUE-series

interface inside the RainVUE-series.

3. Initial inspection

l Check the packaging and contents of the shipment. If damage occurred during transport,

immediately file a claim with the carrier. Contact Campbell Scientific to facilitate repair or

replacement.

l Check model information against the shipping documents to ensure the expected products

and the correct lengths of cable are received. Model numbers are found on each product.

On cables and cabled items, the model number is usually found at the connection end of

the cable. Report any shortages immediately to Campbell Scientific.

RainVUE-Series SDI-12 Precipitation Sensors 1

Page 5

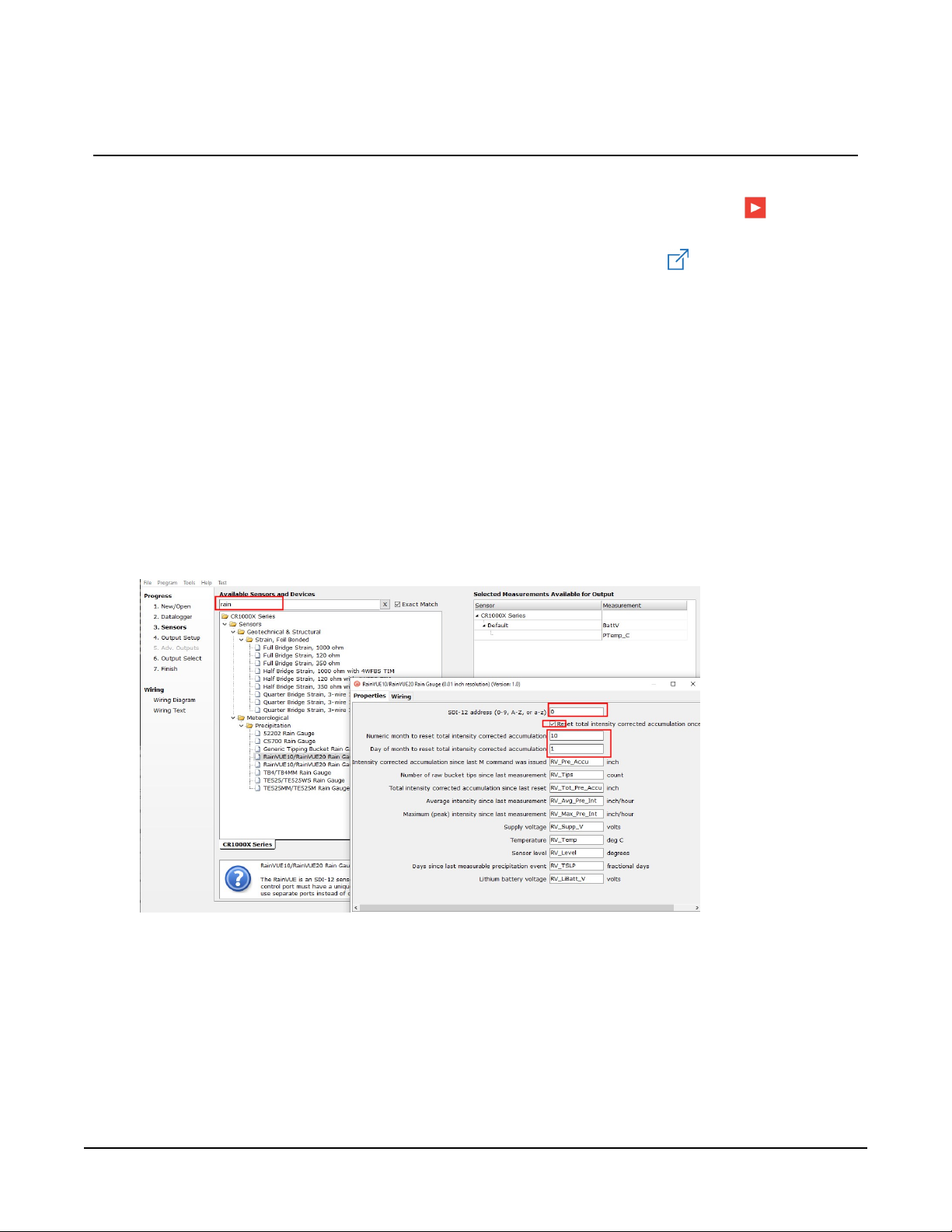

4. QuickStart

A video that describes data logger programming using Short Cut is available at:

www.campbellsci.com/videos/cr1000x-data logger-getting-started-program-part-3 . Short Cut

is an easy way to program your data logger to measure the sensor and assign data logger wiring

terminals. Short Cut is available as a download on www.campbellsci.com . It is included in

installations of LoggerNet, RTDAQ, and PC400.

The following procedure also shows using Short Cut to program the RainVUE-series.

1. Open Short Cut and click Create New Program.

2. Double-click the data logger model.

3. In the Available Sensors and Devices box, type RainVUE or find the sensor in the Sensors >

Meteorological > Precipitation folder, and double-click RainVUE10/RainVUE20 Rain

Gauge. Enter the correct SDI-12 Address for the sensor if it has been changed from the

factory-set default value. Type the numeric month and day for resetting the total

accumulation if you want to do this. Otherwise, uncheck the Reset total intensity corrected

accumulation once a year box.

RainVUE-Series SDI-12 Precipitation Sensors 2

Page 6

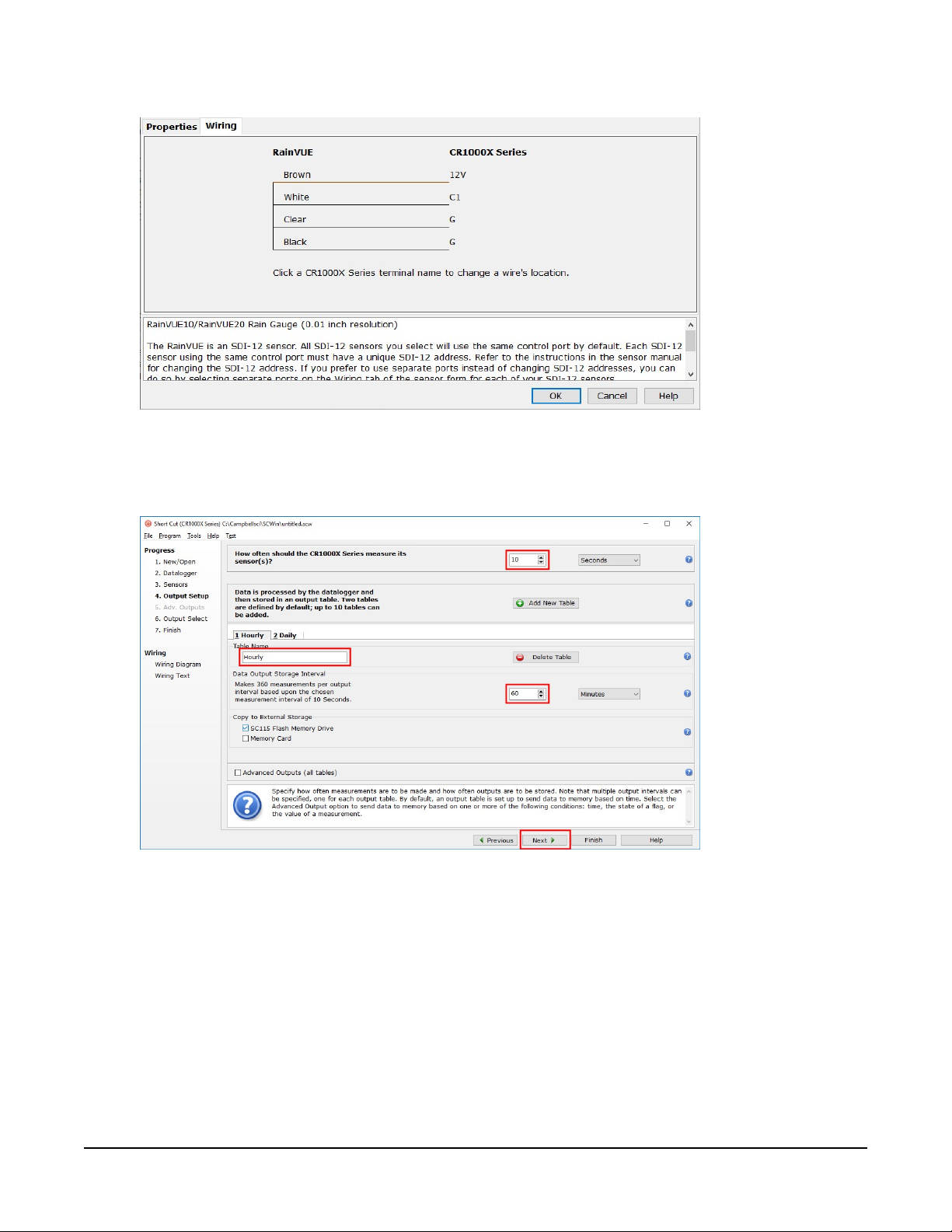

4. Click the Wiring tab. Click OK after wiring the sensor.

5. Repeat steps three and four for other sensors you want to measure. Click Next.

6. In Output Setup, type the scan rate, a Table Name, and Data Output Storage Interval. Click

Next.

