Page 1

NR01 Four-Component

Net Radiation Sensor

Revision: 8/11

Copyright © 2008-2011

Campbell Scientific, Inc.

Page 2

Warranty and Assistance

PRODUCTS MANUFACTURED BY CAMPBELL SCIENTIFIC, INC. are

warranted by Campbell Scientific, Inc. (“Campbell”) to be free from defects in

materials and workmanship under normal use and service for twelve (12) months

from date of shipment unless otherwise specified on the corresponding Campbell

invoice. Batteries, fine-wire thermocouples, desiccant, and other consumables have

no warranty. Campbell's obligation under this warranty is limited to repairing or

replacing (at Campbell's option) defective products, which shall be the sole and

exclusive remedy under this warranty. The customer shall assume all costs of

removing, reinstalling, and shipping defective products to Campbell. Campbell

will return such products by surface carrier prepaid within the continental United

States of America. To all other locations, Campbell will return such products best

way CIP (Port of Entry) INCOTERM

apply to any Campbell products which have been subjected to modification,

misuse, neglect, improper service, accidents of nature, or shipping damage. This

warranty is in lieu of all other warranties, expressed or implied. The warranty for

installation services performed by Campbell such as programming to customer

specifications, electrical connections to products manufactured by Campbell, and

product specific training, is part of Campbell’s product warranty. CAMPBELL

EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Campbell is not liable for any special, indirect, incidental, and/or consequential

damages.

Products may not be returned without prior authorization. The following contact

information is for US and International customers residing in countries served by

Campbell Scientific, Inc. directly. Affiliate companies handle repairs for customers

within their territories. Please visit www.campbellsci.com to determine which

Campbell Scientific company serves your country.

®

2010, prepaid. This warranty shall not

To obtain a Returned Materials Authorization (RMA), contact Campbell Scientific,

Inc., phone (435) 753-2342. After an applications engineer determines the nature

of the problem, an RMA number will be issued. Please write this number clearly

on the outside of the shipping container. Campbell Scientific's shipping address is:

CAMPBELL SCIENTIFIC, INC.

RMA#_____

815 West 1800 North

Logan, Utah 84321-1784

For all returns, the customer must fill out a “Declaration of Hazardous Material and

Decontamination” form and comply with the requirements specified in it. The form

is available from our website at

must be either emailed to repair@campbellsci.com

Campbell Scientific will not process any returns until we receive this form. If the

form is not received within three days of product receipt or is incomplete, the

product will be returned to the customer at the customer’s expense. Campbell

Scientific reserves the right to refuse service on products that were exposed to

contaminants that may cause health or safety concerns for our employees.

www.campbellsci.com/repair

or faxed to 435-750-9579.

. A completed form

Page 3

NR01 Table of Contents

PDF viewers note: These page numbers refer to the printed version of this document. Use

the Adobe Acrobat® bookmarks tab for links to specific sections.

1. Introduction..................................................................1

2. Measurement Principle ...............................................3

2.1 General......................................................................................................3

2.2 NR01 Construction ...................................................................................4

2.3 Pyranometers ............................................................................................5

2.4 Pyrgeometers ............................................................................................6

2.5 Expected Measurement Results................................................................8

2.6 Heating....................................................................................................10

2.7 Data Quality Assurance ..........................................................................10

3. Specifications of NR01..............................................10

3.1 NR01 General Specifications .................................................................11

3.2 SR01 Pyranometer Specifications ..........................................................12

3.3 IR01 Pyrgeometer Specifications ...........................................................13

3.4 Dimensions .............................................................................................14

4. Installation..................................................................14

4.1 Installation ..............................................................................................14

4.2 Electrical Connections ............................................................................16

4.3 Connecting the Sensor to Campbell Scientific Dataloggers ...................17

4.3.1 Connecting and Using the Heater .................................................19

4.4 Installation of the Radiation Shields.......................................................20

4.5 Instrument-Inversion-Test ......................................................................20

5. Datalogger Programming.......................................... 20

5.1 Calibration Factors..................................................................................21

5.2 Example Programs..................................................................................22

5.2.1 Example 1, CR1000 Using Differential Channels ........................22

5.2.2 Example 2, CR3000/CR5000 Using Differential Channels

(no 4WPB100) ..........................................................................25

5.2.3 Example 3, CR23X Program Using Differential Channels...........27

5.2.4 Example 4, CR23X Program Using Single-Ended Channels .......31

6. Maintenance and Troubleshooting ..........................33

6.1 Maintenance............................................................................................33

6.2 Troubleshooting......................................................................................34

Appendix

A. CR3000 Program that Controls the Heater ........................................... A-1

i

Page 4

NR01 Table of Contents

Figures

Tables

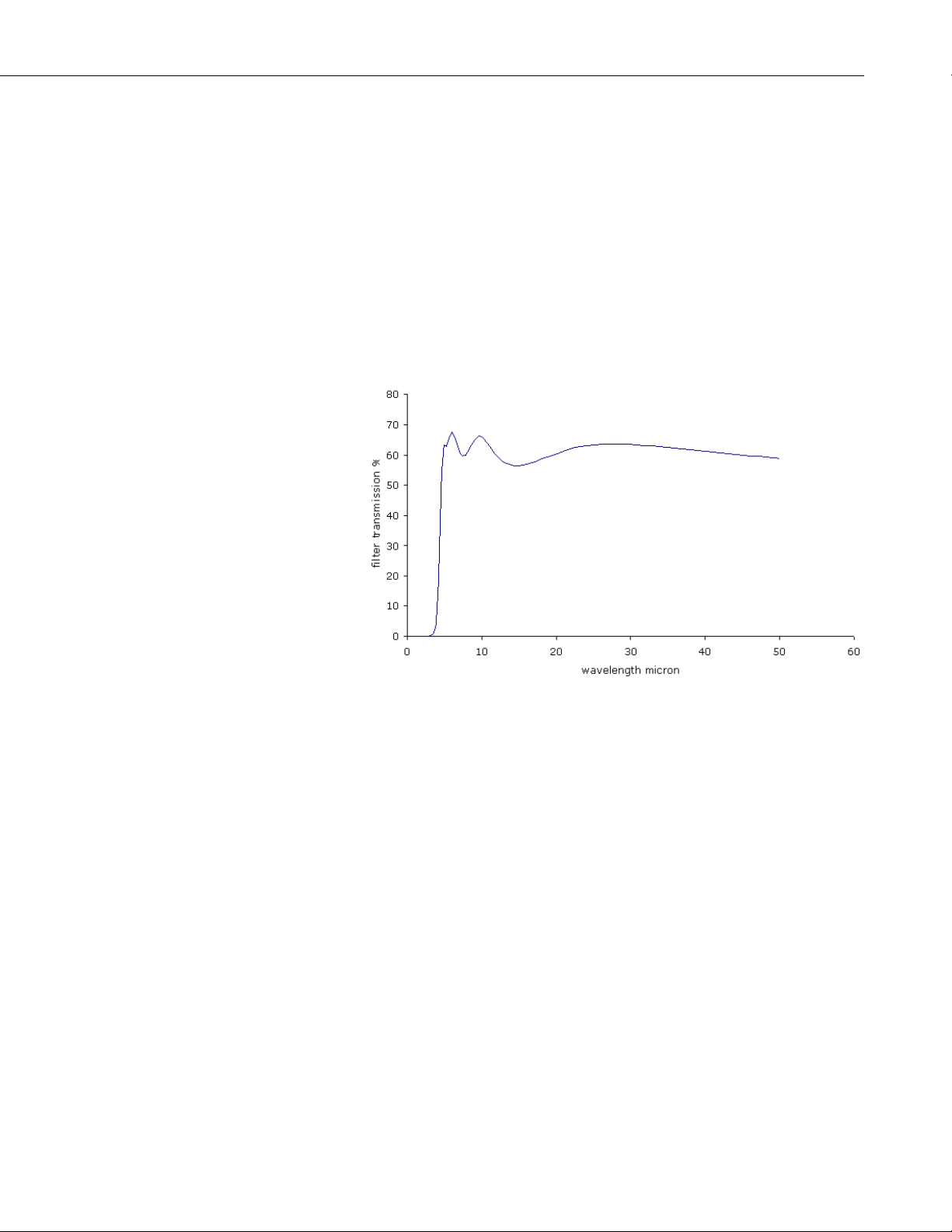

1-1. Atmospheric Radiation as a Function of Wavelength ............................ 2

2.2-1. The NR01 Four-Component Net Radiation Sensor............................. 4

2.3-1. Spectral Response of the Pyranometer Compared to the Solar

Spectrum.......................................................................................... 5

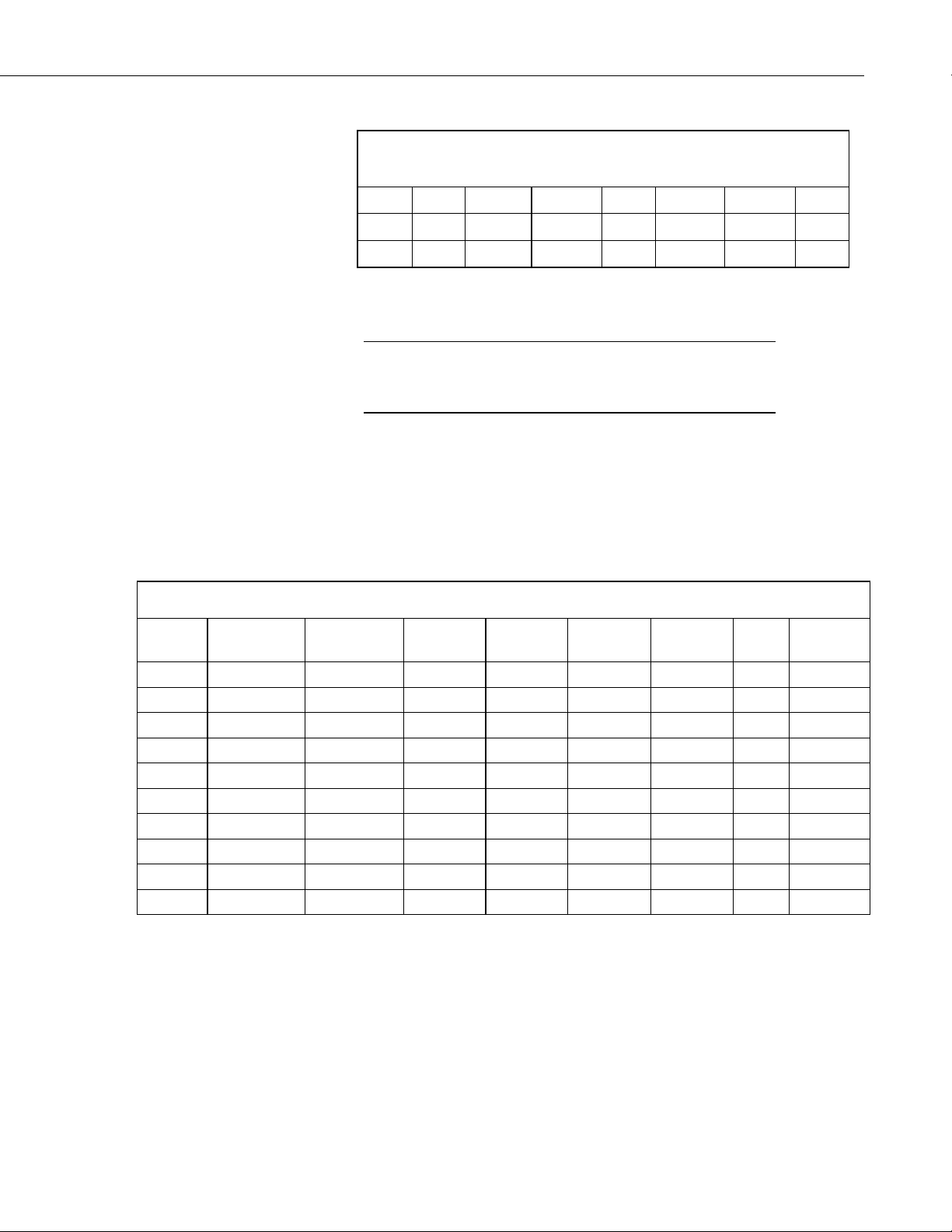

2.4-1. Spectral Response of the Pyrgeometer Compared to the Atmospheric

LW Spectrum................................................................................... 7

3.4-1. Dimensions of the NR01 in mm ........................................................ 14

4.1-1. NR01 with Reducer (P/N 21271) and Mounting Arm....................... 15

4.4-1. Installation and Removal of Radiation Shields.................................. 20

5-1. 4WPB100 Module ................................................................................ 21

