Page 1

RDP500 Remote Data Platform

Revision: 8/10

Copyright © 2007-2010

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The RDP500 REMOTE DATA PLATFORM is warranted by Campbell

Scientific, Inc. to be free from defects in materials and workmanship under

normal use and service for twelve (12) months from date of shipment unless

specified otherwise. Batteries have no warranty. Campbell Scientific, Inc.'s

obligation under this warranty is limited to repairing or replacing (at Campbell

Scientific, Inc.'s option) defective products. The customer shall assume all

costs of removing, reinstalling, and shipping defective products to Campbell

Scientific, Inc. Campbell Scientific, Inc. will return such products by surface

carrier prepaid. This warranty shall not apply to any Campbell Scientific, Inc.

products which have been subjected to modification, misuse, neglect, accidents

of nature, or shipping damage. This warranty is in lieu of all other warranties,

expressed or implied, including warranties of merchantability or fitness for a

particular purpose. Campbell Scientific, Inc. is not liable for special, indirect,

incidental, or consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company

serves your country.

To obtain a Returned Materials Authorization (RMA), contact Campbell

Scientific, Inc., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Declaration of Hazardous Material

and Decontamination” form and comply with the requirements specified in it.

The form is available from our website at

completed form must be either emailed to repair@campbellsci.com

435-750-9579. Campbell Scientific will not process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

www.campbellsci.com/repair

. A

or faxed to

Page 3

RDP500 Remote Data Platform

Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. Introduction and Theory of Operation .......................1

2. Unpacking RDP500......................................................1

2.1 Parts List ...................................................................................................1

2.1.1 Common Accessories......................................................................2

3. Installation....................................................................2

3.1 Rain Gauge Preparation............................................................................2

3.2 Internal Enclosure and Load Cell .............................................................6

3.3 Solar Panel and Grounding Wire Installation Instructions .....................11

3.4 Overload Protection Adjustments...........................................................13

4. Calibration Instructions ............................................14

5. Software......................................................................17

5.1 PC200W Software ..................................................................................17

5.2 DevConfig ..............................................................................................18

5.2.1 Sending OS with DevConfig ........................................................19

6. CompactFlash® (CF) .................................................21

7. RDP500 Wiring Diagram............................................ 22

8. Exploded View of RDP500 ........................................23

Appendices

A. Example CRBasic Program.................................... A-1

B. Updating RDP500 Software.................................... B-1

B.1 Introduction..........................................................................................B-1

B.2 Update Process.....................................................................................B-1

B.2.1 Back Up the RDP500 – Step 1 ...................................................B-1

B.2.2 Send the Operating System – Step 2 ..........................................B-1

i

Page 4

RDP500 Remote Data Platform Table of Contents

B.2.3 Send the CRBasic Program – Step 3 ......................................... B-2

B.2.4 Send the CD295/DataView II Configuration – Step 4 .............. B-2

B.3 Change Log ......................................................................................... B-3

C. Exchanging Internal Enclosure Mounting Bracket . C-1

C.1 Introduction ......................................................................................... C-1

C.2 Exchange Process................................................................................ C-1

Figures

3.1-1. Removal of the screws that hold on the pointer. ................................. 3

3.1-2. Releasing the tension spring................................................................ 3

3.1-3. Bolts that will be loosened to remove punch assembly and tape reel

assembly. ......................................................................................... 4

3.1-4. Adjustment of overload protection screw............................................ 4

3.1-5. Unscrewing zero adjustment knob. ..................................................... 5

3.1-6. Removal of helical spring.................................................................... 5

3.1-7. The parallelogram is stabilized with one hand while

the dashpot rod is unscrewed with the other.................................... 6

3.2-1. A gap of ~1/8” left under the bolt heads allows enclosure bracket to

slide under bolt head........................................................................ 7

3.2-2. Keyholes aligned over bolts. ............................................................... 7

3.2-3. Tightening bolts to attach enclosure to the base. ................................. 8

3.2-4. Properly installed internal enclosure. .................................................. 9

3.2-5. Flat blade screwdriver turns the gain adjusting screw....................... 10

3.2-6. Side view showing cable and arms horizontal

and overload protection screw. ...................................................... 10

3.3-1. Solar panel cable and grounding wire routed through compression

fitting of rain gauge base. .............................................................. 12

3.3-2. Solar panel cable routed through compression fitting of internal

enclosure. ....................................................................................... 12

3.4-1. Calibration weights properly placed in the center of the basin. ........ 13

4-1. Default Campbell Scientific screen on a CR1000KD. ...................... 14

4-2. The Precip_in field displayed on a CR1000KD ................................ 15

4-3. The Initial Setup menu on the CR1000KD. ...................................... 15

4-4. The Cal Results table displayed on a CR1000KD............................. 16

5.1-1. PC200W Setup/Connect Tab............................................................. 18

5.2-1. DevConfig CR1000 Facility.............................................................. 19

5.2-2. DevConfig OS download window for CR1000. ............................... 20

5.2-3. Dialog Box Confirming a Successful OS Download ........................ 20

ii

Page 5

RDP500 Remote Data Platform

1. Introduction and Theory of Operation

The RDP500 is a Remote Data Platform that provides a versatile measurement

system with data storage and control capabilities. When combined with the

load-cell option, it may be used to retrofit NWS Fischer-Porter rain gauges to

take unattended time-stamped readings.

This manual will walk you through the process of using an RDP500. To

accomplish this, you will need the RDP500 Remote Data Platform from

Campbell Scientific and the following tools:

Flat-head screwdriver (provided)

7/16 in. flat wrench (provided)

Dashpot rod removal tool (provided)

2. Unpacking RDP500

Verify that you have all of the equipment (see Section 2.1).

2.1 Parts List

To automate a Fischer Porter/Belfort weighing style rain gauge one of the Load

Cell options must be ordered. Option –SL p/n 21927 includes the standard

load cell configuration. Option –TL p/n 21928 includes the standard load cell

and PRT temperature sensor. Campbell Scientific does not use the PRT for

load cell temperature compensation. The load cell has proven to meet NWS

specs for the Fischer Porter weighing style rain gauge without temperature

compensation. The equipment included with the standard RDP500 system is

listed below.

(1) CR1000-XT-SW-NC

(1) CR1000 OR CR800 STACK MOUNTING KIT [p/n 17565]

(1) PS100-SW W/ 7 Ahr BATTERY

(1) CFM100-XT-SW

(2) CFMC64M COMPACT FLASH MEMORY CARD

(1) CD295 DATAVIEW II [p/n 18131]

(1) SP10 10 W SOLAR PANEL W/ 20ft CABLE & MOUNTING

HARDWARE

(1) 9-PIN FEMALE TO MALE SERIAL DATA CABLE [p/n 10873]

(1) WRENCH 7/16” THIN-HEAD [p/n 21924]

(3) DESICCANT ½ UNIT BAG [p/n 905]

(1) FLATHEAD SCREWDRIVER [p/n 1113]

(1) RDP500 ENCLOSURE FIBER GLASS 11.21 X 9.21 X 6.09 GRAY [p/n

21916]

1

Page 6

RDP500 Remote Data Platform

(1) RDP500 ENCLOSURE MOUNTING BRACKET [p/n 21921]

(1) RDP500 ENCLOSURE BACK PANEL [p/n 21922]

(2) NUT ¼”-20 [p/n1132]

(4) HRD SCREW 5/16-18 X .750 CAP HEX SS [p/n 4364]

(4) HRD SCREW #10-32 X .375 PAN PHILLIPS [p/n 6950]

(4) HRD WASHER 5/16 FLAT [p/n 4365]

(1) HRD CABLE ENTRY SEAL .110 - .260 ID PG7 W/NUT [p/n 8913]

(2) HRD CABLE ENTRY SEAL .187 - .312 ID [p/n 5771]

(1) FAB ENC HEYCO CONNECTOR PLUG .250 DIA [p/n 6688]

(1) FAB ENC CASE GROUND LUG SINGLE CONNECTOR [p/n 5449]

(1) HRD CABLE ENTRY SEAL .187 - .312 ID NPT [p/n 14286]

(1) HRD FITTING PIPE HEX REDUCING BUSHING, 1/2 MNPT X 3/8

FNPT [p/n 21923]

(2) HRD NUT #10-32 [p/n 23]

(1) GROUND CABLE [p/n 5725]

SUB ENCLOSURE GROUND CONNECTION

2.1.1 Common Accessories

3. Installation

3.1 Rain Gauge Preparation

The CR1000KD is ordered as an accessory. This unit allows technicians to

perform installation and calibration functions, but may not be useful to onsite

personnel.

1. Remove the upper hood of the rain gauge, empty and dry the bucket.

2. Lift off the lower housing and disconnect the internal wiring along with

any clamps and terminal strips.

