Page 1

OBS-5+ System

Revision: 11/13

Copyright © 2008-2013

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell’s obligation under this warranty is

limited to repairing or replacing (at Campbell’s option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an application engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction.................................................................1

2. Cautionary Statements............................................... 1

3. Initial Inspection .........................................................1

3.1 Ships With............................................................................................1

4. Overview......................................................................2

4.1 Optics ...................................................................................................2

4.2 SSC-Measurement Principle ................................................................3

5. Specifications .............................................................5

5.1 Measurement Range.............................................................................5

5.2 Accuracy ..............................................................................................6

5.3 OBS-5+ Sensor ....................................................................................6

5.4 Other Data............................................................................................6

5.5 Dimensions...........................................................................................6

6. Operation.....................................................................7

6.1 Instrument Setup ..................................................................................7

6.1.1 Mounting Suggestions...................................................................7

6.1.2 Surveys..........................................................................................7

6.1.3 Logging Data ................................................................................8

6.1.4 Battery Installation........................................................................8

6.2 OBS-5+Utility Software.......................................................................9

6.2.1 Software Installation .....................................................................9

6.2.2 Running the OBS-5+ Utility .......................................................10

6.2.3 Pull-Down Menus .......................................................................11

6.2.4 Communication Settings .............................................................11

6.2.5 Testing Sensors ...........................................................................12

6.2.6 Monitoring Turbidity (NTU).......................................................13

6.2.7 Water Density and Barometric Corrections ................................13

6.2.8 Sample Statistics .........................................................................13

6.2.9 Sampling Modes and Terms........................................................14

6.2.10 Surveying ....................................................................................15

6.2.11 Cyclic Sampling ..........................................................................17

6.2.12 Data Retrieval .............................................................................18

6.2.13 Shutdown ....................................................................................18

6.2.14 Graphing and Printing.................................................................18

6.2.15 Excel Spreadsheets......................................................................19

i

Page 6

Table of Contents

7. Calibration .................................................................20

7.1 Sediment and NTU Calibration......................................................... 20

7.1.1 General Guidance....................................................................... 21

7.1.2 Equipment and Materials............................................................ 24

7.1.3 Procedure for Sediment.............................................................. 24

7.2 Turbidity (NTU) Calibration ............................................................. 28

7.2.1 Equipment and Materials............................................................ 28

7.2.2 Procedure for Turbidity .............................................................. 28

8. Troubleshooting........................................................29

9. Maintenance ..............................................................32

9.1 OBS-5+ Sensor.................................................................................. 32

9.2 Pressure Sensor.................................................................................. 32

9.3 Batteries............................................................................................. 33

9.4 Pressure Housing............................................................................... 33

9.5 User-Serviceable Parts....................................................................... 33

10. Interfering Factors ....................................................34

10.1 Particle Size ....................................................................................... 34

10.2 NIR Reflectivity ................................................................................ 35

10.3 Particle Shape, Flocculation, and Disaggregation ............................. 36

11. References.................................................................38

Appendix

A.

Turbidity Standards ................................................A-1

Figures

4-1. Dimensions (top), sensor endcap with copper antifoulant (Cu a.f.)

collars (left) and connector endcap (right)....................................... 2

4-2. Schematic of optical system................................................................ 3

4-3. Sample calibration curves (fine and bold lines), lookup tables I, II,

and III (bold curves), and sediment concentrations pf ND (open

arrow) and FD (solid arrow) peaks. ................................................. 4

4-4. Calibration curves for four different sediments and SSC values for

near-detector peaks (colored arrowheads). ...................................... 5

6-1. Electrical connections.......................................................................... 8

6-2. Battery installation: A) endcap removal, B) wiping, C) cable

disconnect, and D) battery contact................................................... 9

6-3. New data log prompt......................................................................... 10

6-4. Designating your own file name and destination............................... 10

7-1. Manual (left) and automatic (right) sediment suspenders.................. 21

7-2. Lookup tables and table limits (a, b, and c)....................................... 22

7-3. OBS-5+ in big black tub of clean water ............................................ 25

7-4. OBS-5+ in suspender tub................................................................... 26

7-5. OBS-5+ in 100 mm cup..................................................................... 29

ii

Page 7

Tables

Table of Contents

8-1. Internal components...........................................................................31

10-1. Effects of sediment size .....................................................................35

10-2. Near-infrared reflectivity of minerals.................................................36

10-3. Effects of disaggregation methods.....................................................37

6-1. Working and Maximum Depths...........................................................7

7-1. Schedule of Concentrations for Sediment Calibrations......................23

7-2. SSC-Calculation Spreadsheet.............................................................23

9-1. Battery Life in Hours with 100% Power............................................33

10-1. Relative magnitude of the effects of sediment characteristics on

OBS-5+ sensitivity .........................................................................34

iii

Page 8

Table of Contents

iv

Page 9

OBS-5+ System

1. Introduction

The manual describes the features of the OBS-5+®, as well as its use for

surveys and battery-powered, internal-storage operations. Using backscatter

from a 780 nm laser diode and a patented dual-detection system (U.S. Patent

Number 5,796,481), a calibrated OBS-5+ measures suspended sediment

concentrations, suspended solids concentration (SSC), as large as 200 g L

which is about 10 times higher than standard OBS technology.

Before installing the OBS-5+, please study:

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

2. Cautionary Statements

• Although the OBS-5+ is rugged, it should be handled as a precision

scientific instrument.

–1

,

• Maximum depth for the OBS-5+ is limited by the installed pressure

sensor. If the maximum depths are exceeded, the pressure sensor will

rupture and the housing will flood. See Section 6.1, Instrument Setup, for

more information.

• Always orient the unit so that the OBS-5+ sensor “looks” into water clear

of reflective surfaces.

• Pad the end caps that contact metal with electrical tape, neoprene, or

expanded polyethylene tubes.

• Never mount the instrument by its end caps or attach anything to them.

This could a cause a leak.

• Always put the OBS-5+ in sleep mode when it will not be used for a while

to conserve battery capacity (see Section 6.2.13, Shutdown).

3. Initial Inspection

• Upon receipt of the OBS-5+, inspect the packaging and contents for

damage. File damage claims with the shipping company.

• Check this information against the shipping documents to ensure the

correct product is received (see Section 3.1, Ships With).

3.1 Ships With

21304 Accessory Kit

20919 Software Support CD

ResourceDVD

1

Page 10

OBS-5+ System

4. Overview

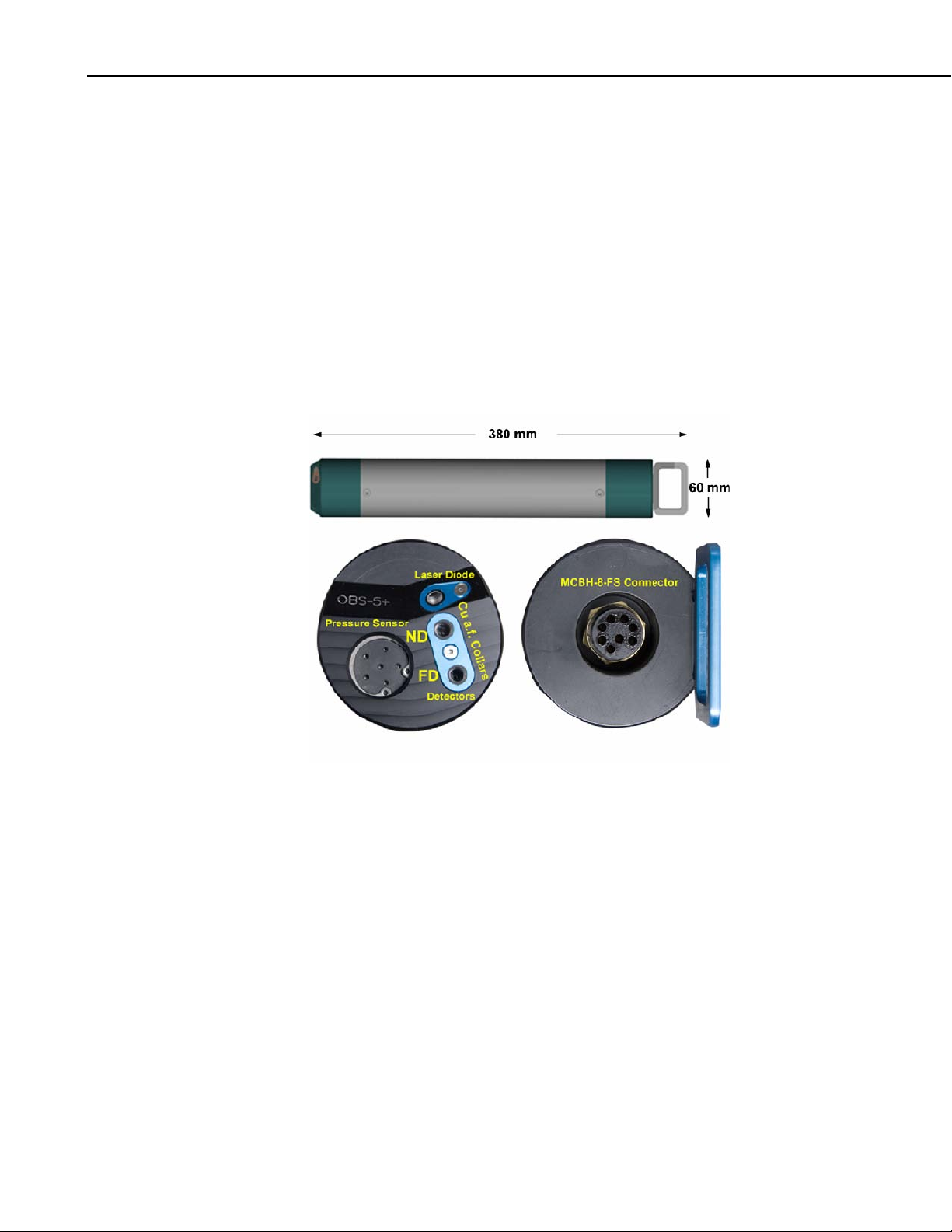

FIGURE 4-1 shows the dimensions of the OBS-5+, the sensors in the sensor

endcap, and underwater connection. Detailed specifications are provided in

Section 5, Specifications. The OBS-5+ can be operated in Survey or Cyclic

Modes. In Survey Mode, the unit sends data via RS-232 or RS-485 to a PC at

two hertz, and in Cyclic Mode, it logs as many as 200,000 scans of time, date,

depth, and g L

sampling continuously, the unit will run about 125 hours on three C-size

alkaline batteries in 20ºC water (about two weeks of eight-hour survey days).