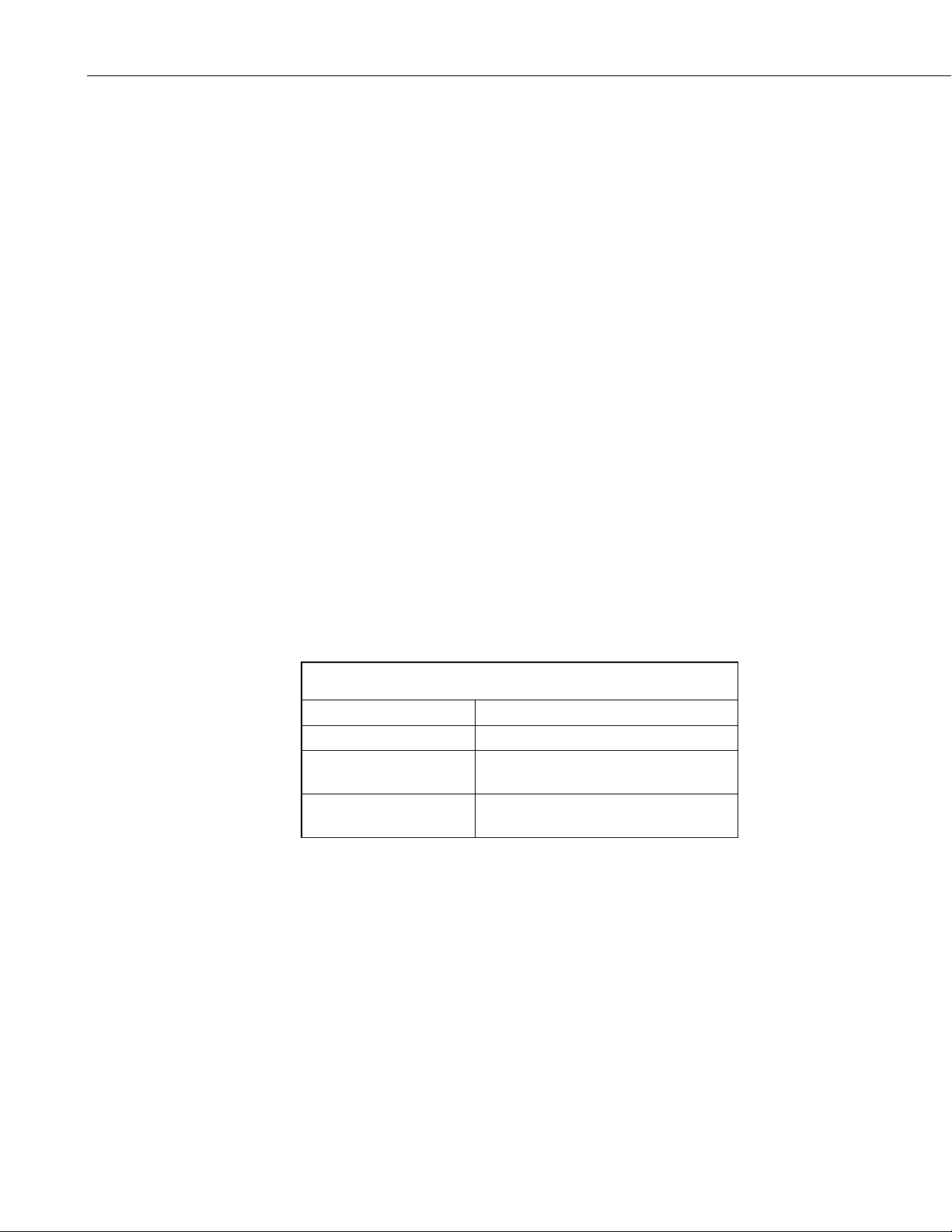

2.3-1. Main Measurement Errors in the SW Signal....................................... 6

2.4-2. Main Measurement Errors in the LW Signal....................................... 8

2.5-1. Average Global Radiation Values at the Earth Surface....................... 9

2.5-2. Expected SENSOR Outputs when Measuring with the NR01 ............ 9

3.1-1. General Specifications of the NR01 .................................................. 11

3.2-1. Specifications of SR01 ...................................................................... 12

3.3-1. Specifications of IR01 ....................................................................... 13

4.1-1. Recommendations for Installation of the NR01 ................................ 15

4.2-1. Internal Electrical Diagram of the NR01........................................... 17

4.3-1. Datalogger Connections for Differential Measurement,

when using a 4WPB100................................................................. 18

4.3-2. Datalogger Connections for Single-Ended Measurement,

when using a 4WPB100................................................................. 18

4.3-3. Pt-100 Temperature Sensor Connections to 4WPB100 and

Datalogger...................................................................................... 18

4.3-4. CR3000 and CR5000 Connections for Differential Measurement

and using the Current Excitation to Measure the PT100 Sensor ... 19

6.1-1. The NR01 Recommendations for Maintenance................................. 33

6.2-1. Troubleshooting for the NR01........................................................... 34

ii

Page 5

NR01 Four-Component Net Radiation Sensor

The NR01 is a four-component net radiation sensor that is used for scientific-grade energy

balance studies.

1. Introduction

The NR01 has separate measurements of solar (Short Wave or SW) and Far

Infra-Red (Long Wave or LW) radiation. It offers a professional solution to

the measurement of net radiation and its four main components. The NR01 is

robust and requires only limited maintenance.

Measurement of the separate components of the net radiation is useful because

it:

• Enhances accuracy by having separately calibrated instruments (similar

accuracy cannot be attained with sensors with single outputs or dual

outputs). Single-output or dual-output instruments will always suffer from

instrument asymmetry or from errors due to sensitivity differences for LW

and SW radiation.

• Provides more detailed information than sensors with single or dual

outputs (e.g., albedo of the ground, cloud condition).

• Allows more thorough quality assurance of the instrument data (compared

to sensors with single or dual outputs). Quality assurance with fourcomponent radiometers is done by analyzing trends in SW

signal, SW albedo, correlation of SW

and correlation LW

and surface temperature.

out

and LWin, SW night time signals,

in

absolute

in

1

Page 6

NR01 Four-Component Net Radiation Sensor

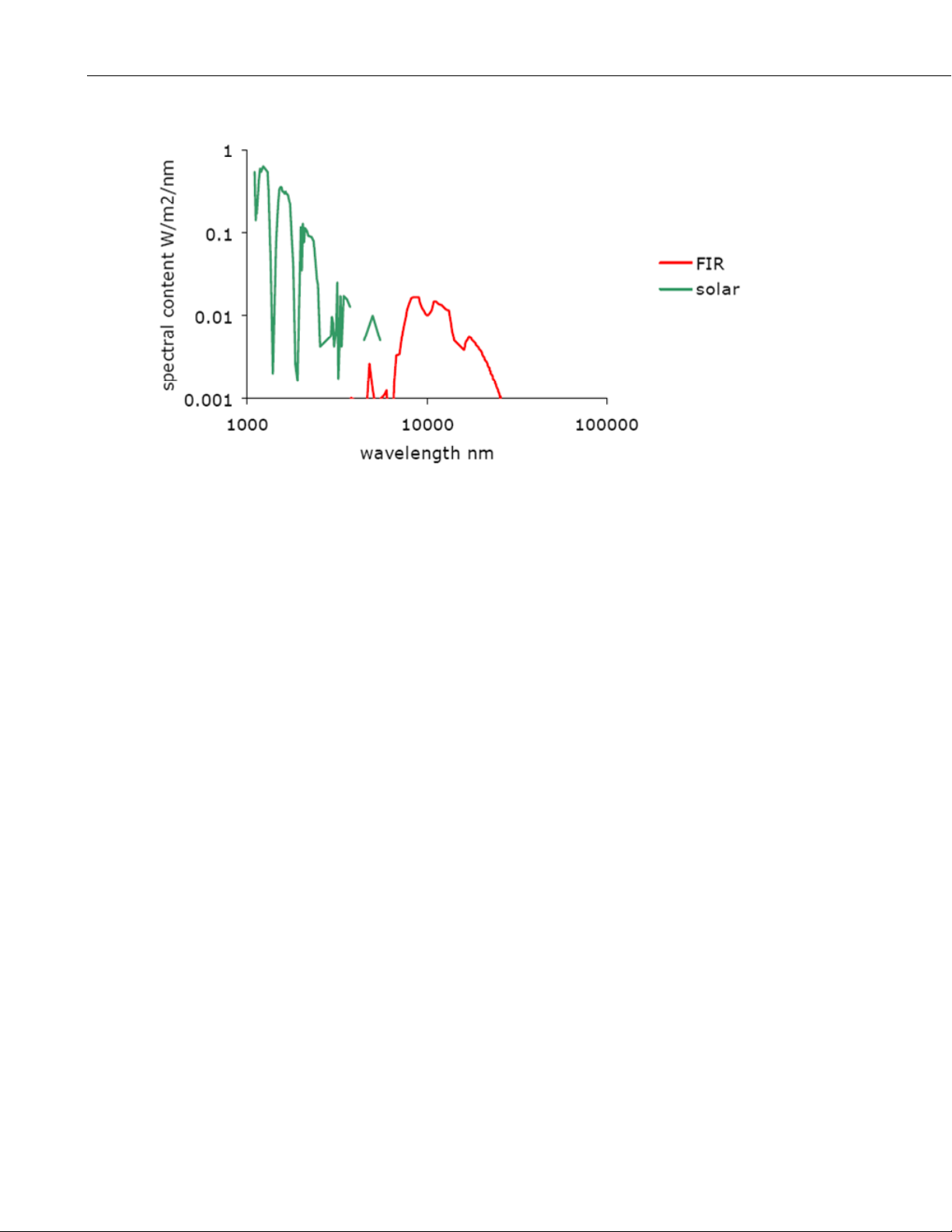

FIGURE 1-1. Atmospheric Radiation as a Function of Wavelength

LW or FIR radiation is mainly present in the 4500 to 50000 nm region, while SW or solar radiation is

mainly present in the 300 to 3000 nm region. The two are measured separately.

Major improvements of the NR01 relative to comparable instruments include

reduced weight, reduced solar offsets in the LW signal, ease of leveling

(because a 2-axis leveling assembly is built-in).

The NR01 serves to measure the four separate components of the surface

radiation balance. Working completely passive, using thermopile sensors, the

NR01 generates four small output voltages proportional to the incoming and

outgoing SW and LW fluxes; SW

solar radiation, LW

or infrared emitted by the sky and LW

in

or global solar radiation, SW

in

or reflected

out

or infrared

out

emitted by the ground surface.

From these also parameter like SW “albedo”, “sky temperature”, “(ground)

surface temperature” and off course “net-radiation” (net value of all SW and

LW fluxes) can be calculated.

The SW sensors are also called pyranometers (type SR01); the LW sensors are

called pyrgeometers (type IR01). For calculation of the sky and surface

temperature, a PT100 temperature sensor is included in the connection body of

the pyrgeometers. A heater is also included in the pyrgeometers’ connection

body to heat the pyrgeometers, which prevents the deposition of dew.

The NR01 requires leveling; a two-axis leveling facility is incorporated in the

design. See the chapter on installation.

Using the NR01 is easy. For readout one only needs four analog input

channels, and, only if sky and surface temperature are required, a way to

measure the PT100. If power is available, Campbell Scientific recommends

heating the pyrgeometers from sundown to sunset.

2

Page 7

NR01 Four-Component Net Radiation Sensor

The NR01 is supplied with four separate instrument sensitivities. As a brief

explanation, to calculate the radiation level, the sensor output voltage, U, must

be divided by the sensor sensitivity; a constant, E, that is supplied with each

individual instrument. For example:

Φ = SW

in

= U

pyrano, up

More information can be found in the chapter on instrument performance.

WARNING

The NR01 is a passive sensor, and does not need any

power. The NR01 pyrgeometer can, however, be

heated to prevent dew-deposition.

Putting more than 12 Volt across the NR01 sensor

wiring can permanently damage the sensor.

2. Measurement Principle

The following chapters explain the measurement principles of the NR01.

Pyranometers and pyrgeometers are treated in different paragraphs. The last

section is about expected measurement results.

2.1 General

In its most common application, the NR01 measures net-radiation. The four

components of net radiation are measured and the net radiation is calculated:

/ E

pyrano, up

NOTE

The temperature (T

) for the following formula is in Kelvin.

pyrgeo

If the temperature is measured in degrees Celsius, add 273.15 to

pyrgeo

out

= (U

in

out

net

net

= U

= (U

= U

= U

value.

pyrano, up

pyrano, down

pyrgeo, up

pyrgeo, down

pyrgeo, up

pyrano, up

+ LW

net

/ E

/ E

/ E

net

/ E

/ E

net

2.1-1

pyrano, up

pyrano, down

pyrgeo, up

/ E

pyrgeo, down

2.1-2

) + 5.67.10-8 (T

) + 5.67.10-8 (T

pyrgeo

4

)

)4 2.1-4

pyrgeo

the instrument temperature is cancelled:

pyrgeo, up

pyrano, up

- U

- U

pyrgeo, down

pyrano, down

/ E

/ E

pyrano, down

pyrgeo, down

2.1-5

2.1-6

2.1-7

the T

SWin = U

SW

LW

LW

NOTE: in the LW

LW

SW

NR = SW

Special parameters that could be deducted:

SW albedo = SW

/ SW

in

out

2.1-3

2.1-8

3

Page 8

NR01 Four-Component Net Radiation Sensor

NOTE

The following equations assume the temperature is in Kelvin.

Add 273.15 to equations 2.1-9 and 2.1-10 for temperature in

degree Celsius.