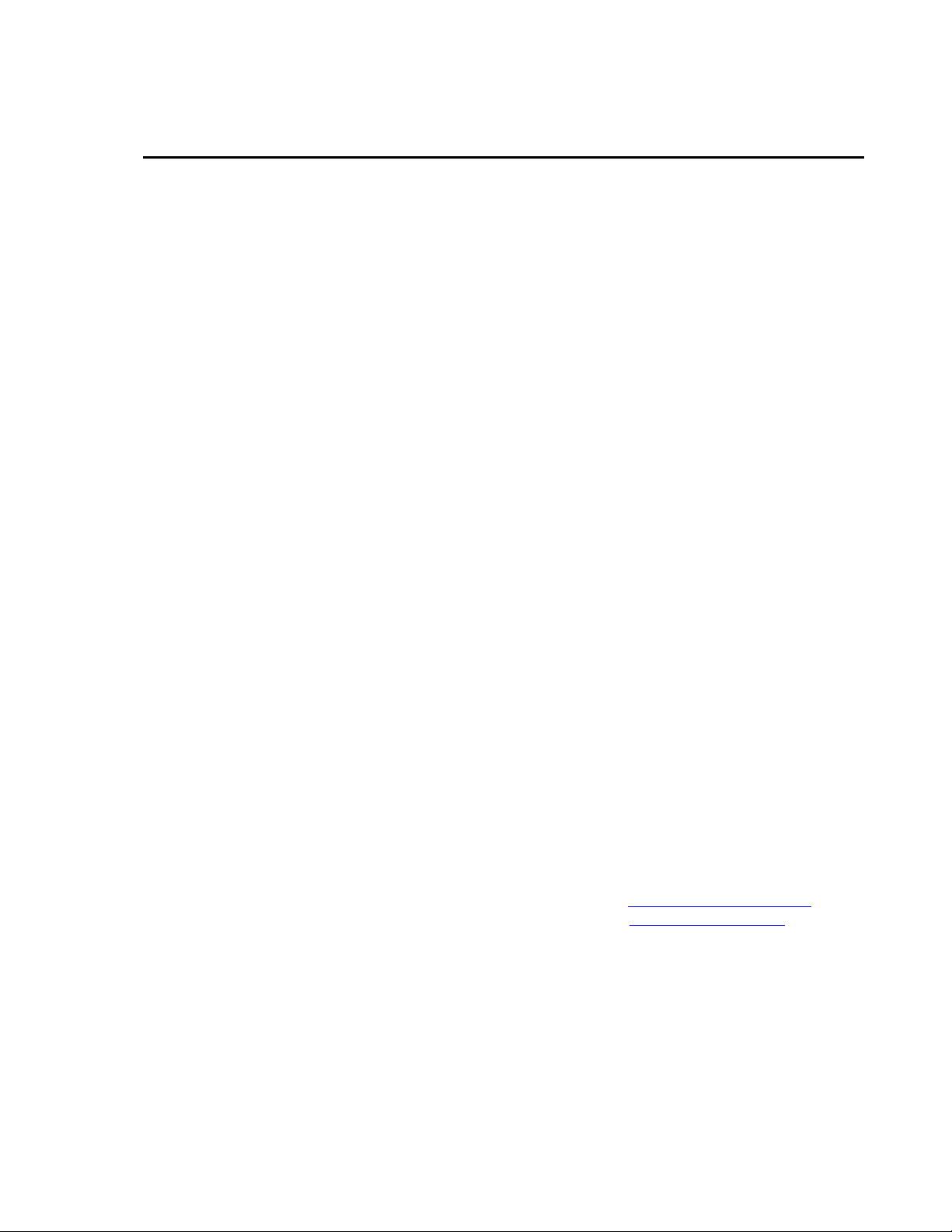

3. Unscrew the two screws holding the pointer from the front arm of the

parallelogram (Figure 3.1-1).

2

Page 7

RDP500 Remote Data Platform

Zero Adjustment Knob

Front Moving End of the

Parallelogram

FIGURE 3.1-1. Removal of the screws that hold on the pointer.

4. Remove the screw holding the eyelet end of the steel cable from the front

movable member of the parallelogram and release the cable. The flexures

of the parallelogram mechanism can be damaged if the front arm is side

loaded or moved beyond the specified travel.