When using the instrument for surveys, the data are captured by a PC running

the OBS-5+ software. Pressure is measured with a silicon strain-gauge

pressure sensor and the depth of the instrument is calculated from water density

and barometric pressure entered by the operator.

–1

in flash memory (one sample per hour for 23 years). When

2

FIGURE 4-1. Dimensions (top), sensor endcap with copper antifoulant

(Cu a.f.) collars (left) and connector endcap (right)

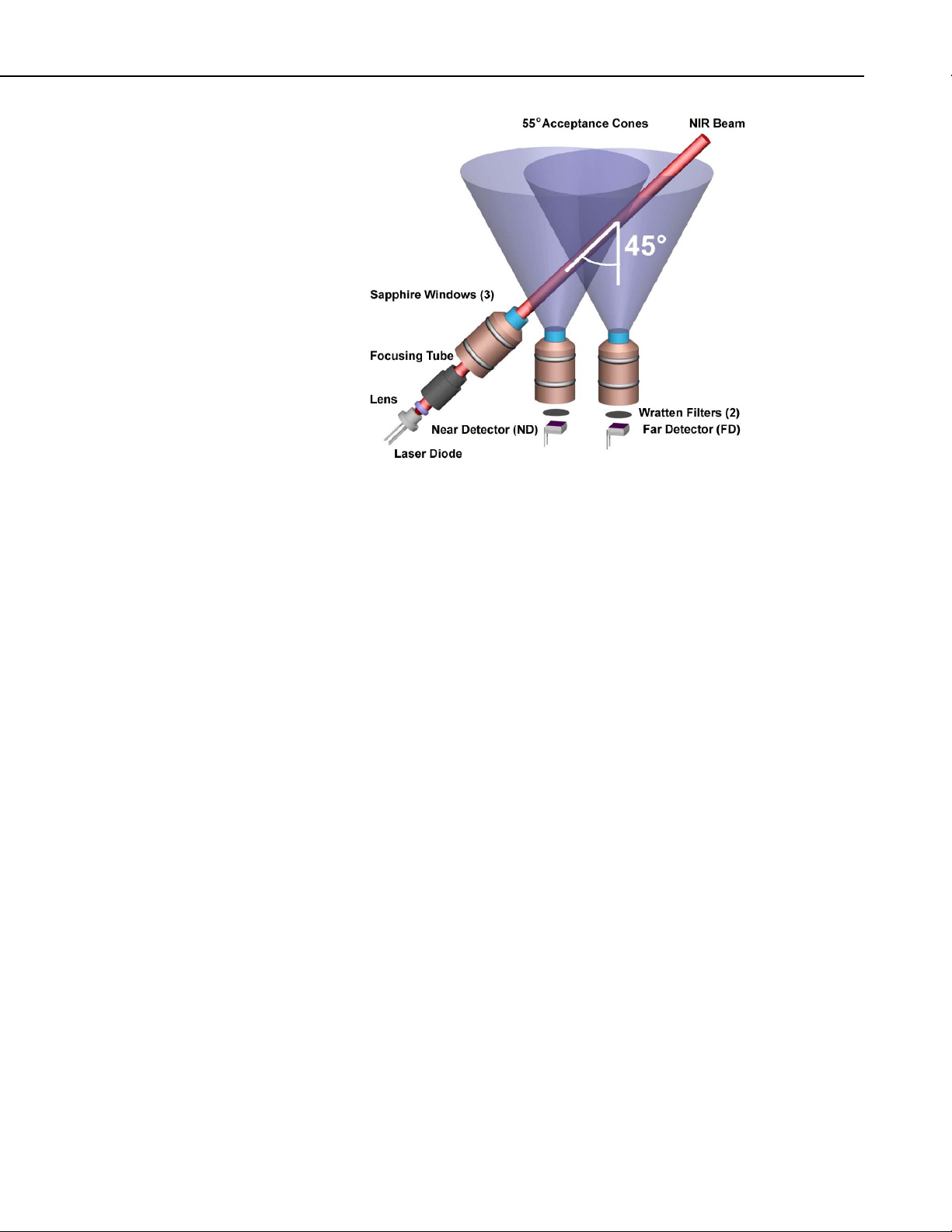

4.1 Optics

The heart of the OBS-5+ is an optical system comprised of a near infrared

(NIR) laser diode and a photodetector positioned 10 mm from the laser, called

the near detector (ND), and one mounted 25 mm from the laser, called the far

detector (FD), see FIGURE 4-2. The detector acceptance-cone angle is 55º,

which means that photons must enter the detector sapphire windows at angles

less than 27.5º to be detected. The laser light is collimated to a 3 mm by 1 mm

elliptical beam with convergence < 2.5 mrad. The angle between the NIR

beam and detector acceptance-cone axes is 45º. The OBS-5+ can detect light

scattered by particles illuminated by the NIR beam at angles between 105º to

165º. With its automatic-power-control circuit, the laser diode provides stable

optical power over time and the 0 to 30ºC operating temperature range.

Page 11

FIGURE 4-2. Schematic of optical system

OBS-5+ System

4.2 SSC-Measurement Principle

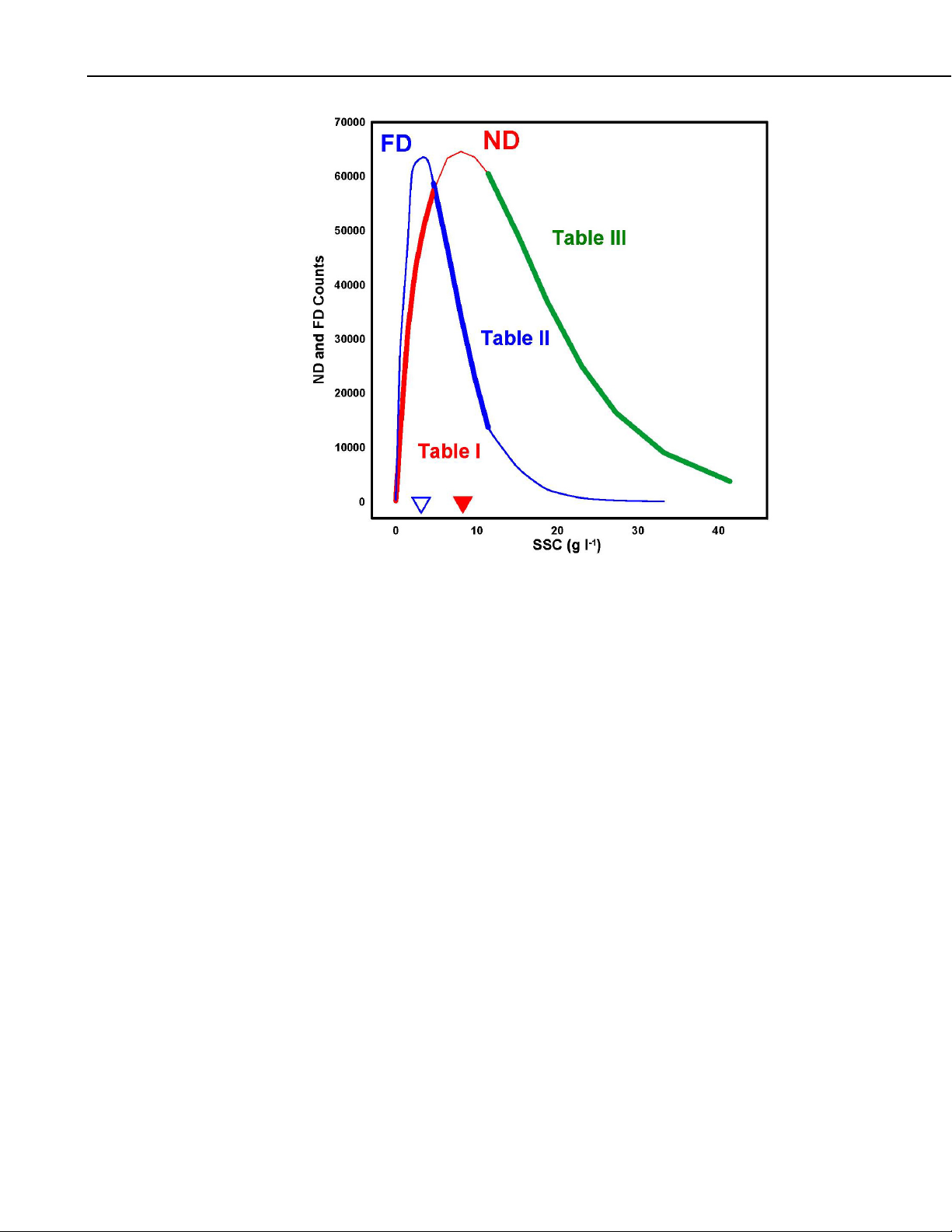

In FIGURE 4-2, suspended particles scatter light from the NIR beam onto the

near and far detectors, and suspended solids concentration (SSC) is estimated

with signals counts from these detectors by a microcontroller, using a set of

logic rules and lookup tables derived from calibration data. Counts are the

digital equivalents of the ND and FD signals and are proportional to

backscatter intensity. Sample calibration curves relating ND and FD counts to

sediment concentration in g L

concentration increases from 0, the ND and FD signals rise to maxima at peak

concentrations, shown by the red (open) and blue (solid) arrowheads above the

x axis. Beyond the peak sediment concentrations, light attenuation is the

dominant factor controlling the light level at the detectors, and so the ND and

FD counts decline. The scattered NIR must travel farther to be detected by the

FD than by the ND, and therefore the peak of the FD curve occurs at a lower

sediment concentration than the peak of the ND curve. The instrument exploits

these peak offsets to estimate sediment concentration. Using either the ND or

FD counts, whichever is indicated by the logic rules, the microcontroller does a

spline interpolation between calibration values to derive an SSC value. It then

combines this value with time and pressure data, and sends the results to a PC.