T

= (LW

surface

T

= (LW

sky

in

2.2 NR01 Construction

/5.67.10-8)

out

/5.67.10-8)

1/4

2.1-9

1/4

2.1-10

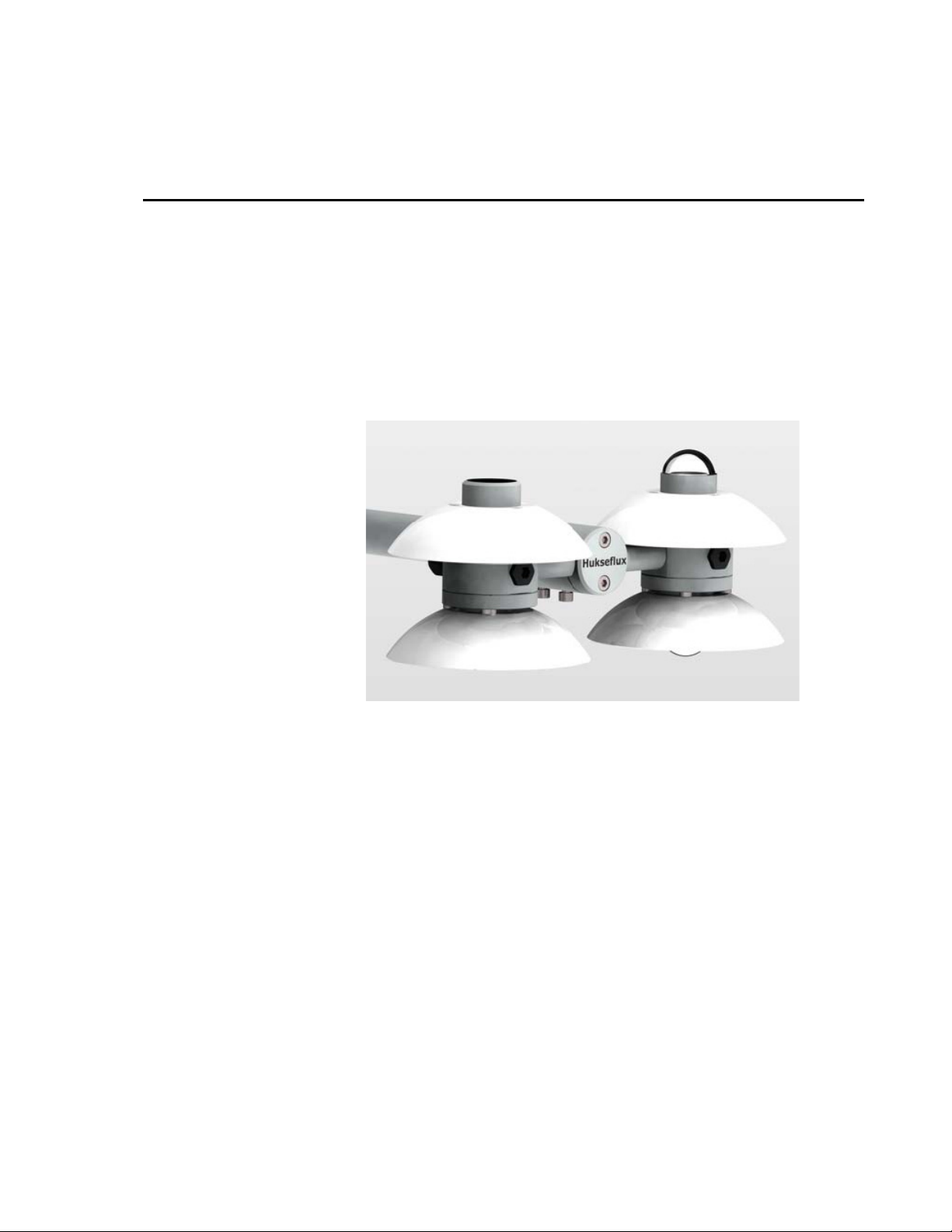

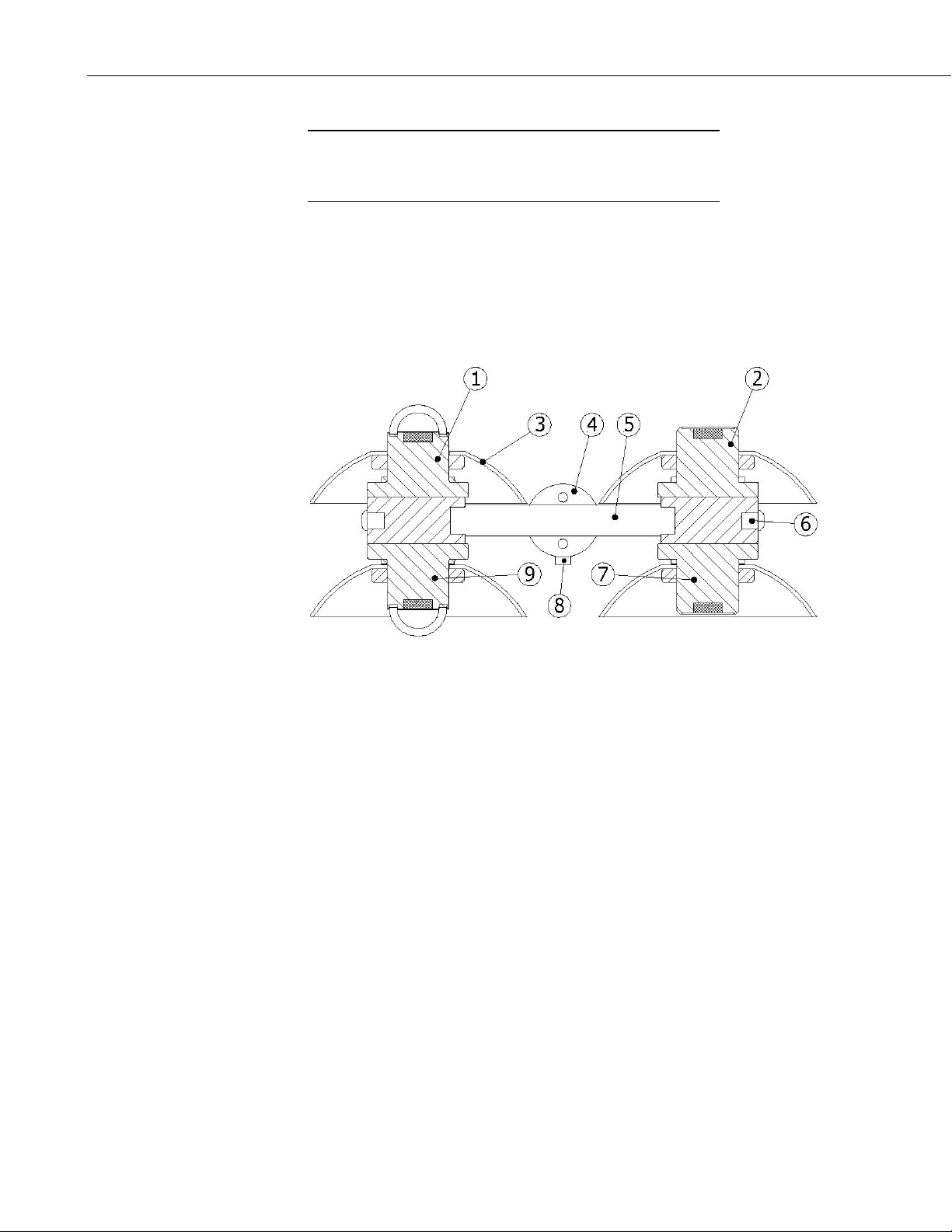

FIGURE 2.2-1. The NR01 Four-Component Net Radiation Sensor

(1) SW

(2) LW

solar radiation sensor or pyranometer,

in

Far Infrared radiation sensor or pyrgeometer

in

(3) radiation shield

(4) leveling assembly for x- and y axis, block plus bolts for x-axis

adjustment

(5) leveling assembly for x- and y axis, horizontal rod

(6) connection body containing the Pt100 temperature sensor, heater,

and hole for user-supplied temperature sensor (add cable gland M8)

(7) LW

Far Infrared radiation sensor or pyrgeometer

out

(8) leveling assembly for x- and y-axis, bolts for y-axis adjustment

(9) SW

solar radiation sensor or pyranometer

out

A level is located under the radiation screens.

4

Page 9

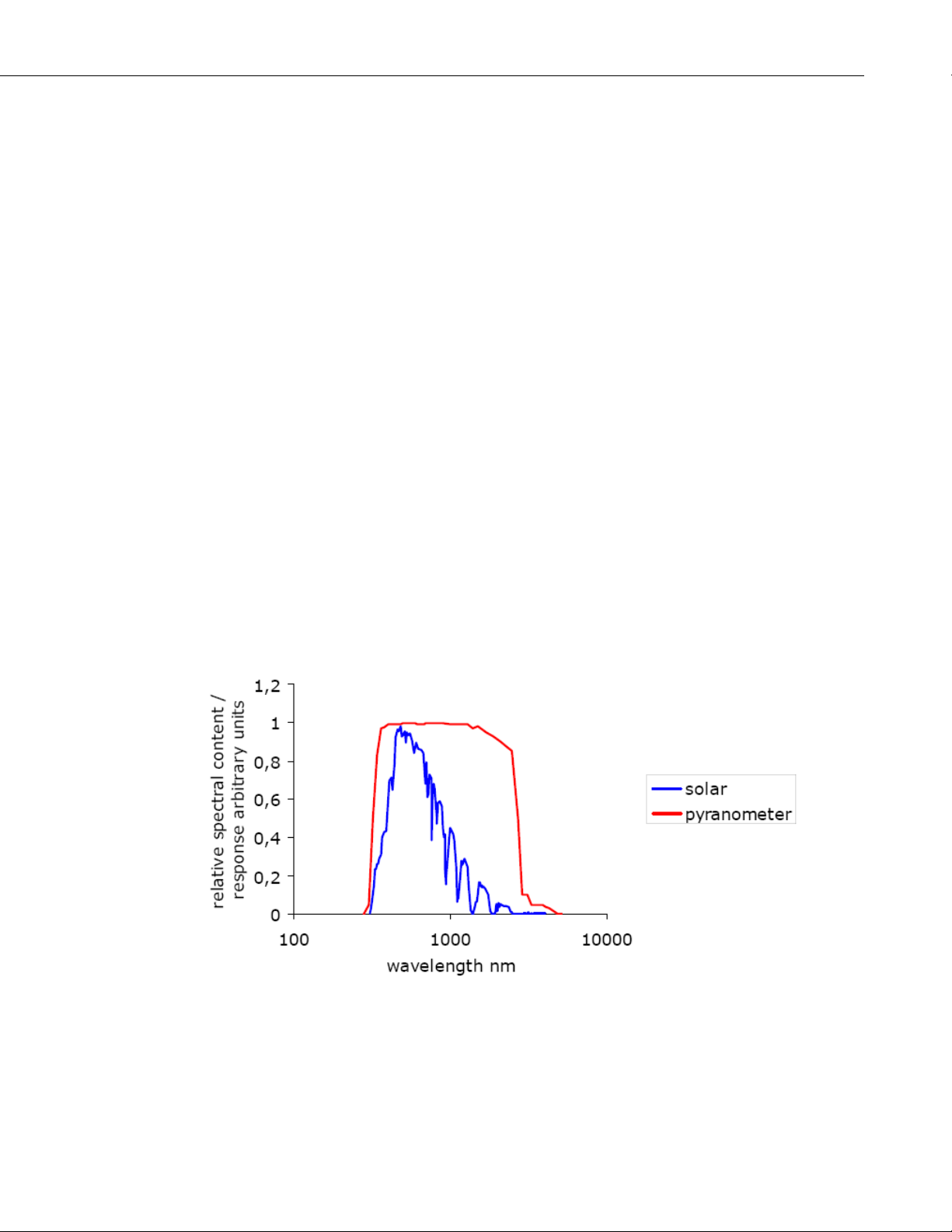

2.3 Pyranometers

A pyranometer should measure the solar or SW radiation flux from a field of

view of 180 degrees. The atmospheric SW radiation spectrum extends roughly

from 300 to 2800 nm. It follows that a pyranometer should cover that

spectrum with a spectral sensitivity that is as “flat” as possible.

For a flux measurement, it is required by definition that the response to “beam”

radiation varies with the cosine of the angle of incidence. For example, full

response occurs when the solar radiation hits the sensor perpendicularly

(normal to the surface, sun at zenith, 0 degrees angle of incidence); zero

response occurs when the sun is at the horizon (90 degrees angle of incidence,

90 degrees zenith angle), and half a response occurs at 60 degrees angle of

incidence. It follows from the definition that a pyranometer should have a socalled “directional response” or “cosine response” that is close to the ideal

cosine characteristic.

In order to attain the proper directional and spectral characteristics, a

pyranometer’s main components are:

1. Thermopile sensor with a black coating—absorbs all solar radiation,

NR01 Four-Component Net Radiation Sensor

provides a flat spectrum covering the 300 to 50000-nanometer range, and

has a near-perfect cosine response.

2. Glass dome—limits the spectral response from 300 to 2800 nanometers

(cutting off the part above 2800 nm) while preserving the 180 degrees

field of view. Another function of the dome is that it shields the

thermopile sensor from convection.

FIGURE 2.3-1. Spectral Response of the Pyranometer Compared to the Solar Spectrum

The pyranometer only cuts off a negligible part of the total solar spectrum.

5

Page 10

NR01 Four-Component Net Radiation Sensor

The black coating on the thermopile sensor absorbs the solar radiation. This

radiation is converted to heat. The heat flows through the sensor to the

pyranometer housing. The thermopile sensor generates a voltage output signal

that is proportional to the solar radiation.

SW

in

= U

pyrano, up

/ E

2.3-1

pyrano, up

In case of the NR01, the pyranometer is type SR01. This is a second-class

pyranometer according to the WMO and ISO classification system (ISO 9060).

The atmospheric solar radiation consists of two components—direct radiation

(in a beam from the sun) and diffuse radiation from the sky.

For down facing instruments, the earth surface reflects part of the solar

radiation, depending on the local surface properties. If there is direct radiation,

this often is the dominant source of energy. Because the solar position is

changing, this implies that for a pyranometer the directional response is quite

important.

Table 2.3-1 summarizes the main sources of measurement errors for the SR01.

The error in the directional response is caused by non-perfect optical properties

of the dome and coating. The infrared offset is produced when the low

temperature “sky” cools off the instrument dome. Because the LW radiation

balance between dome and sky is negative, a negative sensor offset occurs as

the dome cools.

TABLE 2.3-1. Main Measurement Errors in the SW Signal

Source Maximum Error

Directional response +/- 30 W/m2 on SW

+/- 15 W/m

2

on SW

in practice this level is

in

at 1000 W/m

in

2

SWin

Infrared offset - 15 W/m2 on SW

Temperature dependence +/- 5 % for the entire range

2.4 Pyrgeometers

A pyrgeometer should measure the far infrared or LW radiation flux from a

field of view of 180 degrees. The atmospheric LW radiation spectrum extends

roughly from 4500 to 50000 nm. The pyrgeometer should cover that spectrum

with a spectral sensitivity that is as “flat” as possible.

