Page 1

PWS100

Present Weather Sensor

Revision: 3/12

Copyright © 2006-2012

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell's obligation under this warranty is

limited to repairing or replacing (at Campbell's option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a "Statement of Product Cleanliness

and Decontamination" form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer's expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

PWS100 Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction...............................................................1-1

2. Cautionary Statements.............................................2-1

2.1 Sensor Unit Safety ................................................................................ 2-1

2.2 Laser Safety .......................................................................................... 2-1

3. Initial Inspection .......................................................3-1

4. Overview....................................................................4-1

5. Specifications ...........................................................5-1

5.1 Mechanical Specifications .................................................................... 5-1

5.2 Electrical Specifications ....................................................................... 5-1

5.3 Optical Specifications........................................................................... 5-2

5.3.1 Laser Head Specifications........................................................... 5-2

5.3.2 Sensor Head Specifications......................................................... 5-2

5.4 Environmental Specifications............................................................... 5-2

5.5 CS215-PWS Specifications .................................................................. 5-2

5.6 Measurement Capabilities and Limitations........................................... 5-2

5.6.1 Visibility Measurements ............................................................. 5-2

5.6.2 Precipitation Measurements........................................................ 5-3

5.6.3 Data Storage and Buffering ........................................................ 5-3

6. Installation.................................................................6-1

6.1 Location and Orientation ...................................................................... 6-1

6.2 Unloading and Unpacking .................................................................... 6-2

6.2.1 Unpacking Procedure.................................................................. 6-2

6.2.2 Storage Information .................................................................... 6-2

6.3 Installation Procedures.......................................................................... 6-3

6.3.1 Assembling the PWS100 ............................................................ 6-3

6.3.2 Mounting the PWS100................................................................ 6-3

6.3.3 Connecting Cables ...................................................................... 6-7

6.3.4 Basic Wiring ............................................................................... 6-7

6.3.5 Desiccant..................................................................................... 6-9

6.3.6 Communication Options ............................................................. 6-9

6.3.6.1 RS-485 Half-duplex mode .............................................. 6-11

6.3.7 Installing Power Supply............................................................ 6-13

6.3.8 Start-Up Testing........................................................................ 6-13

6.3.9 Initial Settings ........................................................................... 6-13

6.3.10 Load Factory Defaults............................................................. 6-13

6.3.11 Lubricating the Enclosure Screws........................................... 6-13

i

Page 6

PWS100 Table of Contents

7. Operation .................................................................. 7-1

6.4 Grounding and Lightning Protection .................................................. 6-14

6.4.1 Equipment Grounding............................................................... 6-14

6.4.2 Internal Grounding .................................................................... 6-14

6.4.3 Lightning Rod ...........................................................................6-14

7.1 Introduction........................................................................................... 7-1

7.2 PWS100 Configuration......................................................................... 7-1

7.2.1 Using the Present Weather Viewer Program............................... 7-1

7.3 Terminal Mode...................................................................................... 7-2

7.3.1 Using the Help Command........................................................... 7-3

7.3.2 Entering / Exiting the Menu System ...........................................7-3

7.3.3 Message Polling ..........................................................................7-4

7.4 PWS100 Menu System ......................................................................... 7-4

7.4.1 Top Menu Options 0, 1 and 2 (Message n) ................................. 7-5

7.4.1.1 Message 0 (the Default Output)......................................... 7-9

7.4.1.2 Message Field 1 and 2 User Defined Message.................. 7-9

7.4.1.3 Message Field 10 To 19 Fixed Messages........................ 7-10

7.4.1.4 Message Field 20 Visibility Range (m) ........................... 7-10

7.4.1.5 Message Field 21 Present Weather Code (WMO) .......... 7-10

7.4.1.6 Message Field 22 Present Weather Code (METAR)....... 7-10

7.4.1.7 Message Field 23 Present Weather Code (NWS)............ 7-10

7.4.1.8 Message Field 24 Alarms ............................................... 7-10

7.4.1.9 Message Field 25 Fault Status of the PWS100................ 7-11

7.4.1.10 Message Field 30 External Sensor Temperature,

RH% and Wetbulb........................................................ 7-11

7.4.1.11 Message Field 31 External Sensor Maximum and

Minimum Temperature................................................. 7-11

7.4.1.12 Message Field 33 External Sensor Wetness .................. 7-11

7.4.1.13 Message Field 34 External Sensor Aux......................... 7-11

7.4.1.14 Message Field 40 Precipitation Intensity....................... 7-11

7.4.1.15 Message Field 41 Precipitation Accumulation .............. 7-12

7.4.1.16 Message Field 42 Drop Size Distribution...................... 7-12

7.4.1.17 Message Field 43 Average Velocity (ms-1) and

Average Size (mm)....................................................... 7-12

7.4.1.18 Message Field 44 Type Distribution.............................. 7-12

7.4.1.19 Message Field 45 Size / Velocity Type Map 1

(20 x 20) .......................................................................7-12

7.4.1.20 Message Field 46 Size / Velocity Type Map 2

(32 x 32) .......................................................................7-13

7.4.1.21 Message Field 47 Campbell Scientific Standard Size /

Velocity Map (34 x 34) ................................................7-15

7.4.1.22 Message Field 48........................................................... 7-17

7.4.1.23 Message Field 49 Visibility (m), 10 minute average..... 7-17

7.4.1.24 Message Field 100 Upper, Lower LED temperature..... 7-18

7.4.1.25 Message Field 101 Upper, Lower Detector

Temperature.................................................................. 7-18

7.4.1.26 Message Field 102 Laser Hood, Laser Temperature

and Laser Drive Current ............................................... 7-18

7.4.1.27 Message Field 103 Laser, Upper, Lower Detector DC

Voltage Offsets............................................................. 7-18

7.4.1.28 Message Field 104 Laser, Upper and Lower Dirty

Window Detector ......................................................... 7-18

ii

Page 7

PWS100 Table of Contents

7.4.1.29 Message Field 105 DSP PSU Voltage, Hood and

Dew Heater % Duty ..................................................... 7-18

7.4.1.30 Message Field 106 Upper, Lower Detector Differential

Voltage, Calibrated Visibility mV............................... 7-18

7.4.1.31 Message Field 150 Serial Number, Operating System

and Hardware Version.................................................. 7-18

7.4.1.32 Message Field 151 Day Count, Hours, Minutes,

Seconds ........................................................................ 7-18

7.4.1.33 Message Field 152 Product Name................................. 7-18

7.4.1.34 Message Field 153 Statistics Period.............................. 7-18

7.4.1.35 Message Field 154 Watchdog Count, Maximum Particles

Per Second, Particles Not Processed, Time Lag........... 7-19

7.4.1.36 Message Field 155 Processing Statistics ....................... 7-19

7.4.1.37 Message Field 156 Year, Month, Day........................... 7-19

7.4.1.38 Message Field 157 Hours, Minutes, Seconds................ 7-19

7.4.1.39 Message Field 158 Averaged Corrected Visibility

Voltage and Averaged Upper Head Voltage............... 7-19

7.4.1.40 Message Field 159 Output a CCITT CRC-16

(checksum) of the message .......................................... 7-19

7.4.1.41 Message Field Error ...................................................... 7-19

7.4.2 Top Menu Option 3 (Set Time and Date) ................................. 7-21

7.4.3 Top Menu Option 4 (Configuration)......................................... 7-22

7.4.4 Top Menu Option 5 (Password)................................................ 7-30

7.4.5 Top Menu Option 6 (Weather and Alarm Parameters)............. 7-31

7.4.6 Top Menu Option 7 (Terminal) ................................................ 7-34

7.4.7 Top Menu Option 8 (Info) ........................................................ 7-34

7.4.8 Top Menu Option 9 (Done) ...................................................... 7-35

7.5 Message Related Commands.............................................................. 7-36

7.5.1 Automatic and Polled Message Sending................................... 7-36

7.5.2 Retrieving Historical Data ........................................................ 7-38

7.5.3 Viewing Data Output on the Command Line ........................... 7-40

7.5.4 Collection of Data in Text File Format..................................... 7-40

7.6 Weather Related Commands .............................................................. 7-40

7.6.1 Setting and Viewing Weather Parameters................................. 7-40

7.6.2 Receiving Data from Remote Sensors ...................................... 7-41

7.7 System Configuration Commands...................................................... 7-41

7.7.1 Setting System Parameters........................................................ 7-41

7.8 Maintenance Commands..................................................................... 7-43

7.8.1 Loading a New OS.................................................................... 7-43

7.8.2 Running a Diagnostic Test........................................................ 7-44

7.8.3 Running the Calibration............................................................ 7-45

7.8.4 Rotating the Calibration Disc.................................................... 7-45

7.9 Other Commands................................................................................ 7-45

7.9.1 Setting the Time and Date......................................................... 7-45

7.9.2 Resetting the System................................................................. 7-46

7.10 Connecting the PWS100 to a Datalogger ......................................... 7-46

7.10.1 Connections ............................................................................ 7-46

7.10.2 Example Logger Programs...................................................... 7-46

8. Functional Description.............................................8-1

8.1 General.................................................................................................. 8-1

8.2 Optical Measurement............................................................................ 8-1

8.2.1 Optical Arrangement................................................................... 8-1

iii

Page 8

PWS100 Table of Contents

9. Maintenance ............................................................. 9-1

8.3 Additional Sensor Connections............................................................. 8-3

8.3.1 Using a CS215-PWS on the PWS100......................................... 8-4

8.3.2 Using Other Sensors on the PWS100.......................................... 8-4

8.4 PWS100 Control Unit........................................................................... 8-5

8.5 Measurement Signal Processing ...........................................................8-5

8.6 Algorithm Description .......................................................................... 8-6

8.6.1 Detecting and Classifying Precipitation ...................................... 8-6

8.6.2 Precipitation Intensity .................................................................8-8

8.6.3 Precipitation Accumulation....................................................... 8-10

8.6.4 Present Weather ........................................................................ 8-10

8.6.4.1 Precipitation Types .......................................................... 8-10

8.6.4.2 Visibility Types ...............................................................8-11

8.6.4.3 Weather Classes............................................................... 8-11

8.6.4.4 Weather Code Selection ..................................................8-11

8.6.5 Visibility.................................................................................... 8-11

8.7 Applications ........................................................................................ 8-12

8.8 Internal Monitoring............................................................................. 8-13

9.1 General.................................................................................................. 9-1

9.2 Cleaning ................................................................................................ 9-1

9.3 Calibration............................................................................................. 9-2

10. Troubleshooting................................................... 10-1

10.1 Introduction....................................................................................... 10-1

10.2 Possible Problems ............................................................................. 10-1

10.2.1 No response from PWS100..................................................... 10-1

10.2.2 PWS100 responds but no data output given ........................... 10-1

10.2.3 Ice has formed in the end of the hoods.................................... 10-2

10.2.4 The visibility output is clearly in error.................................... 10-2

10.2.5 The sensor does not detect particles during a precipitation

event .................................................................................... 10-2

