Page 1

INSTRUCTION MANUAL

Q-7.1 Net Radiometer

Revision: 5/96

Copyright (c) 1991-1996

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

The Q-7.1 NET RADIOMETER is warranted by CAMPBELL SCIENTIFIC,

INC. to be free from defects in materials and workmanship under normal use

and service for twelve (12) months from date of shipment unless specified

otherwise. Batteries have no warranty. CAMPBELL SCIENTIFIC, INC.'s

obligation under this warranty is limited to repairing or replacing (at

CAMPBELL SCIENTIFIC, INC.'s option) defective products. The customer

shall assume all costs of removing, reinstalling, and shipping defective products

to CAMPBELL SCIENTIFIC, INC. CAMPBELL SCIENTIFIC, INC. will

return such products by surface carrier prepaid. This warranty shall not apply

to any CAMPBELL SCIENTIFIC, INC. products which have been subjected to

modification, misuse, neglect, accidents of nature, or shipping damage. This

warranty is in lieu of all other warranties, expressed or implied, including

warranties of merchantability or fitness for a particular purpose. CAMPBELL

SCIENTIFIC, INC. is not liable for special, indirect, incidental, or

consequential damages.

Products may not be returned without prior authorization. The following

contact information is for US and International customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle repairs

for customers wi thin their territories. Please visi t www.campbellsci.com to

determine which Campbell Scientific company serves your country. To obtain

a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 753-2342. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container.

CAMPBELL SCIENTIFIC's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

CAMPBELL SCIENTIFIC, INC. does not accept collect calls.

Page 3

Q-7.1 NET RADIOMETER

The Q-7.1 is a high-output thermopile sensor which measures the algebraic sum of incoming and

outgoing all-wave radiation (i.e. short-wave and long-wave components). Incoming radiation consists of

direct (beam) and diffuse solar radiation plus long-wave irradiance from the sky. Outgoing radiation

consists of reflected solar radiation plus the terrestrial long-wave component.

1. SPECIFICATIONS

• 60-junction thermopile with low electrical

resistance (4 ohms nominal) to reduce

susceptibility to noise

• Nominal calibration factors 9.6 W m

(for positive values), 11.9 W m

negative values)

• Spectral response 0.25 to 60 µm

• Uncorrected wind effect: up to 6%

reduction @ 7 m s

to 1% reduction @ 7 m s

-1

for positive fluxes, up

-1

for negative

fluxes.

-2

mV

-2 mV-1

1

-

(for

CAUTION: Ensure that the cable is tied to

the support arm close to the ball joint. If

the wires are allowed to flex where they

emerge from the sensor head they will

break. Sensors are shipped with an

appropriate cable tie already installed.

• Time constant: Approximately 30 seconds

• Top and bottom surfaces painted black and

protected from convective cooling by

hemispherical heavy-duty polyethylene

windshields (0.25 mm thick)

• Windshields do not require pressurization

• O-ring seals for easy windshield

replacement

• Desiccant contained in support arm;

volume of desiccant tube 45 cm

3

; breather

port on the end of the support arm.

• No power required

• Size of sensing head 57 x 72 x 177 mm;

support arm 20 mm diameter, 750 mm long

2. INSTALLATION

Attach the square mounting plate to a vertical or

horizontal pipe or rod that is less than 38 mm

(1.5 inches) in diameter with the two larger Ubolts. Attach the radiometer support arm to the

mounting plate with the two smaller U-bolts.

The radiometer support arm does not need to be

level. Fasten the cable to the pipe or rod with

tape or plastic ties to prevent strain on the wires

and damage to the instrument.

In the northern hemisphere install the

radiometer so that the sensor head is pointing

south. Likewise, in the southern hemisphere

point the sensor head to the north.

2.1 LEVELING

The Q-7.1 must be level. The bubble level is

accurate to ±1° and the bubble should be within

the bulls-eye. An error of 5° in leveling may

cause a cosine response error of 6% under

normal conditions; much greater errors are

possible under other conditions (e.g. sunrise,

sunset and winter use with low sun angles).

To level the Q-7.1, use a 5/8" wrench on the

hexagonal coupling nut on the instrument stem

to bend the ball joint between the support arm

and the instrument. If the instrument does not

stay in position, tighten the large hexagonal nut

on the support arm slightly with a 15/16"

wrench.

CAUTION: Do not attempt to bend the ball

joint by holding the instrument head alone,

as this may break the stem.