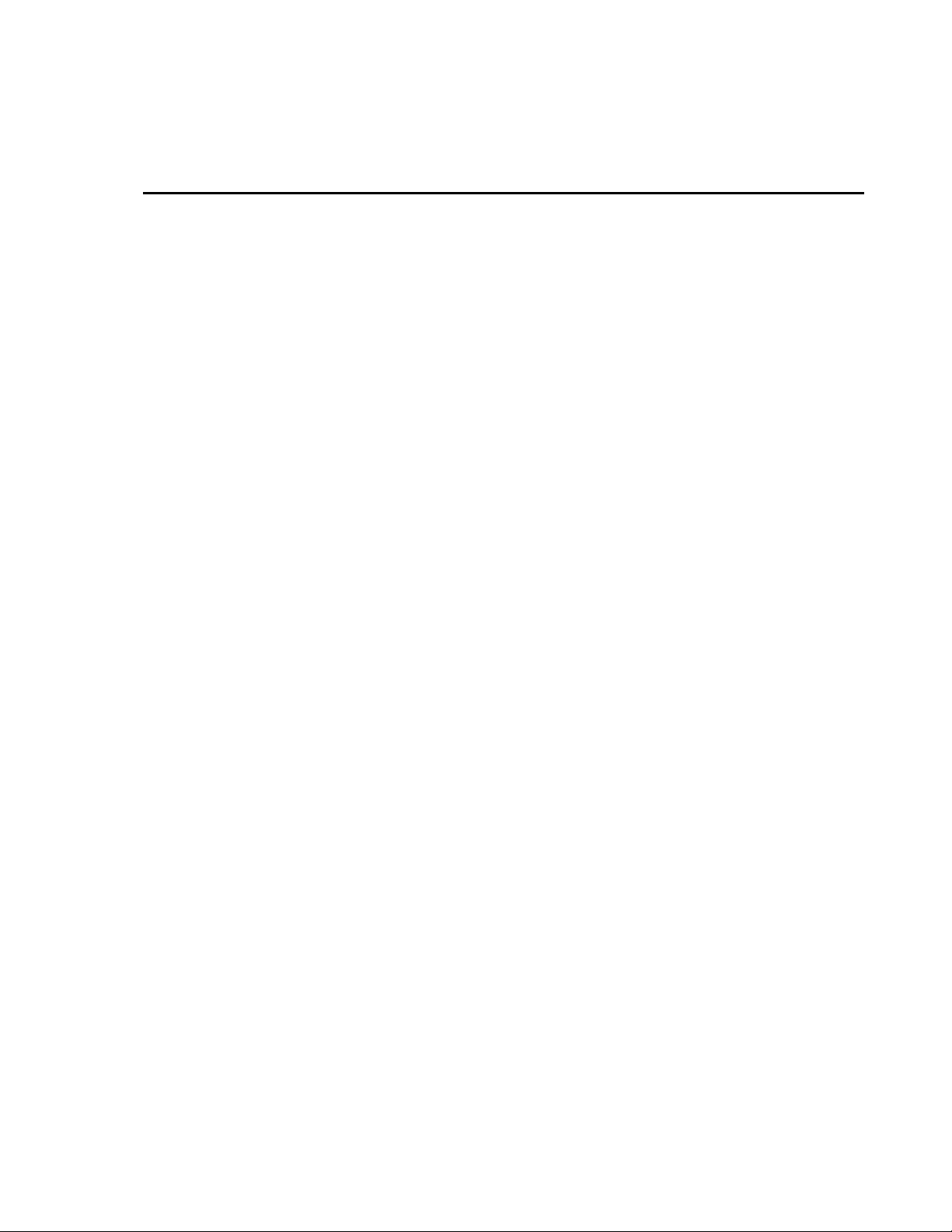

5. Release the tension spring from the movable support arm (Figure 3.1-2).

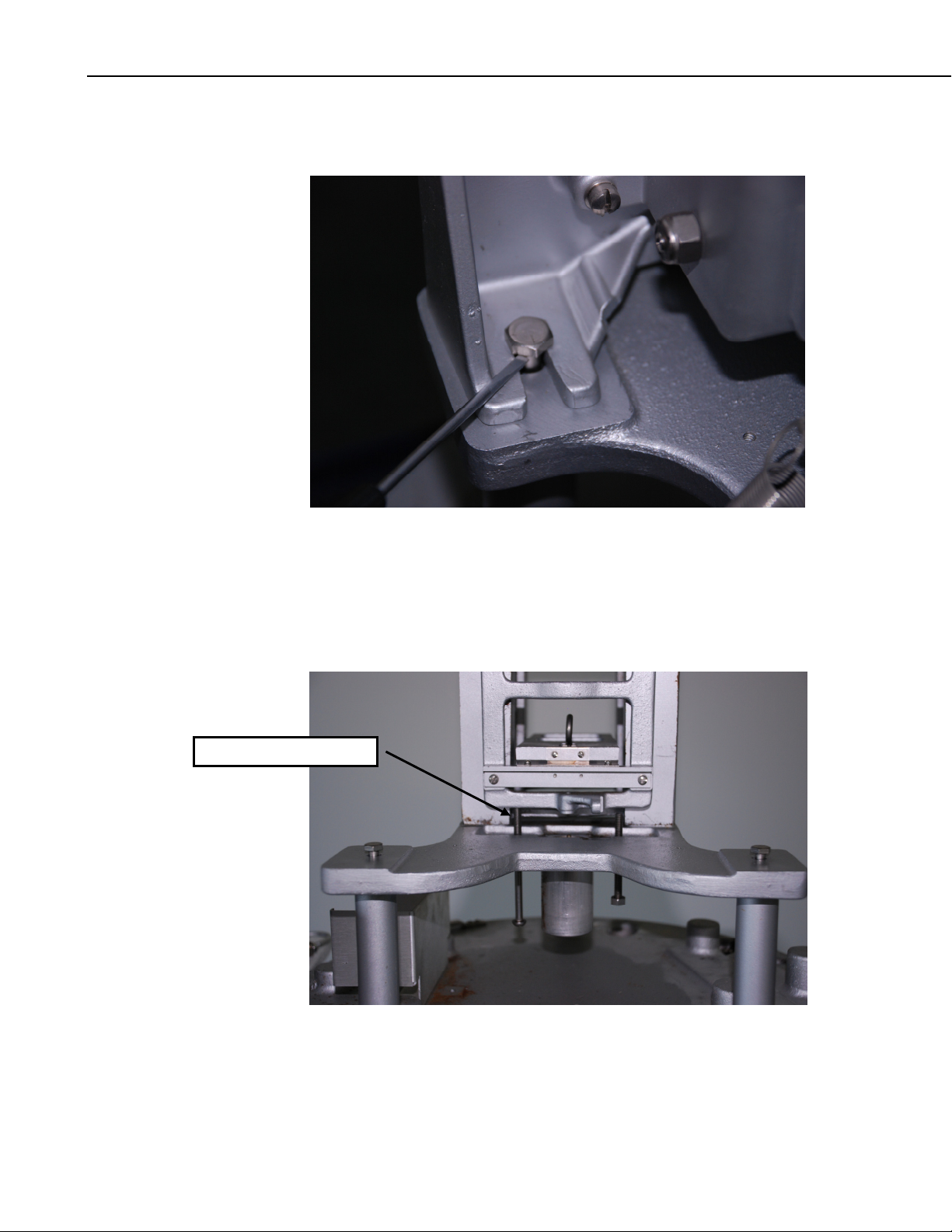

Vertical Flexures

Horizontal Flexures

FIGURE 3.1-2. Releasing the tension spring.

3

Page 8

RDP500 Remote Data Platform

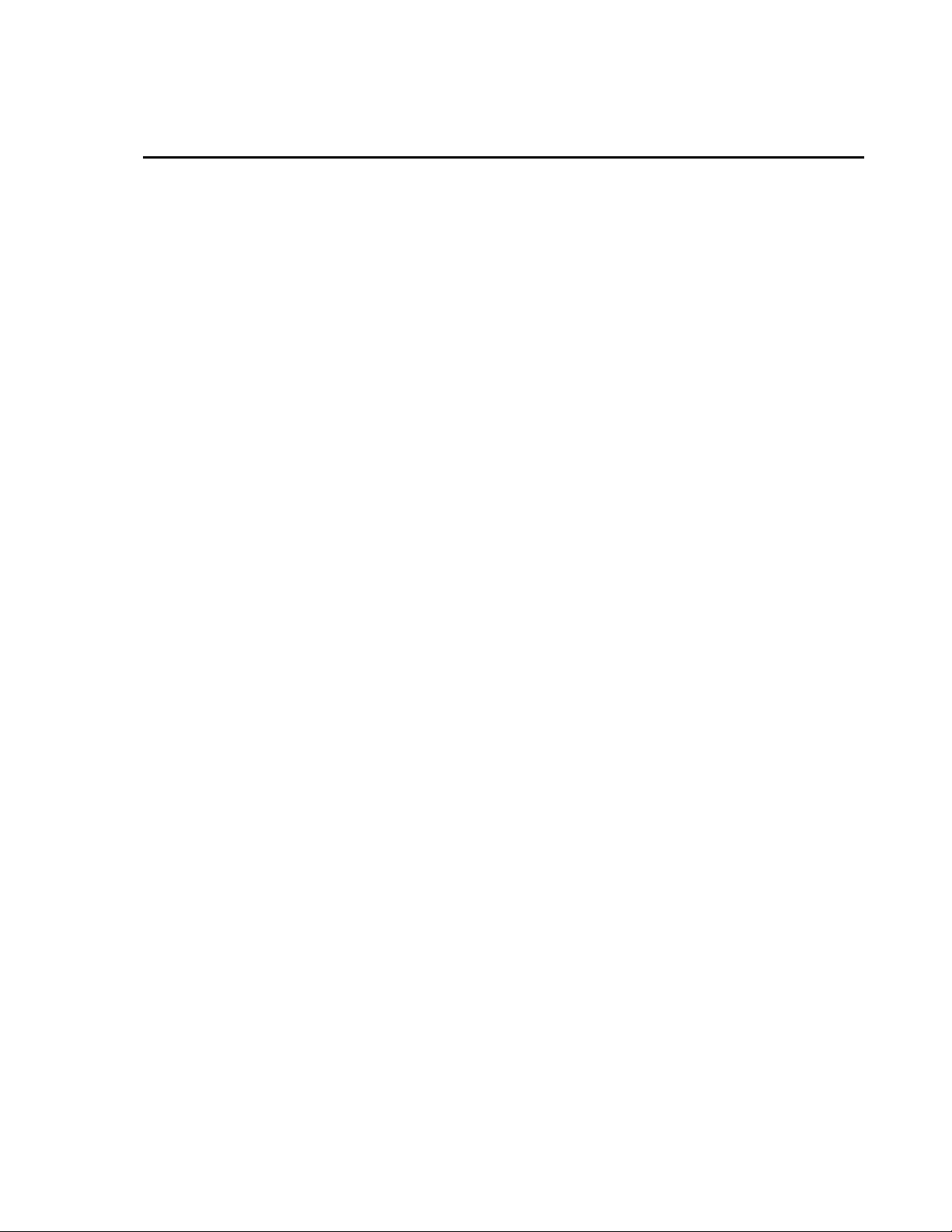

6. Take off the punch assembly and tape reel assembly (Figure 3.1-3).

FIGURE 3.1-3. Bolts that will be loosened to remove punch assembly

7. Using the overload protection screw, lift the front arm assembly until the

parallelogram arms are horizontal (Figure 3.1-4).

Overload Protection Screw

and tape reel assembly.

4

FIGURE 3.1-4. Adjustment of overload protection screw.

Page 9

RDP500 Remote Data Platform

8. Unscrew the zero adjustment knob (Figure 3.1-5) until the two load-

supporting helical springs can be taken out (Figure 3.1-6).

FIGURE 3.1-5. Unscrewing zero adjustment knob.

FIGURE 3.1-6. Removal of helical spring.

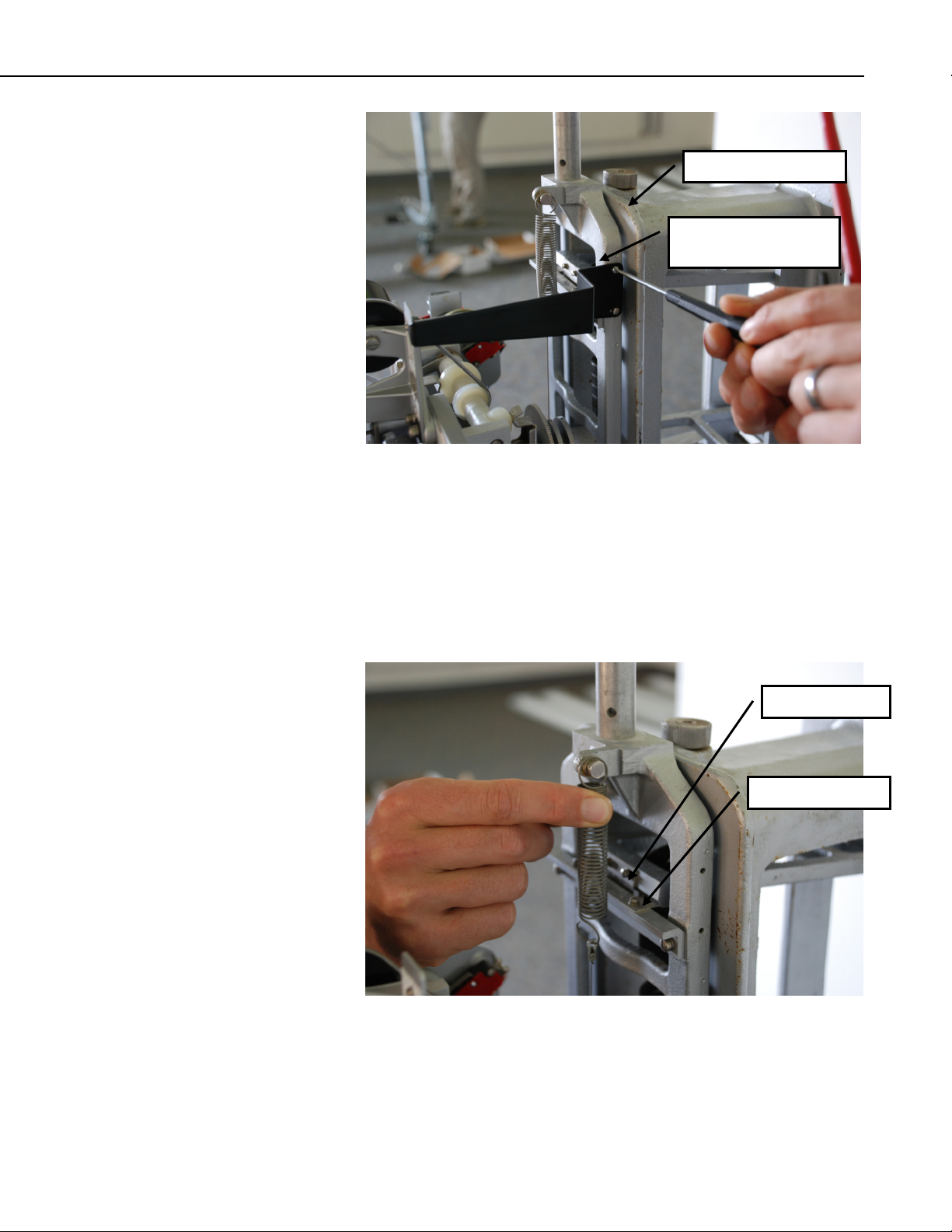

9. Unscrew the rod of the dashpot from the front arm and let it rest on the

bottom of the reservoir (Figures 3.1-6 and 3.1-7).