10.2.6 The sensor detects particles when there are none present ....... 10-2

10.2.7 The OS update did not work ...................................................10-3

Appendices

A. PWS100 Output Codes ........................................... A-1

B. Wiring ....................................................................... B-1

C. Cable Selection........................................................C-1

C.1 Power Cable ........................................................................................ C-1

C.2 Communication Cable......................................................................... C-3

D. Software Flowchart .................................................D-1

E. Menu System Map ................................................... E-1

iv

Page 9

List of Figures

4-1. PWS100............................................................................................... 4-1

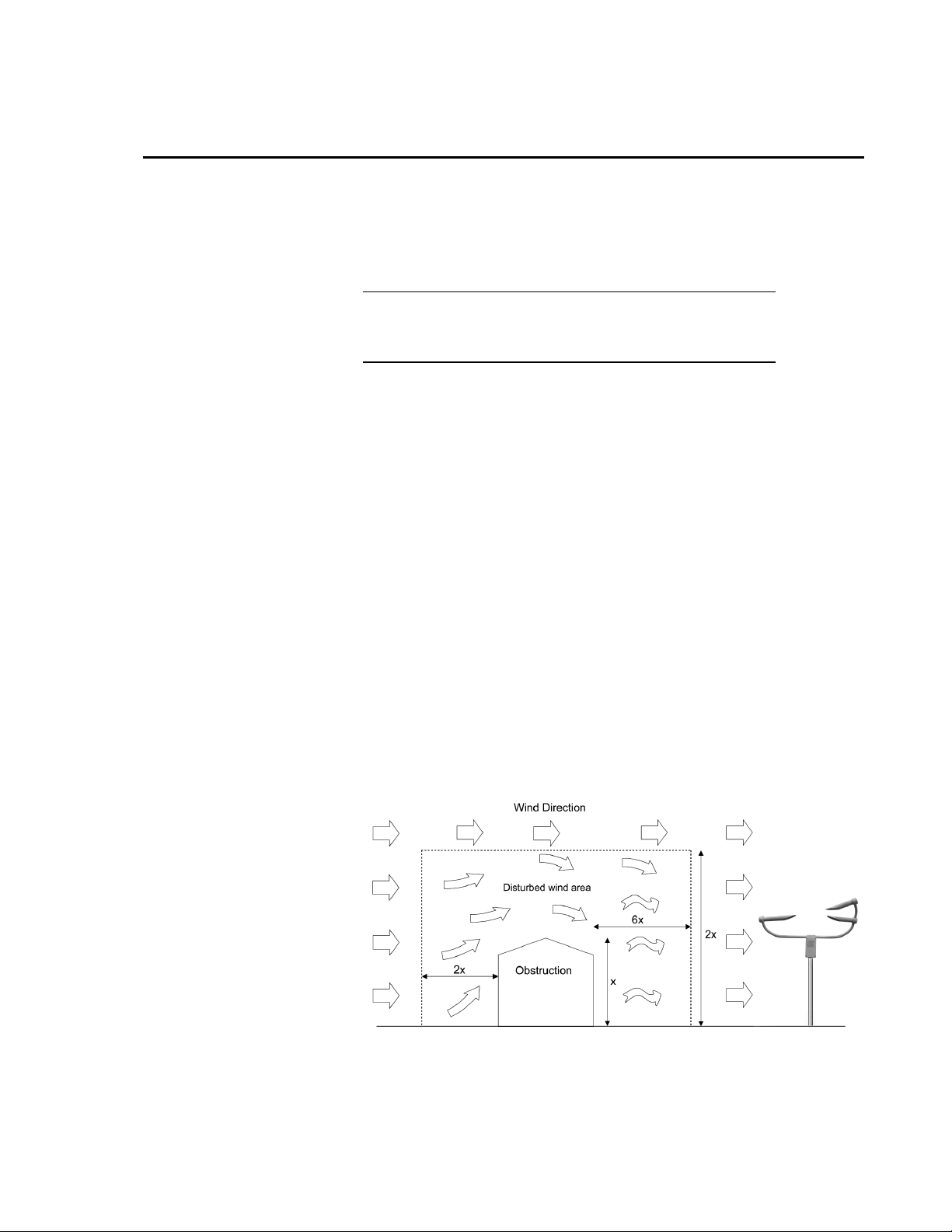

6-1. Effect of structure on air flow ............................................................. 6-1

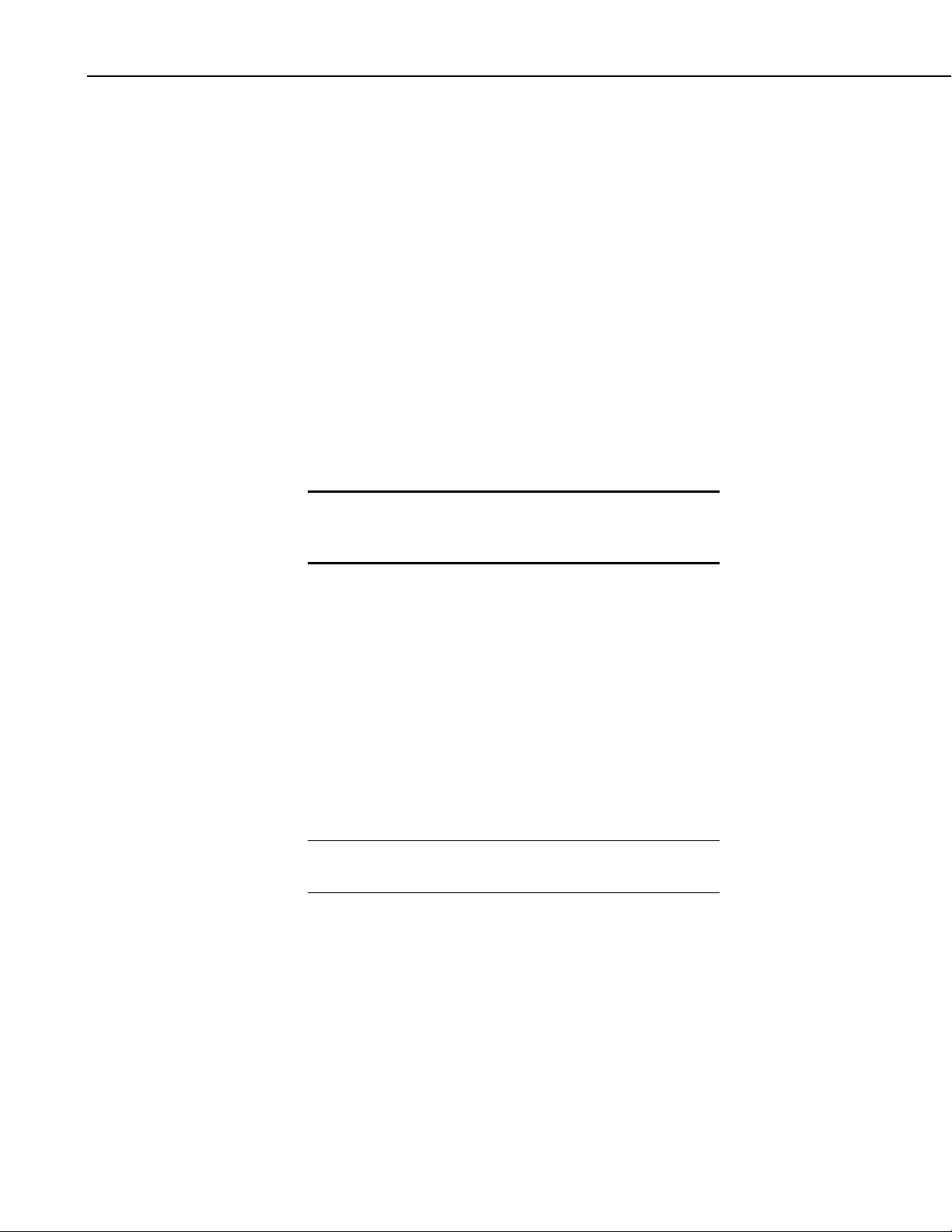

6-2. Hardware for mounting the top of the DSP plate to a pole ................. 6-4