–1

are shown on FIGURE 4-3. As particle

3

Page 12

OBS-5+ System

FIGURE 4-3. Sample calibration curves (fine and bold lines), lookup

tables I, II, and III (bold curves), and sediment concentrations pf ND

(open arrow) and FD (solid arrow) peaks.

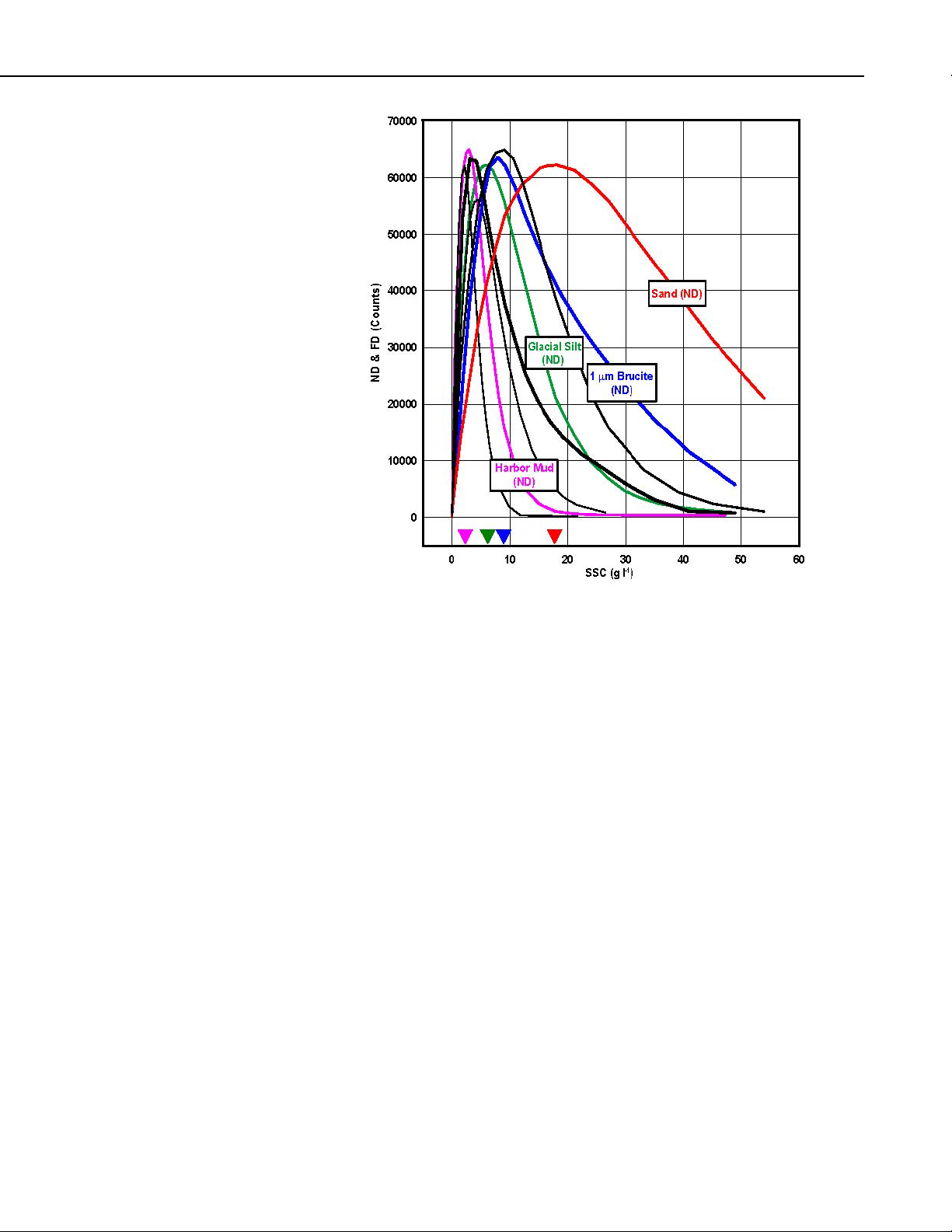

The concentrations associated with the ND and FD peaks depend on sediment

characteristics as shown by the variety of response curves and the colored

arrowheads on FIGURE 4-4. Other sediment characteristics being equal, such

as shape and NIR reflectivity (see Section 10, Interfering Factors), larger

particles produce higher peak concentrations and greater OBS-5+ measurement

ranges than smaller particles.

4

Page 13

OBS-5+ System

FIGURE 4-4. Calibration curves for four different sediments and SSC

5. Specifications

Features:

5.1 Measurement Range

Mud (D50=20μm): 0 to 50,000 mg/l

values for near-detector peaks (colored arrowheads).

• Connects directly to a PC—no datalogger needed

• Operates up to six months on three C-cell batteries

• Monitors high sediment concentrations (up to 200g/L)

• Logs depth, wave height, wave period, temperature, and salinity

• Records 200,000 scans of data in the OBS-5+ flash memory

Sand (D

Pressure

Turbidity: 0.4 to 1,000 NTU

=250μm): 0 to 200,000 mg/l

50

1

: 0 to 10, 20, 50, 100, or 200 m

5

Page 14

OBS-5+ System

5.2 Accuracy

5.3 OBS-5+ Sensor

5.4 Other Data

Mud: 2.0% of reading

Sand: 4.0% of reading

Pressure: 0.5% of full scale

Turbidity: 1.5% of full scale

Laser wavelength: 780 nm

Scattering angles (clean water): 105º to 165º

Drift over time: <30 ppm per month

Drift over temperature: <200 ppm per ºC

Maximum sampling rate: 25 Hz

Maximum data rate: 2 Hz

Data capacity: 8 MB/200,000 lines

Battery capacity: 8 A h

Maximum battery life

External supply voltage: 6 to 18 Vdc

External supply current: 55 mA

Serial-data protocols: RS-232 & RS-485

Maximum housing depth: 300 m (984 ft)

Operating temperature range: 0º to 40ºC

Storage temperature range: –20º to 70ºC

5.5 Dimensions

Length / diameter: 380 mm (15 in) / 60 mm (2.4 in)

2

: 3,000 hrs

6

Weight: 2.04 kg (4.5 lb)

Weight (submerged): 1.02 kg (2.3 lb)

1

Range depends on pressure sensor option chosen.

2

Sampling interval is two hours and duration is two minutes.

Page 15

6. Operation

6.1 Instrument Setup

6.1.1 Mounting Suggestions

OBS-5+ System

CAUTION

Maximum depth for the OBS-5+ is limited by the installed

pressure sensor. If the maximum depths are exceeded,

the pressure sensor will rupture and the housing will flood.

The depth limits are listed in TABLE 6-1.

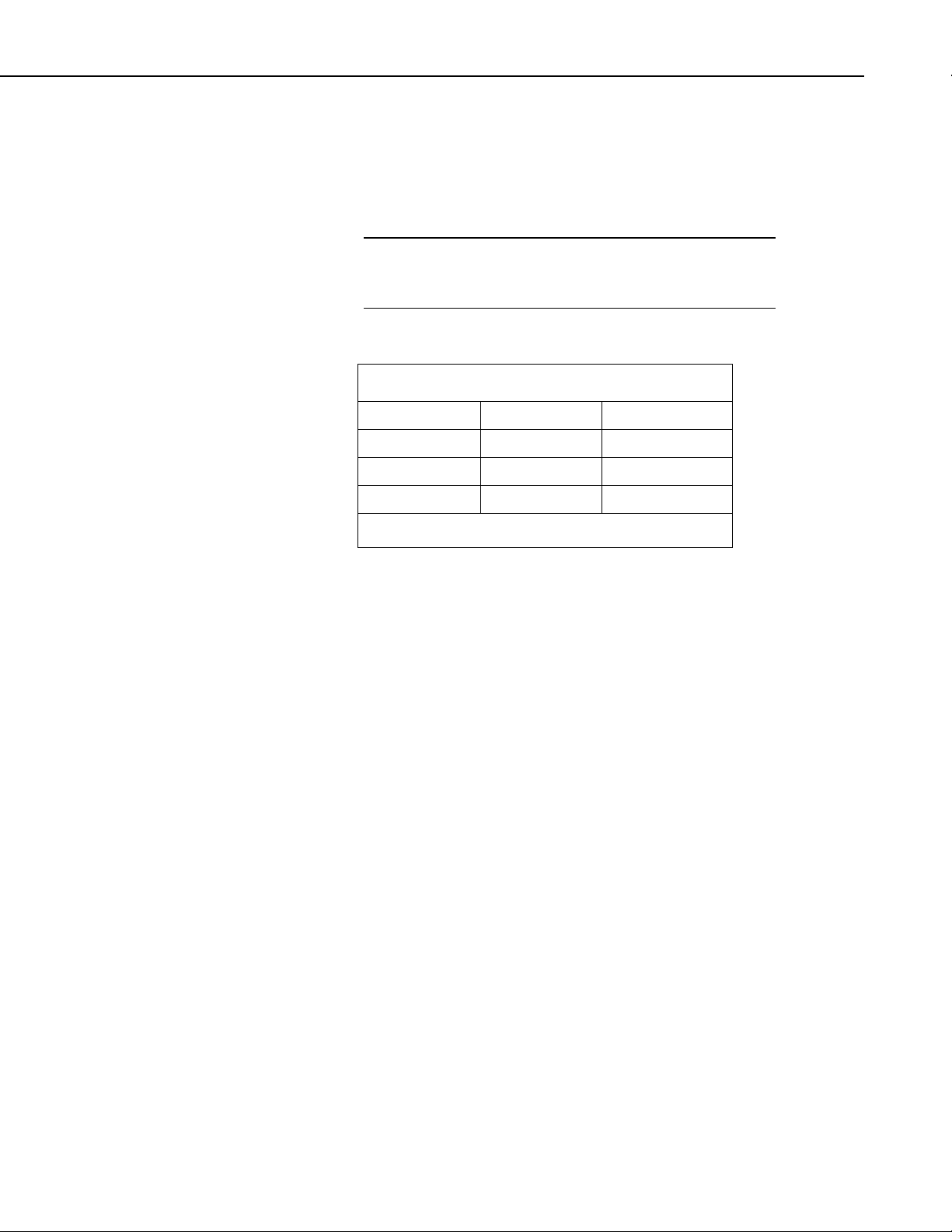

TABLE 6-1. Working and Maximum Depths

Pressure Sensor Working Depth Maximum Depth

5 Bar 0 to 50 meters 75 meters

10 Bar 0 to 100 meters 150 meters

20 Bar 0 to 200 meters 300 meters

(1 Bar = 10 dBar ≅ 10 meters of fresh water)

The following precautions should be followed to ensure the unit can function

properly and is not lost or damaged.