RainVUE-Series SDI-12 Precipitation Sensors 3

Page 7

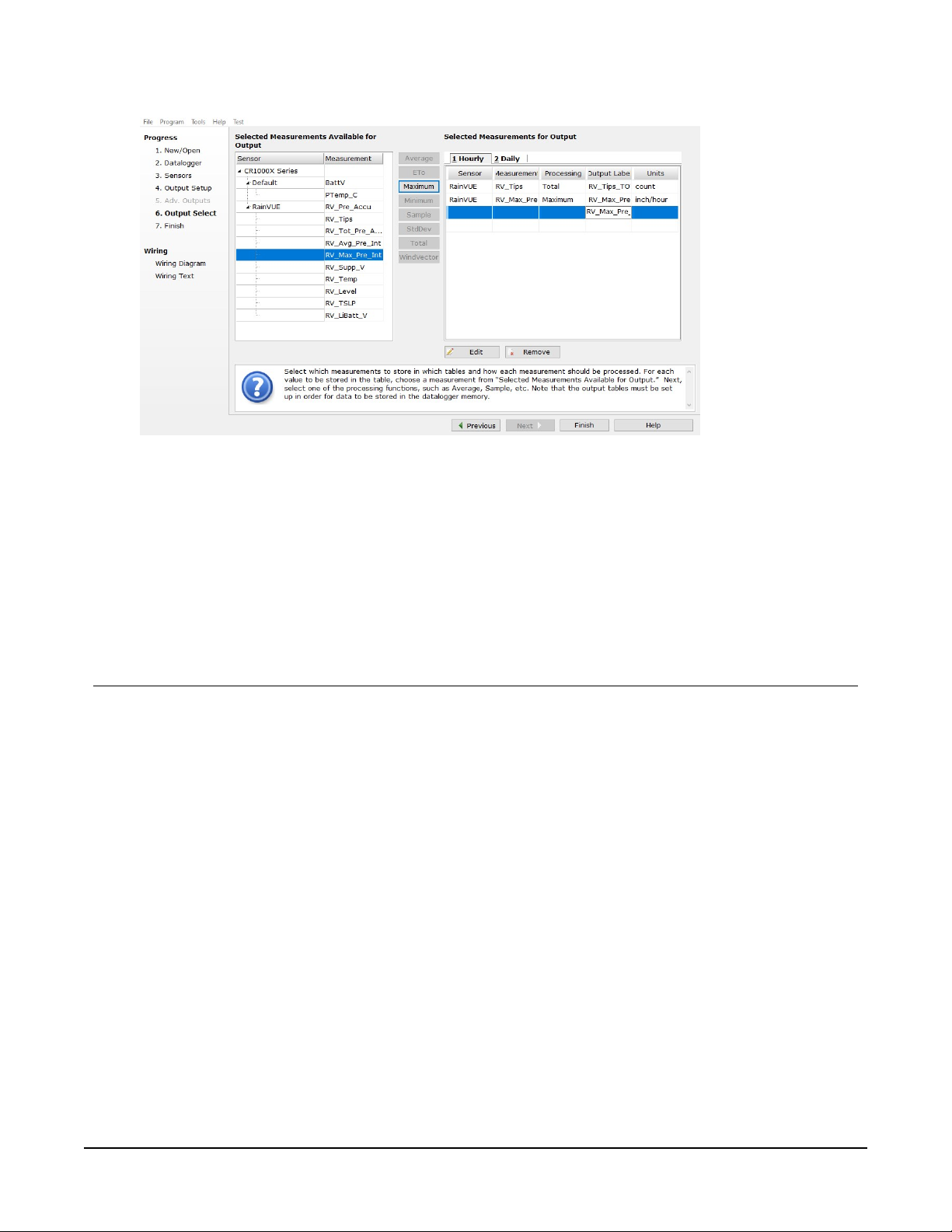

7. Select the output options.

8. Click Finish and save the program. Send the program to the data logger if the data logger

is connected to the computer.

9. If the sensor is connected to the data logger, check the output of the sensor in the data

display in LoggerNet, RTDAQ, or PC400 to make sure it is making reasonable

measurements.

5. Overview

The RainVUE-series funnels rainfall through a stainless-steel screen that traps debris, preventing

it from impeding the flow of precipitation. Rainfall flows through a nozzle into one of two bucket

halves. The internal tipping mechanism assembly rotates around a pivot point. The tipping

mechanism tips when the first bucket fills to a fixed calibrated level, then the tipping mechanism

moves the second bucket under the funnel. A magnet attached to the tipping mechanism

actuates a reed switch as the bucket tips. The outgoing water drains through outlets.

The aerodynamic design of the RainVUE-series reduces the amount of rain that wind carries away

from the collecting vessel. With traditional cylindrical tipping bucket rain sensors, wind can

reduce the rainfall catch by up to 20%. The RainVUE-series also includes a microprocessor that

corrects for rainfall intensity and outputs an SDI-12 signal. Refer to Rainfall intensity correction (p.

19) for more information.

RainVUE-Series SDI-12 Precipitation Sensors 4

Page 8

Features:

l Suitable for nonfreezing precipitation and high intensity rain events

l Digital processing to correct for high-intensity precipitation errors (see Specifications (p. 5))

l Unique aerodynamic shape increases measurement accuracy in windy conditions

l Meets WMO recommendations for accuracy and funnel area

l Adjustable mounting feet to simplify leveling

l Tilt, internal temperature, and voltage measurement for remote diagnostics on the sensor

l Compatible CRBasic data loggers: GRANITE-series, CR6, CR3000, CR1000X, CR800-series,

CR300-series, and CR1000

6. Specifications

Sensor type:

Rainfall per tip:

Output:

Response time:

Tipping bucket with magnetic reed switch

0.01 in (0.254 mm) or 0.1 mm (0.004 in)

SDI-12 version 1.4

0 s for

M0!

command and 1 s for

M1!

command

Accuracy

Rainfall: ±1% at 0 to 500 mm/h (0 to 20 in/hr) intensity

NOTE:

Accuracy over the rain intensity range requires a mechanical

calibration that is within 1% at a 1 in/h intensity. RainVUE-series

sensors are calibrated at the factory to meet this specification but

should be verified prior to deployment.

Tilt:

Temperature:

Supply voltage:

±1 °

±0.25 °C (±0.45 °F)

±0.5 V

Operating temperature:

Funnel diameter:

Height:

Power:

1 to 70 °C (34 to 158 °F)

20.0 cm (7.87 in)

43.5 to 46.5 cm (17.1 to 18.3 in) with feet adjustment

6 to 18 VDC

RainVUE-Series SDI-12 Precipitation Sensors 5

Page 9

Compliance documents: View at:

www.campbellsci.com/rainvue10

www.campbellsci.com/rainvue20

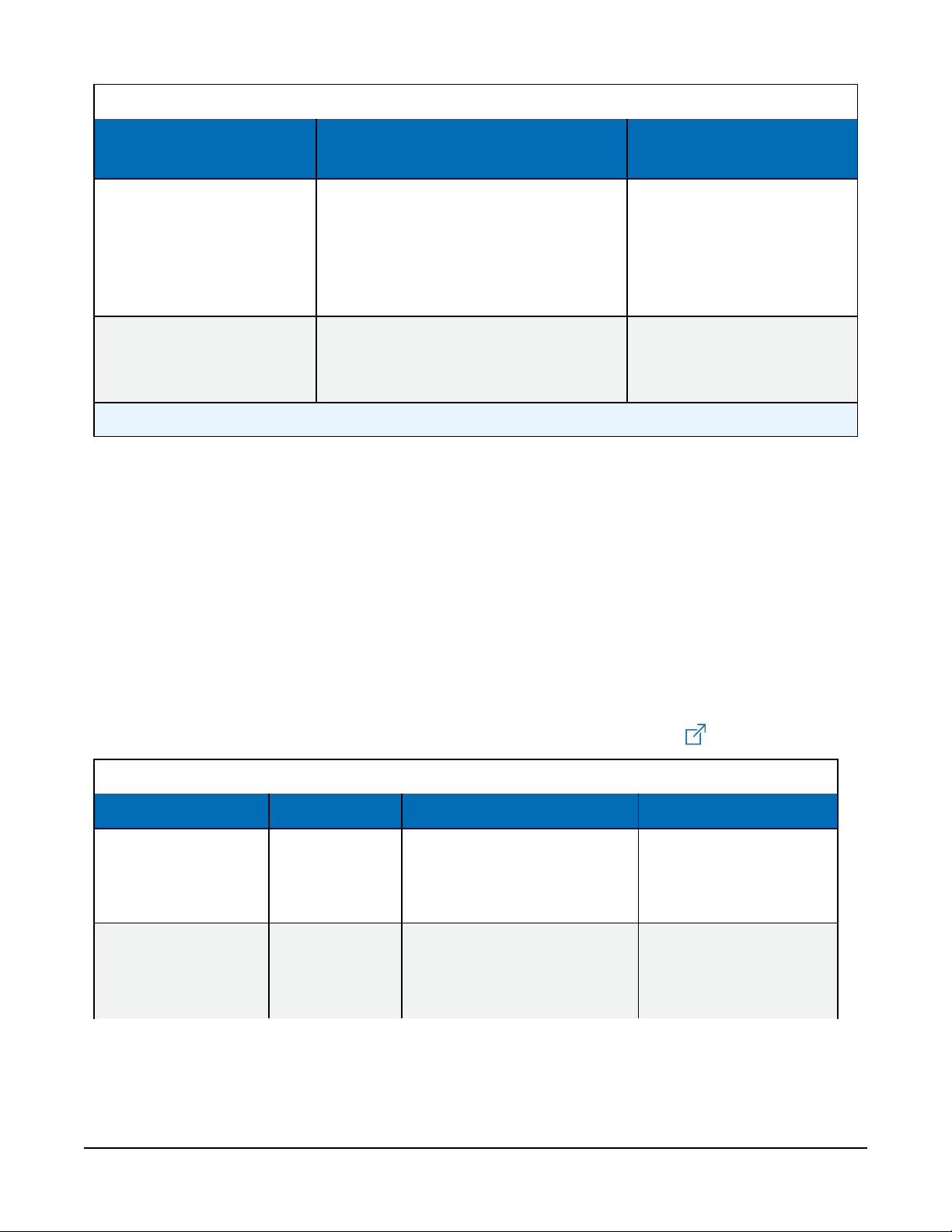

Table 6-1: RainVUE-series comparison

Specification RainVUE 10 RainVUE 20

Maximum rainfall intensity 1000 mm/h (39.4 in/h) 1500 mm/h (60 in/h)

Main collector body: 2-mm thick,

Material White, ASA LI-911 plastic

Weight 2 kg (4.5 lb) 6 kg (13 lb)

powder-coated aluminum

Base: LM6 marine-grade aluminum

7. Installation

If you are programming your data logger with Short Cut, skip Wiring (p. 6), and Data logger

programming (p. 7). Short Cut does this work for you. See QuickStart (p. 2), for a Short Cut

tutorial.