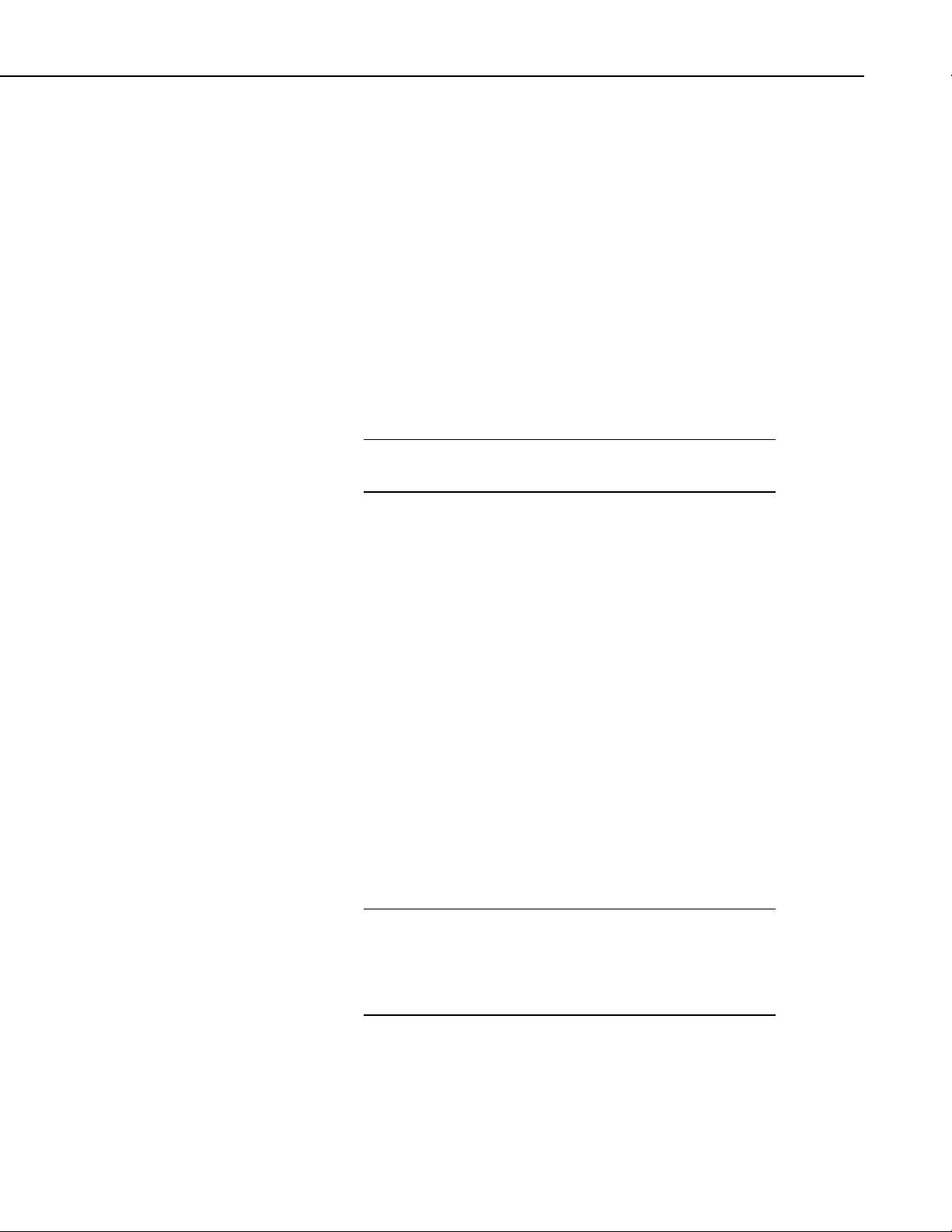

6-3. Placing the PWS100 onto the bracket ................................................. 6-5

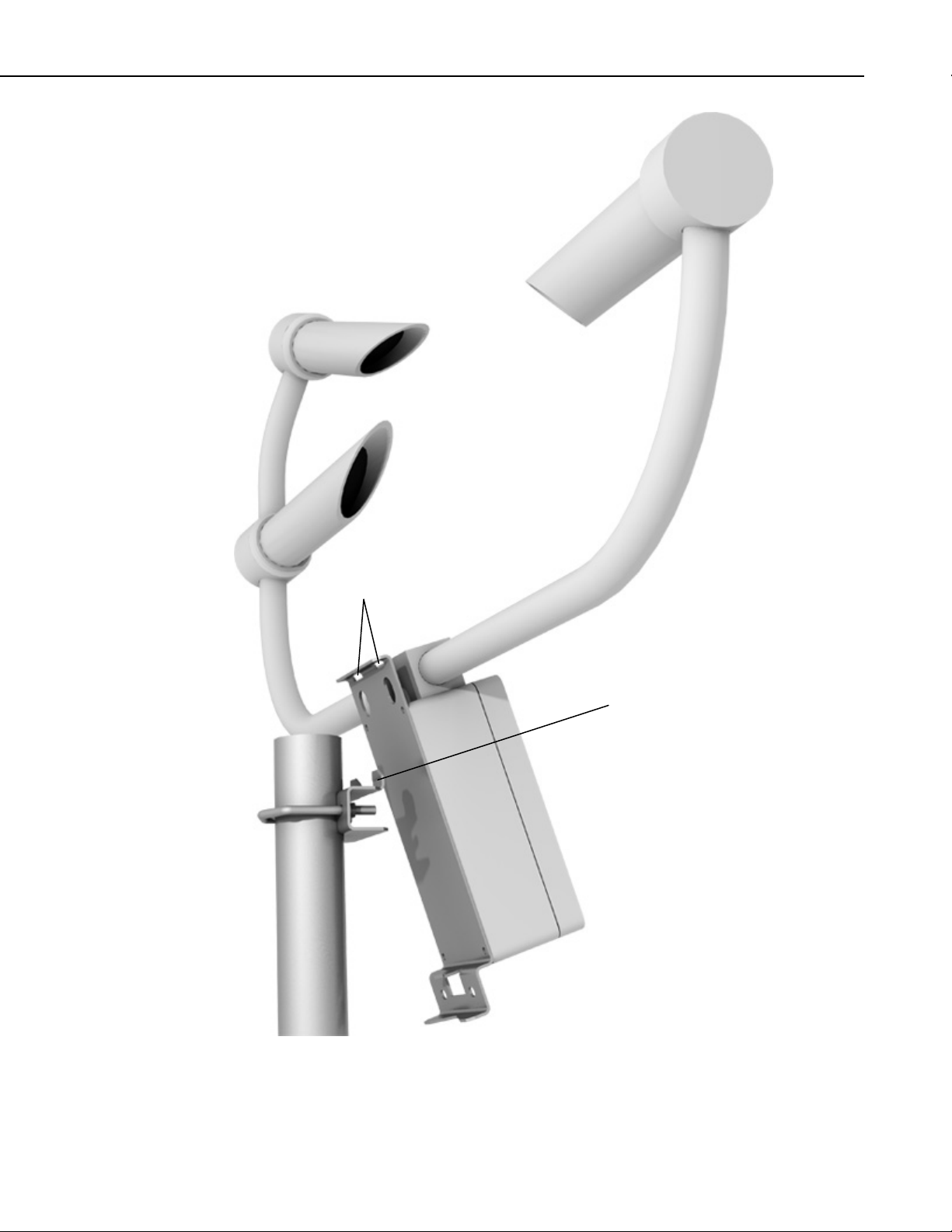

6-4. PWS100 mounted to a mast or pole .................................................... 6-6

6-5. Underside of DSP enclosure ............................................................... 6-8

6-6. Mounting the desiccant pack on the DSP cover.................................. 6-9

6-7. Removal of DSP cover...................................................................... 6-10

6-8. Exposing the DSP board ................................................................... 6-10

6-9. DSP board dip switch location (circled)............................................ 6-12

6-10. Dip switches (defaults set - 00011100) ........................................... 6-12

6-11. Labeled DIN-RAIL contacts ........................................................... 6-13

7-1. PWS100 setup menu ........................................................................... 7-5

7-2. Message menu ..................................................................................... 7-5

7-3. Message parameters and fields menu.................................................. 7-6

7-4. Message interval menu........................................................................ 7-6

7-5. Message mode menu ........................................................................... 7-7

7-6. Message field menu........................................................................... 7-20

7-7. Delete message menu ........................................................................ 7-21

7-8. Time and date menu .......................................................................... 7-21

7-9. Configuration menu........................................................................... 7-22

7-10. PWS100 ID menu............................................................................ 7-23

7-11. TRH probe menu............................................................................. 7-23

7-12. Wetness probe menu ....................................................................... 7-24

7-13. Aux probe menu.............................................................................. 7-24

7-14. Hood heater temperature menu ....................................................... 7-25

7-15. Dew heater mode menu................................................................... 7-25

7-16. Output mode menu .......................................................................... 7-26

7-17. Calibration warning screen.............................................................. 7-27

7-18. Calibration top menu....................................................................... 7-27

7-19. Calibration disc constants menu...................................................... 7-28

7-20. View / adjust calibration menu........................................................ 7-29

7-21. Terminal mode menu....................................................................... 7-29

7-22. PSU shut down voltage menu ......................................................... 7-30

7-23. Password menu............................................................................... 7-30

7-24. Weather parameters menu ............................................................... 7-31

7-25. Visibility range alarm menu ............................................................ 7-31

7-26. Snow water content adjustment....................................................... 7-33

7-27. Mixed precipitation threshold adjustment....................................... 7-34

7-28. Terminal active screen..................................................................... 7-34

7-29. Information menu............................................................................ 7-35

7-30. Done menu ...................................................................................... 7-36

8-1. Laser unit............................................................................................. 8-2

8-2. Laser unit showing light sheet production (not to scale)..................... 8-2

8-3. Sensor unit........................................................................................... 8-3

8-4. Sensor unit showing light path extents (not to scale) .......................... 8-3

8-5. Block diagram of PWS100 control unit .............................................. 8-5

8-6. Signal to pedestal ratio values for different precipitation types .......... 8-7

9-1. Baffle removal and fitting ................................................................... 9-1

B-1. Underside of DSP enclosure...............................................................B-1

B-2. DSP PCB to DSP enclosure connections............................................B-2

C-1. PWS100 power cable..........................................................................C-2

C-2. Enclosure wiring details for power cable ...........................................C-2

PWS100 Table of Contents

v

Page 10

PWS100 Table of Contents

List of Tables

C-3. PWS100 communication cable .......................................................... C-4

C-4. Enclosure wiring details for communication cable............................ C-4

7-1. Command Set ......................................................................................7-2

7-2. Message Field parameters.................................................................... 7-7

7-3. Assumed bulk density of various particle types. ...............................7-32

7-4. Weather parameters. .......................................................................... 7-41

7-5. Detectable sensors. ............................................................................7-43

8-1. Precipitation intensities........................................................................ 8-9

A-1. PWS100 output codes........................................................................ A-1

A-2. Light, moderate and heavy precipitation defined with respect to

type of precipitation and to intensity, i, with intensity values

based on a three-minute measurement period ................................. A-7

A-3. Intensity bounds for rain and drizzle .................................................A-8

A-4. Intensity bounds for rain and snow.................................................... A-8

A-5. Intensity bounds for drizzle and snow ............................................... A-8

A-6. Intensity bounds for rain, drizzle and snow....................................... A-9

A-7. Intensity bounds for rain, drizzle, ice pellets, hail and snow............. A-9

A-8. Intensity bounds for ice pellets, hail and snow.................................. A-9

B-1. Cable identifier................................................................................... B-1

C-1. Communication cable connections .................................................... C-3

vi

Page 11

Section 1. Introduction

The PWS100 is a laser-based sensor that measures precipitation and visibility

by accurately determining the size and velocity of water droplets in the air. It

can be used in weather stations in road, airport, and marine applications. The

PWS100 uses advanced measurement techniques and algorithms to calculate

individual precipitation particle type.