• Always orient the unit so that the OBS-5+ sensor “looks” into water clear

of reflective surfaces.

• Pad the endcaps that contact metal with electrical tape, neoprene, or

expanded polyethylene tubes.

6.1.2 Surveys

• Never mount the instrument by its endcaps or attach anything to them.

This could a cause a leak.

The OBS-5+ will usually be towed with a cable harness for surveys. The serial

cable can tow the OBS-5+ without a depressor weight or vane as long as the

connector is strain relieved. Strain relief can be provided by attaching the

cable to the stainless steel housing (FIGURE 4-1) with a cable grip and a

length of 3 mm (1/8 in) wire rope. Install a cable clamp with a 0.5 m wire rope

to the serial cable, and clamp the wire rope to the pressure housing with two

stainless steel hose clamps, providing a small loop of slack cable to absorb

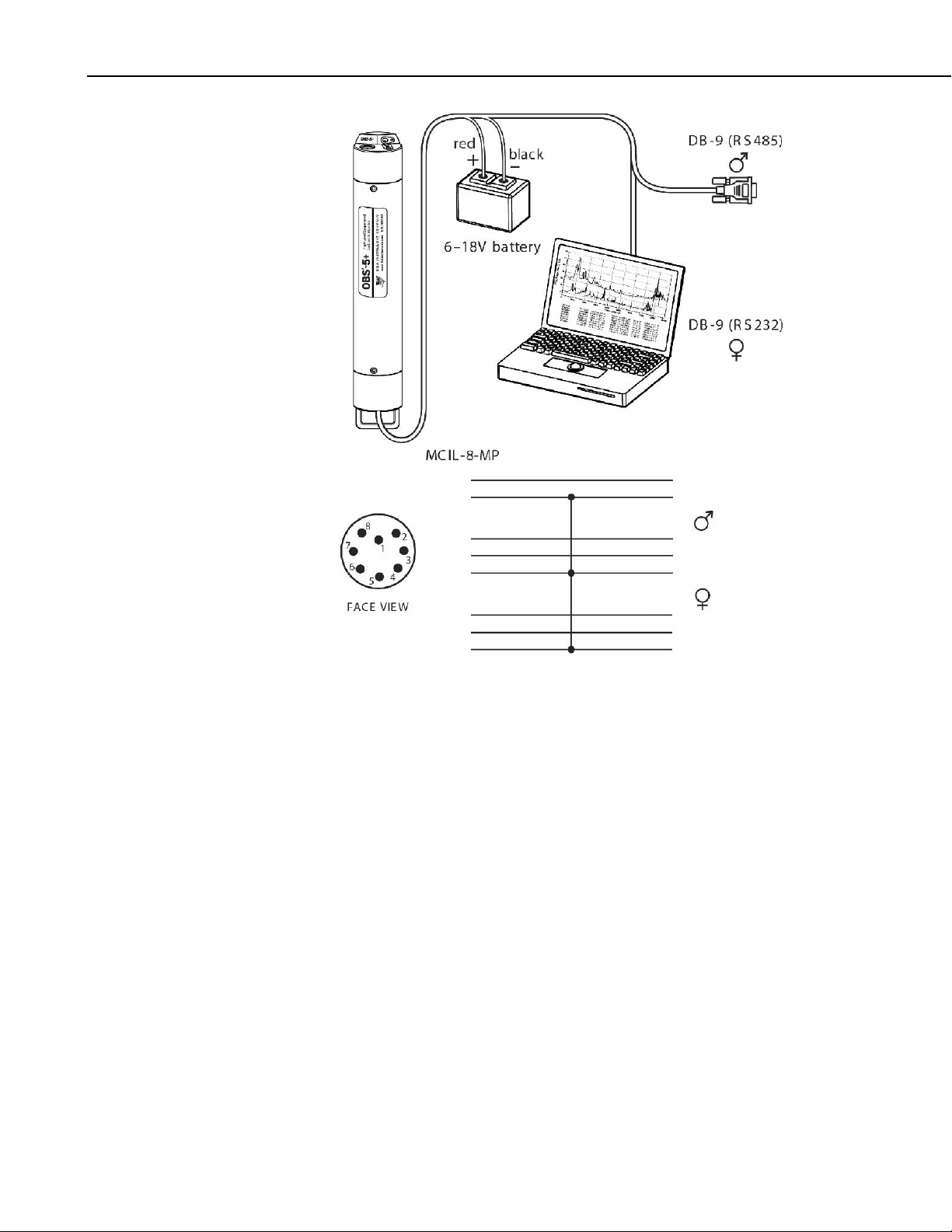

towing forces. The unit can be powered with an external battery, as shown on

FIGURE 6-1, and the serial output can be transmitted by either RS-232 or

RS-485 protocols. The latter protocol is recommended for cable lengths

greater than 25 m. An RS-485/232 serial converter is provided with each unit.

An RS-232 to USB converter is an available option.

7

Page 16

OBS-5+ System

FIGURE 6-1. Electrical connections

6.1.3 Logging Data

In applications where a survey cable is impractical or when the OBS-5+ must

be attached to an instrument frame, it can be powered by the internal batteries

and the data can be logged by the data flash memory

Cyclic Mode sampling in Section 6.2.11, Cyclic Sampling.

6.1.4 Battery Installation

Remove the set screws from the endcap with the handle and connector. If the

unit was submerged during the previous day, turn the sensor end up, so water

around the O-rings can drain out when the endcap is removed, FIGURE 6-2

(A). Pull endcap out and disconnect the inline connector (B). Wipe water

from the inside wall of the housing tube with a paper towel (C). Turn the

connector end up and push the ridge on the battery sliding contact until the

spent batteries pop out (D). Insert new batteries with the positive terminal (+)

toward the sliding contact. Push the batteries down and slide the contact over

the top of them and against the housing wall. Inspect the O-ring in the cap,

clean and grease or replace it if necessary, and replace the cap and set screws.

8

6

7

5

4

3

2

6

6 – 18 V d.c. (Red)

Power GND (Black)

DB-9

3

8

4, 1, 5, 6, 9

DB-9

2

3

5

(RS485)

(A)

(B)

(GND)

(RS232)

(RD)

(TD)

(GND)

. See instructions for

8

Page 17

OBS-5+ System

For extended deployment time, lithium batteries are a good alternative to

alkaline batteries. Campbell Scientific sells a C-cell-sized battery spacer

(pn 21905) that allows lithium C-cell batteries to be used with the OBS-5+.

Lithium C-cell batteries have a higher voltage than their alkaline counterparts,

necessitating the spacer. Campbell Scientific does not sell lithium C-cell

batteries.

FIGURE 6-2. Battery installation: A) endcap removal, B) wiping,

C) cable disconnect, and D) battery contact

6.2 OBS-5+Utility Software

6.2.1 Software Installation

Insert the CD and select “Install OBS-5+ Utility”. Follow the installation

wizard to install the software. The OBS-5+ Utility is the GUI interface with

the OBS-5+. As part of the installation, there are several additional files

included.

This section explains how to program and operate the unit with the OBS-5+

Utility. It covers: 1) turning the OBS-5+ ON and OFF and testing the sensors,

2) selecting sensors and data statistics, 3) scheduling data logging, 4) recording

9

Page 18

OBS-5+ System

6.2.2 Running the OBS-5+ Utility

data with a PC or uploading data from the OBS-5+, 5) importing data into a

spreadsheet, and 6) plotting data with OBS-5+ Utility.

1) Set PC to the time standard for your project.

2) Select the OBS-5+ program to start the OBS-5+ Utility and open the Data

Window and Toolbar with the View pull-down menu.

3) The OBS-5+ Utility will create a new data log file and prompt you to

accept the name (see FIGURE 6-3). Files are automatically named with

Greenwich Date and Time as follows: OBS5+_20010808_172433.log. Or

you can create your own file name and destination by choosing N

FIGURE 6-4). Data received from the OBS-5+ while it is connected to the

PC will be stored in this file.

o (see

FIGURE 6-3. New data log prompt

FIGURE 6-4. Designating your own file name and destination

4) Connect the OBS-5+ to a PC with the test cable (FIGURE 6-1).

5) Click

OBS-5+ clock with your PC by clicking

Connect/Disconnect to get a green light and synchronize the

.

10

Page 19

6.2.3 Pull-Down Menus

The OBS-5+ Utility has four pull-down menus for File, OBS-5+, View, and

Help.

OBS-5+ System

The File menu allows you to select the location and formatting for OBS-5+

files. Files can be opened as plots or ASCII text that can be brought into

spreadsheet programs or text editors. Plot files display OBS-5+ data

graphically in the main GUI window.

The OBS-5+ menu is used to: 1) put the instrument into a low-power Sleep, 2)

wake it up if it is sleeping (Wakeup), 3) make a Barometric Correction (see

Section 6.2.7, Water Density and Barometric Corrections), 4) view a list of

calibration tables, 5) set detector gains (Set Gains), 6) Retrieve an Active

Table, 7) Retrieve detector Gains, or 8) switch to RS-485 serial

communication.

The View menu controls the display on your PC. Switches are provided for:

• Toolbar toggles the icons ON and OFF.

• Status Bar toggles the status bar at the bottom of the screen ON or OFF.

• Data Window pops the data window into view.

6.2.4 Communication Settings

The Plot and Port Settings button has a serial port tab for configuring the

communication settings. The default settings are: 115 kB, 8 data bits, no

parity, no flow control. These settings will work for most applications and

with most PCs. In order to pick a slower baud rate and avoid data-transfer

errors, select the desired rate from the dialog box and click Apply. The rate

11

Page 20

OBS-5+ System

adjustment takes two seconds. If your PC is set to the wrong rate for some

reason, use the check box to select ONLY change host computer port. Then

click Apply and the

If you get the OBS-5+ information box, the baud rate of the unit is

synchronized with your PC. If you don’t get an information box, repeat the

above procedure until communication is established.

6.2.5 Testing Sensors

1) Before daily operations and deployments, verify that the instrument works

by clicking

sensors and click Start Survey. An example plot of data is shown below.