7.1 Wiring

Connect the wires in the order shown in the following table.

Table 7-1: Wire color, function, and data logger connection

Wire color Wire function Data logger connection

White SDI-12 signal C, SDI-12, or U configured for SDI-12

Clear Shield ⏚ (analog ground)

Brown Power 12V

Black Power ground G

1

U and C terminals are automatically configured by the measurement instruction.

If multiple SDI-12 sensors are connected to a data logger, Campbell Scientific recommends using

separate terminals when possible. However, multiple SDI-12 sensors can connect to the same

data logger control or U terminal. Each must have a unique SDI-12 address. Valid addresses are 0

through 9, a through z, and A through Z.

1

RainVUE-Series SDI-12 Precipitation Sensors 6

Page 10

For the CR6 and CR1000X data loggers, triggering conflicts may occur when a companion

terminal is used for a triggering instruction such as TimerInput(), PulseCount(), or

WaitDigTrig(). For example, if the RainVUE-series is connected to C3 on a CR1000X, C4

cannot be used in the TimerInput(), PulseCount(), or WaitDigTrig() instructions.

7.2 Data logger programming

Short Cut is the best source for up-to-date programming code for Campbell Scientific data

loggers. If your data acquisition requirements are simple, you can probably create and maintain a

data logger program exclusively with Short Cut. If your data acquisition needs are more complex,

the files that Short Cut creates are a great source for programming code to start a new program

or add to an existing custom program.

NOTE:

Short Cut cannot edit programs after they are imported and edited in CRBasic Editor.

A Short Cut tutorial is available in QuickStart (p. 2). If you wish to import Short Cut code into

CRBasic Editor to create or add to a customized program, follow the procedure in Importing

Short Cut code into CRBasic Editor (p. 29). Programming basics for CRBasic data loggers are

provided in the following sections. Downloadable example program is available at

www.campbellsci.com/downloads/rainvue-example-program .

7.2.1 SDI-12 programming

The SDI12Recorder() instruction is used to measure a RainVUE-series. This instruction sends

a request to the sensor to make a measurement and then retrieves the measurement from the

sensor. See SDI-12 measurements (p. 13) for more information.

For most data loggers, the SDI12Recorder() instruction has the following syntax:

SDI12Recorder(Destination, SDIPort, SDIAddress, “SDICommand”, Multiplier,

Offset, FillNAN, WaitonTimeout)

For the SDIAddress, alphabetical characters need to be enclosed in quotes (for example,

“A”). Also enclose the SDICommand in quotes as shown. The Destination parameter must

be an array. The required number of values in the array depends on the command (see Table 8-1

(p. 14)).

FillNAN and WaitonTimeout are optional parameters (refer to CRBasic Help for more

information).

RainVUE-Series SDI-12 Precipitation Sensors 7

Page 11

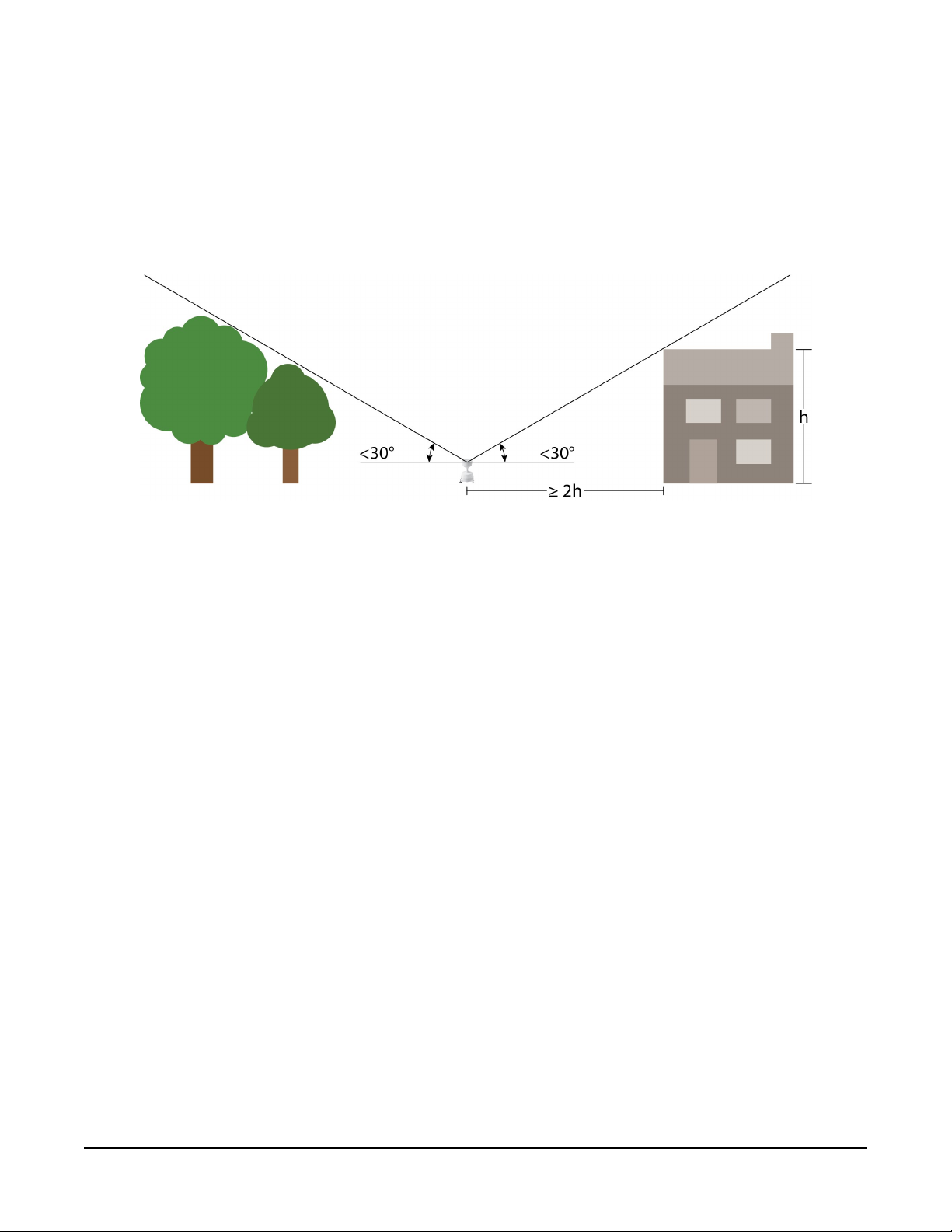

7.3 Siting

Mount the RainVUE-series in a relatively level location representative of the surrounding area.

Ensure that the funnel is horizontal. Place the sensor away from objects that obstruct the wind.

The distance should be at least 2 times the height of the obstruction. A concrete pad is

recommended, but the RainVUE-series should not be installed over a large paved or concrete

surface.

7.4 Mounting

The RainVUE-series has three equally-spaced leveling feet. Next to each leveling foot is a hole for

securing the sensor to a flat surface. The CM241 mounting bracket offered by Campbell Scientific

allows the RainVUE-series to be mounted on a CM300-series mounting pole or to a usersupplied 1.5 in. IPS (1.9 in. OD) unthreaded pipe.

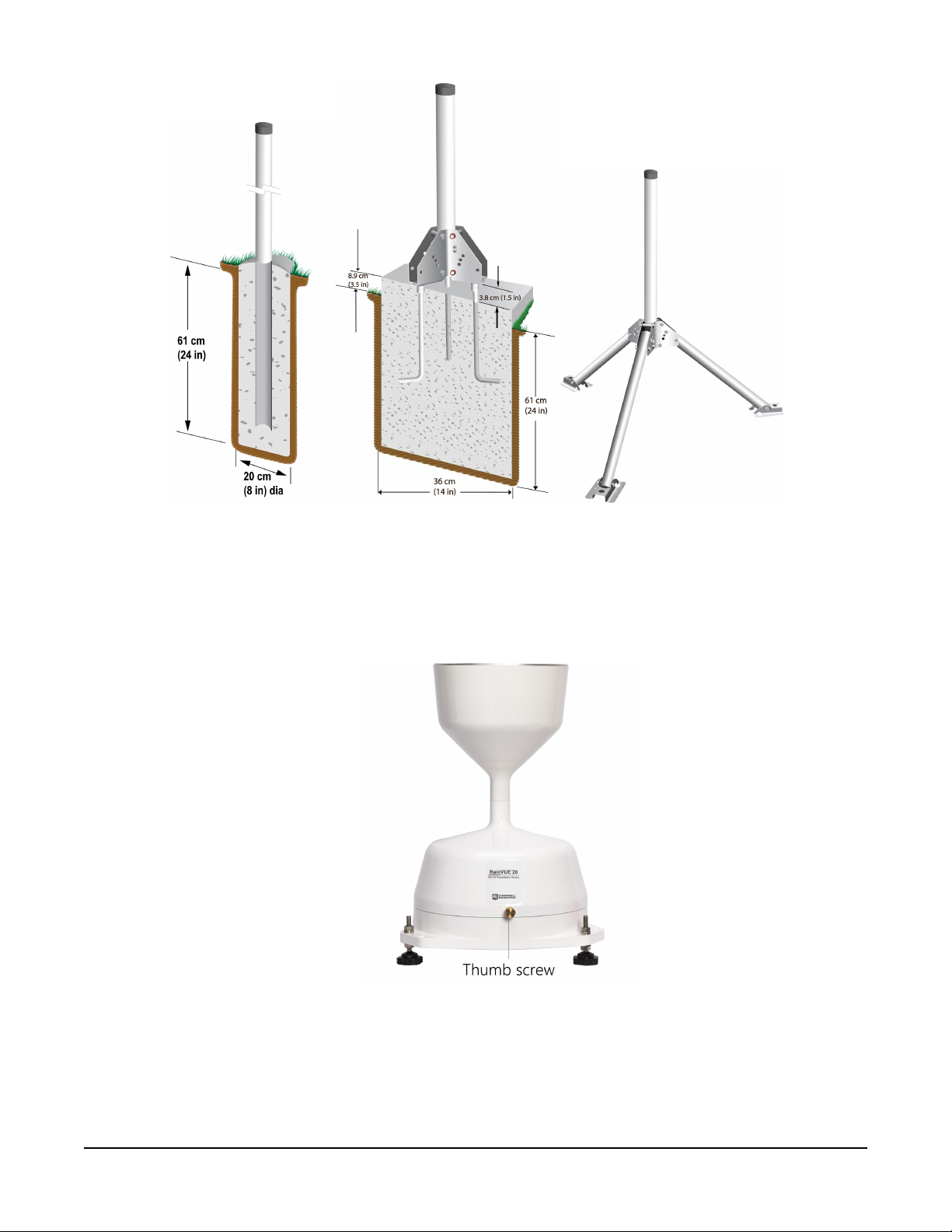

Mounting poles are placed directly into a concrete foundation, attached to a concrete