1

Page 4

Q-7.1 NET RADIOMETER

2.2 WIRING

If a differential measurement is made, connect

the red (+) lead to the high side (e.g. 1H) of any

datalogger differential channel and the black (-)

lead to the low side (e.g. 1L). Also, connect a

jumper wire between the low channel and

analog ground to prevent common mode

errors. Connect the clear (shield) lead to

ground (G on the CR10(X), ground on the 21X

and CR7).

If a single-ended measurement is made,

connect the red lead to any datalogger singleended channel (H or L) and the black lead to

ground (AG on the CR10(X), ground on the 21X

and CR7).

The black lead is negative with respect to the

red lead when the net radiometer is mounted

with the level up and there is more incoming

radiation than outgoing.

3. PROGRAMMING

Measure the output of the Q-7.1 with either

Instruction 2 (Differential Volts) or Instruction 1

(Single-Ended Volts). Use the 250 mV range

for the CR10(X) and the 500 mV range for the

21X or CR7. The slow integration with 60 Hz

rejection yields a more noise-free reading.

For still air, net radiation (Q*) can be computed

from the thermopile voltage (V

If V

> 0, Q*(Wm-2) = Vt(mV) x F

t

If Vt < 0, Q*(Wm-2) = Vt(mV) x F

) by:

t

p

n

where Fp and Fn are the positive and negative

calibration factors respectively.

The calibration factors and serial number are

given on a label under the sensor head.

The above formula give the correct readings

for conditions of zero wind speed. Additional

corrections can be applied to reduce errors for

non-zero wind speeds.

