Page 1

NR-LITE2 Net Radiometer

Revision: 3/13

Copyright © 1998-2013

Campbell Scientific, Inc.

Page 2

Page 3

Warranty

“PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12)

months from date of shipment unless otherwise specified in the corresponding

Campbell pricelist or product manual. Products not manufactured, but that are

re-sold by Campbell, are warranted only to the limits extended by the original

manufacturer. Batteries, fine-wire thermocouples, desiccant, and other

consumables have no warranty. Campbell’s obligation under this warranty is

limited to repairing or replacing (at Campbell’s option) defective products,

which shall be the sole and exclusive remedy under this warranty. The

customer shall assume all costs of removing, reinstalling, and shipping

defective products to Campbell. Campbell will return such products by surface

carrier prepaid within the continental United States of America. To all other

locations, Campbell will return such products best way CIP (Port of Entry)

INCOTERM® 2010, prepaid. This warranty shall not apply to any products

which have been subjected to modification, misuse, neglect, improper service,

accidents of nature, or shipping damage. This warranty is in lieu of all other

warranties, expressed or implied. The warranty for installation services

performed by Campbell such as programming to customer specifications,

electrical connections to products manufactured by Campbell, and product

specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Campbell is not liable for any special, indirect,

incidental, and/or consequential damages.”

Page 4

Assistance

Products may not be returned without prior authorization. The following

contact information is for US and international customers residing in countries

served by Campbell Scientific, Inc. directly. Affiliate companies handle

repairs for customers within their territories. Please visit

www.campbellsci.com to determine which Campbell Scientific company serves

your country.

To obtain a Returned Materials Authorization (RMA), contact CAMPBELL

SCIENTIFIC, INC., phone (435) 227-9000. After an applications engineer

determines the nature of the problem, an RMA number will be issued. Please

write this number clearly on the outside of the shipping container. Campbell

Scientific’s shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Statement of Product Cleanliness

and Decontamination” form and comply with the requirements specified in it.

The form is available from our web site at www.campbellsci.com/repair. A

completed form must be either emailed to repair@campbellsci.com or faxed to

(435) 227-9106. Campbell Scientific is unable to process any returns until we

receive this form. If the form is not received within three days of product

receipt or is incomplete, the product will be returned to the customer at the

customer’s expense. Campbell Scientific reserves the right to refuse service on

products that were exposed to contaminants that may cause health or safety

concerns for our employees.

Page 5

Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction.................................................................1

2. Cautionary Statements............................................... 1

3. Initial Inspection .........................................................1

3.1 Ships With............................................................................................2

4. Quickstart .................................................................... 2

4.1 Siting Considerations ...........................................................................2

4.2 Mounting..............................................................................................3

4.3 Use SCWin to Program Datalogger and Generate Wiring Diagram....4

5. Overview......................................................................8

5.1 Electrical Properties .............................................................................8

5.2 Spectral Properties ...............................................................................9

5.3 Directional/Cosine Response ...............................................................9

5.4 Sensitivity to Wind Speed ..................................................................10

6. Specifications ...........................................................11

6.1 Spectral...............................................................................................12

6.2 Directional..........................................................................................12

6.3 Mechanical.........................................................................................12

6.4 Environmental....................................................................................12

7. Operation...................................................................13

7.1 Wiring ................................................................................................13

7.2 Datalogger Programming...................................................................14

7.2.1 Input Range and Integration........................................................14

7.2.2 Calibration Factor .......................................................................14

7.2.3 Example Programs ......................................................................15

7.2.3.1 CR3000 Example Program without Wind Speed

Correction .....................................................................15

7.2.3.2 CR1000 Example Program with Wind Speed

Correction .....................................................................16

7.2.3.3 CR10(X) Example Program without Wind Speed

Correction .....................................................................17

7.2.3.4 CR10X Example Program with Wind Speed

Correction .....................................................................18