1-1

Page 12

Section 1. Product Overview

1-2

Page 13

Section 2. Cautionary Statements

2.1 Sensor Unit Safety

The PWS100 sensor has been checked for safety before leaving the factory and

contains no internally replaceable or modifiable parts.

WARNING

WARNING

CAUTION

2.2 Laser Safety

Do not modify the PWS100 unit. Such modifications

will lead to damage of the unit and could expose users

to dangerous laser light levels and voltages.

In unusual failure modes and environmental

conditions the sensor hood could become hot. In

normal operation they will be at ambient temperature

or slightly above.

Ensure that the correct voltage supply is provided to the sensor.

The PWS100 sensor incorporates a laser diode which is rated as a class 3B

device. This is an embedded laser where the output from the sensor unit,

through the optics, is minimized to class 1M. This classification indicates that

viewing of the beam with the naked eye is safe but looking directly into the

beam with optical instruments, e.g. binoculars can be dangerous.

From the laser head the output has the following characteristics:

Maximum pulse energy: 73 nJ

Pulse duration: 5.2 μs

Wavelength: 830 nm

EN 60825-1:2001

The sensor is marked with the following warning:

INVISIBLE LASER RADIATION

DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS

CLASS 1M LASER PRODUCT

Opening the laser head unit with the power applied to the PWS100 may expose

the user to hazardous laser radiation. To open the unit requires the use of tools

and should not be carried out except by authorized personnel using appropriate

safety eyewear.

2-1

Page 14

Section 2. Cautionary Statements

If the laser is operated outside of the housing then the following warning

applies:

INVISIBLE LASER RADIATION

AVOID EXPOSURE TO BEAM

CLASS 3B LASER PRODUCT

WARNING

Check that the laser warning label on the sensor is still

visible and can be clearly read on an annual basis.

When installing the sensor avoid pointing the laser

housing towards areas where binoculars are in

common use.

2-2

Page 15

Section 3. Initial Inspection

Upon receipt of the PWS100, inspect the packaging and contents for damage.

File damage claims with the shipping company.

3-1

Page 16

Section 3. Initial Inspection

3-2

Page 17

Section 4. Overview

The PWS100 Present Weather Sensor is a laser based sensor capable of

determining precipitation and visibility parameters for automatic weather

stations including road, marine and airport stations. Due to its advanced

measurement technique and fuzzy logic algorithms, the PWS100 can determine

each individual precipitation particle type from accurate size and velocity

measurements and the structure of the received signal.

The system can output visibility and precipitation related weather codes such

as those detailed in the World Meteorological Organisation (WMO) SYNOP

code, those used as part of a METAR weather report and those previously used

by the US National Weather Service (NWS).

Further details of precipitation can be given in terms of drop size distributions

(DSD) and particle size / velocity maps to give better indications of

precipitation intensity. Such distributions can then be used in soil erosion

studies.

The PWS100 comprises a Digital Signal Processor (DSP) housing unit

connected to a sensor arm, comprising one laser head and two sensor heads.

Each of the sensor heads is 20° off axis to the laser unit axis, one in the

horizontal plane, the other in the vertical plane. The DSP housing is fixed via a

mounting bracket to a mast, though a tripod can be used for temporary sites.

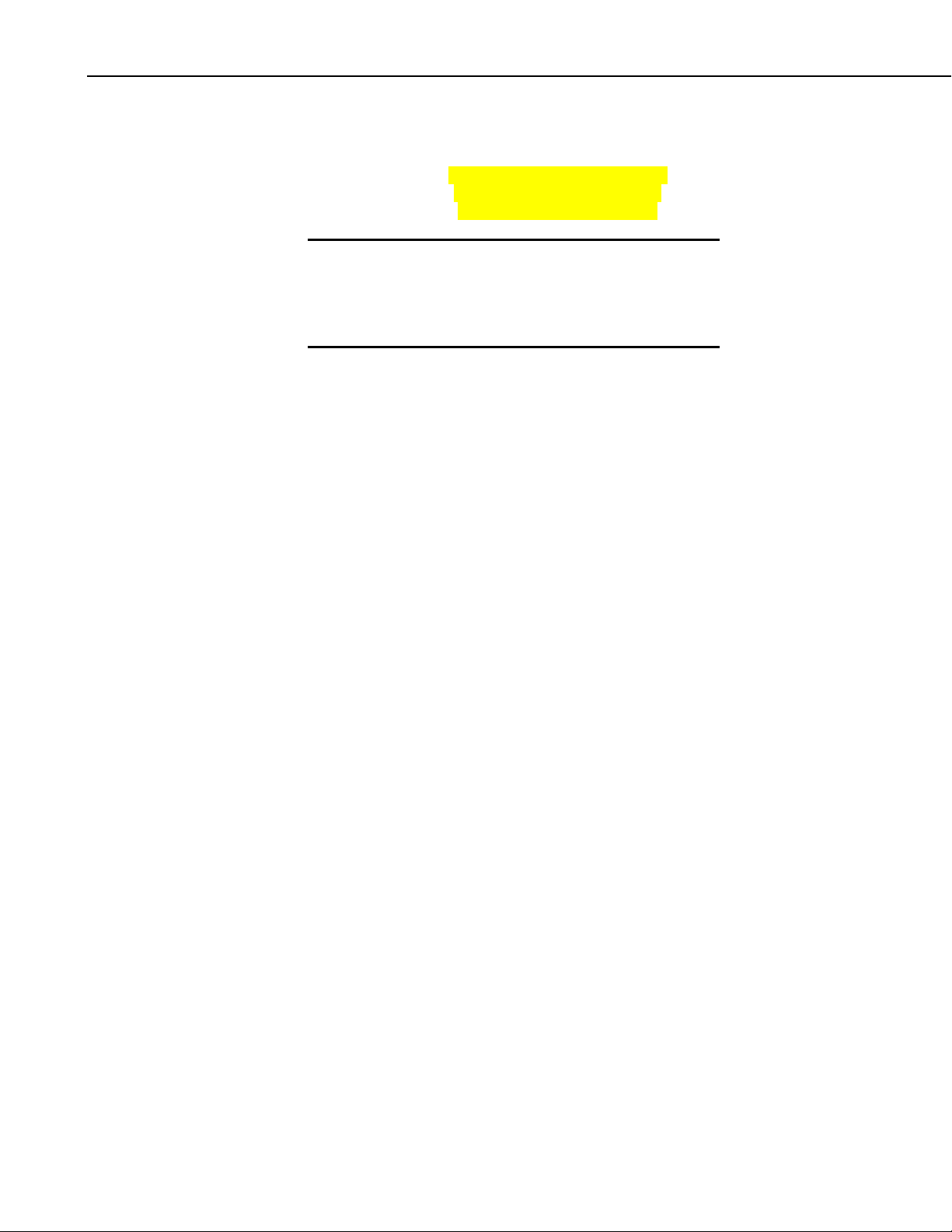

Figure 4-1 shows the PWS100 mounted on a pole.

An optional CS215-PWS temperature and humidity sensor is normally

supplied and plugs directly into the PWS100. That sensor is used to improve

the accuracy of weather coding by the PWS, in particular in respect of

discriminating between snow and rain and also fog/mist and dust.

FIGURE 4-1. PWS100

4-1

Page 18

Section 4. Overview

4-2

Page 19

Section 5. Specifications

5.1 Mechanical Specifications

Measuring Area: 40 cm2 (6.2 in2)

Housing Materials: Iridite NCP conversion coated aluminium

(RoHS compliant) and hard anodized

aluminium. Outer parts also coated with marine

grade paint.

Weight: 8.2 kg (18 lb) excluding power supply /

communications enclosure

Shipping Weight: 20.4 kg (45 lb)

Dimensions: 115 cm × 70 cm × 40 cm (42.3 in × 27.6 in ×

15.8 in)

Mountings: U-bolt mounting to mast or pole with outer

diameter from 1.25 in to 2.07 in

5.2 Electrical Specifications

NOTE

Power Requirements: DSP power 9 to 24 V, (9 to 16 V limit when

using CS215-PWS or other SDI-12 sensors).

Current consumption 200 mA no dew heater or

SDI-12, 1 A with dew heater and SDI-12. The

currents are lower at high supply voltages as

the sensor uses SMPS technology. Hood

heater 24 Vac or dc, 7 A.

It is the responsibility of the user to ensure that any local

regulations, regarding the use of power supplies, are adhered to.

Communication: RS-232, RS-422, RS-485. Baud rate of 300 bps

to 115.2 kbps supported.

Control Unit: Custom DSP board

EMC Compliance: Tested and conforms to BS EN 61326:1998.

Class A device. May cause interference in a

domestic environment.