For a flux measurement, by definition, the response to “beam” radiation varies

with the cosine of the angle of incidence. For example, full response occurs

when the radiation hits the sensor perpendicularly (normal to the surface,

source at zenith, 0 degrees angle of incidence); zero response occurs when the

radiation comes from the horizon (90 degrees angle of incidence, 90 degrees

zenith angle), and half a response occurs at 60 degrees angle of incidence. It

follows from the definition that a pyrgeometer should have a so-called

“directional response” or “cosine response” that is close to the ideal cosine

characteristic.

at -200 W/m2 LW

in

net

6

Page 11

NR01 Four-Component Net Radiation Sensor

To attain the proper directional and spectral characteristics, a pyrgeometer’s

main components are:

1 Thermopile sensor with a black coating—absorbs all LW and SW

radiation, provides a flat spectrum covering the 300 to 50000 nanometer

range, and has a near-perfect cosine response.

2 Silicon window with solar blocking—limits the spectral response from

4500 to 50000 nanometers (cutting off the part below 4500 nm) while

preserving the 150 degrees field of view (not the ideal 180 degrees).

Another function of the window is that it shields the thermopile sensor

from convection.

FIGURE 2.4-1. Spectral Response of the Pyrgeometer Compared to

the Atmospheric LW Spectrum

The black coating on the thermopile sensor absorbs the LW radiation. This

radiation is converted to heat. The heat flows through the sensor to the

housing. The thermopile sensor generates a voltage output signal that is

proportional to the LW radiation that is exchanged between sensor and source.

However, the sensor itself also irradiates LW radiation. This is according to

Plank’s law, so that the pyrgeometer thermopile signal is composed of the

incoming radiation minus the outgoing radiation. In order to estimate the

outgoing component, the pyrgeometer temperature is measured independently,

using a Pt100 or a user-supplied temperature sensor. Equation 2.4-1 calculates

the incoming LW radiation assuming T

LW

= (U

in

For LW

out

pyrgeo, up

/ E

) + 5.67.10-8 (T

pyrgeo, up

a similar formula is valid. The equations are the same for up- and

is in Kelvin:

pyrgeo

)4 2.4-1

pyrgeo

down facing instruments.

It is possible to calculate temperatures of the objects within the field of view of

the instrument, assuming these are uniform- temperature blackbodies (emission

7

Page 12

NR01 Four-Component Net Radiation Sensor

coefficient of 1). For example, equation 2.4-2 calculates, in Kelvin, the sky

temperature:

T

sky

= (LW

/5.67.10-8)

in

1/4

2.4-2

The NR01’s pyrgeometers are type IR01. Pyrgeometers are not classified by

the ISO or WMO.

The atmospheric LW

radiation essentially consists of two components:

in

1 Low temperature radiation from the universe, filtered by the atmosphere.

The atmosphere is transparent for this radiation in the so-called

atmospheric window (around 10 to 15 micrometer wavelength).

2 Higher temperature radiation emitted by atmospheric gasses.

Down facing instruments are presumably looking directly at the surface, which

behaves like a normal blackbody.

As a first approximation, the sky can, be seen as a cold temperature source

with its lowest temperatures at zenith and getting warmer at the horizon. The

uniformity of this LW source is much better than that in the solar (SW) range,

where the sun is a dominant and non-uniform contributor. This explains why a

pyrgeometer with 150 degrees field of view can perform a good measurement.

Table 2.4-2 summarizes the main measurement errors for the IR01. The error

in the directional response is caused by non-perfect field of view. The windowheating offset occurs when solar radiation heats up the instrument window,

producing a positive sensor offset.

TABLE 2.4-2. Main Measurement Errors in the LW Signal

Source Maximum Error

Directional response 8 W/m2 on LWin at -100 W/m2 LW

Window heating offset +15 W/m2 on LW

SW

in

Temperature

dependence

+/- 5 % for the entire range

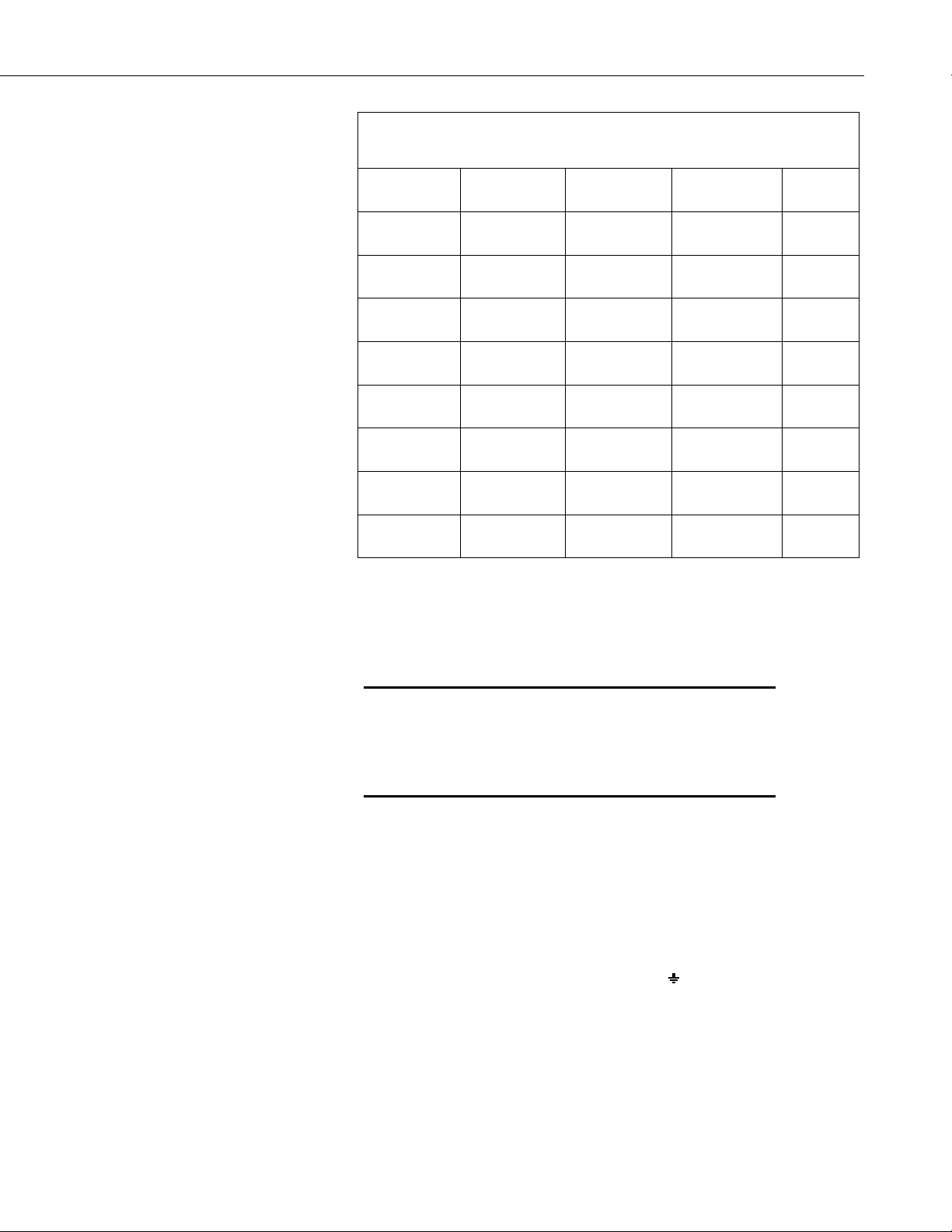

2.5 Expected Measurement Results

The average energy balance at the earth surface strongly depends on the:

• Latitude (mostly for SW)

• Local surface properties (SW and LW)

• Local surface temperature (LW)

Table 2.5-1 summarizes the average global values. The average net radiation at

the earth surface is positive, and the remaining energy is used for convective

heat transport and evaporation.

net

at 1000 W/m2

in

8

Page 13

NR01 Four-Component Net Radiation Sensor

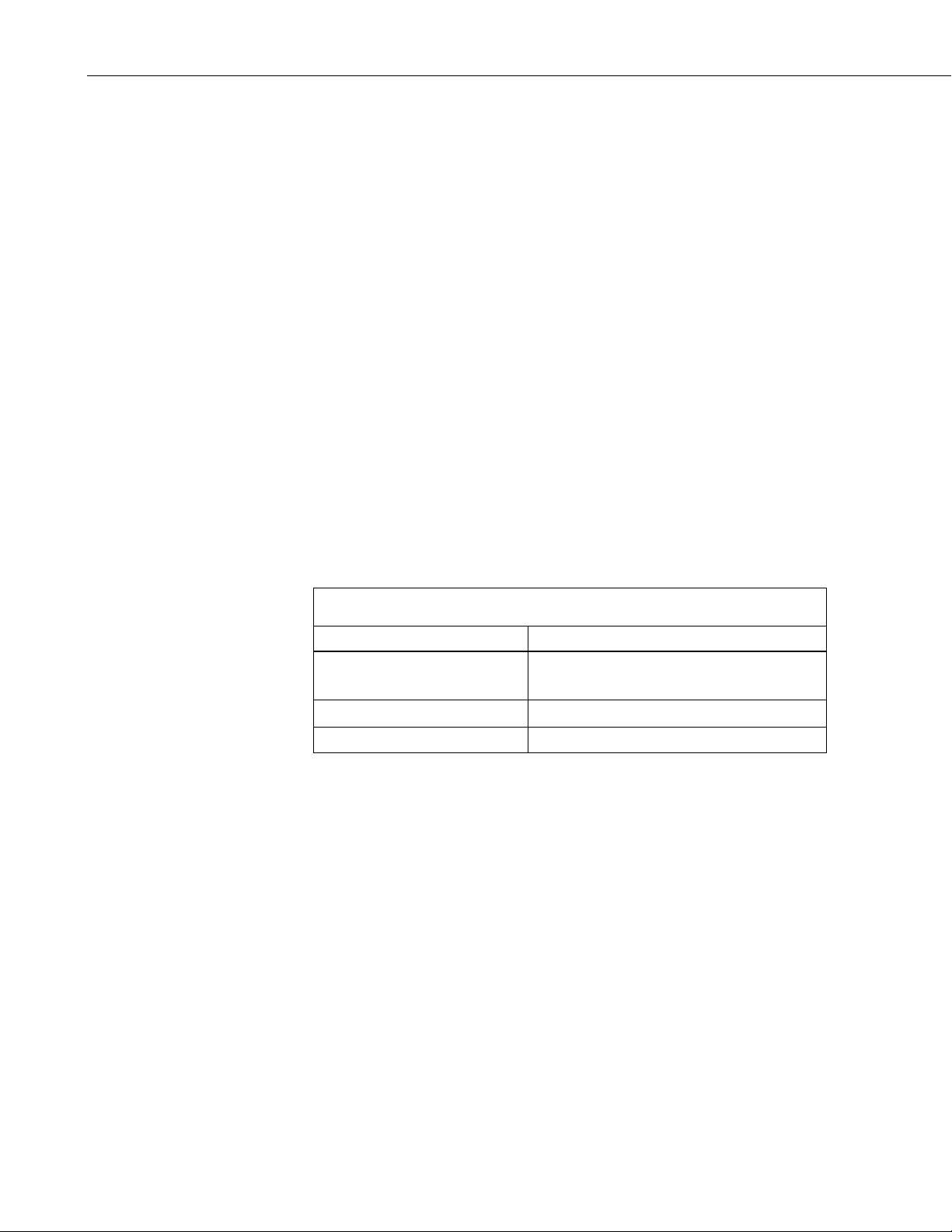

TABLE 2.5-1. Average Global Radiation Values

at the Earth Surface

Type SW in SW

SW

out

LW in LW

net

LW

out

Net

net

Units W/m2 W/m2 W/m2 W/m2 W/m2 W/m2 W/m2

Value 198 - 30 168 324* -390** -66 102

value assumes a sky temperature of 2ºC.

in

value assumes a surface temperature of 14ºC.

out

NOTE

* LW

** LW

The LW radiation values in Table 2.5-1 are corrected for sensor

temperature. The values in Table 2.5-2 are not corrected for

sensor temperature.

On a smaller timescale, the most important factors are:

• solar position

• cloud cover

The ambient air temperature is less important because cloud base temperature

tends to follow surface temperature.