OBS Settings button.

Open Plot, and then clicking Survey. Select all

12

Page 21

OBS-5+ System

2) Wave your hand in front of the OBS-5+ sensor; the turbidity and SSC

levels on the top plot will fluctuate as data scrolls across the plot.

3) Blow into the pressure sensor or press your thumb on it to compress air on

the diaphragm (FIGURE 4-1). A small elevation in the pressure signal

will occur (bottom plot).

4) Click

depth corrections, and software versions.

Stop and then OBS Settings to view time, serial numbers,

6.2.6 Monitoring Turbidity (NTU)

The OBS-5+ was calibrated and factory-certified using AMCO Clear, U.S.

EPA-approved turbidity standards (www.gfschemicals.com). In order to

measure turbidity, the electronic gain of the near detector is set to the

calibration value and the active lookup table is overridden. Consequently, the

unit cannot simultaneously measure SSC (g L

NTU is selected. You must choose one or the other.

–1

) and NTU when either g L–1 or

6.2.7 Water Density and Barometric Corrections

Instrument depth is estimated from pressure and it is important to set the water

temperature and salinity so the OBS-5+ can correct for water density and

calculate depth correctly. The sensor measures absolute pressure so the

instrument must also correct for barometric pressure. Be sure to do this while

the OBS-5+ is at the surface. Depending on the magnitude of barometric

pressure fluctuations at the site and the desired accuracy, you may want to

correct data for atmospheric effects using barometric pressure simultaneously

recorded at a nearby site.

6.2.8 Sample Statistics

The individual measurements are not recorded in the data flash memory and

you must select the sample statistics that will be recorded. Two types of

statistics can be selected for OBS-5+ measurements.

13

Page 22

OBS-5+ System

6.2.9 Sampling Modes and Terms

1) Measures of central tendency, including the mean and median.

2) Measures of variation or spread in sample values, including the standard

deviation (σ) and cumulative percentages, such as X

25 and X75 (where X is

the depth, SSC, or NTU values).

The mean is the arithmetic average of the values (∑ x / n), where ∑ x is the

sum of the sample values (x) and n is the number of values (sample size). The

median (X50) is the value that exceeds 50% of the sample values and is the

best measure of central tendency when a sample has outliers. The percentages

X25, X50, X75, etc., exceed 25, 50, and 75% of the sample values.

The following terms concern OBS-5+ sampling schedules.

Interval: The time in seconds between the start of one sample and the

beginning of the next. The interval must be longer than the duration to allow

for statistical computations and data storage. The computer will prompt you if

you select an interval that is too short.

Duration: This is the length of time in seconds that the OBS-5+ will measure

its sensors. The duration must always be less than the interval. The minimum

duration is five seconds and the maximum is 2,048 seconds (0.57 hour).

Rate: Rate is the frequency of sampling for the duration of measurements. All

sensors are sampled at the same rate, typically 2, 5, 10, or 25 times per second

(Hz).

Power: This indicates the percentage of time over the duration of a sample that

sensors are ON. Higher power levels mean larger samples and better statistics,

but shorter battery life. Lower levels spare the batteries but result in more

random noise in sample statistics (lower signal-to-noise ratios, SNR)

Sample Size: The number of measurements made by a sensor in each interval;

sample size equals rate times duration.

The main factors to consider when setting up OBS-5+ Cyclic sampling

schedules include:

• Sampling interval needed to characterize the processes of interest (for

example, water level fluctuations, flood and transport duration, tidal

conditions, dredge operations, etc.).

• Maximum sediment concentration.

• Statistical requirements, such as sample size and sampling rates.

• Battery capacity.

14

The goal is to pick a sampling scheme that gets essential information about the

process of interest without taking too many samples or sampling too often.

Inefficient sampling produces excessive battery consumption and a data

avalanche with unnecessary processing. Sampling schedules are set with the

Interval, Duration, and Rate parameters. Interval sets how often data are

Page 23

OBS-5+ System

recorded. Select the longest interval that will show the changes in turbidity and

water depth that you wish to investigate. Rate sets measurement frequency.

The quicker turbidity and depth change, the higher the sampling rate should be

to get a stable average value for a sample. Finally, Duration sets how long

sensor outputs will be averaged. For example, with an interval of 30 seconds

and a duration of five seconds, the OBS-5+ will make measurements for five

seconds starting every 30 s. The sample size would be 5 x 25 = 125

measurements for a rate of 25 Hz. Always select duration and rate to give a

sample size of at least 30, and to reduce random sampling noise below 50% of

its maximum value, select them to give a size greater than 200.

Survey: Select the survey mode when operating the unit with a cable

connection to a PC and when high data rates are desired. Data can be logged

with a PC at rates up to 120 lines per minute (2 Hz).

Cyclic Sampling: Use cyclic sampling to record data internally in the 8

MB, flash memory at regular intervals; for example, every 1, 5, 15, or 30

minutes. Depending on the number of sensors measured and the statistics

selected, the OBS-5+ can log as many as 200,000 lines of data, one per hour

for 23 years, including time, date, depth, NTUs, and SSC.

6.2.10 Surveying

CAUTION

Click the OBS-5+ menu and select Barometric Correction.

Do not do this while the OBS-5+ is submerged.

The OBS-5+ takes about five seconds to measure the surface pressure and

compute a barometric correction.

1) Connect the OBS-5+ to PC with survey cable and start OBS-5+ Utility.

2) Open the Data Window with the View pull-down menu.

15

Page 24

OBS-5+ System

3) Click the

lookup table icon and select a calibration table for your

survey. The last active table will be used otherwise.

4) Click

Survey to select: sensors, lines per minute, and depth units

(Meters or Feet). Set temperature and salinity for the survey area.

16

5) Click Start Survey and check the data flow in the Data Window.

6) A file for logging data was created when you started the OBS-5+ Utility.

You can review data at any time with

Open and import the log file

directly into an Excel spreadsheet for post-survey processing and plotting

(see Section 6.2.15, Excel Spreadsheets).

Page 25

6.2.11 Cyclic Sampling

This mode is for logging data at regular intervals such as 1, 10, 15, 30, etc.

minutes, for example.

1) Request Barometric Correction from the OBS-5+ menu. Be sure to do

this while the OBS-5+ is at the surface (see Section 6.2.10, Surveying ).

2) Open the Data Window with the View pull-down menu.

3) Activate the lookup table for your survey area with and

activate buttons (Step 3, Section 6.2.10, Surveying).

OBS-5+ System

4) Click Cyclic Sampling and select sensors, statistics, depth units (meters or

feet), water temperature, and salinity.

5) Select Interval, Duration, Rate, and Power level; see recommendations

in Section 6.2.9, Sampling Modes and Terms.

6) Click Start Sampling to begin logging data and watch a few lines as they

are displayed in the data window to be sure the schedule is what you want.

Unplug test cable; install dummy plug and locking sleeve. The instrument

is ready for deployment.

17

Page 26

OBS-5+ System

6.2.12 Data Retrieval

1) Remove dummy plug and connect OBS-5+ to PC with test cable (FIGURE

6-1).

2) Run OBS-5+ Utility.

3) Open the Data Window to verify that the instrument is transmitting data.

6.2.13 Shutdown

4) Click

a file.

5) Highlight the data with the start and end times you want.

to end data collection and use Offload Data to save data in

6) Click Browse, select a destination file and click OK.

7) Wait for the progress bar to disappear and examine data as a plot or text

file (see Section 6.2.5, Testing Sensors).

From the OBS-5+ menu, select Sleep.

18

6.2.14 Graphing and Printing

1) Use File menu to select how the data file will be opened.

Page 27

OBS-5+ System

2) Click

when Open As Plot is selected. To print a text file, select Open As Text,

and use the Word Pad file print functions. For spreadsheet operations, see

the next section. The

your plot looks.

3) Use the Min and Max and Sample Range (End and Start) values to

bracket the data you need on the graph. Plot Width allows the graph to be

sized to fit a PC screen. On the depth plot, select Max = 0 and Min = the

maximum depth to display depth increasing downward.

Open and select a file to view. Print will print a graph

Plot and Port Settings is used for setting up

6.2.15 Excel Spreadsheets

To make an Excel spreadsheet from OBS-5+ data, start Excel and set file type

to All. Open a data file and select Delimited in Step 1 of 3 of the Text Import

Wizard. Click Next > and select the delimiter Space; check Treat consecutive

delimiters as one; and {none} for Text qualifier. In Step 3 of 3, select the

General Column data format and click Finish.

19

Page 28

OBS-5+ System

7. Calibration

7.1 Sediment and NTU Calibration

In addition to the concentration, the size, shape, and reflectivity of suspended

sediment particles vary from one location to another and will influence OBS5+ measurements. When these sediment characteristics change, they will

produce apparent changes in SSC by themselves unless sediment calibrations

are performed. All sediments produce a unique set of calibration curves like

the examples shown in FIGURE 4-4. The sediment calibration procedure is

complicated, and for a modest fee, we will calibrate an OBS-5+ sensor with

your sediment. Call for a quotation to perform this service.

20

Page 29

FIGURE 7-1. Manual (left) and automatic (right) sediment suspenders

7.1.1 General Guidance

The OBS-5+ uses response curves from the near and far detectors to create

three lookup tables like those shown on FIGURE 4-3 and FIGURE 7-2. The

objective of sediment calibration is to create lookup tables from the sediment

you will monitor. The OBS-5+ can store lookup tables for as many as 14

sediments. The fifteenth table is reserved for auto-saved archives.

OBS-5+ System

To view a calibration table, click

button (step 3 in Section 6.2.10,

Surveying), highlight a table number and click on the Activate button; then

click View Active. The calibration data table contains all the information

needed by the OBS-5+ to interpolate SSC values from the detector signals.

From left to right, the column lists: 1) SSC values (g L

derivatives for ND curve, 4) FD counts, and 5) 2

–1

nd

), 2) ND counts, 3) 2nd

derivatives for FD curve.

During a calibration, the first table, highlighted in red, is created from the

rising limb of the near detector response between zero counts and point “a”

(FIGURE 7-2). The second table, bold blue curve, is used for mid-range SSC

values. It is derived from the descending limb of the far detector curve

between points “a” and “c”. High SSC values are estimated from a third

lookup table, indicated by the bold green line and point “b”, and are derived

21

Page 30

OBS-5+ System

from the descending limb of the near detector curve. A calibration consists of

a set of 15 to 30 calibration points that each includes an SSC value, a near

detector count, and a far detector count.