foundation with the J-bolts, or are self-supporting with three legs (see FIGURE 7-1 (p. 9)).

RainVUE-Series SDI-12 Precipitation Sensors 8

Page 12

FIGURE 7-1. CM300-series mounting options

Procedure for mounting to a CM241 bracket and leveling the sensor:

1. Loosen and remove the three base thumb screws then lift the funnel upward.

FIGURE 7-2. Thumbscrew on RainVUE 20

RainVUE-Series SDI-12 Precipitation Sensors 9

Page 13

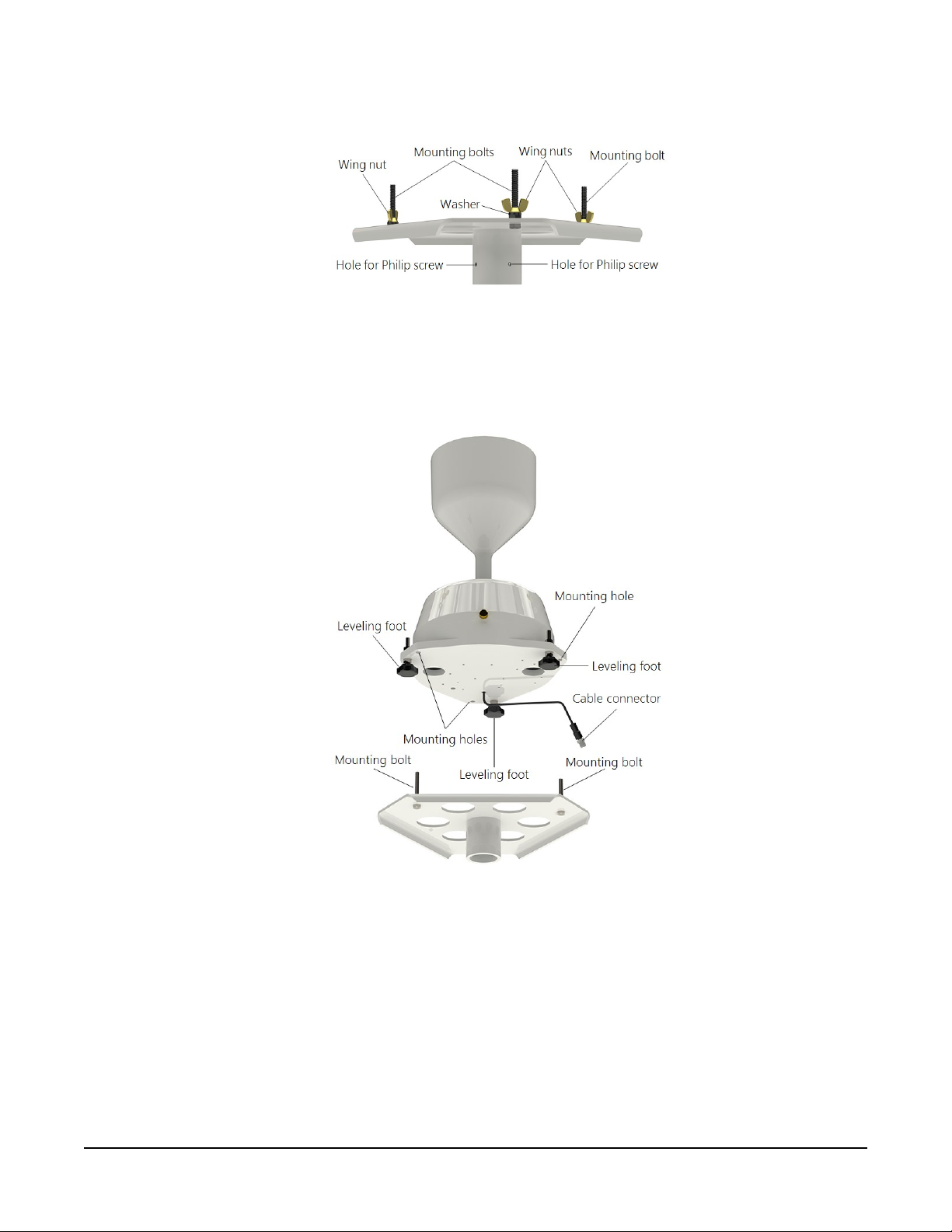

2. Remove the wing nuts and washers from the CM241 mounting bracket.

FIGURE 7-3. CM241 mounting bracket

3. Line up the RainVUE-series mounting holes over the CM241 mounting bolts and place the

sensor on the bracket.

FIGURE 7-4. Exploded view of RainVUE-series and CM241 bracket.

Wing nuts and pole not shown.

4. Loosely secure the RainVUE-series to the CM241 using the washers and wing nuts.

5. Place the CM241 on the pole or pipe and secure it to the pole or pipe by tightening the

screws with a Philips screwdriver (see FIGURE 7-3 (p. 10) and FIGURE 7-7 (p. 12)).

RainVUE-Series SDI-12 Precipitation Sensors 10

Page 14

6. Adjust the three leveling feet on the RainVUE-series to level the RainVUE-series. The

RainVUE 10 has a bubble level next to a leveling foot. On the RainVUE 20, the funnel needs

to be removed to view the bubble level. See FIGURE 7-5 (p. 11).

FIGURE 7-5. Bubble levels on the RainVUE-series

7. Once level, tighten the wing nuts by hand until hand-tight and recheck the level.

8. Remove the piece of foam from under the tipping mechanism. This foam may be saved and

used whenever the sensor is transported.

9. Tip the tipping assembly several times to ensure the tipping mechanism is moving freely.

RainVUE-Series SDI-12 Precipitation Sensors 11

Page 15

10. Pull and remove the insulator tab used to prevent draining of the backup coin cell battery

during shipping and storage. The tab extends from the bottom of the RainVUE-series

interface inside the RainVUE-series.

FIGURE 7-6. RainVUE-series interface and insulator tab

11. Replace the funnel and tighten the three base thumb screws to secure the funnel to the

base.

FIGURE 7-7. RainVUE-series mounted on a pole

12. Mate the extension cable connector to the cable connector. Only hand tighten the

connectors.

RainVUE-Series SDI-12 Precipitation Sensors 12

Page 16

8. Operation

This section discusses the following:

8.1 SDI-12 measurements 13

8.2 SDI-12 extended commands 15

8.3 SDI-12 version 1.4 identify measurement commands and responses 17

8.4 Rainfall intensity correction 19

8.5 Device Configuration Utility 19

8.1 SDI-12 measurements

The RainVUE-series responds to the SDI-12 measurement commands shown in Table 8-1 (p. 14).

When the data logger issues an M! command, the sensor should respond immediately indicating

how long it will take to perform the measurement. The data logger then waits that amount of

time or if the sensor finishes sooner, it will send a service request to the data logger indicating

data can be collected. After receiving the service request or waiting the indicated time, the data

logger will send the D! command to collect the data.

The C! command follows the same pattern as an M! command with the exception that it does

not require the data logger to pause its operation until the values are ready. Rather, the data

logger retrieves the data with the D! command on the next scan through the program. Another

measurement request is then sent so that data are ready on the next scan.

NOTE:

SDI-12 sensor support (p. 32) describes the SDI-12 commands. Additional SDI-12 information

is available at www.sdi-12.org .

RainVUE-Series SDI-12 Precipitation Sensors 13

Page 17

Table 8-1: SDI-12 measurement commands

SDI-12 command

aM!, aMC!,

aC!, aCC!,

aR0!, aRC0!

1

Values returned Units Comments

1. Intensity corrected

accumulation since last M, MC,

C, CC, R0, or RC0 command

was issued.

2. Number of raw bucket tips

since last measurement

3. Total intensity corrected

accumulation since reset

4. Average precipitation intensity

since last measurement

5. Maximum (peak) intensity

since last measurement

1. Supply voltage

2. Temperature

1. mm or inch

2. Counts

3. mm or inch

4. mm/hr or in/hr

5. mm/hr or in/hr

1. VDC

2. °C

Command

resets

accumulators

aM1!

aMC1!, aC1!,

aCC1!, aRC1!

3. Sensor level

4. Time since last measurable

precipitation event

5. Lithium battery voltage

1. Supply voltage

2. Temperature

3. Sensor level

4. Time since last measurable

precipitation event

5. Lithium battery voltage

3. Degrees from

normal, flat

4. Days

5. VDC

1. VDC

2. °C

Command

3. Degrees from

resets

normal, flat

accumulators

4. Days

5. VDC

RainVUE-Series SDI-12 Precipitation Sensors 14

Page 18

Table 8-1: SDI-12 measurement commands

SDI-12 command

aR9!

aI!