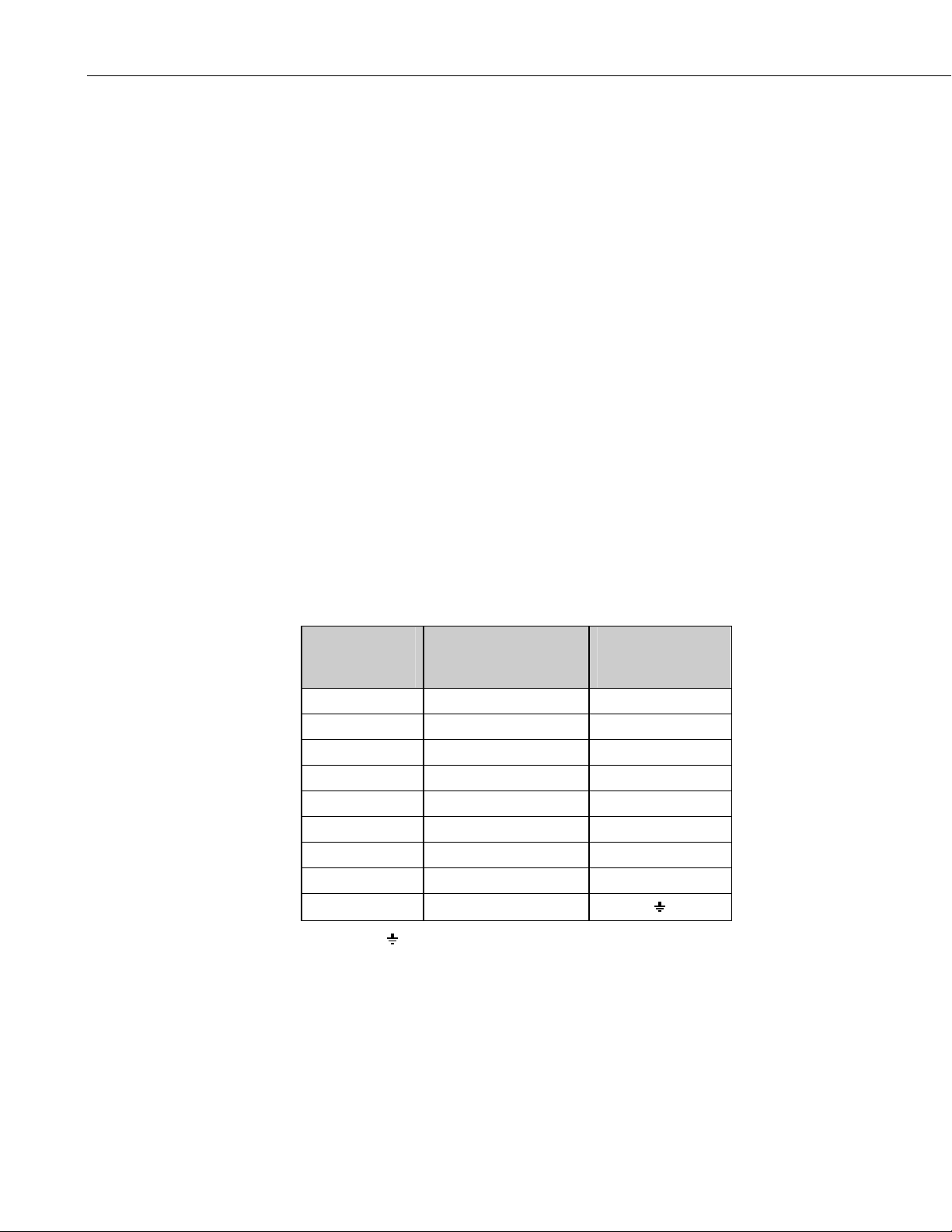

TABLE 2.5-2. Expected SENSOR Outputs when Measuring with the NR01

D / N CD / CR

Ambient

air temp.

pyrgeo

#

down

pyrgeo

up#

pyrano

down

pyrano

up

T

T

sky

ground

°C W/m2 W/m2 W/m2 W/m2 °C °C

D CD +20 0 0 0-500 0-150 20 +20

D CD -20 0 0 0-500 0-150 -20 -20

D CR +20 -70** 0 0-1500 0-400 +1 +20

D CR -20 -70** 0 0-1500 0-400 -50 -20

N CD +20 0 0 0 0 +20 +20

N CD -20 0 0 0 0 -20 -20

N CR +20 -70* 0 0*** 0 1 +20

N CR -20 -70* 0 0*** 0 50 -20

The table makes a distinction between the day and night (D/N), cloudy and

clear (CD / CR) conditions, and high and low ambient air temperatures.

The instrument temperature is normally close to air temperature.

9

Page 14

NR01 Four-Component Net Radiation Sensor

#Outputs listed for both of the pyrgeometers are not compensated for sensor

temperature. For example, to correct for sensor temperature when the sensor

temperature is 14 ºC, you should add 385 W/m

The raw reading of the upward facing pyrgeometer will generally be close to

zero when the sensor temperature is close to the ground temperature. You

should expect small negative readings when the sensor is located above cooled

surfaces (e.g. water or transpiring vegetation) or small positive readings when

the surface is emitting heat (e.g. warm soil at night).

2

to the pyrgeometer signals.

* At night, dew deposition may affect the downward facing pyrgeometer’s

output. In that case, the signal may drop to 0 W/m

error of +100 W/m

avoid dew deposition.

** During the day, the window-heating offset may affect the downward facing

pyrgeometer’s output. This can produce a maximum error of +15 W/m

***At night, the infrared offset may affect the downward facing pyranometer’s

output. The maximum error of this offset is -25 W/m

2.6 Heating

A heater is located in the connection body of the pyrgeometers to prevent dew

deposits on the sensor that may occur at night. Because of the heater’s current

drain, Campbell Scientific recommends using the heater only when necessary.

A relay can turn the heater on when the solar radiation is less than 20 W/m

See Section 4.3.1.

2.7 Data Quality Assurance

To assure quality data, look for unrealistic values when analyzing:

• Trends in SW

• SW albedo

• Correlation of SW

• SW night time signals

• Correlation of relation LW

in

2

2

. Campbell Scientific recommends activating the heater to

absolute signal,

and LWin

in

and surface temperature

out

, producing a maximum

2

.

2

.

2

.

3. Specifications of NR01

The NR01 is a four-component net-radiometer consisting of two pyranometers

of type SR01, two pyrgeometers of type IR01, a heater, and a Pt100

temperature sensor.

10

Page 15

3.1 NR01 General Specifications

TABLE 3.1-1. General Specifications of the NR01

NR01 Four-Component Net Radiation Sensor

ISO and WMO

See pyranometer and pyrgeometer specification

classification

Expected accuracy +/- 10 % for 12 hour totals, day and night

Operating temperature -40 to +80 ° C

Pyranometer Type SR01, see below

Pyrgeometer Type IR01, see below

Sensitivity All sensors have individual calibration factors

T

pyrgeometer

T

pyrgeometer

T

pyrgeometer

Pt100 DIN class A

accuracy Within +/- 1 ºC

options A user-supplied temperature sensor can be inserted

into the pyrgeometer connection body. Add gland

M12 x 1.5

Heater 90 Ohms, 1.6 Watts at 12 VDC; 16 V DC Max

2 axis leveling assembly Included, hexagon drive set screw size

2.0mm, pipe size ¾ inch NPS

Radiation shields 4 shields are included

Cable gland Accepts cable diameter from 3 to 6.5 mm

Cable extension Longer cables are available on request. Specify

additional cable length in feet (up to 50 ft can be

added)

Standard cable length /

50 ft / 5.4 mm (2 cables)

diameter

Weight including 5 m

cable

NR01 including 50ft cable: 5.0 lbs. NR01

instrument only 2.0 lbs

Dimensions 263 x 113 x 121 mm

Recommended

Every 2 years

recalibration interval

CE compliance NR01 is compliant with CE directives.

11

Page 16

NR01 Four-Component Net Radiation Sensor

3.2 SR01 Pyranometer Specifications

SR01 ISO / WMO Specifications

Overall classification

according to ISO 9060 /

WMO

TABLE 3.2-1. Specifications of SR01

Second class pyranometer

Response time for 95 %

18 s

response

Zero offset a (response to

200 W/m

2

net thermal

< 15 W/m

2

radiation)

Zero offset b (response to 5

<4 W/m

2

k/h change in ambient

temperature)

Non-stability < 1% change per year

Non-Linearity < +/- 2.5%

Directional response for

Within +/- 25 W/m

2

beam radiation:

Spectral selectivity +/- 5% (305 to 2000 nm)

Temperature response

Within 6% (-10 to +40 degrees C)

(within an interval of 50

degrees C)

Tilt response Within +/- 2%

SR01 Additional Measurement Specifications

Sensitivity 10-40 μV/Wm

-2

Expected voltage output Application with natural solar radiation: 0.1 to +

50 mV

12

Sensor resistance Between 40 and 60 Ohms (without trimming)

Power required Zero (passive sensor)

Range To 2000 Wm

-2

Spectral range 305 to 2800 nm (50% transmission points)

Required programming Φ = U / E

Expected accuracy for daily

+/- 10%

sums

Calibration

Calibration traceability To WRR, procedure according to ISO 9847

Page 17

NR01 Four-Component Net Radiation Sensor

3.3 IR01 Pyrgeometer Specifications

TABLE 3.3-1. Specifications of IR01

IR01 Specifications

Overall classification

according to ISO / WMO

Response time for 95 %

response

Window heating offset

(response to 1000 W/m

2

thermal radiation)

Zero offset b (response to 5

k/h change in ambient

temperature)

Non-Stability < 1% change per year

Non-Linearity < +/- 2.5%

Field of view 150 degrees

Spectral selectivity Not specified

Temperature response

(within an interval of 50

degrees C)

Tilt response Within +/- 2%

IR01 Additional Measurement Specifications

Sensitivity 5 – 15 μV/Wm

Expected voltage output Meteorological application: -5 to + 5 mV

Sensor resistance Between 100 and 400 Ohms

Power required Zero (passive sensor)

Range To 1000 Wm

Spectral range 4500 to 50000 nm (50% transmission points)

Required programming Φ = U / E (in case of net radiation only) Φ = (U /

Expected accuracy for daily

sums

Calibration

Calibration traceability International temperature standard

Not applicable

18 s

< 15 W/m

net

<4 W/m

Within 6% (-10 to +40 degrees C)

E) + 5.67.10

from Pt100 measurement

+/- 10%

2

2

-2

-2

-8

T4 (absolute radiation), with T

13

Page 18

NR01 Four-Component Net Radiation Sensor

3.4 Dimensions

FIGURE 3.4-1. Dimensions of the NR01 in mm:

(1) 2-Axis Leveling Assembly, (2) Mounting Arm

263 mm

027 mm (3/4 inch NPS)

4. Installation

4.1 Installation

A 1” to ¾” pipe reducer fitting (P/N 21271) is used for mounting the NR01

onto a CM204 or CM206 crossarm. The crossarm can be mounted to any pole

with a 25-mm to 54-mm outer diameter. However, for most applications,

Campbell Scientific recommends attaching the crossarm to a CM310-series

pole so that the sensor is above vegetation. You can also mount the crossarm

to the tripod or tower that supports the datalogger’s enclosure.

To attach the pipe reducer to the sensor, loosen the leveling assembly’s Allen

bolts (8 in Figure 2.2-1). Insert the pipe reducer inside of the cup in the center

of the sensor (see Figure 4.1-1) and then tighten the Allen bolts so that they

grip the pole. Slightly loosen the two bolts at the opposite end of the tube

mount (4 in Figure 2.2-1) and rotate the sensor mount tube to level the sensor

in the two axes. Once the sensor is leveled, tighten all of the Allen bolts,

restricting further movement of the sensor.

Table 4.1-1 gives other general guidelines for the positioning and installation

of the sensor.

14

Page 19

NR01 Four-Component Net Radiation Sensor

FIGURE 4.1-1. NR01 with Reducer (P/N 21271) and Mounting Arm

TABLE 4.1-1. Recommendations for Installation of the NR01

Location Location of measurement should be representative of the total

surrounding area, in particular in case the NR01 is used for

environmental net radiation measurements. If possible, mount

the sensor on a separate pole at least 25 ft away from main

logger tower or tripod.

Mechanical

mounting

A 2-axis leveling assembly is included as part of the sensor

mount which is suitable for a range of pipe diameters, max 27

mm or ¾ inch NPS.

Radiation

Avoid objects that cast shadows on the instrument.

detection

Leveling Use the bubble-level to see if the instrument is mounted

horizontally For viewing the level, the radiation screens must

be removed. Alternatively a spirit level can carefully be put on

the pyrgeometer window.

Orientation By convention with the wiring to the nearest pole (so north in

the northern hemisphere, south in the southern hemisphere)

Height of

installation

In case of inverted installation, a height of approximately 4 ft

(1.5 meters) above ground is recommended by the WMO (to

get good spatial averaging)

Tilt The NR01 should typically be installed horizontally, but for

some applications, may be installed in a tilted position. In all

cases, it will measure the fluxes that are incident on the surface

that is parallel to the sensor surface.

15

Page 20

NR01 Four-Component Net Radiation Sensor

4.2 Electrical Connections

The NR01 is a passive sensor that does not need any power. However there is

an on-board heating resistor in the pyrgeometer connection body that may be

switched on to prevent dew deposition.

Cables generally act as a source of signal distortion by picking up capacitively

coupled noise. Campbell Scientific generally recommends keeping the distance

between the datalogger and sensor as short as possible. For cable extension,

see Appendix A. Table 4-2 provides the electrical connections of the NR01.

Cable 1 (Solar)

Color

Red Pyranometer Up Sig + 2

Blue Pyranometer Up Ref - 1

White Pyranometer Down Sig + 8

Green Pyranometer Down Ref - 7

Brown Pyrgeometer Up Sig + 4

Yellow Pyrgeometer Up Ref - 3

Purple Pyrgeometer Down Sig + 6

Grey Pyrgeometer Down Ref - 5

Clear Shield Ground 11, 12

Cable 2 (Temperature/Heater)

Color

Red Current Excite + 2

Blue Current Return - 4

White PT100 Signal + 3

Green PT100 Signal Ref - 5

Brown Heater Power SW12V + 1

Yellow Heater Ground - 6

Purple Ground GND 7

Grey Shield GND 8

Clear Shield Ground 9, 10

Wire Label

Wire Label

Polarity

Polarity

PCB04

Connection

PCB05

Connection

16

NOTES:

(1) + connections of radiometers give + signal when radiation comes in.

(2) Pt100 red and white end at same side of the sensor (both +)

(3) Pt100 and heater polarity are not critical.

Page 21

NR01 Four-Component Net Radiation Sensor

TABLE 4.2-1. Internal Electrical Diagram of the NR01

(for servicing purposes only)

PCB04

Connection

3

4

5

6

13

14

9

10

Table 4-2 shows the NR01 wiring connections for the four radiation outputs,

Pt-100 temperature sensor, and the heater. Table 4.2-1 shows the internal

connections to the terminal blocks, which should only be required for

servicing, e.g. cable replacement.