8. Maintenance ..............................................................20

i

Page 6

Table of Contents

9. Troubleshooting........................................................20

9.1 Checking Sensor Operation............................................................... 20

9.2 Radiometer Produces No Apparent Output ....................................... 21

9.3 Readings Are Not As Expected ......................................................... 21

Figures

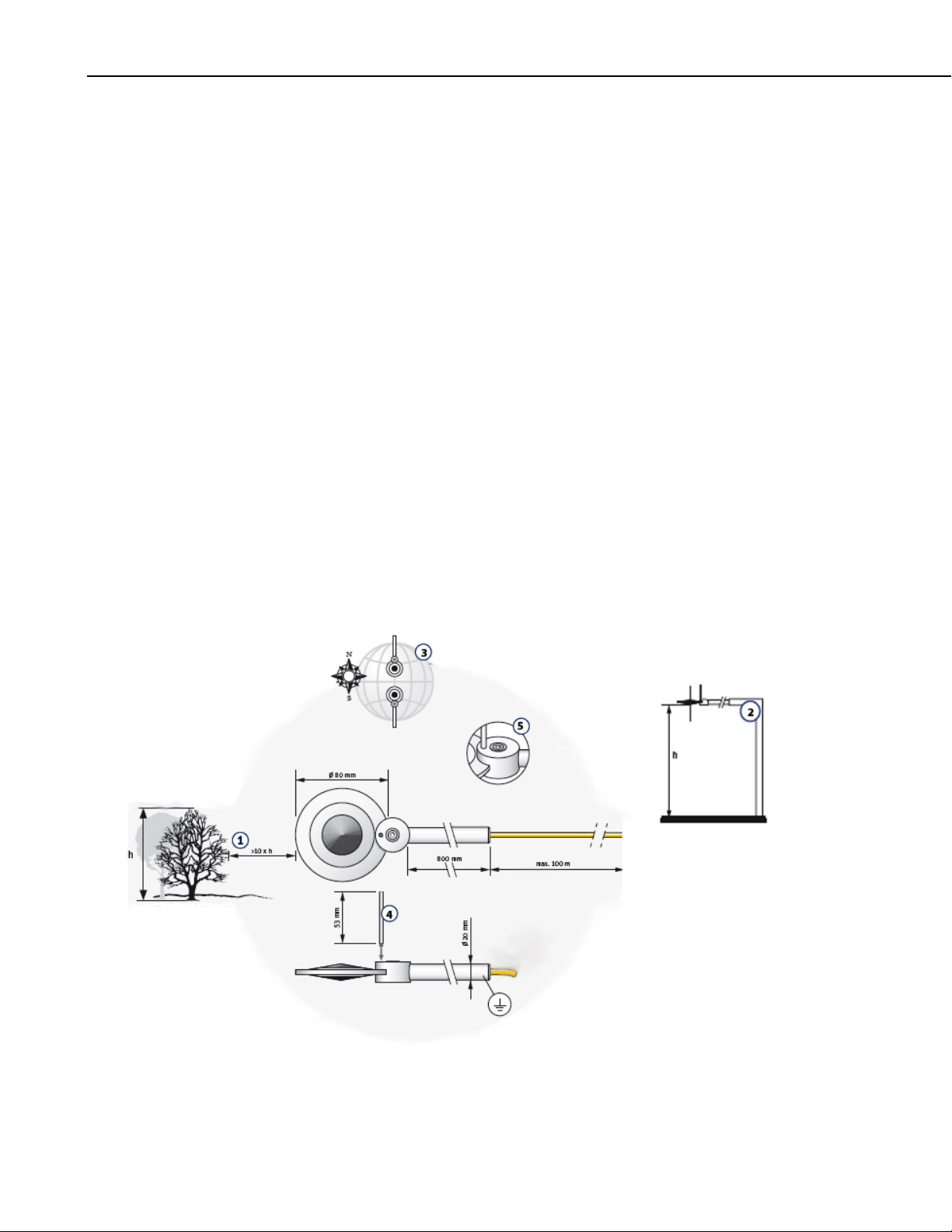

4-1. Siting and mounting diagram for the NR-LITE2................................. 2

4-2. Mounting the NR-LITE2 onto a pole (top) and crossarm (bottom)

via the 26120 Mounting Kit ............................................................. 4

5-1. Electrical circuit for the NR-LITE2 Net Radiometer .......................... 9

5-2. Cosine response of a typical net radiometer ...................................... 10

5-3. NR-LITE2 wind sensitivity ............................................................... 11

6-1. NR-LITE2’s components and dimensions (in millimeters)............... 12

7-1. NR-LITE2 to datalogger connections................................................ 13

Tables

7-1. Datalogger Connections for Differential Measurement..................... 13

7-2. Datalogger Connections for Single-Ended Measurement.................. 14

7-3. Wiring for CR3000 Example............................................................. 15

7-4. Wiring for CR1000 Example............................................................. 16

7-5. Wiring for CR10X Example (without Wind Correction) .................. 17

7-6. Wiring for CR10X Example (with Wind Correction) ....................... 18

ii

Page 7

NR-LITE2 Net Radiometer

1. Introduction

The NR-LITE2 is a high-output thermopile sensor which measures the

algebraic sum of incoming and outgoing all-wave radiation (both short-wave

and long-wave components). Incoming radiation consists of direct (beam) and

diffuse solar radiation plus long-wave irradiance from the sky. Outgoing

radiation consists of reflected solar radiation plus the terrestrial long-wave

component.

The NR-LITE2 is equipped with PTFE-coated (polytetrafluoroethylene) sensor

surfaces. This results in a robust design which provides easy maintenance and

good sensor stability. However, this design is slightly less accurate than the

more traditional radiometers which use plastic domes.