1

1. Intensity corrected

2. Number of raw bucket tips

3. Total intensity corrected

4. Average precipitation intensity

5. Maximum (peak) intensity

014CampbellMMMM100SN=xxxxxx

Where,

MMMM = RV20IN, RV20MM,

RV10IN, or RV10MM

Values returned Units Comments

accumulation since last M

command was issued

since last measurement

accumulation since reset

since last measurement

since last measurement

1. mm or inch

2. Counts

3. mm or inch

4. mm/hr or in/hr

5. mm/hr or in/hr

not applicable (NA)

Command

does not reset

accumulators

xxxxxx = serial number

1. Hardware Revision starting at 1

2. Reset Code

aV!

1

a is the sensor address.

2 = Power On

11=OS Update

12=Watchdog Timeout

NA

8.2 SDI-12 extended commands

Enter the following SDI-12 extended commands using the transparent mode while the computer

is communicating with the data logger through a terminal emulator program. It is accessed

through Campbell Scientific data logger support software or other terminal emulator programs.

Data logger keyboards and displays cannot be used. Refer to SDI-12 transparent mode (p. 38) for

more information.

RainVUE-Series SDI-12 Precipitation Sensors 15

Page 19

Table 8-2: SDI-12 extended commands

SDI-12

command

1

aXRDT! Read sensor date and time.

aXWDT+MM/DD/YYYY

hh:mm:ss!

aXWARA!

aXWA+xx.xx!

Where xx.xx = current rain

value

Values returned or function Comments

Write date and time.

Typically this command is

The extended write adjusted rainfall

issued on the start of the

accumulator command. Resets the

water year, which is

total adjusted rain accumulator to

normally October 1 or

0.00.

January 1.

Resets the total adjusted rain to a

current value and returns the number

of values.

Used when replacing the

RainVUE-series midway

Follow this command with the aD0!

through a water year.

command to get the new adjusted

rain.

aXWRESET! Resets all accumulators

Resets RTC or 24 hour tick counter to

aXWD!

midnight.

Zero tilt sensor (XWTILT) status.

Returns a status flag indicating the

aXWTILT!

success of the leveling process.

s = 0 Success

s = 1 Error (cannot zero the sensor)

Reads the tilt angle (degrees) of

aXRTILT!

the tilt sensor.

This command is a simple

way for data loggers to sync

the time clock without

having to format the SDI-12

command.

Mechanically balance the

sensor, then issue this

command.

When this command is

issued right after the sensor

is zeroed, it should return

0.00 degrees. This

command verifies the

RainVUE-series is level.

RainVUE-Series SDI-12 Precipitation Sensors 16

Page 20

Table 8-2: SDI-12 extended commands

SDI-12

command

aXTEST!

aXHELP!

1

a is the sensor address.

1

Values returned or function Comments

Returns two lines of header

information, then returns updated

data at every tip and every 2 seconds

or until a break is detected with each

line terminated with a <CR><LF>.

Lists the standard measurement and

extended commands supported by the

RainVUE-series.

Command is only intended

for testing and debugging

the sensor.

Command is only intended

for testing and debugging

the sensor.

8.3 SDI-12 version 1.4 identify measurement commands and responses

Version 1.4 compliant sensors must respond to identify commands for each type of measurement

command and each parameter with a command. The broad identify commands return how many

variables will be returned with a given measurement command and the time it will take the

sensor to respond. The specific identify parameter commands will return a SHEF code, the

measurement units, and the type of measurement (sample, count, or average). For more

information see the SDI-12 version 1.4 specification.

(http://sdi-12.org/current_specification/SDI-12_version-1_4-Jan-10-2019.pdf )

Table 8-3: Identify commands for the RainVUE-series

Type of command Command Sensor response Comment

Identify

measurement for

M commands

Identify

measurement for

C commands

aIM!, aIMC!,

aM1!, aIMC1!

aIC!, aICC!,

aIC1!,

aICC1!

atttn

atttnn

RainVUE-Series SDI-12 Precipitation Sensors 17

ttt: response time

(seconds)

n: # of values returned

ttt: response time

(seconds)

nn: # of values returned

Page 21

Table 8-3: Identify commands for the RainVUE-series

Type of command Command Sensor response Comment

Identify

measurement for the

V command

Identify

measurement for

parameter 1 of

M command

Identify

measurement for

parameter 2 of

M command

Identify

measurement for

parameter 3 of

M command

aIV!

aIM_001!

aIM_002!

aIM_003!

atttn

aAdjRain,Inches

or aAdjRain,mm

aRawTips,Tips

aTotAdjRain,Inches

or aTotAdjRain,mm

ttt: response time

(seconds)

n: # of values returned

AdjRain: adjusted or

intensity-corrected

precipitation since last

measurement

Units: inches or mm

RawTips: number of raw

bucket tips since last

measurement (counts)

Units: counts

TotAdjRain: total

adjusted or total

intensity corrected

precipitation since last

reset

Identify

measurement for

parameter 4 of

M command

Identify

measurement for

parameter 5 of

M command

aIM_004!

aIM_005!

aAvgInt,Inches/Hour

or aAvgInt,mm/Hour

aMaxInt,Inches/Hour

or aMaxInt,mm/Hour

Units: inches or mm

AvgInt: average

precipitation intensity

since last measurement

Units: inches/hour or

mm/hour

MaxInt: maximum peak

precipitation intensity

since last measurement

Units: inches/hour or

mm/hour

RainVUE-Series SDI-12 Precipitation Sensors 18

Page 22

8.4 Rainfall intensity correction

During intense rainfall, extra water can accumulate in the bucket before the tipping mechanism

tips. The following graph shows the relationship between bucket volume and rainfall rate. The

RainVUE-series includes a microprocessor that corrects for the intensity sensitivity of the bucket

mechanism. This correction adjusts the rainfall rate based on the time between bucket tips. An

electronic timer precisely measures the time between tips.

8.5 Device Configuration Utility

Use Device Configuration Utility to change the SDI-12 address, view sensor measurements, collect

data, and update an operating system (see Updating operating system (p. 26)).

RainVUE-Series SDI-12 Precipitation Sensors 19

Page 23

1. Loosen and remove the three base thumb screws then lift the funnel upward.

2. Use a Philips screwdriver to remove the four screws on the RainVUE-series interface.

3. Remove the interface cover to access the USB port.

4. Open Device Configuration Utility.

RainVUE-Series SDI-12 Precipitation Sensors 20

Page 24

5. Type RainVUE-series in the Device Type box and click RainVUE-series.

6. If this is the first time connecting the RainVUE-series to the computer, click install USB

driver for the RainVUE before connecting the cable to the computer.

7. Use the supplied USB cable to connect the RainVUE-series USB port to a computer USB

port.

8. Select the Communication Port in the left panel. RAINVUE will appear in the selection

dialog.

NOTE:

It may take a few seconds for the Communication Port to become available for use after

physically connecting the RainVUE-series to the computer.

9. Click Connect.

RainVUE-Series SDI-12 Precipitation Sensors 21

Page 25

10. To change the SDI-12 address, click the SDI-12 Address box and select a different value.

11. Click the Status tab to view tip counts, accumulation, and intensity information.

12. Click the Clock Control tab to change the Reference Clock Setting. Click Set Clock to

manually initiate a clock check of the reference time and station time.

RainVUE-Series SDI-12 Precipitation Sensors 22

Page 26

13. Click the Data Monitor tab to view real-time data. From the list, select the table you want

to display.

14. Click the Data Collection tab to manually collect data. Check the Destination Directory and

File Format to make sure the files are where you want them and in the right format. Select

the Collect Mode, tables, then click Start.

RainVUE-Series SDI-12 Precipitation Sensors 23

Page 27

The following shows data collected from an hourly rain table.

9. Maintenance and troubleshooting

NOTE:

All factory repairs and recalibrations require a returned material authorization (RMA) and

completion of the “Statement of Product Cleanliness and Decontamination” form. Refer to

the Assistance page at the end of this manual for more information.

This section discusses the following:

9.1 Maintenance 25

9.2 Troubleshooting 27

RainVUE-Series SDI-12 Precipitation Sensors 24

Page 28

9.1 Maintenance

To ensure reliable and accurate measurements, Campbell Scientific recommends doing the

following every month.

1. Check the integrity of the cable and data logger connections. Replace cable if damaged.

2. Inspect the funnel for any damage or blockage. To clear a blockage, remove the funnel

from the base and remove debris.

3. Clean the filter using the following procedure:

a. Unscrew the end cap from the filter tube

b. Carefully, remove the stainless-steel screen

c. Gently clean the filter

d. Place the filter on the filter tube and screw on the end cap

4. Level the RainVUE-series if necessary (see aXWTILT! and aXRTILT! command in Table

8-2 (p. 16)). The RainVUE 10 has a bubble level next to a leveling foot. On the RainVUE 20,

the funnel needs to be removed to view the bubble level.

5. Clean dirt from the tipping bucket. Avoid tipping the bucket if the RainVUE-series is still

connected to the data logger.

6. If the data logger is disconnected, check the tipping mechanism for stiffness.

a. Try to balance the bucket in its center position. It should be extremely difficult or

impossible to balance.

b. If the bucket balances easily, closely examine the tipping bucket assembly for dirt or

wear on the pivot pin and bucket tubs.

9.1.1 Internal lithium battery

An internal lithium coin cell battery powers the RainVUE-series during power loss of the main

12V power source. The battery allows the RainVUE-series to capture rain events for 12 to 15 days

depending on battery age, temperature, and frequency of rain detections and SDI-12

measurement request.

The M1! and IM1_005! SDI-12 commands report the lithium battery voltage (see Table 8-1 (p.

14) and Table 8-3 (p. 17)). Replace the battery when voltage is approximately 2.7VDC.

