Page 1

P2546A-L Anemometer

8/12

Copyright © 2012

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell's obligation under this warranty is

limited to repairing or replacing (at Campbell's option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

33

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a "Statement of Product Cleanliness

and Decontamination" form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer's expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction.................................................................1

2. Cautionary Statements...............................................1

3. Initial Inspection .........................................................1

4. Quickstart .................................................................... 2

4.1 Step 1 — Mount the Sensor .................................................................2

4.2 Step 2 — Use SCWin ShortCut to Program Datalogger and

Generate Wiring Diagram.................................................................3

5. Overview......................................................................5

6. Specifications .............................................................6

6.1 Calibration............................................................................................7

6.2 Switching Characteristics.....................................................................7

7. Installation...................................................................7

7.1 Wiring ..................................................................................................7

7.2 Programming........................................................................................8

7.2.1 Example Program..........................................................................9

8. Troubleshooting........................................................10

9. Maintenance ..............................................................10

10. References ................................................................11

Figures

4-1. 27739 pole mounted to a crossarm via the CM220..............................2

5-1. P2546A Anemometer...........................................................................5

Tables

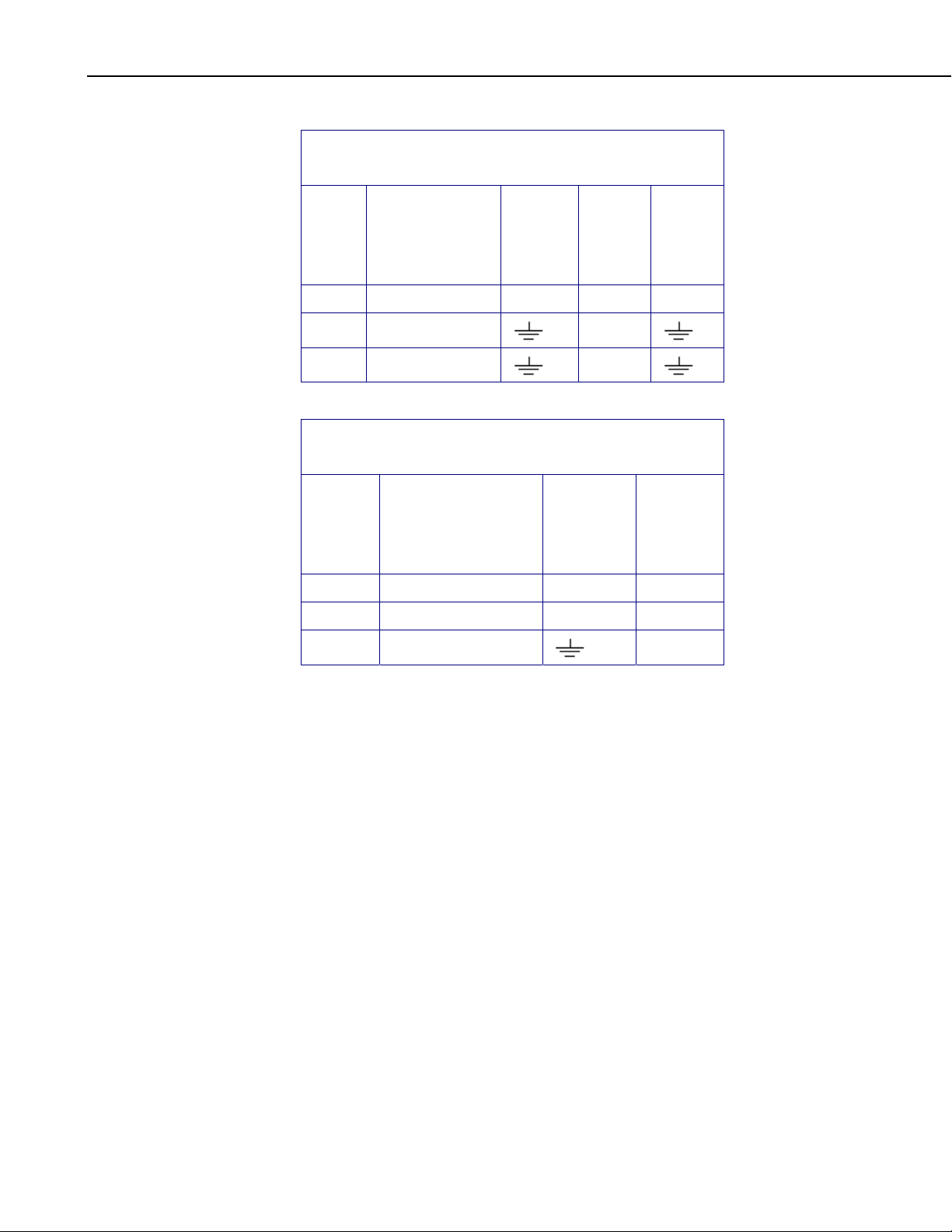

7-1. Connections to Campbell Scientific Dataloggers Pulse Channels .......8

7-2. Connections to Campbell Scientific Dataloggers Control Ports...........8

7-3. Wind Speed Multiplier and Offset .......................................................9