Before using the NR-LITE2, please study:

• Section 2, Cautionary Statements

• Section 3, Initial Inspection

• Section 4, Quick Start

2. Cautionary Statements

• Although the NR-LITE2 is rugged, it is also a highly precise scientific

instrument and should be handled as such.

• Care should be taken when opening the shipping package to not damage or

cut the cable jacket. If damage to the cable is suspected, consult with a

Campbell Scientific applications engineer.

• When installing the NR-LITE2, use only the support arm to rotate the NR-

LITE2. Using the sensor head to rotate the instrument may damage it.

3. Initial Inspection

• Upon receipt of the NR-LITE2, inspect the packaging and contents for

damage. File damage claims with the shipping company.

• The model number and cable length are printed on a label at the

connection end of the cable. Check this information against the shipping

documents to ensure the correct product and cable length are received.

• Refer to Section 3.1, Ships With, to ensure that parts are included.

1

Page 8

NR-LITE2 Net Radiometer

3.1 Ships With

4. Quickstart

4.1 Siting Considerations

(1) WRR traceable calibration certificate

(1) Mounting arm from original manufacturer

(1) Bird stick from original manufacturer

(1) ResourceDVD

Please review Section 7, Operation, for wiring, CRBasic programming, and

Edlog programming.

1. Mount the sensor so that no shadow will be cast on it at any time of day

from obstructions such as trees, buildings, the mast, or structure on which

it is mounted (1 in FIGURE 4-1).

2. To avoid shading effects and to promote spatial averaging, the NR-LITE2

should be mounted at least 1.5 m above the ground surface. It is

recommended that the NR-LITE2 be mounted to a separate vertical pipe at

least 25 ft from any other mounting structures (2 in FIGURE 4-1).

3. Orient the sensor towards the nearest pole to avoid potential problems

from shading (3 in FIGURE 4-1).

2

FIGURE 4-1. Siting and mounting diagram for the NR-LITE2

Page 9

4.2 Mounting

NR-LITE2 Net Radiometer

The mounting bracket kit, pn 26120, is used to mount the NR-LITE2 directly

to a vertical pipe, or to a CM202, CM204, or CM206 crossarm. Mount the

sensor as follows:

1. Screw in the bird repellent stick, which is shipped with the calibration

documentation (4 in FIGURE 4-1).

2. Attach the 26120 mounting bracket to the vertical mounting pipe, or

CM200-series crossarm using the provided U-bolt (FIGURE 4-2).

3. Insert the sensor’s support arm into the mounting block of the mounting

bracket kit. Make sure the sensor points in the direction of the arrows that

appear after the word SENSOR on top of the bracket (FIGURE 4-2).

4. Perform a coarse leveling of the sensor using the sensor’s bubble level (5

in FIGURE 4-1).

5. Tighten the four screws on top of the mounting bracket to properly secure

the support arm so that it does not rotate (FIGURE 4-2).

CAUTION

Do not attempt to rotate the instrument using the sensor

head or you may damage the sensor — use the support

arm only.

6. Perform the fine leveling using the two spring-loaded leveling screws—

one on the front and the other on the back of the bracket (FIGURE 4-2).

7. Route the sensor cable to the instrument enclosure.

8. Use cable ties to secure the cable to the vertical pipe or crossarm and

tripod/tower.

3

Page 10

NR-LITE2 Net Radiometer

Support Arm

26120

Pole

26120

FIGURE 4-2. Mounting the NR-LITE2 onto a pole (top) and

crossarm (bottom) via the 26120 Mounting Kit

Support Arm

Crossarm

4.3 Use SCWin to Program Datalogger and Generate Wiring Diagram

4

The simplest method for programming the datalogger to measure the NRLITE2 is to use Campbell Scientific’s SCWin Program Generator.

Page 11

NR-LITE2 Net Radiometer

NOTE

The SCWin example provided here is for no wind speed

correction. SCWin also supports dynamic wind speed

correction; refer to the SCWin help for more information.

1. Open Short Cut and click on New Program.

2. Select the datalogger and enter the scan interval.

5

Page 12

NR-LITE2 Net Radiometer

3. Select NR-LITE2 Net Radiometer (no wind speed correction), and

select the right arrow (in center of screen) to add it to the list of sensors to

be measured, and then select Next.

4. Define the name of the public variable and enter the calibration factor.

The public variable defaults to NR_Wm2. The calibration factor is unique

to each sensor. This value is provided on the certification of calibration

that is shipped with your sensor. After entering the information, click on

OK, and then select Next.

6

Page 13

NR-LITE2 Net Radiometer

5. Choose the outputs and then select Finish.

6. In the Save As window, enter an appropriate file name and select Save.

7. In the Confirm window, click Yes to download the program to the

datalogger.

8. Click on Wiring Diagram and wire according to the wiring diagram.

7

Page 14

NR-LITE2 Net Radiometer

5. Overview

The NR-LITE2 is used for measuring solar and far infrared radiation balance.