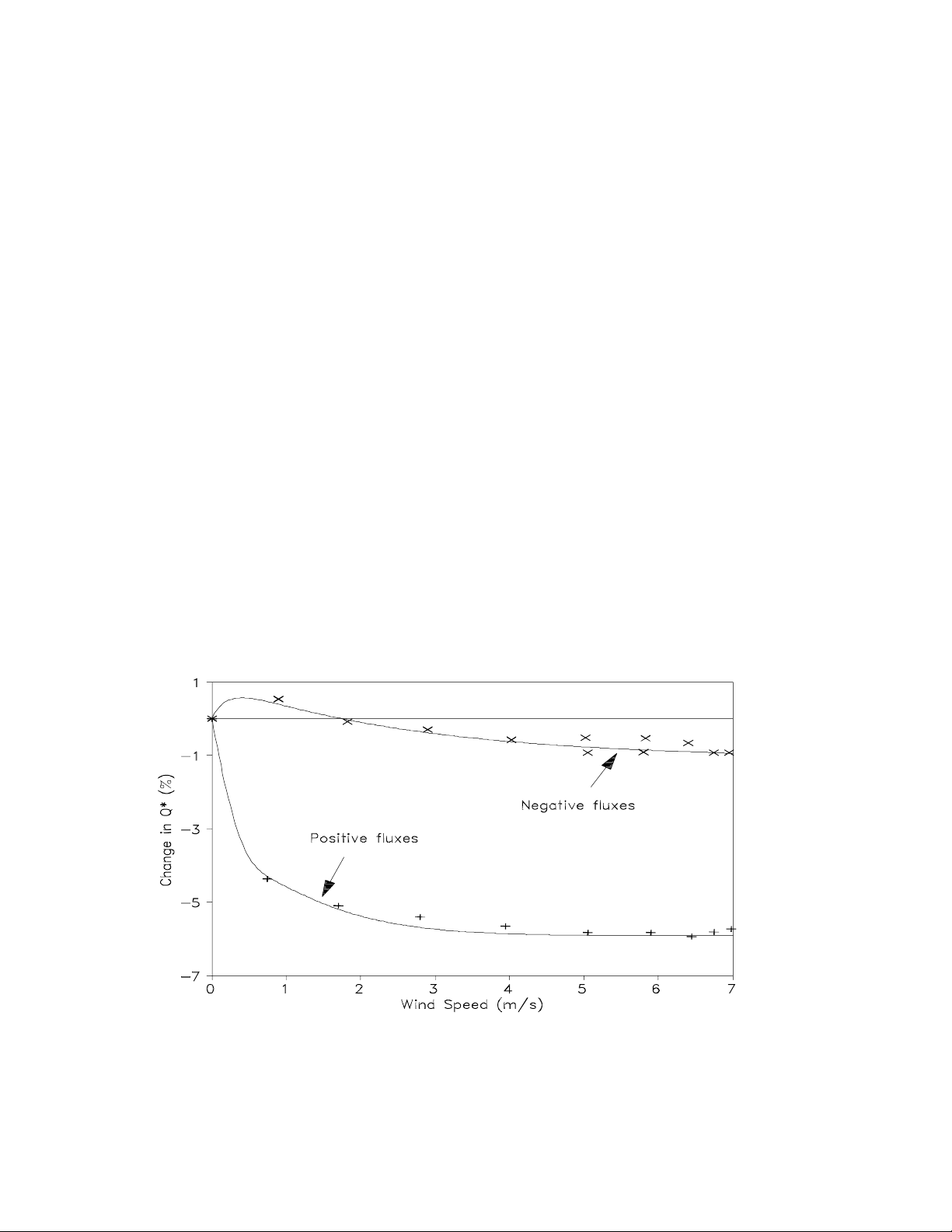

3.1 CORRECTING ERRORS CAUSED BY WIND EFFECT

Most sensors which measure long wave

radiation are subject to some degree of error

caused by convective cooling as air moves

past the sensors. The response of the Q-7.1

sensor has been determined by the

manufacturer using a specially constructed

wind tunnel. Curves fitted to experimental data

by the manufacturer are given in Figure 1.

These functions show the change in reading in

response to increasing wind speed.

FIGURE 1. Percentage Change in Reading as a Function of Wind Speed

2

Page 5

Q-7.1 NET RADIOMETER

FIGURE 2. Correction Functions as a Function of Wind Speed

The inverse of this data gives the required

correction factors to give the correct reading as

a function of wind speed (u). Figure 2 shows

the manufacturer’s data plus correction curves

fitted by Campbell Scientific, using functions

which can be easily encoded in a datalogger.

Note that the functions fitted and shown in both

graphs have been amended slightly to allow for

a small under-estimate of the error (about 2%

of the error) which is the result of a known error

of the calibration technique in the wind tunnel.

The correction function for positive fluxes is:

××

(. . )

Correction factor = 1 +

For negative fluxes a linear function is used:

Correction factor =

If the wind speed is not measured it is often

sufficient to correct the original calibration

constant using a fixed correction factor. The

manufacturer suggests using fixed correction

factors of 1.045 for positive fluxes and 1.000

for negative fluxes.

0 066 0 2

()

()

0 00174. ×

+×

..

0 066 0 2

u

u

()

u

+ 0.99755

If the wind speed is measured, the functions

above can be programmed into the datalogger

to give a real-time correction of net radiation

for the effects of wind speed. Note that the

wind speed is expressed in units of meters per

second. If the wind speed is measured in units

other than meters per second, convert the wind

speed to meters per second before inputting it

into the above correction functions.

If AC power is available, a special ventilator

(RV2) is available for the Q-7.1 which gives a

typical wind speed of 3.3 ms

negative fixed corrections are 1.06 and 1.0033

respectively. The fan is also useful for

reducing the risk of external condensation

(dew) on the windshields.

The above corrections were calculated at sea

level under conditions close to standard

temperature and pressure. The magnitude of

the wind speed error will vary in relation to the

air density and the heat capacity of air. These

changes are generally small enough to be

ignored unless extreme temperatures or

atmospheric pressures are experienced.

-1

. Positive and

3

Page 6

Q-7.1 NET RADIOMETER

3.2 PROGRAMMING EXAMPLE WITH FIXED WIND SPEED CORRECTION

The following CR10(X) program measures the

output of a Q-7.1. A static wind correction is

applied to each measurement.

Example 1. CR10(X) Program with the

Static Wind Speed Correction

;Measure the Q7.1.

;

01: Volt (Diff) (P2)***

1: 1 Reps

2: 24** ± 250 mV 60 Hz

Rejection Range

3: 1* DIFF Channel

4: 3* Loc [ Rn_W_m2 ]

5: 1 Mult

6: 0 Offset

02: IF (X<=>F) (P89)

1: 3* X Loc [ Rn_W_m2 ]

2: 3 >=

3: 0 F

4: 30 Then Do

;Enter the positive multiplier (p.ppp).