Campbell Scientific recommends replacing the battery every 2 to 3 years and after each loss of

power event. High temperature can reduce the battery life and low temperatures can decrease

battery capacity lowering available power and sensor runtime.

RainVUE-Series SDI-12 Precipitation Sensors 25

Page 29

Remove the backup battery when the sensor is removed from service. Replace the battery when

the RainVUE-series is placed back in service.

Battery replacement procedure:

1. Loosen and remove the three base thumb screws then lift the funnel upward.

2. Use a Philips screwdriver to remove the four screws on the RainVUE-series interface.

3. Remove the interface cover.

4. Replace the old lithium battery with the new battery (3 V Coin Cell CR2032).

5. Place the interface cover on the interface and secure with the four screws.

6. Replace the funnel and tighten the three base thumb screws to secure the funnel to the

base.

9.1.2 Updating operating system

1.

Go to www.campbellsci.com/downloads/rainvue-os , click Download Now, and click

Save File. This will download an .exe file on your computer.

RainVUE-Series SDI-12 Precipitation Sensors 26

Page 30

2. Double-click the .exe file. This will save the operating system file in

C:/Campbellsci/Lib/OperatingSystems.

3. Access Device Configuration Utility (see Device Configuration Utility (p. 19)).

4. Click the Send OS tab.

5. Click Start

6. Select the file. It will have an .a43 extension.

7. Click OK.

9.2 Troubleshooting

Symptom:

On a CRBasic data logger, data values report NAN, or on a non-Campbell Scientific data logger,

data values do not change when the tipping mechanism is activated and new measurement

commands are issued.

Solution:

1. Verify the RainVUE-series is wired correctly (Table 7-1 (p. 6)).

NOTE:

Connect the power wire to the data logger 12V terminal and not the SW12 terminal.

2. Verify the power to the RainVUE-series is in the appropriate range (6 to 18 VDC).

RainVUE-Series SDI-12 Precipitation Sensors 27

Page 31

3. Verify the correct SDI-12 address is being used when communicating with the RainVUEseries. Use the transparent mode to verify the data logger can communicate with the it. For

additional information, refer to SDI-12 transparent mode (p. 38).

Symptom:

Reported data values are lower than expected.

Solution:

1. Ensure that the filter is clean and allows water to flow through it.

2. Check that the tipping mechanism can move freely.

3. Use a voltmeter on the switch to verify the switch is activated as expected while

transitioning from one side to the other. While the tipping mechanism is in its resting

positions, the volt meter should read 3 to 5 V. When at the mid- point as it transitions from

one side to the other side, the volt meter should read 0 V.

4. Ensure that the RainVUE-series is level. The RainVUE 10 has a bubble level next to a

leveling foot. On the RainVUE 20, the funnel needs to be removed to view the bubble level.

5. Check the wires and connections between the switch and the interface are secure.

6. Verify no obstacles are preventing rain from entering the funnel.

Symptom:

Reported data values are higher than expected.

Solution:

1. Verify the tipping mechanism is not stuck near the center of its movement from one side to

the other.

2. Verify that the wires and connections between the switch and the interface are secure.

3. Verify that the RainVUE-series is not under a structure that will drip into the it.

For more information refer to:

www.campbellsci.com/videos/sdi12-sensors-transparent-mode

www.campbellsci.com/videos/sdi12-sensors-watch-or-sniffer-mode

RainVUE-Series SDI-12 Precipitation Sensors 28

Page 32

Appendix A. Importing Short

Cut code into CRBasic Editor

Short Cut creates a .DEF file that contains wiring information and a program file that can be

imported into the CRBasic Editor. By default, these files reside in the C:\campbellsci\SCWin

folder.

Import Short Cut program file and wiring information into CRBasic Editor:

1. Create the Short Cut program. After saving the Short Cut program, click the Advanced tab

then the CRBasic Editor button. A program file with a generic name will open in CRBasic.

Provide a meaningful name and save the CRBasic program. This program can now be

edited for additional refinement.

NOTE:

Once the file is edited with CRBasic Editor, Short Cut can no longer be used to edit the

program it created.

2. To add the Short Cut wiring information into the new CRBasic program, open the .DEF file

located in the C:\campbellsci\SCWin folder, and copy the wiring information, which is at

the beginning of the .DEF file.

3. Go into the CRBasic program and paste the wiring information into it.

4. In the CRBasic program, highlight the wiring information, right-click, and select Comment

Block. This adds an apostrophe (') to the beginning of each of the highlighted lines, which

instructs the data logger compiler to ignore those lines when compiling. The Comment

Block feature is demonstrated at about 5:10 in the CRBasic | Features video .

RainVUE-Series SDI-12 Precipitation Sensors 29

Page 33

Appendix B. XTEST! operation

Use the XTEST! SDI-12 command to validate the calibration. Enter this command in the

transparent mode while the computer is communicating with the data logger through a terminal

emulator program.

This command displays simulated rain fall data that does not affect rain accumulators used for

the normal operation. It runs for 60 minutes then returns to normal operation. The XTEST!

command can also be aborted by a break on the SDI-12 data line. Therefore, suspend the data

logger program before you begin field calibration.

To validate the calibration, first run a fixed amount of water through the RainVUE-series, then

use the XTEST! command and compare the results. A common amount of simulated rain is 946

ml which equates to 115 tips on the 0.01 inch rain gauge at a rate of 2 inches of rain per hour or

slower.

Initially, the command sends the following header information.

Raw

Tip

For each second or each tip detected, the command displays a new line of data, such as the

following.

Raw

Tip

0 0.000 0.000 0

0 0.000 0.000 0

Eventually, the numbers should start changing and the latest data should give an indication of

how close the gauge is to calibration.

Corrected

Rain Fall

Corrected

Rain Fall

Total

Rain Fall Balance

Total

Rain Fall Balance

RainVUE-Series SDI-12 Precipitation Sensors 30

Page 34

Raw

Tip

0 0.000 0.000 0

0 0.000 0.000 0

1 0.010 0.010 33

2 0.011 0.021 68

3 0.011 0.032 51

4 0.012 0.044 50

5 0.010 0.054 51

6 0.011 0.065 49

8 0.023 0.088 51

|

|

110 0.011 1.180 51

Corrected

Rain Fall

Total

Rain Fall Balance

111 0.011 1.191 50

112 0.011 1.202 51

113 0.012 1.214 51

114 0.010 1.224 51

114 0.000 1.224 51

114 0.000 1.224 51

The corrected rain fall and total rain fall values include intensity correction. When the simulated

rain is ran through the gauge at a fast rate, the number of tips may be lower than expected, but

the corrected rain fall should be close to the actual amount of simulated rain.

The balance value represents how balanced the tipping mechanism is as it tips from one side to

the other. If the gauge needs to be adjusted, it is best to try to keep the balance as close to 50%

as possible. The balance value is only valid if the simulated rain is being applied at a constant

rate. It is best to look at this value after the test has been running for consistently for a few tips.

RainVUE-Series SDI-12 Precipitation Sensors 31

Page 35

Appendix C. SDI-12 sensor support

SDI-12, Serial Data Interface at 1200 baud, is a protocol developed to simplify sensor and data

logger compatibility. Only three wires are necessary — serial data, ground, and 12 V. With unique

addresses, multiple SDI-12 sensors can connect to a single SDI-12 terminal on a Campbell

Scientific data logger.

This appendix discusses the structure of SDI-12 commands and the process of querying SDI-12

sensors. For more detailed information, refer to version 1.4 of the SDI-12 protocol, available at

www.sdi-12.org .

For additional information, refer to the SDI-12 Sensors | Transparent Mode and SDI-12 Sensors |

Watch or Sniffer Mode videos.

C.1 SDI-12 command basics

SDI-12 commands have three components:

l Sensor address (a) – a single character and the first character of the command. Use the

default address of zero (0) unless multiple sensors are connected to the same port.

l Command body – an upper case letter (the “command”), optionally followed by one or

more alphanumeric qualifiers.

l Command termination (!) – an exclamation mark.

An active sensor responds to each command. Responses have several standard forms and always

terminate with <CR><LF> (carriage return and line feed). Standard SDI-12 commands are listed

in Table C-1 (p. 32).

Table C-1: Campbell Scientific sensor SDI-12 command and response set

Name Command

Acknowledge Active

Send Identification

Start Verification

a!

aI!

aV!

Response

a<CR><LF>

allccccccccmmmmmmvvvxxx...xx

<CR><LF>

atttn <CR><LF>

1

RainVUE-Series SDI-12 Precipitation Sensors 32

Page 36

Table C-1: Campbell Scientific sensor SDI-12 command and response set

Name Command

Address Query

Change Address

Start Measurement

Start Measurement

and Request CRC

Start Concurrent Measurement

StartConcurrentMeasurement

and Request CRC

Send Data

Continuous Measurement

?!

aAb!

aM!

aM1!...aM9!

aMC!

aMC1!...aMC9!

aC!

aC1!...aC9!

aCC!

aCC1!...aCC9!

aD0!...aD9!

aR0!...aR9!

Response

a<CR><LF>

b<CR><LF>

atttn<CR><LF>

atttn <CR><LF>

atttnn<CR><LF>

atttnn<CR><LF>

a<values><CR><LF> or

a<values><CRC><CR><LF>

a<values><CR><LF>

1

Continuous Measurement

and Request CRC

Extended Commands

1

Information on each of these commands is given in the following sections.

aRC0!...aRC9!

aXNNN!

a<values><CRC><CR><LF>

a<values><CR><LF>

C.1.1 Acknowledge active command (a!)

The Acknowledge Active command (a!) is used to test a sensor on the SDI-12 bus. An active

sensor responds with its address.

C.1.2 Send identification command (al!)