This balance is known as the net (total) radiation. Its upwards facing sensor

measures the solar energy and far infrared energy that is received from the

entire hemisphere (180° field of view). Its downwards facing sensor measures

the energy received from the surface of the soil. The two readings are

automatically subtracted and the result converted to a single output signal.

This output represents the net radiation (which can be interpreted as meaning

the radiative energy that is seen at the surface) and is expressed in Watts per

square meter (W m

The NR-LITE2 is designed for continuous outside use. The sensor surfaces are

coated with PTFE. This ensures sensor stability, long life, and easy

maintenance compared to the more usual radiometers fitted with plastic domes.

However, it does have some disadvantages, particularly a higher sensitivity to

wind speed with a subsequent lessening of accuracy. It is, though, possible to

correct for the wind speed sensitivity if the sensor is installed in a system

where wind speed is also being measured.

Although net radiometers are usually used in meteorology to measure radiation

balance, the NR-LITE2 can also be used to measure indoor climate radiative

stress.

-2

).

The NR-LITE2 is manufactured by Kipp & Zonen, but cabled for use with

Campbell Scientific dataloggers. Its cable can terminate in:

• Pigtails that connect directly to a Campbell Scientific datalogger

(cable termination option –PT).

• Connector that attaches to a prewired enclosure (cable termination

option ─PW).

5.1 Electrical Properties

The thermopile consists of a number of thermocouples connected in series,

essentially providing a highly sensitive differential temperature sensor. The

thermopile generates a voltage output — the sensor itself is passive, and so no

power supply is required.

The upwards and downwards facing sensor surfaces are connected to the upper

and lower thermopile junctions respectively, allowing the sensor to measure

the differential temperature (FIGURE 5-1). This temperature differential can

be measured to a high accuracy (in the order of 0.001 degrees), and is

proportional to the net radiation.

The thermopile determines the electrical characteristics of the instrument. Both

upper and lower facing sensors have a field of view of 180 degrees, and their

angular characteristics conform closely to the cosine response (see following

sections).

8

The electrical sensitivity for the thermopile changes with temperature, and no

nominal sensitivity value is available.

Page 15

FIGURE 5-1. Electrical circuit for the NR-LITE2 Net Radiometer

5.2 Spectral Properties

NR-LITE2 Net Radiometer

The upwards facing sensor is calibrated for solar radiation wavelengths. The

following assumptions are made:

• The downwards facing sensor has the same sensitivity. However, since

the two sensors may not be perfectly symmetrical, this assumption may

not always be true, but differences are small.

• The NR-LITE2’s sensitivity is the same for both solar and infrared

radiation.

5.3 Directional/Cosine Response

The measurement of the radiation falling on a surface (also known as

irradiance or radiative flux) is based on two assumptions:

1. The sensor surface is spectrally black — that it absorbs all radiation from

all wavelengths (Section 5.2, Spectral Properties).

2. That it has a true field of view of 180°.

These two properties, taken together, with which the net radiometer needs to

comply, are generally known as the cosine response.

A perfect cosine response will show maximum sensitivity at an angle of

incidence of zero degrees (perpendicular to the sensor surface) and zero

sensitivity at an angle of incidence of 90 degrees (radiation passing over the

sensor surface). At any angle between 0 and 90 degrees the sensitivity should

be proportional to the cosine of the angle of incidence.

FIGURE 5-2 shows the behavior of a typical net radiometer. The vertical axis

shows the deviation from ideal behavior, expressed in percentage deviation

from the ideal value.

9

Page 16

NR-LITE2 Net Radiometer

Error

Angle of Incidence

FIGURE 5-2. Cosine response of a typical net radiometer

5.4 Sensitivity to Wind Speed

The calibration of the NR-LITE2 is carried out at zero wind speed. At any

other wind speed, the sensitivity will decrease. It has been shown that this

decrease in sensitivity is less than 1% of reading per meter per second wind

speed, and the effect is essentially independent of the radiation level.

Net radiation readings can be corrected for wind speed sensitivity using the

following equation, which was developed by Jerry Brotzge at the Oklahoma

Climate Survey:

Wind Sensitivity equation for the NR-LITE2:

Rn,cor = Rn,obs U < 5 m s

Rn,cor = Rn,obs ∗ (1.0 + A × (U ─ 5.0)) U > 5 m s

Where,

Rn,cor = Net radiation corrected for wind speed

Rn,obs = Net radiation not corrected for wind speed

U = Horizontal wind speed in m s

A = empirical constant derived from data = 0.021286

-1

-1

-1

10

FIGURE 5-3 provides scatter plots showing the wind sensitivity for both the

NR-LITE2 and CNR1 net radiometer models.

Page 17

NR-LITE2 Net Radiometer

Differences between the NR-Lite and CNR1 as a function of wind speed for

daytime conditions during 7 May ─ 6 June, 1998. (a) No correction. (b) Eq. (4)

applied as a correction.