WARNING

The moving end of the parallelogram must be held in

place while unscrewing the rod, otherwise, the

parallelogram might be damaged.

5

Page 10

RDP500 Remote Data Platform

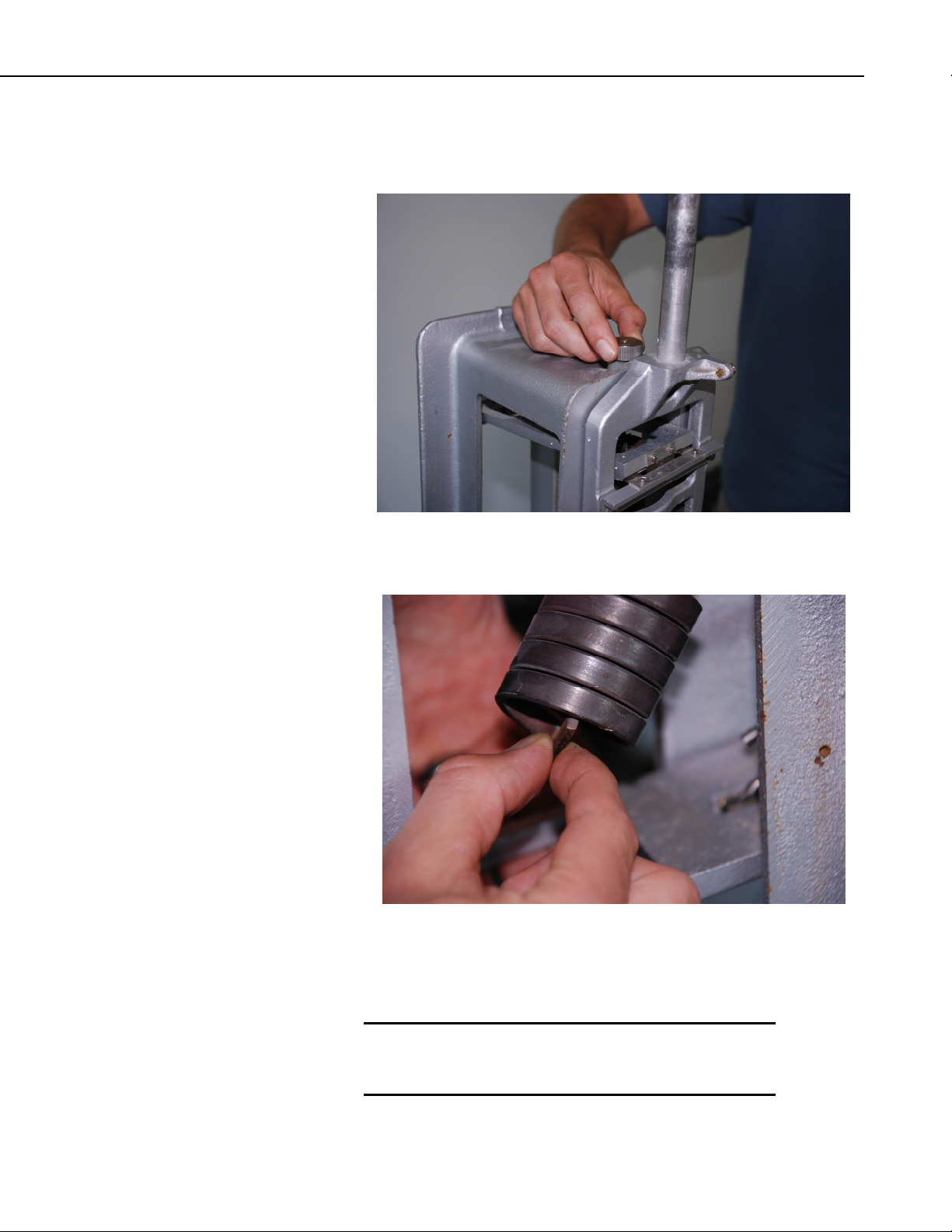

Dashpot Rod Removal Tool

Dashpot Rod

FIGURE 3.1-7. The parallelogram is stabilized with one hand while

the dashpot rod is unscrewed with the other.

10. Clean the inside of the instrument.

11. Inspect all flexures (leaf springs). There are two pair—one horizontal and

one vertical at each fulcrum of the parallelogram (see Figure 3.1-2).

12. Replace the ones that are damaged (broken, bent, kinked or cracked).

13. Check if all screws holding the flexures are tight. The measurement

accuracy, resolution, and stability of the instrument depend on the

parallelogram mechanism being properly secured.

3.2 Internal Enclosure and Load Cell

1. Unpack the enclosure, but leave the load cell taped to the top until the

enclosure is firmly attached to the base.

2. Re-install the two bolts that held the punch mechanism, but remove all

washers. Do not tighten the two bolts at this point; leave a gap of

approximately 1/8” under the bolt head to allow clearance for the

enclosure bracket to slide freely under the bolt head (Figure 3.2-1).

6

Page 11

RDP500 Remote Data Platform

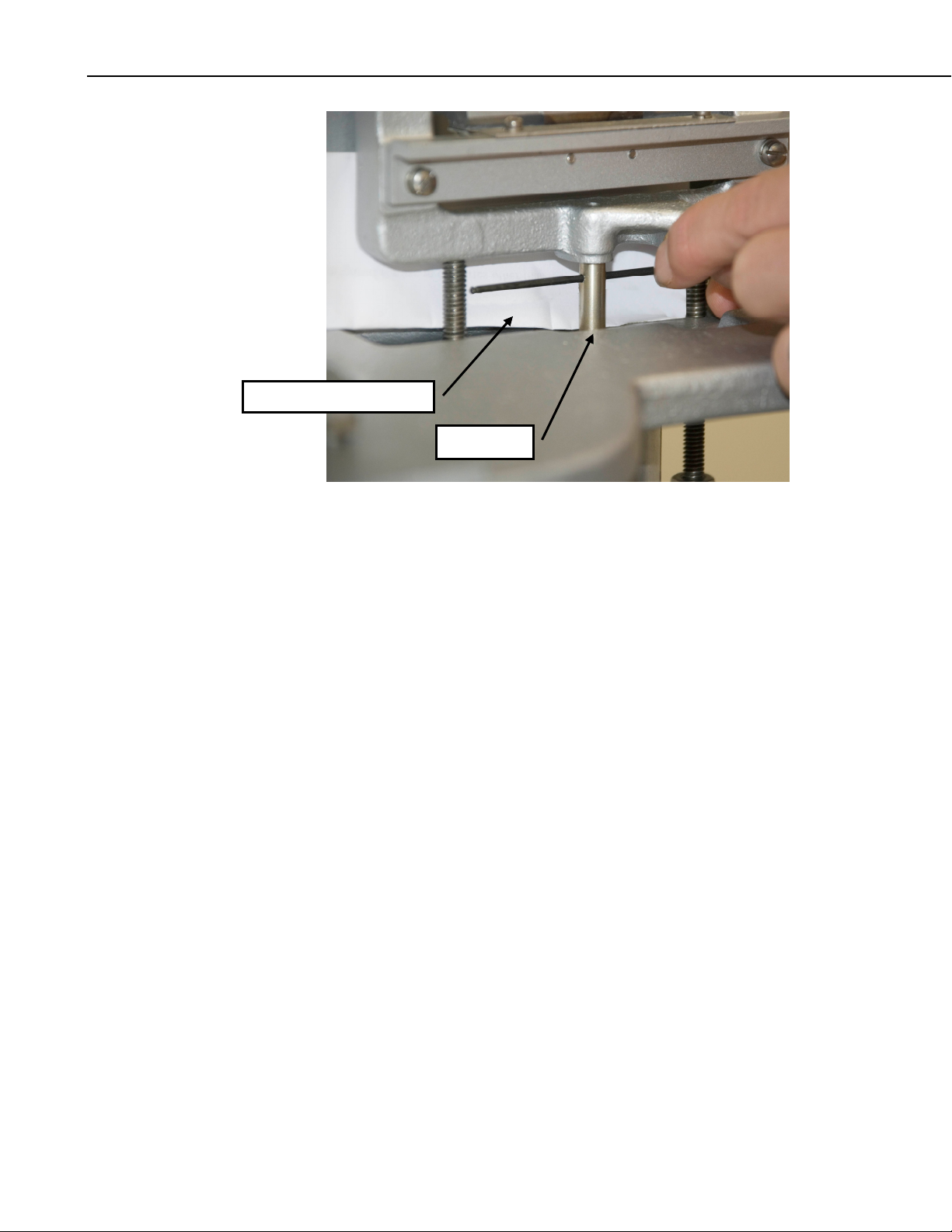

Gap Gap

FIGURE 3.2-1. A gap of ~1/8” left under the bolt heads allows

enclosure bracket to slide under bolt head.

3. Install the enclosure assembly onto the base.

4. Align the two keyholes in the bottom of the enclosure bracket over the two

bolts; then slide the enclosure to the right until the keyhole slots bottom

against the bolts (Figure 3.2.-2).

FIGURE 3.2-2. Keyholes aligned over bolts.

7

Page 12

RDP500 Remote Data Platform

5. Using the small 7/16” wrench provided, tighten the two bolts to firmly

attach the enclosure to the base. The two bolts are easily accessed through

the slots on either side of the enclosure bracket (Figure 3.2-3 and 3.2-4).