5-1

Page 20

Section 5. Specifications

5.3 Optical Specifications

5.3.1 Laser Head Specifications

Laser Source: Near-infrared (IR) diode, eye safe Class 1M

Peak Wavelength: 830 nm

Modulation Frequency: 96 kHz

Laser Head Lens Diameter: 50 mm (1.97 in)

5.3.2 Sensor Head Specifications

Receivers: Photodiode with band pass filters

Spectral Response: Maximum spectral sensitivity at 850 nm, 0.62

Sensor Head Lens Diameter: 50 mm (1.97 in)

unit output

A/W (0.6 A/W at 830 nm)

Lens Check Light Source: Near-IR LED

5.4 Environmental Specifications

Standard Operating

Temperature Range: -25° to +50°C

Optional Extended Operating

Temperature Range: -40° to +70°C

Relative Humidity Range: 0 to 100%

IP Rating: IP 66 (NEMA 4X)

5.5 CS215-PWS Specifications

Please refer to the CS215 manual or product brochure for the specifications.

5.6 Measurement Capabilities and Limitations

5.6.1 Visibility Measurements

5-2

Visibility Range: 0 to 20,000 m (0 to 65,620 ft)

Visibility Accuracy: ± 10% (0 to 10,000 m)

Measurement Interval: User selectable from 10 seconds to 2 hours

Page 21

5.6.2 Precipitation Measurements

Particle Size*: 0.1 mm to 30 mm (0.004 in to 1.18 in)

Size Accuracy*: ± 5% (for particles >0.3 mm)

Section 5. Specifications

Particle Velocity: 0.16 ms

-1

to 30 ms-1

Velocity Accuracy*: ± 5% (for particles >0.3 mm)

Types of Precipitation

Detected: Drizzle, rain, snow grains, snow flakes, hail,

ice pellets, graupel (heavily rimed solid

precipitation), freezing rain, freezing drizzle,

mixed (combination of types above)

-1

Rain Rate Intensity Range: 0 to 400 mm h

(M-P Distributed)

Rainfall Resolution: 0.0001 mm

Rain Total Accuracy*: Typically ±10% (accuracy will be degraded for

windy conditions, frozen precipitation, and

very high rainfall rates).

DSD bin sizes: 0.1 mm (diameter) 0.1 ms

-1

(velocity)

Data Output: Raw parameter output (particle size, particle

velocity, signal peak value, signal pedestal

value), WMO SYNOP codes (4680, W

a Wa

precipitation and obscurant type), WMO

METAR codes (4678, W

- precipitation

a Wa

and obscurant type), NWS code, drop size

distribution (DSD) statistics, particle type

distribution, size / velocity intensity maps,

precipitation rate, precipitation accumulation,

visibility range and internal checks

(temperatures, lens contamination, processing

limits).

External Sensors: CS215-PWS supported for temperature / RH

*Accuracy values are for laboratory conditions with reference particles and

visibility standards.

5.6.3 Data Storage and Buffering

The PWS100 has a large internal memory that is split up to store different

types of data. One buffer, the particle buffer, is used to hold raw signal data

captured from the detectors. The size of this buffer and the speed at which it

can be processed is a limit on the maximum rainfall rates the sensor can

measure. For most users, this is not a limitation; if it may be a limitation, please

read the description below.

measurement; SDI-12 compatible sensors

supported.

5-3

Page 22

Section 5. Specifications

The particle buffer is able to hold raw data for 500 typical particles. The

processor is able to process the particles at a rate of 120 particles per second,

typically. This means if more than 120 particles per second fall through the

sample volume of 40 cm

2

the particle buffer will start to fill up. If the rain rate

exceeds 120 particles per second for a prolonged period, the buffer could run

out of space and particles will be lost.

The fact that the processor is running behind real-time and/or particles are

being missed can be monitored in the alarm message which can be selected for

data output.

The particle processor then places data about each particle in the Large Particle

Array (LPA). The LPA is 100000 records long. It uses 5 records every 10

seconds plus a record for every processed particle that passes through the

volume. For example if 20 particles per second are processed then 20.5 records

are used per second. Since 100000 records can be stored, the system can store

100000 / 20.5 = 4878 seconds worth of data in the LPA. The user needs to be

aware of the size of this buffer as it is used to hold data that is processed when

a message is output. The size of the buffer may become a limiting factor if a

very long message interval is selected and rainfall rates are high.

The PWS100 has the capability to store measured data in a buffer called the

message storage buffer, which is 1 MB (1000000 characters) in size. All ASCII

characters including CrLf must be included in any storage calculations. This

buffer stores the user defined messages (see Section 7.5, Message Related

Commands for the types of messages available to the user). A typical message

containing 120 characters can be stored 1000000 / 120 = 8333 times which at

minute intervals for the data output would be over 138 hours worth of storage.

5-4

Page 23

Section 6. Installation

6.1 Location and Orientation

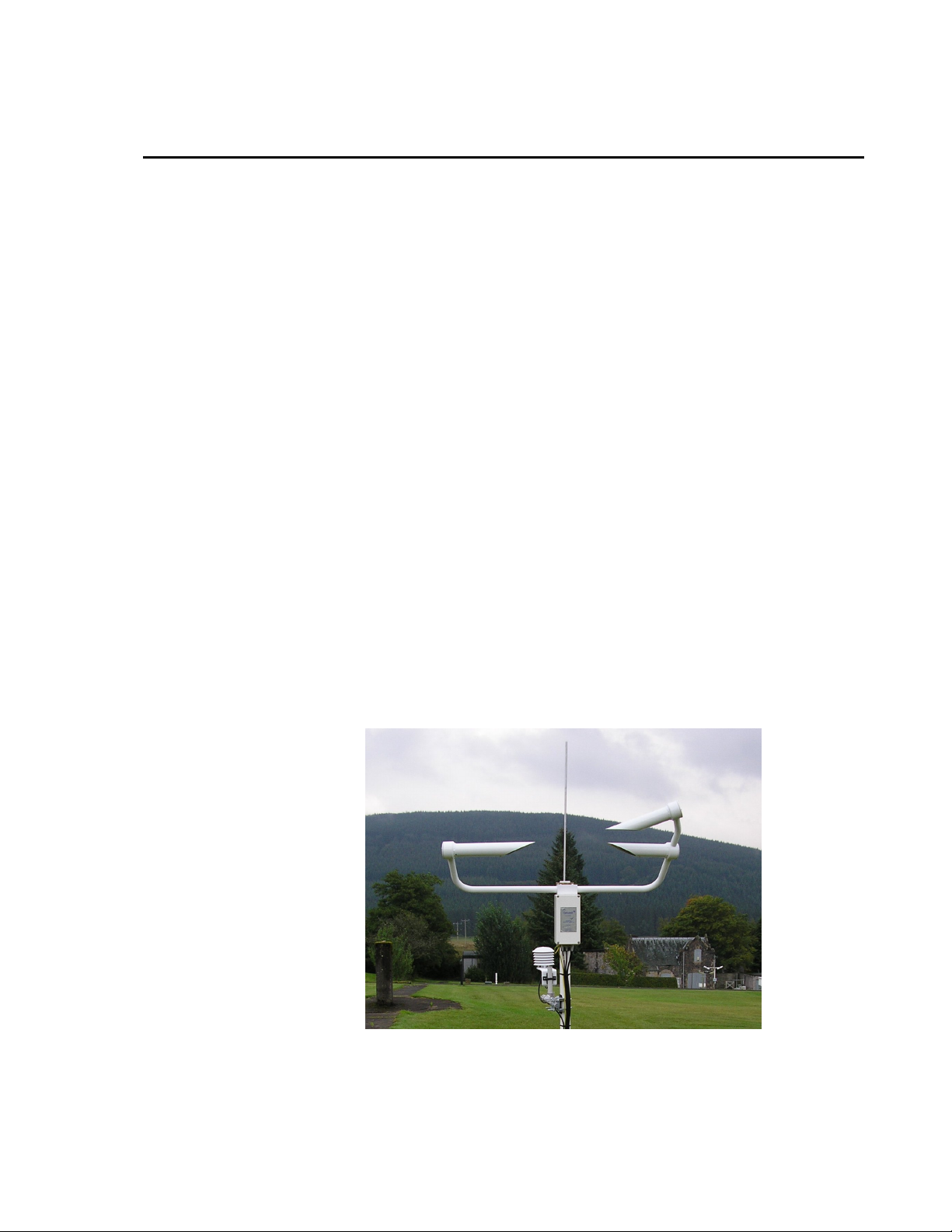

The PWS100 measures environmental variables and is designed to be located

in harsh weather conditions. However there are a few considerations to take

into account if accurate and representative data from a site are to be obtained.

NOTE

The descriptions in this section are not exhaustive. Please refer to

meteorological publications for further information on the

locating of weather instruments.

The PWS100 should be sited in a position representative of local weather

conditions and not of a specific microclimate (unless the analysis of

microclimate weather is being sought).

To give non-microclimatic measurements the PWS100 should be sited away

from possible physical obstructions that could affect the fall of precipitation.

The PWS100 should also be positioned away from sources of heat, electrical

interference and in such a position as to not have direct light on the sensor

lenses.

Whenever possible, the PWS100 should be located away from windbreaks.

Several zones have been identified upwind and downwind of a windbreak in

which the airflow is unrepresentative of the general speed and direction. Eddies

are generated in the lee of the windbreak and air is displaced upwind of it. The

height and depth of these affected zones varies with the height and to some

extent the density of the obstacle.

Generally, a structure disturbs the airflow in an upwind direction for a distance

of about twice the height of the structure, and in a downwind direction for a

distance of about six times the height. The airflow is also affected to a vertical

distance of about twice the height of the structure. Ideally, therefore, the

PWS100 should be located outside this zone of influence in order to obtain

representative values for the region (see Figure 6-1).

FIGURE 6-1. Effect of structure on air flow

6-1

Page 24

Section 6. Installation

In order to minimize user interaction with the unit, the PWS100 should be

placed away from sources of contamination, in the case of roadside monitoring,

larger mounting poles can be used. More regular maintenance will be required

when the instrument is placed in areas where contamination is unavoidable or

where measurements may be safety critical.

The orientation of the unit should be such that the horizontal sensor head points

north in the northern hemisphere and south in the southern hemisphere. The

angle of inclination of the second sensor head is such that the deviation from

north/south orientation causes no increase in system noise.