FIGURE 5-3. NR-LITE2 wind sensitivity

6. Specifications

Features:

Compatible dataloggers: CR800

CR850

CR1000

CR3000

CR5000

CR9000(X)

CR7

CR500

CR510

CR10(X)

CR23X

• Compatible with most Campbell Scientific dataloggers

• Integrated bubble level ensures proper installation

• Includes rod that deters birds from roosting on the radiometer

• PTFE-coated absorbers are weather resistant without using a fragile

plastic dome

11

Page 18

NR-LITE2 Net Radiometer

k

6.1 Spectral

6.2 Directional

Spectral range: 0.2 to 100 μm

Detector type: Thermopile

Detector protection: PTFE coating

Detector profile: Conical

Directional error

(0° to 60°C at 1000 W m

Sensor asymmetry: ±5% typical, (±10% worst case)

6.3 Mechanical

Housing material: Anodized aluminum

Cable material: Polyurethane

Weight: 200 g

Cable length: 15 m (can be extended up to 100 m)

Physical dimensions (FIGURE 6-1)

Sensor: 8.0 cm (3.1 in) diameter

Support arm: 1.6 cm (0.6 in) diameter x 80 cm (31.5 in) L

Weight: 635 g (23 oz)

∅16 x 800 Support Arm

∅80

-2

): <30 W m-2

Bird repelling stic

12

Bubble level indicator

FIGURE 6-1. NR-LITE2’s components and dimensions (in millimeters)

6.4 Environmental

Working temperature: ─30° to +70°C

Temperature dependence: 0.12% per °C

Support arm

Adjustable mounting arm

Page 19

7. Operation

k

7.1 Wiring

NR-LITE2 Net Radiometer

The NR-LITE2 can be measured with a differential or single-ended channel on

the datalogger; a differential channel is recommended.

FIGURE 7-1 provides the NR-LITE2 wiring. Datalogger connections are

shown in TABLE 7-1 for differential measurements and TABLE 7-2 for

single-ended measurements.

Red Radiation Signal

Blue Signal Reference

FIGURE 7-1. NR-LITE2 to datalogger connections

TABLE 7-1. Datalogger Connections for Differential Measurement

Function

Radiation Signal Red Differential H Differential H Differential H

Signal Reference Blue Differential L Differential L Differential L

Jumper to AG

Shield Black G

Color

(User supplied jumper wire for differential measurement only)

Blac

Shield

CR10X,

CR510,

CR500

CR23X,

21X, CR7

CR800,

CR850,

CR1000,

CR3000,

CR5000,

CR9000(X)

13

Page 20

NR-LITE2 Net Radiometer

TABLE 7-2. Datalogger Connections for Single-Ended Measurement

Function

Radiation Signal Red S.E. Channel S.E. Channel S.E. Channel

Signal Reference Blue AG

Shield Black G

Color

7.2 Datalogger Programming

NOTE

This section is for users who write their own datalogger

programs. A datalogger program to measure this sensor can be

generated using Campbell Scientific’s Short Cut Program

Builder Software. You only need to read the calibration portion

of this section if using Short Cut.

The NR-LITE2 outputs a low-level voltage ranging from 0 to a maximum of

about 15 mV. A differential voltage measurement (VoltDiff() in CRBasic or

instruction Volt (Diff) (P2) in Edlog) is recommended because it has better

noise rejection than a single-ended measurement. If a differential channel is

not available, a single-ended measurement (VoltSE() in CRBasic or instruction

Volt (SE) (P1) in Edlog) can be used. The acceptability of a single-ended

measurement can be determined by simply comparing the results of singleended and differential measurements made under the same conditions.

CR10X,

CR510,

CR500

CR23X,

21X, CR7

CR800,

CR850,

CR1000,

CR3000,

CR5000,

CR9000(X)

14

7.2.1 Input Range and Integration

Normally the 15 mV range for the 21X or CR7, the 25 mV range for the

CR800, CR850, CR1000, CR10(X), or CR500/CR510, and the 50 mV range

for the CR3000, CR5000, CR9000X, or CR23X are suitable.

The slow or 60 Hz rejection integration gives a more noise-free reading. A fast

integration takes less power and allows for faster throughput.

7.2.2 Calibration Factor

Each NR-LITE2 is provided with a Certificate of Calibration by the

manufacturer which shows the sensor serial number and a sensitivity or

calibration factor. This calibration factor, after conversion, is used in the

datalogger program. Always cross check to ensure that the serial number of

your NR-LITE2 and the number on the calibration certificate are identical.

The serial number and sensitivity are also shown on a small label attached to

the connecting arm near the head of the sensor itself.