FIGURE 7-2. Lookup tables and table limits (a, b, and c)

Six to ten calibration points are needed to define each table. For the lookup

tables to function properly, the peaks in the ND and FD curves must be within

± 2,500 counts of one another, and to maximize resolution, the peak heights

should be between 62,000 and 64,500 counts. Start with the schedule shown in

TABLE 7-1 and adapt it to your sediment as required during the calibration

procedure.

Sediment preparation is a critical factor in calibration quality. Use dry material

whenever possible because it can be accurately weighed. Keep in mind that

mixing, grinding, and sieving can produce smaller sediment than you will

measure in the field and that the OBS-5+ is very sensitive to particle size (see

Section 10, Interfering Factors). This means that disaggregation can produce

measurement errors. Vigorous disaggregation with a sonic probe, for example,

can produce smaller particles that result in more ND and FD counts per unit of

SSC than less aggressive methods. An OBS-5+ calibrated with the former

material will underestimate SSC in the field.

22

Page 31

OBS-5+ System

TABLE 7-1. Schedule of Concentrations for Sediment Calibrations

MUD (D60 < 62 µm) Sand (D60 > 62 µm)

Low

SSC

(0-5 g/l)

Mid-

range

(5-20 g/l)

High

SSC

(> 20 g/l)

Low

SSC

(0-10 g/l)

Mid-

range

(10-40 g/l)

High

SSC

(> 49 g/l)

0.0 5 25 0.0 12 50

1.0 6 30 2.0 14 60

1.5 7 40 3.0 15 70

2.0 8 50 4.0 20 80

2.5 9 60 5.0 25 90

3.0 10 6.0 30 100

3.5 15 8.0 35 140

4.0 20 10.0 40 160

The operator can control the electronic gain of the detector circuits to optimize

the instrument for his sediment. This can be done with the ND Gain and FD

Gain boxes in the OBS-5+ program during the calibration using the + and –

buttons to toggle gain up or down. The unit automatically scales all calibration

counts to match the selected gain. Set the initial ND and FD gain values to 16,

starting with the third SSC value in TABLE 7-2, adjust the gain to keep the ND

and FD counts in the range of 50,000 to 60,000.

CAUTION

While calibration points can be deleted at any time, never

start a new SSC value until you are satisfied with the

current values and gain setting.

The FD counts will peak first at around 2 to 7 g L–1 and the ND will peak

between 5 to 20 g L

calibration in cells D1 and E1 (default volume and density are 3.0 l and

2,650 g L

–1

). Every time sediment is added to the suspender, enter the grams

–1

. Set the water volume and sediment density for your

added to column A and read the current SSC value in column C.

TABLE 7-2. SSC-Calculation Spreadsheet

A

Grams

Added

0.00 0.00 0.00

1

1.00 1.00 0.33

2

2.00 3.00 1.00

2

3.00 6.00 2.00

3

4.00 10.00 3.33

4

B

Total

Grams

C

Cs (g/l)

(g/l)

D

Water

Volume (l)

E

Sediment

Density (g/l)

3.0 2650

23

Page 32

OBS-5+ System

=

Sediment concentrations can also be calculated manually with the following

equations:

M

=

l/g

s

⎡

M

+

V

i

⎢

ρ

⎣

7.1.2 Equipment and Materials

• Dry, completely disaggregated bottom sediment or suspended matter from

the monitoring site

• Large black, neoprene or polyethylene tub

• 1-gallon (4 l) brown Nalgene polypropylene bottle with top cut off

• 1-liter volumetric flask

• Hand-drill motor (manual suspender)

• Mixing propeller (manual suspender)

• Scale with 10 mg accuracy

• Automatic suspender (optional)

s

=

⎤

s

⎥

s

⎦

i

=

ρ

s

(g) mass SedimentM

(liters) volume nitialIV

density edimentS

g/l) 103 x 2.65(usually

• Tea cup with round bottom and teaspoon

7.1.3 Procedure for Sediment

1) Put batteries in the OBS-5+ and connect it to a PC with test cable using the

RS-232 plug (FIGURE 6-1).

2) Start OBS-5+ Utility program; wake the OBS-5+; and click the

Settings button to verify its response.

OBS

24

Page 33

OBS-5+ System

3) Click the

Select an EMPTY Table number for the sediment calibration.

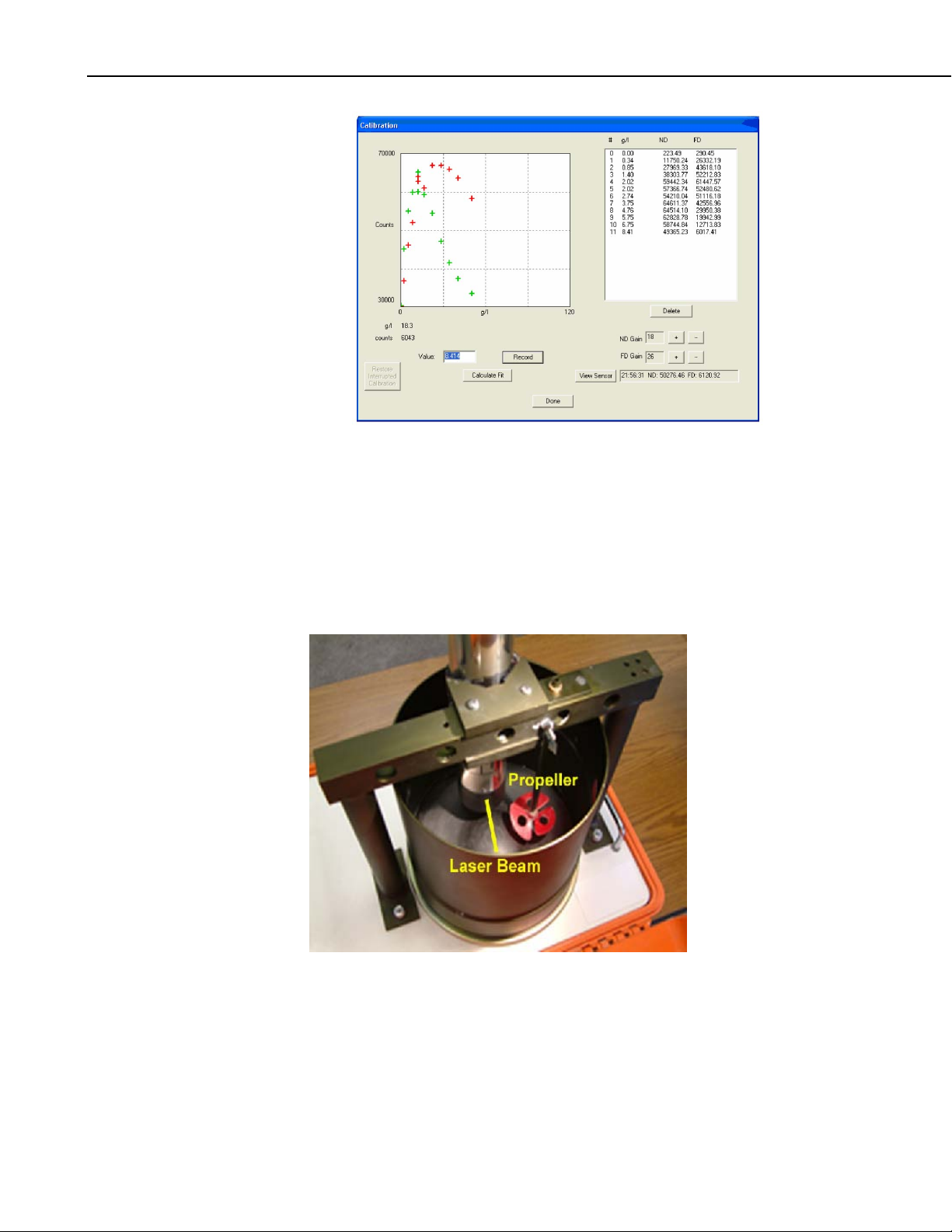

4) Start the calibration with the button and secure the unit in a big black tub

filled with clean tap water (FIGURE 7-3). The sediment-calibration dialog

will appear (the initial display will not show the red and green symbols).

button to view the list of lookup tables stored in the unit.

FIGURE 7-3. OBS-5+ in big black tub of clean water

25

Page 34

OBS-5+ System

5) Enter 0.001 in the value box and click the Record button to log the clear-

water data point. The unit will take 1,200 measurements in 60 seconds.

When the process is complete, the data appear in the data table and the ND

(red) and FD (green) points will be plotted on the calibration graph. If you

are satisfied with the data, mount the unit in the suspender.

6) Position the OBS-5+ so that it produces the minimum FD signal in clear

water (FIGURE 7-4).

FIGURE 7-4. OBS-5+ in suspender tub

26

7) Weigh the first increment of sediment with the electronic balance (see

TABLE 7-1) and transfer it to a tea cup with a rounded bottom.

Page 35

OBS-5+ System

8) Withdraw about 10 ml of water from the suspender and add it to the tea

cup containing the dry sediment. Stir the water-sediment mixture into a

homogeneous slurry, breaking up clumps of sediment as you go.

9) Pour the sediment slurry into the suspender and rinse the cup with

suspender water until it is clean. Make sure all the sediment gets from the

cup to the suspender.

–1

10) Compute the SSC value in g L

for the current calibration point with

SSCcalculator spreadsheet (TABLE 7-2), or use the SSC formula, Section

7.1.1, General Guidance, and enter the SSC value in the Value box.

11) Click the View Sensor button to see the ND and FD counts before they are

recorded. Adjust the gain if necessary, then click the Record button.

12) The second calibration pair of points will appear on the graph and the data

will be listed in the table. If the data for the current point is unacceptable

for any reason, too much or too little gain for example, highlight the data

line number (#) and click the Delete button. Adjust the gain and record it

again with the same SSC value.

CAUTION

Do not proceed to the next SSC value until you are

satisfied with the current data. Once you add sediment to

the suspender, you cannot remove it.

13) Repeat Steps 7 through 12 for the remaining SSC values following the

guidelines provided above. When the calibration data is complete, the data

table and plot will look like the ones shown below.