High frequency light sources can lead to increased system noise and hence

erroneous weather classification and so the PWS100 should be positioned in a

location where such interference is minimized. Ideally this should be a

minimum of 100 m from the nearest high frequency light source, with the

sensor heads pointing away from the light source. In any case the sensor heads

should be positioned to be away from any high frequency light source.

Avoid locations where the transmitter is pointing at a light scattering or

reflective surface.

WARNING

When installing the sensor, avoid pointing the laser

housing toward areas where binoculars are commonly

used.

To be at any risk from the laser light source, the operator must look directly

down the beam of light and must be at the same height and in exact alignment

with the sensor. In addition, the beam diverges slightly so the risk decreases

with distance from the sensor.

6.2 Unloading and Unpacking

6.2.1 Unpacking Procedure

Depending on the power and mounting options selected for the PWS100 there

will be up a number of boxes containing the PWS sensor unit, power supply/

external communications enclosure and grounding equipment.

CAUTION

Handle the boxes carefully, taking care not to drop them as

the sensor can be damaged if dropped.

Unpack the boxes carefully and check the contents, ensuring that the contents

match those listed on the packing slip. Carefully remove the items and replace

all packing materials back into the empty boxes and store in case the unit is

required to be repacked for shipping.

6-2

6.2.2 Storage Information

The PWS100 should be stored between -40° to +70°C in a dry place,

preferably with the enclosures securely fastened with desiccant in place. The

optics should be protected from possible accidental damage.

Page 25

6.3 Installation Procedures

6.3.1 Assembling the PWS100

The PWS100 comes as a single unit, with the DSP enclosure attached to the

base of the sensor arms. The PWS100 and power/communication enclosure (if

purchased) are typically mounted to a Campbell Scientific tripod. Usersupplied mounting structures should be strong enough to withstand high winds,

without significant movement.

See the manuals supplied with your tripod for details on how to set up ready

for PWS100 mounting. Tripods need to be firmly secured to a base with the

central pole vertical to ensure correct measurements with the PWS100. See the

relevant tripod or tower manual for further details.

6.3.2 Mounting the PWS100

Section 6. Installation

NOTE

A PWS100 purchased from Campbell Scientific Europe will

have a different mounting bracket.

A pole mounting kit is supplied with the PWS100. This kit includes a DSP

plate, a bracket, two u-bolts, four flat washers, four split washers, and four

nuts. The PWS100 usually comes with the DSP plate attached to it. The

PWS100 mounts onto a Campbell Scientfiic tripod, tower, or a user-supplied

pole with a 1.5 inch (3.81 cm) to 2.1 inch (5.25 cm) outer diameter as follows.

1. Fasten the bracket to the pole using one u-bolt, two flat washers, two split

washers, and two nuts (see Figure 6-2).

2. Place the DSP plate on the bracket. The tabs of the bracket fit in the

notches at the top of the DSP plate (see Figure 6-3).

3. Fasten the bottom of the DSP plate using the remaining u-bolt, washers,

and nuts (see Figure 6-4).

4. Mount the power supply enclosure if purchased. This enclosure can be

mounted to the same tripod, tower, or user-supplied pole as the PWS100.

Alternatively the power supply can be mounted elsewhere (e.g., on a wall

at some distance from the sensor). The power supply enclosure should be

mounted away from the sensor head to avoid wind flow disturbance or rain

drops bouncing back up into the sensor’s sensing volume.

CAUTION

Take care not to overtighten the nuts on the u-bolts, as it

may be possible to distort and/or damage the bracket or

DSP plate by doing so, and/or the nuts may seize up. Only

tighten the nuts to a degree necessary to hold the PWS100

firmly in place.

6-3

Page 26

Section 6. Installation

Bracket Tab

U-bolt

Bracket

DSP Plate

FIGURE 6-2. Hardware for mounting the top of the DSP plate to a pole

6-4

Page 27

Section 6. Installation

Notches

Bracket Tab

FIGURE 6-3. Placing the PWS100 onto the bracket

6-5

Page 28

Section 6. Installation

6-6

CAUTION

FIGURE 6-4. PWS100 mounted to a mast or pole

Ensure that the PWS100 is mounted according to Figures

6-2 through 6-4. Do not reposition, once fixings are

tightened, by forcing the arms of the unit as this can

damage the unit.

Page 29

6.3.3 Connecting Cables

The sensor unit comes with the DSP control unit fixed to the sensor arm. All

cabling between the sensor heads and the DSP unit is premade. An SDI-12

sensor connection is fixed into the DSP terminal strip. The connection is

terminated with a LEMO socket on the lower face of the DSP housing. This is

primarily wired for the CS215-PWS but is also used with the PWC100

Calibrator. Power, communications and additional sensor connections are to

be routed through the cable glands on the lower face of the DSP housing to the

DSP terminal strip. As a factory default, a power cable and a communications

cable are pre-wired in the unit. The third cable gland will be sealed off by

default but can be used for further external sensor connections or a separate

power cable for the hood heaters (rather than sharing the main power cable).

There should be no need to alter any wiring within the DSP housing and the

housing cover should only be removed periodically to renew desiccant packs or

if any of the hardware switches need to be used. However if cable lengths are

to be changed then these will have to be rewired in the DSP housing. If the unit

remains sealed during operation, the packs should only need replacing once

every 6 months. Replace the desiccant pack in the holder and secure the cover.

6.3.4 Basic Wiring

Section 6. Installation

The PWS100 wiring block is shown on the internal layout diagram in Figure

B-2. Connection points for power and communications are shown in the

diagram. There are two power inputs (one 24V for hood heater and one 12V

for the processor board) one communications connection and two SDI-12 ports

for peripheral connection. For RS-485 communications a 120 Ω termination

resistor may need to be placed across the RTS-B and RX-A connections at

either end of the cable, although this is normally not required for most

installations unless electronic noise interference is prevalent or cable runs are

very long.

A 1K LEMO socket (IP66 rated) is used for connection of a peripheral (often

the CS215-PWS temperature / relative humidity probe). The cable for any

peripheral to be connected to the LEMO socket should be terminated with the

appropriate 4 pin 1K series LEMO plug. Ensure when fitting the peripheral

plug into the socket that the red tabs are aligned.

The power and communications cables are routed through two of the three

cable glands on the base of the PWS100 DSP enclosure. If power and

communications cables are replaced refer to Appendix C.1 and C.2 for further

details.

Figure 6-5 shows the lower face of the DSP enclosure with the cable gland and

LEMO connector positions.

6-7

Page 30

Section 6. Installation

PG9 CABLE GLAND

EARTH GROUND

LEMO 4-PIN

(CONNECTOR FOR

CS215-PWS)

FIGURE 6-5. Underside of DSP enclosure

PG11 CABLE GLAND

(HOOD HEATER)

6-8

Page 31

6.3.5 Desiccant

Section 6. Installation

The desiccant bags should be removed from the plastic bags in which they are

shipped before placing them inside the enclosure. Two 100 g bags of desiccant

are supplied with the PWS100. Desiccant use depends on your application (see

below). The desiccant should be firmly strapped to the DSP cover inside the

PWS electronics enclosure using the strap provided and as shown in Figure

6-6.

FIGURE 6-6. Mounting the desiccant pack on the DSP cover

The second bag of desiccant should be re-sealed in the plastic shipping bag as a

replacement for the initial bag

6.3.6 Communication Options

The communications options are RS-232, RS-422 and RS-485. Baud rate is

selectable between 300 bps and 115.2 kbps. The communications are set on a

series of dip switches on the DSP board itself. The get to the board the DSP

cover must be removed as shown in Figure 6-7. Unscrew the four retaining

screws and carefully lift off to expose the board as shown in Figure 6-8.

6-9

Page 32

Section 6. Installation

FIGURE 6-7. Removal of DSP cover.

6-10

FIGURE 6-8. Exposing the DSP board.

Page 33

Section 6. Installation

The location of the dip switches on the board is shown in Figure 6-9 and the

dip switches themselves are shown in detail in Figure 6-10. The following

settings are available:

PWS100 dip switch settings:-

0 = off; 1 = on.

switch 1 slew rate

0 slow slew rate (default)

1 fast slew rate

switch 2 communication mode

0 RS232 (default)

1 RS485 (note – load resistor may be required – see Section 6.3.6.1)

switch 3 duplex mode

0 full duplex (default)

1 half duplex (RS485 – see Section 6.3.6.1 below)

switch 4-6 serial communication baud rate

switch

654 Baud Rate

000 300

001 1200

010 9600

011 19200

100 38400

101 57600

110 76800

111 115200 (default)

switch 7 reserved for future use (default off)

switch 8 load factory defaults at power up

0 normal operation (default)

1 load factory defaults

6.3.6.1 RS-485 Half-duplex mode

In half duplex mode, the transition from transmits (Tx) to receive (Rx) modes

and vice versa are subject to the following timing rules which may need to be

considered when interfacing other devices:

• The sensor waits for a gap of 1 byte period plus 10 ms without receiving

data before switching from Rx to Tx and echoing/responding.

• Sensor has a 1 millisecond Tx to Rx turn around time.

6-11

Page 34

Section 6. Installation

FIGURE 6-9. DSP board dip switch location (circled)

6-12

FIGURE 6-10. Dip switches (defaults set - 00011100)

Page 35

6.3.7 Installing Power Supply

Power supply connections can be made in the PWS100 24 Vdc/12 Vdc power

supply cabinet using the power cable supplied with the PWS100.

Din rail contacts are mounted inside the power supply enclosure that allows

connection to the two power supplies (see Figure 6-11).

Section 6. Installation

FIGURE 6-11. Labeled DIN-RAIL contacts

6.3.8 Start-Up Testing

On start-up the PWS100 will run internal diagnostic tests and check the status

of any connections to the instrument.

6.3.9 Initial Settings

Initially the PWS100 will be set up with a series of default options set. These

can be altered by entering the command mode of the sensor.

6.3.10 Load Factory Defaults

To load the factory default settings (retaining only the time, date and

calibration values) power down the sensor move dip switch 8 to position 1 and

power up the sensor. Once powered switch dip switch 8 back to position 0.

This removes the password and all other user entered values.