NOTE

Slight variability may exist among Fischer/Porter and Belfort

rain gauge bases. If the internal enclosure cannot be mounted so

that the rain gauge’s outer housing will not slide on, please

contact Campbell Scientific, Inc.

Thin Head Wrench

FIGURE 3.2-3. Tightening bolts to attach enclosure to the base.

8

Page 13

RDP500 Remote Data Platform

FIGURE 3.2-4. Properly installed internal enclosure.

Notice it is slightly shifted to the right.

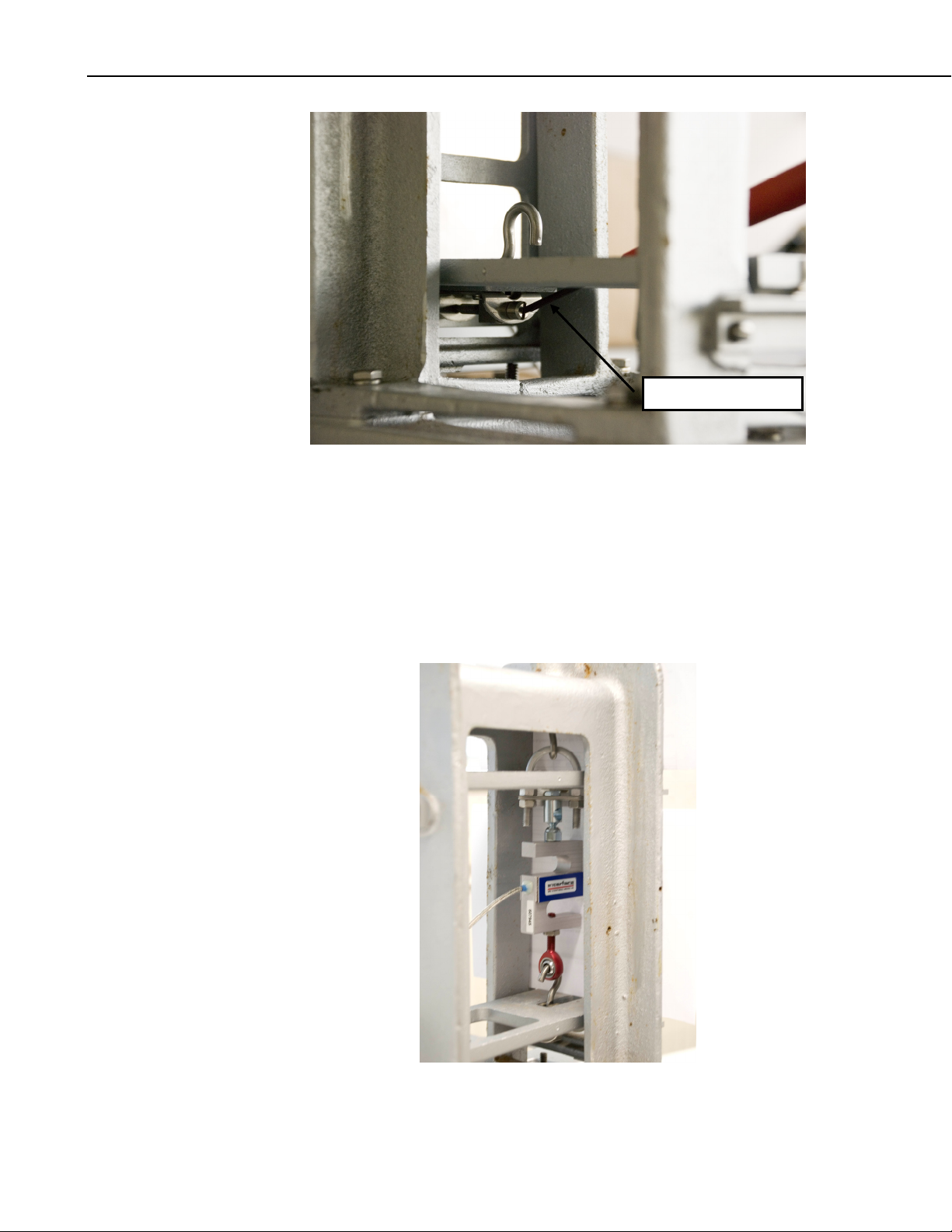

6. Once the datalogger enclosure is firmly mounted, remove the load cell

from the top of the enclosure.

7. Route the load cell from the backside of the support structure and suspend

it from the upper hook with the U-bolt bracket facing up.

8. Using a flat blade screwdriver, turn the gain adjusting screw to move the

lower hook all the way inward—towards the fixed end of the

parallelogram (Figure 3.2-5).

9

Page 14

RDP500 Remote Data Platform

Flat Blade Screwdriver

FIGURE 3.2-5. Flat blade screwdriver turns the gain adjusting screw.

9. Lift the front member of the parallelogram carefully and route the lower

hook through the eyebolt and slowly lower the front-end parallelogram.

10. Use the upper hook adjusting nut to shorten the distance between the two

hooks so that the weight of the moving end of the parallelogram is

supported by the load cell (Figure 3.2-6).

10

FIGURE 3.2-6. Side view showing cable and arms horizontal

and overload protection screw.

Page 15

RDP500 Remote Data Platform

For optimal operation, the arms of the parallelograms should be horizontal

and parallel to the base of the rain gauge. If the front end is too high,

lower the shipping bolt and unscrew the adjusting nut on the top hook. If

the front end is too low, then tighten the adjusting nut on the top hook.

11. Orient the U-bolt bracket so that it is perpendicular to the upper hook, the

eye bolt is perpendicular to the lower hook, and the load cell is parallel to

the arms of the parallelogram.

12. Check to see if the eyebolt is centered on the lower hook.

13. Strain relief the load cell cable with cable ties so that it comes straight and

horizontally from the load cell without applying any forces on it.

14. Power up the datalogger and look at the load cell readings on the CD295

data display while slightly pushing down on the front member of the

parallelogram. The reading “Precip_in” should increase when applying

vertical force and come back to its original value once the force is

removed.

3.3 Solar Panel and Grounding Wire Installation Instructions

The RDP500 includes a 10-watt solar panel, 15’ cable, and mounting hardware.

The user must supply a mounting pole (for attaching the solar panel)

compatible with U-bolts that have a 2.125" inside leg length and a 2.5"

centerline width.

The RDP500 is also outfitted with a grounding lug located on the outside of the

internal enclosure. The user must establish a good earth ground and route it to

the grounding lug to ensure proper operation.

1. Thread the brass hex-reducing bushing into the threaded port recessed in

the rain gauge base.

11

Page 16

RDP500 Remote Data Platform

2. Feed the solar panel cable and grounding wire through the plastic

compression fitting and brass hex bushing into the base of the rain gauge

(Figure 3.3-1).

FIGURE 3.3-1. Solar panel cable and grounding wire routed through

compression fitting of rain gauge base.

3. Route the solar panel cable through the compression fitting attached to the

internal enclosure and up into the PS100 charging source (Figure 3.3-2).

Grounding Wire

Load Cell Cable

Solar Panel Cable

12

FIGURE 3.3-2. Solar panel cable routed through compression fitting of

internal enclosure.

Page 17

4. Wire the red and black leads into the terminals labeled “charge” on the

PS100 (see wiring diagram at the end of the manual). The polarity of the

solar panel is not important.

5. Route the grounding wire to the grounding lug and secure with screw

provided. The instruments located inside the internal enclosure are already

routed to the grounding lug from the factory.

3.4 Overload Protection Adjustments

1. Install the catch basin tare in the instrument.

2. Carefully place all of the available calibration weights in the basin—

around 20000 grams (Figure 3.4-1).

RDP500 Remote Data Platform

FIGURE 3.4-1. Calibration weights properly placed in the

center of the basin.

3. If either load protection screw touches the front member of the

parallelogram, back them out until there is approximately 1/16 of an inch

distance (thickness of a penny) between the bottom of the front member

and the top end of the screw.

4. Wait for the load cell readings to stabilize and make a note of it.

5. Turn one of the shipping screws until it touches the bottom of the front

member by observing the corresponding change in the load cell reading.

6. Back up the screw slowly until all the weight is supported by the load cell

and the reading returns to the previously noted value. This will ensure that

the load cell will be able to measure a full basin of water, but applying any

larger force will cause the parallelogram to bottom out on the load

protection screws thus protecting the load cell from overloading.

13

Page 18

RDP500 Remote Data Platform

4. Calibration Instructions

A two-point calibration is adequate because the load cell is linear to within 2.5

grams (0.003” rain equivalent). This calibration procedure assumes the user

has a properly mounted, level, and fully functional RDP500 weighing style rain

gauge.

1. Begin by removing the top hood from the rain gauge and emptying,

drying, and cleaning out the rain gauge catch basin. Make sure proper

HAZMAT protocols are followed to dispose of the liquid in catch basins

containing oil or antifreeze.

2. Open the exterior rain gauge access door and the internal enclosure door to

gain access to the datalogger.

3. Insert the male end of the SC12 cable (provided) into the CS I/O port on

the wiring panel of the CR1000 datalogger and connect either female end

to the CR1000KD keyboard display module.

NOTE

A standard serial cable may be substituted for the SC12 cable.

Once powered, the CR1000KD will light up and display the default

Campbell Scientific screen.

14

FIGURE 4-1. Default Campbell Scientific screen on a CR1000KD.

If the CR1000KD times out and the screen goes blank, simply press any

key to re-activate the keyboard display. The Esc key is used to navigate

backwards through the custom menu.