The calibration factor included on the Certificate of Calibration is in units of

µV/(W m

multiplier parameter in the datalogger program. To convert the units, divide

-2

), which needs to be converted to units of (W m-2)/mV for the

Page 21

NR-LITE2 Net Radiometer

the calibration factor into 1000. For example, if the calibration factor is 15.8

µV/(W m

1000/15.8 = 63.29 (W m

-2

), the multiplier is:

-2

)/mV

7.2.3 Example Programs

7.2.3.1 CR3000 Example Program without Wind Speed Correction

Shown below is an example program written for the CR3000 datalogger.

TABLE 7-3 provides the wiring for the example program. In this example, the

datalogger measures the output from the sensor every 5 seconds and outputs

the average net radiation every hour. The calibration factor used will only

apply for one specific sensor. A new value will need to be calculated for every

different sensor based on the Certificate of Calibration for that sensor (Section

7.2.2, Calibration Factor).

TABLE 7-3. Wiring for CR3000 Example

Color Function CR3000 Channels

Red Radiation Signal 1H

Blue Signal Reference 1L

Jumpered to

Black Shield

'CR3000

'Declare Variables and Units

Public BattV

Public NR_Wm2

Units BattV=Volts

Units NR_Wm2=W/meter^2

'Define Data Tables

DataTable(Table1,True,-1)

DataInterval(0,60,Min,10)

Average(1,NR_Wm2,FP2,False)

EndTable

DataTable(Table2,True,-1)

DataInterval(0,1440,Min,10)

Minimum(1,BattV,FP2,False,False)

EndTable

'Main Program

BeginProg

Scan(5,Sec,1,0)

'Default Datalogger Battery Voltage measurement BattV

Battery(BattV)

'NR-LITE2 Net Radiometer (no wind speed correction) measurement NR_Wm2

VoltDiff(NR_Wm2,1,mV50,1,True,0,_60Hz,100,0)

'Call Data Tables and Store Data

CallTable(Table1)

CallTable(Table2)

NextScan

EndProg

15

Page 22

NR-LITE2 Net Radiometer

7.2.3.2 CR1000 Example Program with Wind Speed Correction

Shown below is an example program written for the CR1000 datalogger.

TABLE 7-4 provides the wiring for the example program. Besides measuring

the NR-LITE2, the program also measures wind speed and applies the

correction factor as described in Section 5.4, Sensitivity to Wind Speed.

Average net radiation and wind speed are output every hour.

TABLE 7-4. Wiring for CR1000 Example

Color Function CR1000 Channels

Red Radiation Signal 2H

Blue Signal Reference 2L

Jumpered to

Black Shield

'CR1000

'Declare Variables and Units

Dim WindCor_7

Public BattV

Public WS_ms

Public WindDir

Public NR_Wm2

Public CNR_Wm2

Units BattV=Volts

Units WS_ms=meters/second

Units WindDir=Degrees

Units NR_Wm2=W/m^2

Units CNR_Wm2=Watts/meter^2

'Define Data Tables

DataTable(Table1,True,-1)

DataInterval(0,60,Min,10)

Average(1,WS_ms,FP2,False)

Sample(1,WindDir,FP2)

Average(1,NR_Wm2,FP2,False)

Average(1,CNR_Wm2,FP2,False)

EndTable

DataTable(Table2,True,-1)

DataInterval(0,1440,Min,10)

Minimum(1,BattV,FP2,False,False)

EndTable

'Main Program

BeginProg

Scan(5,Sec,1,0)

'Default Datalogger Battery Voltage measurement BattV

Battery(BattV)

'05103 Wind Speed & Direction Sensor measurements WS_ms and WindDir

PulseCount(WS_ms,1,1,1,1,0.098,0)

BrHalf(WindDir,1,mV2500,1,1,1,2500,True,0,_60Hz,355,0)

If WindDir>=360 Then WindDir=0

'NR-LITE2 Net Radiometer (dynamic wind speed correction)

'measurement NR_Wm2 and CNR_Wm2

16

Page 23

NR-LITE2 Net Radiometer

VoltDiff(NR_Wm2,1,mv25,2,True,0,_60Hz,100,0)

If WS_ms>=5 Then

CNR_Wm2=NR_Wm2*(1+0.021286*(WS_ms-5))

Else

CNR_Wm2=NR_Wm2

EndIf

'Call Data Tables and Store Data

CallTable(Table1)

CallTable(Table2)

NextScan

EndProg

7.2.3.3 CR10(X) Example Program without Wind Speed Correction

Shown below is an example program written for the CR10(X) datalogger.

TABLE 7-5 provides the wiring for the example program. In this example, the

datalogger measures the output from the sensor every 60 seconds and outputs

the average net radiation every hour.

The calibration factor used will only apply for one specific sensor. A new

value will need to be calculated for every different sensor based on the

Certificate of Calibration for that sensor (Section 7.2.2, Calibration Factor).