Sensor identifiers are requested by issuing command aI!. The reply is defined by the sensor

manufacturer but usually includes the sensor address, SDI-12 version, manufacturer’s name, and

sensor model information. Serial number or other sensor specific information may also be

included.

aI!

a Sensor SDI-12 address

allccccccccmmmmmmvvvxxx...xx<CR><LF>

ll SDI-12 version number (indicates compatibility)

RainVUE-Series SDI-12 Precipitation Sensors 33

Page 37

cccccccc 8-character vendor identification

mmmmmm 6 characters specifying the sensor model

vvv 3 characters specifying the sensor version (operating system)

xxx…xx

<CR><LF>

Source: SDI-12: A Serial-Digital Interface Standard for Microprocessor-Based Sensors (see References).

Up to 13 optional characters used for a serial number or other specific

sensor information that is not relevant for operation of the data logger

Terminates the response

C.1.3 Start verification command (aV!)

The response to a Start Verification command can include hardware diagnostics, but like the aI!

command, the response is not standardized.

Command: aV!

Response: atttn<CR><LF>

a = sensor address

ttt = time, in seconds, until verification information is available

n = the number of values to be returned when one or more subsequent D! commands are issued

C.1.4 Address query command (?!)

Command ?! requests the address of the connected sensor. The sensor replies to the query with

the address, a. This command should only be used with one sensor on the SDI-12 bus at a time.

C.1.5 Change address command (aAb!)

Multiple SDI-12 sensors can connect to a single SDI-12 terminal on a data logger. Each device on

a single terminal must have a unique address.

A sensor address is changed with command aAb!, where a is the current address and b is the

new address. For example, to change an address from 0 to 2, the command is 0A2!. The sensor

responds with the new address b, which in this case is 2.

NOTE:

Only one sensor should be connected to a particular terminal at a time when changing

addresses.

RainVUE-Series SDI-12 Precipitation Sensors 34

Page 38

C.1.6 Start measurement commands (aM!)

A measurement is initiated with the M! command. The response to each command has the form

atttn<CR><LF>, where

a = sensor address

ttt = time, in seconds, until measurement data is available. When the data is ready, the sensor

notifies the data logger, and the data logger begins issuing D commands.

n = the number of values returned when one or more subsequent D commands are issued. For

the aM! command, n is an integer from 0 to 9.

When the aM! is issued, the data logger pauses its operation and waits until either it receives the

data from the sensor or the time, ttt, expires. Depending on the scan interval of the data logger

program and the response time of the sensor, this may cause skipped scans to occur. In this case

make sure your scan interval is longer than the longest measurement time (ttt).

Table C-2: Example aM! sequence

0M!

00352<CR><LF>

0<CR><LF>

0D0!

0+.859+3.54<CR><LF>

The data logger makes a request to sensor 0 to start a measurement.

Sensor 0 immediately indicates that it will return two values within

the next 35 seconds.

Within 35 seconds, sensor 0 indicates that it has completed the

measurement by sending a service request to the data logger.

The data logger immediately issues the first D command to collect

data from the sensor.

The sensor immediately responds with the sensor address and the two

values.

C.1.7 Start concurrent measurement commands (aC!)

A concurrent measurement (aC!) command follows the same pattern as the aM! command with

the exception that it does not require the data logger to pause its operation, and other SDI-12

sensors may take measurements at the same time. The sensor will not issue a service request to

notify the data logger that the measurement is complete. The data logger will issue the aD0!

command during the next scan after the measurement time reported by the sensor has expired.

To use this command, the scan interval should be 10 seconds or less. The response to each

command has the form atttn<CR><LF>, where

a = the sensor address

ttt = time, in seconds, until the measurement data is available

RainVUE-Series SDI-12 Precipitation Sensors 35

Page 39

nn = the number of values to be returned when one or more subsequent D commands are

issued.

See the following example. A data logger has three sensors wired into terminal C1. The sensors

are addresses X, Y, and Z. The data logger will issue the following commands and receive the

following responses:

Table C-3: Example aC! sequence

XC!

X03005<CR><LF>

YC!

Y04006<CR><LF>

ZC!

Z02010<CR><LF>

ZD0!

The data logger makes a request to sensor X to start

a concurrent measurement.

Sensor X immediately indicates that it will have 5

(05) values ready for collection within the next 30

(030) seconds.

The data logger makes a request to sensor Y to start

a concurrent measurement.

Sensor Y immediately indicates that it will have 6

(06) values ready for collection within the next 40

(040) seconds.

The data logger makes a request to sensor Z to start

a concurrent measurement.

Sensor Z immediately indicates that it will have 10

values ready for collection within the next 20 (020)

seconds.

After 20 seconds have passed, the data logger starts

the process of collecting the data by issuing the first

D command to sensor Z.

Z+1+2+3+4+5+6+7+8+9+10<CR><LF>

XD0!

X+1+2+3+4+5<CR><LF>

Sensor Z immediately responds with the sensor

address and the 10 values.

10 seconds later, after a total of 30 seconds have

passed, the data logger starts the process of

collecting data from sensor X by issuing the first D

command.

The sensor immediately responds with the sensor

address and the 5 values.

RainVUE-Series SDI-12 Precipitation Sensors 36

Page 40

Table C-3: Example aC! sequence

YD0!

Ten seconds later, after a total of 40 seconds have

passed, the data logger starts the process of

collecting data from sensor Y by issuing the first D

command.

Y+1+2+3+4+5+6<CR><LF>

The sensor immediately responds with the sensor

address and the 6 values.

C.1.8 Start measurement commands with cyclic redundancy check (aMC! and aCC!)

Error checking is done by using measurement commands with cyclic redundancy checks (aMC!

or aCC!). This is most commonly implemented when long cable lengths or electronic noise may

impact measurement transmission to the data logger. When these commands are used, the data

returned in response to D or R commands must have a cyclic redundancy check (CRC) code

appended to it. The CRC code is a 16-bit value encoded within 3 characters appended before the

<CR><LF>. This code is not returned in the data table but checked by the data logger as it

comes. The code returned is based on the SDI-12 protocol. See the SDI-12 communication

specification for version 1.3 available at www.sdi-12.org to learn more about how the CRC code is

developed.

C.1.9 Stopping a measurement command

A measurement command (M!) is stopped if it detects a break signal before the measurement is

complete. A break signal is sent by the data logger before most commands.

A concurrent measurement command (C!) is aborted when another valid command is sent to the

sensor before the measurement time has elapsed.

C.1.10 Send data command (aD0! … aD9!)

The Send Data command requests data from the sensor. It is issued automatically with every type

of measurement command (aM!, aMC!, aC!, aCC!). When the measurement command is aM!

or aMC!, the data logger issues the aD0! command once a service request has been received

from the sensor or the reported time has expired. When the data logger is issuing concurrent

commands (aC! or aCC!), the Send Data command is issued after the required time has elapsed

(no service request will be sent by the sensor). In transparent mode (see SDI-12 transparent mode

(p. 38) ), the user asserts this command to obtain data.

Depending on the type of data returned and the number of values a sensor returns, the data

logger may need to issue aD0! up to aD9! to retrieve all data. A sensor may return up to 35

RainVUE-Series SDI-12 Precipitation Sensors 37

Page 41

characters of data in response to a D command that follows an M! or MC! command. A sensor

may return up to 75 characters of data in response to a D command that follows a C! or CC!

command. Data values are separated by plus or minus signs.

Command: aD0! (aD1! … aD9!)

Response: a<values><CR><LF> or a<values><CRC><CR><LF>

where:

a = the sensor address

<values> = values returned with a polarity sign (+ or –)

<CR><LF> = terminates the response

<CRC> = 16-bit CRC code appended if data was requested with aMC! or aCC!.

C.1.11 Continuous measurement command (aR0! … aR9!)

Sensors that are able to continuously monitor the phenomena to be measured can be read

directly with the R commands (R0! … R9!). The response to the R commands mirrors the Send

Data command (aD0!). A maximum of 75 characters can be returned in the <values> part of the

response to the R command.

C.1.12 Extended commands

Many sensors support extended SDI-12 commands. An extended command is specific to a make

of sensor and tells the sensor to perform a specific task. They have the following structure.

Responses vary from unit to unit. See the sensor manual for specifics.

Command: aXNNNN!

The command will start with the sensor address (a), followed by an X, then a set of optional

letters, and terminate with an exclamation point.

Response: a<optional values><CR><LF>

The response will start with the sensor address and end with a carriage return/line feed.

C.2 SDI-12 transparent mode

System operators can manually interrogate and enter settings in probes using transparent mode.

Transparent mode is useful in troubleshooting SDI-12 systems because it allows direct

communication with probes. Data logger security may need to be unlocked before activating the

transparent mode.

RainVUE-Series SDI-12 Precipitation Sensors 38

Page 42

Transparent mode is entered while the computer is communicating with the data logger through

a terminal emulator program. It is accessed through Campbell Scientific data logger support

software or other terminal emulator programs. Data logger keyboards and displays cannot be

used.

The terminal emulator is accessed by navigating to the Tools list in PC400 or the Datalogger list

in the Connect screen of LoggerNet.

Watch the video: SDI-12 Sensors | Transparent Mode.

Data loggers from other manufacturers will also have a transparent mode. Refer to those manuals

on how to use their transparent mode.

The following examples show how to enter transparent mode and change the SDI-12 address of

an SDI-12 sensor. The steps shown in Changing an SDI-12 address (p. 39) are used with most

Campbell Scientific data loggers.

C.2.1 Changing an SDI-12 address

This example was done with a CR1000X, but the steps are only slightly different for CR6, CR3000,

CR800-series, CR300-series, CR1000 data loggers.

1. Connect an SDI-12 sensor to the CR1000X.

2. In LoggerNet Connect, under Datalogger, click Terminal Emulator. The terminal emulator

window opens.

3. Under Select Device, located in the lower left side of the window, select the CR1000X

4. Click Open Terminal.

5. Select All Caps Mode.

6. Press Enter until the data logger responds with the CR1000X> prompt.

RainVUE-Series SDI-12 Precipitation Sensors 39

Page 43

7. Type SDI12 and press Enter.

8. At the Select SDI12 Port prompt, type the number corresponding to the control port where

the sensor is connected and press Enter. The response Entering SDI12 Terminal indicates

that the sensor is ready to accept SDI-12 commands.