i

Page 6

Page 7

P2546A-L Anemometer

1. Introduction

The P2546A is a Class 1 anemometer used in wind energy applications. It

primarily provides wind speed resource assessment, and wind turbine power

performance monitoring. Wind speed is sensed by a three-cup rotor assembly.

Magnets mounted on the shaft cause a switch to close and open two times per

revolution. Our dataloggers measure the switch closure and convert the signal

to engineering units (mph, m/s, knots).

Before using the P2546A-L Anemometer, please study

• Section 2. Cautionary Statements

• Section 3. Initial Inspection

• Section 4. Quickstart

More details are available in the remaining sections.

2. Cautionary Statements

• The P2546A is a precision instrument. Please handle it with care.

• If the P2546A is to be installed at heights over 6 feet, be familiar with

tower safety and follow safe tower climbing procedures.

• Danger — Use extreme care when working near overhead electrical wires.

Check for overhead wires before mounting the P2546A or before raising a

tower.

3. Initial Inspection

• Upon receipt of the P2546A, inspect the packaging and contents for

damage. File damage claims with the shipping company. Immediately

check package contents against the shipping documentation. Contact

Campbell Scientific about any discrepancies.

• The model number and cable length are printed on a label at the

connection end of the cable. Check this information against the shipping

documents to ensure the expected product and cable length are received.

• Each P2546A anemometer is shipped with a MEASNET calibration

certificate that contains information concerning where the anemometer

was calibrated, the calibration procedure used, the calibration equation

obtained, and the serial number of the anemometer. Cross check the serial

number in the calibration certificate against the serial number on the

anemometer to ensure that the given sensitivity value corresponds to your

sensor.

1

Page 8

P2546A-L Anemometer

4. Quickstart

4.1 Step 1 — Mount the Sensor

To mount the sensor, do the following.

1. Mount a CM202, CM204, or CM206 crossarm to a tripod or tower.

2. Orient the crossarm north-south, with the CM220 Mount on the north end.

3. Place the 27739 30 inch pole in the bottom of the P2546A.

4. Place the bottom of the 27739 pole in the CM220's u-bolt and tighten the

nuts (see FIGURE 4-1).

5. Use a bubble level to ensure that the anemometer is level.

6. Route the sensor cable along the underside of the crossarm to the tripod or

tower, and to the instrument enclosure.

7. Secure the cable to the 27739 pole, crossarm, and tripod or tower using

cable ties.

2

FIGURE 4-1. 27739 pole mounted to a crossarm via the CM220

Page 9

P2546A-L Anemometer

4.2 Step 2 — Use SCWin ShortCut to Program Datalogger and Generate Wiring Diagram

The simplest method for programming the datalogger to measure an P2546A is

to use Campbell Scientific's SCWin Short Cut Program Generator.

1. Open Short Cut and click on New Program.

2. Select datalogger and enter scan interval.

3

Page 10

P2546A-L Anemometer

3. Select P2546A and select the right arrow to add it to the list of sensors to

be measured then select next.

4. Select the outputs then select finish.

4

Page 11

P2546A-L Anemometer

5. Wire according to the wiring diagram generated by SCWin Short Cut.

5. Overview

The P2546A-L cup anemometer is a sturdy device that senses wind speed with

a three-cup rotor assembly (see FIGURE 5-1). Permanent magnets mounted on

the shaft cause a switch to close and open two times per revolution. The switch

has no bounce, and is equipped with a special mechanism that reduces the

variation in operating time over the frequency range. This feature facilitates

obtaining instantaneous wind speed by measuring the time interval of each

revolution.

FIGURE 5-1. P2546A Anemometer

5

Page 12

P2546A-L Anemometer

The P2546A anemometer is manufactured by Windsensor and cabled by

Campbell Scientific. Lead length for the P2546A is specified when the sensor

is ordered.

The P2546A's cable can terminate in:

6. Specifications

Features:

• Pigtails that connect directly to a Campbell Scientific datalogger

(option –PT).

• Connector that attaches to a prewired enclosure (option –PW). Refer

to www.campbellsci.com/prewired-enclosures for more information.