14) To compute the lookup tables, click the Calculate Fit button and supply

the requested information. Referring to FIGURE 7-2, pick point ‘a’ by

counting the number of data points on the ND curve from the origin (0, 0)

to the first point beyond where the ND and FD curves cross, 6 in FIGURE

7-2. Select ‘b’ at the first point on the falling limb beyond the ND peak

where it becomes linear, 10 on FIGURE 7-2. Point ‘c’ is the first point in

27

Page 36

OBS-5+ System

7.2 Turbidity (NTU) Calibration

7.2.1 Equipment and Materials

7.2.2 Procedure for Turbidity

the FD curve where it starts decay exponentially, also 10 on FIGURE 7-2

9. Points ‘b’ and ‘c’ will usually have the same numerical value.

15) Save the table in the EMPTY Table number selected at Step 3.

• Large black, neoprene or polyethylene tub

• 100 mm test cylinder (www.deslinc.com, No. TC4)

• AMCO Clear turbidity standards (GFS No. 8429, 8430, and 8431,

www.gfschemicals.com)

1) Put batteries in the OBS-5+ and connect it to a PC with test cable using the

RS-232 plug (FIGURE 6-1).

2) Start the OBS-5+ Utility software; wake the OBS-5+; and click the OBS

Settings button to verify its response.

3) Use the OBS-5+ pull-down menu, select Gain and set ND and FD gain to

2. This is the setting used for the factory calibration.

4) Start the calibration with the button and secure the unit in a big black tub

filled with clean tap water (FIGURE 7-3). The NTU-calibration dialog

will appear.

28

5) Enter 0.3 in the value box and click the record button to log the clear-water

data point. The unit will take 1,200 measurements in 60 seconds. When

the process is complete, the data appear in the data table and the point will

be plotted on the calibration graph. If you are satisfied with the data,

mount the unit in a 100 mm calibration cup as shown on FIGURE 7-5.

Page 37

OBS-5+ System

FIGURE 7-5. OBS-5+ in 100 mm cup

6) Add enough 250-NTU standard to cover the sensor end (FIGURE 4-1) and

swipe bubbles off the sapphire windows with your finger. Click the

Record button.

7) Repeat Step 6 for the 500 and 1,000 NTU standards.

8) Review the data table and graph, and if they look satisfactory, click the

Calculate Fit button.

9) Verify that the fit curve passes through the calibration points and that the

residuals are less than 10 NTU. Then click the Done button.

8. Troubleshooting

This section will help isolate problems that can be easily fixed, such as cablecontinuity, processor reset, and battery replacement, or more serious ones, such

as sensor, computer and electronic malfunctions, and damaged mechanical

parts that will require assistance. The problem symptoms are shown in bold

text.

Power failed because of contact corrosion or a broken power wire.

Check for a broken red wire connecting the battery tube and circuit board.

Green powder or tarnish on the battery contact parts indicates salt-water

corrosion. Remove the electronics by removing the set screws from the sensor

endcap and sliding it out of the pressure housing. Pull battery-contact-retainer

pin out with needle-nose pliers and slide the contact from its track. Clean the

29

Page 38

OBS-5+ System

corroded surfaces of the contact and track with a scouring pad and reassemble

unit.

Unit does not communicate with PC.

There are several possible causes for this symptom.

1) The batteries are dead.

2) The OBS-5+ will not wake up.

3) The test/umbilical cable is damaged or improperly connected

4) The OBS-5+ and PC are set to different baud rates or communication

protocols (for example, RS-232 versus RS-485).

• Click

port tab. The default baud rate is 115.2 kbps. If the PC is not set to

this speed, follow the steps in Section 6.2.4, Communication Settings,

to set it.

• If the OBS-5+ still fails to respond, try changing PC speeds and

clicking

example, 57.6, 38.4, 19.6, 9.6 kbps, etc.). If this fails, switch the PC

back to 115.2 kbps and do the following steps.

• Reconnect the cable and click

• Replace the batteries and click

• If you have a survey cable, connect instrument to external power and

click

• Remove the unit from the pressure housing and press and release the

RESET button. Click

Plot and Port Settings and check port settings on the serial

OBS Settings until communication is established (for

.

.

.

.

30

Page 39

OBS-5+ System

FIGURE 8-1. Internal components

OBS-5+ or pressure sensor malfunction.

• Open unit and inspect for: 1) broken sensor wires, and 2) loose pressure

sensor connector (FIGURE 8-1).

• Check sensor power by clicking

green LEDs should illuminate. If they do not, the sensor power circuit

may not be working.

• If the depth sensor reads high and does not change, it may need to be

cleaned (see Section 9.2, Pressure Sensor).

• If the sensors appear to be in working order, the digitizer or

microcontroller may be damaged. Such problems require factory service.

Survey and selecting all sensors; the

31

Page 40

OBS-5+ System

Bright sun near the surface (< 2 m) or black-colored sediments cause

erroneous OBS readings.

Do not survey in shallow water between 10:00 and 14:00 local time and avoid

areas with suspended black mud; see Section 10.2, NIR Reflectivity.

OBS-5+ indicates different NTU values in the field than other

turbidimeters.

Not all turbidity meters read the same! OBS-5+ sensors are checked with U.S.

EPA-approved AMCO Clear turbidity standards before leaving our factory (see

Appendix A). Other turbidimeters will read different NTU values on natural

water samples.

OBS-5+ indicates different suspended sediment levels in the field than in

the laboratory.

This results from a change in sediment size or color (see Section 10, Interfering

Factors). You may have to perform a field calibration with water samples.

9. Maintenance

9.1 OBS-5+ Sensor

The sapphire windows over the laser diode and the detectors must be kept

clean to make accurate SSC measurements (FIGURE 4-1 and FIGURE 4-2). A

gradual signal decline over a period of days to weeks indicates fouling with

mud, oil, or biological material. Regular cleaning with a water jet, mild

detergent and warm water, or a scouring pad will remove most contaminants

encountered in the field. A cloth with solvent or mineral spirits can be used to

remove oil and grease. However, do not use MEK, benzene, toluene, acetone,

TCE, or electronic cleaners as they could damage the epoxy bond between the

sapphire and the optic bushings. At the conclusion of each survey or

deployment, clean the OBS-5+ sensor. If thick bio-fouling has developed,

scrape the material off the window with a flexible knife then swipe it with a

scouring pad.

9.2 Pressure Sensor

The silicon strain-gauge pressure sensor is located under a perforated disk and

spring-clip that protects the Hastelloy diaphragm isolating it from water

(FIGURE 4-1). Do not touch the diaphragm with tools or pointed objects, as

the instrument will leak if it is pierced. Clean the sensor with a water jet

directed at the disk after each survey or deployment to flush sediment from

between the disk and the sensor. Do not allow sediment to dry on the sensor

diaphragm because dry sediment will reduce accuracy and is difficult to wash

off. To clean the diaphragm, remove the spring clip with tru-arc pliers and the

disk with plastic tweezers, then gently wipe sediment off the diaphragm with a

wet cotton-tipped swab. Replace the disk and spring clip and flush with a water

jet.

32

Page 41

9.3 Batteries

OBS-5+ System

The unit runs on three, C-size, alkaline batteries. Buy the expensive ones with

the longest expiration date (“use before May 20XX”). While operating

continuously, the OBS-5+ will run 125 hours (15, eight-hour surveys) in

Survey Mode and for as long as 3,000 hours in the Cyclic Mode.

CAUTION

Always put OBS-5+ to sleep for storage to conserve

battery capacity (see Section 6.2.13, Shutdown).

Refer to FIGURE 6-2 for battery installation. Battery life will depend on the

percentage of time the unit is sampling. TABLE 9-1 shows battery life as a

function of sample duration and interval to assist with planning your sampling

schedule (see Power in Section 6.2.9, Sampling Modes and Terms).

TABLE 9-1. Battery Life in Hours with 100% Power

Interval

(s)

60

600

900

1800

3600

> 3000 2050 780 1180 400

> 3000 > 3000 1100 2040 600

> 3000 > 3000 1930 > 3000 1100

> 3000 > 3000 > 3000 > 3000 1930

9.4 Pressure Housing

10

100%

480 NO NO NO NO

60

50%

60

100%

120

50%

120

100%

The pressure housing and O-ring seals require little maintenance other than

careful inspection every six months and service before moored deployments.

1) Disassemble O-ring seals and inspect mating surfaces for pits and

scratches.

2) Inspect O-rings for cuts and nicks; replace if necessary.

3) Clean O-rings and mating surfaces with a cotton swab and alcohol.

Remove fibers from groove and mating surfaces then grease O-rings

Molykote

®

Compound 55 and reassemble.

9.5 User-Serviceable Parts

Alkaline C cells and the components of the 21304 Accessory Kit can be

purchased as replacement parts. Campbell Scientific manufacturing part

numbers and product descriptions follow:

pn 20993 End-cap O-ring, Parker 2-136

pn 20989 Optic Bushings O-ring, ARP5 7.5 X 1.2 mm OBN

pn 21141 S.S. End-cap Screws, 5/16” X 3/8”

pn 21120 Dummy Plug, Subconn

pn 21122 Plug Locking Sleeve, Subconn

®

MCDC8M

®

MCDLSF

33

Page 42

OBS-5+ System

pn 4576 Alkaline C-Cells Batteries

pn 20806 OBS-5+ Test Cable, 2 m (6.5 ft)

pn 21381 7-piece Allen Wrench Set, 5/64 to 3/16 Ball End

pn 21139 SS Hex Socket Screw, #2-56 x .187

10. Interfering Factors

Changes in sediment concentration (SSC) are the primary cause for OBS-5+

output fluctuations in the environment. In some monitoring areas, however,

factors other than SSC, will cause the OBS-5+ to indicate SSC variation that

are invalid and which the user does not wish to measure. These factors are

called interferences because they cause apparent shifts in SSC that are not real.

Interferences include particle size, shape, reflectivity, flocculation, and

disaggregation. This section summarizes some of the important ones that you

might encounter while using an OBS-5+.