;

03: Z=X*F (P37)

1: 3* X Loc [ Rn_W_m2 ]

2:

3: 3* Z Loc [ Rn_W_m2 ]

04: Z=X*F (P37)

1: 3* X Loc [ Rn_W_m2 ]

2: 1.045 F

3: 3* Z Loc [ Rn_W_m2 ]

05: Else (P94)

p.ppp

F

;Enter the negative multiplier (n.nnn).

;

06: Z=X*F (P37)

1: 3* X Loc [ Rn_W_m2 ]

2:

3: 3* Z Loc [ Rn_W_m2 ]

07: End (P95)

n.nnn

F

3.3 PROGRAMMING EXAMPLE WITH DYNAMIC WIND SPEED CORRECTION

The following CR10(X) program measures an

R. M. Young wind sentry anemometer model

03101 and a Q-7.1. The wind speed is used to

give a real-time wind correction to net

radiation. The wind speed must be measured

before the wind corrections are applied.

Example 2. CR10(X) Program with the

Dynamic Wind Speed Correction

;Measure the 03101 wind sentry.

;

01: Pulse (P3)

1: 1 Reps

2: 1* Pulse Channel 1

3: 21 Low Level AC, Output Hz

4: 1* Loc [ ws_m_s ]

5: .75 Mult

6: .2 Offset

02: IF (X<=>F) (P89)

1: 1* X Loc [ ws_m_s ]

2: 1 =

3: .2 F

4: 30 Then Do

03: Z=F (P30)

1: 0 F

2: 0 Exponent of 10

3: 1* Z Loc [ ws_m_s ]

04: End (P95)

;Measure the Q7.1.

;

05: Volt (Diff) (P2)***

1: 1 Reps

2: 24** ± 250 mV 60 Hz

Rejection Range

3: 1* DIFF Channel

4: 2* Loc [ Rn_mV ]

5: 1 Mult

6: 0 Offset

* Proper entries will vary with program, and

datalogger channel and input location

assignments.

** On the 21X and CR7 use 500 mV input

range.

*** For a Single-Ended measurement use

Instruction 1.

4

06: IF (X<=>F) (P89)

1: 2* X Loc [ Rn_mV ]

2: 3 >=

3: 0 F

4: 30 Then Do

;Apply the positive calibration and

;wind speed correction.

;

Page 7

Q-7.1 NET RADIOMETER

07: Do (P86)

1: 1* Call Subroutine 1*

08: Else (P94)

;Apply the negative calibration and

;wind speed correction.

;

09: Do (P86)

1: 2* Call Subroutine 2*

10: End (P95)

*Table 3 Subroutines

;Positive calibration and wind

;speed correction.

;

01: Beginning of Subroutine (P85)

1: 1* Subroutine 1

02: Z=X*F (P37)

1: 1* X Loc [ ws_m_s ]

2: .2 F

3: 6* Z Loc [ C ]

03: Z=X*F (P37)

1: 6* X Loc [ C ]

2: .066 F

3: 4* Z Loc [ A ]

04: Z=X+F (P34)

1: 6* X Loc [ C ]

2: .066 F

3: 5* Z Loc [ B ]

09: End (P95)

;Negative calibration and wind

;speed corrections

;

10: Beginning of Subroutine (P85)

1: 2* Subroutine 2*

11: Z=X*F (P37)

1: 1* X Loc [ ws_m_s ]

2: .00174 F

3: 4* Z Loc [ A ]

12: Z=X+F (P34)

1: 4* X Loc [ A ]

2: .99755 F

3: 7* Z Loc [ Corr_Fact ]

;Enter the negative multiplier (n.nnn).

;

13: Z=X*F (P37)

1: 2* X Loc [ Rn_mV ]

2:

3: 3* Z Loc [ Rn_W_m2 ]

14: Z=X*Y (P36)

1: 3* X Loc [ Rn_W_m2 ]

2: 7* Y Loc [ Corr_Fact ]

3: 3* Z Loc [ Rn_W_m2 ]

15: End (P95)

* Proper entries will vary with program, and

datalogger channel and input location

assignments.

n.nnn

F

05: Z=X/Y (P38)

1: 4* X Loc [ A ]

2: 5* Y Loc [ B ]

3: 7* Z Loc [ Corr_Fact ]

06: Z=Z+1 (P32)

1: 7* Z Loc [ Corr_Fact ]

;Enter the positive multiplier (p.ppp).