Page 19

RDP500 Remote Data Platform

4. Carefully reinstall the catch basin and wait for 5 minutes until the

“Precip_in” field is stable. This delay is to allow post processing in the

datalogger program to sweep from one end of the measurement range to

another.

5. The “Precip_in” field can be viewed by pressing enter on the keyboard

display two times from its default Campbell Scientific start up screen

(Figure 4-2) or by pressing the right arrow key twice on the CD295

external display screen.

FIGURE 4-2. The Precip_in field displayed on a CR1000KD.

6. To initiate the calibration procedure, navigate to the “Initial Setup” menu

in the CR1000KD, where you will find “Step 1”, “Step 2”, and “Cal

Results” (Figure 4-3).

FIGURE 4-3. The Initial Setup menu on the CR1000KD.

15

Page 20

RDP500 Remote Data Platform

7. You must first tare the gauge by selecting “Tare Gauge” under “Step 1”.

This will zero out the rain gauge and result in a “Precip_in” value within

+/- 0.001” of 0. If the desired results are not achieved, ensure the catch

basin is properly mounted and that the rain gauge is level then repeat the

steps listed above to re-tare the rain gauge.

8. When the tare is complete, “Step 1” will show “Complete” and “Step 2”

will show “Ready” (almost instantaneously after selecting “Tare Gauge”).

9. Once “Step 2” shows “Ready”, the calibration weights should be carefully

placed in the center of the catch basin. For best results, the weights should

be between 8,000 and 20,000 grams. Maximum capacity is 20,000 grams.

10. Select the appropriate weight, in grams, from the pick list under “Step 2”.

11. “Step 2” will then show “In Progress” for approximately 5 minutes and

then show “Complete”.

12. Once complete, the gauge has been calibrated to measure Precip_in within

+/- 0.005” of the water inch equivalent of the calibration weight and hold

steady. The resolution of the load cell is better than 0.0005” and will

respond to slight changes in the applied load due to extraneous forces

(wind, vibrations or out of level shifts). You may now remove the cal

weights.

13. The RDP500 has a built-in calibration data table (Cal Results) where the

calibration results will be stored at the end of a calibration procedure. The

failure or success of the calibration will be noted in the Cal Results table.

The entire standard table lists the TS, RN, Success, Mult, Offset, Weight,

Post Cal Measured Weight, Cal Weight used.

16

FIGURE 4-4. The Cal Results table displayed on a CR1000KD.

Page 21

RDP500 Remote Data Platform

WARNINGS

5. Software

5.1 PC200W Software

Care should be taken when handling the catch basin

and the lower cover of the rain gauge. Sideways

pressure applied to the supporting rod will damage the

flexures resulting in a need for their replacement.

The load cell is sensitive to shocks and overloading.

Handle with care.

To achieve the best possible performance, the rain

gauge must be level and firmly secured.

The RDP500 includes a datalogger pre-programmed to make the measurements

(see Appendix A). PC200W software is used to retrieve the measurements.

The operating system of the CR1000 may be updated using our Device

Configuration Utility (DevConfig).

Obtain and install PC200W. PC200W is available on the Campbell Scientific

Resource CD or at www.campbellsci.com.

When PC200W is first opened, the EZSetup Wizard is launched. Click the

Next button and follow the prompts to select the CR1000, the COM port on

the computer that will be used for communications, 115200 baud, and PakBus

Address 1. When prompted with the option to Test Communications, click

the Finish button.

If a datalogger was not added with the Wizard, click the + (add) button to

invoke the Wizard.

After exiting the EZSetup wizard, the Clock / Program tab is presented, as

shown in Figure 5.1-1. Current Datalogger Profile, Clock, and Datalogger

Program features are integrated into this tab. Tabs to the right are used to

select Monitor Data and Collect Data options. Buttons to the right of the tabs

are used to run Split, View, and Short Cut applications.

17

Page 22

RDP500 Remote Data Platform

FIGURE 5.1-1. PC200W Setup/Connect Tab

5.2 DevConfig

DevConfig (Device Configuration Utility) is the preferred tool for configuring

the CR1000. It is made available as part of LoggerNet, PC400, RTDAQ, and

at www.campbellsci.com. Most settings can also be entered through the

CR1000KD.

Features of DevConfig include:

• Communicates with devices via direct RS-232 only.

• Sends operating systems to supported device types.

• Sets datalogger clocks and sends program files to dataloggers.

• Identifies operating system types and versions.

• Provides a reporting facility wherein a summary of the current

configuration of a device can be shown, printed or saved to a file. The file

can be used to restore settings, or set settings in like devices.

• Provides a terminal emulator useful in configuring devices not directly

supported by DevConfig’s graphical user interface.

• Shows Help as prompts and explanations. Help for the appropriate

settings for a particular device can also be found in the user’s manual for

that device.

18

• Updates from Campbell Scientific's web site.

Page 23

RDP500 Remote Data Platform

As shown in Figure 5.2-1, the DevConfig window is divided into two main

sections: the device selection panel on the left side and tabs on the right side.

After choosing a device on the left, choose from the list of the serial ports

(COM1, COM2, etc.) installed on the PC. A selection of baud rates is offered

only if the device supports more than one baud rate. The page for each device

presents instructions to set up the device to communicate with DevConfig.

Different device types offer one or more tabs on the right.

FIGURE 5.2-1. DevConfig CR1000 Facility

When the Connect button is pressed, the device type, serial port, and baud rate

selector controls become disabled and, if DevConfig is able to connect to the

CR1000, the button will change from "Connect" to "Disconnect".

5.2.1 Sending OS with DevConfig

The CR1000 is shipped with the operating system pre-loaded. However, OS

updates are made available at www.campbellsci.com and can be sent to the

CR1000. Figure 5.2-2 and Figure 5.2-3 show DevConfig windows displayed

during the OS download process.

CAUTION

Sending an operating system with DevConfig will erase all

existing data and reset all settings to factory defaults.

19

Page 24

RDP500 Remote Data Platform

FIGURE 5.2-2. DevConfig OS download window for CR1000.

The text at right gives the instructions for sending the OS. Follow these

instructions.

When the Start button is clicked, DevConfig offers a file open dialog box that

prompts for the operating system file (*.obj file). When the CR1000 is then

powered-up, DevConfig starts to send the operating system.

When the operating system has been sent, a message dialog will appear similar

to the one shown in Figure 5.2-3.

20

FIGURE 5.2-3. Dialog Box Confirming a Successful OS Download

The information in the dialog helps to corroborate the signature of the

operating system sent.

Page 25

RDP500 Remote Data Platform

6. CompactFlash

CAUTION

NOTE

®

(CF)

When installing

off CR1000 po

Removing a card from the CFM100 while the CF card is

active can cause g

the card. Always press the button to disable the card for

removal and wait for the green LED before switching off

the CR1000 power.

To prevent losing data, collect data from the CF card

before sending a p

program is sent to the datalogger all data on the CF card is

erased.

The CFM100 connects to the CR1000 Peripheral Port. It has a slot for a Type I

or Type II CF card. A CF card expands the CR1000’s storage capacity. A

maximum of 30 data tables can be created on a CF card.

CardConvert software, included with LoggerNet,

RTDAQ, and PC200W support software, converts CF card data

to the standard Campbell Scientific data format.

or removing the CFM100 module, first turn

wer.

arbled data and can actually damage

rogram to the datalogger. When a

PC400,

When a data table is sent to a CF card, a data table of the same name in SRAM

is used as a buffer for transferring data to the card. When the card is present,

the status table will show the size of the table on the card. If the card is

removed, the size of the table in SRAM will be shown.

When a new program is compiled that sends data to the CF card, the CR1

checks if a card is present and if the card has adequate sp

If the card has adequate space, the tables will be allocated and the CR1000 wil

start storing data to them. If there is no card or if there is not enough space, the

CR1000 will warn that the card is not being used and will run the program,

storing the data in SRAM only. When a card with enough available memory is

inserted the CR1000 will create the data tables on the card and store the data

that is accumulated in SRAM.

The CR1000 accepts cards formatted as FAT or FAT32. Older CR1000

operating systems formatted ca

systems always format cards as FAT32.

rds as FAT or FAT32. Newer operating

ace for the data tables.

000

l

21

Page 26

RDP500 Remote Data Platform

7. RDP500 Wiring Diagram

22

16

Page 27

8. Exploded View of RDP500

RDP500 Remote Data Platform

23

Page 28

RDP500 Remote Data Platform

24

Page 29

Appendix A. CRBasic Program for Version 18

'CR1000 Series Datalogger

'FISCHER & PORTER/BELFORT WEIGHING RAINGAUGE RETROFIT.

'VERSION: RDP500_V18.CR1

'Note: The PRT is not needed to achieve the specification, however it is included in this

' system in an effort to create a sensor-temperature dataset that can be analized by

' any questioning party.

'Change Log:

' 2008-08-08

' Program released for manual

' 2010-04-20

' Changed data record interval from 5 min to 15 min.

' Added rounding of precip to 1/100th of inch

' Expanded information available through keypad display

' Added PreserveVariables program modifier

'-----------------------------------------------------------------------------------'Wiring Setup.