• Calibration — The P2546A-L is shipped with a MEASNET

certificate containing information about where the anemometer was

calibrated, the calibration procedure used, the calibration equation

obtained, and the serial number of the anemometer.

• Quality — Constructed only of durable materials such as anodized

aluminum and stainless steel.

NOTE

Compatibility

Dataloggers: CR800 / 850, CR1000, CR3000, CR5000,

CR10(X), CR510, CR23X, 21X, CR7

The specifications are based on 80 wind tunnel calibrations

performed according to the Measnet Cup Anemometer

Calibration Procedure. The specified offset and gain figures

represent the mean values of these calibrations. Variation among

units designates the maximum deviation of any unit from the

straight line representing these mean values. All units are run-in

for 225 hours at 9 m/s, in order to reduce the initial bearing

friction to a level close to the steady state value. After run-in,

bearing friction is tested at –15 °C and at room temperature. The

allowed limits for this test assures that the temperature influence

on the calibration is within the specified limit.

Starting Threshold: < 0.4 m/s

Starting Speed: 0.27 m/s

Gain: 0.6201 m

Distance Constant: λ0 = 1.81 ± 0.04 m

6

Standard Deviation of Offset: 0.014 m/s

Standard Deviation of Gain: 0.027 m

Variation Among Units: ±1%

Page 13

Nonlinearity: < 0.04 m/s

Temperature Influence

(-15° to 60°C): < 0.05 m/s

6.1 Calibration

Standard: U=A0+B0×f ,

Where:

U=Wind speed in m/s

f = Output frequency in Hz

A0 = 0.27 m/s

B

6.2 Switching Characteristics

Signal Type: potential free contact closure

Duty Cycle: 40% to 60%

Maximum Switching Voltage: 30 V

= 0.620 m

0

P2546A-L Anemometer

7. Installation

7.1 Wiring

Maximum Recommended

Switching Current: 10 mA

Series Resistance: 330 Ω, 1 W

Operating Temperature: –35° to 60°C

Locate wind sensors away from obstructions (e.g., trees and building). As a

general rule, there should be a horizontal distance of at least ten times the

height of the obstruction between the wind set and the obstruction. If mounting

the sensors on the roof of a building, the height of the sensors above the roof

should be at least 1.5 times the height of the building. See Section 10 for a list

of references that discuss siting wind speed and direction sensors. For power

performance applications, refer to IEC 61400-12-1 which specifies the

mounting and location of anemometers.

Connections to Campbell Scientific dataloggers are given in TABLE 7-1 and

TABLE 7-2. When Short Cut program generator software is used to create the

datalogger program, wire the sensor to the datalogger as directed by the wiring

diagram created by Short Cut.

7

Page 14

P2546A-L Anemometer

TABLE 7-1. Connections to Campbell Scientific Dataloggers

Pulse Channels

Color

White Signal Pulse Pulse Pulse

Brown Signal Reference

Clear Shield

TABLE 7-2. Connections to Campbell Scientific Dataloggers

Color

White Signal C1-C8 C6-C8

Brown Signal Reference 5V 5V

Clear Shield

Wire Label

Wire Label

CR800

CR850

CR5000

CR3000

CR1000

Control Ports

CR510

CR500

CR10X

G

G

CR800

CR850

CR5000

CR3000

CR1000

21X

CR7

CR23X

CR10X

G

8

7.2 Programming

This section is for users who write their own programs. A datalogger program

to measure this sensor can be created using Campbell Scientifics’ Short Cut

Program Builder software. You do not need to read this section to use Short

Cut.

Wind speed is typically measured an a datalogger pulse channel. The P2546A

uses the CRBasic PulseCount() instruction configuring the pulse channel for

switch closure with frequency counting. For dataloggers programmed with

EDLOG, specify configuration code 22 to output frequency in Hertz.

The expression for wind speed (U) is:

U = MX + B

where

M = multiplier

X = number of pulses per second (Hertz)

B = offset

Page 15

The following table lists the multiplier and offset to obtain meters per second

(m/s) when the pulse count instruction is configured to output the result in Hz.

Standard Calibration is listed below. Using the MEASNET calibration will

give measurements in m/s. MEASNET calibration multiplier and offset will

be listed on the MEASNET calibration sheet included with each sensor.

Model m/s

P2546A Multiplier = 0.6207

7.2.1 Example Program

The following CR1000 example program uses a pulse port to measure the

P2546A once a second. The program stores the mean, maximum, minimum,

and standard deviation of the measured wind speed over a 10 minute interval.

Wiring for the example is given in the following table.