PCB04

Terminal

Pyranometer

UP

Pyranometer

UP

Pyranometer

DOWN

Pyranometer

DOWN

PCB05

Connection

8

7

12

11

PCB05

Terminal

Pyrgeometer

UP

Pyrgeometer

UP

Pyrgeometer

DOWN

Pyrgeometer

DOWN

Polarity

-

+

-

+

+

-

+

-

WARNING

The sensor has two cables with similar color schemes.

It is important to make sure you identify cable 1 and

cable 2 correctly, especially before connecting any

source of power such as to the heater. Failure to do

so may damage the sensor.

4.3 Connecting the Sensor to Campbell Scientific Dataloggers

This section shows the typical connection schemes.

The four radiation outputs can be measured using Differential (Table 4.3-1) or

Single-Ended inputs on the datalogger (Table 4.3-2). A differential voltage

measurement (VoltDiff or Instruction 2) is recommended because it has better

noise rejection than a single-ended measurement. When differential inputs are

used, jumper the low side of the input to AG or

the common mode range.

to keep the signal within

17

Page 22

NR01 Four-Component Net Radiation Sensor

TABLE 4.3-1. Datalogger Connections for Differential Measurement, when using a 4WPB100

Wire Label Color (cable 1) CR10X CR1000, CR23X, CR7

Pyranometer Up Sig Red Differential Input (H) Differential Input (H)

Pyranometer Up Ref *Blue Differential Input (L) Differential Input (L)

Pyranometer Down Sig White Differential Input (H) Differential Input (H)

Pyranometer Down Ref *Green Differential Input (L) Differential Input (L)

Pyrgeometer Up Sig Brown Differential Input (H) Differential Input (H)

Pyrgeometer Up Ref *Yellow Differential Input (L) Differential Input (L)

Pyrgeometer Down Sig Purple Differential Input (H) Differential Input (H)

Pyrgeometer Down Ref *Grey Differential Input (L) Differential Input (L)

Shield Shield G

*Jumper to AG or with user supplied wire.

TABLE 4.3-2. Datalogger Connections for Single-Ended Measurement, when using a 4WPB100

Wire Label Color (Cable 1) CR10X CR1000, CR23X, CR7

Pyranometer Up Sig Red Single-Ended Input Single-Ended Input

Pyranometer Up Ref Blue AG

Pyranometer Down Sig White Single-Ended Input Single-Ended Input

Pyranometer Down Ref Green AG

Pyrgeometer Up Sig Brown Single-Ended Input Single-Ended Input

Pyrgeometer Up Ref Yellow AG

Pyrgeometer Down Sig Purple Single-Ended Input Single-Ended Input

Pyrgeometer Down Ref Grey AG

Shield Shield G

All dataloggers apart from the CR3000 and CR5000 require the 4WPB100

module to interface the PT-100 to the datalogger. Table 4.3-3 shows the

wiring connections for the 4WPB100 (note this is using cable 2).

TABLE 4.3-3. Pt-100 Temperature Sensor Connections to 4WPB100 and Datalogger

Wire Label Color (Cable 2) 4WPB100 Datalogger

Black Wire Voltage Excitation (VX)

H Differential Input (H)

Current Excite Red L Differential Input (L)

Current Return Blue G (AG CR10X)

PT100 Signal White Differential Input (H)

PT100 Signal Ref Green Differential Input (L)

18

Page 23

NR01 Four-Component Net Radiation Sensor

The PT-100 sensor can connect directly to the CR3000 and CR5000

dataloggers because they have current excitation outputs. Refer to Table 4.3-4

and Program Example 5.2.2 for information on using the current excitation

technique with a CR3000 or CR5000 datalogger.

TABLE 4.3-4. CR3000 and CR5000 Connections

for Differential Measurement and using the Current Excitation to

Measure the PT100 Sensor

Wire Label Color CR3000/CR5000

Pyranometer Up Sig

Pyranometer Up Ref

Pyranometer Down Sig

Pyranometer Down Ref

Pyrgeometer Up Sig

Pyrgeometer Up Ref

Pyrgeometer Down Sig

Pyrgeometer Down Ref

PT100 Signal

PT100 Signal Ref

Red

*Blue

White

*Green

Brown

*Yellow

Purple

*Grey

**White

**Green

Differential Input (H)

Differential Input (L)

Differential Input (H)

Differential Input (L)

Differential Input (H)

Differential Input (L)

Differential Input (H)

Differential Input (L)

Differential Input (H)

Differential Input (L)

Current Excite **Red Current Excitation IX

Current Return - **Blue Current Excitation IXR

Shield (both cables) Clear

*Jumper to AG or with user-supplied wire.

**Note these are in Cable 2.

4.3.1 Connecting and Using the Heater

Only use the sensor heater when there is risk of dew forming on the sensors,

especially for low power installations. Furthermore, the heater should be

turned on and off infrequently as it may take some time for the sensor to come

to thermal equilibrium. No damage will result if the heater is powered

permanently, but as with all thermopile sensors, it is best if the sensor operates

at ambient temperatures and is not subject to rapidly changes of temperature.

The sensor power can be controlled using one of the 12V power switches built

into Campbell dataloggers or using an external solid-state switch such as a

PSW12/SW12. The heater current drain is approximately 140 mA from a 12 V

battery. Connect the ground return from the heater, either directly to the

battery, or to a G terminal close the power input to the logger (i.e., not to an

analog ground near the measurement inputs).

The heater power can be controlled by adding instructions to the datalogger

program, that turns on the heater only when the light level falls below 20 W m

2

or, if a measurement of air humidity is available, when the dew point of the

air falls to within 1ºC of the sensor body temperature. Appendix A provides an

example CR3000/CR5000 program that controls the NR01 heater.

-

19

Page 24

NR01 Four-Component Net Radiation Sensor

4.4 Installation of the Radiation Shields

Radiation shields can be installed and removed using a hex-head wrench (bolt

size 2.0 mm). See the drawing below. Radiation shields are beneficial for

instrument measurement accuracy and instrument and cable lifetime. They also

serve as rain- and snow shield. However, the instrument should function within

specifications without the radiation shield.

FIGURE 4.4-1. Installation and Removal of Radiation Shields:

(1) Hex-Head Wrench, (2) Radiation Screen

(3) Hexagon Drive Set Screw

4.5 Instrument-Inversion-Test

Campbell Scientific recommends performing the instrument-inversion test after

installation. This test consists of inverting the instrument position (180 degrees

turn) and looking at the output signals. The instrument output should have the

same magnitude but a reversed sign (so + to – and – to +). For best results,

perform this test on a clear day—preferably around noon (with the sun high in

the sky).

Roughly speaking, deviations within ±10% can be tolerated. For optimal

testing of pyrgeometers, the test should be repeated on a clear night.

5. Datalogger Programming

The NR01 outputs four voltages that typically range from 0 to 50 mV for the

SR01 sensors, and ±5 mV for the IR01 sensors. A differential voltage

measurement (VoltDiff in CRBasic or Instruction 2 in Edlog) is recommended

because it has better noise rejection than a single-ended measurement. If

differential channels are not available, a single-ended measurement (VoltSE or

Instruction 1) can be used. The acceptability of a single-ended measurement

can be determined by simply comparing the results of single-ended and

differential measurements made under the same conditions.

20

Page 25

NR01 Four-Component Net Radiation Sensor

For the CR3000 and CR5000 dataloggers, one differential channel and a

current excitation channel are used to measure the PT-100.

For the other dataloggers, two differential channels and the 4WPB100 module

are required to measure the Pt-100 temperature sensor.

NOTE

If free channels are limited it is possible to measure the PT100

sensor using a 3WHB10K terminal input module, with only a

slight loss of accuracy. This only requires one differential

channel. Please refer to the documentation for that module for

further details.

5.1 Calibration Factors

Each NR01 is provided with a ‘Certificate of Calibration’ by the manufacturer.

This certificate shows the sensor serial number and ‘sensitivity’ of each of the

four component sensors. Unlike some other models of sensor, the individual

components are not modified in an attempt to have a common calibration.

Therefore, individual calibration factors must be applied in the datalogger

program to convert the voltages to energy fluxes in W m

The calibration factor is in units of uV/(W m

units of (W m

To convert the units, divide the calibration factor into 1000. For example, if

the calibration factor is 7.30 uV/(W m

-2

)/mV.

(W m

FIGURE 5-1. 4WPB100 Module

-2

-2

-2

)/mV for the multiplier parameter in the datalogger program.

-2

), which needs to be converted to

), the multiplier is 1000/7.3 = 136.99

21

Page 26

NR01 Four-Component Net Radiation Sensor

5.2 Example Programs

5.2.1 Example 1, CR1000 Using Differential Channels

Program Example 1 requires six differential channels and the 4WPB100

module to measure the four radiation outputs and the Pt-100 temperature

sensor, connected on differential channels 1..6. The program measures the

sensors every two seconds, then calculates and stores the following data to

final storage every 60 minutes:

Year

Julian Day

Hour/Minute

Avg SR01 Up (short wave radiation)

Avg SR01 Down (short wave radiation)

Avg IR01 Up (long wave radiation)

Avg IR01 Down (long wave radiation)

Avg NR01 temperature (degrees C)

Avg NR01 temperature (degrees K)

Avg Net shortwave radiation

Avg Net long wave radiation

Avg Albedo

Avg Total Net radiation

Avg temperature corrected IR01 Up

Avg temperature corrected IR01 Down

Wiring for Program Example 1

Color

Red SR01 Up Signal 1H

*Blue SR01 Up Reference 1L

White SR01 Down Signal 2H

*Green SR01 Down Reference 2L

Brown IR01 Up Signal 3H

*Yellow IR01 Up Reference 3L

Purple IR01 Down Signal 4H

*Grey IR01 Down Reference 4L

Shield Shield

*Jumper to with user supplied wire.

Function

Example CR1000

Program

Channels Used

22

Page 27

NR01 Four-Component Net Radiation Sensor

Pt-100 Temperature Sensor Connections to 4WPB100 and Datalogger

Color Function 4WPB100 CR1000

Black Wire EX1

H 5H

Red Pt-100 Excitation + L 5L

Blue Pt-100 Excitation - G

White Pt-100 Signal + 6H

Green Pt-100 Signal - 6L

'CR1000

'Declare Variables and Units

Public Batt_Volt

Public SR01Up

Public SR01Dn

Public IR01Up

Public IR01Dn

Public NR01TC

Public NR01TK

Public NetRs

Public NetRl

Public Albedo

Public UpTot

Public DnTot

Public NetTot

Public IR01UpCo

Public IR01DnCo

Units Batt_Volt=Volts

Units SR01Up=W/m2

Units SR01Dn=W/m2

Units IR01Up=W/m2

Units IR01Dn=W/m2

Units NR01TC=Deg C

Units NR01TK=K

Units NetRs=W/m2

Units NetRl=W/m2

Units Albedo=W/m2

Units UpTot=W/m2

Units DnTot=W/m2

Units NetTot=W/m2

Units IR01UpCo=W/m2

Units IR01DnCo=W/m2

‘Typical data on the calibration sheet might be

‘ Sensitivity uV/W/m^2

‘Pyranometer UP SR01 15.35

‘Pyranometer DOWN SR01 13.30

‘Pyrgeometer UP IR01 8.5

‘Pyrgeometer DOWN IR01 8.2

23

Page 28

NR01 Four-Component Net Radiation Sensor

‘So load the four calibration coefficients specific to this sensor (1000/Sensitivity)

Const SR01Upcal = 65.146

Const SR01Downcal = 75.18

Const IR01Upcal = 117.65

Const IR01Downcal = 121.95

'Define Data Tables

DataTable(Table1,True,-1)

DataInterval(0,60,Min,10)

Average(1,SR01Up,FP2,False)

Average(1,SR01Dn,FP2,False)

Average(1,IR01Up,FP2,False)

Average(1,IR01Dn,FP2,False)

Average(1,NR01TC,FP2,False)

Average(1,NR01TK,FP2,False)

Average(1,NetRs,FP2,False)

Average(1,NetRl,FP2,False)

Average(1,Albedo,FP2,False)

Average(1,UpTot,FP2,False)

Average(1,DnTot,FP2,False)

Average(1,NetTot,FP2,False)

Average(1,IR01UpCo,FP2,False)

Average(1,IR01DnCo,FP2,False)

EndTable

'Main Program

BeginProg

Scan(2,Sec,1,0)

'Default Datalogger Battery Voltage measurement Batt_Volt:

Battery(Batt_Volt)

'NR01 Net Radiometer measurements SR01Up, SR01Dn, IR01Up, IR01Dn, NR01TC, NR01TK,

'NetRs, NetRl, Albedo, UpTot, DnTot, NetTot, IR01UpCo, and IR01DnCo

‘For the CR1000, use autorange for the SR01 measurements due to the wide dynamic range

* VoltDiff(SR01Up,1,autorange,1,True,0,_50Hz,SR01UpCal,0)

* VoltDiff(SR01Dn,1,autorange,2,True,0,_50Hz,SR01DownCal,0)

* VoltDiff(IR01Up,1,mV7_5,3,True,0,_50Hz,IR01Upcal,0)

* VoltDiff(IR01Dn,1,mV7_5,4,True,0,_50Hz,IR01DownCal,0)

** BrHalf4W (NR01TC,1,mV25,mV25,5,Vx1,1,2100,True ,True ,0,250,1.0,0)

PRT(NR01TC,1,NR01TC,1,0)

NR01TK=NR01TC+273.15

NetRs=SR01Up-SR01Dn

NetRl=IR01Up-IR01Dn

Albedo=SR01Dn/SR01Up

UpTot=SR01Up+IR01Up

DnTot=SR01Dn+IR01Dn

NetTot=UpTot-DnTot

IR01UpCo=IR01Up+5.67*10^-8*NR01TK^4

IR01DnCo=IR01Dn+5.67*10^-8*NR01TK^4

'Call Data Tables and Store Data

CallTable(Table1)