'S shape load cell INTERFACE SSM-AJ-100

'Red + --- V_Ex1

'Black - --- V_G

'Green Sig + --- 1H

'White Sig - --- 1L

'Shield --- V_G

'PRT

'Red --- TIM_G

'ReD --- TIM_H

'TIM

'H --- 7H

'L --- 7L

'G --- V_G

'Black --- V_Ex2

PreserveVariables

'Declare Public Variables

Public PTemp_C 'degrees. Temperature of datalogger wiring panel

Public PTemp_F 'degrees. Temperature of datalogger wiring panel

Public batt_volt 'Volts. external power supply voltage

Public PRT_raw 'millivolts. Raw mV reading from PRT

Public PRT_C 'deg C. PRT temp in Celcius

Public PRT_F 'deg F. PRT temp in Fahrenheit

Public LC_mV 'millivolts. Raw mV reading from the load sell

Public LC_mV_Avg 'millivolts. Averaged raw mV reading from the load cell

Public Lc_mV_Ofst 'millivolts. Load cell mV offset with no load (TARE)

Public LC_mV_Diff 'millivolts. Absolute difference between LC_mV_Avg and LC_mV

Public mVtoGram 'grams/millivolts. Conversion factor

Public LC_gr 'grams. weight applied to load cell

A-1

Page 30

Appendix A. CRBasic Program for Version 18

Public PrecipF_in 'inches. Precipitation amount in inches

Public Precip_in 'inches. Rrecipitatoin amount in inches rounded to nearest 1/100th

Public FifteenMinAccum 'inches. Precipitation Accumulation Over 15 min period

Public TotFAccum 'inches. Total precip accumulation

Public TotAccum 'inches. Total precip accumulation rounded to nearest 1/100th

Public RecordAccumulation As Boolean

Public CalWeight_gr 'Weight in Grams of Calibration weight used.

Public TareGauge As String * 32

Public TriggerCalibration As String * 32

Public Cal_Result As String * 32

Public CalibrateNow

Public RecordCalibration As Boolean

Public TimeStampOfLastCal As String * 32

Public CalibrationTimer As Long 'This tracks the number of seconds the calibration

routine is running.

Public CalTime As Long 'This is the number of seconds to run the

calibration.

Public PostCalTimer As Long 'This tracks the number of seconds since the

calibration routine finished.

Public Time As String * 31

Dim StaName As String * 31

Dim OSVer As String * 31

Dim StartTime As String * 31

Dim ProgName As String * 31

'Declare units associated with public variables.

Units PTemp_C=degC

Units PTemp_F=degF

Units batt_volt=volts

Units LC_mV=mV

Units Lc_mV_Ofst=mV

Units LC_mV_Avg=mV

Units LC_gr=gr

Units PrecipF_in=in

Units Precip_in=in

Units FifteenMinAccum=in

Units TotFAccum=in

Units TotAccum=in

Units PRT_raw=mV

Units PRT_C=degC

Units PRT_F=degF

''Declaration of constants:

'Timer Constants so I can keep track of what timer is for what.

Const CalTim = 2

Const PostCalTim = 3

'Define Data Tables

DataTable (Rain_15m,1,-1)

DataInterval (0,15,Min,10)

CardOut (0,35136) ' (366*24*60)/15

Minimum (1,batt_volt,FP2,False,False)

Sample (1,Precip_in,IEEE4)

Sample (1,TotAccum,IEEE4)

Average (1,PRT_F,IEEE4,False)

Average (1,PTemp_F,FP2,False)

EndTable

A-2

Page 31

Appendix A. CRBasic Program for Version 18

DataTable (Accum_15m,1,96)

TableHide

DataInterval (0,15,Min,10)

Sample (1,PrecipF_in,IEEE4)

EndTable

DataTable (Rain_1h,1,720)' 30 days

DataInterval (0,60,Min,10)

Sample (1,TotAccum,IEEE4)

Sample (1,PrecipF_in,IEEE4)

EndTable

DataTable (Rain_1d,1,30)' 30 days

DataInterval (0,1440,Min,10)

Sample (1,TotAccum,IEEE4)

Sample (1,PrecipF_in,IEEE4)

EndTable

DataTable (CalData,1,5000)'Table used to record calibration data

Sample(1,Cal_Result,String)

Sample(1,mVtoGram,IEEE4)

Sample(1,Lc_mV_Ofst,IEEE4)

Sample (1,LC_gr,IEEE4)

Sample(1,CalWeight_gr,IEEE4)

EndTable

'Begin custom menu instructions.

DisplayMenu ("----- RDP500 -----",-1)

'To view current rain values

SubMenu (" Current Precip")

DisplayValue (" Precip Inches",Precip_in)

EndSubMenu

'To view key system params

SubMenu (" Status")

DisplayValue (" Time", Time)

DisplayValue (" Stat Name",StaName)

DisplayValue (" Supply Volt",batt_volt)

DisplayValue (" Low 12V Cnt",Status.Low12VCount)

DisplayValue (" Inten Batt",Round(Status.LithiumBattery,2))

DisplayValue (" Panel Temp",Round(PTemp_F,2))

DisplayValue (" OS Version",OSVer)

DisplayValue (" Serial Num",Status.SerialNumber)

DisplayValue (" Prog Name",ProgName)

DisplayValue (" Prog Start",StartTime)

EndSubMenu

'To initialize a gauge

SubMenu (" Initial Setup")

MenuItem(" Step 1",TareGauge) 'Item for Submenu

MenuPick (Tare Gauge)

MenuItem (" Step 2 ",TriggerCalibration)

MenuPick (3289.0,4111.0,6578.0,7400.0,8222.0)

SubMenu (" Cal Results")

DisplayValue("Cal Result ",Cal_Result)

DisplayValue("Time ",TimeStampOfLastCal)

DisplayValue("Multiplier ",CalData.mVtoGram(1,1))

DisplayValue("Offset ",CalData.Lc_mV_Ofst(1,1))

DisplayValue("Weight ",CalData.LC_gr(1,1))

DisplayValue("Cal Weight Used",CalData.CalWeight_gr(1,1))

EndSubMenu

EndSubMenu

EndMenu 'End of custom menu.

A-3

Page 32

Appendix A. CRBasic Program for Version 18

'Main Program

BeginProg

'If an old offset exists in a prior datarecord, then it will be loaded. Otherwise,

'a default value of -0.260829 will be loaded.

Lc_mV_Ofst = CalData.Lc_mV_Ofst(1,1)

If Lc_mV_Ofst = NaN Then

Lc_mV_Ofst = -0.260829

EndIf

'Factory cal = 1/(3.31 mV/V*2.5v/100lbs/435.59237gr/lb) [gr/mV]

'Calibrated with weight and accounting for the leverage amplification

'If an old mV to Gram conversiong exists in a prior datarecord, then it will be loaded.

'Otherwise, a default value of -0.260829 will be loaded.

mVtoGram = CalData.mVtoGram(1,1)

If mVtoGram = NaN Then

mVtoGram = 11139.15

EndIf

CalTime = 180 'Number of seconds to run the calibration routine

TareGauge = "Ready"

TriggerCalibration = "Tare First"

'Begin Main Program.

Scan (200,mSec,1000,0) '5Hz scan rate.

'Measure temp of wiring panel and voltage of power supply

PanelTemp (PTemp_C,250)

PTemp_F = PTemp_C * 1.8 + 32

Battery (batt_volt)

'Measure load cell

BrFull (LC_mV,1,mV7_5,1,Vx1,1,2500,True ,True ,0,_60Hz,1,0)

AvgRun(LC_mV_Avg,1,LC_mV,750) 'compute 2.5 min running average

LC_mV_Diff = ABS(LC_mV_Avg - LC_mV)

'Tare the raingage (measure electronics offset with no load). This displays as Step 1:

If TareGauge = "Tare Gauge" Then

If LC_mV_Diff < 0.001 Then

Lc_mV_Ofst=LC_mV_Avg

TareGauge = "Complete"

TriggerCalibration = "Ready"

RecordAccumulation = FALSE

RecordCalibration = FALSE

CalibrationTimer = Timer(CalTim,Sec,3)

PostCalTimer = Timer(PostCalTim,Sec,3)

Else

TareGauge = "Failed Equalizing"

EndIf

EndIf

If TareGauge <> "Complete" AND TareGauge <> "In Progress" Then

If LC_mV_Diff > 0.001 AND TareGauge <> "Failed Equalizing" Then

TareGauge = "Equalizing"

ElseIf LC_mV_Diff <= 0.001 Then

TareGauge = "Ready"

EndIf

EndIf

A-4

Page 33

Appendix A. CRBasic Program for Version 18

'Subtracts electronics offset and convert to grams assuming 9.81 m/s2

acceleration due to gravity.