;

07: Z=X*F (P37)

1: 2* X Loc [ Rn_mV ]

2:

3: 3* Z Loc [ Rn_W_m2 ]

08: Z=X*Y (P36)

1: 3* X Loc [ Rn_W_m2 ]

2: 7* Y Loc [ Corr_Fact ]

3: 3* Z Loc [ Rn_W_m2 ]

p.ppp

F

** On the 21X and CR7 use 500 mV input

range.

***For a Single-Ended measurement use

Instruction 1.

4. MAINTENANCE

4.1 DESICCANT

The Q-7.1 is supplied with heavy duty

polyethylene windshields (approximately 0.25

mm thick); no pressurization is required.

Air spaces inside the windshields are

connected to a dryer filled with silica gel

(referred to as the desiccant tube) to prevent

internal condensation. The desiccant tube is

located in the support arm and is accessible by

removing the end plug and vinal cap.

5

Page 8

Q-7.1 NET RADIOMETER

Inspect the silica gel monthly to ensure it is still

blue and white. If the color changes to pink

and white, replace it with dry silica gel (this

may have to be done more frequently in wet

weather). Wet (pink and white) silica gel can

be dried by removing it from the desiccant tube

and baking at 130°C until it returns to a blue

and white color. Remove the desiccant tube

end cap to remove and replace the silica gel.

CAUTION: After the desiccant tube has

been replaced, install the end plug and

vinal cap. Be sure the holes in the vinal

cap point towards the ground.

If the Q-7.1 is installed at a remote site it may

be convenient to have a spare desiccant tube

for quick replacement (be sure to remove the

outer end caps from both tube ends before

installing). Spare desiccant tubes are available

from Radiation Energy Balance Systems.

4.2 CONDENSATION

Condensation on net radiometer windshields

causes incorrect measurements. This is

because water does not transmit longwave

energy. An example of this problem can be

seen by comparing measured net radiation

values from two different net radiometers at

night, one on which dew is allowed to form and

another on which dew is prevented. Without

dew both instruments would indicate a similar

-2

net radiation level, e.g. -50 W m

. However,

on the instrument on which dew was allowed to

form a net radiation level of about zero would

be indicated, while the other radiometer would

-2

maintain the reading of -50 W m

. The RV2

ventilator can be used to prevent dew from

forming on the windshields.

4.2.1 Causes of Internal Condensation

If condensation develops inside the domes

check the following:

Desiccant

Make sure that the desiccant is dry (i.e. still

blue and white).

If it has turned pink, replace it with dry

desiccant or bake it until it is dry (see section

4.1 above). If the desiccant is pink only at the

tube end nearest the sensor head, this

indicates a leak somewhere on the sensor.

Windshields and O-rings

Check that the windshields and O-rings are in

good condition and are properly seated against

the radiometer frame (see below).

If there is still no obvious reason for the internal

condensation, check for possible leaks in the

sensor as follows:

1. Remove the desiccant tube.

2. Immerse the radiometer in water and blow

gently into the open end of the support

arm. A stream of bubbles will indicate the

location of any leaks.

3. Dry the instrument with a soft facial tissue.

If the windshields get dented, reinflate

them by blowing into the end of the support

arm.

CAUTION: When drying the windshields,

dabbing rather than wiping them will help to

prevent scratches.

4.2.2 Possible Internal Condensation

Problems After Installation

There is a small possibility that condensation

may occur on the inside of the windshields

when the Q-7.1 is first installed in the field.

This condensation is caused by evaporation of

hydrocarbon solvents used in the

manufacturing process and may be more

apparent after several hot, sunny days if

ambient temperatures are low enough.

If you notice condensation inside the

windshields after the first few days of sunshine

following installation, remove the windshields

as described below. Allow the solvent vapor or

condensation to escape or evaporate from the

inner air space for 15 minutes then replace the

windshields.

4.3 CLEANING

The windshields may be washed with a camel

hair brush or with a paper tissue and distilled

water.

CAUTION: Coarse paper or cloth will

scratch the windshields and should be

avoided.

6

Page 9

Q-7.1 NET RADIOMETER

4.4 WINDSHIELD REPLACEMENT

Polyethylene deteriorates with exposure to

solar radiation. Inspect the windshields

frequently and replace as required (probably

every 3-6 months).

Always check for:

1. Condensation inside the windshields,

possibly indicating a leak.

2. Cracking or crazing of the windshields

(which usually appears first along the base).

Prompt replacement is essential if any of these

conditions occur. Also, if the windshields are

removed for any reason after more than one

month’s use, replace them with new ones. The

windshields should always be replaced as a set.