NextScan

EndProg

24

Note: Proper entries will vary with program and input channel usage. For other loggers use:

* mV50 range for the CR3000/5000

** mV50 range (both) with 4200 mV excitation for CR3000/5000

Page 29

NR01 Four-Component Net Radiation Sensor

5.2.2 Example 2, CR3000/CR5000 Using Differential Channels (no 4WPB100)

Program Example 2 requires five differential channels and one current

excitation channel to measure the four radiation outputs and the Pt-100

temperature sensor. Connection details are given in the header of the program

below. The program measures the sensors every second and calculates and

stores the following data to final storage every 60 minutes:

Year

Julian Day

Hour/Minute

Avg SR01 Up (shortwave radiation)

Avg SR01 Down (shortwave radiation)

Avg IR01 Up (longwave radiation)

Avg IR01 Down (longwave radiation)

Avg NR01 temperature (degrees C)

Avg NR01 temperature (degrees K)

Avg Net shortwave radiation

Avg Net longwave radiation

Avg Albedo

Avg Total Net radiation

Avg temperature corrected IR01 Up

Avg temperature corrected IR01 Down

'CR3000 or CR5000 Series Datalogger

'ANALOG INPUT

'1H SR01 UP - downwelling shortwave radiation signal (red)

'1L SR01 UP - downwelling shortwave radiation signal reference (blue)

'gnd NR01 shield (clear)

'2H SR01 DOWN - upwelling shortwave radiation signal (white)

'2L SR01 DOWN - upwelling shortwave radiation signal reference (green)

'3H IR01 UP - downwelling longwave radiation signal (brown)

'3L IR01 UP - downwelling longwave radiation signal reference (yellow)

'4H IR01 DOWN - upwelling longwave radiation signal (purple)

'4L IR01 DOWN - upwelling longwave radiation signal reference (grey)

'6H NR01 Pt100 (white)

'6L NR01 Pt100 (green)

'Current Excitation

'IX1 NR01 Pt100 (red)

'IXR NR01 Pt100 (blue)

'Declare Variables and Units

Public Batt_Volt

Public SR01Up

Public SR01Dn

Public IR01Up

Public IR01Dn

Public NR01TC

Public NR01TK

25

Page 30

NR01 Four-Component Net Radiation Sensor

Public NetRs

Public NetRl

Public Albedo

Public UpTot

Public DnTot

Public NetTot

Public IR01UpCo

Public IR01DnCo

Units Batt_Volt = Volts

Units SR01Up = W/m2

Units SR01Dn = W/m2

Units IR01Up = W/m2

Units IR01Dn = W/m2

Units NR01TC = Deg C

Units NR01TK = K

Units NetRs = W/m2

Units NetRl = W/m2

Units Albedo = W/m2

Units UpTot = W/m2

Units DnTot = W/m2

Units NetTot = W/m2

Units IR01UpCo = W/m2

Units IR01DnCo = W/m2

'Load the four calibration coefficients specific to this sensor (see example 1)

Const SR01Upcal = 65.146

Const SR01Downcal = 75.18

Const IR01Upcal = 117.65

Const IR01Downcal = 121.95

'Define Data Tables

DataTable(Table1,True,-1)

DataInterval(0,60,Min,10)

Average(1,SR01Up,FP2,False)

Average(1,SR01Dn,FP2,False)

Average(1,IR01Up,FP2,False)

Average(1,IR01Dn,FP2,False)

Average(1,NR01TC,FP2,False)

Average(1,NR01TK,FP2,False)

Average(1,NetRs,FP2,False)

Average(1,NetRl,FP2,False)

Average(1,Albedo,FP2,False)

Average(1,UpTot,FP2,False)

Average(1,DnTot,FP2,False)

Average(1,NetTot,FP2,False)

Average(1,IR01UpCo,FP2,False)

Average(1,IR01DnCo,FP2,False)

EndTable

'Main Program

BeginProg

Scan(1,Sec,1,0)

'Default Datalogger Battery Voltage measurement Batt_Volt:

Battery(Batt_Volt)

26

Page 31

NR01 Four-Component Net Radiation Sensor

'NR01 Net Radiometer measurements SR01Up, SR01Dn, IR01Up, IR01Dn, NR01TC, NR01TK,

'NetRs, NetRl, Albedo, UpTot, DnTot, NetTot, IR01UpCo, and IR01DnCo

'Uses fixed ranges as they fall more in line with the range of sensor outputs, so no need to

'autorange

VoltDiff(SR01Up,1,mV50,1,True,200,250,SR01Upcal,0)

VoltDiff(SR01Dn,1,mV50,2,True,200,250,SR01DownCal,0)

VoltDiff(IR01Up,1,mV20,3,True,200,250,IR01Upcal,0)

VoltDiff(IR01Dn,1,mV20,4,True,200,250,IR01DownCal,0)

'Note maximum sensor temperature with this excitation setting is just over +50 C.

Resistance (NR01TK,1,mV200,6,Ix1,1,1675,True ,True,200,250,1.0,0)

'Formulate the ratio Rs/R0

NR01TK=NR01TK/100

PRT(NR01TK,1,NR01TK,1,273.15)

'Compute Net short-wave radiation, Net long-wave radiation, Albedo and Net Radiation

NR01TC=NR01TK-273.15

NetRs=SR01Up-SR01Dn

NetRl=IR01Up-IR01Dn

Albedo=SR01Dn/SR01Up

UpTot=SR01Up+IR01Up

DnTot=SR01Dn+IR01Dn

NetTot=UpTot-DnTot

IR01UpCo=IR01Up+5.67*10^-8*NR01TK^4

IR01DnCo=IR01Dn+5.67*10^-8*NR01TK^4

'Call Data Tables and Store Data

CallTable(Table1)

NextScan

EndProg

NOTE

Proper entries for the input channels will vary with program and

input channel usage.

5.2.3 Example 3, CR23X Program Using Differential Channels

Program Example 3 requires six differential channels and the 4WPB100

module to measure the four radiation outputs and the Pt-100 temperature

sensor. Wiring is shown in Tables 4.3-1 and 4.3-3 above, using differential

channels 1..5. The program measures the sensors every 2 seconds, then

calculates and stores the following data to final storage every 60 minutes:

Array ID

Year

Julian Day

Hour/Minute

Avg SR01 Up (shortwave radiation)

Avg SR01 Down (shortwave radiation)

Avg IR01 Up (longwave radiation)

Avg IR01 Down (longwave radiation)

Avg NR01 temperature (degrees C)

Avg NR01 temperature (degrees K)

Avg Net shortwave radiation

Avg Net longwave radiation

27

Page 32

NR01 Four-Component Net Radiation Sensor

Avg Albedo

Avg Total Net radiation

Avg temperature corrected IR01 Up

Avg temperature corrected IR01 Down

;{CR23X}

;Program Example 3 for CR23X datalogger

;

;*Table 1 Program

01: 2 Execution Interval (seconds)

;Measure all four sensor elements with one instruction, use auto-ranging for best resolution

1: Volt (Diff) (P2)

1: 4 Reps

2: 30 Auto, 50 Hz Reject, Slow Range (OS>1.06)

3: 1* DIFF Channel

4: 1 Loc [ SR01_up ]

5: 1.0 Multiplier

6: 0.0 Offset

;Apply the individual calibration factors to each component

;with one scaling instruction

;Typical data on the data sheet might be

;Sensor Sensitivity uV/W/m^2

;Pyranometer UP SR01 15.35

;Pyranometer DOWN SR01 13.30

;Pyrgeometer UP IR01 8.5

;Pyrgeometer DOWN IR01 8.2

; Multipliers calculated at 1000/sensitivity

2: Scaling Array (A*Loc+B) (P53)

1: 1 Start Loc [ SR01_up ]

2: 65.146 A1 ;SR01 up

3: 0 B1

4: 75.18 A2 ;SR01 down

5: 0.0 B2

6: 117.65 A3 ;IR01 up

7: 0.0 B3

8: 121.95 A4 ;IR01 down

9: 0.0 B4

;Measure NR01 temperature

3: Full Bridge w/mv Excit (P9)

1: 1 Reps

2: 32** 50 mV, 50 Hz Reject, Slow, Ex Range

3: 32** 50 mV, 50 Hz Reject, Slow, Br Range

4: 5* DIFF Channel

5: 1 Excite all reps w/Exchan 1

6: 4200*** mV Excitation

7: 5* Loc [ Temp_C ]

8: 1 Mult

9: 0 Offset

28

Page 33

NR01 Four-Component Net Radiation Sensor

4: Temperature RTD (P16)

1: 1 Reps

2: 5 R/R0 Loc [ Temp_C ]

3: 5 Loc [ Temp_C ]

4: 1.0 Mult

5: 0 Offset

5: Z=X+F (P34)

1: 5 X Loc [ Temp_C ]

2: 273.18 F

3: 6 Z Loc [ Temp_K ]

;Net SR01 shortwave radiation = SR01 Up - SR01 Down

6: Z=X-Y (P35)

1: 1 X Loc [ SR01_up ]

2: 2 Y Loc [ SR01_dn ]

3: 7 Z Loc [ Net_Rs ]

;Net IR01 longwave radiation = IR01 Up - IR01 Down

7: Z=X-Y (P35)

1: 3 X Loc [ IR01_up ]

2: 4 Y Loc [ IR01_dn ]

3: 8 Z Loc [ Net_Rl ]

;Albedo = SR01 Down / SR01 Up

8: Z=X/Y (P38)

1: 2 X Loc [ SR01_dn ]

2: 1 Y Loc [ SR01_up ]

3: 9 Z Loc [ Albedo ]

;Net total radiation = (SR01 Up + IR01 Up) - (SR01 Down + IR01 Down)

9: Z=X+Y (P33)

1: 1 X Loc [ SR01_up ]

2: 3 Y Loc [ IR01_up ]

3: 23 Z Loc [ Up_total ]

10: Z=X+Y (P33)

1: 2 X Loc [ SR01_dn ]

2: 4 Y Loc [ IR01_dn ]

3: 24 Z Loc [ Dn_total ]

11: Z=X-Y (P35)

1: 23 X Loc [ Up_total ]

2: 24 Y Loc [ Dn_total ]

3: 10 Z Loc [ Net_total ]

;Correct IR01 Up and IR01 Down for temperature

29

Page 34

NR01 Four-Component Net Radiation Sensor

; IR01_upCor = IR01_up+5.67 10-8 Temp_K4

; IR01_dnCor = IR01_dn+5.67 10-8 Temp_K4

12: Z=F (P30)

1: 5.67 F

2: -8 Exponent of 10

3: 25 Z Loc [ scratch_1 ]

13: Z=F (P30)

1: 4 F

2: 0 Exponent of 10

3: 26 Z Loc [ scratch_2 ]

14: Z=X^Y (P47)

1: 6 X Loc [ Temp_K ]

2: 26 Y Loc [ scratch_2 ]

3: 27 Z Loc [ scratch_3 ]

15: Z=X*Y (P36)

1: 25 X Loc [ scratch_1 ]

2: 27 Y Loc [ scratch_3 ]

3: 28 Z Loc [ scratch_4 ]

16: Z=X+Y (P33)

1: 3 X Loc [ IR01_up ]

2: 28 Y Loc [ scratch_4 ]

3: 11 Z Loc [ IR01_upCor ]

17: Z=X+Y (P33)

1: 4 X Loc [ IR01_dn ]

2: 28 Y Loc [ scratch_4 ]

3: 12 Z Loc [ IR01_dnCor ]

;

;Output data to final storage every 60 minutes

18: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

19: Real Time (P77)

1: 0220 Day,Hour/Minute (midnight = 2400)

20: Average (P71)

1: 12 Reps

2: 1 Loc [ SR01_dn ]

30

Note: Proper entries will vary with program and *input channel usage. For other loggers use:

** 25 mV range for CR10X, 50 mV for 21X and CR7

*** 4200 mV for 21X and CR7, 2100 mV for CR10X

Page 35

NR01 Four-Component Net Radiation Sensor

5.2.4 Example 4, CR23X Program Using Single-Ended Channels

Program Example 4 requires four single-ended channels to measure the four

radiation outputs, and four single-ended channels and one differential channel

for the 4WPB100 module to measure the Pt-100 temperature sensor. Wiring is

as in Table 4.3-2, using SE channels 1..4 and 4.5 above using differential

channel 3 and 4 for the PT100 sensor. The program measures the sensors every

2 seconds, then stores the following data to final storage every 60 minutes:

Array ID

Year

Day

Hour/Minute

Avg SR01 down (shortwave radiation)

Avg SR01 up (shortwave radiation)

Avg IR01 down (longwave radiation)

Avg IR01 up (longwave radiation)

Avg NR01 temperature (degrees C)

Avg NR01 temperature (degrees K)

;{CR23X}

;Example for SE measurements of the NR01 using a CR23X

;

*Table 1 Program

01: 2 Execution Interval (seconds)

;Measure all four sensor elements with one instruction, use auto-ranging for best resolution

1: Volt (SE) (P1)

1: 4 Reps

2: 30 Auto, 50 Hz Reject, Slow Range (OS>1.06)

3: 1* SE Channel

4: 1 Loc [ SR01_up ]

5: 1.0 Multiplier

6: 0.0 Offset

;Apply the individual calibration factors to each component

;with one instruction

;Typical data on the data sheet might be

;Sensor Sensitivity uV/W/m^2

;Pyranometer UP SR01 15.35

;Pyranometer DOWN SR01 13.30

;Pyrgeometer UP IR01 8.5

;Pyrgeometer DOWN IR01 8.2

; Multipliers calculated at 1000/sensitivity

31

Page 36

NR01 Four-Component Net Radiation Sensor

2: Scaling Array (A*Loc+B) (P53)

1: 1 Start Loc [ SR01_up ]

2: 65.146 A1 ;SR01 up

3: 0 B1

4: 75.18 A2 ;SR01 down

5: 0.0 B2

6: 117.65 A3 ;IR01 up

7: 0.0 B3

8: 121.95 A4 ;IR01 down

9: 0.0 B4

;Measure the IR01 temperature

3: Full Bridge w/mv Excit (P9)

1: 1 Reps

2: 32 50 mV, 50 Hz Reject, Slow, Ex Range**

3: 32 50 mV, 50 Hz Reject, Slow, Br Range**

4: 3* DIFF Channel

5: 1 Excite all reps w/Exchan 1

6: 4200 mV Excitation***

7: 5 Loc [ IR01_TC ]

8: 1 Multiplier

9: 0.0 Offset

4: Temperature RTD (P16)

1: 1 Reps

2: 5 R/R0 Loc [ IR01_TC ]

3: 5 Loc [ IR01_TC ]

4: 1.0 Multiplier

5: 0.0 Offset

;Also create a temperature in K for use in optional online

;calculation of fluxes

5: Z=X+F (P34)

1: 5 X Loc [ IR01_TC ]

2: 273.15 F

3: 6 Z Loc [ IR01_TK ]

;In this example just output the scaled flux measurements

6: If time is (P92)

1: 0 Minutes (Seconds --) into a

2: 60 Interval (same units as above)

3: 10 Set Output Flag High (Flag 0)

7: Real Time (P77)

1: 0220 Day,Hour/Minute (midnight = 2400)

8: Average (P71)

1: 6 Reps

2: 1 Loc [ SR01_up ]

32

Note: Proper entries will vary with program and *input channel usage. For other loggers use:

** 25 mV range for CR10X, 50 mV for 21X and CR7

*** 4200 mV for 21X and CR7, 2100 mV for CR10X

Page 37

NR01 Four-Component Net Radiation Sensor

6. Maintenance and Troubleshooting

6.1 Maintenance

Once installed the NR01 is essentially maintenance free apart from cleaning

dirt off the domes every few weeks. Usually errors in functionality will appear

as unreasonably large or small measured values.