Sensitivity is the change in light scattering intensity, indicated by ND and FD

counts, per unit change in SSC or an interfering factor. It is therefore a good

measure of relative interference. An interference that reduces sensitivity will

cause SSC to appear to decrease and one that makes an OBS-5+ more sensitive

will cause the opposite effect. Interfering factors are ranked by the ratio of the

sensitivity change that is caused when the factor changed over its full range in

the environment. For example, the size of suspended sediment particles in the

environment ranges from about 0.5 to 125 μm. This range causes relative OBS

sensitivity to change from 2 to 0.008, (see next section), giving a factor of 250.

Interfering factors ranked in this way are summarized in TABLE 10-1. The

ranking shows, for instance, that the size of suspended particles can affect

OBS-5+ measurements more than particle shape or NIR reflectivity by a factor

of 25. Interferences can be tolerated so long as the resulting errors fall within

acceptable limits.

Relative Magnitude <250 10 10 2

10.1 Particle Size

The trend of the line on FIGURE 10-1 shows that relative sensitivity declines

at a rate inversely proportional to the particle diameter. The graph provides a

useful method for estimating the relative effect of grain size on OBS-5+

sensitivity. Using this method, for example, one gram of silt with a grain size

of 10 microns, suspended in a liter of water, might produce an OBS signal of

55,000 counts, whereas a gram of sand per liter with a grain size of 100

microns would produce only 5,500 counts, with other factors such as shape and

reflectivity being the same.

TABLE 10-1. Relative magnitude of the effects of sediment

characteristics on OBS-5+ sensitivity

Interfering Factor

Size Shape Reflectivity Flocculation

34

Page 43

OBS-5+ System

FIGURE 10-1. Effects of sediment size

10.2 NIR Reflectivity

The output of an OBS-5+ will increase with the NIR reflectivity of suspended

sediment independent of SSC. This can degrade accuracy when unknown

reflectivity changes occur during a monitoring campaign. For instance, when a

dredge cuts through a layer of oxidized, light-brown, reflective mud into an

underlying layer of black anoxic mud, the OBS-5+ will indicate that SSC of

mud stirred up by the cutter has dropped even when it has not. The relative

signal level per unit of SSC varies from a low of about one for dark, nonreflective sediment to a high of about ten for white, reflective sediment

(FIGURE 10-2). In areas where sediment color changes with time, more than

one calibration curve may be required to measure SSC with an OBS-5+.

35

Page 44

OBS-5+ System

Reactive Sensitivity

FIGURE 10-2. Near-infrared reflectivity of minerals

10.3 Particle Shape, Flocculation, and Disaggregation

Particle shape can be an interfering factor. The sensitivity of an OBS-5+

sensor to plate-shaped particles is about ten times higher than it is to spherical

particles. Disaggregation of dry sediment by grinding can cause the sediment

to become finer grained than it was in the environment and this will bias a

sediment calibration. A good example of how much OBS-5+ readings can

change as a result of the disaggregation is shown in FIGURE 10-3. The slope

of each line on the graph indicates the sensitivity of an OBS sensor when

calibrated with sediment disaggregated in a particular way. The more

mechanically aggressive a disaggregation method is, the more sensitive the

sensor will be. Sediments susceptible to disaggregation effects include: 1)

organic-rich estuarine mud, 2) cohesive and flocculated suspended matter, and

3) clay-rich sediment.

36

Page 45

OBS-5+ System

FIGURE 10-3. Effects of disaggregation methods

Finally, flocculation of clay particles in estuaries can affect sensitivity by

causing small particles to clump together into larger ones to which the OBS-5+

is less sensitive. For example, when a dredge works into a zone of saline water

where flocculation occurs, an OBS-5+ can indicate less than the actual level of

SSC.

A summary of interference effects on OBS-5+ measurements follows.

1) Any action that makes sediment particles smaller, such as disaggregation,

or larger, aggregation, during the calibration process than they will be in

the environment will cause SSC to appear to increase or decrease when

there has been no actual change.

2) Processes in the environment that make sediment particles larger than they

were during a calibration will produce an apparent decline in SSC.

Conversely, an environmental process that makes particles smaller, such as

deflocculation or disaggregation, will cause SSC to appear to increase.

3) When particles become more or less reflective than they were during

calibration, or their shape changes, SSC will appear to decrease or increase

independent of an actual SSC change.

37

Page 46

OBS-5+ System

11. References

Black, K.P., M.A. Rosenberg. 1994. Suspended Sand Measurements in a

Turbulent Environment: Field Comparison of Optical and Pump Sampling.

Coastal Engineering, 24, pp. 137-150.

Conner, C.S. and A.M. De Visser. 1992. A Laboratory Investigation of Particle

Size Effects on an Optical Backscatterance Sensor. Marine Geology, 108, pp.

151-159.

Downing, John. 2006. 25 Years with OBS Sensors: The Good, the Bad, and the

Ugly. Continental Shelf Research.

Downing, John. 2005. Turbidity Monitoring. In: Environmental

Instrumentation and Analysis Handbook. John Wiley & Sons, New York, pp.

511-546.

Downing, John. 1998. Suspended Particle Concentration Monitor. U.S. Patent

Number 5,796,481.

Downing, John and Reginald A. Beach. 1989, Laboratory Apparatus for

Calibrating Optical Suspended-solids Sensors. Marine Geology, 86, pp. 243-

249.

Gibbs, R.J. 1978. Light Scattering from Particles of Different Shapes. Journal

of Geophysical Research, 83, pp. 501-502.

Gibbs, R.J., E. Wolanski. 1992. The Effects of Flocs on Optical Backscattering

Measurements of Suspended Material Concentration. Marine Geology, 107, pp.

289-291.

Sutherland, T.F., P.M. Lane, C.L. Amos, and John Downing. 2000. The

Calibration of Optical Backscatter Sensors for Suspended Sediment of Varying

Darkness Level. Marine Geology, 162, pp. 587-597.

38

Page 47

Appendix A. Turbidity Standards

AMCO Clear, supplied by GFS Chemicals (www.gfschemicals.com), is an

approved calibration standard and is the one we use to certify our instruments.

It is made from styrene divinylbenzene (SDVB) microspheres. SDVB spheres

have a median size and standard deviation of 0.28μm (~1/5 that of formazin

particles) and 0.10 μm respectively and a refractive index of 1.56. As shown

on the SEM image, they are dimensionally uniform. SDVB standards are

formulated especially for OBS meters and cannot be used with different

meters. Superior physical consistency of AMCO Clear results in a more

precise calibration standard, giving standard errors less than 1% compared to

2.1% for formazin and better linearity, 0.15 NTU compared to 0.32 for

formazin.

(Photos courtesy of GFS Chemicals)

The key benefits of SDVB standards are: 1) < 1% lot-to-lot variation in

turbidity; 2) consistent optical properties from 10 to 30°C; 3) guaranteed oneyear stability; 4) mixing and dilution are not required; and 5) they are not toxic.

Two drawbacks are that SDVB standards can only be used with the instruments

for which they are made and they are more expensive than formazin. For

example, one liter of 4000-NTU standard costs about twice as much as an

equivalent amount of 4000-NTU formazin. Our instruction manuals explain

how to use turbidity standards and the instructions provided by the suppliers

tell how they should be handled.

A-1

Page 48

Appendix A. Turbidity Standards

In the USA, formazin is a primary standard for the calibration of

turbidimeters. The median particle size of formazin is 1.5 μm; the standard

deviation of size is 0.6 μm (see size distribution graph); and as shown by the

SEM images below, formazin particles have many different shapes. The

preparation, storage, and handling of formazin will affect its accuracy and

stability. Recommended formazin storage times are listed in the accompanying

table. Working standards are prepared by volumetric dilution of 4000-NTU

stock formazin with distilled water. For example, a 2000 NTU calibration

standard is made by mixing equal volumes of stock formazin and distilled

water.

Turbidity

(NTU)

Maximum

Storage Time

1 – 10 1 day

2 – 20 1 day

10 – 40 1 day

20 – 400 1 month

> 400 1 year

Besides being the primary standard, formazin has two other advantages. It is

available from several chemical and scientific suppliers (www.vwrsp.com,

www.ColePalmer.com, www.riccachemical.com, and www.labchem.net) and it

is the least-expensive, commercially available standard. Formazin also has a

couple of disadvantages: 1) it has a MSDS health-hazard rating of 2;

2) turbidity can vary by ± 2% from the lot to lot; 3) the size, shape, and

aggregation of formazin particles change with temperature, time, and

concentration; 4) it settles in storage and must be mixed immediately prior to

use; and 5) dilute formazin standards have a storage life as short as one hour.

A-2

Page 49

Appendix A. Turbidity Standards

We must emphasize that unlike SSC, which has physical units, turbidity values

(NTUs, FTUs, etc.) do not. Therefore, if you measure water turbidity to be 100

NTU, you cannot directly infer any physical quantities from it. Turbidity

values do not represent particular SSC values, indicate light levels at the

bottom of a stream, or quantify biological process’. Moreover, it is often

assumed that turbidity standards behave optically like sediment. This is

possible when the size, NIR reflectivity, refractive index, and shape of the

sediment and the turbidity standard are similar; this is an extremely rare

occurrence. For example, even the median diameters of the two approved

calibration standards differ by a factor of more that five and the shape of

SDVB and formazin particles also differ; see NTU-SSC relationships.

Reference:

John Downing. 2005. Turbidity Monitoring. Chapter 24 in: Environmental

Instrumentation and Analysis Handbook. John Wiley & Sons, Pages: 511-

546. 2005.

Sadar, M. 1998. Turbidity Standards. Hach Company Technical Information

Series – Booklet No. 12. 18 pages.

Papacosta, K. and Martin Katz. 1990. The Rationale for the Establishment of

a Certified Reference Standard for Nephelometric Instruments. In:

Proceedings, American Waterworks Assoc. Water Quality Technical

Conference. Paper Number ST6-4, pp. 1299-1333.

Zaneveld, J.R.V., R.W. Spinrad, and R. Bartz. 1979. Optical Properties of

Turbidity Standards. SPIE Volume 208 Ocean Optics VI. Bellingham,

Washington. pp. 159-158.

A-3

Page 50

Appendix A. Turbidity Standards

A-4

Page 51

Page 52

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (CSL France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Ltd. (CSL Germany)

Fahrenheitstraße 13

28359 Bremen

GERMANY

www.campbellsci.de • info@campbellsci.de

Campbell Scientific Spain, S. L. (CSL Spain)

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Loading...

Loading...