TABLE 7-5. Wiring for CR10X Example

(without Wind Correction)

Color Function CR10X Channels

Red Radiation Signal 1H

Blue Signal Reference 1L

Jumpered to AG

Black Shield G

;{CR10X}

;

*Table 1 Program

01: 60 Execution Interval (seconds)

1: Volt (DIFF) (P2)

1: 1 Reps

2: 3** 25 mV Slow Range ;range code for CR10(X) datalogger

3: 1* DIFF Channel

4: 1* Loc [ Net_rad ]

5: 63.29 Mult ;Multiplier for specific sensor

6: 0.0 Offset ;in units of (W m-2)/mV (see above)

2: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

3: Real Time (P77)

1: 110 Day,Hour/Minute (midnight = 0000)

4: Average (P71)

1: 1 Reps

2: 1 Loc [ Net_rad ]

17

Page 24

NR-LITE2 Net Radiometer

7.2.3.4 CR10X Example Program with Wind Speed Correction

;{CR10X}

;

*Table 1 Program

01: 60 Execution Interval (seconds)

;measure 05103 wind speed

1: Pulse (P3)

1: 1 Reps

2: 1 Pulse Channel 1

3: 21 Low Level AC, Output Hz

4: 1 Loc [ Wspd_m_s ]

5: .0980 Mult

6: 0 Offset

;measure NR-LITE2 net radiation

2: Volt (SE) (P1)

1: 1 Reps

2: 3** 25 mV Slow Range

3: 1* SE Channel

4: 2* Loc [ Rn_obs ]

5: 63.29 Mult ;Multiplier for specific sensor

6: 0 Offset ;in units of (W m-2)/mV (see above)

;apply wind speed correction factor

;Rn,cor = Rn,obs*(1.0+0.021286*(U-5.0)) when U > 5 m/s

3: If (X<=>F) (P89)

1: 1 X Loc [ Wspd_m_s ]

2: 3 >=

3: 5 F

4: 30 Then Do

This example measures the NR-LITE2 using a single-ended input and

instruction Volt (SE) (P1). The program also measures wind speed and applies

the correction factor as described in Section 5.4, Sensitivity to Wind Speed.

Average net radiation and wind speed are output every hour. TABLE 7-6

provides the wiring for this example program.

TABLE 7-6. Wiring for CR10X Example

(with Wind Correction)

Color Function CR10X Channels

Red Radiation Signal S.E. Channel 1

Blue Signal Reference AG

Black Shield G

18

Page 25

4: Z=X+F (P34)

1: 1 X Loc [ Wspd_m_s ]

2: -5 F

3: 24 Z Loc [ scratch_1 ]

5: Z=X*F (P37)

1: 24 X Loc [ scratch_1 ]

2: .021286 F

3: 25 Z Loc [ scratch_2 ]

6: Z=X+F (P34)

1: 25 X Loc [ scratch_2 ]

2: 1 F

3: 26 Z Loc [ scratch_3 ]

7: Z=X*Y (P36)

1: 26 X Loc [ scratch_3 ]

2: 2 Y Loc [ Rn_obs ]

3: 3 Z Loc [ Rn_cor ]

8: Else (P94)

9: Z=X (P31)

1: 2 X Loc [ Rn_obs ]

2: 3 Z Loc [ Rn_cor ]

10: End (P95)

11: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

12: Real Time (P77)

1: 1220 Year,Day,Hour/Minute (midnight = 2400)

13: Average (P71)

1: 1 Reps

2: 3 Loc [ Rn_cor ]

14: Average (P71)

1: 1 Reps

2: 1 Loc [ Wspd_m_s ]

NR-LITE2 Net Radiometer

* Proper entries will vary with program and input channel assignments.

** 25 mV range for CR10(X) and CR510, the 50 mV range for CR23X, and the 15 mV range for

21X and CR7.

19

Page 26

NR-LITE2 Net Radiometer

8. Maintenance

The radiometer is an ‘all weather’ instrument and is very stable, but should be

handled with care. It requires little periodic maintenance, apart from cleaning

the sensor surfaces carefully with a soft cloth using water or alcohol.

The NR-LITE2 should be recalibrated every two years. An RMA number is

required before returning the sensor for recalibration; refer to the Assistance

section in the beginning of this manual for more information.

9. Troubleshooting

9.1 Checking Sensor Operation

To effectively check the instrument’s operation, you will need:

• NR-LITE2

• Voltmeter, range 0 to 50 mV, with an input impedance greater than

• Light source

• Table or bench

5000 Ohms

Position the radiometer so that its downward facing sensor is about 10 mm (0.4

in) above a flat surface (table or bench), and the upwards facing sensor is

facing the light source (lamp). Do not touch the sensor head itself, as this will

introduce thermal shocks. Hold the instrument only by its mounting arm at all

times.

Follow the procedure outlined below:

1. Connect the NR-LITE2 wires to the voltmeter. Connect the red wire to the

positive lead and the blue wire to the negative lead.