LC_gr=(LC_mV_Avg-Lc_mV_Ofst)*mVtoGram

'Calibrate the raingage with calibration weights in the gauge. This displays

as Step 2:

If TriggerCalibration = "3289.0" OR TriggerCalibration = "4111.0" OR

TriggerCalibration = "6578.0" OR TriggerCalibration = "7400.0" OR TriggerCalibration

= "8222.0" Then

CalibrateNow = TRUE 'enable calibration process

CalWeight_gr = TriggerCalibration '

TriggerCalibration = "In Progress"

Cal_Result = "In Progress"

CalibrationTimer = Timer(CalTim,Sec,2) 'reset and start calibration timer

PostCalTimer = Timer(PostCalTim,Sec,3) 'stop and reset post calibration timer

EndIf

CalibrationTimer = Timer(CalTim,Sec,4) 'read calibration timer

PostCalTimer = Timer(PostCalTim,Sec,4) 'read postcalibration timer

If TareGauge = "Complete" AND CalibrateNow AND CalibrationTimer<CalTime Then

'tare is completed and in the middle of the calibration process

mVtoGram = CalWeight_gr/(LC_mV_Avg-Lc_mV_Ofst) 'calculate mVtoGram multiplier

ElseIf TareGauge <> "Complete" AND CalibrateNow Then

'tare has NOT been completed and calibration process has been started

CalibrateNow = FALSE 'stop calibration process

Cal_Result = "Cal Failed" 'flagged as failed because we didn't tare first

CallTable CalData 'record the event

TareGauge = "Repeat Step 1" 'prompt user to tare

TriggerCalibration = "Repeat Step 1" 'prompt user to tare

RecordAccumulation = TRUE 'enable recording of accumulation

CalibrationTimer = Timer(CalTim,Sec,3) 'stop and reset calibration timer

ElseIf CalibrationTimer>=CalTime AND RecordCalibration = FALSE Then

'calibration is complete and calibration recording is not flagged

CalibrateNow = FALSE 'disable calibration process

Cal_Result = "Cal Succeeded" 'note success

CallTable CalData 'save calibration data

TareGauge = "Complete" 'note completion

TriggerCalibration = "Complete" 'note completion

RecordAccumulation = TRUE 'enable recording of accumulation

RecordCalibration = TRUE 'record calibration information

CalibrationTimer = Timer(CalTim,Sec,3) 'stop and reset calibration timer

PostCalTimer = Timer(PostCalTim,Sec,2) 'reset and start post calibration timer

TimeStampOfLastCal = CalData.TimeStamp(1,1) 'note time of last calibration record saved

ElseIf PostCalTimer>=60 Then

'post calibration period is done

'it seems that this post cal period is simple used for refreshing keyboard

interface - note completion, then note ready

RecordCalibration = FALSE 'enable calibration recording

TareGauge = "Ready" 'notify ready state

TriggerCalibration = "Tare First" 'notify ready state

PostCalTimer = Timer(PostCalTim,Sec,3) 'stop and reset post cal timer

EndIf

'Convert weight to depth.

PrecipF_in=0.001214*LC_gr

Precip_in = Round (PrecipF_in,2) 'round to nearest 1/100 of inch for storage

A-5

Page 34

Appendix A. CRBasic Program for Version 18

'Measure PRT and convert to C and Deg F.

'The PRT was originally included so that we could perform temperature corrections on

'the load cell. However, after several cycles in the temperature chamber, it was found

'that a temperature correction was not necessicary. We left the PRT on the sensor

'so anyone who wanted to could verify our findings.

BrHalf3W (PRT_raw,1,mV250C,13,Vx2,2,2500,True,0,250,10,0)

PRT (PRT_C,1,PRT_raw,1.0,0)

PRT_F=((PRT_C)*1.8)+32

If TimeIntoInterval (0,15,Min) AND RecordAccumulation Then

If Accum_15m.PrecipF_in(1,1) <> NAN Then

FifteenMinAccum = PrecipF_in - Accum_15m.PrecipF_in(1,1)

Else

FifteenMinAccum = PrecipF_in '- 0 ''subtracting zero

EndIf

If FifteenMinAccum < 0.002 Then 'Register only if the difference is more than 0.002"

'the assumption here is that the load cell will drift less than the accumulation.

FifteenMinAccum=0

EndIf

TotFAccum = TotFAccum + FifteenMinAccum

TotAccum = Round (TotFAccum,2)

CallTable (Accum_15m)

EndIf

'Call Data Tables to output data.

CallTable (Rain_15m)

CallTable (Rain_1h)

CallTable (Rain_1d)

If PrecipF_in <0.002 Then PrecipF_in = 0

If Precip_in<0.002 Then Precip_in = 0

NextScan

SlowSequence

Scan (1,Sec,3,0)

Time = Status.TimeStamp(1,1)

StaName = Status.StationName

OSVer = Status.OSVersion

ProgName = Status.ProgName

StartTime = Status.StartTime(1,1)

NextScan

EndProg

A-6

Page 35

Appendix B. Updating RDP500 Software

B.1 Introduction

During the lifetime of the RDP500, software updates and enhancements may

become available. The user can take advantage of those updates by completing

a few simple steps outlined below.

B.2 Update Process

The update process can be performed using Campbell Scientific's free software

package PC200W. Depending on the update made available, the end user may

need to execute one or more of the following steps.

1. Back up the RDP500

2. Send the Operating System

3. Send the CRBasic Program

4. Send the CD295/DataView II Configuration

B.2.1 Back Up the RDP500 – Step 1

The user should backup the RDP500 program and data before proceeding with

a software update. The following steps (2 and 3) will erase the settings and data

storage.

Establish communications with the CR1000 by following Section 5.1

(PC200W Software).

Retrieve the program on the CR1000 by selecting the Clock / Program tab and

clicking the Retrieve Program button. Make note of where the retrieved

program is saved.

Collect all RDP500 data by ejecting the removable Compact Flash card or

using the PC200W software. If using PC200W, select the Collect Data tab,

choose New data from datalogger, and click the Collect button.

B.2.2 Send the Operating System – Step 2

Core enhancements will be made available through the update of the CR1000

operating system. If the CR1000 operating system is updated, step 3 is

required.

Device Configuration Utility is available through the main toolbar of PC200W.

With Device Configuration Utility launched, send the CR1000 operating

system by following the instructions included in section 5.2.1.

B1

Page 36

Appendix B. Updating RDP500 Software

B.2.3 Send the CRBasic Program – Step 3

The RDP500 includes a CR1000 pre-programed to acquire and store

measurements. The program instructions are written using the CRBasic

programming language. The program may be updated using PC200W or

Device Configuration Utility.

Using PC200W, establish communications with the CR1000 by following

Section 5.1 (PC200W Software).

Send the program by selecting the Clock / Program tab and clicking the Send

Program button. Locate the .CR1 file and click Open.

The compact flash card (CRD drive) may need to be reinitialized after sending

a new program. If the CFM100 LED is solid orange, the card needs to be

reinitialized.

B-2

To reinitialize the card, use PC200W to launch the File Control utility.

Highlight the CRD drive and click the Format button.

Allow the format process to complete before closing File Control and

PC200W.

B.2.4 Send the CD295/DataView II Configuration – Step 4

The RDP500 includes a CD295/DataView II pre-programmed to display

current data without opening the enclosure. The CD295 configuration may

need to be updated after sending a new CRBasic program. Updates may be

applied using Device Configuration Utility.

Disconnect the CD295 from the CR1000 RS232 port.

Page 37

Appendix B. Updating RDP500 Software

B.3 Change Log

Connect the CD295 to the computer using a NULL modem cable.

Open Device Configuration Utility and select CD295 in the Device Type

menu.

Select the correct PC Serial Port and click Connect.

Click Send Program and use the file dialog to locate and open the .DV2 file to

be sent.

Reconnect the CD295 to the CR1000 RS232 port.

July 15, 2010:

• Operating system updated to CR1000.Std.20.obj

See revision history, 2010 July 09, at http://www.campbellsci.com/

• CRBasic program updated to RDP500_v18.CR1

Changed data record interval from 5 minute to 15 minute

Implemented rounding of recorded/reported precipitation to 1/100th of an

inch

Updated custom menu contents

B-3

Page 38

Appendix B. Updating RDP500 Software

B-4

Page 39

Appendix C. Exchanging Internal Enclosure Mounting Bracket

C.1 Introduction

A replacement mounting bracket may be required for RDP500 units shipped

prior to August of 2010. The new bracket provides additional clearance

between the RDP500 enclosure and the lower access door of the rain gauge

housing.

C.2 Exchange Process

The equipment required for the exchange includes the items below.

(1) WRENCH 7/16” THIN-HEAD

(1) WRENCH 1/2”

(1) REPLACEMENT ENCLOSURE MOUNTING BRACKET

(1) FLATHEAD SCREWDRIVER

Use the 7/16” wrench to loosen the two bolts securing the RDP500 enclosure

to the rain gauge base. The two bolts are located at the bottom corners of the

RDP500 enclosure and can be accessed through the slot located along the

bottom corners of the RDP500 mounting bracket.

C-1

Page 40

Appendix C. Exchanging Internal Enclosure Mounting Bracket

Facing the CD295, slide the enclosure to the left and lift to remove.

Place the enclosure face down on a clean surface next to the rain gauge. Use

the 1/2” wrench to remove the four bolts securing the mounting bracket to the

fiberglass enclosure, then remove the mounting bracket from the back of the

fiberglass enclosure.

C-2

Page 41

Appendix C. Exchanging Internal Enclosure Mounting Bracket

C-3

Page 42

Appendix C. Exchanging Internal Enclosure Mounting Bracket

Align the replacement bracket to the back of the fiberglass enclosure. Ensure

that the tab is oriented towards the bottom of the fiberglass enclosure. Reinstall

the four bolts previously removed, securing the new mounting bracket.

C-4

Page 43

Appendix C. Exchanging Internal Enclosure Mounting Bracket

Reinstall the enclosure onto the rain gauge base. See Section 3.2, steps 3

through 5, for installation instructions. Ensure the enclosure is installed so that

the parallelogram tab lies below the ship tab on the enclosure mounting

bracket.

C-5

Page 44

Appendix C. Exchanging Internal Enclosure Mounting Bracket

Ensure that the load cell and parallelogram are properly aligned and oriented.

Ensure the load cell is vertical and bearing the weight of the moving end of the

parallelogram. The arms of the parallelogram should be horizontal and parallel

to the base of the rain gauge. See Section 3.2, steps 8 through 14, for detailed

information on load cell and parallelogram alignment.

C-6

Page 45

Page 46

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringowa Central

QLD 4812 AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br • suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...