6.3.11 Lubricating the Enclosure Screws

The PWS100 enclosure screws should be lubricated with a suitable anti-seize

grease (often copper loaded) to protect the threads from corrosion. This should

be reapplied when resealing the enclosure at regular intervals, normally after

6-13

Page 36

Section 6. Installation

replacing the desiccant. This is of particular importance if using the sensor in

corrosive or salt laden atmospheres.

6.4 Grounding and Lightning Protection

6.4.1 Equipment Grounding

The present weather sensor must be properly grounded to protect it from

transients and secondary lightning discharges. The PWS100 has a ground lug

on the outside of its enclosure. This ground lug is connected to a tripod’s

grounding system via a 12 AWG copper wire. A 12 AWG copper wire is

included with Campbell Scientific’s tripods or towers.

To ground the system, first install the tripod’s grounding system as described

in the tripod or tower manual. The 12 AWG wire should be fastened to the

tripod or tower’s ground clamp. Route the 12 AWG wire from the clamp to the

PWS100 ground lug. Strip one inch of insulation from each end of the wire

and insert the end of wire into the ground lug and tighten.

6.4.2 Internal Grounding

The DSP enclosure of the unit and associated electronics are grounded through

the power cable assembly. The sensor components are in contact with each

other or have internal copper contacts.

6.4.3 Lightning Rod

Campbell Scientific suggests that a lightning rod is only fitted where there is

significant risk of lightning strike. During rainfall events water can accumulate

and shed from the rod and cause erroneous measurements. The rod itself can

also interfere with the passage of precipitation particles and ice accumulation

can exacerbate the situation.

If required, the lightning rod included with our tripods, UT10 Tower, or

UTGND Ground Kit should be used. The process of mounting the lightning

rod is described in our tripod and tower manuals.

6-14

Page 37

Section 7. Operation

7.1 Introduction

The best way of becoming familiar with the sensor is to setup the sensor and

connect it to a PC running Windows and the Campbell Scientific Present

Weather Viewer program.

This software allows easy setup of the sensor and a graphical display of the

measurements being made. It also provides an easy way of upgrading the

firmware of the sensor. It is not intended to capture or store data on a

permanent basis but is provided as a demonstration, test and setup tool. Brief

details of use of the program are described below. The program includes a

more detailed multi-lingual help system which can be accessed from the Help

menu option once the program is running.

The PWS100 Present Weather Sensor is capable of outputting a range of data,

from single particle parameters, to codes representing those from WMO and

other standard meteorological tables. The sensor is setup with some factory

defined output messages but the user often will need to change these to meet

their own requirements. The setup can be done using either the Present

Weather Viewer program or using a terminal emulator and interacting with the

sensor directly.

7.2 PWS100 Configuration

7.2.1 Using the Present Weather Viewer Program

The latest copy of which can be downloaded from:

www.campbellsci.com/downloads

To use this program install it on your PC. When first run you will be prompted

to chose a connection port and speed. Set these to match the serial port on the

PC being used and the baud rate. With a new sensor the PWS100 address/ID

will be set to zero and there will be no password. With these set you can then

connect icon (top right hand corner) to establish a connection with the sensor.

After the program has checked the sensor setup it will switch to a mode of

displaying data transmitted at regular intervals (one minute by default). The

graphs will then be updated, although they will largely look blank if there is no

precipitation falling. Clicking on the data values and status tab of the display

gives access to basic data which shows the sensor is working OK.

To change settings in the sensor click on the icon near the connection button

which brings up the sensor control panel.

The PWS viewer also provides a simple terminal emulator screen which can be

used to setup the sensor using it’s built in menu system rather than the

graphical interface the viewer provides.

To understand the operation of the sensor and the relevance of the settings in

the graphical interface it is necessary to understand the messages and

7-1

Page 38

Section 7. Operation

configuration options. These are discussed below within the context of setting

up the sensor using a terminal emulator.

7.3 Terminal Mode

In normal operating mode the sensor will respond to a number of “root”

commands, shown in Table 7-1. Those commands allow the configuration of

the sensor in a non-interactive fashion, the polling of data and also switching

the sensor into an interactive user menu mode.

They are accessed via the command TERM PWS_1d Password ↵

Commands are entered in the format ‘Command Pws_1d Password ↵

Command Description

PASSWORD Sets user password

HELP* Gives a list of available commands

OPEN* Activate user menu

TERM Enter command mode

TABLE 7-1. Command Set

CLOSE Exit command mode

MSEND* Poll messages

MSET Set message parameters

HDATA Retrieve historical particle data from sensor

SETPARAM Set weather parameters

FUZZY DIAG* Extra particular information (see Section 7.5.2)

CONFIG View system configuration

SETCONFIG Set system configuration

LOADOS Load a new operating system

DIAGSET Set diagnostic test parameters

DIAG Run diagnostic test

TIME Display or set time and date

RSENSOR Receive remote sensor values (T °C and H %)

RESET Reset hardware

XHMDATA Historic `MSET’ data download using Xmodem

HMDATA Output historic data to the command line

RUNDISC

*These commands are available outside terminal mode.

Rotate the calibration disc for test / demonstration

purposes

7-2

The most commonly used commands are MSEND, HELP and OPEN.

Page 39

Section 7. Operation

In the descriptions which follow ↵ symbolizes the pressing of the ENTER key.

Input parameters in italics should be user-defined characters appropriate for the

command. Unless otherwise stated, all command parameters should be

separated by a space.

To support addressed RS-485 networks, each PWS100 can be assigned an

identifier, shown as Pws_Id below. By default the PWS_Id is set to 0 (zero).

NOTE

When operating at the root level, commands are not echoed back

to the terminal as this mode is intended primarily for polled data

collection and echoed commands will complicate the issue of

decoding the responses sent back from the sensor. Local echo

can be turned on in Hyperterminal if required. Start

Hyperterminal, select the pulldown ‘File’ menu and select

‘Properties’. Click the ‘ASCII setup’ tab and check the ‘Echo

typed characters locally’ checkbox.

7.3.1 Using the Help Command

To list available commands, the HELP command can be used as follows with

the correct PWS100 Pws_Id:

HELP Pws_Id↵

e.g., HELP 0↵

The PWS100 will respond with a list of available commands and their basic

function.

7.3.2 Entering / Exiting the Menu System

The user can enter the menu system by using the OPEN command with the

correct Pws_Id. If a password is set, then it should also be entered. The

command is then as follows:

NOTE

OPEN Pws_Id Password↵

e.g., OPEN 0 campbell↵

The PWS100 will then display the SETUP menu of the menu system

To close the menu system and return the PWS100 to operation, option

9 should be chosen from the SETUP menu (see Figure 7-1). At this

point either option 1 should be chosen to save changes and quit the

menu system, or option 2 should be chosen to lose changes made and

quit the menu system. Option 0 will return the user to the SETUP

menu.

Changes made to the unit calibration and time and date settings

while in the menu system are immediate and as such will remain

changed independent of the quit option chosen from the menu.

7-3

Page 40

Section 7. Operation

NOTE

The data storage function will not store data while the terminal

or menu is active. This means data will be missing during these

periods. To reduce data loss reduce the amount of time that the

terminal or menu are active.

7.3.3 Message Polling

While the menu system or terminal mode are closed, it is possible to poll data

from a suitable set sensor (see Sections 7.4.1 and 7.6.1 for information on how

to set up messages for polling). In order to poll a message the MSEND

command must be used with the correct Pws_Id, stats_period and message_ID.

Statistics are calculated over the stats_period in seconds which completely

overrides any period defined within the message. The message can be either a

fixed or user defined message from 0 to 19. The command for message polling

is as follows:

MSEND Pws_Id stats_period message_ID ↵

e.g., MSEND 0 3600 10↵

In the example given above, the PWS100 will respond with fixed message_ID

10 statistics calculated or sampled over the stats_period of 3600 seconds for

the PWS100 with a Pws_Id of 0. If the stats_period is zero then the statistics

are calculated from the last collection interval. So the polling interval controls

the interval at which statistics are calculated over, up to a maximum of 2 hours.

Setting stat_period to less than 10 seconds will result in repeated data due to

the ten seconds measurement cycle (see Section 8.5).

7.4 PWS100 Menu System

From the command line the use of the OPEN command, as detailed in Section

7.3.2, will initiate the menu system which can be used to set up the operation of

the PWS100.

NOTE

NOTE

If there is no activity for 10 minutes with the menu system open

it will automatically close.

The menu system map is shown in Appendix D. The menu is controlled by

means of numeric selections followed by the enter key. Pressing enter by itself

will return the user to the previous menu. A selection followed by the enter key

will lead to the display of a specific menu or allow a specific parameter value

to be input. Entering an incorrect selection or parameter value will return the

user to the same menu. Pressing the delete key will delete the current entry.

Pressing the escape key will clear the current entry and return to the previous

menu.

Entering the command line (terminal mode) from the menu

system will lead to a loss of all changes made during navigation

of the menu system.

7-4

Page 41

Section 7. Operation

Section 7.4.6 gives further details of how to set up the PWS100 with the

command set in the terminal mode (option 7 from the SETUP menu).

FIGURE 7-1. PWS100 setup menu

7.4.1 Top Menu Options 0, 1 and 2 (Message n)

The options 0, 1 and 2 from the SETUP menu are entitled ‘message 0’,

‘message 1’ and ‘message 2’. These are used to setup the message outputs for

messages with ID 0, 1 and 2. Selecting one of these brings up the MESSAGE

menu as shown in Figure 7-2. Each message allows the user to select message

intervals, modes and fields (option 1).

FIGURE 7-2. Message menu

7-5

Page 42

Section 7. Operation

If option 1 is chosen from the MESSAGE menu then the system will display

the MESSAGE PARAMETERS and FIELDS menu for that message as shown

in Figure 7-3. From here 19 fields can be filled in. Field 0 is the message

interval. This is set in seconds and will be the interval between which output

messages are given. Field 1 is the message mode and fields 2 to 19 are output

parameters which can be user set.