2. Select the most sensitive range on the voltmeter.

3. With the lamp switched off, read the sensor output signal — allow a

minute or so for the signal to fully stabilize.

4. Switch on the lamp. The sensor should now produce a higher positive

reading.

5. Turn the lamp off again, when the signal should slowly return to its

original level, proving the sensor’s sensitivity to light.

6. Turn the sensor upside down. The signal value should reverse in sign; a

+10 mV signal should become a ─10 mV signal. Don’t worry if the two

values are not exactly the same (up to 10% difference) as the sensor

profiles can vary. After completing this test, return the sensor to its

original orientation and let it stabilize.

20

7. Put your hand over the upper sensor. Assuming that your hand is at a

higher temperature than the sensor, the positive reading should increase.

Page 27

NR-LITE2 Net Radiometer

Conversely, if the sensor is warmer than your hand, the reading will

decrease.

8. Check the radiometer’s sensitivity to thermal shocks by touching the edge

of the sensor (the blank metal) with your hand for some seconds. The

resultant shock will result in a signal drift, or a zero offset that will take

some time to settle back to zero.

9. Adjust the range of the voltmeter so that the expected full-scale output of

the radiometer is about the same as the range of the voltmeter. A

(theoretical) way to calculate the maximum expected output for normal

meteorological applications is shown below:

-2

Max. expected radiation +1500 W m

Min. radiation –200 W m

-2

Sensitivity of the net radiometer 10 μV/(W m

Expected output range of the radiometer is (1500 + 200) × 10 =

1700 × 10 = 17.0 mV or 0.017 V.

9.2 Radiometer Produces No Apparent Output

-2

)

If your net radiometer does not appear to be working at all, do the following

checks:

1. Check the instrument’s sensitivity to radiation, following the procedure

shown in Section 9.1, Checking Sensor Operation.

2. If this appears to produce no results, measure the impedance of the sensor

across the red and blue wires. The impedance reading should be close to

2.3Ω. If it is virtually zero, a short circuit is indicated. If it is ‘infinite’,

the thermopile is blown.

9.3 Readings Are Not As Expected

1. Under full sunlight, the expected radiation value is about 1000 W m-2.

Under lamps it may be greater. For indoor climate studies, smaller values

are to be expected unless solar radiation is present. A typical value for a

room when facing a wall and a relatively cold window is 50 W m

2. Are you using the correct calibration factor? Note that this factor is unique

for each individual sensor as noted on the calibration certificate provided

with that sensor. Did you convert the factor to the correct value for the

datalogger program? (Section 7.2, Datalogger Programming.)

3. Check the datalogger program for errors.

-2

.

If you cannot resolve your problems, please contact Campbell Scientific for

further advice.

21

Page 28

NR-LITE2 Net Radiometer

22

Page 29

Page 30

Campbell Scientific Companies

Campbell Scientific, Inc. (CSI)

815 West 1800 North

Logan, Utah 84321

UNITED STATES

www.campbellsci.com • info@campbellsci.com

Campbell Scientific Africa Pty. Ltd. (CSAf)

PO Box 2450

Somerset West 7129

SOUTH AFRICA

www.csafrica.co.za • cleroux@csafrica.co.za

Campbell Scientific Australia Pty. Ltd. (CSA)

PO Box 8108

Garbutt Post Shop QLD 4814

AUSTRALIA

www.campbellsci.com.au • info@campbellsci.com.au

Campbell Scientific do Brasil Ltda. (CSB)

Rua Apinagés, nbr. 2018 ─ Perdizes

CEP: 01258-00 ─ São Paulo ─ SP

BRASIL

www.campbellsci.com.br • vendas@campbellsci.com.br

Campbell Scientific Canada Corp. (CSC)

11564 - 149th Street NW

Edmonton, Alberta T5M 1W7

CANADA

www.campbellsci.ca • dataloggers@campbellsci.ca

Campbell Scientific Centro Caribe S.A. (CSCC)

300 N Cementerio, Edificio Breller

Santo Domingo, Heredia 40305

COSTA RICA

www.campbellsci.cc • info@campbellsci.cc

Campbell Scientific Ltd. (CSL)

Campbell Park

80 Hathern Road

Shepshed, Loughborough LE12 9GX

UNITED KINGDOM

www.campbellsci.co.uk • sales@campbellsci.co.uk

Campbell Scientific Ltd. (France)

3 Avenue de la Division Leclerc

92160 ANTONY

FRANCE

www.campbellsci.fr • info@campbellsci.fr

Campbell Scientific Spain, S. L.

Avda. Pompeu Fabra 7-9, local 1

08024 Barcelona

SPAIN

www.campbellsci.es • info@campbellsci.es

Please visit www.campbellsci.com to obtain contact information for your local US or international representative.

Loading...

Loading...