As a general rule, this means that a critical review of the measured data is the

best form of maintenance.

At regular intervals the quality of the cables can be checked.

On a 2 yearly interval the calibration can be checked in an indoor facility.

TABLE 6.1-1. The NR01 Recommendations for Maintenance

Critical review of data

Cleaning of dome using water or alcohol

Inspection of dome interior; no condensation

Inspection of cables for open connections

For the NR01: sensor inversion test as in 4.5.

Recalibration: suggested every 2 years, typically by intercomparison with

a higher standard in the field.

33

Page 38

NR01 Four-Component Net Radiation Sensor

6.2 Troubleshooting

This table contains information used to diagnosis problems whenever the

sensor does not function properly.

TABLE 6.2-1. Troubleshooting for the NR01

The sensor does

not give any

signal

The sensor signal

is unrealistically

high or low.

The sensor signal

shows

unexpected

variations

Typically an error is due to either a short circuit or an

open connection. Both can be detected by impedance /

resistance measurements at the cable end.

In case of open circuits: open the instrument and check

the internal connections (see wiring diagram of Table 4.2-

1.)

Check if the right calibration factors are entered into the

algorithm. Please note that each sensor has its own

individual calibration factor.

Check if the voltage reading is divided by the calibration

factor by review of the algorithm.

Check the condition of the leads at the logger.

Check the cabling condition looking for cable breaks.

Check the data acquisition by applying an mV source to it

in the 1 mV range.

Perform a sensor-inversion test as written down in 4.5.

Open the instrument and check the internal connections

(see wiring diagram of Table 4.2-1).

Check the presence of strong sources of electromagnetic

radiation (radar, radio etc.)

Check the condition of the shielding.

Check the condition of the sensor cable.

Open the instrument and check the internal connections

(see wiring diagram of Table 4.2-1).

34

Page 39

Appendix A. CR3000 Program that Controls the Heater

This program applies power to the NR01 heater using the SW12V relay

controller and the pulse width modulation instruction (PWM ()).

Rather than using 0 degrees C as a set point for the heater, the program below

uses the dew point value. The datalogger calculates dew point using the

relative humidity (RH) measurements provided by the HMP45C

Temperature/Relative Humidity probe. Enter 0 degrees C as the set point for

the heater when a temperature/RH probe is not used.

The algorithm turns the heater on/off at 4 Hz. The duty cycle of the pulse is

changed depending on how close the radiometer body temperature is to the

dew point temperature. At or below the dew point, the duty cycle is 100%. It

drops off linearly to 20% until the body temperature is 5 degrees C above the

dew point. For body temperatures greater than 5 degrees C above the dew

point, the duty cycle continue to drop linearly, but with a different slope, until

0% at 33 degrees C above the dew point. If necessary, the user can change the

two duty-cycle slope transitions.

'CR3000 Series Datalogger

'*** Wiring ***

'ANALOG INPUT

'5H HMP45C temperature signal (yellow)

'5L HMP45C signal reference (white)

'gnd HMP45C shield (clear)

'6H HMP45C relative humidity signal (blue)

'6L short jumper wire to 5L

'10H NR01 Pt100 signal (white)

'10L NR01 Pt100 signal reference (green)

'gnd NR 01 Pt100 shield (silver)

'11H NR01 downwelling shortwave radiation signal (red)

'11L NR01 downwelling shortwave radiation signal reference (blue)

'gnd NR01 shield (silver)

'12H NR01 upwelling shortwave radiation signal (white)

'12L NR01 upwelling shortwave radiation signal reference (green)

'13H NR01 downwelling longwave radiation signal (brown)

'13L NR01 downwelling longwave radiation signal reference (yellow)

'14H NR01 upwelling longwave radiation signal (purple or pink)

'14L NR01 upwelling longwave radiation signal reference (gray)

A-1

Page 40

Appendix A. CR3000 Program that Controls the Heater

'CURRENT EXCITATION

'IX1 NR01 Pt100 current excitation (red)

'IXR NR01 Pt100 current excitation reference (blue)

'CONTROL PORTS

'C1 SW12V control (green)

'G SW12V control/power reference (black)

'POWER OUT

'12V HMP45C power (red)

' SW12V power (red)

'G HMP45C power reference (black)

'POWER IN

'12V datalogger (red)

'G datalogger (black)

'EXTERNAL POWER SUPPLY

'POS datalogger (red)

'NEG datalogger (black)

'SW12V Power Control Module

'SW12V NR 01 heater excitation (brown)

'G NR 01 heater excitation reference (yellow)

PipeLineMode

'*** Constants ***

Const NR01_SHORT_DW_CAL = 1000/13.41 'Unique NR 01 shortwave downwelling multiplier (1000/15.5).

Const NR01_SHORT_UW_CAL = 1000/13.93 'Unique NR 01 shortwave upwelling multiplier (1000/13.5).

Const NR01_LONG_DW_CAL = 1000/8.8 'Unique NR 01 longwave downwelling multiplier (1000/10.5).

Const NR01_LONG_UW_CAL = 1000/9.4 'Unique NR 01 longwave upwelling multiplier (1000/10.3).

Const MAX_DUTY_CYCLE_1 = 1

Const MAX_DUTY_CYCLE_2 = 0.2

Const DELTA_SET_POINT_1 = 5

Const DELTA_SET_POINT_2 = 28

Const SLOPE_1 = (MAX_DUTY_CYCLE_2-MAX_DUTY_CYCLE_1)/DELTA_SET_POINT_1

Const SLOPE_2 = (-MAX_DUTY_CYCLE_2)/DELTA_SET_POINT_2

'*** Variables ***

Public no_heat_flag As Boolean 'Turn off heater control when TRUE.

Public panel_temp 'Datalogger panel temperature.

Public batt_volt 'Datalogger battery voltage.

Public hmp(2) 'HMP45C temperature and relative humidity.

Alias hmp(1) = t_hmp 'HMP45C temperature.

Alias hmp(2) = rh_hmp 'HMP45C relative humidity.

Public e_hmp 'HMP45C vapor pressure.

Public nr01(9) 'NR 01 net radiometer.

Alias nr01(1) = Rn

Alias nr01(2) = albedo

Alias nr01(3) = Rs_downwell

Alias nr01(4) = Rs_upwell

A-2

Page 41

Appendix A. CR3000 Program that Controls the Heater

Alias nr01(5) = Rl_downwell

Alias nr01(6) = Rl_upwell

Alias nr01(7) = t_nr01

Alias nr01(8) = Rl_down_meas

Alias nr01(9) = Rl_up_meas

Units panel_temp = C

Units batt_volt = V

Units t_hmp = C

Units rh_hmp = percent

Units e_hmp = kPa

Units nr01 = W/m^2

Units albedo = unitless

Units t_nr01 = K

'Net radiometer heater control variables.

Public set_point_temperature

Public duty_cycle

'Working Variables

Dim scratch_out(3)

Alias scratch_out(1) = t_hmp_mean

Alias scratch_out(2) = e_hmp_mean

Alias scratch_out(3) = e_sat_hmp_mean

Dim rh_hmp_mean 'Mean HMP45C relative humidity.

Dim t_dew_hmp_mean 'Mean dew point temperature.

Dim e_sat_hmp 'HMP45C saturation vapor pressure.

Units t_hmp_mean = C

Units e_hmp_mean = kPa

Units e_sat_hmp_mean = kPa

Units rh_hmp_mean = percent

Units t_dew_hmp_mean = C

DataTable (stats,TRUE,-1)

DataInterval (0,5,Min,10)

Sample (1,t_hmp_mean,IEEE4)

Sample (1,e_hmp_mean,IEEE4)

Sample (1,rh_hmp_mean,IEEE4)

Sample (1,t_dew_hmp_mean,IEEE4)

Sample (1,duty_cycle,IEEE4)

Average (9,Rn,IEEE4,FALSE)

EndTable

DataTable (scratch,TRUE,1)

TableHide

DataInterval (0,5,Min,10)

Average (1,t_hmp,IEEE4,FALSE)

Average (1,e_hmp,IEEE4,FALSE)

Average (1,e_sat_hmp,IEEE4,FALSE)

EndTable

A-3

Page 42

Appendix A. CR3000 Program that Controls the Heater

BeginProg

Scan (1,Sec,0,0)

'Control the net radiometer heater.

PWM (duty_cycle,4,250,mSec)

'Datalogger panel temperature.

PanelTemp (panel_temp,250)

'Measure battery voltage.

Battery (batt_volt)

'Measure the HMP45C temperature and relative humidity.

VoltDiff (t_hmp,1,mV1000C,5,TRUE,200,250,0.1,-40)

VoltDiff (rh_hmp,1,mV1000C,6,TRUE,200,250,0.1,0)

'Measure NR 01 Net Radiometer.

Resistance (t_nr01,1,mV200,10,Ix1,1,1675,TRUE,TRUE,200,250,1,0)

VoltDiff (Rs_downwell,1,mV20C,11,TRUE,200,250,NR01_SHORT_DW_CAL,0)

VoltDiff (Rs_upwell,1,mV20C,12,TRUE,200,250,NR01_SHORT_UW_CAL,0)

VoltDiff (Rl_down_meas,1,mV20C,13,TRUE,200,250,NR01_LONG_DW_CAL,0)

VoltDiff (Rl_up_meas,1,mV20C,14,TRUE,200,250,NR01_LONG_UW_CAL,0)

'Find the HMP45C vapor pressure and saturation vapor pressure (kPa).

VaporPressure (e_hmp,t_hmp,rh_hmp)

SatVP (e_sat_hmp,t_hmp)

'Compute net radiation, albedo, downwelling and upwelling longwave radiation.

t_nr01 = t_nr01/100

PRT (t_nr01,1,t_nr01,1,273.15)

Rn = Rs_downwell-Rs_upwell+Rl_down_meas-Rl_up_meas

albedo = Rs_upwell/Rs_downwell

Rl_downwell = Rl_down_meas+(5.67e-8*t_nr01*t_nr01*t_nr01*t_nr01)

Rl_upwell = Rl_up_meas+(5.67e-8*t_nr01*t_nr01*t_nr01*t_nr01)

CallTable (scratch)

If ( scratch.Output(1,1) ) Then

GetRecord (scratch_out(1),scratch,1)

rh_hmp_mean = 100*e_hmp_mean/e_sat_hmp_mean

DewPoint (t_dew_hmp_mean,t_hmp_mean,rh_hmp_mean)

'Control the NR 01 heater using 4 Hz pulse width modulation. Below the dew

' point temperature applies 100% power. Above the dew point, power is reduced

' linearly to 20% until the dew point plus DELTA_SET_POINT_1. After the dew

' point plus DELTA_SET_POINT_1 and until the dew point plus

' DELTA_SET_POINT_2 plus DELTA_SET_POINT_2, the power is reduced linearly to 0%.

If ( (t_nr01 <> NaN) AND (t_dew_hmp_mean <> NaN) AND (no_heat_flag <> TRUE) ) Then

set_point_temperature = t_dew_hmp_mean+273.15

Select Case t_nr01

Case Is < ( set_point_temperature )

duty_cycle = 1

Case Is < ( set_point_temperature+DELTA_SET_POINT_1 )

duty_cycle = MAX_DUTY_CYCLE_1+(t_nr01-(t_dew_hmp_mean+273.15))*SLOPE_1

A-4

Page 43

Appendix A. CR3000 Program that Controls the Heater

Case Is < ( set_point_temperature+DELTA_SET_POINT_1+DELTA_SET_POINT_2 )

duty_cycle = MAX_DUTY_CYCLE_2+(t_nr01 (t_dew_hmp_mean+273.15+DELTA_SET_POINT_1))*SLOPE_2

Case Else

duty_cycle = 0.01

EndSelect

Else

duty_cycle = 0.01

EndIf

EndIf

CallTable (stats)

NextScan

EndProg

A-5

Page 44

Appendix A. CR3000 Program that Controls the Heater