P2546A-L Anemometer

TABLE 7-3. Wind Speed Multiplier and Offset

Offset = 0.27

'Pulse Port Example

'CR1000 Series Datalogger

'Program to measure P2546A and store ten minute averages

'Wiring

' Datalogger

'Color Description Channel

'----- ----------- -------

'Brown Signal Reference P1

'White Signal

'Clear Shield

Const P2546A_mult = .6201

Const p2546a_offset = .27

Public PTemp, batt_volt

Public P2546A

'Define Data Tables

DataTable (Test,1,1000)

DataInterval (0,10,Min,10)

Minimum (1,batt_volt,FP2,0,False)

Sample (1,PTemp,FP2)

Average (1,P2546A,FP2,False)

Maximum (1,P2546A,FP2,False,False)

Minimum (1,P2546A,FP2,False,False)

StdDev (1,P2546A,FP2,False)

EndTable

'Main Program

BeginProg

Scan (1,Sec,0,0)

PanelTemp (PTemp,250)

Battery (batt_volt)

'Measure P2546A and correct measurement if wind speed is zero

PulseCount (P2546A,1,1,2,1,P2546A_mult,p2546a_offset)

If P2546A <= p2546a_offset Then P2546A = 0

9

Page 16

P2546A-L Anemometer

'Call data tables

CallTable Test

NextScan

EndProg

8. Troubleshooting

Symptom: No wind speed

1. Check that the sensor is wired to the pulse channel specified by the pulse

count instruction.

2. Verify that the Configuration Code, and Multiplier and Offset parameters

for the Pulse Count instruction are correct for the datalogger type.

Symptom: Wind speed does not change

1. For the dataloggers that are programmed with Edlog, the input location for

wind speed is not updated if the datalogger is getting “Program Table

Overruns”. Increase the execution interval (scan rate) to prevent overruns.

9. Maintenance

Every month do a visual/audio inspection of the anemometer at low wind

speeds. Verify that the anemometer bearing rotate freely. Inspect the sensor

for physical damage. Replace the anemometer bearings when they become

noisy, or the wind speed threshold increases above an acceptable level.

CAUTION

Disassembling an anemometer to change the bearings will

invalidate the MEASNET calibration.

MEASNET calibrations are normally valid for 12 months in the field

(assuming the anemometer is installed within 6 months of the calibration test).

In high-accuracy applications, Campbell Scientific recommends that the

anemometer be returned to us for maintenance/overhaul between deployments;

we can arrange for a new MEASNET calibration after maintenance/overhaul

where required.

Before the anemometer is sent to Campbell Scientific, the customer must get

an RMA (returned material authorization) and fill out the Declaration of

Hazardous Material and Decontamination form.

10

Page 17

10. References

P2546A-L Anemometer

IEC 61400 Part 12-1, “Wind turbine generator systems Part 12: Wind Turbine

Power Performance Testing”.

The following references give detailed information on siting wind speed and

wind direction sensors.

EPA, 1989: Quality Assurance Handbook for Air Pollution Measurements

System, Office of Research and Development, Research Triangle Park,

NC, 27711.

EPA, 1987: On-Site Meteorological Program Guidance for Regulatory

Modeling Applications, EPA-450/4-87-013, Office of Air Quality Planning

and Standards, Research Triangle Park, NC 27711.

The State Climatologist, 1985: Publication of the American Association of

State Climatologists: Height and Exposure Standards, for Sensors on

Automated Weather Stations, vol. 9, No. 4.

WMO, 1983: Guide to Meteorological Instruments and Methods of

Observation, World Meteorological Organization, No. 8, 5th edition,

Geneva, Switzerland.

11

Page 18

P2546A-L Anemometer

12

Page 19

Page 20

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

Garbutt Post Shop QLD 4814

www.campbellsci.com.au

Campbell Scientific do Brazil Ltda. (CSB)

Rua Luisa Crapsi Orsi, 15 Butantã

CEP: 005543-000 São Paulo SP BRAZIL

www.campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

www.campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

www.campbellsci.cc

Campbell Scientific Ltd. (CSL)

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk

Campbell Scientific Ltd. (France)

3 Avenue de la Division Leclerc

www.campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

www.campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or interna tional representative.

• info@campbellsci.com

PO Box 2450

• cleroux@csafrica.co.za

PO Box 8108

AUSTRALIA

• info@campbellsci.com.au

• suporte@campbellsci.com.br

CANADA

• dataloggers@campbellsci.ca

COSTA RICA

• info@campbellsci.cc

Campbell Park

80 Hathern Road

• sales@campbellsci.co.uk

92160 ANTONY

FRANCE

• info@campbellsci.fr

08024 Barcelona

SPAIN

• info@campbellsci.es

Loading...

Loading...