FIGURE 7-3. Message parameters and fields menu

Selecting field 0 brings up the MESSAGE INTERVAL menu shown in Figure

7-4. Here the interval is input. An input of 0 means that the message is polled

(i.e., will be given when the user requests it, either manually or in an automated

fashion using a datalogger).

7-6

FIGURE 7-4. Message interval menu

Page 43

Section 7. Operation

From the MESSAGE PARAMETERS and FIELDS menu if field 1 is chosen

then the MESSAGE MODE menu (see Figure 7-5) will be displayed. Here the

options are to store and output to the serial port (option 1) which is useful for

on screen analysis of real-time data, or store only (option 2) more useful when

logging data.

FIGURE 7-5. Message mode menu

From the MESSAGE PARAMETERS and FIELDS menu if fields 2 to 19 are

chosen then the MESSAGE FIELD menu will be displayed as shown in Figure

7-6. Here an output parameter for that message field can be chosen from a

number of different output parameters as detailed in Table 7-2 and described in

Sections 7.4.1.1 to 7.4.1.40.

TABLE 7-2. Message Field parameters

Message

Parameter Output

Field

0 – 2 User set message types

10 – 19 Fixed messages

20 Average visibility (m)

21 Present weather code (WMO)

22 Present weather code (METAR)

23 Present weather code (NWS)

24 Alarms

25 Fault status of PWS100

30 Average temperature, RH%, wet bulb

31 Minimum and maximum temperature

33 External sensor (Wetness)

7-7

Page 44

Section 7. Operation

TABLE 7-2. Message Field parameters

Message

Parameter Output

Field

34 External sensor (Aux)

40 Precipitation intensity (mmh-1)

41 Precipitation accumulation

42 Drop size distribution bin values (0.1 mm increment

per value)

43 Average velocity (ms-1), average size (mm)

44 Type distribution

45

46

47

Size / velocity map type 1 (20 × 20)

Size / velocity map type 2 (32 × 32)

Campbell Scientific standard size / velocity map (34 × 34)

48 Peak-to-Pedestal ratio distribution histogram

49 Visibility range, in meters, averaged over 10 minutes

100 Internal LED temperatures: upper LED, lower LED

101 Internal detector temperatures: upper, lower

102 Laser hood temperature, laser temperature and laser

current

103 DC offsets: upper, lower, laser

104 Dirty window: upper, lower, laser

105 Battery voltage, hood %, dew %

106 Upper and lower detector differential voltage (mV) and

calibrated visibility voltage (mV)

150 Device s/n, operating system and hardware versions

151 Date and time: day count (from 01/01/2007) HH MM SS

152 Product name “PWS100”

153 Statistics period (s)

154 Watchdog count, maximum particles per second, particles

not processed, time lag

155 Processing statistics

156 Year, month, day

157 Hours, minutes, seconds

158 Averaged corrected visibility voltage (mV) and average

upper head voltage (mV)

159 CRC16-CCITT Checksum

7-8

Page 45

Note that user defined messages cannot make field references to other user

defined messages but can make reference to fixed messages from field 10 to 19

and all other message fields.

7.4.1.1 Message 0 (the Default Output)

User message 0 can be set by setting the Message Field parameters as required

using other message fields from 10 upwards.

By default and after a hardware reset (see Section 6.3.10, Load Factory

Defaults) or a software reset (see Section 7.9.2, Resetting the System) this

outputs the message fields below (in the format as seen in the interactive

menu). These fields have been used as defaults so they give a full display of

the PWS100’s capabilities when used with the Present Weather Sensor Viewer

program.

The user can delete and completely reconfigure this message as required.

(0) Message interval = 60 seconds

(1) Mode = Store and Output

(2) 49 Vis range Av (m) over 10 minutes

(3) 21 WMO code

(4) 22 Metar code

(5) 23 NWS code

(6) 24 Alarms

(7) 25 System fault status 0=pws_ok

1=degraded_performance 2=maintenance

(8) 30 Temp Av (C), RH Samp (%), Wetbulb Av (C)

(9) 31 Temp Max (C), Temp Min (C)

(10) 40 Precipitation Intensity (mm / hour)

(11) 41 Precipitation accumulation (mm)

(12) 42 Particle size distribution (300 values 0.1 to 30mm)

(13) 43 Particle Av velocity (m/s), Av size (mm)

(14) 44 Particle type distribution (fd, d, fr, r, sg,

sf, ip, h, g, e, u)

(15) 47 Size and velocity map Campbell 34x34

(16) 48 Ped ratio distribution (50 values 1.0 to 6.0)

(17) 156 Date (year, month, day)

(18) 157 Time (hours, minutes, seconds)

(19) 159 CRC16-CCITT

Section 7. Operation

Note that in the default message, the start and end characters (STX/ETX) are

included in the message – see “Output options” described in Section 7.4.3.

7.4.1.2 Message Field 1 and 2 User Defined Message

These user messages are set in the same way as message 0 but are cleared and

do not output as default after a master reset.

7-9

Page 46

Section 7. Operation

7.4.1.3 Message Field 10 To 19 Fixed Messages

7.4.1.4 Message Field 20 Visibility Range (m)

7.4.1.5 Message Field 21 Present Weather Code (WMO)

7.4.1.6 Message Field 22 Present Weather Code (METAR)

7.4.1.7 Message Field 23 Present Weather Code (NWS)

No fixed messages have been defined yet. The user cannot change the fixed

messages.

This field will output the average visibility range (m) calculated over the

Message_Interval defined.

This field will output the Present Weather Code (WMO) calculated over the

Message_Interval defined.

This field will output the Present Weather Code (METAR) calculated over the

Message_Interval defined.

This field will output the Present Weather Code (NWS) calculated over the

Message_Interval defined.

7.4.1.8 Message Field 24 Alarms

This field will output the Alarms. The alarms are output as a string of 16 ‘0’s

and ‘1’s delimited with spaces, for example 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1.

Each alarm has the following definition starting from the left hand side:

1. Visibility range less than alarm 1 trigger point set by user. The factory

default is 5 km.

2. Visibility range less than alarm 2 trigger point set by user. The factory

default is 1.5 km.

3. Visibility range less than alarm 3 trigger point set by user. The factory

default is 0.5 km.

4. Laser drive current greater than 80 mA. This may indicate the laser is

failing or recalibration is required.

5. Power supply voltage for dsp less than 11 V.

6. Laser window needs cleaning. There is sufficient build up on the

window that if not cleaned could reduce accuracy.

7. Upper detector window needs cleaning. There is sufficient build up on

the window that if not cleaned could reduce accuracy.

8. Lower detector window needs cleaning. There is sufficient build up on

the window that if not cleaned could reduce accuracy.

7-10

9. DC voltage of laser dirty window detector greater than 1.5 V. This can

be caused by sun directly shining into lens or a pws fault.

Page 47

Section 7. Operation

10. DC voltage of upper detector greater than 1.5 V. This can be caused

by sun directly shining into lens or a pws fault.

11. DC voltage of lower detector greater than 1.5 V. This can be caused

by sun directly shining into lens or a pws fault.

12. Particle processor is unable to process all particles due to limited time

and buffer resources. Particles are missed and data could be

inaccurate. This alarm may activate when there are 120 or more

particles per second going through the volume, sustained for a period

that fills all available space in the buffers.

13. Particle processor lags real time by more than 5% of the user

requested statistics interval.

14. Particle stripper is unable to process all particles due to limited time

and buffer resources. Particles are missed and data will be inaccurate.

This alarm may activate if there are more than ~150 particles per

second going through the volume.

15. Reserved for future use. Outputs ‘0’.

16. Reserved for future use. Outputs ‘0’.

7.4.1.9 Message Field 25 Fault Status of the PWS100

This field will output the fault status of the PWS100. The value output is from

0 to 4. 0 = no fault, 1 = Possible degraded performance, 2 = Degraded

performance, 3 = Maintenance required, 4 = Laser fault.

7.4.1.10 Message Field 30 External Sensor Temperature, RH% and Wetbulb

This field will output the averaged temperature (°C), sampled relative humidity

and averaged wetbulb temperature (°C) calculated over the Message_Interval

defined.

7.4.1.11 Message Field 31 External Sensor Maximum and Minimum Temperature

This field will output the maximum and minimum temperature (°C) calculated

over the Message_Interval defined.

7.4.1.12 Message Field 33 External Sensor Wetness

This field will output the sampled wetness (0-100%).

7.4.1.13 Message Field 34 External Sensor Aux

This field will output the sampled auxiliary sensor output. Such an auxiliary

sensor needs to be defined.

7.4.1.14 Message Field 40 Precipitation Intensity

This field will output the precipitation intensity (mm / hour) calculated over the

Message_Interval defined.

7-11

Page 48

Section 7. Operation

NOTE

The PWS100 only measures particles / visibility 90% of the time

so precipitation intensity is scaled appropriately.

7.4.1.15 Message Field 41 Precipitation Accumulation

This field will output the precipitation accumulation (mm) calculated over the

Message_Interval defined.

NOTE

The PWS100 only measures particles / visibility 90% of the time

so precipitation totals are scaled appropriately.

7.4.1.16 Message Field 42 Drop Size Distribution

This field will output the drop size distribution table which is output as 300

values, starting with the 0 to 0.1 mm bin, in steps of 0.1 mm up to 30 mm. This

is calculated over the Message_Interval defined.

7.4.1.17 Message Field 43 Average Velocity (ms

-1

) and Average Size (mm)

This field will output the average velocity and average size values ignoring any

particle type classifications.

7.4.1.18 Message Field 44 Type Distribution

This field will output the type distribution which is a series of 11 values for

each particle type which shows the number of each type of particle classified.

The order of the output is: drizzle, freezing drizzle, rain, freezing rain, snow

grains, snow flakes, ice pellets, hail, graupel, error, unknown.

7.4.1.19 Message Field 45 Size / Velocity Type Map 1 (20 x 20)

This field will output a size and velocity map with the following classes:

Particle diameter class

Class Diameter [mm] Class width [mm]

*1 =>0.00 0.24

2 =>0.24 0.12

3 =>0.36 0.14