9. To query the sensor for its current SDI-12 address, type ?! and press Enter. The sensor

responds with its SDI-12 address. If no characters are typed within 60 seconds, the mode is

exited. In that case, simply type SDI12 again, press Enter, and type the correct control port

number when prompted.

10. To change the SDI-12 address, type aAb!, where a is the current address from the previous

step and b is the new address. Press Enter. The sensor changes its address and responds

with the new address. In the following example, the sensor address is changed from 0 to B.

11. To exit SDI-12 transparent mode, click Close Terminal.

RainVUE-Series SDI-12 Precipitation Sensors 40

Page 44

NOTE:

The transparent mode for the CR6, CR3000, CR800-series, CR300-series, and CR1000 data

loggers is similar to that shown for the CR1000X.

C.3 References

SDI-12 Support Group. SDI-12: A Serial-Digital Interface Standard for Microprocessor-Based

Sensors – Version 1.4. River Heights, UT: SDI-12 Support Group, 2017. http://www.sdi-

12.org/current_specification/SDI-12_version-1_4-Dec-1-2017.pdf.

RainVUE-Series SDI-12 Precipitation Sensors 41

Page 45

Limited warranty

Products manufactured by Campbell Scientific are warranted by Campbell Scientific to be free

from defects in materials and workmanship under normal use and service for twelve months from

the date of shipment unless otherwise specified on the corresponding product webpage. See

Product Details on the Ordering Information pages at www.campbellsci.com. Other

manufacturer's products, that are resold by Campbell Scientific, are warranted only to the limits

extended by the original manufacturer.

Refer to www.campbellsci.com/terms#warranty for more information.

CAMPBELL SCIENTIFIC EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Campbell Scientific hereby

disclaims, to the fullest extent allowed by applicable law, any and all warranties and conditions

with respect to the Products, whether express, implied or statutory, other than those expressly

provided herein.

Page 46

Assistance

Products may not be returned without prior authorization.

Products shipped to Campbell Scientific require a Returned Materials Authorization (RMA) or

Repair Reference number and must be clean and uncontaminated by harmful substances, such as

hazardous materials, chemicals, insects, and pests. Please complete the required forms prior to

shipping equipment.

Campbell Scientific regional offices handle repairs for customers within their territories. Please

see the back page for the Global Sales and Support Network or visit

www.campbellsci.com/contact to determine which Campbell Scientific office serves your country.

To obtain a Returned Materials Authorization or Repair Reference number, contact your

CAMPBELL SCIENTIFIC regional office. Please write the issued number clearly on the outside of

the shipping container and ship as directed.

For all returns, the customer must provide a “Statement of Product Cleanliness and

Decontamination” or “Declaration of Hazardous Material and Decontamination” form and

comply with the requirements specified in it. The form is available from your CAMPBELL

SCIENTIFIC regional office. Campbell Scientific is unable to process any returns until we receive

this statement. If the statement is not received within three days of product receipt or is

incomplete, the product will be returned to the customer at the customer’s expense. Campbell

Scientific reserves the right to refuse service on products that were exposed to contaminants that

may cause health or safety concerns for our employees.

Page 47

Safety

DANGER — MANY HAZARDS ARE ASSOCIATED WITH INSTALLING, USING, MAINTAINING, AND WORKING ON OR AROUND TRIPODS, TOWERS,

AND ANY ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES, ANTENNAS, ETC. FAILURE TO PROPERLY

AND COMPLETELY ASSEMBLE, INSTALL, OPERATE, USE, AND MAINTAIN TRIPODS, TOWERS, AND ATTACHMENTS, AND FAILURE TO HEED

WARNINGS, INCREASES THE RISK OF DEATH, ACCIDENT, SERIOUS INJURY, PROPERTY DAMAGE, AND PRODUCT FAILURE. TAKE ALL

REASONABLE PRECAUTIONS TO AVOID THESE HAZARDS. CHECK WITH YOUR ORGANIZATION'S SAFETY COORDINATOR (OR POLICY) FOR

PROCEDURES AND REQUIRED PROTECTIVE EQUIPMENT PRIOR TO PERFORMING ANY WORK.

Use tripods, towers, and attachments to tripods and towers only for purposes for which they are designed. Do not exceed design limits. Be

familiar and comply with all instructions provided in product manuals. Manuals are available at www.campbellsci.com. You are responsible for

conformance with governing codes and regulations, including safety regulations, and the integrity and location of structures or land to which

towers, tripods, and any attachments are attached. Installation sites should be evaluated and approved by a qualified engineer. If questions or

concerns arise regarding installation, use, or maintenance of tripods, towers, attachments, or electrical connections, consult with a licensed and

qualified engineer or electrician.

General

l Protect from over-voltage.

l Protect electrical equipment from water.

l Protect from electrostatic discharge (ESD).

l Protect from lightning.

l Prior to performing site or installation work, obtain required approvals and permits. Comply with all governing structure-height

regulations.

l Use only qualified personnel for installation, use, and maintenance of tripods and towers, and any attachments to tripods and towers.

The use of licensed and qualified contractors is highly recommended.

l Read all applicable instructions carefully and understand procedures thoroughly before beginning work.

l Wear a hardhat and eye protection, and take other appropriate safety precautions while working on or around tripods and towers.

l Do not climb tripods or towers at any time, and prohibit climbing by other persons. Take reasonable precautions to secure tripod and

tower sites from trespassers.

l Use only manufacturer recommended parts, materials, and tools.

Utility and Electrical

l You can be killed or sustain serious bodily injury if the tripod, tower, or attachments you are installing, constructing, using, or

maintaining, or a tool, stake, or anchor, come in contact with overhead or underground utility lines.

l Maintain a distance of at least one-and-one-half times structure height, 6 meters (20 feet), or the distance required by applicable law,

whichever is greater, between overhead utility lines and the structure (tripod, tower, attachments, or tools).

l Prior to performing site or installation work, inform all utility companies and have all underground utilities marked.

l Comply with all electrical codes. Electrical equipment and related grounding devices should be installed by a licensed and qualified

electrician.

l Only use power sources approved for use in the country of installation to power Campbell Scientific devices.

Elevated Work and Weather

l Exercise extreme caution when performing elevated work.

l Use appropriate equipment and safety practices.

l During installation and maintenance, keep tower and tripod sites clear of un-trained or non-essential personnel. Take precautions to

prevent elevated tools and objects from dropping.

l Do not perform any work in inclement weather, including wind, rain, snow, lightning, etc.

Maintenance

l Periodically (at least yearly) check for wear and damage, including corrosion, stress cracks, frayed cables, loose cable clamps, cable

tightness, etc. and take necessary corrective actions.

l Periodically (at least yearly) check electrical ground connections.

Internal Battery

l Be aware of fire, explosion, and severe-burn hazards.

l Misuse or improper installation of the internal lithium battery can cause severe injury.

l Do not recharge, disassemble, heat above 100 °C (212 °F), solder directly to the cell, incinerate, or expose contents to water. Dispose of

spent batteries properly.

WHILE EVERY ATTEMPT IS MADE TO EMBODY THE HIGHEST DEGREE OF SAFETY IN ALL CAMPBELL SCIENTIFIC PRODUCTS, THE CUSTOMER

ASSUMES ALL RISK FROM ANY INJURY RESULTING FROM IMPROPER INSTALLATION, USE, OR MAINTENANCE OF TRIPODS, TOWERS, OR

ATTACHMENTS TO TRIPODS AND TOWERS SUCH AS SENSORS, CROSSARMS, ENCLOSURES, ANTENNAS, ETC.

Page 48

Campbell Scientific regional offices

Australia

Location:

Phone:

Email:

Website:

Brazil

Location:

Phone:

Email:

Website:

Canada

Location:

Phone:

Email:

Website:

China

Location:

Phone:

Email:

Website:

Garbutt, QLD Australia

61.7.4401.7700

info@campbellsci.com.au

www.campbellsci.com.au

São Paulo, SP Brazil

11.3732.3399

vendas@campbellsci.com.br

www.campbellsci.com.br

Edmonton, AB Canada

780.454.2505

dataloggers@campbellsci.ca

www.campbellsci.ca

Beijing, P. R. China

86.10.6561.0080

info@campbellsci.com.cn

www.campbellsci.com.cn

France

Location:

Phone:

Email:

Website:

Germany

Location:

Phone:

Email:

Website:

India

Location:

Phone:

Email:

Website:

South Africa

Location:

Phone:

Email:

Website:

Vincennes, France

0033.0.1.56.45.15.20

info@campbellsci.fr

www.campbellsci.fr

Bremen, Germany

49.0.421.460974.0

info@campbellsci.de

www.campbellsci.de

New Delhi, DL India

91.11.46500481.482

info@campbellsci.in

www.campbellsci.in

Stellenbosch, South Africa

27.21.8809960

sales@campbellsci.co.za

www.campbellsci.co.za

Thailand

Location:

Phone:

Email:

Website:

UK

Location:

Phone:

Email:

Website:

USA

Location:

Phone:

Email:

Website:

Bangkok, Thailand

66.2.719.3399

info@campbellsci.asia

www.campbellsci.asia

Shepshed, Loughborough,

UK

44.0.1509.601141

sales@campbellsci.co.uk

www.campbellsci.co.uk

Logan, UT USA

435.227.9120

info@campbellsci.com

www.campbellsci.com

Costa Rica

Location:

Phone:

Email:

Website:

San Pedro, Costa Rica

506.2280.1564

info@campbellsci.cc

www.campbellsci.cc

Spain

Location:

Phone:

Email:

Website:

Barcelona, Spain

34.93.2323938

info@campbellsci.es

www.campbellsci.es

Loading...

Loading...