Windshield replacement may cause a slight

change in calibration, although this is unlikely

to exceed 3%.

CAUTION: There are very fine wires

inside the head of the Q-7.1 which are very

susceptible to corrosion if subjected to

moisture, e.g. standing water. It is

essential to carry out the preemptive

maintenance mentioned above to prevent

serious damage to the sensor.

Replace the windshields as follows:

1. Remove the mounting screws and clamping

rings.

2. Replacement windshields are pre-cut and

punched with holes. Make sure the O-rings

are in their grooves before clamping the new

windshields into place as described in step

3.

3. Gently tighten the screws in the following

sequence: first, third, fifth, second, fourth,

sixth. It does not matter which screw you

treat as the first. Continue the sequence

until the windshields are evenly in contact

with the clamping rings and frame.

4. Tighten the screws in the same sequence

until no space remains between either

windshield flange and its corresponding

mounting ring or frame surface. Make sure

both upper and lower windshields are

completely seated on the frame around the

entire periphery.

CAUTION: Do not attempt to dismantle

the instrument body. If internal attention is

needed, contact Campbell Scientific, Inc.

for repair.

If the windshields become dented, remove the

dents as follows:

1. Remove the vinal cap from the support arm.

2. Blow gently into the end plug breather hole

to inflate the windshields.

Remember to replace the support arm vinal

cap. Orient the vinal cap so the holes point

towards the ground.

CAUTION: When replacing the

windshields, take great care not to touch or

mark the black surfaces of the thermopile

as this may affect the performance of the

instrument. Take care also to avoid

overtightening the mounting screws.

4.4.1 Bird Damage

One other cause of damage to windshields is

birds pecking at the domes. A simple measure

to prevent this is to attach two or three 8 inches

cable ties to the support arm at the end near

the sensor head, with the free ends of the ties

pointing upwards to form an array of ‘spikes’.

This may discourage birds from landing on the

arm. If this does not work you may have to

resort to more drastic techniques such as

installing an artificial snake on the support arm

or commercial bird scarers.

4.5 CALIBRATION

Q-7.1 net radiometers show excellent stability

over long periods, but for serious use, regular

calibration checks are recommended. The

calibration can be checked in the field by

mounting another net radiometer alongside and

comparing results. The instruments should be

examined carefully if the results differ by more

than a few percent. Under normal

circumstances, a calibration check every six

months is adequate providing the sensitive

thermopile surface has not been marked,

damaged or exposed to the weather.

If the calibration can not be checked in the

field, Radiation Energy Balance Systems

7

Page 10

Q-7.1 NET RADIOMETER

recommends recalibration every six months,

depending on the climate where the sensors

are used.

Each instrument is calibrated by the

manufacturer in a temperature-controlled

calibration chamber by comparison to a

transfer standard. The chamber uses a

combination of tungsten-halide source and

black body chambers. The transfer standard is

calibrated by comparison to a precision

pyranometer using a partial shading technique

developed by Radiation Energy Balance

Systems. The long wave calibration of the

standard has also been verified using black

body chambers.

Care should, however, be taken when

comparing readings with sensors from different

manufacturers or even older models from

Radiation Energy Balance Systems. This is

because in recent years academic studies have

reported inadequacies both in the design and

calibration of net radiometers from most

manufacturers. Radiation Energy Balance

Systems aim to keep at the forefront of such

developments and have published corrections

for the calibration of older sensors. However,

these corrections cannot fully bring the

instruments to the same level of performance

as the new sensors. It is, however, possible to

upgrade and recalibrate the sensor heads of

older models.

8

Page 11

This is a bla nk page.

Page 12

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com

info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za

sales@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 444

Thuringo wa Cent ra l

QLD 4812 AUSTRALIA

www.campbellsci.com.au

info@campbellsci.com.au

Campbell Scientific do Brazil Ltda . (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br

suporte@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca

dataloggers@campbellsci.ca

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk

sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

Miniparc du Verger - Bat. H

1, rue de Terre Neuve - Les Ulis

91967 COURTABOEUF CEDEX

FRANCE

www.campbellsci.fr

campbell.scientific@wanadoo.fr

Campbell Scientific Spain, S. L.

Psg. Font 14, local 8

08013 Barcelona

SPAIN

www.campbellsci.es

info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or International representative.

Loading...

Loading...